Simulation to Enable a Data-Driven Circular Economy

Abstract

:1. Introduction

2. Methodology

2.1. Qualitative Data Collection

2.2. Use Case

2.3. Simulation

2.3.1. Discrete Event Simulation Model

2.3.2. System Dynamics Model

2.4. Validation

3. Development of Simulation Models

3.1. Data in Manufacturing and the Notion of CPQ

- CPQ is a function of physical condition (PC), part remanufacturing history (PRM), part replacement history (PRH) and data from sensors (DS), as shown in Equation (1) and defined in Table 2. In Equation (1),, , , are individual weights that are dependent on a number of factors including the nature of the product, nature of the industry, etc. For example, for a mechanical component such as a shaft of an electric motor, would be higher as compared to , or as the physical condition of the returned mechanical component is a clear indicator of its actual condition. Another example is if a battery has always been used in a protected configuration, excellent external physical condition is not a good indicator of its quality and hence would be lower as compared to , or .where sum of weights (, , , ) is equal to 1 and PC, PRM, PRH and DS are normalised.

- CPQ has an impact on the time spent in a remanufacturing process and associated costs (details in Section 3.2).

- The nature of the product determines the CPQ and the level of disassembly to which a component might go. Data from sensors could help to determine the uncertainty and CPQ.

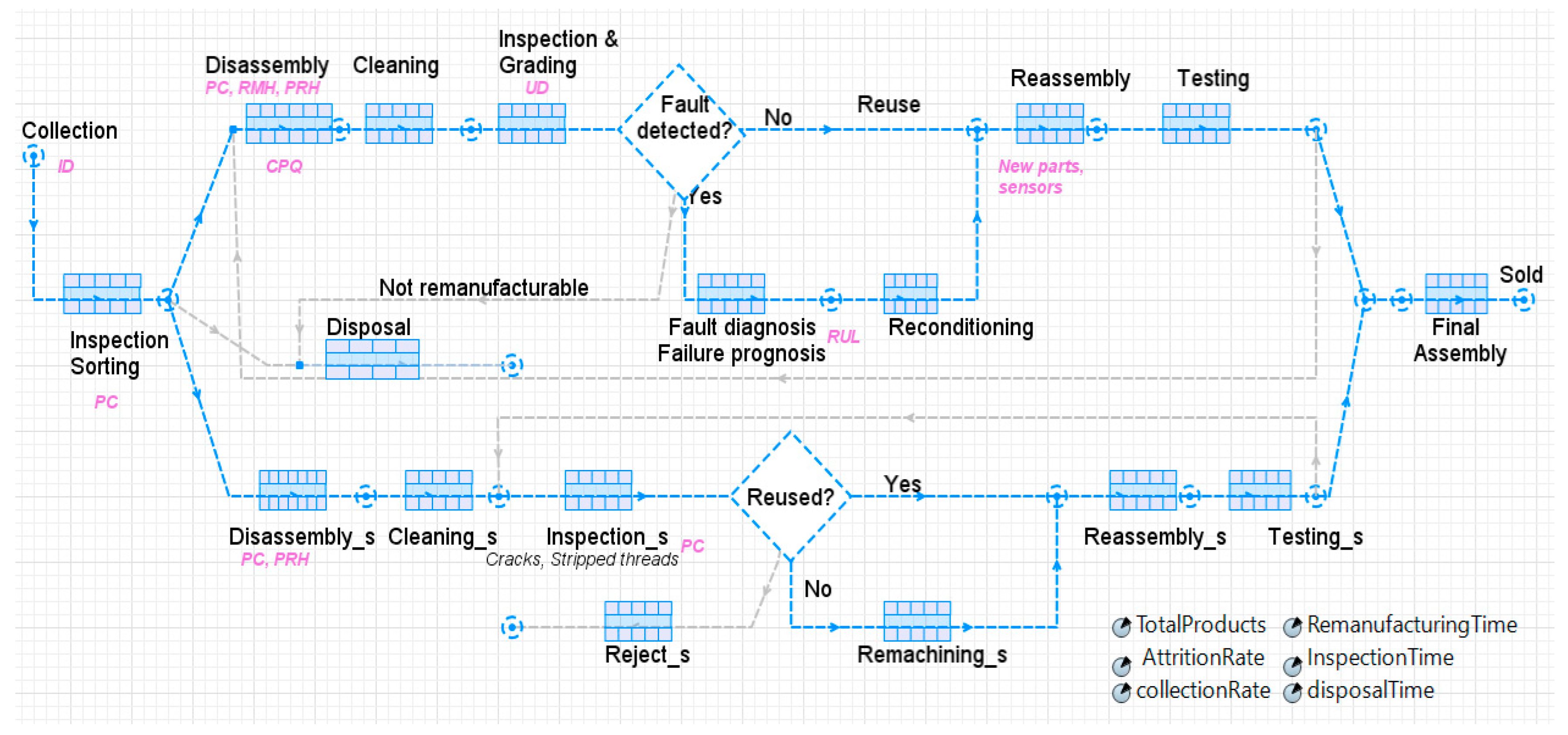

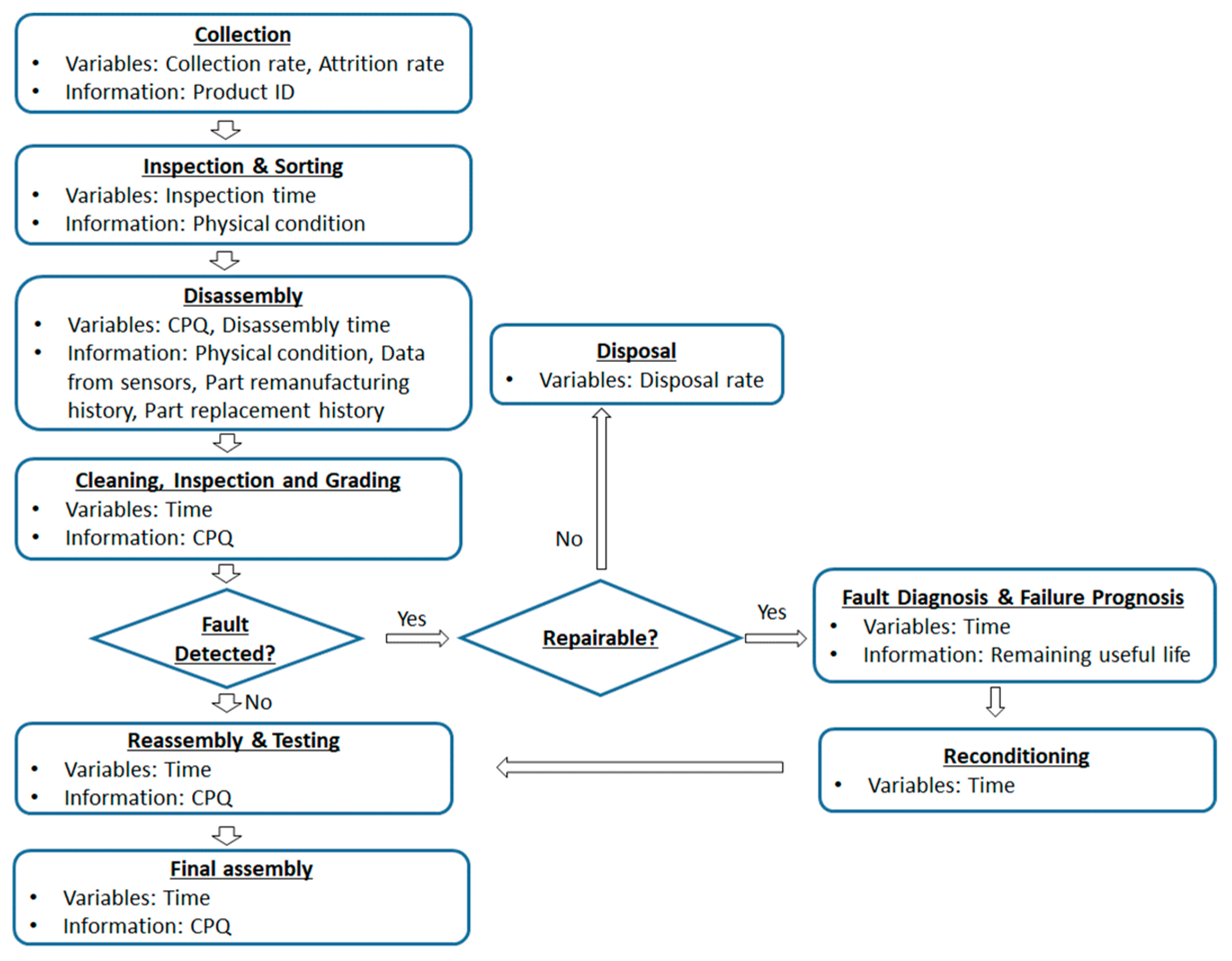

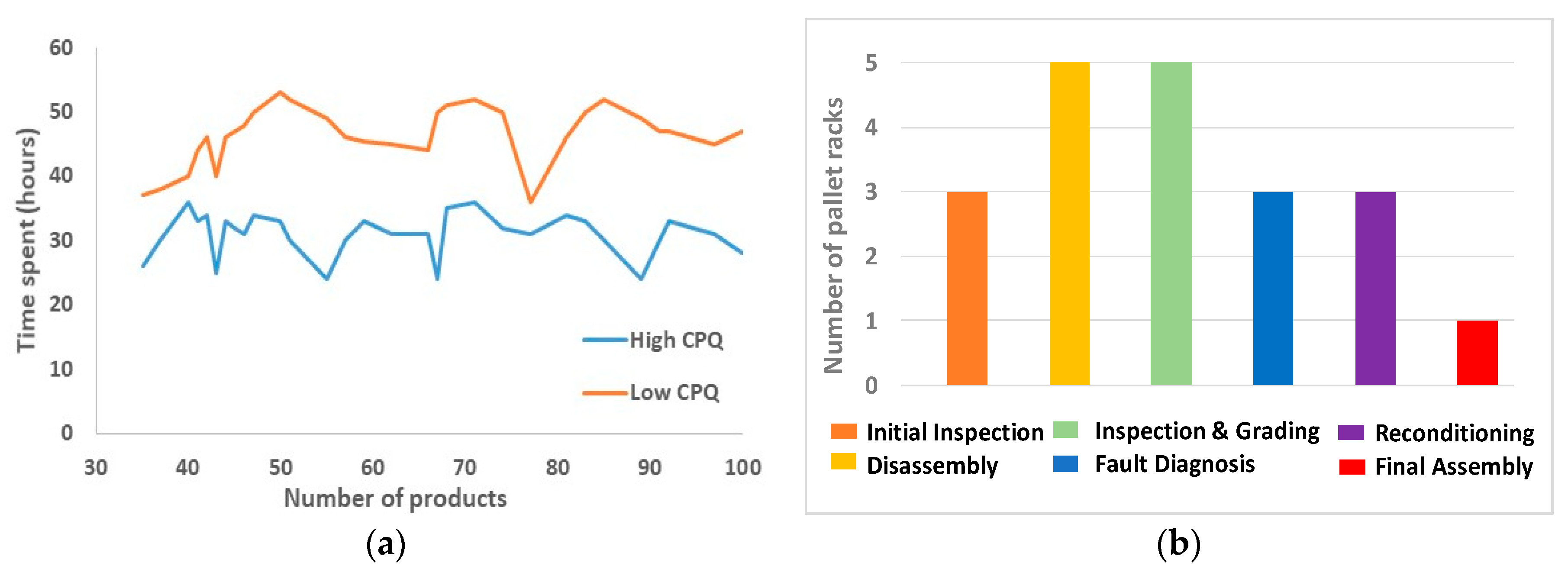

3.2. Discrete Event Simulation Model

- Collection (returned products): The remanufacturing process starts with the collection of returned products. As suggested in the literature, the attrition rate for electrical products was kept at 3% [30]. The number of total products currently in use was assumed as 1000. The rate of collection of returned products is given in Equation (2):

- Inspection and sorting: After collection, the products are inspected based on their physical condition (PC) and the product identification number (ID). Approximately 10% of the products are rejected and sent for disposal at this stage. The electric motor is then disassembled and sorted into electrical components (rotor) and mechanical components (shaft). Inspection and sorting time per component was a triangular distribution (0.5, 1, 1.5) hours, with a minimum, maximum and mode of 0.5, 1.5 and 1 h, respectively.

- Disassembly: The actual disassembly of a return is not necessarily an exact reversal of its assembly sequence, due to various factors: degradation of components, damage to components during use, missing components, product upgrade during maintenance and remanufacturing tasks. Some components of an electric motor (e.g., rotor) can be reused directly without the need for full disassembly, whereas other components (e.g., shaft) require proper reconditioning and disassembly so that they can be reused in a remanufactured product [31]. At this stage, the CPQ of the returned product is determined and given a value between 0.1 and 1.

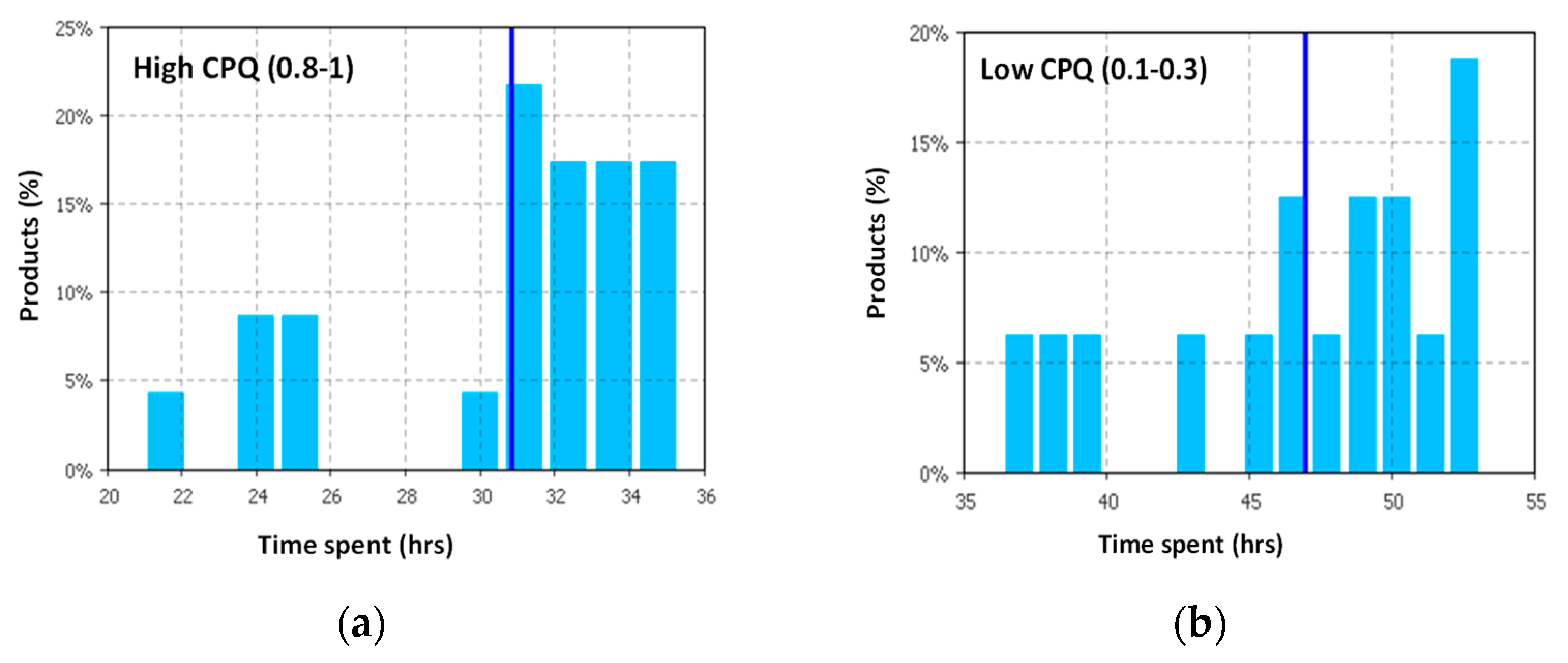

- Time spent in disassembly, cleaning and inspection: The CPQ of the returned product would affect the disassembly time, cleaning time and inspection time in the remanufacturing process. For example, if the CPQ for the product is very high, then in most cases you can directly inspect/disassemble/replace the faulty part and may not need to go down to the lowest level of disassembly. Equations (3)–(5) demonstrate that time spent in disassembly, cleaning and inspection operations (for both the rotor and the shaft) is inversely proportional to the value of the CPQ. The time spent in the above-mentioned remanufacturing processes is directly proportional to the associated labour costs and the costs associated with the repair/replacement of parts. Hence, the CPQ of a product could be useful for predicting the remanufacturing time and costs.

- Inspection and grading: Inspection is required to measure and detect the current condition of a component. Generally, the components are graded into three categories [32]: (a) directly reusable, (b) reusable after proper repair or reconditioning and (c) cannot be repaired or reconditioned. Components that fall in the category of “directly usable” can be sent for reuse directly. Components in the category of “reusable after proper repair or reconditioning” are sent for fault diagnosis and prognosis, whereas components classified as “cannot be repaired or reconditioned” are considered as not remanufacturable and are sent for disposal.

- Fault Diagnosis and prognosis: Diagnosis detects the failure that has occurred in a component, and isolates and identifies the root of the failure based on the data collected by the embedded sensors. Prognosis estimates the time at which a component will fail to operate at its stated specifications based on its current condition as well as the future load and environmental exposure (i.e., the prediction of the remaining useful life (RUL) of the component).

- Reconditioning and repair: The reconditioning strategies are dependent on the current condition and the failure mode of the used parts. A damaged or worn part can be repaired either by removing the damaged area or by adding new material to the area, depending on the severity of the damage [33]. The PRM, as well as the performance and reliability of the previous remanufactured versions of a component, will provide insight into the effectiveness of the reconditioning methods.

- Reassembly and testing: Generally, the reassembly sequence is the same as for the original new product, but may differ if there has been a significant upgrade during remanufacturing.

- Final assembly: This step involves the final assembly of electrical components (rotor) and mechanical components (shaft) before they are finally sent to the market for sale. The simulation used first-in, first-out (FIFO) logic to control the order in which products were processed.

- Disposal: The products that are not remanufacturable are sent for controlled disposal. The disposal time per component was a triangular distribution (1, 1.5, 2) hours.

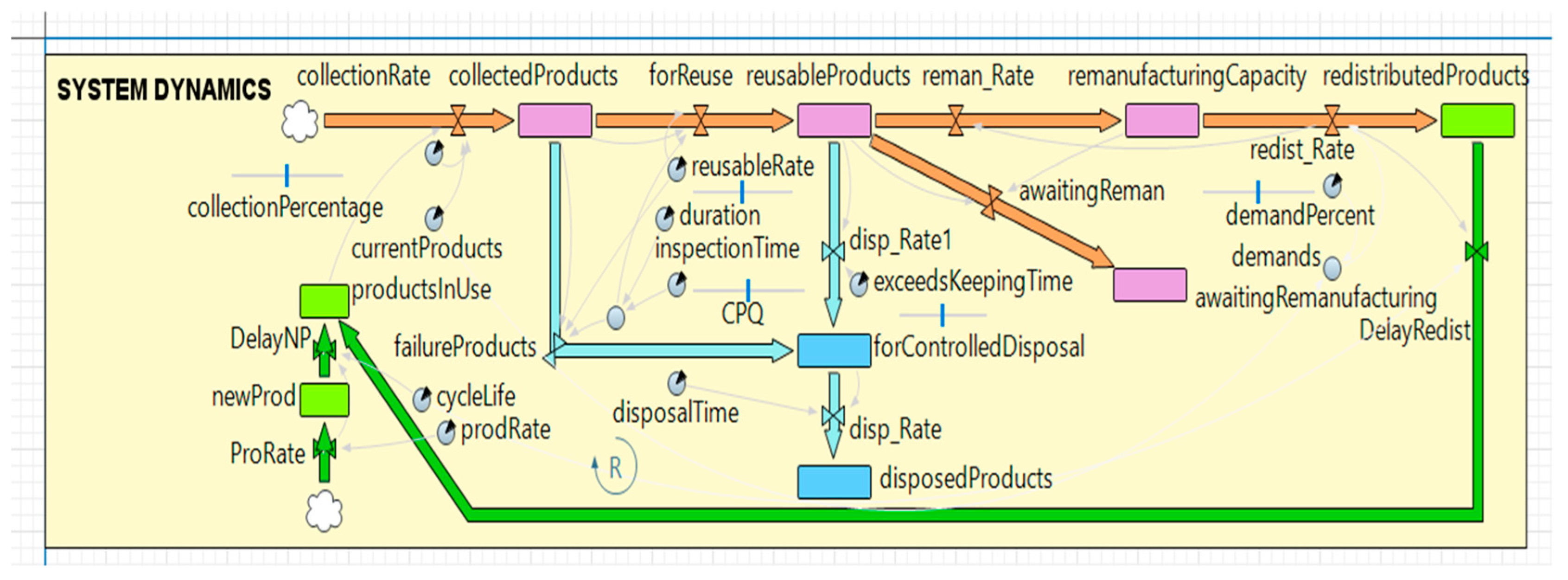

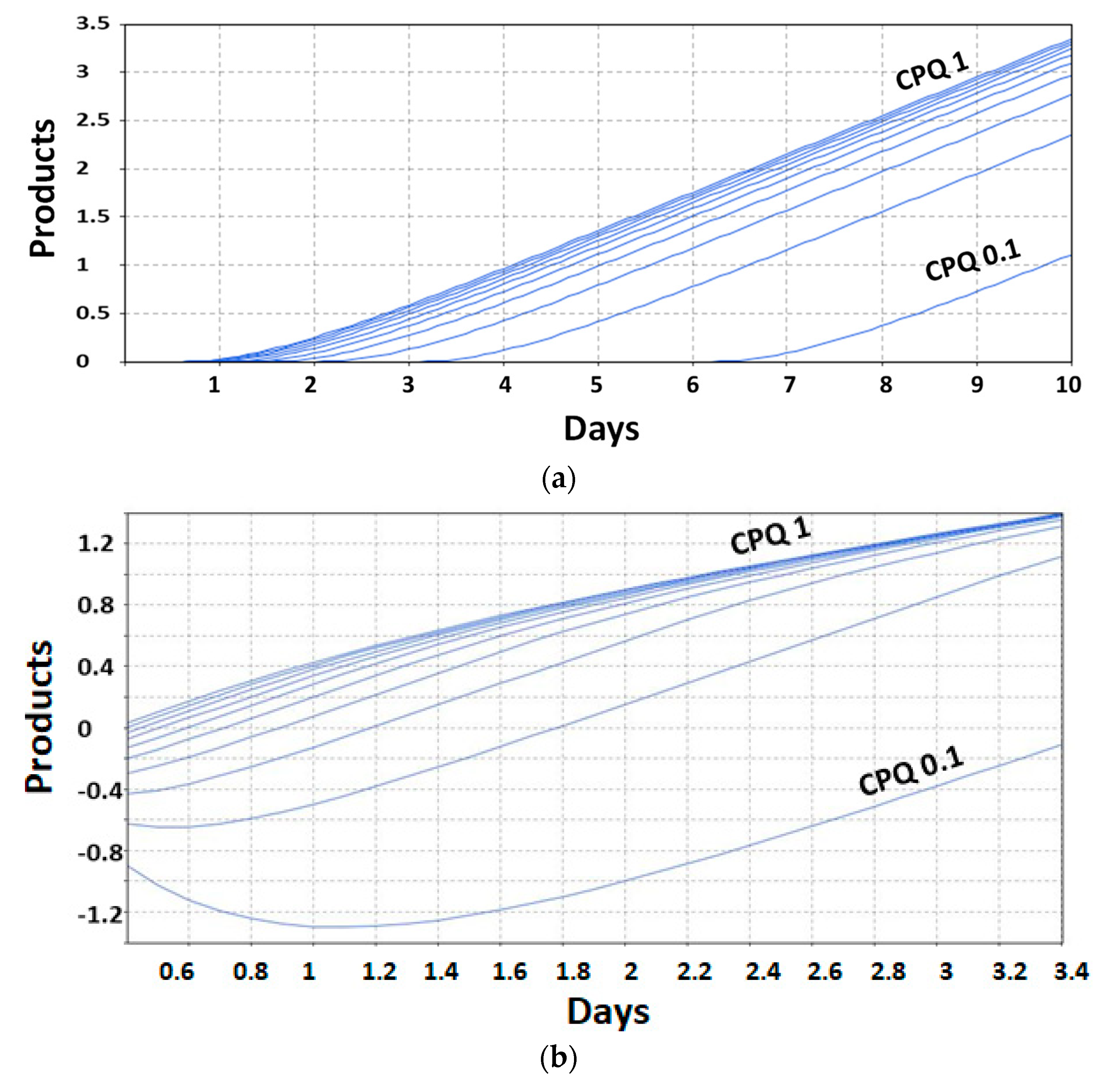

3.3. System Dynamics Model

- Collection (returned products): The remanufacturing process starts with the collection of returned products. The attrition rate for fuel cells, as suggested in the literature, was kept at 3% [30].

- Reusable products: 80% of products going through the inspection process were expected to be remanufactured into reusable products; the remaining 20% were sent for disposal.

- Inspection time: Inspection time of the product would be inversely proportional to the CPQ of the returned product. Inspection time per component was a triangular distribution (0.5, 1, 1.5) hours over the CPQ of that product (Table 3).

- Controlled disposal: 20% of products went through the inspection process for controlled disposal. They were disposed of with respect to disposal time and rate. Some products (valid in the case of batteries, etc.) that exceeded the keeping time were also sent for disposal. The number that exceeded the keeping time was 1%.

- Demand: This element controls the remanufacturing rate and redistribution rate.

- Awaiting remanufacturing: Products that passed the inspection and are awaiting remanufacture.

- Redistributed products: Given a product life time of 5 years. After 5 years, they automatically join the collected products (returned products).

- New products: Given a production rate and cycle life time of 5 years and after that they automatically join the collected products.

4. Summary of Results: The Value of Data

4.1. DES Model

4.2. SD Model

4.3. Interview Analysis

- Discussion of the most prevalent scenario in their company in terms of the actual quality and the certainty of product quality (CPQ) of returned products, as shown in Figure 8.

- How would they rate the four elements of the CPQ in Equation (1) in the order of their importance and impact on the decision to remanufacture and impact on remanufacturing?

- How would the intrinsic knowledge play a role if the CPQ was low (quality is uncertain)? What would the company’s strategies be to reduce costs when assessing a component?

- Would CPQ be able to substitute the intrinsic knowledge of remanufacture, or could they be complementary?

- What if CPQ could be made into a standard according to the type of component being assessed? Would this increase/decrease the certainty and decision to remanufacture a component?

“Data from sensors will be hugely important, but will be product dependent. Depending on the availability and how valuable the data is, it will be hugely important”

4.4. CPQ and Wider Applications

5. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Characteristics | Company A | Company B | Company C | Company D |

|---|---|---|---|---|

| Ownership | Independent business | Independent, private business | Independent, private business | Independent, private business |

| Main product | Digital manufacturing research | OEM steering sys, remanufacturing of vehicle hydraulics and steering, military engineering. | Science-led research consultancy for the Circular Economy. | Science-led research consultancy for the Circular Economy. |

| Role of Respondent(s) | Manager, Circular Economy and Digital Manufacturing. | Managing Head of Remanufacturing | Circular Economy and remanufacturing business model innovation, sustainability and performance. | Director (Remanufacturing). |

| Year(s) of Experience | 6 | 8 | 4 | 20 |

| Customers | Global, Europe- focused | Global | Europe, UK- focused | Europe, UK- focused |

| Plant Location(s) | UK, three locations | UK | UK, Belgium | UK, Belgium |

| Year of Establishment | 2012 | 1971 | 1994 | 1994 |

| Certification | NA | ISO 9001: 2015 | ISO 9001, ISO 14001 | ISO 9001, ISO 14001 |

| Main Clients | Private businesses, Government-funded research, universities and research institutes | Jaguar Land Rover, Textron, Leyland trucks, Ministry of Defence, Berendsen | EU, M&S, Department for Environment Food & Rural Affairs, Microsoft, Innovate UK. | EU, M&S, Microsoft, Innovate UK. |

| Remanufacturing knowledge | Extensive | Extensive | Extensive | Extensive |

References

- WRAP. WRAP and the Circular Economy 2017. Available online: http://www.wrap.org.uk/about-us. (accessed on 30 April 2019).

- Rubmann, M. Industry 4.0 The Future of Productivity and Growth in Manufacturing Industries. The Boston Consulting Group. 2015. Available online: http://www.inovasyon.org/pdf/bcg.perspectives_Industry.4.0_2015.pdf (accessed on 30 April 2019).

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A review of the circular economy in China: Moving from rhetoric to implementation. J. Clean. Prod. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- Babiceanu, R.F.; Seker, R. Big data and virtualization for manufacturing cyber-physical systems: a survey of the current status and future outlook. Comput. Ind. 2016, 81, 128–137. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Intelligent Assets: Unlocking the Circular Economy Potential. 2016. Available online: www.ellenmacarthurfoundation.org (accessed on 30 April 2019).

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0 Bus. Inf. Sys. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Do Noh, S. Smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf. Green Tech. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Int. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Okorie, O.; Salonitis, K.; Charnley, F.; Moreno, M.; Turner, C.; Tiwari, A. Data-driven approaches for circular economy in manufacturing for digital technologies: a review of current research and proposed framework. Preprints 2018. [Google Scholar] [CrossRef]

- Hofmann, E.; Rusch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.J.; Garmulewicz, A.; Knowles, S.; Minshall, T.H.W.; Mortara, L.; Reed-Tsochas, F.P. Unlocking value for a circular economy through 3D printing: A research Agenda. Technol. Forecast. Soc. Chang. 2017, 115, 75–84. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring how usage-focused business models enable circular economy through digital technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef]

- Neely ‘Manufacturing Analytics: The Role of Big Data in the Future of Manufacturing’. Available online: http://cambridgeservicealliance.eng.cam.ac.uk (accessed on 30 April 2019).

- Towards the Circular Economy Vol. 1–3. Available online: http://www.ellenmacarthurfoundation.org (accessed on 30 April 2019).

- Saavedra, Y.M.B.; Barquet, A.P.B.; Rozenfeld, H.; Forcellini, F.A.; Ometto, A.R. Remanufacturing in Brazil. Case studies on the automotive sector. J. Clean. Prod. 2013, 53, 267–276. [Google Scholar] [CrossRef]

- Sundin, E. Circular economy and design for remanufacturing. In Designing for the Circular Economy, 1st ed.; Charter, M., Ed.; Taylor & Francis Group, Routledge: London, UK, 2018; pp. 186–199. [Google Scholar]

- SMMT. The Digitalization of the UK Automotive Industry. 2016. Available online: www.smmt.co.uk/reports (accessed on 30 April 2019).

- Bocken, N.M.P.; Samuel, W.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef]

- Glöser-Chahoud, S.; Pfaff, M.; Walz, R.; Schultmann, F. Simulating the service lifetimes and storage phases of consumer electronics in Europe with a cascade stock and flow model. J. Clean. Prod. 2019, 213, 1313–1321. [Google Scholar] [CrossRef]

- Lieder, M.; Asif, F.M.; Rashid, A.; Mihelič, A.; Kotnik, S. Towards circular economy implementation in manufacturing systems using a multi-method simulation approach to link design and business strategy. Int. J. Adv. Manuf. Technol. 2017, 93, 1953–1970. [Google Scholar] [CrossRef] [Green Version]

- Ghani, U.; Monfared, R.; Harrison, R. Integration approach to virtual-driven discrete event simulation for manufacturing systems. Int. J. Comput. Integr. Manuf. 2015, 28, 844–860. [Google Scholar] [CrossRef]

- Turner, C.J.; Hutabarat, W.; Oyekan, J.; Tiwari, A. Discrete event simulation and virtual reality use in industry: new opportunities and future trends. IEEE Trans. Hum. Mach. Syst. 2016, 46, 882–894. [Google Scholar] [CrossRef]

- Bagchi, S.; Chen-Ritzo, C.H.; Shikalgar, S.T.; Toner, M. A full-factory simulator as a daily decision-support tool for 300 mm wafer fabrication productivity. In Proceedings of the Winter Simmer Conference IEEE, Miami, FL, USA, 7–10 December 2008; pp. 2021–2029. [Google Scholar]

- Wang, J.; Chang, Q.; Xiao, G.; Wang, N.; Li, S. Data driven production modelling and simulation of complex automobile general assembly plant. Comput. Ind. 2011, 765–775. [Google Scholar] [CrossRef]

- Azimi, R.; Lee, S.; AbouRizk, S. Intelligent look-ahead scheduling for structural steel fabrication projects. Int. J. Adv. Soft. 2011, 4, 207–217. [Google Scholar]

- Okorie, O.; Salonitis, K.; Charnley, F.; Turner, C. A systems dynamics enabled real-time efficiency for fuel cell data-driven remanufacturing. J. Manuf. Mater. Process. 2018, 2, 77. [Google Scholar] [CrossRef]

- Goodall, P.; Sharpe, R.; West, A. A data-driven simulation to support remanufacturing operations. Comput. Ind. 2019, 105, 48–60. [Google Scholar] [CrossRef]

- Aras, N.; Boyaci, T.; Verter, V. The effect of categorizing returned products in remanufacturing. IIE Trans. 2004, 36, 319–331. [Google Scholar] [CrossRef]

- Warken Industrial and Social Ecology PTY LTD. Analysis of lead acid battery consumption, recycling and disposal in Western Australia. 2012. Available online: http://www.batteryrecycling.org.au/wp-content/uploads/2012/06/120522-ABRI-Publication-Analysis-of-WA-LAB-Consumption-and-Recycling.pdf (accessed on 30 April 2019).

- Kara, S.; Manmek, S.; Kaebernick, H.; Ibbotson, S. Assessment of products for optimal lifetime. CIRP Ann. 2008, 57, 1–4. [Google Scholar] [CrossRef]

- Steinhilper, R. Remanufacturing—The Ultimate form of Recycling; Fraunhofer IRB: Stuttgart, Germany, 1998; pp. 255–260. [Google Scholar]

- Bras, B. Design for Remanufacturing Processes: Environmentally Conscious Mechanical Design; Wiley: Hoboken, NJ, USA, 2008; pp. 283–318. [Google Scholar]

| Data Flows | ||||||

|---|---|---|---|---|---|---|

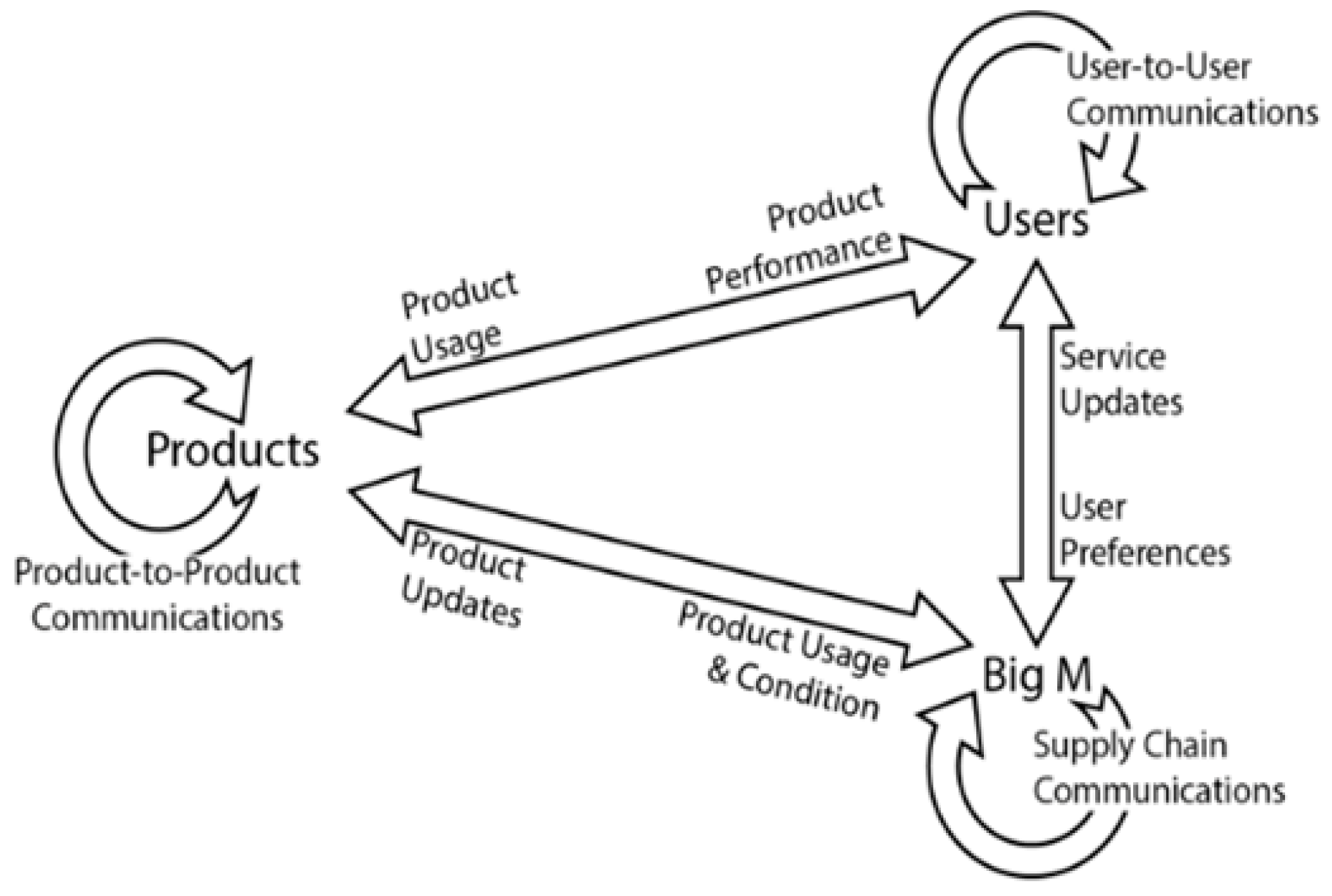

| Product-Product | Product-User-Product | Product-Big M-Product | User-Big M-User | |||

| Circular Strategies | End-of-Current-Life | Cascading & Recycling | Component harvesting | Assess material & product value | Assess material & supply chain value | Inform end of life behaviour |

| Product Life Extension | Refurbish/Remanufacture | Share upgrade needs | Identify upgrade options | Share product integrity | Identify user preferences | |

| Reuse/Redistribute | Adjust lifetime expectancy | Inform second life role | Inform design for second life | Inform second life preferences | ||

| Maintenance | Share product faults | Assess product performance | Assess product degradation | Assess service performance | ||

| Increasing Utilisation | Product as a Service | Share product status | Assess product & service faults | Predict servitisation | Identify user patterns | |

| Element Name | Element Definition | Weight Definition |

|---|---|---|

| Physical condition (PC) | A measure that captures the product’s discernible physical characteristics. | Measures the expected correlation between the product’s discernible physical characteristics with the product’s performance degradation. |

| Part remanufacturing history (PRM) | A quantity that represents the number of remanufacturing cycles this product has experienced. | Measures the expected correlation between the number of remanufacturing cycles and the product’s performance degradation. |

| Part replacement history (PRH) | A quantity that represents how many new replacement parts are present in the product. It is only applicable for product having multiple parts. | Measures the expected correlation between the number of remaining original parts and the product’s performance degradation. |

| Data from sensors (DS) | This element represents the availability of relevant in-use data. It is only applicable to products capable of generating use data. Data from sensors can be of many different types. We assume that the sensor data are selected such that it is possible to isolate the number of significant events which have detrimental impact on the product’s remaining life. | Measures the expected correlation between the number of recorded use events and the product’s performance degradation. |

| Stock/Flow | Equation |

|---|---|

| Collection rate | (currentProducts * collectionPercentage) + productsInUse |

| Inspection time | (triangular (0.5, 1, 1.5))/CPQ |

| Failed products | (collectedProducts * (1 − reuseRate))/inspectionTime |

| Reuse rate | max(0, (collectedProducts * reuseRate)/inspectionTime) |

| Failed products | (collectedProducts * (1 − reuseRate))/inspectionTime |

| Delay in redistribution | delay(redist_Rate, cycleLife) |

| Delay in new products | delay(proRate, cycleLife) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Charnley, F.; Tiwari, D.; Hutabarat, W.; Moreno, M.; Okorie, O.; Tiwari, A. Simulation to Enable a Data-Driven Circular Economy. Sustainability 2019, 11, 3379. https://doi.org/10.3390/su11123379

Charnley F, Tiwari D, Hutabarat W, Moreno M, Okorie O, Tiwari A. Simulation to Enable a Data-Driven Circular Economy. Sustainability. 2019; 11(12):3379. https://doi.org/10.3390/su11123379

Chicago/Turabian StyleCharnley, Fiona, Divya Tiwari, Windo Hutabarat, Mariale Moreno, Okechukwu Okorie, and Ashutosh Tiwari. 2019. "Simulation to Enable a Data-Driven Circular Economy" Sustainability 11, no. 12: 3379. https://doi.org/10.3390/su11123379

APA StyleCharnley, F., Tiwari, D., Hutabarat, W., Moreno, M., Okorie, O., & Tiwari, A. (2019). Simulation to Enable a Data-Driven Circular Economy. Sustainability, 11(12), 3379. https://doi.org/10.3390/su11123379