Abstract

Fly ash and slag have been widely used to produce low-CO2 concrete. However, previous studies have not paid enough attention to the lower carbonation resistance of fly-ash-and-slag-blended concrete and the aggravations of carbonation due to climate change. This study proposes a technique for the design of fly-ash-and-slag-blended concrete considering carbonation durability coupled with various climate change scenarios. First, CO2 emissions are evaluated from concrete mixtures. Concrete strength and carbonation depth are evaluated using efficiency factors of fly ash and slag. A genetic algorithm (GA) is used to find the optimal mixture with the lowest CO2 emissions considering the requirements of strength, carbonation durability, and workability. Second, we clarify the effect of cost on the mixture design of low-CO2 concrete. A genetic algorithm is also used to find the optimal mixture with the lowest cost. We found that the optimal mixture with the lowest cost is different from that with the lowest CO2 emissions. Third, by adding the additional constraint of cost, Pareto optimal mixtures are determined, which consider both lower CO2 emissions and lower material cost. The analysis results show that carbonation durability is the control factor of mixture design of fly ash-slag blended concrete. To mitigate the challenge of climate change, the binder content of blended concrete should be increased.

1. Introduction

Fly ash and slag are widely used as mineral admixtures for producing environmentally friendly concrete. The additions of fly ash and slag present many advantages for the performance of concrete, such as increased early age workability, improved late-age strength, and enhanced chloride ingress durability. However, the carbonation resistance of concrete is lowered because of the addition of fly ash and slag. For the material design of fly-ash-and-slag-blended concrete in an atmospheric environment, carbonation resistance should be carefully checked [1,2].

Many studies have evaluated the CO2 emissions of mineral admixtures blended concrete. Dijk et al. [3] made a practical engineering tool that can design a steel-reinforced concrete structural element and consider environmental performances, such as climate change, metal depletion, and fossil depletion. Randl et al. [4] reported that for ultra-high-performance concrete, when 45% of cement is replaced with fine slag, 42% of the global warming potential and 20% of acidification potential reductions can be achieved. Yu et al. [5] produced ultra-high-performance concrete using fly ash, slag, and limestone powders. They found that given the same compressive strength, the addition of mineral admixtures can reduce 25% of CO2 emissions. Fantilli and Chiaia [6] and Chiaia et al. [7] proposed an eco-mechanical index for structural concrete. They found that when 25% fly ash and 0.5% steel fiber were added into concrete, the eco-mechanical performance of concrete could be improved. Heede and De Belie [8] proposed that the total CO2 emissions are related to both the CO2 emissions of unit volume concrete and the volume of the structural element member. Proske et al. [9] found that when fly ash and limestone are used to replace 55% of cement, 50% of the environmental impact can be reduced because of the reduction of cement content.

Compared with numerous studies about CO2 emission evaluations of concrete, studies on the mixture design of fly-ash-and-slag-blended low-CO2 concrete are limited. Miller et al. [10,11] proposed equations for evaluating water-to-binder ratios of blended concrete and also proposed comparison indices that combine global warming potential with material properties. Muller et al. [12] proposed a mixture development procedure for green concrete containing fly ash, slag sand, and inert fillers and evaluated the relations between global warming potential and concrete strength. Yang et al. [13] proposed a mixture proportioning design method for fly-ash-and-slag-blended low-CO2 concrete considering the requirements of CO2 reduction, strength, and workability. However, Miller et al. [10,11], Muller et al. [12], and Yang et al. [13] mainly focused on CO2 emissions and strength. Their studies [10,11,12,13] did not consider the limit of lower carbonation resistance of fly-ash-and-slag-blended concrete. Especially due to global warming, CO2 concentration, atmospheric environment increase, and rate of carbonation have consequently accelerated [14]. Hence, it is necessary to consider carbonation durability when designing fly-ash-and-slag-blended concrete. On the other hand, Miller et al. [10,11], Muller et al. [12], and Yang et al. [13] did not consider the material cost for producing low-CO2 concrete. Eleftheriadis et al. [15] proposed that the design of reinforced concrete mixtures with the lowest CO2 emissions may not have cheapest price. Because concrete factories are interested in both CO2 emissions and cost, it is important to consider material cost when designing low-CO2 concrete.

This research proposes a technique for the design of low-CO2 cement–fly ash–slag ternary-blended concrete that considers carbonation coupled with various climatic change scenarios. A genetic algorithm is adopted to obtain the mixtures of CO2 concrete satisfying the constraint conditions of strength, carbonation durability along with climatic change, and workability. Furthermore, we clarify the impact of material cost on the mixing style of low-CO2 concrete. We also find the Pareto optimal mixtures that have lower CO2 emissions and lower material cost.

2. Optimization Design of Concrete Mix Proportions

To optimize the concrete mixing proportions, the objective function and constraint conditions ought to be established. As CO2 emissions from the cement industry account for about 7% of global CO2 emissions. The reduction of CO2 emissions is an emerging and valuable topic in the concrete industry. In this study, CO2 emissions were the objective function. The constraint conditions considered the needs of concrete strength, carbonation durability, workability, component contents, component ratios, and absolute volume [16].

2.1. Objective Function

The total CO2 emissions of fly-ash-and-slag-blended concrete includes CO2 emissions from concrete materials, transport, and the mixing of concrete [17,18]. These emissions can be calculated as follows [17,18]:

where CO2−e, CO2−eM, CO2−eT, and CO2−eP represent total CO2 emissions, CO2 emissions from concrete materials, CO2 emissions from transport, and CO2 emissions from the mixing operation of concrete, respectively. CO2−eM can be calculated according to concrete mixture and unit CO2 emissions of concrete components as follows:

where CO2−c, CO2−SG, CO2−FA, CO2−W, CO2−CA, CO2−S, and CO2−SP are unit CO2 emissions of cement, slag, fly ash, water, coarse aggregate, sand, and superplasticizer, respectively, and C, SG, FA, W, CA, S, and SP are the mass of cement, slag, fly ash, water, coarse aggregate, sand, and superplasticizer in concrete mixtures, respectively. Table 1 shows the CO2 emissions of the concrete components. As this study concentrates on the influence of global warming on carbonation durability and concrete mixtures, the objective function was set to CO2−eM.

Table 1.

CO2 emissions of the concrete components [13].

2.2. Constraint Conditions

The objective function (minimum of CO2 emissions, CO2−eM) is exposed to various constraints, for example, concrete strength, carbonation durability, workability, component contents, component ratios, and absolute volume [16].

The strength constraint means the design strength ought to be higher than the required strength. The formula for the strength constraint is as follows:

where is the concrete strength at age t and is the required strength at age t.

When fly ash and slag are used to replace partial cement, the fly ash and slag reaction will produce secondary calcium silicate hydrate, fill up the space of capillary pores, and contribute to the long-term strength of the concrete. However, the carbonation resistance decreases because of the increase of concrete porosity and the decrease of the content of calcium hydroxide from the additions of fly ash and slag. Hence, for fly-ash-and-slag-blended concrete in an atmospheric environment, strength alone cannot guarantee the carbonation durability of the fly-ash-and-slag-blended concrete. The carbonation constraint of concrete is shown as follows:

where is the carbonation depth at the exposure service life and CV is the cover depth of the concrete.

The workability constraint of fresh concrete is

where is the needed slump of concrete.

The components of concrete consist of cement, slag, fly ash, water, fine aggregate, coarse aggregate, and water-reducing agents. The range of component contents is

where the component represents cement, fly ash, slag, water, fine aggregate, coarse aggregate, and superplasticizer. Table 2 shows the lower and upper limits of the concrete components [16].

Table 2.

Lower and upper limits of the concrete components [16].

The component ratio constraint is

where Ri is the component ratio (for example, water-to-binder ratio, fly-ash-to-binder ratio, slag-to-binder ratio, mineral-admixtures-to-binder ratio, fine-aggregate-to-total-aggregate ratio, total-aggregate-to-binder ratio, and water-to-solid ratio). and are the lower and upper limits of the component ratio, respectively. Table 3 shows the component ratio constraints [16].

Table 3.

Component ratio constraints [16].

The absolute volume constraint is as follows:

where , , , ,, , and are the density of water, cement, slag, fly ash, sand, coarse aggregate, and superplasticizer, respectively, and is the volume of air in the concrete. The densities of water, cement, slag, fly ash, sand, coarse aggregate, and superplasticizer are 1000, 3150, 2900, 2130, 2610, 2700, and 1220 kg/m3, respectively. Equation (8) implies that the sum of each concrete component should be equal to 1 m3 [16].

2.3. Properties Evaluation of Fly-Ash-and-Slag-Blended Concrete

2.3.1. Strength Model

Papadakis [19,20] proposed that for concrete that incorporates supplementary cementitious materials (SCMs), the strength of such concrete can be evaluated using efficiency factors of SCMs. The efficiency factor is dependent on the type of SCMs and ages. Yeh [21] conducted widely experimental studies about the compressive strength of fly-ash-and-slag-blended concrete. A total of 427 mixing proportions were used, and the maximum replacement ratios of slag, fly ash, and slag plus fly ash were 0.61, 0.55, and 0.75, respectively. Based on Yeh’s study [21], the compressive strength of fly-ash-and-slag-blended concrete at 28 days can be evaluated using Abrams’ law:

where 0.773 and 0.385 are the strength efficiency factors of slag and fly ash, respectively. Because slag has higher reactivity than fly ash, the efficiency factor of slag is also higher than that of fly ash.

2.3.2. Carbonation Model

Papadakis [19,20] proposed a general equation for evaluating the carbonation depth of concrete containing fly ash and slag. The equation considers both concrete material properties and environmental exposure conditions. As the relative humidity of the exposure environment is higher than 50%, the carbonation depth of fly-ash-and-slag-blended concrete can be determined as follows [19,20,22]:

where xc is the carbonation depth of the concrete, D is CO2 diffusivity, (CO2)0 is the CO2 molar concentration at the concrete surface, αH is the degree of reaction of binders () [19,20,22], and RH is environmental relative humidity.

The carbonation efficiency factors of slag and fly ash are 0.7 and 0.5, respectively [19,20]. In the denominator of Equation (10), refers to the content of carbonatable substances in concrete. In the numerator of Equation (11), is the porosity of carbonated concrete. For climate change conditions, CO2 concentration and CO2 diffusivity are time dependent. The time-averaged CO2 concentration and CO2 diffusivity are used for the climate change conditions [17,18].

The effect of environmental temperature on CO2 diffusivity can be viewed as using the Arrhenius law as follows [17,18,22]:

where Dref is CO2 diffusivity at reference temperature Tref, D(T) is CO2 diffusivity at temperature T, and β is the activation energy of CO2 (β = 4300).

2.3.3. Workability Model

According to the experimental results shown in [23,24], the slump of fly-ash-and-slag-blended concrete can be determined as follows:

where is the water-to-binder ratio, is the sand ratio, is the slag substitute ratio in binder, is the fly ash substitute ratio in binder, and SP is the content of superplasticizer. This equation shows that concrete slump increases with water content, slag and fly ash substitute ratios, and superplasticizer content and decreases with the sand ratio. The unit of slump in Equation (13) is mm.

According to the mixing proportions in [23,24], the superplasticizer content in concrete could be roughly determined as a function of the water-to-binder ratio:

This equation shows that when the water-to-binder ratio decreases, the superplasticizer content in the concrete mixtures should increase.

2.3.4. Summary of Properties Evaluation Models and Genetic Algorithm

Summarily, within this section, we determine the objective function and constraints of the concrete mixing proportions. The objective function is minimum CO2 emissions, CO2−eM. The properties evaluation models consist of a strength model, carbonation model, and slump model. The calculation results of properties evaluation models can be used as constraints of optimal design. The constraints include various performance standards, for example, compressive strength, carbonation coupled with climate change scenarios, workability of fresh concrete, component contents, component ratios, and absolute volume of the concrete mixture. The objective function and constraints can be determined from concrete mixtures and the environment. Once the objective function and constraints are solved, the concrete mixtures that meet various performance standards can be acquired.

A genetic algorithm can deal with constraints well, analyze beyond the local optimum, and finally get the global optimal solution, with strong global search ability. Hence, in this study, we used a genetic algorithm for solving the objective function with constraints. A genetic algorithm is an adaptive global optimization probability search algorithm that simulates the genetic and evolutionary processes of living things in the natural environment [25]. The process of the genetic algorithm is summarized as follows: step 1: generate the initial population; step 2: calculate the fitness; step 3: select cross mutation operations and compute fitness function; and step 4: check convergence criteria. Repeat step 3 until the convergence criteria are met.

In this study, we used the MATLAB (version R2019a, The Mathworks Korea, Seoul, Korea) global optimization toolbox for solving objective optimization with constraints [25]. The objective function and constraints equation can be set in the MATLAB global optimization toolbox. According to the genetic algorithm, the optimal mixture that has the minimum CO2 emissions and can meet various constraints was found.

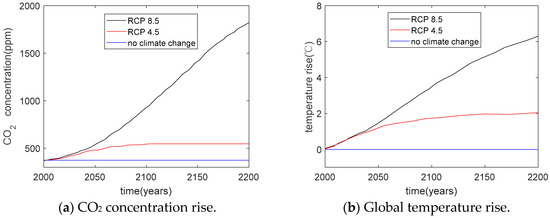

3. Illustrative Examples

In this section, regarding the carbonation durability issue, temperate exposure conditions coupled with three climate change scenarios are considered. Table 4 shows the exposure conditions of a temperate climate. The required 28-day compressive strength of concrete is 25 MPa [26], the cover depth is 30 mm [26], and the average exposure temperature is assumed to be 15 °C [26]. Figure 1 shows three climate change scenarios. The representative concentration pathway (RCP) 8.5 and 4.5 scenarios suggested by the Intergovernmental Panel on Climate Change (IPCC) were considered in this study [14]. Additionally, the case of constant climate (no climate change) was also considered for clarifying the effect of climate change on concrete mixtures design. RCP 8.5 showed higher CO2 concentration and temperature increases than RCP 4.5 or constant climate. For these three cases (temperate climate exposure conditions coupled with three climate change scenarios), the aimed carbonation service life was 50 years. The air content in the concrete mixtures Vair was assumed to be 2%. The design slump of concrete was 180 mm. The relative humidity was 0.65. The starting time of carbonation exposure was the year 2000.

Table 4.

Summary of exposure condition of temperate climate [26].

Figure 1.

Climate change scenarios.

3.1. Proportional Design without Considering Carbonation

As shown in Table 4, for a temperate climate exposure, the required strength of concrete was 25 MPa. In this section, we consider a proportional design without considering carbonation. In our calculation, the number of the sample population of the generic algorithm (GA) was set to 1500, the fitness function of the GA was CO2 emission, and the constraints of the GA were concrete strength, slump, concrete component, component ratio, and absolute volume of the concrete mixture. Because this section ignores the requirement of carbonation durability, the constraints of the GA in this section did not include carbonation durability. According to the genetic algorithm, the concrete mixture was calculated and named mix 1, as shown in Table 5. For mix 1, the water-to-solid ratio was 0.08. This was because of the constraint equation of the water-to-solid ratio (the minimum value of water-to-solid ratio is 0.08). The substitution ratio of slag plus fly ash was 0.75. This was because of the constraint equation of the mineral-admixture-to-binder ratio (the maximum value of mineral-admixture-to-binder ratio is 0.75).

Table 5.

Mixing proportions of 25-MPa concrete without considering carbonation.

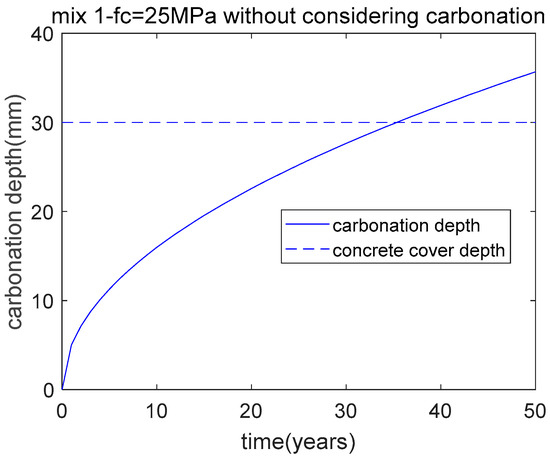

The performance of mix 1 is shown in Table 6. The 28-day compressive strength of mix 1 was 25 MPa, and the slump was 180 mm. According to the carbonation model, for concrete mixtures and exposure conditions (temperate climate without climate change), a carbonation depth of mix 1 was calculated and is shown in Figure 2. The carbonation depth at 50 years was much higher than the cover depth of 30 mm. Because the carbonation depth was higher than the cover depth, carbonation durability was not satisfied. This means that the required strength and cover depth in Table 4 were not compatible with the high-volume fly-ash-and-slag ternary-blended concrete. To satisfy carbonation durability, the strength of the concrete should be higher than that shown in Table 4. In summary, for the proportional design of high-volume fly-ash-and-slag ternary-blended concrete, carbonation durability cannot be ignored and must be considered.

Table 6.

Performance of 25-MPa concrete without considering carbonation.

Figure 2.

Carbonation depth of mix 1.

3.2. Proportional Design Considering Carbonation

As discussed in Section 3.1, for the proportional design of high-volume fly-ash-and-slag ternary-blended concrete, when we only considered compressive strength, the requirement of carbonation durability could not be met. Hence, in this section, we present a proportional design considering both strength and carbonation durability.

Considering both strength and carbonation, concrete mixtures for temperate climate exposure coupled with three climate change scenarios were calculated (as shown in Table 7). The performance of each mixture, including the strength, slump, and carbonation depth, is shown in Table 8. Mix 2, mix 3, and mix 4 apply to no climate change, the RCP 4.5 scenario, and the RCP 8.5 scenario, respectively. As shown in Table 7, as the climate change scenario shifted from no change to RCP 8.5, and the binder contents increased due to increases in the CO2 concentration and temperature. This means that, to meet the challenges of climate change, a richer mix of concrete is necessary. A richer mix can increase the content of carbonatable substances, lower concrete porosity, and subsequently increase the carbonation resistance of concrete.

Table 7.

Mixtures of concrete for various climate change scenarios considering carbonation.

Table 8.

Performance of the concrete in various climate change scenarios considering carbonation.

As shown in Table 8, the compressive strengths of concrete (29–31 MPa) tended to be greater than the designed compressive strengths (25 MPa). The carbonation depth at 50 years was equal to the cover depth of 30 mm. Basically, for high-volume fly-ash-and-slag ternary-blended concrete, the concrete mixtures were controlled by carbonation durability, because fly ash and slag impaired the carbonation resistance of the concrete.

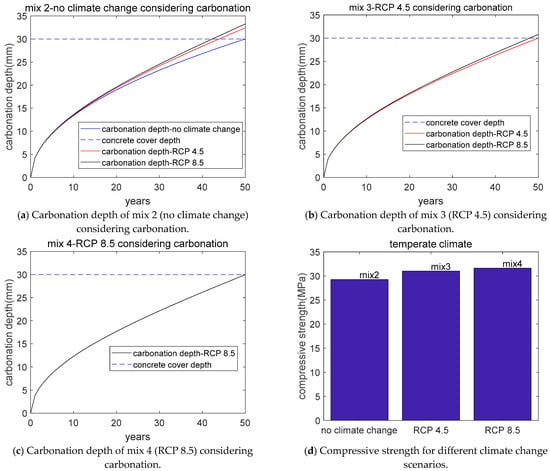

Figure 3 shows the carbonation depth and strength for temperate climate exposure in three climate change scenarios. As shown in Figure 3a, in the case of no climate change, after 50 years of exposure, the carbonation depth of mix 2 was equal to the cover depth of 30 mm. On the other hand, for the RCP 4.5 and 8.5 scenarios, the carbonation depth of mix 2 is higher than 30 mm. This means that mix 2 could meet the carbonation durability design in the no climate change scenario but could not meet the requirements of the RCP 4.5 and 8.5 climate change scenarios.

Figure 3.

Carbonation depth and CO2 emissions for various climate change scenarios.

As shown in Figure 3b, in the RCP 4.5 scenario, after 50 years of exposure, the carbonation depth of mix 3 was equal to the cover depth of 30 mm. Meanwhile, for the RCP 8.5 scenario, the carbonation depth of mix 3 was greater than 30 mm. This means that mix 3 could meet the carbonation durability design of the RCP 4.5 scenario but could not meet the requirements of the RCP 8.5 climate change scenario.

As shown in Figure 3c, in the RCP 8.5 scenario, after 50 years of exposure, the carbonation depth of mix 4 was equal to the cover depth of 30 mm. This means that mix 4 could meet the carbonation durability design of the RCP 8.5 climate change scenario.

Figure 3d shows the compressive strength for the various climate change scenarios. As the climate change scenario shifts from no change to the RCP 8.5 scenario, the compressive strength of the concrete increased. To satisfy the challenges of global warming, the design compressive strength of concrete should be increased.

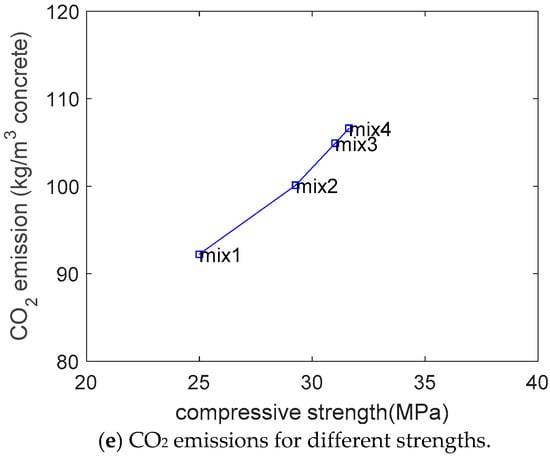

Figure 3e shows CO2 emissions for mixes 1–4. As the compressive strength increased, the CO2 emissions also increased.

3.3. Effect of Cost on the Design of Low-CO2 Concrete

In Section 3.1 and Section 3.2, the objective function of genetic optimization was set to CO2 emissions. In the concrete industry, concrete producers and construction companies are interested in not only CO2 emissions, but also the cost of concrete. Similar to CO2 emissions, the cost of concrete also can be calculated from the contents and unit prices of concrete components (as shown in Table 9).

Table 9.

Cost of the concrete components [16].

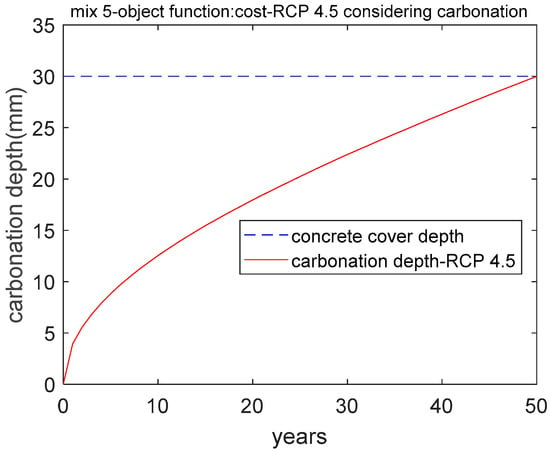

Based on similar methods presented in Section 3.2, the concrete mixture with the lowest price considering various constraint equations was determined. The climate change scenario was assumed to be RCP 4.5. The objective function of the genetic algorithm was min (COST). The calculated concrete mixture was named mix 5, as shown in Table 10. As shown in Figure 4, the carbonation depth of mix 5 after 50 years of service equaled the cover depth (30 mm). As shown in Table 11, the strength of mix 5 was 27.54 MPa, which was higher than the design strength (25 MPa).

Table 10.

Concrete mixtures with the lowest prices considering carbonation.

Figure 4.

Carbonation depth of mix 5—objective function: Cost—RCP 4.5 considering carbonation.

Table 11.

Performance of concrete with lowest price considering carbonation.

The climate change scenario for mixes 3 and 5 was the same, i.e., RCP 4.5, while the optimization object of mixes 3 and 5 were different. The object of mix 3 was lowest CO2 emissions and the object of mix 5 was lowest price. The component compositions of mix 3 were different from that of mix 5. In other words, the aims of lowest CO2 emissions and lowest price could not be achieved simultaneously. The fly ash content in mix 5 was much higher than that in mix 3. This was because the price of fly ash was much less than that of slag (as shown in Table 9). The water content in mixes 3 and 5 was similar because of the constraint equation of the water-to-solid ratio (the minimum value of the water-to-solid ratio was 0.08). The substitution ratios of slag plus fly ash in mixes 3 and 5 were 0.75. This was because of the constraint equation of the mineral-admixture-to-binder ratio (the maximum value of the mineral-admixture-to-binder ratio was 0.75).

Although the aim of lowest CO2 emissions and lowest price could not be achieved simultaneously, we could compromise between low CO2 emissions and low price. In other words, we could design concrete with relatively lower CO2 emissions at a relatively lower price. To design concrete with both lower cost and lower CO2 emissions, we set an additional constraint for the cost of concrete. The constraint equation of cost was an equality constraint:

where the values of (1000, 1010, 1020) are between the prices of mixes 3 and 5 (the cost of mixes 3 and 5 are 1023.5 and 995.89, respectively).

COST = (1000, 1010, 1020)

The design requirements can be summarized as follows: objective function is lowest CO2 emission, the cost of each mixture equaled 1000, 1010, or 1020, respectively, and other items were the same as mix 3 or mix 5. In this section, the additional equality constraint was cost of concrete, while in Section 3.2, there was no constraint for cost.

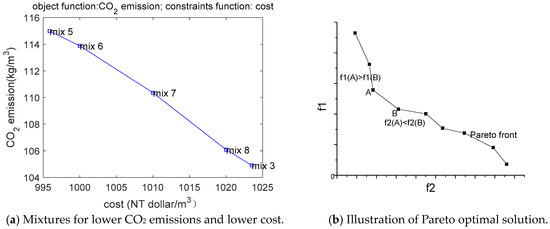

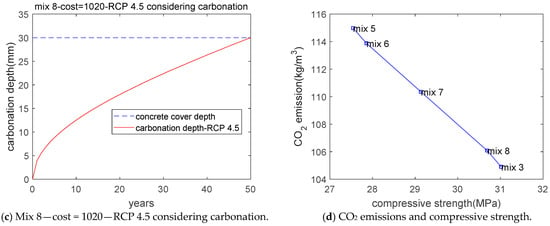

Based on the genetic algorithm, the mixtures were determined and named mixes 6–8, respectively. The results of the concrete mixtures are shown in Table 12. As shown in Table 13, the cost of mixes 6–8 were 1000, 1010, and 1020, respectively, and the CO2 emissions of mixes 6–8 were 113.88, 110.36, and 106.08, respectively. The cost and CO2 emissions of mixes 6–8 were generally between mixes 3 and 5. In other words, mixes 6–8 had both lower cost and lower CO2 emissions. Figure 5a shows CO2 emissions versus concrete cost. As CO2 emissions increased, concrete cost decreased.

Table 12.

Concrete mixtures considering both cost and CO2 emissions.

Table 13.

Performance of the concrete considering both cost and CO2 emissions.

Figure 5.

Pareto optimal mixtures for lower CO2 emissions and lower cost.

Pareto optimal solutions mean that improving any objective function based on a nondominated solution will inevitably weaken at least one other objective function. Figure 5b shows an example of a Pareto optimal solution [25,27]. The x and y axes represent the values of functions f2 and f1, respectively. Points A and B are two points on the Pareto optimal solution. At point A, the function value of f1 is higher, while at point B, the function value of f2 is higher. Hence, mixes 6–8 are the Pareto optimal solutions for the design of low-CO2 emissions and low-cost concrete.

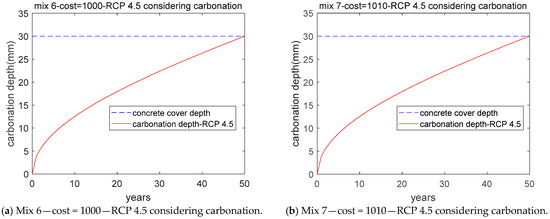

The performances of mixes 6–8 are shown in Table 13. As shown in Table 13, the compressive strengths of mixes 6–8 were higher than the design strength of 25 MPa. The fly-ash-plus-slag replacement ratios for mixes 6–8 were 0.75. The carbonation depth equaled the concrete cover depth of 30 mm (as shown in Figure 6a–c). Additionally, as shown in Figure 6d, as concrete strength increased, CO2 emissions decreased. This is different from that in Figure 3e. This is due to the additional equality constraint of price.

Figure 6.

Carbonation depth of concrete with lower CO2 emissions and lower cost.

3.4. Generalization of the Proposed Method

A genetic algorithm is widely used for optimal mixture design of concrete [16,23,27]. However, previous studies [16,23,27] mainly focused on cost, concrete strength, and workability and did not consider the impact of climate change or carbonation durability of blended concrete. This study filled these gaps and considered climate change and carbonation durability. In addition, for a number of countries, the restrictions on the component content, component ratios, equations for CO2 emissions, compressive strength, carbonation depth, slump, and climate change scenarios might be different from the individual equations utilized in this study. For example, the calculation equations of concrete carbonation depth from Europe [19,20], Australia [26], and Japan [27] are different. Other researchers may use their own equations instead of the related equations within this study. Even though the calculation equations might be different, the calculation procedure remains similar. Through the use of the genetic algorithm, researchers should be able to design low-CO2 concrete that meets the domestic needs of their respective countries. Hence, to some degree, the method presented in this study is really a general method that considers both sustainability and sturdiness for a number of regional conditions.

4. Conclusions

In this study, we proposed a technique for designing low-CO2 cement–fly ash–slag ternary-blended concrete. The proposed method combined a genetic algorithm with properties evaluation models, such as a strength model, workability model, and carbonation model coupled with climate change.

First, CO2 emissions were calculated from concrete mixing proportions. Concrete strength and carbonation depth were calculated using efficiency factors of fly ash and slag. CO2 emissions were the target of a genetic algorithm. The genetic algorithm was used to obtain the concrete mixtures that had the lowest CO2 emissions and satisfied the constraint conditions of strength, workability, and carbonation durability along with climatic change. The optimization results could reflect the effect of climate change on the mixture design of low-CO2 concrete. For high-volume fly-ash-and-slag ternary-blended concrete, the concrete mixtures were controlled by carbonation durability, because fly ash and slag impair the carbonation resistance of concrete. To meet the challenges of climate change, a richer mix of concrete is necessary, and the design compressive strength of blended concrete should be increased.

Second, the effect of the cost of materials on the mixing style of low-CO2 concrete was clarified, and the mixture with the lowest cost was determined. We found that the mixture with the lowest cost was different from that with the lowest CO2 emissions. The aims of lowest CO2 emissions and lowest price could not be achieved simultaneously. Pareto optimal solutions were determined, which considered both low CO2 emissions and material cost. The mixtures of Pareto optimal solutions were between lowest CO2 emissions and lowest material cost. The Pareto optimal mixtures had lower CO2 emissions and lower material cost. For the Pareto optimal solutions, as CO2 emissions increased, concrete cost decreased. Additionally, by replacing a properties evaluation model with relevant design codes, the proposed method can be generalized to apply to various countries.

Funding

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (No. 2015R1A5A1037548) and an NRF grant (NRF-2017R1C1B1010076).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, T.F.; Gao, X.J.; Ren, M. Effects of autoclave curing and fly ash on mechanical properties of ultra-high performance concrete. Constr. Build. Mater. 2018, 158, 864–872. [Google Scholar] [CrossRef]

- Doug Hooton, R.; Bickley, J.A. Design for durability: The key to improving concrete sustainability. Constr. Build. Mater. 2014, 67, 422–430. [Google Scholar] [CrossRef]

- Dijk, M.; Blom, I.; Salet, T.; Marinus, P. Environmental impact as a parameter in concrete structure parametric associative models. Constr. Build. Mater. 2014, 67, 360–365. [Google Scholar] [CrossRef]

- Randl, N.; Steiner, T.; Ofner, S.; Baumgartner, E.; Meszoly, T. Development of UHPC mixtures from an ecological point of view. Constr. Build. Mater. 2014, 67, 373–378. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef]

- Fantilli, A.P.; Chiaia, B. Eco-mechanical performances of cement-based materials: An application to self-consolidating concrete. Constr. Build. Mater. 2013, 40, 189–196. [Google Scholar] [CrossRef]

- Chiaia, B.; Fantilli, A.P.; Guerini, A.; Volpatti, G.; Zampini, D. Eco-mechanical index for structural concrete. Constr. Build. Mater. 2014, 67, 386–392. [Google Scholar] [CrossRef]

- Van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ‘green’ concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Proske, T.; Hainer, S.; Rezvani, M.; Graubner, C.A. Eco-friendly concretes with reduced water and cement content—Mix design principles and application in practice. Constr. Build. Mater. 2014, 67, 413–421. [Google Scholar] [CrossRef]

- Miller, S.A.; Monteiro, P.J.M.; Ostertag, C.P.; Horvath, A. Comparison indices for design and proportioning of concrete mixtures taking environmental impacts into account. Cem. Concr. Compos. 2016, 68, 131–143. [Google Scholar] [CrossRef]

- Miller, S.A.; Monteiro, P.J.M.; Ostertag, C.P.; Horvath, A. Concrete mixture proportioning for desired strength and reduced global warming potential. Constr. Build. Mater. 2016, 128, 410–421. [Google Scholar] [CrossRef]

- Muller, H.S.; Haist, M.; Vogel, M. Assessment of the sustainability potential of concrete and concrete structures considering their environmental impact, performance and lifetime. Constr. Build. Mater. 2014, 67, 321–337. [Google Scholar] [CrossRef]

- Yang, K.H.; Tae, S.H.; Choi, D.U. Mixture Proportioning Approach for Low-CO2 Concrete Using Supplementary Cementitious Materials. ACI Mater. J. 2016, 113, 533–542. [Google Scholar]

- Pachauri, R.K.; Allen, M.R.; Barros, V.R.; Broome, J.; Cramer, W.; Christ, R.; Church, J.A.; Clarke, L.; Dahe, Q.; Dasgupta, P.; et al. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Pachauri, R.K., Meyer, L.A., Eds.; IPCC: Geneva, Switzerland, 2014; p. 151. [Google Scholar]

- Eleftheriadis, S.; Duffour, P.; Greening, P.; James, J.; Stephenson, B.; Mumovic, D. Investigating relationships between cost and CO2 emissions in reinforced concrete structures using a BIM-based design optimization approach. Energy Build. 2018, 166, 330–346. [Google Scholar] [CrossRef]

- Yeh, I.C. Computer-aided design for optimum concrete mixtures. Cem. Concr. Compos. 2007, 29, 193–202. [Google Scholar] [CrossRef]

- Lee, H.S.; Wang, X.Y. Evaluation of compressive strength development and carbonation depth of high volume slag-blended concrete. Constr. Build. Mater. 2016, 124, 45–54. [Google Scholar]

- Wang, X.Y.; Park, K.B. Analysis of the compressive strength development of concrete considering the interactions between hydration and drying. Cem. Concr. Res. 2017, 102, 1–15. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Tsimas, S. Supplementary cementing materials in concrete Part I: Efficiency and design. Cem. Concr. Res. 2002, 32, 1525–1532. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Antiohos, S.; Tsimas, S. Supplementary cementing materials in concrete Part II: A fundamental estimation of the efficiency factor. Cem. Concr. Res. 2002, 32, 1533–1538. [Google Scholar] [CrossRef]

- Yeh, I.C. Modeling of strength of high-performance concrete using artificial neural networks. Cem. Concr. Res. 1998, 28, 1797–1808. [Google Scholar] [CrossRef]

- Yoon, I.S.; Copuroglua, O.; Park, K.B. Effect of global climatic change on carbonation progress of concrete. Atmos. Environ. 2007, 41, 7274–7285. [Google Scholar] [CrossRef]

- Lim, C.H.; Yoon, Y.S.; Kim, J.H. Genetic algorithm in mix proportioning of high-performance concrete. Cem. Concr. Res. 2004, 34, 409–420. [Google Scholar] [CrossRef]

- Thomas, M. Supplementary Cementing Materials in Concrete; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Available online: www. mathworks.com (accessed on 1 April 2019).

- Stewart, M.G.; Wang, X.M.; Nguyen, M.N. Climate change impact and risks of concrete infrastructure deterioration. Eng. Struct. 2011, 33, 1326–1337. [Google Scholar] [CrossRef]

- Noguchi, T.; Maruyama, I.; Kanematsu, M. Performance based design system for concrete mixture with multi-optimizing genetic algorithm. In Proceedings of the 11th International Congress on the Chemistry of Cement (ICCC), Durban, South Africa, 11–16 May 2003. [Google Scholar]

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).