Stability Charts for Sustainable Infrastructure: Collapse Loads of Footings on Sandy Soil with Voids

Abstract

1. Introduction

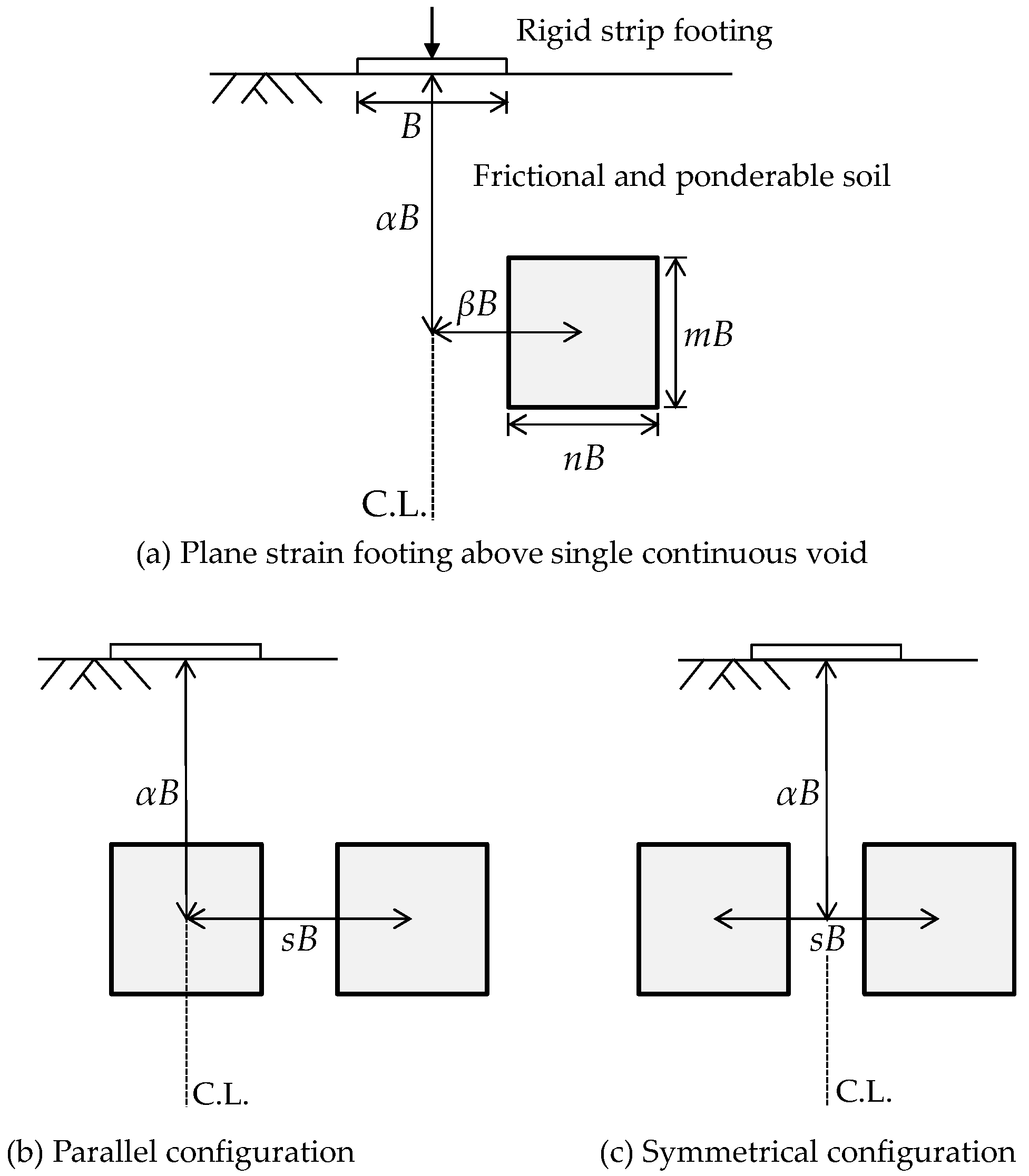

2. Problem Statement

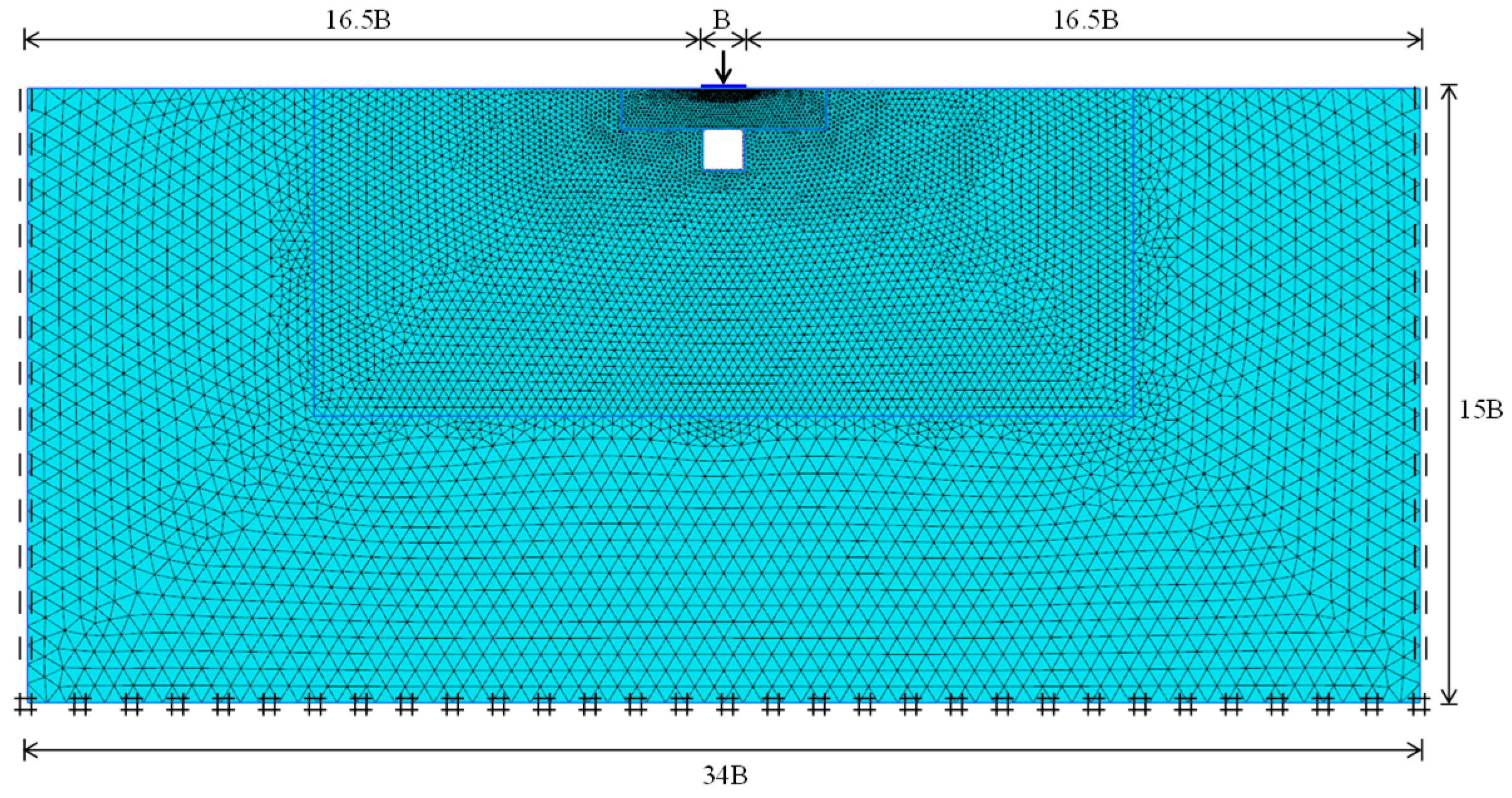

3. Finite Element Model

4. Results and Discussion

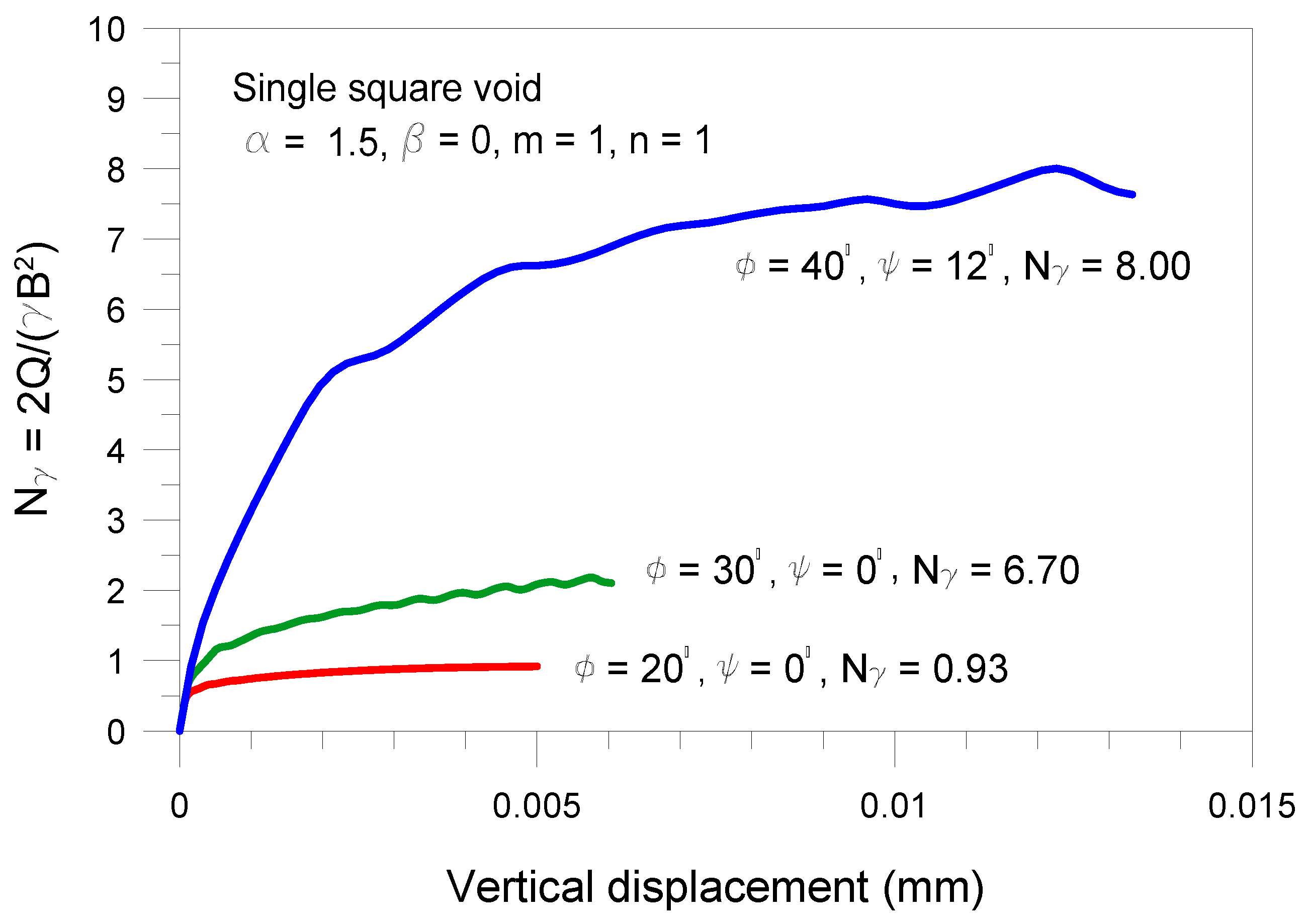

4.1. Validation

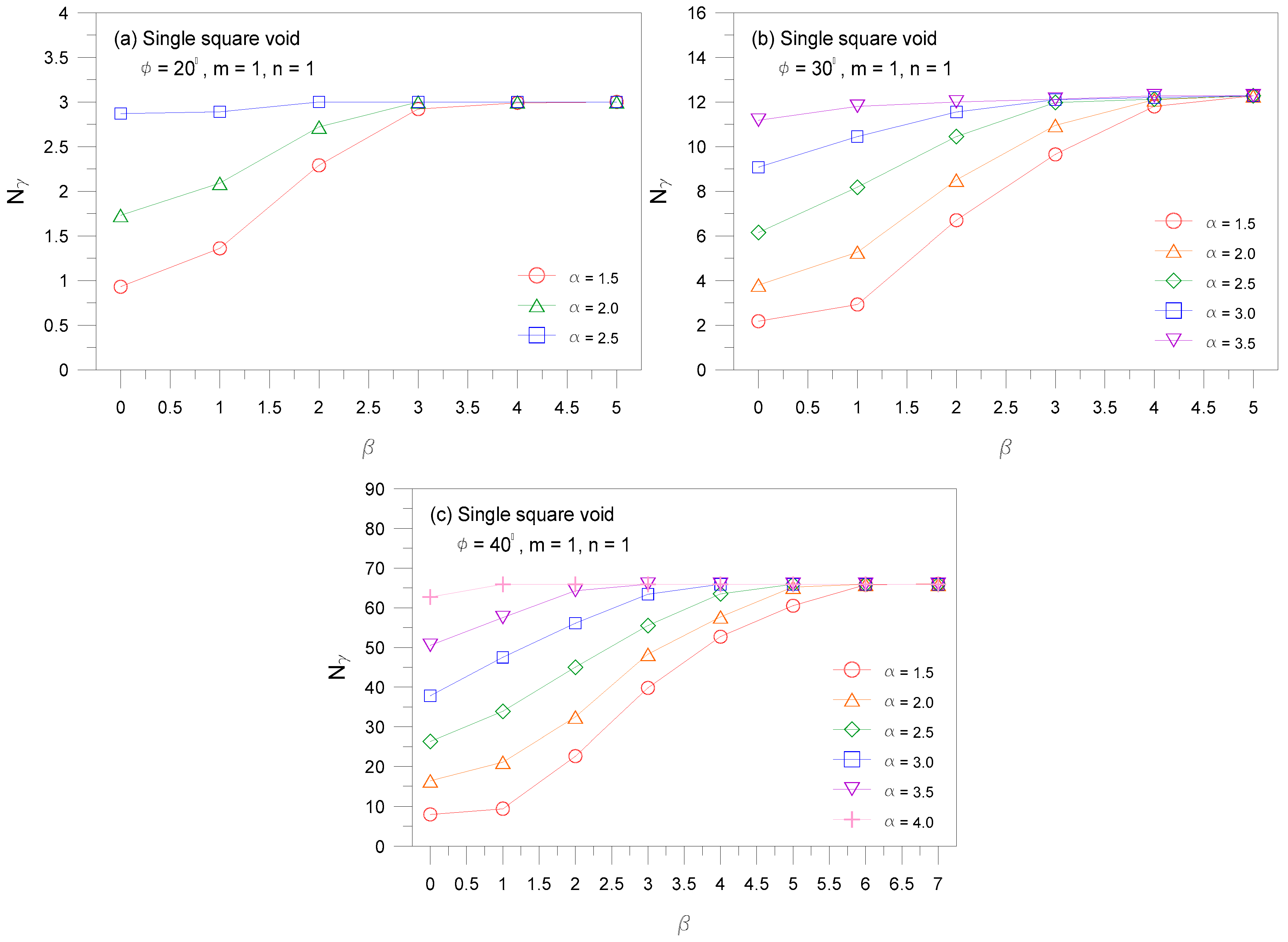

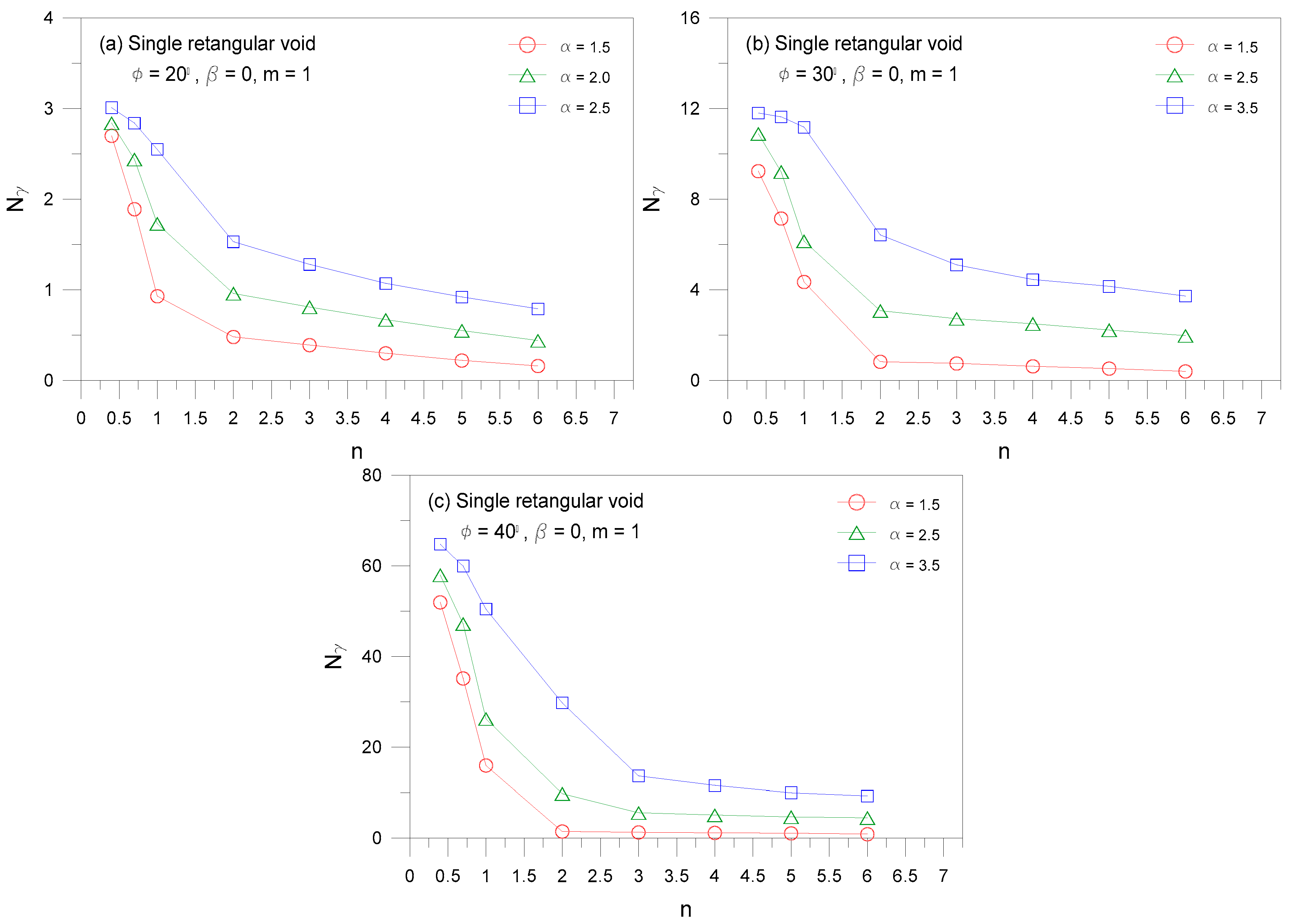

4.2. Case of Single Void

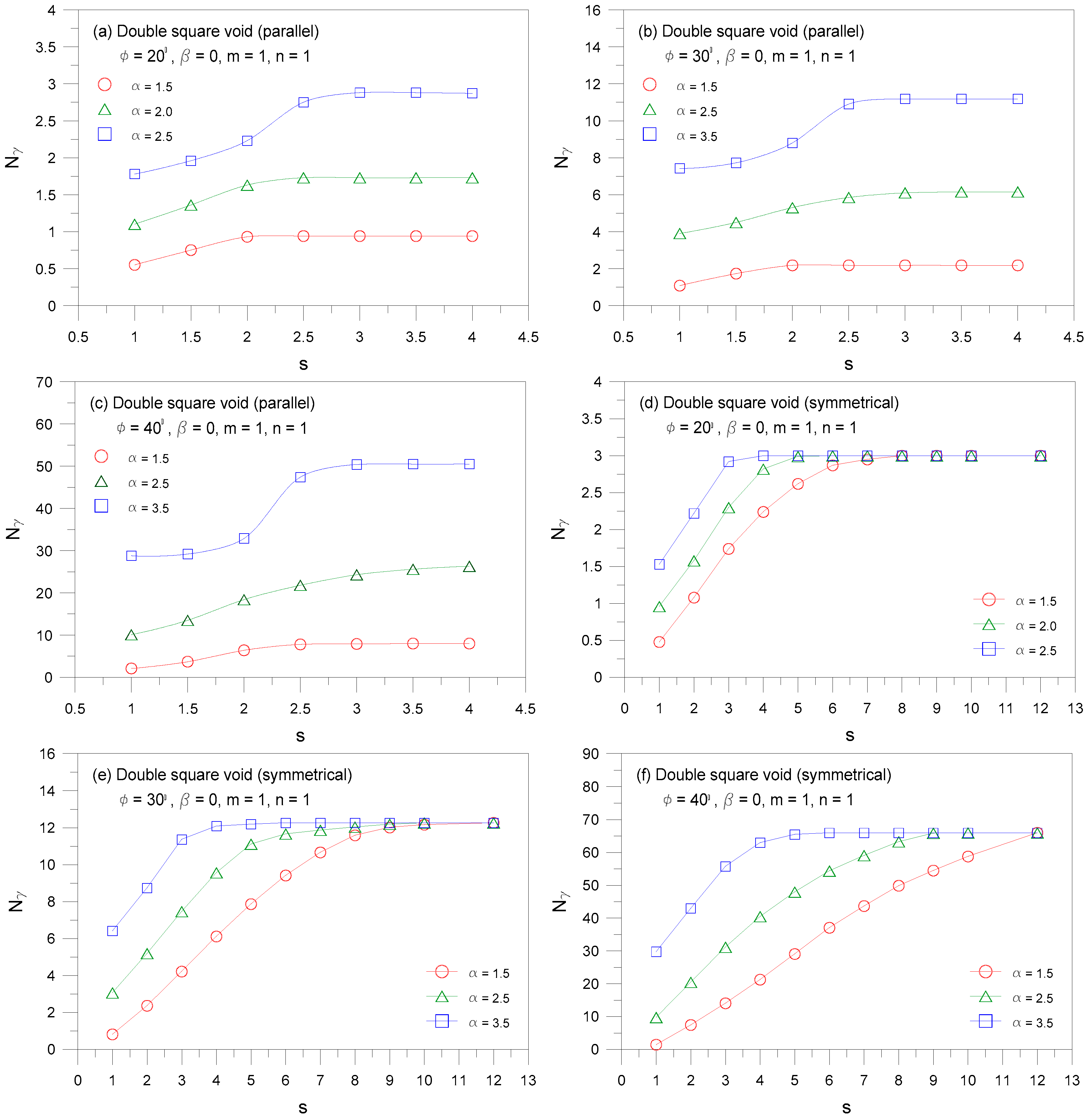

4.3. Case of Double Void

4.4. Failure Pattern

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Holt, D.G.A.; Jefferson, I.; Braithwaite, P.A.; Chapman, D.N. Embedding sustainability into geotechnics. Part A: Methodology. Eng. Sustain. 2010, 163, 127–135. [Google Scholar] [CrossRef]

- Menaa, M.; Meguid, M.A.; Assaf, G. On the effects of subgrade erosion on the contact pressure distribution under rigid surface structure. J. Geotech. Geoenviron. Eng. 2009, 135, 1538–1542. [Google Scholar] [CrossRef]

- Baus, R.L.; Wang, M.C. Bearing capacity of strip footing above void. J. Geotech. Eng. 1983, 109, 1–14. [Google Scholar] [CrossRef]

- Badie, A.; Wang, M.C. Stability of spread footing above void in clay. J. Geotech. Eng. 1984, 110, 1591–1605. [Google Scholar] [CrossRef]

- Wang, M.C.; Hsieh, C.W. Collapse load of strip footing above circular void. J. Geotech. Eng. 1987, 113, 511–515. [Google Scholar] [CrossRef]

- Azam, G.; Hsieh, C.W.; Wang, M.C. Performance of strip footing on stratified soil deposit with void. J. Geotech. Eng. 1991, 117, 753–772. [Google Scholar] [CrossRef]

- Kiyosumi, M.; Kusakabe, O.; Ohuchi, M. Model tests and analyses of bearing capacity of strip footing on stiff ground with voids. J. Geotech. Geoenviron. Eng. 2011, 137, 363–375. [Google Scholar] [CrossRef]

- Lee, J.K.; Jeong, S.; Ko, J. Effect of load inclination on the undrained bearing capacity of surface spread footings above voids. Comput. Geotech. 2015, 66, 245–252. [Google Scholar] [CrossRef]

- Lavasan, A.; Talsaz, A.; Ghazavi, M.; Schanz, T. Behavior of shallow strip footing on twin voids. Geotech. Geo. Eng. 2016, 34, 1791–1805. [Google Scholar] [CrossRef]

- Zhou, H.; Zheng, G.; He, X.; Xu, X.; Zhang, T.; Yang, X. Bearing capacity of strip footings on c-φ soils with square voids. Acta Geotech. 2018, 13, 747–755. [Google Scholar] [CrossRef]

- Das, B.M.; Khing, K.H. Foundation on layered soil with geogrid reinforcement–effect of a void. Geotext. Geomembr. 1994, 13, 545–553. [Google Scholar] [CrossRef]

- Wang, M.C.; Feng, Y.X.; Jao, M. Stability of geosynthetic-reinforced soil above a cavity. Geotext. Geomembr. 1996, 14, 95–109. [Google Scholar] [CrossRef]

- Agaiby, S.W.; Jones, C.J.F.P. Design of reinforced fill systems to support footings overlying cavities. Geotext. Geomembr. 1996, 14, 57–72. [Google Scholar] [CrossRef]

- Sireesh, S.; Sitharam, T.G.; Dash, S.K. Bearing capacity of circular footing on geocell-sand mattress overlying clay bed with void. Geotext. Geomembr. 2009, 27, 89–98. [Google Scholar] [CrossRef]

- Mohamed, M.H.A. Two dimensional experimental study for the behavior of surface footings on unreinforced and reinforced sand beds overlying soft pockets. Geotext. Geomembr. 2010, 28, 589–596. [Google Scholar] [CrossRef]

- Tafresho, S.N.M.; Khalaj, O.; Halvaee, M. Experimental study of a shallow strip footing on geogrid-reinforced sand bed above a void. Geosynth. Int. 2011, 18, 178–195. [Google Scholar] [CrossRef]

- Asakereh, A.; Ghazavi, M.; Tafreshi, S.N.M. Cyclic response of footing on geogrid-reinforced sand with void. Soils Found 2013, 53, 363–374. [Google Scholar] [CrossRef]

- Lai, F.; Chen, F.; Li, D. Bearing capacity characteristics and failure modes of low geosynthetic-reinforced embankments overlying voids. Int. J. Geomech. 2018, 18, 0401805. [Google Scholar] [CrossRef]

- Terzaghi, K. Theoretical Soil Mechanics; Wiley: New York, NY, USA, 1943. [Google Scholar]

- Hjiaj, M.; Lyamin, A.V.; Sloan, S.W. Numerical limit analysis solutions for the bearing capacity factor Nγ. Int. J. Solids Struct. 2005, 42, 1681–1704. [Google Scholar] [CrossRef]

- Bolton, M.D.; Lau, C.K. Vertical bearing capacity factors for circular and strip footings on Mohr-Coulomb soil. Can. Geotech. J. 1993, 30, 1024–1033. [Google Scholar] [CrossRef]

- Prandtl, L. Uber die Eindringungs-festigkeit (Harte) plastischer Baustoffe und die Festigkeit von Schneiden. Z. Angew. Math. Mech. 1921, 1, 15–20. [Google Scholar] [CrossRef]

- Griffiths, D.V. Computation of bearing capacity factors using finite elements. Geotechnique 1982, 32, 195–202. [Google Scholar] [CrossRef]

- Manoharan, N.; Dasgupta, S.P. Bearing capacity of surface footings by finite elements. Comput. Geotech. 1995, 54, 563–586. [Google Scholar] [CrossRef]

- Frydman, S.; Burd, H.J. Numerical studies of bearing capacity factor Nγ. J. Geotech. Geoenviron. Eng. 1997, 123, 20–29. [Google Scholar] [CrossRef]

- Erickson, H.L.; Drescher, A. Bearing capacity of circular footings. J. Geotech. Geoenviron. Eng. 2002, 128, 38–43. [Google Scholar] [CrossRef]

- Diaz-Segura, E.G. Assessment of the range of variation of Nγ from 60 estimation methods of footings on sand. Can. Geotech. J. 2013, 50, 793–800. [Google Scholar] [CrossRef]

- Yin, J.; Wang, Y.; Selvadurai, A.P.S. Influence of nonassociativity on the bearing capacity of a strip footing. J. Geotech. Geoenviron. Eng. 2001, 127, 985–989. [Google Scholar] [CrossRef]

- Cassidy, M.J.; Houlsby, G.T. Vertical bearing capacity factors for conical footings on sand. Geotechnique 2002, 52, 687–692. [Google Scholar] [CrossRef]

- Ukritchon, B.; Whittle, A.J.; Klangvijit, C. Calculations of bearing capacity factor Nγ using numerical limit analyses. J. Geotech. Geoenviron. Eng. 2003, 129, 468–474. [Google Scholar] [CrossRef]

- Kumar, J.; Kouzer, K.M. Effect of footing roughness on bearing capacity factor Nγ. J. Geotech. Geoenviron. Eng. 2007, 133, 502–511. [Google Scholar] [CrossRef]

- Lyamin, A.V.; Salgado, R.; Sloan, S.W.; Perzzi, M. Two- and three-dimensional bearing capacity of footings in sand. Geotechnique 2007, 57, 647–662. [Google Scholar] [CrossRef]

- Kumar, J.; Khatri, V.N. Effect of footing roughness on lower bound Nγ values. Int. J. Geomech. 2008, 8, 176–187. [Google Scholar] [CrossRef]

- Loukidis, D.; Salgado, R. Effect of relative density and stress level on the bearing capacity of footings on sand. Geotechnique 2011, 61, 107–119. [Google Scholar] [CrossRef]

- Ma, Z.; Liao, H.; Dang, F. Influence of intermediate principal stress on the bearing capacity of strip and circular footings. J. Eng. Mech. 2014, 140, 04014041. [Google Scholar] [CrossRef]

- Wang, M.C.; Badie, A.M. Effect of underground void of foundation stability. J. Geotech. Eng. 1985, 111, 1008–1019. [Google Scholar] [CrossRef]

- Kiyosymi, M.; Kusakabe, O.; Ohuchi, M.; Peng, F.L. Yielding pressure of spread footing above multiple voids. J. Geotech. Geoenviron. Eng. 2007, 133, 1522–1531. [Google Scholar] [CrossRef]

- Lee, J.K.; Jeong, S.; Ko, J. Undrained stability of surface strip footings above voids. Comput. Geotech. 2014, 62, 128–135. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhao, M.; Zhoa, H. Undrained stability of strip footing above voids in two-layered clays by finite element limit analysis. Comput. Geotech. 2018, 97, 124–133. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhao, M.; Zhoa, H.; Zhang, R. Finite element limit analysis of the bearing capacity of strip footing on a rock mass with voids. Int. J. Geomech. 2018, 18, 04018108. [Google Scholar] [CrossRef]

- Bolton, M.D. Strength and dilatancy of sands. Geotechnique 1986, 36, 65–78. [Google Scholar] [CrossRef]

- Loukidis, D.; Salgado, R. Bearing capacity of strip and circular footings in sand using finite elements. Comput. Geotech. 2009, 36, 871–879. [Google Scholar] [CrossRef]

- Drescher, A.; Detournay, E. Limit load in translational failure mechanisms for associative and non-associative materials. Geotechnique 1993, 43, 443–456. [Google Scholar] [CrossRef]

- Silvestri, V.A. limit equilibrium solution for bearing capacity of strip foundations on sand. Can. Geotech. J. 2003, 40, 351–361. [Google Scholar] [CrossRef]

- Meyerhof, G.G. Some recent research on the bearing capacity of foundations. Can. Geotech. J. 1963, 1, 16–31. [Google Scholar] [CrossRef]

- Smith, C.C. Complete limiting stress solutions for the bearing capacity of strip footings on a Mohr-Coulomb soil. Geotechnique 2005, 55, 607–612. [Google Scholar] [CrossRef]

| Reference | Method | φ (○) | ||

|---|---|---|---|---|

| 20 | 30 | 40 | ||

| Terzaghi (1943) | Limit equilibrium | 4.80 | 20.0 | - |

| Meyerhof (1963) | Semi-empirical | 2.87 | 15.7 | 93.7 |

| Bolton and Lau (1993) | Method of characteristics | 5.97 | 23.6 | 121 |

| Frydman and Burd (1997) | Finite difference | - | 16.7 | 73.0 |

| Erickson and Drescher (2002) | Finite difference | 2.5 | - | 73.0 |

| Silvestri (2003) | Limit equilibrium | - | 19.5 | 107 |

| Smith (2005) | Method of characteristics | 2.84 | 14.8 | 85.6 |

| Hjiaj et al. (2005) | Upper bound limit analysis | 2.96 | 15.2 | 88.4 |

| Hjiaj et al. (2005) | Lower bound limit analysis | 2.82 | 14.6 | 83.3 |

| Kumar and Kouzer (2007) | Upper bound limit analysis | 3.16 | 16.5 | 98.5 |

| Kumar and Khatri (2008) | Lower bound limit analysis | 2.65 | 13.7 | 77.9 |

| Loukidis and Salgado (2009) | Finite element | - | 12.9 | 67.9 |

| This study | Finite element | 3.01 | 11.9 | 65.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.K.; Kim, J. Stability Charts for Sustainable Infrastructure: Collapse Loads of Footings on Sandy Soil with Voids. Sustainability 2019, 11, 3966. https://doi.org/10.3390/su11143966

Lee JK, Kim J. Stability Charts for Sustainable Infrastructure: Collapse Loads of Footings on Sandy Soil with Voids. Sustainability. 2019; 11(14):3966. https://doi.org/10.3390/su11143966

Chicago/Turabian StyleLee, Joon Kyu, and Jaehong Kim. 2019. "Stability Charts for Sustainable Infrastructure: Collapse Loads of Footings on Sandy Soil with Voids" Sustainability 11, no. 14: 3966. https://doi.org/10.3390/su11143966

APA StyleLee, J. K., & Kim, J. (2019). Stability Charts for Sustainable Infrastructure: Collapse Loads of Footings on Sandy Soil with Voids. Sustainability, 11(14), 3966. https://doi.org/10.3390/su11143966