1. Introduction

Based primarily on offshore and centralized facilities with large scale assembly lines to supply a mass market, the current manufacturing model is driven to change, by new technologies promoted in visions such as Industry 4.0, into a decentralized, on demand, localised, and customizable manufacturing model known as re-distributed manufacturing (RdM). The UK Engineering and Physical Sciences Research Council (EPSRC) [

1] have a working definition of Re-Distributed Manufacturing (RdM) as “Technology, systems, and strategies that change the economics and organisation of manufacturing, particularly with regard to location and scale”. Moreno and Charnley [

2] corroborate this definition and state that RdM “enables a connected, localised, and inclusive model of consumer goods production and consumption that is driven by the exponential growth and embedded value of big data”. This new model aims to apply Industry 4.0 technologies to help change the organisation of manufacturing in terms of location and scale in order to reduce supply chain costs, improve sustainability, and provide customizable products more akin to an individual customer’s needs. Industry 4.0 is an initiative between the German government and national industries to envisage and promote the use of new technologies and organisational methods for manufacturing [

3].

The advent of this new manufacturing paradigm has brought on the need for models and methods that manufacturers can rely on as guides for the implementation of RdM processes into their operations. The use of emerging technologies in the design and manufacture of consumer goods [

4] such as information communication technologies, automation and robotics, big data analytics, additive manufacturing, cloud computing, and mobile technologies could enable intelligent and digitally networked manufacturing system, resulting in the redistribution of manufacturing towards smaller scale manufacturing processes [

5].

A case study is used to develop an initial distributed and circular business model. The Circular Economy concept aims to promote a move from the current take-make-dispose model of production to one that minimizes waste through improved product design and encourages reuse and recycling of materials [

6,

7,

8]. The selected case study was drawn from the ShoeLab project, a collaboration which aims to develop a proof of concept for a smart and sustainable shoe. This case study [

9] was perceived as the most suitable for answering the research question of: How could we develop a re-distributed and circular business model? The developed business model was used to investigate how data captured from, and communicated between, supply, production, distribution, and use can be used to design improved processes.

As part of ‘the ShoeLab’ model, a pair of 3D-printed trainers were designed and prototyped by considering circular economy aspects such as the elimination of waste through the efficient use of materials and production technologies, the removal of toxic chemicals that impair reuse, a reduction in manufacturing processes and parts use, and design for disassembly (to enable maintenance, reuse, and refurbishment of produced goods). A Selective Laser Sintering (SLS) technology was selected with a Thermoplastic Polyurethane Elastomer (e.g., Duraform Flex) as the base material to produce the trainers. This material is fully recyclable and can be used again in a SLS printer. SLS is a form of Additive Manufacturing (also known as 3D printing), a production technique that utilises digital designs to be created in 3D physical form through layer-by-layer deposition of material [

10]. Its properties are ideal for the footwear industry as it is flexible, durable, tear-resistant, soft-touch, and washable. The design of this pair of trainers allows new disruptive business models, such as offering trainers as a service through a subscription model. This model provides a personalised service if the trainers need to be repaired, maintained, or parts need to be replaced, as the main body detaches from the sole with a mechanical joint. In addition, trainers will be produced in local stores. The model also includes the use of other technologies such as the ability to scan your foot to produce every trainer to measure and an augmented reality application to virtually try the trainers on. These technologies will allow the custom production of trainers avoiding a surplus of unsold products and utilizing the minimal amount of material.

This study aims to explore through IDEF0 (Icam DEFinition for Function Modelling) the viability of a new business model for manufacturers employing additive manufacturing processes, such as 3D printing, as part of a circular and re-distributed production and consumption model for the footwear industry. A review of existing literature will reveal if there are business models designed using IDEF0 that can directly support the implementation of a re-distributed way of manufacturing. In particular, models containing parameters concerned with transportation, customer involvement, servitisation, and circularity will be sought. In seeking to establish if such models for circular and redistributed production exist, this paper will scope an agenda by putting forward new models derived from the ShoeLab case study.

To achieve this aim, a five-step method of the IDEF0 Model, presented in

Section 4, was used to model an As-Is value chain as well as a new business model to make a comparison of traditional and re-distributed manufacture. To develop the IDEF0 model, a literature review was conducted to establish the state-of-the-art in re-distributed manufacturing and its constituent technologies and existing business models (

Section 2). Both ShoeLab models and their validation are further explained in

Section 4.

Section 5 discusses the reasoning behind the selection of IDEF0 as a tool and its application in modelling a consumer goods manufacturing As-Is value chain, how criteria where developed in order to determine the inputs, outputs, resources, and controls terminology to be used by each model, and a comparison of both models revealing some important insights about the challenges of implementing re-distributed models of production and consumption in the consumer goods sector. Finally, the paper concludes in

Section 6 by giving some recommendations on how a RdM model could thrive within this industry.

2. Relevant Research

Underpinning the RdM movement are a number of enabling concepts such as servitisation, customisation, and localisation [

11]. This literature review research was conducted on these three main subjects for RdM and further expanded upon by exploring concepts such as Circular Economy, and manufacturing processes in more depth, alongside the related technology espoused in Industry 4.0 initiatives.

In terms of servitisation, this concept is exemplified by Baines et al. [

12] as the “… customer pays for using an asset, rather than its purchase, and so benefits from a restructuring of the risks, responsibilities, and costs traditionally associated with ownership.” This means that the line between what’s considered a product and a service could be blurred into a product-service system which would help manufacturers “… sustain competitiveness, … ‘move up the value chain’ and (deliver) knowledge intensive products and services.” [

12] (p. 1543).

While helping to develop and maintain customer loyalty by providing more complete offerings through a product-service system [

13], Kastalli and Van Looy [

14] mention that the choice of business model for a manufacturer turned service provider, and their managerial practices, are crucial to successfully create products that can be complemented by services and vice versa. Providing solutions through a combination of products and services implies more participation between the manufacturer and customer during the product’s life. The focus could then be placed on providing a purposeful service model that would mostly make “manufacturers or retailers retain ownership of their products (or have an effective take-back arrangement) and, where possible, act as service providers, selling the use or performance of products, not their consumption.” [

15] (p. 687). According to Moreno and Charnley [

16], benefits from the implementation of RdM in the consumer goods sector could bring ways to “… effectively manage resources within markets, ensure waste is eliminated and monetized [

17], and support selling products as services, which will enable keeping products in longer use to minimize waste and resources” [

17] (p. XXV) [

18].

This new paradigm of manufacturer-customer relationship and product/materials use and re-use is known as a Circular Economy (CE).

CE draws attention to the entire life cycle of the materials from the moment they are sourced raw from suppliers to when they are transformed by manufacturers, dispensed by distributors, and sold by retailers, to the end consumer for use and even further into considering the reverse supply chain, in which expended products are used as new input to initiate another cycle in what is understood as a closed-loop supply chain system [

19]. In this way, CE aims to increase the efficiency of resource use, with a special focus on urban and industrial waste, to achieve a better balance and harmony between economy, environment, and society [

19]. This considers the technological, societal, and environmental aspects in terms of individual industrial processes [

20].

Being able to take products which would be considered at the end of their useful life and give them a new purpose (reuse) can be very beneficial in many ways. There are obvious environmental and economic benefits from requiring less resources and therefore, less energy and less labour compared to when a product is being created from raw materials, recycled, or disposed [

20]. Ghisellini et al. [

20] continue to explain that if the reuse of products is to be propagated then products themselves must be designed to be durable and prepared for multiple use cycles, coupled with incentives from companies to encourage take-back of products.

The customer is constantly cultivating and refining their tastes and requirements for novel products. This need from the customer can be satisfied by manufacturers by providing a service of mass customisation [

21]. Mass customisation (MC) can be defined as the ability to manufacture tailor-made personalized products and services utilizing technologies and systems with near mass production costs and efficiency [

22].

There are some substantial hurdles to overcome in the application of mass customization models. Currently, the extent to which customization can be completed is limited by the manufacturers particular production capabilities, competitive position, and technology and methods available to them. Technology can currently only manage to personalise a limited amount of attributes and products [

23]. Therefore, any manufacturer wishing to implement a mass customisation model should consider their “ability to deliver on and integrate the three strategic elements: elicitation, process flexibility, and logistics. Thus, highly flexible production technologies such as 3D printing can be used to respond quickly to customers’ wants and needs” [

23] (p. 71).

3D printing is a type of additive manufacturing in which an item is built by adding layer after layer of its component material in a successive process until a three dimensional object is created “which differs from the more usual “subtractive” (when an object is carved out of a block of raw material) or moulding/die-casting (when a molten material is injected into a solid mould) forms of manufacturing” [

24] (p. 215). In addition to enabling the production of tailor-made personalised products, 3D printing allows for design and manufacturing ideas to be tried and tested at significantly greater speeds, consequently improving the rate at which product innovation occurs [

24].

In addition, concepts such as Industry 4.0, a term that comprises the horizontal integration of the value creation network created by emerging technologies and applications (like additive and cloud manufacturing), can help to create an end-to-end commerce system that covers the entire product life cycle with a network of distributed manufacturing arrangements [

25]. This type of facility will be ‘smart’ in the sense of being composed of networks of intelligent processes that allow the product to dictate when it will be produced as well as what machine or group of machines will carry out the process and their efficient utilisation in meeting the requested quantities [

26]. Therefore, concepts such as servitisation, customisation, and localisation, alongside the introduction of new technologies, give rise to what is now known as RdM manufacturing. RdM can be defined as “… an emerging concept which captures the anticipated reshoring and localisation of production from large-scale mass manufacturing plants to smaller-scale localised, customisable production units, largely driven by new digital production technologies” [

27] (p. 577). According to Moreno and Charnley [

16], localisation is a concept that brings manufacturing closer to the consumer. This holds the potential to reduce carbon emissions through reduced transport needs, utilise locally sourced components in the product produced, reduce waste, and implement reverse logistics (whereby parts of or the whole product may be taken back at the end of its useful life for remanufacturing or recycling).

A successful implementation of this new manufacturing paradigm will combine all the new technologies and methods into a coherent system. The best way of achieving this is by first creating suitable business models to follow. This new “… business model represents a new subject of innovation, which complements the traditional subjects of process, product, and organizational innovation and involves new forms of cooperation and collaboration” [

28] (p. 1032). Since new technologies like additive manufacturing must be integrated into the current processes this “can open up new subspaces in the existing technical performance and functionality space, which in turn requires a new business model if the economic value potential of the new technology is to be captured” [

28]. New business models will realise the benefits from all novel commercial offerings that the implementation of a new manufacturing paradigm will create.

Matt et al. [

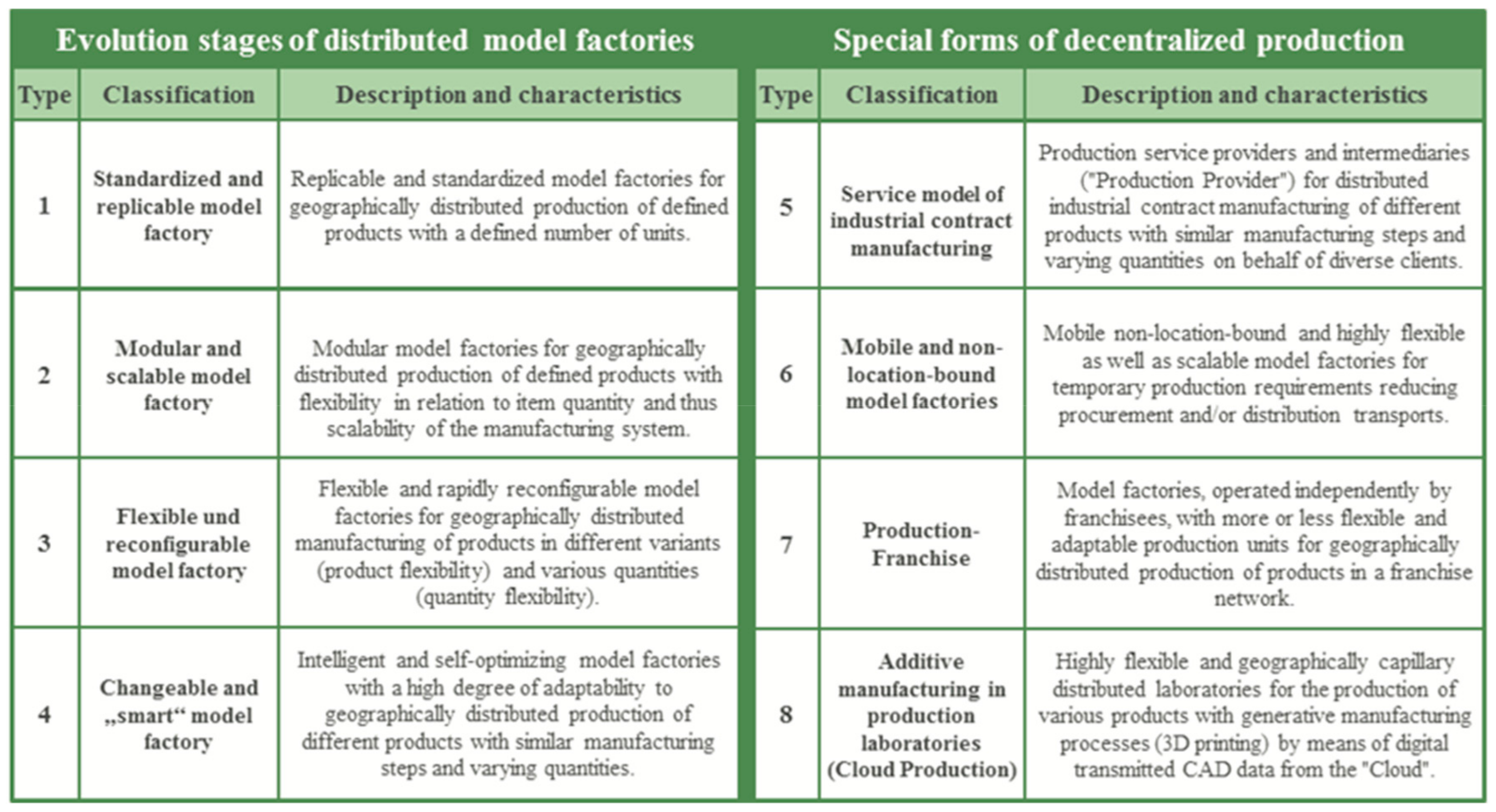

26] provide a classification of eight different models for RdM (shown in

Figure 1), which provides a complete spectrum from the most basic to the most visionary. Manufacturing facilities of type one will apply the most elementary concepts of RdM by replicating the same standardized procedures in geographically dispersed facilities. Manufacturing facilities of type four would incorporate a degree of flexibility to adapt to their surroundings. This would come in the form of changes in customer trends and also environmental changes. This would be achieved by implementing digital network technology that would enable the product itself to dictate how many units, with what specifications, and the configuration of machines required to produce it. Manufacturing facilities of type eight would represent the most innovative model using cloud manufacturing and additive manufacturing, selling product data and bringing the physical production to close proximity of the customer [

26]. Waddilove et al. [

29] add that businesses exploring innovation through a circular value chain are further challenged because “the scope of the business model is both broader and more complex than in the traditional linear model” (p. 382). Based on the review of existing literature, it is evident that there are no business models designed using IDEF0 that can directly support the implementation of a re-distributed way of manufacturing. In particular, parameters concerned with transportation, customer involvement, servitisation, and circularity are lacking in published models. If a business in the manufacturing industry is interested in converting to a distributed and sustainable way of production, then the lack of proper business models to implement can be a hindrance to that process. Coupled with a general lack of guidance in how to approach the implementation of RdM within an organisation, these elements are the focus of the research presented in this paper.

3. Methodological Approach

The IDEF0 (Icam DEFinition for Function Modelling) modelling standard is one of the most popular graphical notations for business systems and process planning [

30,

31]. IDEF0 could provide a clear picture of how value can be created and then transferred through the help of different functions and resources during the implementation of a distributed and circular business model. Such a model requires a systemic perspective in order to connect and deliver value to the region where it should integrate in order to be meaningful and provide value as expected [

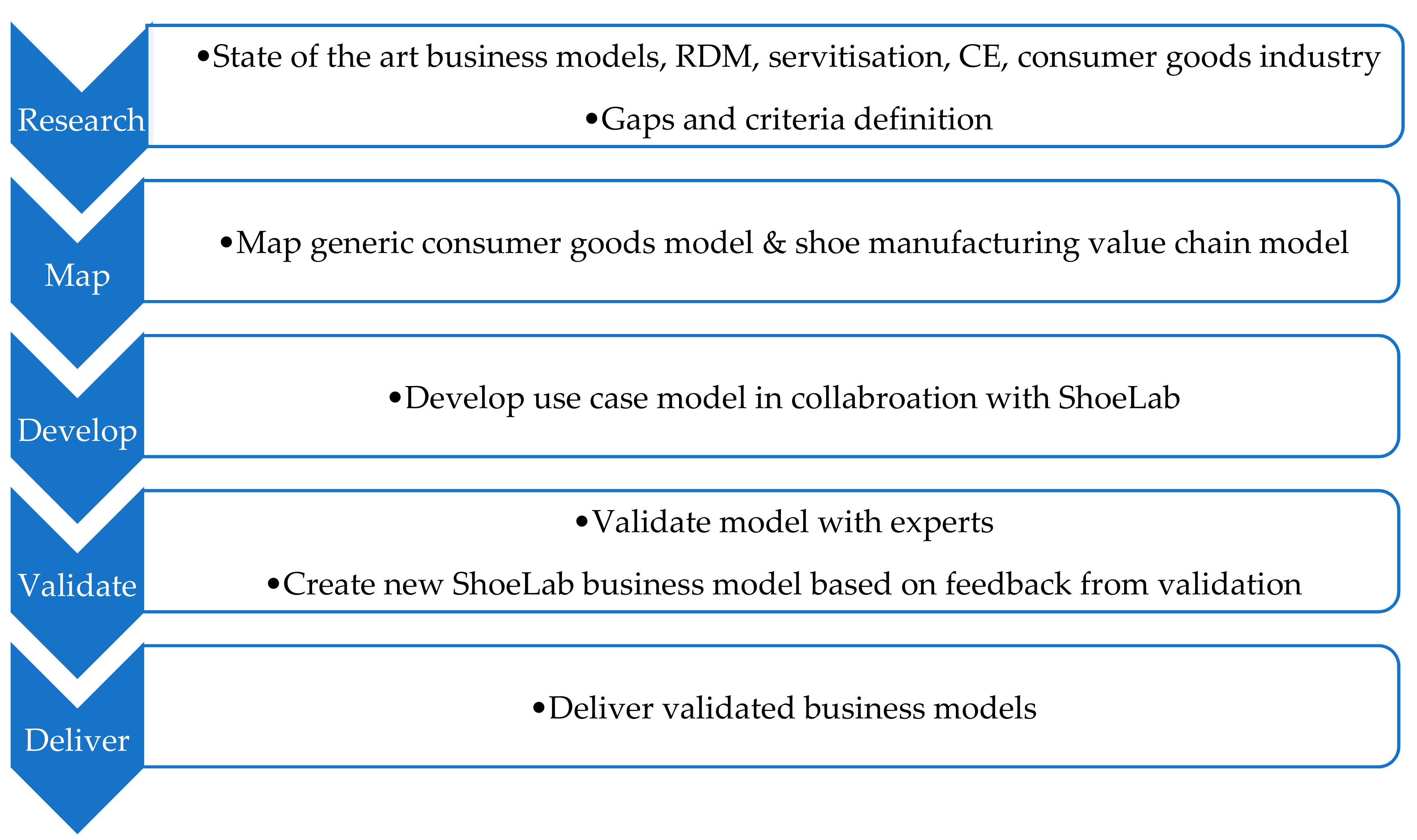

30]. This study followed a linear development path involving the establishment of the state-of-the-art through value chain mapping in the consumer goods industry to the development of a business model for sustainable RdM based on a case study (shown in

Figure 2). A generalized manufacturing value chain serves as a foundation for all of the models as they follow a procure, produce, retail, consume, and dispose flow of functions as a structure/initial blueprint. The case study as a methodological tool for intensive investigation into one research case instance is now well established [

32]. The case study development process, shown in

Figure 3, involved three broad stages: brainstorming within the team for development of initial scenario areas, literature review and research gap identification, development of As-Is and To-Be scenarios, feedback on initial scenarios from ShoeLab internal and steering groups, validation of completed Integration Definition for Function Modelling (IDEF) model scenarios by experts, and re-evaluation of case study models. The main procedures for the development of the models were followed according to Integration Definition for Function Modelling (IDEF) [

33] model creation methodology.

Prior to the development of the models, a value chain approach helped determine the main functions that each of the models would roughly contain, providing a general flow to define inputs and outputs from one function to the next. Furthermore, criteria were developed based on the understanding of the subjects in the literature review in order to provide guidance for the definition of controls and resources that each function would contain. These criteria consisted of parameters identified while developing the models around four major concepts dealing with transportation, customer involvement, servitisation, and circularity. On development of the ShoeLab case study, an As-Is was created specific to the shoe manufacturing process in order to have a more accurate reference model to compare against the completed case study business model. During the case study development stage, information was gathered about the intelligent shoe concept through a variety of meetings with experts developing the ShoeLab project. These meetings consisted of presentations made to ShoeLab project and steering group members as well as two different focus groups, during which information regarding the concept was further explored with participants who were not directly involved in the project. The focus groups took the form of professionally facilitated and led discussions utilising brainstorming, idea wall/post it notes, and mind mapping tools Once sufficient knowledge on the subject was acquired, a draft model of the ShoeLab value chain was created.

The ShoeLab model was then validated through the creation of a closed question survey with open comment sections (the questionnaire may be found in

Supplementary Materials). The Survey was completed by ten experts drawn from both industry and academia. The feedback recovered from the survey answers was then utilised to further improve the ShoeLab case study model. A new ShoeLab concept model based on the knowledge gathered throughout the project was then created in order to explore other possible variations on the RdM models already created. This would allow further contrast between the As-Is shoe manufacturing process model, the ShoeLab case study, and concept models. All models produced at this stage were compared in order to gather insights into the possible contributions that the models could provide to the future development of RdM models and their implementation.

4. Proposed Business Model for Sustainable Re-Distributed Manufacturing (RdM) and Case Study

As previously mentioned, the case study is drawn from the ShoeLab case study. ShoeLab was a collaboration between Cranfield University, The Clearing, and CISCO to improve the current model for designing, manufacturing, distributing, selling, using, and disposing of shoes by developing a novel business model based on RdM and circular economy concepts to provide an enhanced product-service offering to the customer.

The concept is based on a modular shoe design which is made up of few components, allowing a more efficient use of materials, reparability, and upgradability. These components can be separated at end-of-life for re-use or recycling. This is enabled by the use of 3D scanning and printing technology to manufacture the different components of the shoe according to the specific customer’s foot dimensions, intended product use (serious runner, casual runner, fashion) and aesthetic preferences. The shoes will be embedded with sensors in order to provide benefits to the customer such as performance monitoring, location tracking, and shoe condition depending on the customer’s intended use and preferences. Depending on the type of sensor used, the technology could provide information on how the wearer moves and when the shoe needs to be repaired or replaced and additionally, inform the manufacturer on the flow of materials and how frequently shoes are used, upgraded, repaired, and replaced, providing insight into future trends in fashion and style across markets. These shoes are intended to be manufactured as close to the customer as possible through the implementation of decentralized mini factories which would also serve as store fronts and repair centres where worn shoe modules can be replaced, upgraded, or updated. The payment method is flexible and could be subscription based, bundling shoes and services, such as repairs and upgrades, according to the customer’s preferences.

4.1. Shoe Manufacturing As-Is

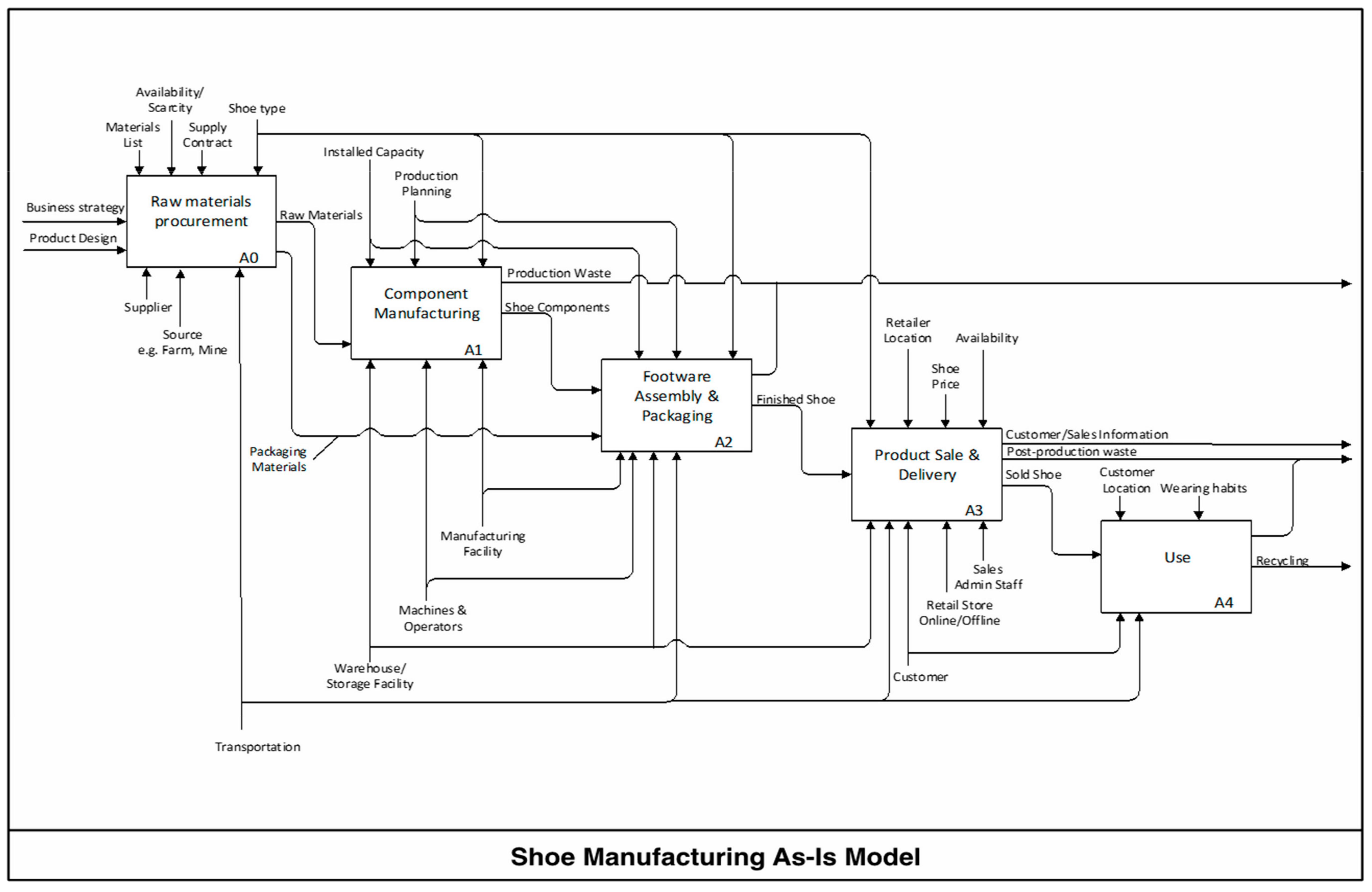

In preparation for the ShoeLab case study, a generic shoe manufacturing consumer goods As-Is model was created (

Figure 4). The following function, Component Manufacturing (A1,

Figure 4) details the process of making the different parts of the shoe prior to assembly. Shoe components are the output of this function together with production waste. Footwear Assembly and Packaging is combined in the next function (A2,

Figure 4), during which shoe components are assembled and packaged in preparation for retail. The finished shoe product is then taken into the Product Sale and Delivery function (A3,

Figure 4) which substitutes the control of Shelf Life (since shoes don’t have a perishable attribute) into an availability control which, in a sense, represents the fluctuation of supply and availability similar to that in function A0 (

Figure 4).

4.2. The ShoeLab Model

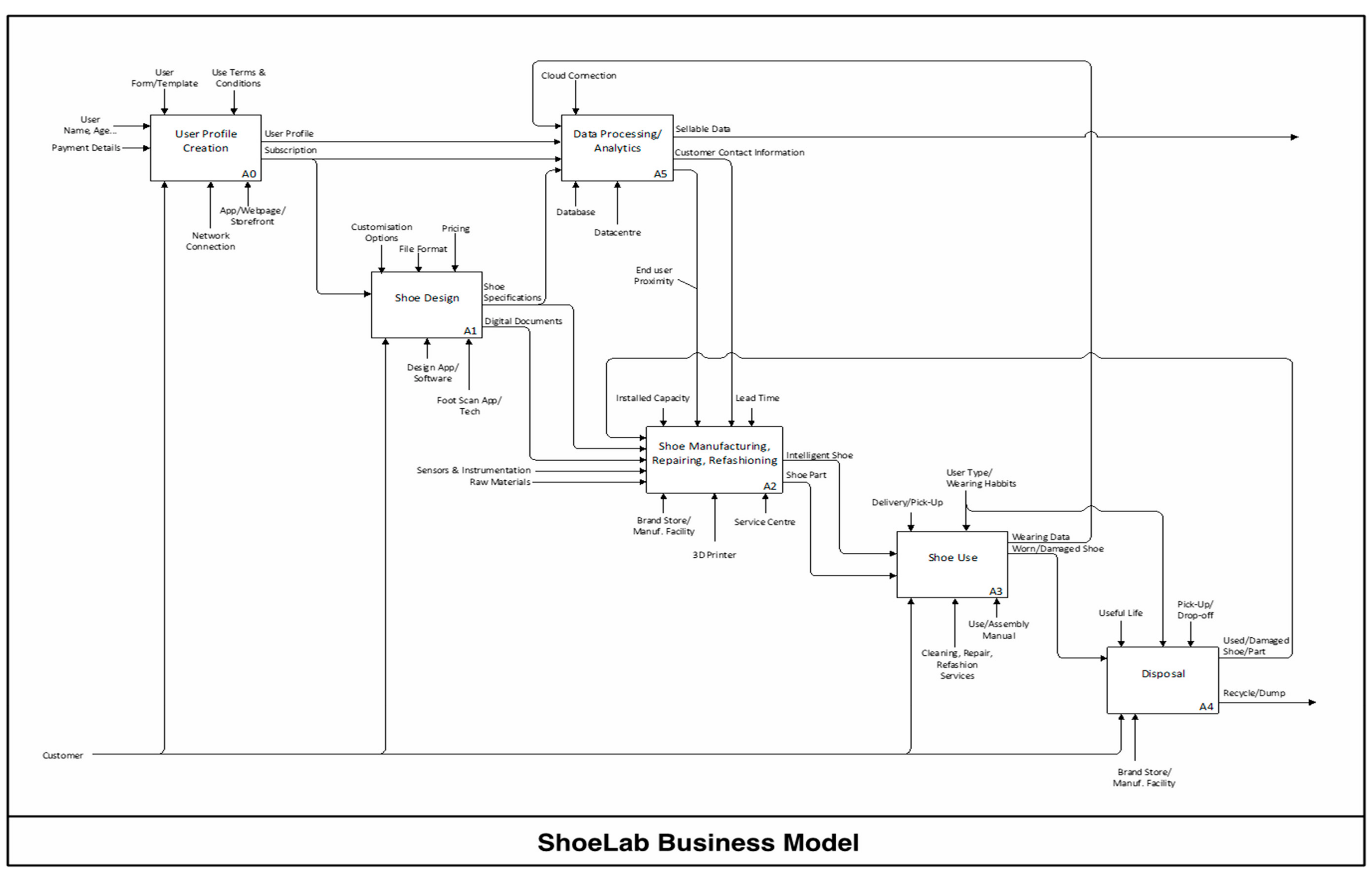

The ShoeLab business model starts with the User Profile Creation (A0,

Figure 5) function. During this function, the customer provides their general information as input (name, age) and details regarding their preferred payment method. The resources are the tools that the customer will need in order to input their information, mostly a Network Connection and the Application, which could be in a mobile device app, web app, or in the actual storefront. This function provides the customer information including their subscription and product preferences as output. This output and other information related outputs are centralized in a Data Processing/Analytics function (A5,

Figure 5). The main use of the information provided by A0 is to activate the Shoe Design function (A1,

Figure 5) so that the customer can provide personal preferences in the form of customisation options for the product. Based on these choices, pricing is determined, and in the background, data is captured and transformed to a format suitable for the 3D printing machine to be able to process. The resources are in the form of applications to help the customer scan their foot dimensions and additional technology to carry this out if the customer is in store. The main outputs from this function are in the form of shoe specifications and digital documents. Both are, in essence, the same information being transferred in different formats and for different purposes. The shoe specifications provided by the customer are stored in the Data Processing/Analytics function and this same information but in a 3D printer readable format is provided as a digital document to the following function of Shoe Manufacturing, Repairing, and Refurbishing (A2,

Figure 5).

The manufacturing function (A2,

Figure 5) provides the production, repair, and refurbishing actions. Since this is an RdM model, all of these functions can be performed in the same local (in relation to the customer) facility. Sensors and instrumentation are inputs that represent the technology that is to be included in the shoe according to the customer’s requirements: the sensors can provide GPS tracking, health monitoring, or others. These are sourced from other manufacturers and thus, the assumption is made that they cannot be produced by the ShoeLab manufacturing facility. Raw material is an input, in this case, it is assumed to be the printing material itself since the entire shoe would be manufactured from the least amount of separable materials as possible. The 3D printer is the main resource, together with the brand store/manufacturing facility and the service centre. As previously mentioned, the service centre and the manufacturing facility are concentrated in the same place as the store front. The service centre is the place where shoes are refurbished, extra parts are produced, and other services are fulfilled. This same place contains the 3D printing machines that are used for the manufacturing of the shoe. The outputs from this function are the finished shoe, named as intelligent shoe, and shoe parts which may be requested by the customer in order to repair a damaged part of the shoe. Since the shoe is produced in a modular way, different parts can be disassembled for repair. The shoe or shoe parts are then transformed by the Shoe Use function (A3,

Figure 5). This function is controlled by delivery or pick-up methods involved in transporting the shoe to the customer and the user type/wearing habits. Additionally, there will be resources provided by the manufacturer in the form of Cleaning, Repair, Re-fashion Services, and User/Assembly Manual. The possibility of modifications being made by the customer on his own account is aided by a manufacturer-provided use/assemble manual. The outputs provided by this function are digital in the form of wearing data and physical in the form of a worn/damaged shoe. The wearing data is transferred to the Data Processing/Analytics function (A5,

Figure 5) which uses them as input in order to, for example, activate a service offering or provide other useful information for the manufacturer to support the customer.

The worn/damaged shoe is transferred to the Disposal (A4,

Figure 5) function, most of the information generated throughout this process is meant to be what transforms the end of life product into a possible input for the A2 function, as material for the production of other shoes or the end of life product can be recycled/dumped by the customer. The option is free for the customer to choose if they desire to recycle/dump the shoe, but the intention of the ShoeLab project is to have the damaged end of life product returned to the manufacturer for reprocessing. For this reason, the brand store/manufacturing facility is included in the resources for this function. Furthermore, there is a consideration for the pick-up/drop-off of the used/damaged shoe/part so that it may reach the place where it will be recycled or reprocessed.

Most of the information generated throughout this process is meant to be capitalised on, to make profit and improve processes, therefore, the Data Processing/Analytics function (A5,

Figure 5) was included as part of the model. This function gathers all the information about the customer profile, product specifications, and wearing data by using resources such as a database and datacentre. Through analytics processing of these data sources, the A2 function can locate the manufacturing facility that is closest to the customer as well as provide contact information.

4.3. Validation and Concept Model

The ShoeLab model was validated through the creation of a questionnaire containing a combination of closed and open questions (the questionnaire can be found in

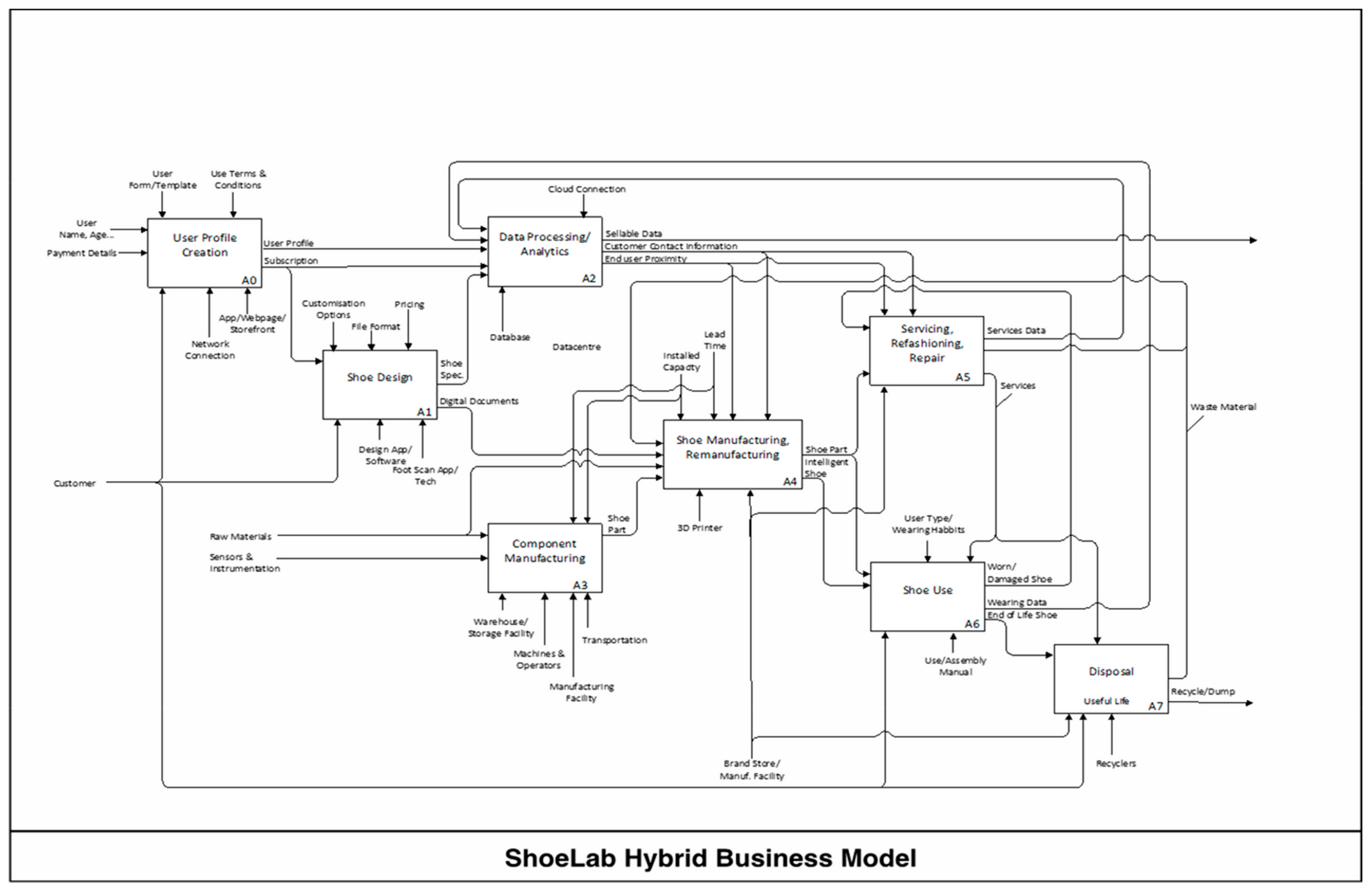

Supplementary Materials). The questionnaire was completed by ten experts drawn from both industry and academia. The feedback was requested in order to validate the ability of the ShoeLab model to convey the main criteria that was used to create it. For this reason, the validation questionnaire was divided into four sections, each one corresponding to one of the four criteria points of transportation, customer involvement, circularity, and servitisation (identified from the review of relevant literature). The feedback regarding the different sections was used as input for the development of a concept model called the ShoeLab Hybrid Business Model (

Figure 6). This model attempts to improve on the ShoeLab Model (

Figure 5) based on the observations gathered from the validation questionnaire and meetings with the ShoeLab project members. The main improvements focus around providing a clearer representation of the services and their involvement in the value chain. This was achieved by including the A5 function (

Figure 4) called Servicing, Re-fashioning, and Repair. This function is controlled by the Data Processing/Analytic function A2 (

Figure 6) by providing customer details such as their contact information and location, both of which are included due to them being critical for the provision of any service. The output is purely services and service data. The services are now controls which shape the Shoe Use (A6,

Figure 6) function in the way of providing re-fashioning and/or repair services. The Disposal (A7,

Figure 6) function is also controlled by services that provide the customer the option of returning the shoe to the manufacturer once it has reached its end of life. This supports the combination of services with circularity criteria. For this reason, shoe parts from the Shoe Manufacturing, Remanufacturing (A4,

Figure 4) function and waste material from the Disposal (A7,

Figure 4) function are inputs to the Servicing function, since they are used to provide repairing and take-back services. In addition to the Servicing function, this model has the inclusion of a Component Manufacturing (A3,

Figure 4) function. This is the reason behind the model being called a hybrid, since it borrows the function in the shoe manufacturing As-Is (

Figure 4), which represents the manufacturing of components that cannot be made, in this case, using additive manufacturing (3D printing).

5. Discussion

The modelling of RdM technologies and methods using IDEF0 has provided insight into the main areas that are influenced by the implementation of such a model in a consumer goods industry. Discussed below is: (1) the reasoning behind the selection of IDEF0 as a tool and its application in modelling a consumer goods manufacturing As-Is value chain, (2) how criteria where developed in order to determine the inputs, outputs, resources, and controls terminology to be used by each model, and (3) what are the main insights gained from the comparison between the As-Is and To-Be models.

5.1. Integration Definition for Function Modelling (IDEF0 as a Tool and Its Application to Define New Business Models

Once the model development methodology was defined, a specific modelling technique, in this case IDEF0, was chosen for the following reasons: such a technique is used for developing an organizational graphic representation of the business and manufacturing process involved in complex systems such as enterprises. It breaks down the main processes into functions to depict, from a high-level perspective, all the inputs, outputs, controls, and mechanisms or resources that are used by these functions [

34].

The main functions are complemented by four different criteria points which were chosen in order to provide a methodical way of including desired elements for controls and resources which could then be compared between the different models. These criteria are transportation, customer involvement, circularity, and servitisation. These main criteria were chosen because they are the most probable aspects to be affected by the transition from the current way of manufacturing towards a re-distributed model. Therefore, providing knowledge into what are the main aspects that will be influenced in the transition from the current As-Is to a re-distributed To-Be scenario.

5.2. Criteria

Transportation Criteria

The transportation criteria represents one of the key concepts of RdM. If a manufacturing company wishes to implement a re-distributed model, they are faced with the challenge that the factory and the customer must be located in close vicinity of each other to improve the model’s success. Therefore, RdM models with facilities that produce in proximity to the customer need to be small and flexible [

26].

Transportation can be represented in the models whenever materials are physically moved, providing specific consideration to the distances between where they are procured, manufactured, sold, consumed, and disposed. The aspects considered and included in the models therefore deal with the transportation of raw materials and components from their sources to the places where they become products. The main benefit of creating an As-Is model using these criteria is that the dependence in transportation resources becomes immediately apparent, it is the most prevalent resource affecting almost all functions in

Figure 2. Bringing forward this dependency is an important step towards reducing it in the implementation of re-distributed business models, as can be seen in

Figure 6.

5.3. Customer Involvement Criteria

The second criteria determines which aspects to include in each function in relation to customer involvement. This is a key concept because RdM implies a greater depth of participation by the customer in each of the different stages of a manufacturing value chain. Customer involvement criteria therefore relates to how much participation and decision-making power the customer has in each function. This could be represented by customisation and personalisation options available to the customer during the different functions, like the option to modify or provide their own designs. These criteria also identify the technology that enables customisation and personalisation, such as additive manufacturing, design applications, and 3D scanning technology, so they can be included as resources.

With future developments in new manufacturing models and novel materials and technologies, 3D printing can encourage participation by communities in a variety of manufacturing industries and also motivate innovation [

24]. 3D printing technology, given its high degree of digitization and automation, can be integrated into modern models in order to fully realise its benefits. As a technology, additive manufacturing can most certainly lead to the creation of value, but in order to achieve a competitive advantage the current business models need to evolve and allow for the capturing of this value [

24]. For this reason, technology such as 3D printing and additive manufacturing must be represented in the models under customer involvement criteria. How much the customer is or is not involved in each function is considered in each model to demonstrate how much the customer defines product and production aspects which can go further than design or aesthetics preferences, such as where and how the product is manufactured, though in the Hybrid model (

Figure 6), this customer co-creation is further highlighted due to improvements made in the servitisation aspects. These criteria are crucial to consider when implementing a re-distributed business model. These criteria represent the consumer’s ability to participate and influence the value chain process through decision making at an individual basis, i.e., the relationship between each customer and the product development process is the main focus of these criteria. These criteria were used in the creation of the models to identify the different functions in the value chain that the customer interacts and the technology which enables this. The relationship between the consumer and the manufacturer and/or retailer is considered under the servitisation criteria.

5.4. Servitization Criteria

The servitisation criteria analyses not only the service offerings that could be put forward by the manufacturer or retailer to the customer but also expresses how the relationship between the consumer, manufacturer, and retailer can be deepened and continued after the retail function. The idea of product ownership, product maintenance, and repair are concepts considered by these criteria. These criteria open up new avenues for the company to gather knowledge on the consumer such as through the use of technology embedded in products which can relay information about performance and use.

As opposed to the standard ShoeLab model (

Figure 5), the Hybrid model (

Figure 6) shows a clearer representation of the services and their involvement in the value chain. This was achieved by including the A5 function (

Figure 4) called Servicing, Re-fashioning, and Repair. This function is controlled by the Data Processing/Analytic function A2 (

Figure 6) by providing customer details such as their contact information and location, both of which are included due to them being critical for the provision of any service. The output is purely services and service data. The services are now controls that shape the Shoe Use (A6,

Figure 6) function in the way of providing re-fashioning and/or repair services. The Disposal (A7,

Figure 6) function is also controlled by services that provide the customer the option of returning the shoe to the manufacturer once it has reached its end of life.

Services permit more interaction and avenues for the company to gather knowledge on their customers while being more sensitive to their needs, effectively building a deeper relationship than if services were not offered. In addition to developing deeper relationships with customers, the information that’s gathered from this interaction can drive future product developments, engineering work [

14]. These follow directly from the previously mentioned Customer Involvement criteria since it provides for increased interaction by the customer, but in these criteria, focus is placed on the relationship between the manufacturer and the customer, as opposed to the customer and their potential to influence the products’ aspects.

The representation of services and how they improve interaction within the consumer-manufacturer relationship are important criteria to consider when implementing a re-distributed manufacturing business model. This is because value is no longer only associated with the tangible products, customers are increasingly placing value on results, which are in many cases best provided by product-service offerings. From the industrial standpoint, this means that offerings to customers can no longer solely depend on the production of better, faster, and cheaper products. There is now greater demand for “solution systems consisting of product-service components throughout the customer’s activity cycle …” [

35]. The modelling of this aspect in IDEF0 provides the visualisation of where and how services can have an effect on the creation of positive value for the customer.

5.5. Circularity Criteria

The last criteria created to contribute as a guide is related to the circular aspects of the business model. The value chain has to become circular, full of feedback in terms of material flows and information to guarantee the sustainability and resilience of the model. This requires a systems perspective to attempt to replicate the “overwhelming majority of real-world systems: these are non-linear, feedback-rich and interdependent” [

6]. Observing the ShoeLab case study (

Figure 5), circularity can be seen in the feedback of used materials and shoes back into the Shoe Manufacturing, Remanufacturing (A4) function. Circularity can also be observed in terms of data being fed back into the system after the user has begun using the product. This valuable data can help improve services and therefore product durability; since it is assumed that the product will enjoy a longer useful life if a suitable maintenance practice is scheduled.

These circularity criteria are paramount to the implementation of re-distributed models due to their transformative effect on value. These criteria therefore pertain mostly to the I/O of each function. Emphasis is made on whether or not this I/O can be reutilised by another function and avoid as much as possible any outputs that exit the model altogether, thus becoming “circular”. When designing an IDEF0 representation of the value chain for implementing re-distributed business models, the benefits of circularity can be visualised as materials that would otherwise be considered of no value are repurposed and reinserted into the value chain, i.e., outputs can become inputs for other functions. Creating a sustainable, self-sufficient business model.

5.6. Model Comparison

The contrast between the different models developed during this process yielded some important insights into the challenges of implementing a re-distributed business model in a consumer goods industry.

The prevalence of transportation as a resource is evident from the As-Is (

Figure 4) and the To-Be (

Figure 5 and

Figure 6) models. The reduction in this resource should be one of the key concerns for the implementation of a re-distributed model. One observation is that only raw materials and data should travel long distances in a re-distributed model. Attention should be paid to logistics for delivery of products and services to the customer. The proximity of the customer to the manufacturing and servicing facilities is an important value generation opportunity, i.e., the closer the facility can be to the customer, the better. This relates to the discovery that having multi-tasking facilities which can manufacture, remanufacture, and provide services all in the same location and with the same equipment, all in close vicinity to the customer, is the main generator of value to the customer and their community.

Some of the limitations encountered when comparing the models using the transportation criteria is that IDEF0 modelling cannot provide details regarding distances. It is not possible to convey exactly how far away, in distance, one facility is to the other or to the customer, this can only be implied by the presence or absence of transportation as a resource for a particular function. Future study is needed to determine the appropriate distribution of manufacturing facilities/store fronts according to the surrounding population and demand. This could answer concerns regarding what is the ideal distance between a manufacturing facility and their potential customers, suppliers, or other facilities. This formula could be used in combination with the models to provide a way of calculating where to place these facilities. If taken further, these models should be made more specific perhaps using other modelling techniques such as IDEF3 to map the specific process flow within each of the functions.

Customer involvement and co-creation shape the Shoe Use function in the hybrid model (A6,

Figure 6) in the way of providing re-fashioning and/or repair services. The Disposal (A7,

Figure 6) function is also controlled by services that provide the customer the option of returning the shoe to the manufacturer once it has reached its end of life. This innovation is much clear in the Hybrid ShoeLab model as opposed to the standard model.

According to Reference [

26], flexibility can be shown in terms of product and quantity. Product and quantity are limited by the availability of resources and installed capacity. It was apparent that the As-Is (

Figure 4) for shoe manufacturing had clear benefits in terms of quantity flexibility and not as much in product flexibility. The product is designed at the initial functions and no other function in the value chain changes the product design or features as opposed to the To-Be model (

Figure 5). The contrast between each model’s type of flexibility means that there are compromises and benefits in transitioning from one model to the other. Installed capacity and lead time are therefore crucial components to the implementation of a re-distributed model, by determining installed capacity according to the particular local demands for flexibility of product and quantity.

With ShoeLab, the intention is to produce only one product with a variety of options for the customer to customise and personalise the shoe, i.e., product flexibility. In terms of quantity flexibility, since the main technology on which the case study depends on is additive manufacturing, mainly 3D printing, it would be possible to not keep inventory of already manufactured shoes, only the other technological components, like sensors, would need to be stocked. This would provide some product flexibility but not in terms of quantity, as opposed to the As-Is (

Figure 4), due to the restriction of having to keep stock of some components in anticipation of demand. For this reason, a Hybrid model was created (

Figure 4), to account for the present need of manufacturing or sourcing certain components of the products and use 3D printing for the remaining necessary components.

Implementation of a re-distributed business model would require further study on additive manufacturing to determine what the ideal installed capacity would have to be to satisfy production needs and local demand, considering the lead time and market size. If the aim is to provide the current standard of quantity flexibility according to demand, then this becomes a necessity. The models developed in this research are limited to providing an initial guide for developing an implementation strategy of re-distributed business. Further study needs to be conducted on the feasibility concerning, for example, costs and technology readiness.

6. Conclusions

The aim of this research was to develop RdM business models using IDEF0 to serve as a guide for the implementation of RdM concepts in the consumer goods industry. To accomplish this goal, it was imperative to understand the current state of consumer goods manufacturing and how elements of servitisation and circularity, together with technology such as additive manufacturing, could potentially influence the organisation of manufacturing in terms of location and scale. Criteria was developed around transportation, customer involvement, servitisation, and circularity concepts to support the development of the models and for their comparison. Through the ShoeLab case study, information was recollected to create models that depict what an RdM value chain would look like if applied to the shoe manufacturing consumer goods industry. Most importantly, the ways in which the different functions representing supply, production, distribution, and use can communicate with each other through the transformation of materials into products, service offerings, and data, providing a guide for the implementation of re-distributed manufacturing processes into a consumer goods operation.

The models have shown that there is a need for robust facilities in close proximity to the customer. These facilities are store fronts which can also manufacture, remanufacture, and provide services. This combination can reduce costs, improve sustainability and provide customizable products and services for customers. Furthermore, the reduction in transportation and increase in customer involvement throughout the process are the main elements that would vary the most if a re-distributed model is implemented.

A number of study limitations have been identified in the course of this research. The implementation of a re-distributed business model would require further study on additive manufacturing to determine what the ideal installed capacity would have to be to satisfy production needs and local demand, considering the lead time and market size. If the aim is to provide the current standard of quantity flexibility according to demand, then this becomes a prerogative. The models developed in this research are limited to providing an initial guide for developing an implementation strategy of re-distributed business, further study needs to be conducted on the feasibility concerning, for example, costs and technology readiness. The operation of redistributed in practice is based on current understanding in the research community, future interpretations of this concept influenced by rapidly changing technology may differ in their implementation.

The hybrid model featured (

Figure 6) may in future research be further developed into an interactive representation utilising an Agent-Based approach to modelling [

36,

37]. Interactive Agent-Based models could allow for real-time data ingest, providing decision makers with an integrated tool on which to evaluate re-distributed manufacturing decisions more rapidly (addressing both financial, logistic and consumer aspects in parallel).

As long the business model is positioned with a high-value proposition this concept could be profitable. As Rayna and Striukova [

24] argue, 3D printing could enable high customer engagement resulting in an increased value proposition in return for their willingness to pay extra for a premium product. As seen in the results, the majority of the revenue generated will come from the after-service element of the model, as it is expected that customers will service their trainers after a period of time, whether is a replacement of the sole upper or sensors. Distribution of manufacturing enabled by 3D printing technologies are ideally positioned to support production on-demand as different variations of the same design, production of spare parts, or repair services can be offered [

38]. However, such printing technologies and materials such as SLS printers and Duraform Flex could be very costly for both existent and new market entrants. Future research is needed to improve the technology, reduce the cost of materials, as well as research to decrease 3D printing process time to increase the capacity of the printer, thus reducing the per unit cost of printers. In future work for the authors, the developed business models will be adapted to other industry cases, utilising the inherent componentisation of the process stages achieved through use of the IDEF0 notation.