Materials Challenges in Reconstruction of Historical Projects: A Case Study of the Old Riwaq Project

Abstract

1. Introduction

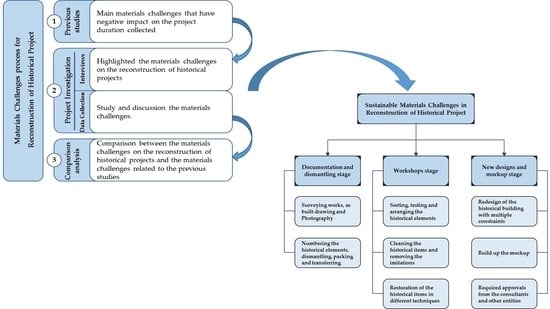

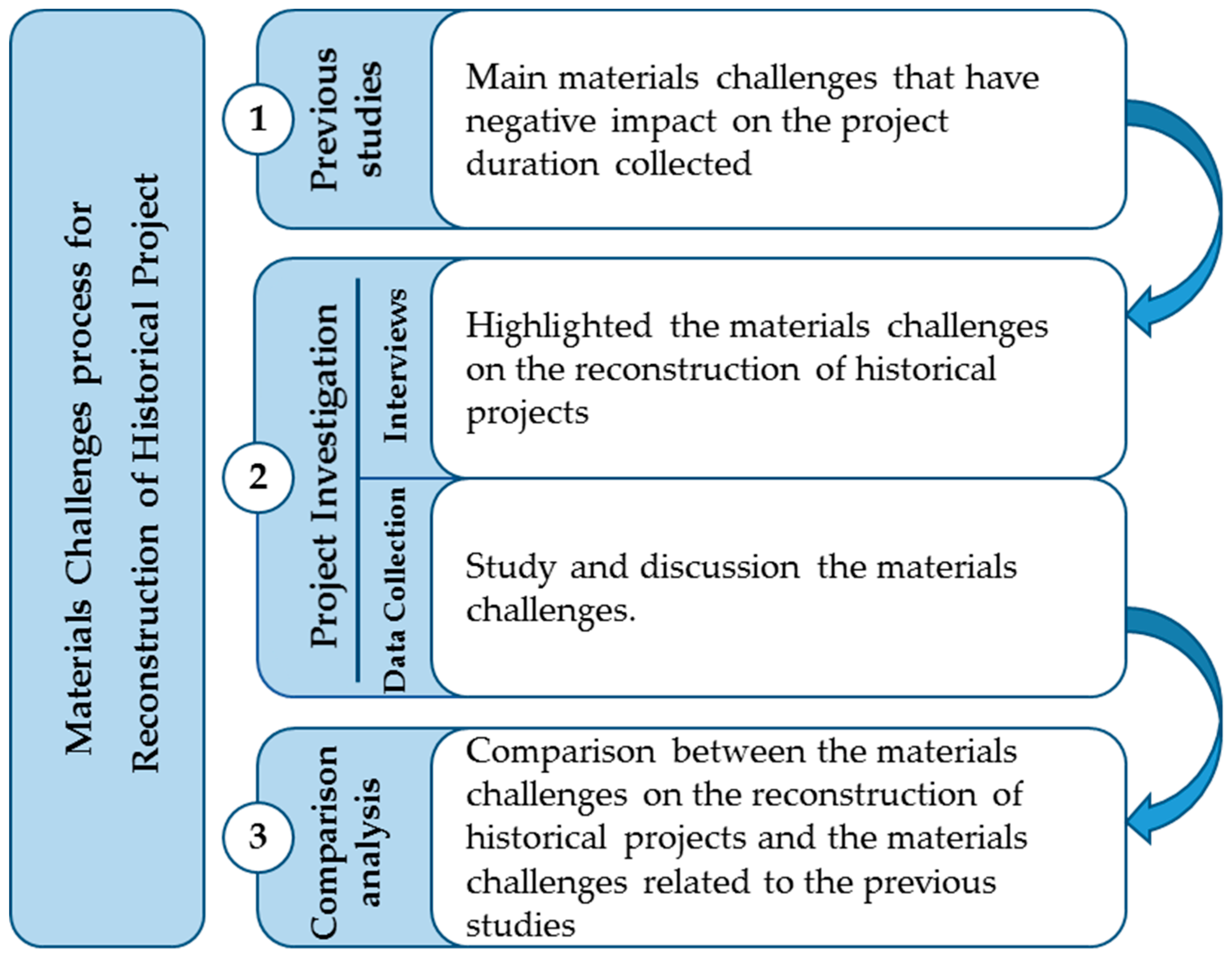

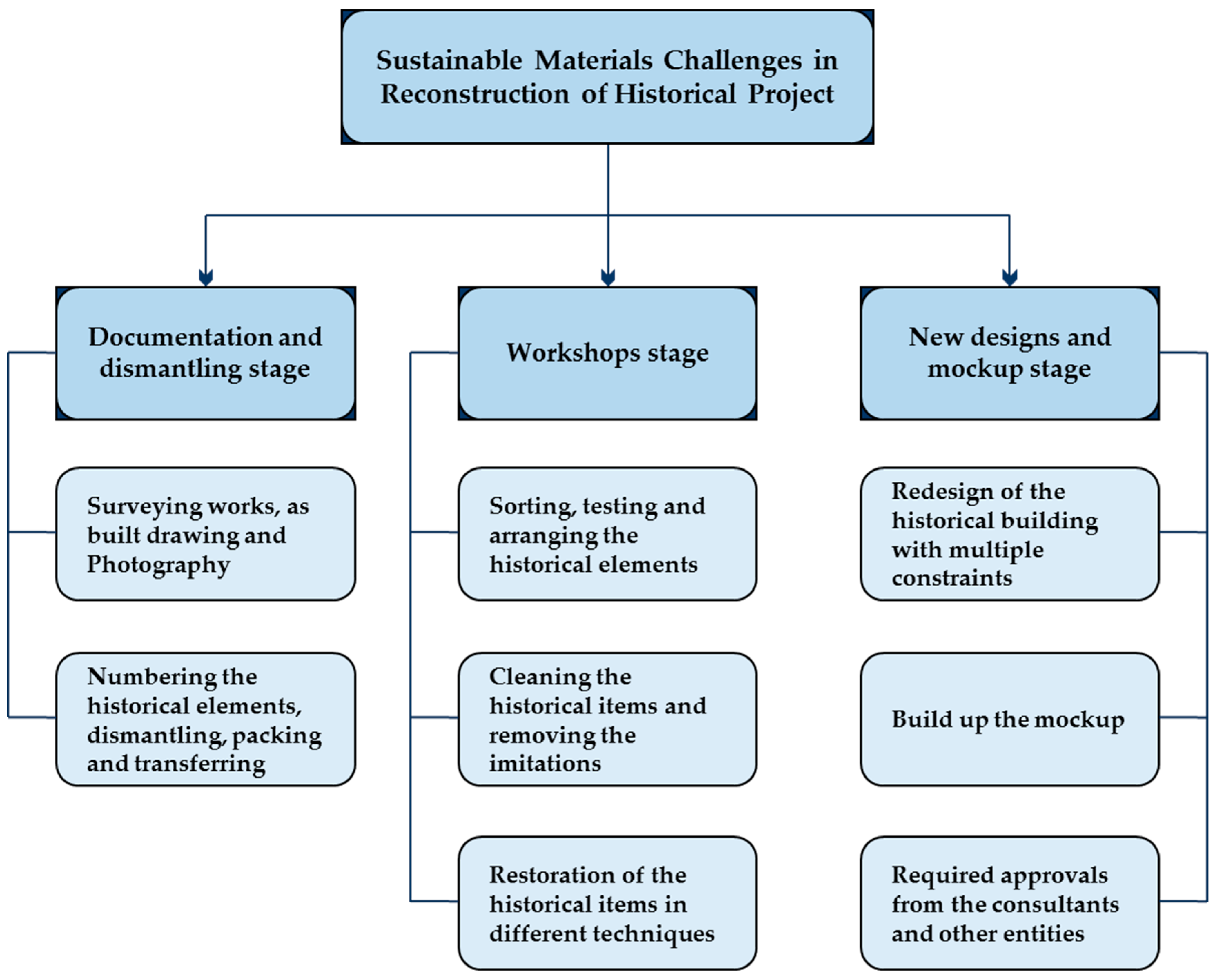

2. Research Methodology

In your view as an expert working on this project, what are the materials-related challenges that have been associated with the documentation and dismantling of the historical building?What are the materials-related challenges associated with the workshop phase?

What are the materials-related challenges that have been associated with the new designs and mockup stage?

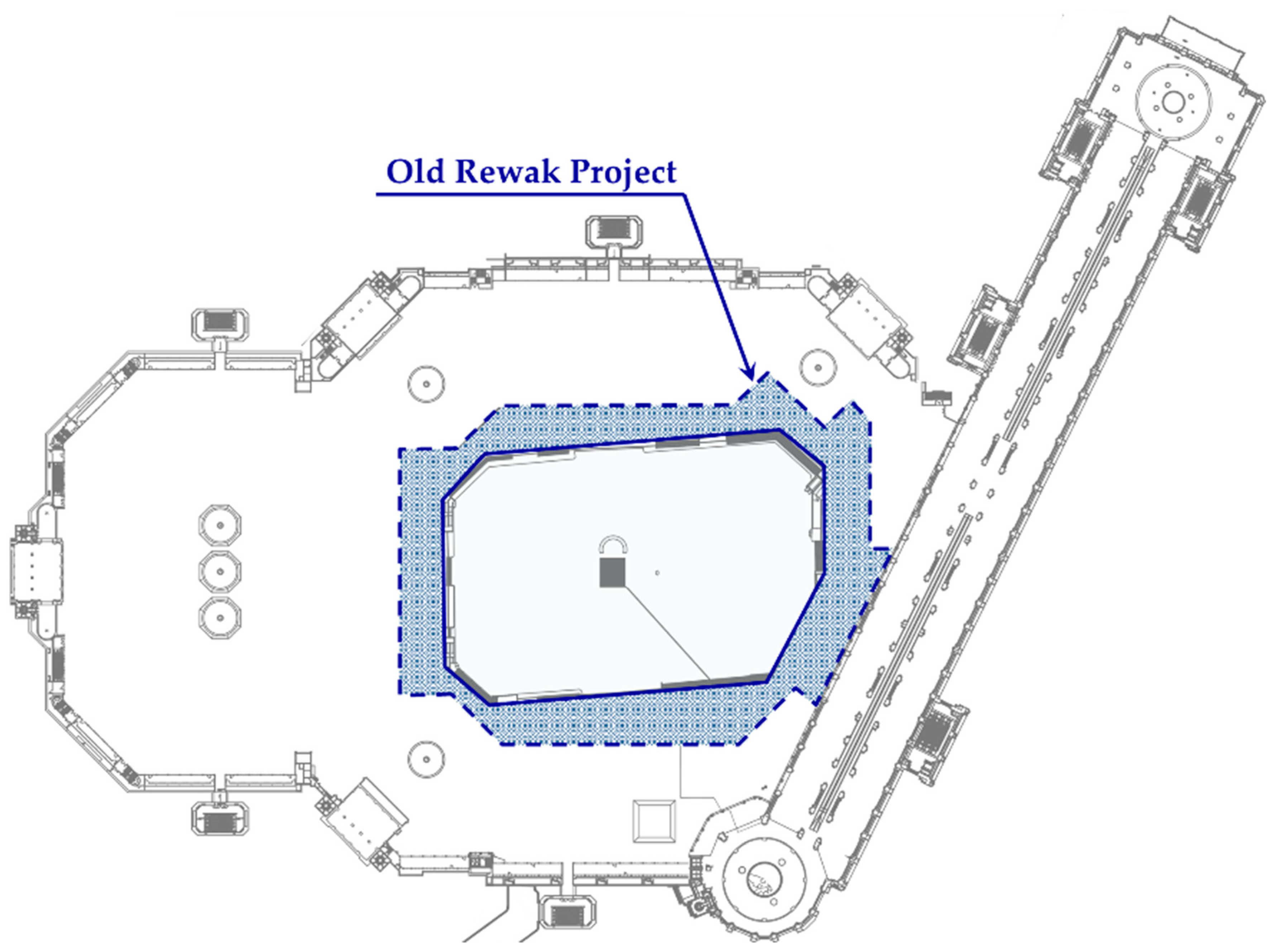

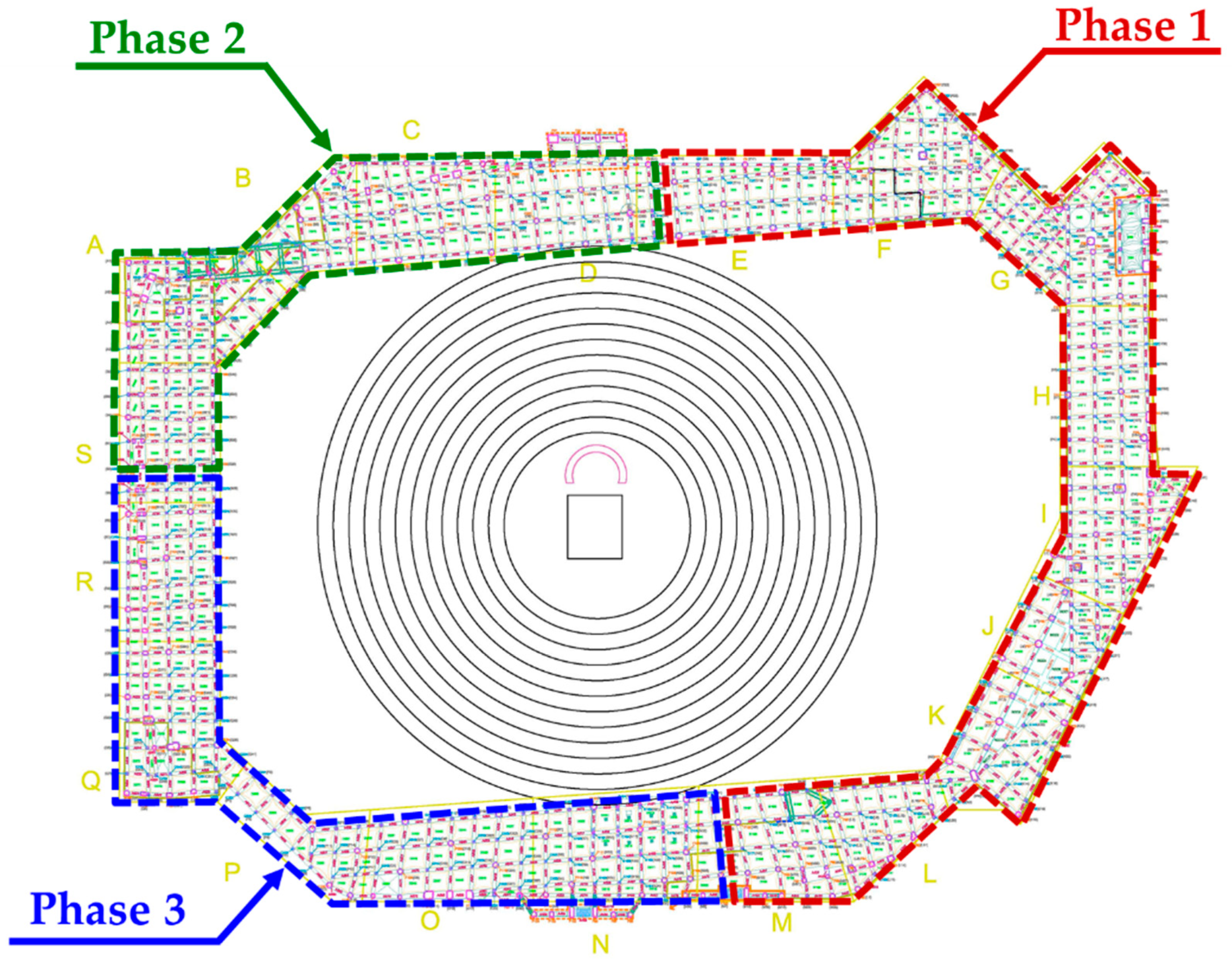

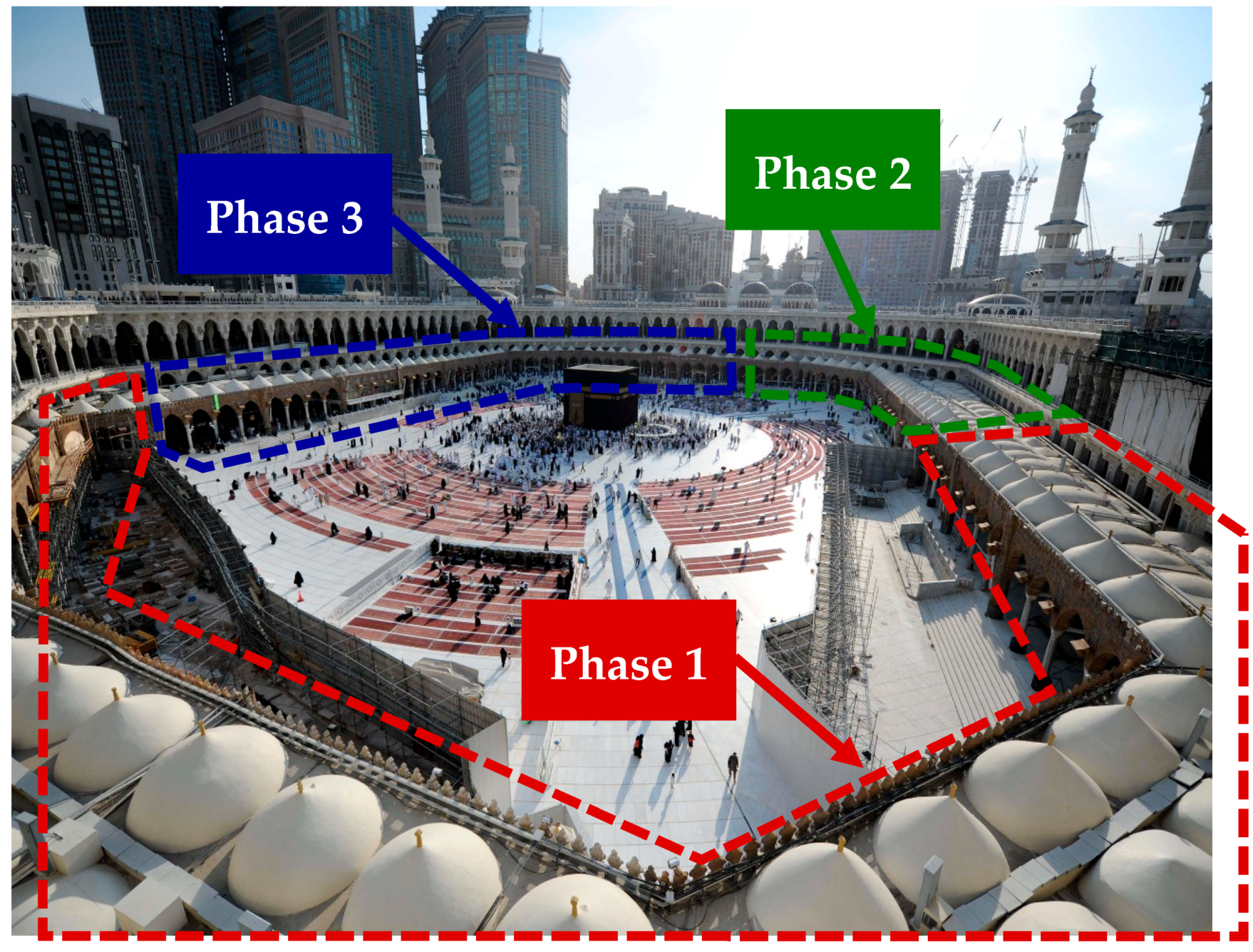

3. Case Study and Data Collection

- Documentation and dismantling stage (Section 3.1);

- Workshops stage (Section 3.2);

- New designs and mockup stage (Section 3.3).

3.1. Documentation and Dismantling Stage

3.2. Workshops Stage

3.3. New Designs and Mockup Stage

4. Discussion

- Surveying works and the preparation of accurate as-built drawings that show the building shape and the location of each element in the historical building.

- Numbering of the historical elements, dismantling works, packaging and transportation to the workshop areas where the second stage of work begins.

- Sorting, testing and arranging the historical elements according to their structural stability and sustainability.

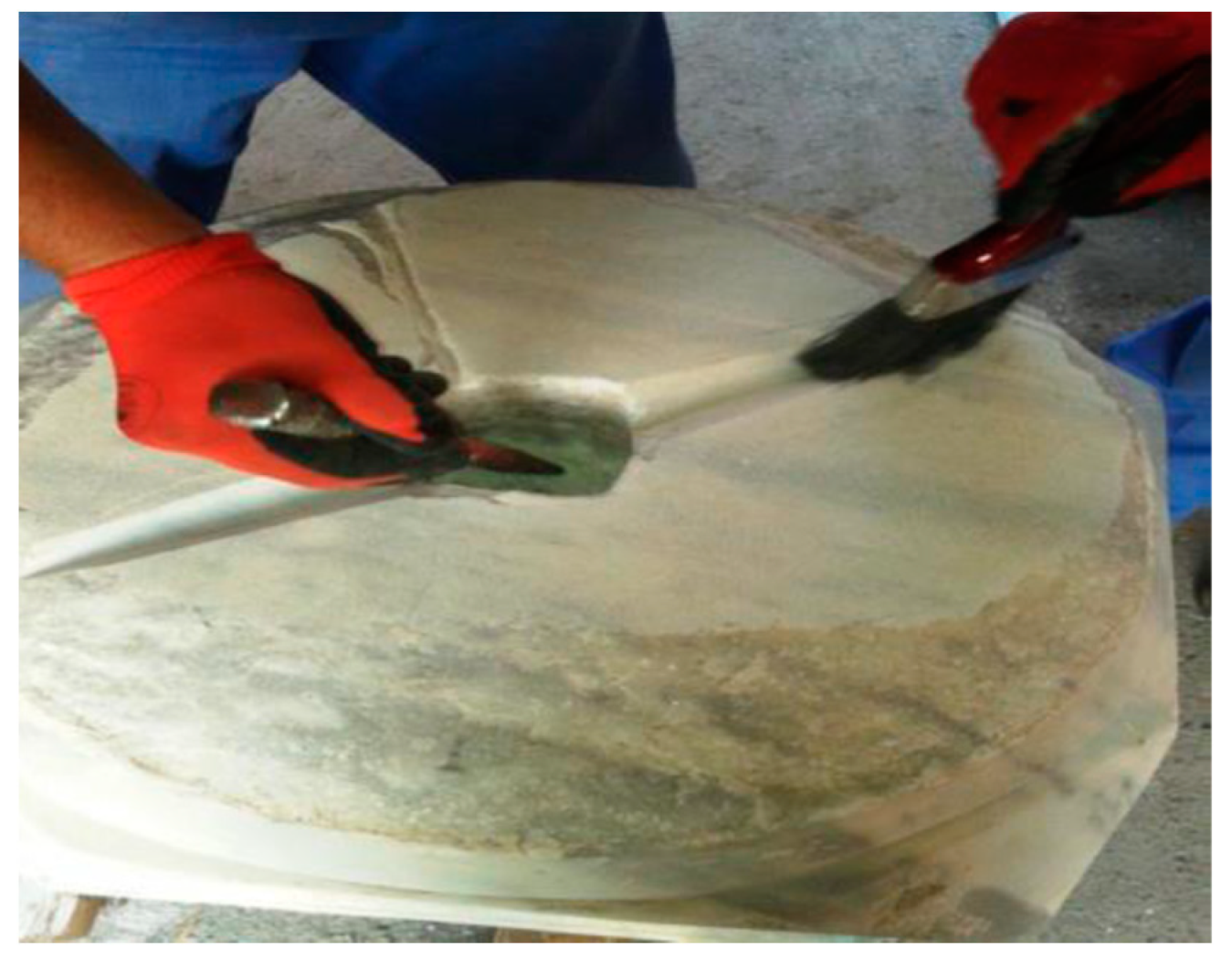

- Cleaning the historical items from the dirt, grease and oil stains in addition to removing the imitations.

- Restoration of historical elements using different methods and techniques depending on the condition of each item by applying special substances.

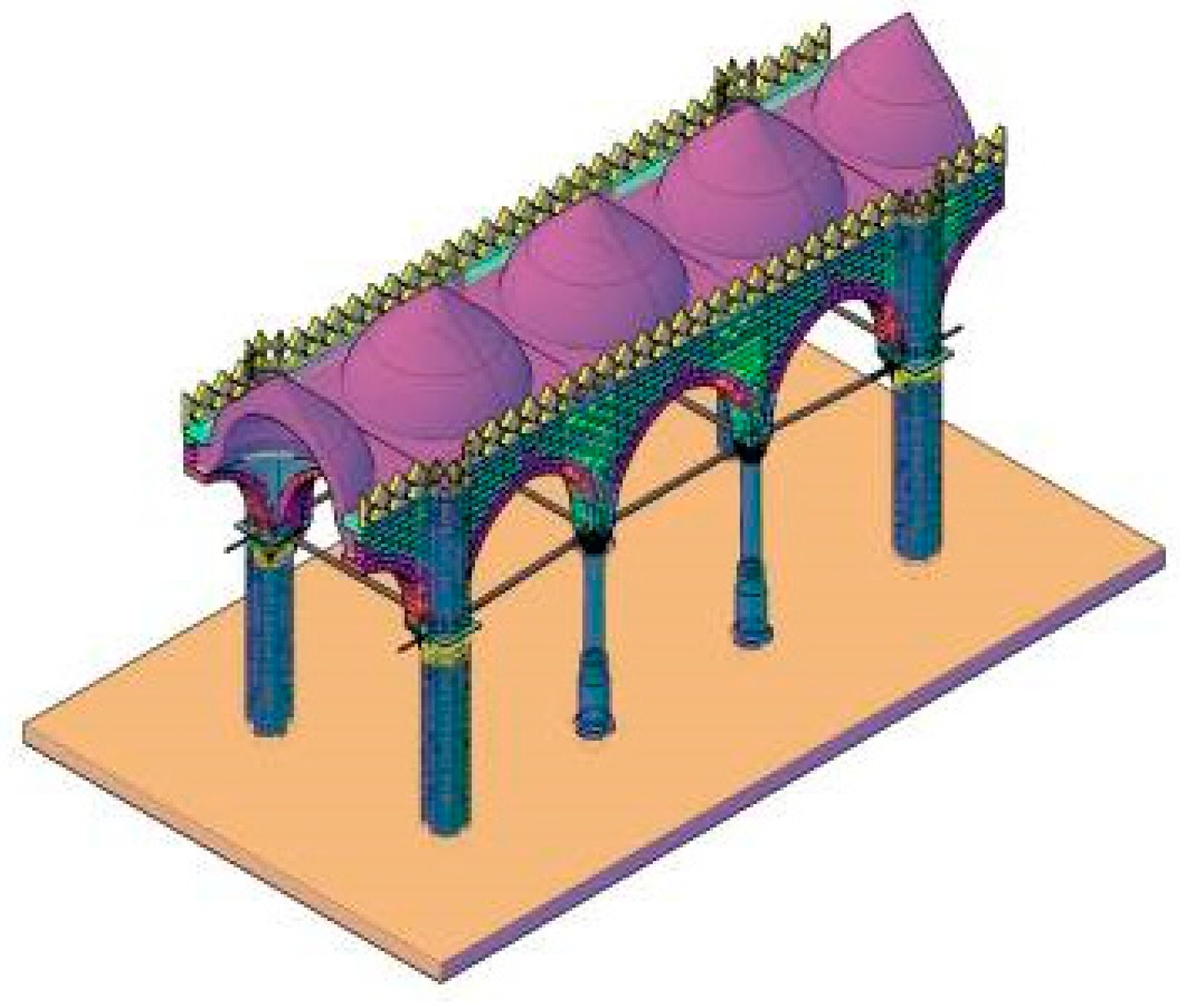

- Design requirements, especially the overall form, which had to simulate the old building and the new project level, which had to make movement and flow for the visitors more easy, as well as conforming to safety and sustainability criteria.

- Building a mockup showing the final shape of the new historical building based on the new integrated designs and the restoration items.

- The speed of obtaining the required consultant and other entities approvals in order to start the actual reconstruction works at site.

- Completing the documentation works, surveying and photographing of the remaining project phases during the construction of first phase of the project. This resulted in shortening the time required of remaining phases and accelerating the start of the dismantling works within the second and third phase of the project.

- Developing the scaffolding, back propping and formwork systems, which accelerated the installation of these systems and facilitated the movement of workers as well as the transfer of historical elements.

- Dividing the workshops into many areas and providing these areas with specialized teams, as follows:

- -

- Specialized teams in surface cleaning of historical elements.

- -

- Deep cleaning teams.

- -

- Teams specialized in the restoration of columns (bases, column bodies and crowns).

- -

- Specialized teams working with stones restoration based on their different types.

5. Conclusions

6. Recommendations

- The previous materials challenges should be studied carefully during the planning phase of similar projects.

- Time impacts for materials challenges should be examined in order to estimate a proper project period.

- Conducting further studies on historical projects to identify the various materials challenges that could delay the project execution.

- Sort the materials challenges in the reconstruction of historical projects according to their impact on the project duration.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Opeyemi, M.K.; Samson, O.A.; Olabode, O.M.; Olanrewaju, D. An Assessment of the Causative Factors and Effects of Delays in Building Construction Projects in Osun State, Nigeria. J. Econ. Sustain. Dev. 2015, 6, 29–38. [Google Scholar]

- Bal, M.; Bryde, D.; Fearon, D. Stakeholder Engagement: Achieving Sustainability in the Construction Sector. Sustainability 2013, 5, 695–710. [Google Scholar] [CrossRef]

- Assaf, S.A.; Al-Hejji, S. Causes of delay in large construction projects. Int. J. Proj. Manag. 2006, 24, 349–357. [Google Scholar] [CrossRef]

- Ahmed, S.M.; Salman, A.; Kappagantula, P.; Gollapudi, D. Delays in Construction: A Brief study of the Florida construction industry. In Proceedings of the 39th Annual ASC Conference, Clemson, SC, USA, 10–12 April 2003. [Google Scholar]

- Le’sniak, A.; Zima, K. Cost Calculation of Construction Projects Including Sustainability Factors Using the Case Based Reasoning (CBR) Method. Sustainability 2018, 10, 1608. [Google Scholar]

- Al Khatib, B.; Poh, Y.S.; El-Shafie, A. Delay Factors in Reconstruction Projects: A Case Study of Mataf Expansion Project. Sustainability 2018, 10, 4772. [Google Scholar] [CrossRef]

- Jarkas, A.M.; Haupt, T.C. Major construction risk factors considered by general contractors in Qatar. J. Eng. Des. Tech. 2015, 13, 165–194. [Google Scholar] [CrossRef]

- Aziz, R.F. Ranking of delay factors in construction projects after Egyptian revolution. Alex. Eng. J. 2013, 52, 387–406. [Google Scholar] [CrossRef]

- Le-Hoai, L.; Lee, Y.; Lee, J. Delay and Cost Overruns in Vietnam Large Construction Projects: A Comparison with Other Selected Countries. KSCE J. Civ. Eng. 2008, 12, 367–377. [Google Scholar] [CrossRef]

- Sambasivan, M.; Soon, Y. Causes and effects of delays in Malaysian construction industry. Int. J. Proj. Manag. 2007, 25, 517–526. [Google Scholar] [CrossRef]

- Enshassi, A.; Mohamed, S.; Abushaban, S. Factors affecting the performance of construction projects in the Gaza strip. J. Civ. Eng. Manag. 2009, 15, 269–280. [Google Scholar] [CrossRef]

- Ogunlana, S.O.; Promkuntong, K.; Jearkjirm, V. Construction delays in a fast-growing economy: Comparing Thailand with other economics. Int. J. Proj. Manag. 1996, 14, 37–45. [Google Scholar] [CrossRef]

- Indhu, B.; Ajai, P. Study of Delay Management in a Construction Project—A Case Study. Int. J. Emerg. Tech. Adv. Eng. 2014, 4, 108–113. [Google Scholar]

- Durdyev, S.; Omarov, M.; Ismail, S. Causes of Delay in Residential Construction Projects in Cambodia. Cogent Eng. 2017, 4, 1291117. [Google Scholar] [CrossRef]

- Alaghbari, W.; Razali, M.; Kadir, S.; Ernawat, G. The significant factors causing delay of building construction projects in Malaysia. Eng. Constr. Arch. Manag. 2007, 14, 192–206. [Google Scholar] [CrossRef]

- Ibironke, O.T.; Oladinrin, T.O.; Adeniyi, O.; Eboreime, I.V. Analysis of Non-Excusable Delay Factors Influencing Contractors’ Performance in Lagos State, Nigeria. J. Constr. Dev. Ctries. 2013, 18, 53–72. [Google Scholar]

- Kaming, P.F.; Olomolaiye, P.O.; Holt, G.D.; Harris, F.C. Factors influencing construction time and cost overrun on high-rise projects in Indonesia. Constr. Manag. Econ. 1997, 15, 83–94. [Google Scholar] [CrossRef]

- Mansfield, N.R.; Ugwu, O.O.; Doran, T. Cause of delay and cost overrun in Nigerian construction projects. Int. J. Proj. Manag. 1994, 12, 254–260. [Google Scholar] [CrossRef]

- Haseeb, M.; Lu, X.; Bibi, A.; Maloof-ud-Dyian; Rabbani, W. Problems of projects and effects of delays in the construction industry of Pakistan. Australian. J. Bus. Manag. Res. 2011, 1, 41–50. [Google Scholar]

- Doloi, H.; Sawhney, A.; Iyer, K.; Rentala, S. Analysing factors affecting delays in Indian construction projects. Int. J. Proj. Manag. 2012, 30, 479–489. [Google Scholar] [CrossRef]

- Sayed, M.; Ali, S.; Ahmed, S. Need for JIT implementation: Material shortage problems as a cause of delay in construction project in Egypt. Int. J. Civ. Eng. Tech. 2017, 8, 30–36. [Google Scholar]

- Fugar, F.D.K.; Agyakwah-Baah, A.B. Delays in building construction projects in Ghana. Australas. J. Constr. Econ. Build. 2012, 10, 103–116. [Google Scholar] [CrossRef]

- Gunduz, M.; AbuHassan, M.H.A. Causes of Construction Delays in Qatar Construction Projects. Int. J. Civ. Env. Eng. 2016, 10, 531–536. [Google Scholar]

- Tumi, S.H.; Omran, A.; Pakir, A.H.K. Causes of delay in construction industry in Libya. In Proceedings of the International Conference on Administration and Business (ICEA–FAA), Bucharest, Romania, 14–15 November 2009; pp. 265–272. [Google Scholar]

- Gündüz, M.; Nielsen, Y.; Özdemir, M. Quantification of Delay Factors Using the Relative Importance Index Method for Construction Projects in Turkey. J. Manag. Eng. 2013, 29, 133–139. [Google Scholar] [CrossRef]

- Ameh, O.; Osegbo, E. Study of relationship between time overrun and productivity on construction sites. Int. J. Constr. Supply Chain Manag. 2011, 1, 56–67. [Google Scholar]

- Faridi, A.; Sayegh, S. Significant factors causing delay in the UAE construction industry. Constr. Manag. Econ. 2006, 24, 1167–1176. [Google Scholar] [CrossRef]

- Aibinu, A.A.; Odeyinka, A. Construction delays and their causative factors in Nigeria. J. Constr. Eng. Manag. ASCE 2006, 132, 667–677. [Google Scholar] [CrossRef]

- Arditi, D.; Akan, G.T.; Gurdamar, S. Reasons for delays in public projects in Turkey. Constr. Manag. Econ. 1985, 3, 171–181. [Google Scholar] [CrossRef]

- Abd-Majid, M.Z.; McCaffer, R. Factors of non-excusable delays that influence contractors’ performance. J. Manag. Eng. 1998, 14, 42–49. [Google Scholar] [CrossRef]

- Koushki, P.A.; Kartam, N. Impact of construction materials on project time and cost in Kuwait. Eng. Constr. Arch. Manag. 2004, 11, 126–132. [Google Scholar] [CrossRef]

- Gebrehiwet, T.; Luo, H. Analysis of Delay Impact on Construction Project Based on RII and Correlation Coefficient: Empirical Study. Procedia Eng. 2017, 196, 366–374. [Google Scholar] [CrossRef]

- Salama, M.; El Hamid, M.A.; Keogh, B. Investigating the causes of delay within oil and gas Projects in the U.A.E. In Proceedings of the 24th Annual ARCOM Conference, Cardiff, UK, 1–3 September 2008; Dainty, A., Ed.; Association of Researchers in Construction Management: Edinburgh, UK, 2008; pp. 819–827. [Google Scholar]

- Alhajri, A.R.; Alshibani, A. Critical Factors behind Construction Delay in Petrochemical Projects in Saudi Arabia. Energies 2018, 11, 1652. [Google Scholar] [CrossRef]

- Frimpong, Y.; Oluwoye, J.; Crawford, L. Causes of delay and cost overruns in construction of groundwater projects in a developing countries; Ghana as a case study. Int. J. Proj. Manag. 2003, 21, 321–326. [Google Scholar] [CrossRef]

- Dlakwa, M.M.; Culpin, M.F. Reasons for overrun in public sector construction projects in Nigeria. Int. J. Proj. Manag. 1990, 8, 237–241. [Google Scholar] [CrossRef]

- Owolabi, J.D.; Amusan, L.M.; Oloke, C.O.; Olusanya, O.; Tunji, O.P.; Owolabi, D.; Peter, J.; Omuh, I. Causes and Effect of Delay on Project Construction Delivery Time. Int. J. Educ. Res. 2014, 2, 197–208. [Google Scholar]

- Koshe, W.; Jha, K.N. Investigating Causes of Construction Delay in Ethiopian Construction Industries. J. Civ. Constr. Environ. Eng. 2016, 1, 18–29. [Google Scholar]

- Pavlovskis, M.; Migilinskas, D.; Antuchevičienė, J.; Urba, I.; Zigmund, V. Problems in reconstruction projects, BIM uses and decision-making: Lithuanian case studies. Procedia Eng. 2017, 208, 125–128. [Google Scholar] [CrossRef]

- Kazaz, A.; Ulubeyli, S.; Tuncbilekli, N. Causes of Delays in Construction Projects in Turkey. J. Civ. Eng. Manag. 2012, 18, 426–435. [Google Scholar] [CrossRef]

- Fallahnejad, M. Delay causes in Iran gas pipeline projects. Int. J. Proj. Manag. 2012, 31, 136–146. [Google Scholar] [CrossRef]

- Guest, G.; Bunce, A.; Johnsons, L. How many interviews are enough? An experiment with data saturation and variability. Field Methods 2006, 18, 59–82. [Google Scholar] [CrossRef]

| No. | Challenge | Main Reason | Reference |

|---|---|---|---|

| I | Shortage of materials | Providing wrong estimation. Damages during handling materials and poor inventory management system. Delay in payments and financial problems. Construction defective and mistakes. Scope of works changes. Late identification of the type of materials needed. | [7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24] |

| II | Late delivery of materials | Delay in payments and financial problems. Delay in procurement of materials. Customs clearance for imported material. Slowness in decision making. | [7,14,15,16,25,26,27,28,29,30,31,32,33,34] |

| III | Fluctuations and Escalation of material price | Change in the cost of raw materials. Changes in market conditions and Shortage of supplies. Instability in local currencies exchange rates and increasing of Inflation rates. The additional cost of transport and import duties. Rising labor or production costs in the supply chain. | [11,18,22,32,35,36,37,38] |

| IV | Long duration of materials procurement | Delay in finalizing material take of list, as well as materials shop drawings. Contractor delay in submission the technical requirement for the consultant’s approval. Delay in consultant’s reviewing and approval. Spending long time in supplier price negotiation and financial problems. | [3,33,35,39] |

| V | Changes of material | Design changes. Scope of works changes. The lead time of material delivery. Late initiation of value engineering process. | [13,40] |

| VI | Poor quality of materials | Selecting poor source of materials. Lack of quality control and assurance systems. Bad shipping and storage handling. Cheap construction materials. Lack of materials test and inspection. | [11,32] |

| VII | Imported materials | Delays in placing purchase orders for imported materials. Long period of delivery. Custom clearance procedures. Seasons such as festivals, vacations, winters, etc. affects the processing procedure. | [41] |

| Elements | Item |

|---|---|

| Marble column | 88 |

| Capital | 92 |

| Base | 70 |

| Profile stone | 50 |

| Arch stone | 1491 |

| Finial | 48 |

| Keystone of arches | 15 |

| Shemasi pillar stone | 678 |

| Egyptian gate | 112 |

| Cornices | 461 |

| Muqarnas | 82 |

| Parapet stone | 215 |

| Rosette | 45 |

| Script | 17 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khatib, B.A.; Poh, Y.S.; El-Shafie, A. Materials Challenges in Reconstruction of Historical Projects: A Case Study of the Old Riwaq Project. Sustainability 2019, 11, 4533. https://doi.org/10.3390/su11174533

Khatib BA, Poh YS, El-Shafie A. Materials Challenges in Reconstruction of Historical Projects: A Case Study of the Old Riwaq Project. Sustainability. 2019; 11(17):4533. https://doi.org/10.3390/su11174533

Chicago/Turabian StyleKhatib, Basem Al, Yap Soon Poh, and Ahmed El-Shafie. 2019. "Materials Challenges in Reconstruction of Historical Projects: A Case Study of the Old Riwaq Project" Sustainability 11, no. 17: 4533. https://doi.org/10.3390/su11174533

APA StyleKhatib, B. A., Poh, Y. S., & El-Shafie, A. (2019). Materials Challenges in Reconstruction of Historical Projects: A Case Study of the Old Riwaq Project. Sustainability, 11(17), 4533. https://doi.org/10.3390/su11174533