A Demountable Connection for Low-Rise Precast Concrete Structures with DfD for Construction Sustainability-A Preliminary Test under Cyclic Loads

Abstract

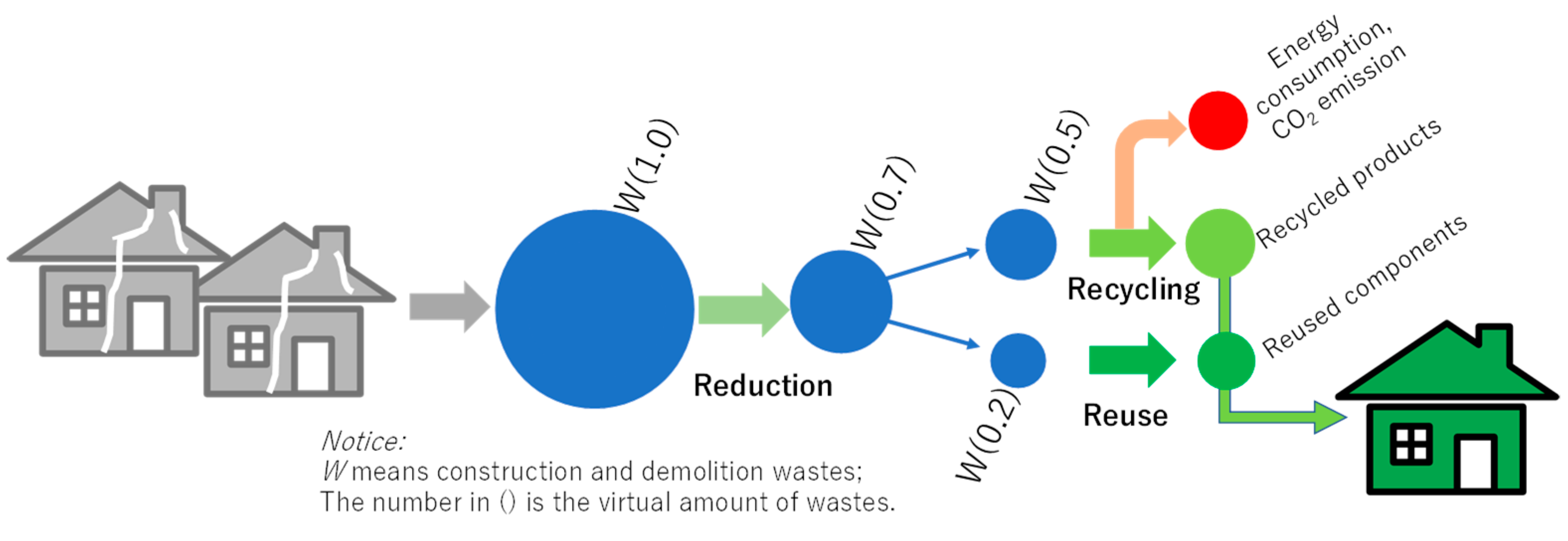

1. Introduction

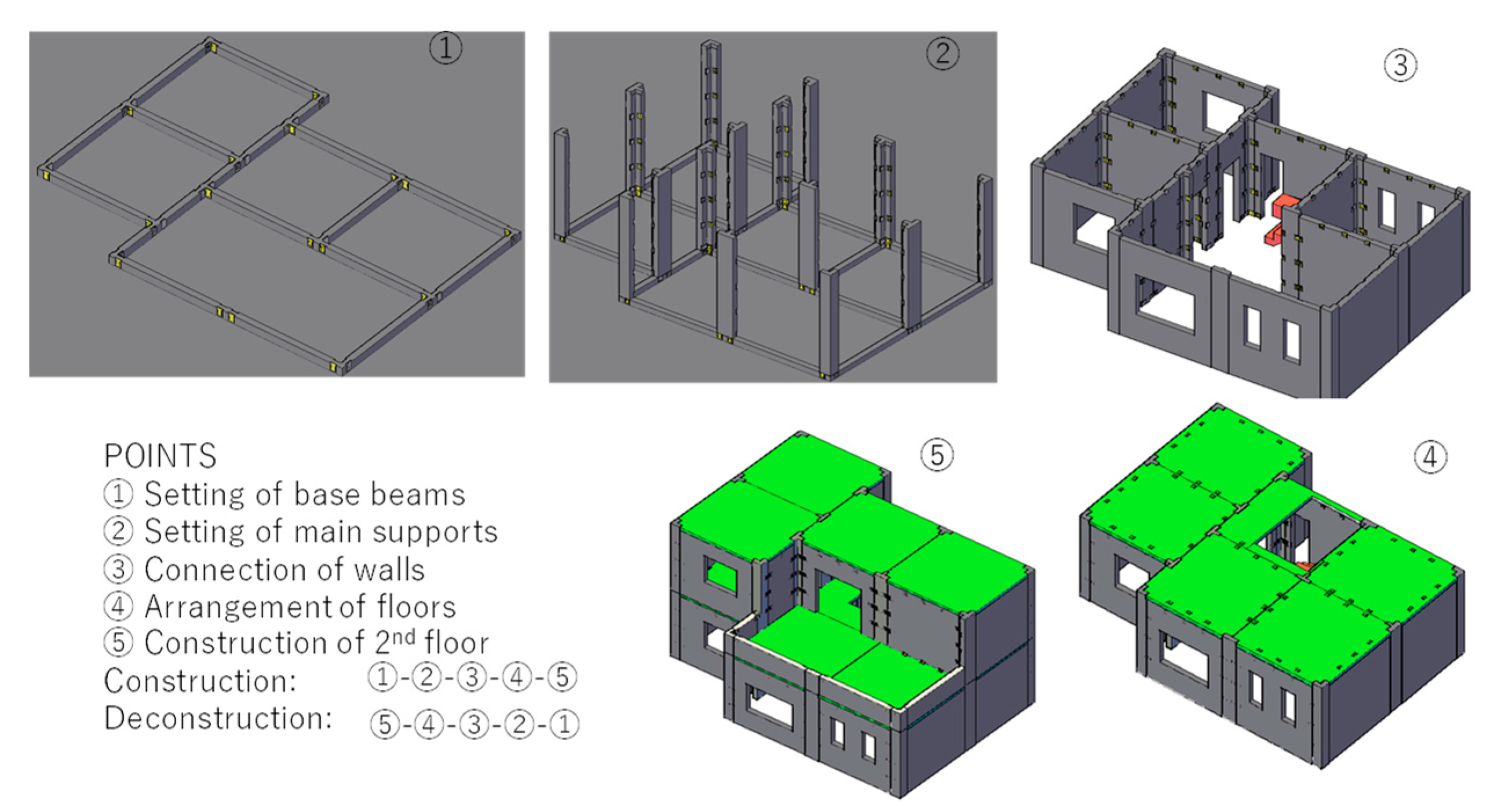

2. Proposal of a Prefabricated Shear Wall System with DfD for Low-Rise Buildings

- 1)

- Prefabricated corner members. The members work as tie columns in frame structures, which are divided into T-shaped, L-shaped or cross-shaped members at the corners of the structures.

- 2)

- Prefabricated wall panels. The panels are connected with their surrounding members by dry nodes around the panels. The joints include horizontal and vertical type joints connected between the panels and corner members. The horizontal joints could be more complex for they are formed by connecting the lower wall panel, floor slab and the upper wall panel at the same time in some cases.

- 3)

- Prefabricated slabs (roof panels). The elements are similar to the prefabricated wall panels described above. The four corners of the prefabricated slab are recessed inwardly to allow the prefabricated corner members to pass through. The edges of the slab are made as invisible beams to reinforce the joint zone and protrude 100 mm to overlap surrounding wall panels. Finally, the wall panel passes through the dry connection.

- 1)

- Leveling the site and pouring foundation beams at the prefabricated corner members and the bottom surface of prefabricated wallboard, and pre-burying dry joints in the foundation beams.

- 2)

- Positioning the prefabricated columns members. The prefabricated members are bolted to the dry joints of the foundation beams by connecting steel plates.

- 3)

- The prefabricated wall panels are connected with the foundation beams and the prefabricated columns by bolting dry joints to make the walls and the foundation beams become a whole.

- 4)

- PcaC floor slabs are overlapped at the reserved groove of wall panels and prefabricated column members, and the positions are determined, and then the dry connections are bolted to the wall panels to form a layer of the structures.

- 5)

- Repeat the above steps to complete the installation of the structure.

3. Experimental Investigation

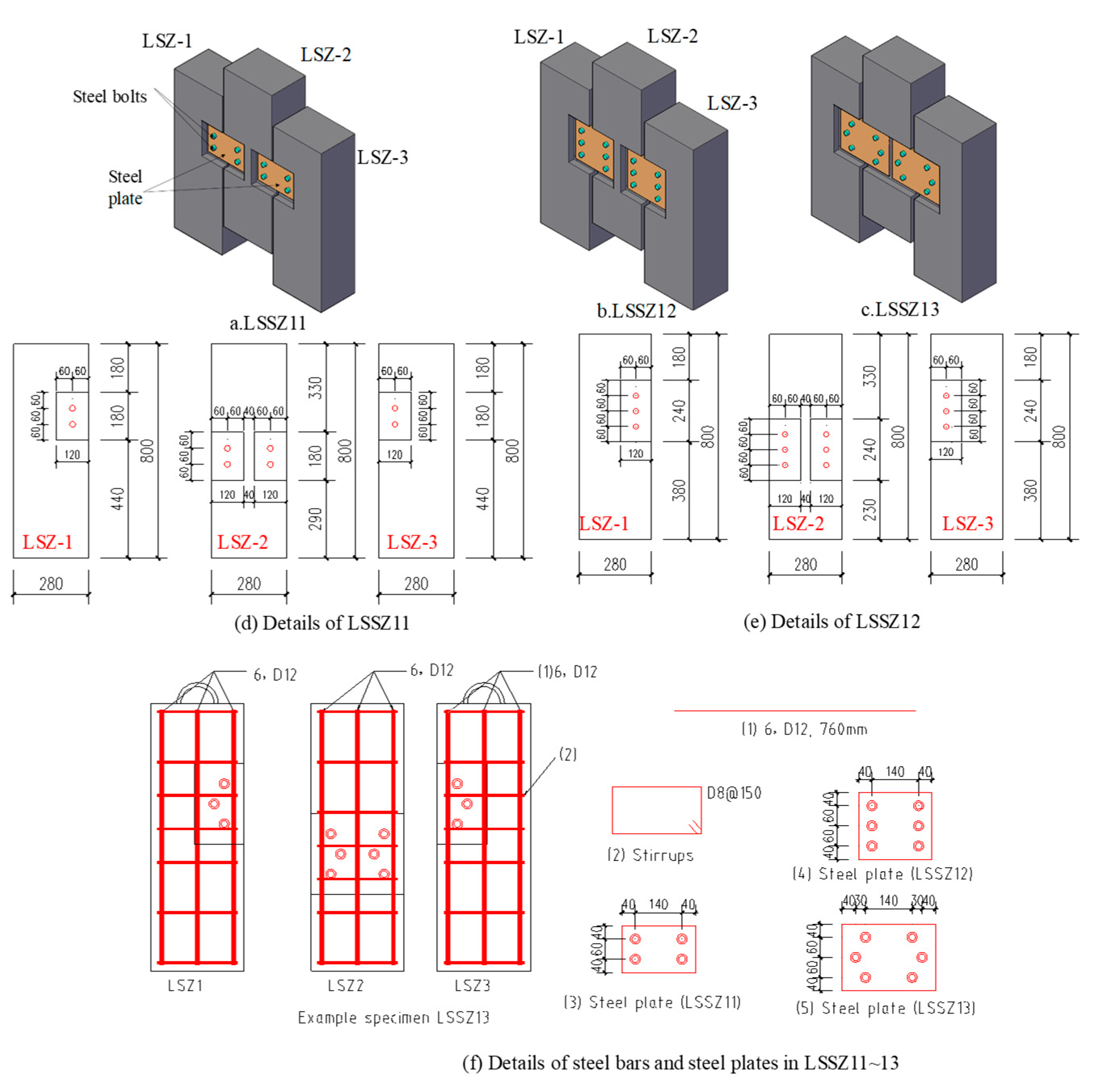

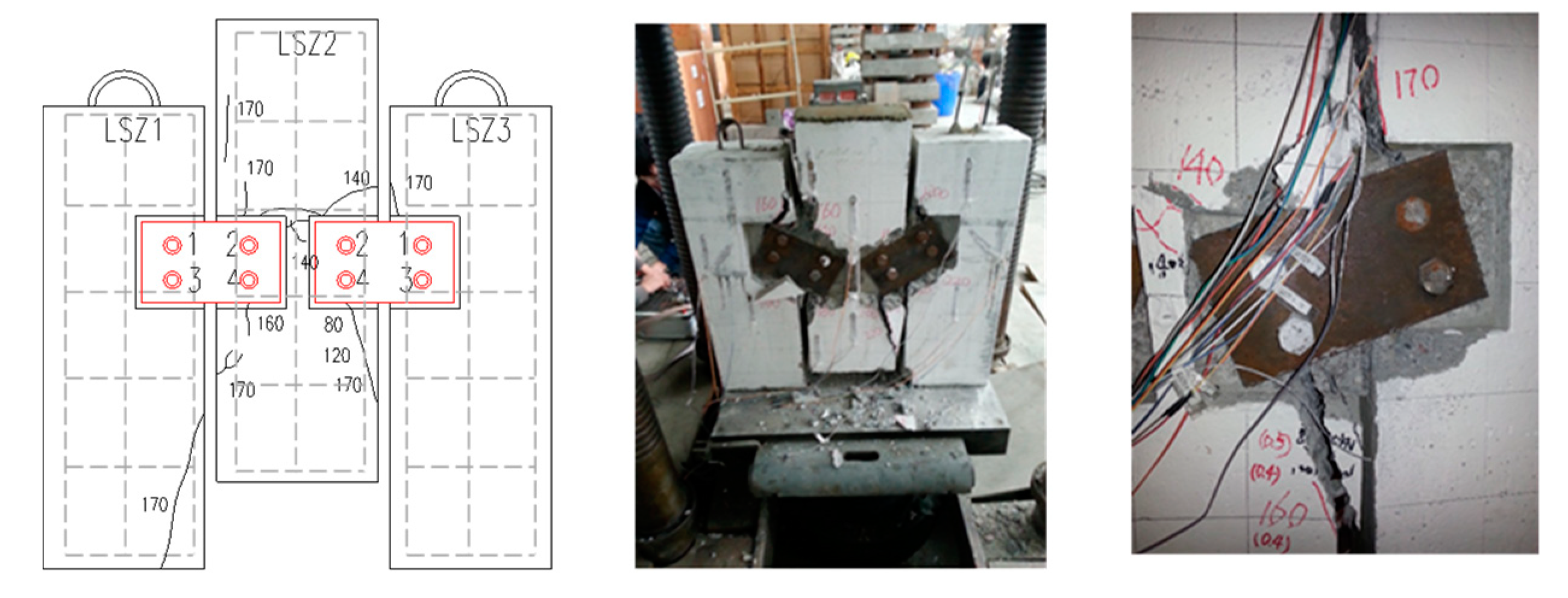

3.1. Details of Test Specimens

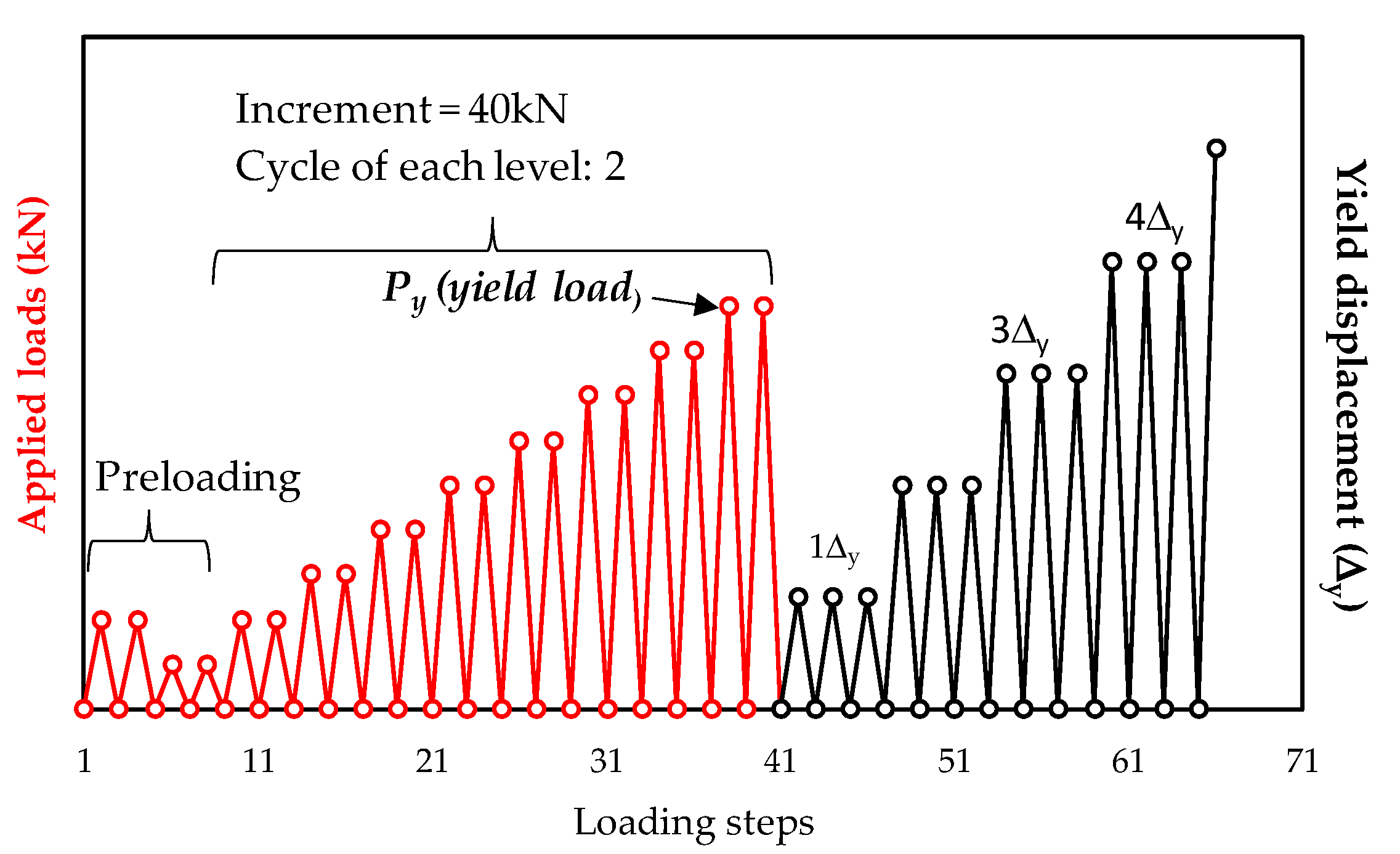

3.2. Loading Method and Measurement

4. Results

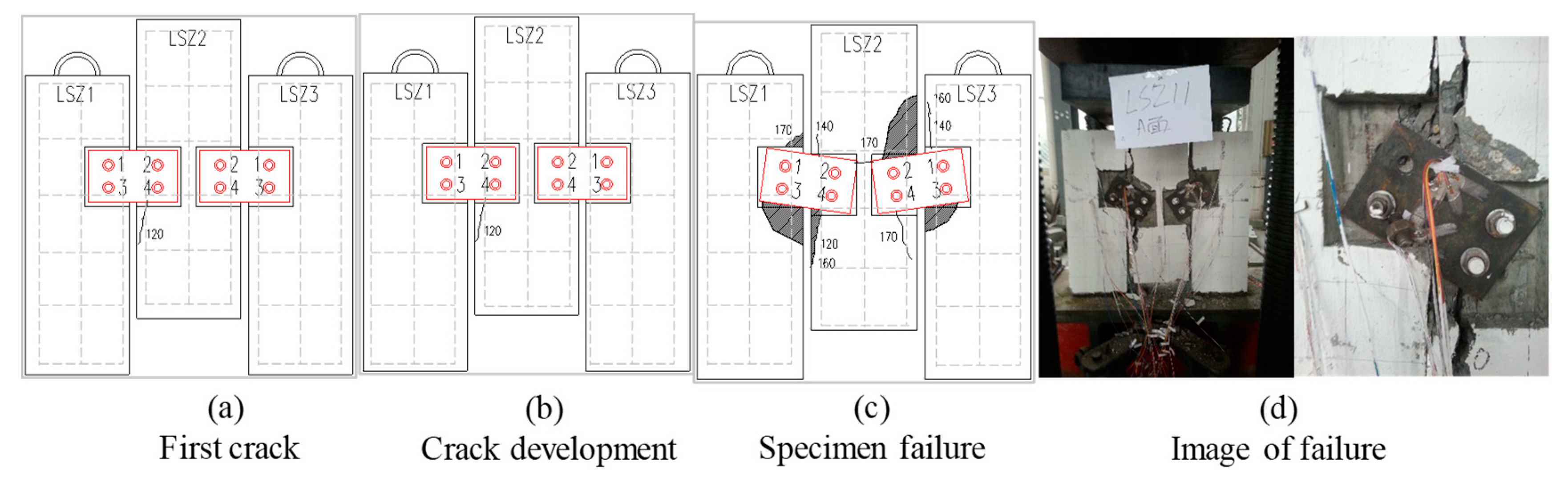

4.1. Damage Observation

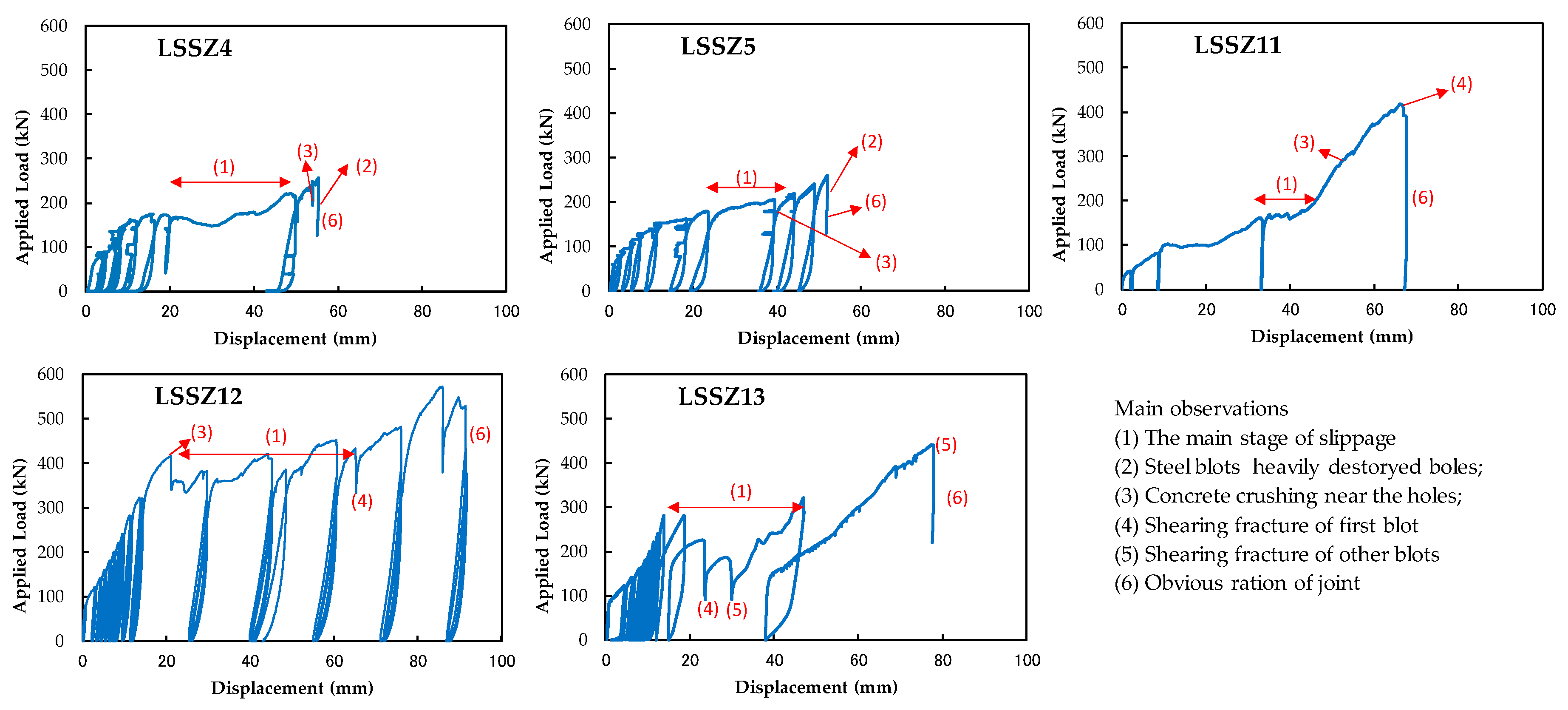

4.2. Load-Displacement Relationship

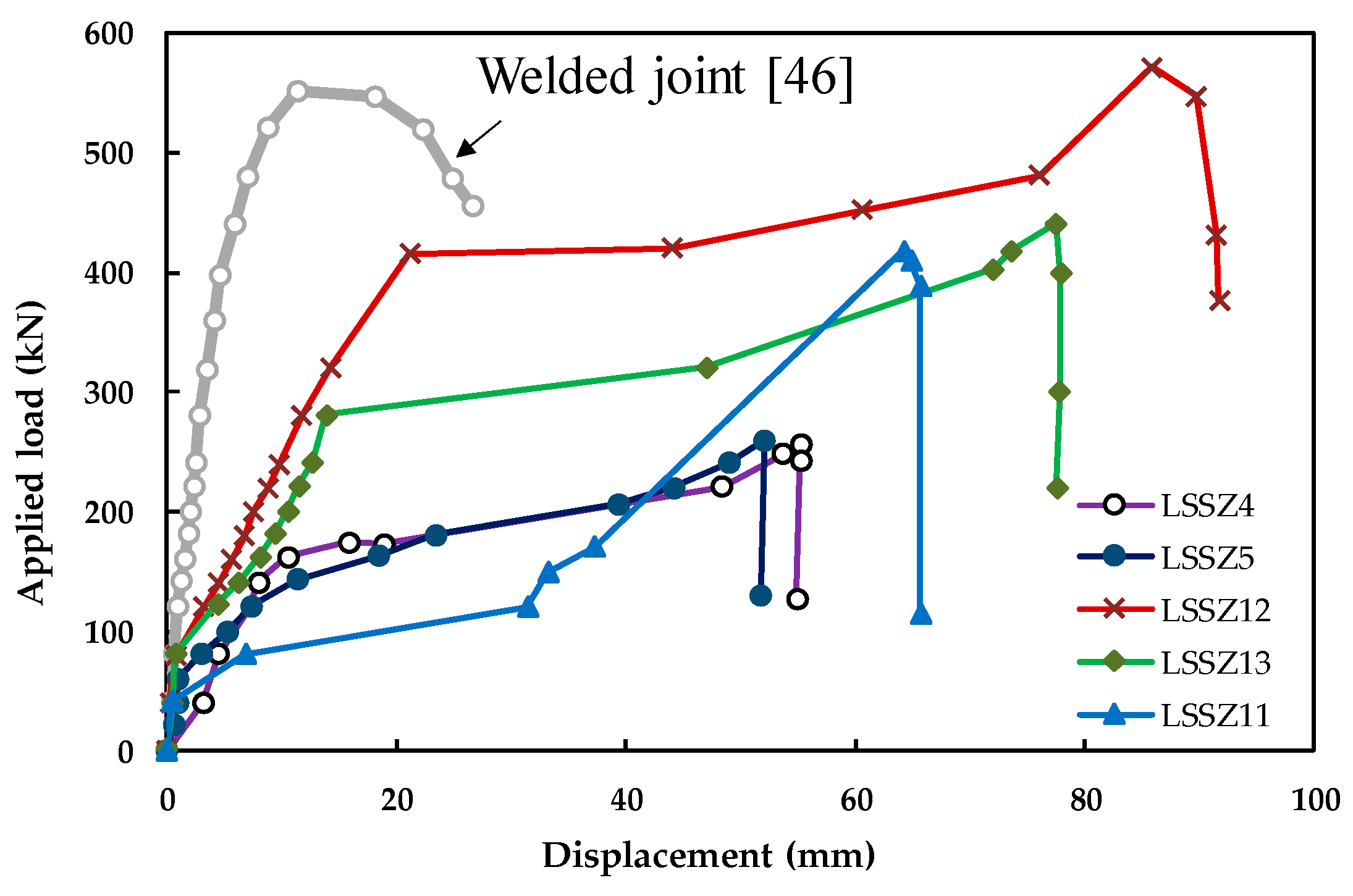

4.3. Skeleton Curves

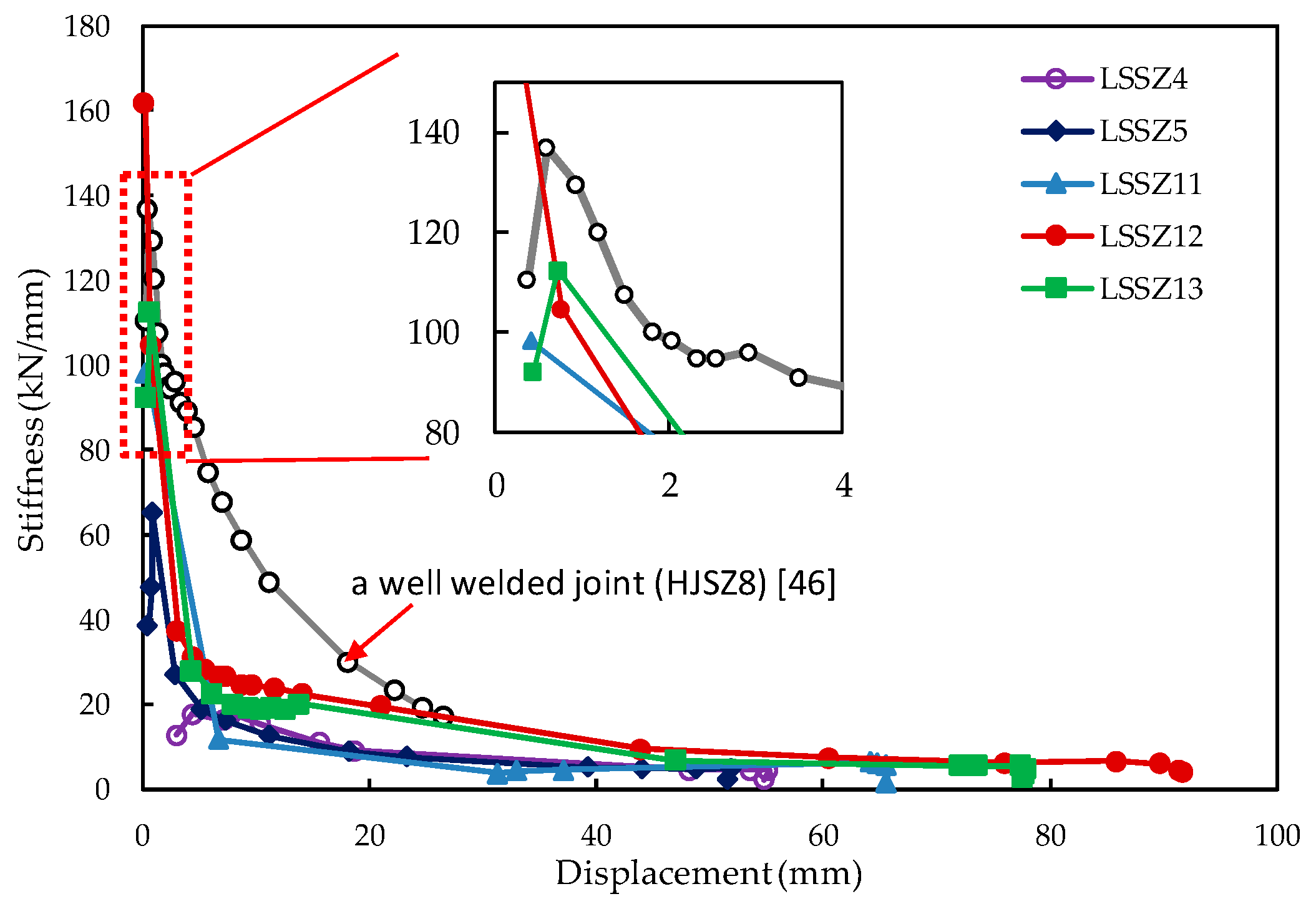

4.4. Stiffness Degradation

5. Discussions on Failure and Recommendations for Design of the Joints

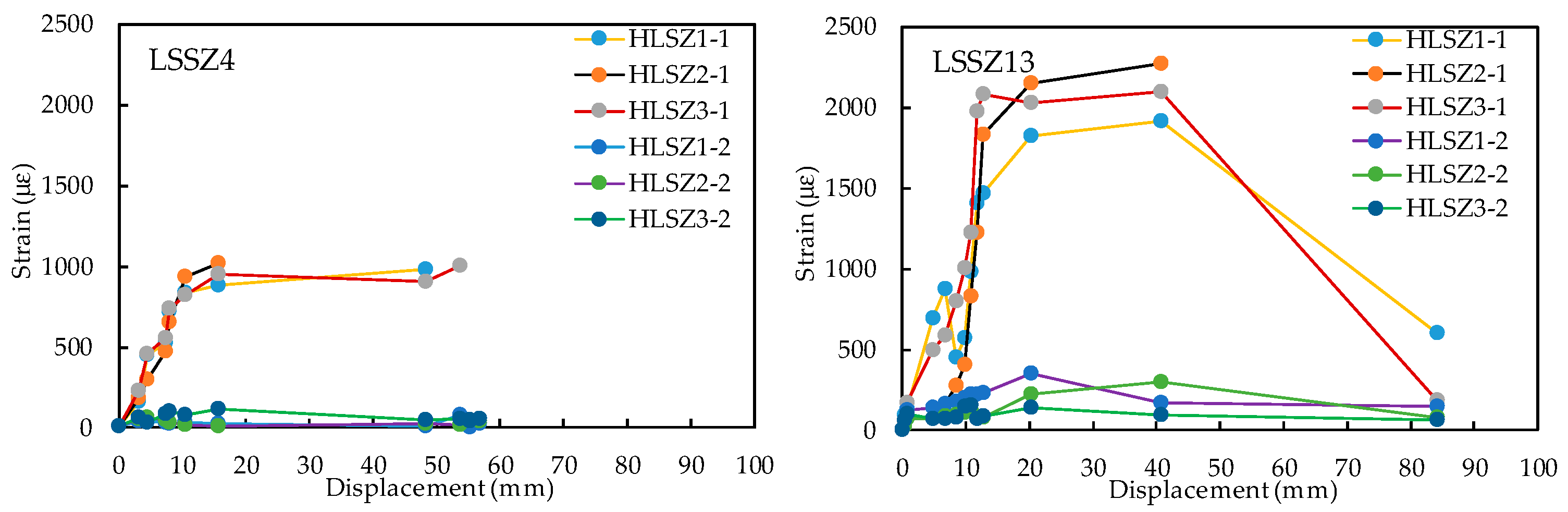

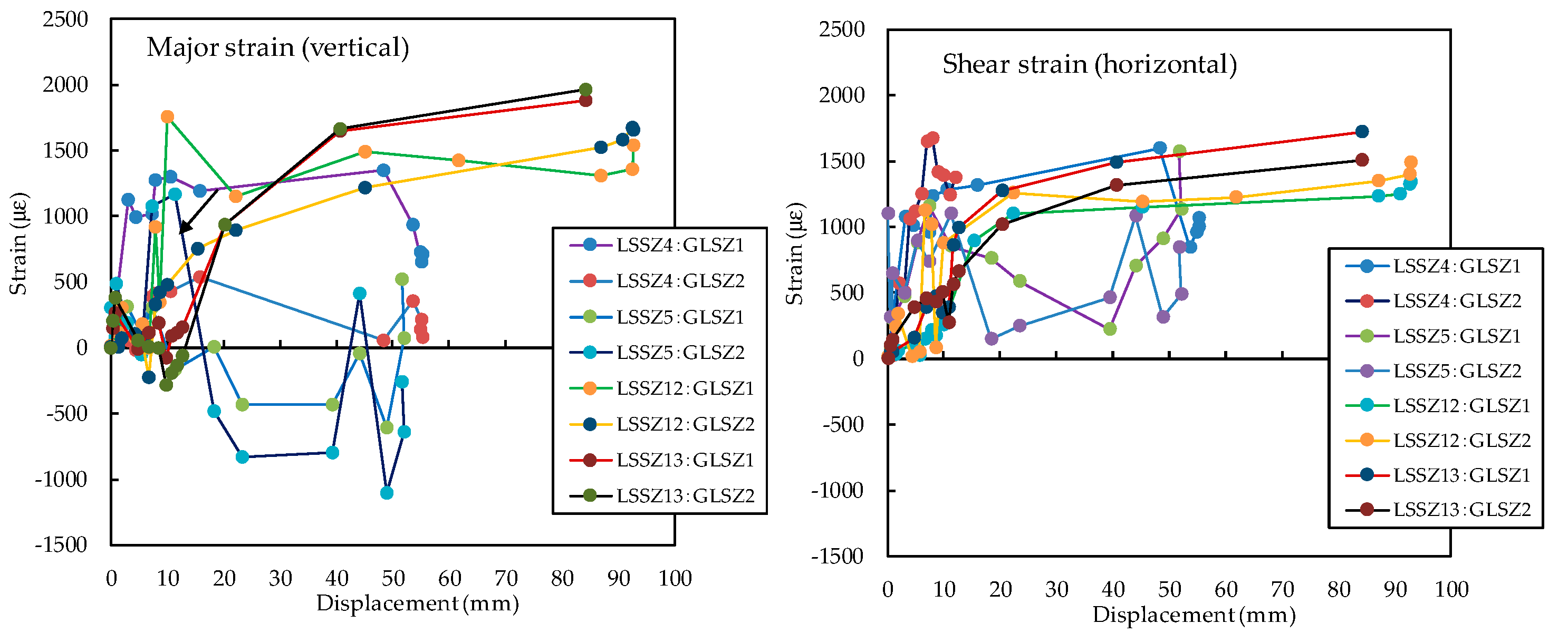

5.1. Deformation and Resistance Mechanism of Joints

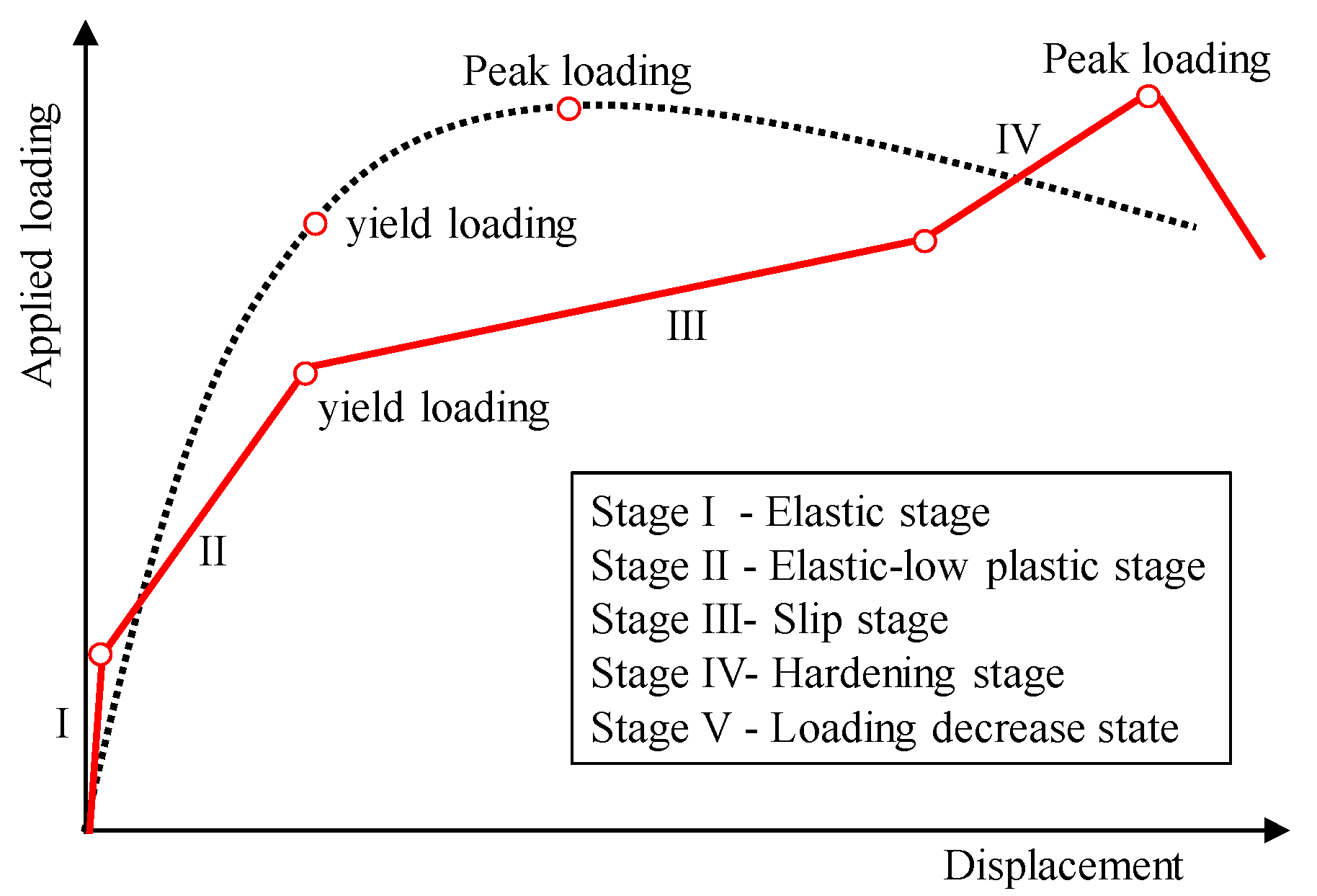

5.2. Main Features of the Load-Displacement Response of the Bolted Joints

5.3. Possible Failure Modes of the Bolted Joints

5.4. Recommendations for Design of Bolted Joints in a RC Structure with DfD

- A)

- Improve the plastic deformation of concrete holes by using high strength concrete, or using a metal pipe inside the hole to increase the bolt-hole interface strength.

- B)

- Arrange a reinforcement enhancing zone to restrain the whole move/slippage of the bolts to help the stirrups to resist the movement of steel bolts.

- C)

- High strength bolts are recommended for the joints.

- D)

- Tightening of the steel bolts is a necessary and key process to controlling the slippage.

- E)

- Prevent the out-plane deformation of joint is also a key factor to avoid the put-out of steel bolts and the tensile fracture of steel bolts. Therefore, a demountable connection set consisting of two steel plates pre-connected with concrete blocks is recommended for the joints, which is being investigated in our next studies.

6. Conclusions

- The study verified that the rotation and slippage of the bolts was a very key factor for the steel-bolted joints. When the concrete was crushed heavily or the holes were destroyed, the large rotation of steel plate could occur.

- A staggered arrangement of the bolts could not improve the load carrying capacity of the joints, which could be explained with the fact that the side bolts of the joints made the steel plate rotate largely at a large deformation stage.

- As the possible failure modes of the steel bolted joints, according the preliminary study, the put-out of steel bolts and fracture of the steel plate also could occur, which complemented the well-understood failure mode of the joints described in the existing literature, such as concrete crushing and stirrup shearing fracture.

- The paper provided several recommendations to improve the structural behavior of the joints based on investigation and analyses, such as using a demountable connection set consisting of two steel plates pre-connected with concrete blocks.

7. Patents

Author Contributions

Funding

Conflicts of Interest

References

- Elliott Kim, S. Precast Concrete Structures; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Aaleti, S.; Sritharan, S. A simplified analysis method for characterizing unbonded post-tensioned precast wall systems. Eng. Struct. 2009, 31, 2966–2975. [Google Scholar] [CrossRef]

- Perez, F.J.; Pessiki, S.; Sause, R. Experimental Lateral Load Response of Unbonded Post-Tensioned Precast Concrete Walls. ACI Struct. J. 2013, 110, 1045–1056. [Google Scholar]

- Frosch, R.J.; Li, W.; Jirsa, J.O.; Kreger, M.E. Retrofit of non-ductile moment-resisting frames using precast infill wall panels. Earthq. Spectra 1996, 12, 741–760. [Google Scholar] [CrossRef]

- Wan, M.; Zeng, B. Design and Calculation of Joints in Assembly Plate Structures. Build. Struct. 1984, 1, 43–50. (In Chinese) [Google Scholar]

- Wan, M.; Zeng, B. Strength and Stiffness of Joints in Large Plate Structures. J. Build. Struct. 1986, 4, 54–69. (In Chinese) [Google Scholar]

- Wan, M. Design of Joints for Large Plate Structures. Build. Sci. 1987, 2, 50–61. (In Chinese) [Google Scholar]

- Wan, M. Explanation on Some Problems in “Code for Design and Construction of Assembled Slab Residential Buildings”. Build. Sci. 1990, 4, 57–60. (In Chinese) [Google Scholar]

- Ministry of Housing and Urban-Rural Development of China (MHURD). JGJ1-1991, Specification for Design and Construction of Fabricated Board Civil Building Structures; MHURD: Beijing, China, 1991.

- Rizkalla, S.H.; Serrette, R.L.; Heuvel, J.S.; Attiogbe, E.K. Multiple Shear Key Connections for Precast Shear Wall Panels. PCI J. 1989, 104–120. [Google Scholar] [CrossRef]

- Foerster, H.R.; Rizkalla, S.H.; Heuvel, J.S. Behavior and design of shear connections for loadbearing wall panels. PCI J. 1989, 34, 102–119. [Google Scholar] [CrossRef]

- Nakaki, S.D.; Englekirk, R.E. PRESSS Industry Seismic Workshops: Concept Development. PCI J. 1991, 36, 54–61. [Google Scholar] [CrossRef]

- Priestley, M.J.N. Overview of PRESSS Research Program. PCI J. 1991, 36, 50–57. [Google Scholar] [CrossRef]

- Stanton, J.F.; Hawkins, N.M.; Hicks, T.R. PRESSS Project 1.3: Connection classification and evaluation. PCI J. 1991, 36, 62–71. [Google Scholar] [CrossRef]

- Priestley, M.J.N. The PRESSS Program: Current Status and Proposed Plans for Phase III. PCI J. 1996, 41, 22–40. [Google Scholar] [CrossRef]

- Priestley, M.J.N.; Sritharan, S.; Conley, J.R.; Pampanin, S. Preliminary Results and Conclusions from the PRESSS Five-Story Precast Concrete Test Buildings. PCI J. 1999, 44, 42–67. [Google Scholar] [CrossRef]

- Han, J.; Li, Z.; Song, X. A New Type of Connection for assembling concrete frame: Study on Prestressed. Assem. Fram. Struct. Constr. Ind. Constr. 2009, 39, 100–103. (In Chinese) [Google Scholar]

- Soudki, K.A.; Rizkalla, S.H.; Daikiw, R.W. Horizontal connections for precast concrete shear walls subjected to cyclic deformations. II: Prestressed connections. PCI J. 1995, 40, 82–96. [Google Scholar] [CrossRef]

- Soudki, K.A.; West, J.S.; Rizkalla, S.H.; Blackett, B. Horizontal connections for precast concrete shear wall panels under cyclic shear loading. PCI J. 1996, 41, 64–80. [Google Scholar] [CrossRef]

- Soudki, K.A.; Rizkalla, S.H.; LeBlanc, B. Horizontal connections for precast concrete shear walls subjected to cyclic deformations part 1: Mild steel connections. PCI J. 1995, 40, 78–96. [Google Scholar] [CrossRef]

- Park, R. A perspective on the seismic design of precast concrete structures in New Zealand. PCI J. 1995, 40, 40–60. [Google Scholar] [CrossRef]

- Crisafulli, F.J.; Restrepo, J.I. Ductile steel connections for seismic resistant precast buildings. J. Earthq. Eng. 2003, 7, 541–553. [Google Scholar] [CrossRef]

- Lian, X.; Ye, X.; Wang, D.; Jiang, Q.; Chang, L. Experimental Analysis of Seismic Behavior of Superimposed Slab Shear Walls. J. Hefei Univ. Technol. (Nat. Sci.) 2009, 32, 1219–1223. [Google Scholar]

- Lian, X.; Ye, X.; Jiang, Q.; Wang, D. A New Green Resident Structure System: The Superimposed Slab Shear Walls System. Ind. Constr. 2010, 40, 79–92. (In Chinese) [Google Scholar]

- Ren, J.; Ye, X. Seismic Behavior Research on the Superimposed Slab Shear Walls for Different Axial-Load Ratios. Struct. Eng. 2010, 26, 66–71. (In Chinese) [Google Scholar]

- Jiang, Q.; Ye, X.; Zhong, X. Calculation Model for Superimposed Slab Shear Walls. China Civ. Eng. J. 2012, 45, 8–12. (In Chinese) [Google Scholar]

- Henry, R.S.; Aaleti, S.; Sritharan, S.; Ingham, J.M. Concept and finite-element modeling of new steel shear connectors for self-centering wall systems. J. Eng. Mech. 2009, 136, 220–229. [Google Scholar] [CrossRef]

- Bournas, D.A.; Negro, P.; Molina, F.J. Pseudodynamic tests on a full-scale 3-storey precast concrete building: Behavior of the mechanical connections and floor diaphragms. Eng. Struct. 2013, 57, 609–627. [Google Scholar] [CrossRef]

- Negro, P.; Bournas, D.A.; Molina, F.J. Pseudodynamic tests on a full-scale 3-storey precast concrete building: Global response. Eng. Struct. 2013, 57, 594–608. [Google Scholar] [CrossRef]

- Architecture Institute of Japan (AIJ). Evaluation Method and Design of Shear Strength for Multi-Story Precast Reinforced Concrete Structural Walls; AIJ: Tokyo, Japan, 2002; p. 116. (In Japanese) [Google Scholar]

- Takagi, J.; Shimonishikida, S.; Kitayama, K.; Minami, S. Development of static analysis models of existing wall-type precast reinforced concrete residential buildings. J. Struct. Constr. Eng. (Trans. AIJ) 2012, 77, 113–120. (In Japanese) [Google Scholar] [CrossRef][Green Version]

- Nagae, T.; Tahara, K.; Fukuyama, K.; Matsumori, T.; Shiohara, H.; Kabeyasawa, T.; Kono, S.; Nishiyama, M.; Nishiyama, I. Seismic performance assessment and improvement of prestressed concrete building based on E-defense shaking table test. J. Struct. Constr. Eng. (Trans. AIJ) 2012, 77, 75–84. (In Japanese) [Google Scholar] [CrossRef]

- Shiohara, H.; Imai, H.; Nishiyama, M. Recent Developments of Structural Regulations for Precast Concrete Buildings. Concr. J. 2003, 41, 3–9. (In Japanese) [Google Scholar] [CrossRef]

- Jiang, H. Research and Application of Prefabricated Concrete Shear Wall Structure Technology. Housing Ind. 2011, 6, 33–36. (In Chinese) [Google Scholar]

- Yang, Y. Experimental Research on Seismic Performance of Precast Shear Wall with Vertical Joint Surface. Master Thesis, Harbin Institute of Technology, Heilongjiang Sheng, China, 2011. (In Chinese). [Google Scholar]

- Liu, W.; Jiang, H.; Geng, Y.; Yan, H. Plug-In Type Preformed Hole Grouting Reinforcement Lapping Connection Component. Chinese Patent ZL200820090150.6, 8 April 2009. (In Chinese with English abstract). [Google Scholar]

- Jiang, H.; Zhang, H.; Liu, W.; Yan, H. Experimental Study on Plug-in Filling Hole for Steel Bar Anchorage of the PC Structure. J. Harbin Inst. Technol. 2011, 43, 28–36. (In Chinese) [Google Scholar]

- Jiang, H.; Chen, Z.; Zhang, J.; Wu, B.; Tian, Y.; Liu, W. Quasi-static test of precast reinforced concrete shear wall structure. J. Build. Struct. 2011, 32, 34–39. (In Chinese) [Google Scholar]

- Zhang, J. Experimental Research on Seismic Behavior of Full-scale Precast Shear Wall Substructure. Master Thesis, Harbin Institute of Technology, Heilongjiang Sheng, China, 2010. (In Chinese). [Google Scholar]

- Qian, J.; Peng, Y.; Zhang, J.; Qin, H.; Li, J.; Liu, G.; Zhao, F.; Li, L. Tests on seismic behavior of pre-cast shear walls with vertical reinforcements spliced by grout sleeves. Build. Struct. 2011, 41, 1–6. (In Chinese) [Google Scholar]

- Zhang, W.; Qian, J.; Chen, K.; Qin, H.; Liu, G.; Li, J. Tests on seismic behavior of precast shear walls with vertical distributed reinforcements spliced by a single row connection rebars. Build. Struct. 2011, 41, 12–16. (In Chinese) [Google Scholar]

- Zhang, W.; Qian, J.; Yu, J.; Qin, H.; Liu, G. Tests on seismic behavior of precast shear walls with cast-in-situ boundary elements and vertical distributed reinforcements spliced by a single row of steel bars. Chin. Civ. Eng. J. 2012, 45, 89–97. (In Chinese) [Google Scholar]

- Sun, J.; Qiu, H.X. Seismic behavior and mechanism analysis of innovative precast shear wall involving vertical joints. J. Cent. South Univ. 2015, 22, 1536–1547. [Google Scholar] [CrossRef]

- China Academy of Building Research. GB/T 50152-2012, Standard for Test Method of Concrete Structures; China Academy of Building Research: Beijing, China, 2012. (In Chinese) [Google Scholar]

- China Academy of Building Research. JGJ/T 101-2015, Specification for Seismic Test of Buildings; China Academy of Building Research: Beijing, China, 2010. (In Chinese) [Google Scholar]

- Xu, Y. Dry Connections for Precast Shear Walls in Rural Housing. Ph.D. Thesis, Sichuan University, Chengdu, China, 2017; p. 183. (In Chinese). [Google Scholar]

- Xiong, F.; Xu, J.; Xu, Y.; Liu, B. Lower Housing Prefabricated Composite Wall Structure of Nodes Connected. Chinese Patent ZL201410171848.0, 10 February 2016. (In Chinese with abstract). [Google Scholar]

| # | Size of Blocks (mm3) | Stirrups (D@ Spacing) | #of bolts / Line# of Bolts | Steel Plate (Length × Width × Thickness; mm3) |

|---|---|---|---|---|

| LSSZ4, 5 | 860 × 200 × 950 | D8@150 | 4/2 Lines | 240 × 140 × 8 |

| LSSZ11 | 880 × 200 × 950 | D8@150 + D8@100 (joint zone) | 4/2 Lines | 220 × 140 × 8 |

| LSSZ12 | 880 × 200 × 950 | 6/3 Lines | 220 × 200 × 8 | |

| LSSZ13 | 880 × 200 × 950 | 6/3 Lines (staggered) | 280 × 200 × 8 |

| Specimens | Concrete Materials | Steel Materials fy (MPa)/ fu (MPa)/εy (10-6) | |||||

|---|---|---|---|---|---|---|---|

| fcu (MPa) | Ec (MPa) | εy (10-6) | C8 | C12 | Q235B | Bolts | |

| LSSZ4 | 24.6 | 28117 | 262 | 438.4/ 619.1/ 2192 | 459.3/ 639.9/ 2297 | 283.3/ 399.8/ 1417 | 320.0/ 407.1/ 1600 |

| LSSZ5 | 22.7 | 23779 | 286 | ||||

| LSSZ11 | 50.4 | 34622 | 292 | 420.9/ 595.0/ 2105 | 447.6/ 623.3/ 2238 | 291.4/ 397.5/ 1457 | 320.0/ 407.1/ 1600 |

| LSSZ12 | 50.4 | 34622 | 292 | ||||

| LSSZ13 | 35.7 | 31525 | 340 | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, G.; Xiong, F.; Xu, Y.; Si Larbi, A.; Lu, Y.; Yoshizawa, M. A Demountable Connection for Low-Rise Precast Concrete Structures with DfD for Construction Sustainability-A Preliminary Test under Cyclic Loads. Sustainability 2019, 11, 3696. https://doi.org/10.3390/su11133696

Cai G, Xiong F, Xu Y, Si Larbi A, Lu Y, Yoshizawa M. A Demountable Connection for Low-Rise Precast Concrete Structures with DfD for Construction Sustainability-A Preliminary Test under Cyclic Loads. Sustainability. 2019; 11(13):3696. https://doi.org/10.3390/su11133696

Chicago/Turabian StyleCai, Gaochuang, Feng Xiong, Yong Xu, Amir Si Larbi, Yang Lu, and Mikio Yoshizawa. 2019. "A Demountable Connection for Low-Rise Precast Concrete Structures with DfD for Construction Sustainability-A Preliminary Test under Cyclic Loads" Sustainability 11, no. 13: 3696. https://doi.org/10.3390/su11133696

APA StyleCai, G., Xiong, F., Xu, Y., Si Larbi, A., Lu, Y., & Yoshizawa, M. (2019). A Demountable Connection for Low-Rise Precast Concrete Structures with DfD for Construction Sustainability-A Preliminary Test under Cyclic Loads. Sustainability, 11(13), 3696. https://doi.org/10.3390/su11133696