2.1. The Building Model and Load Calculation

An office building with two floors is drawn in Google Sketchup to create the 3D building model, as shown in

Figure 1. The area of the building is 1153.04 m

2, the height is 8.4 m, and the window-wall ratios are listed in

Table 1. The office building is located in Suzhou city, which is in the hot summer and cold winter region of China. In order to control and standardize the heat transfer through the building envelope, the thermal property parameters of the building envelope are designed using the baseline values of the Chinese national standard “Design Standard for Energy Efficiency of Public Buildings (GB 50189-2015)” [

32]. This method for creating a reference building model using baseline of design standard for studying energy efficient building design has been used by many researchers [

33,

34,

35]. The main parameters are listed in

Table 2.

The 3D building model is input to Multizone Building Modeling (TRNbuild), which is a part of the TRNSYS program in which multi-zone 3D buildings can be imported and building data and parameters can be defined. TRNSYS is a graphically based software environment that is flexibly used to simulate the behavior of transient systems [

36]. It has been successfully used and verified in various studies to analyze the performance of GSHP systems for all types of buildings in different areas in the world [

35,

37,

38,

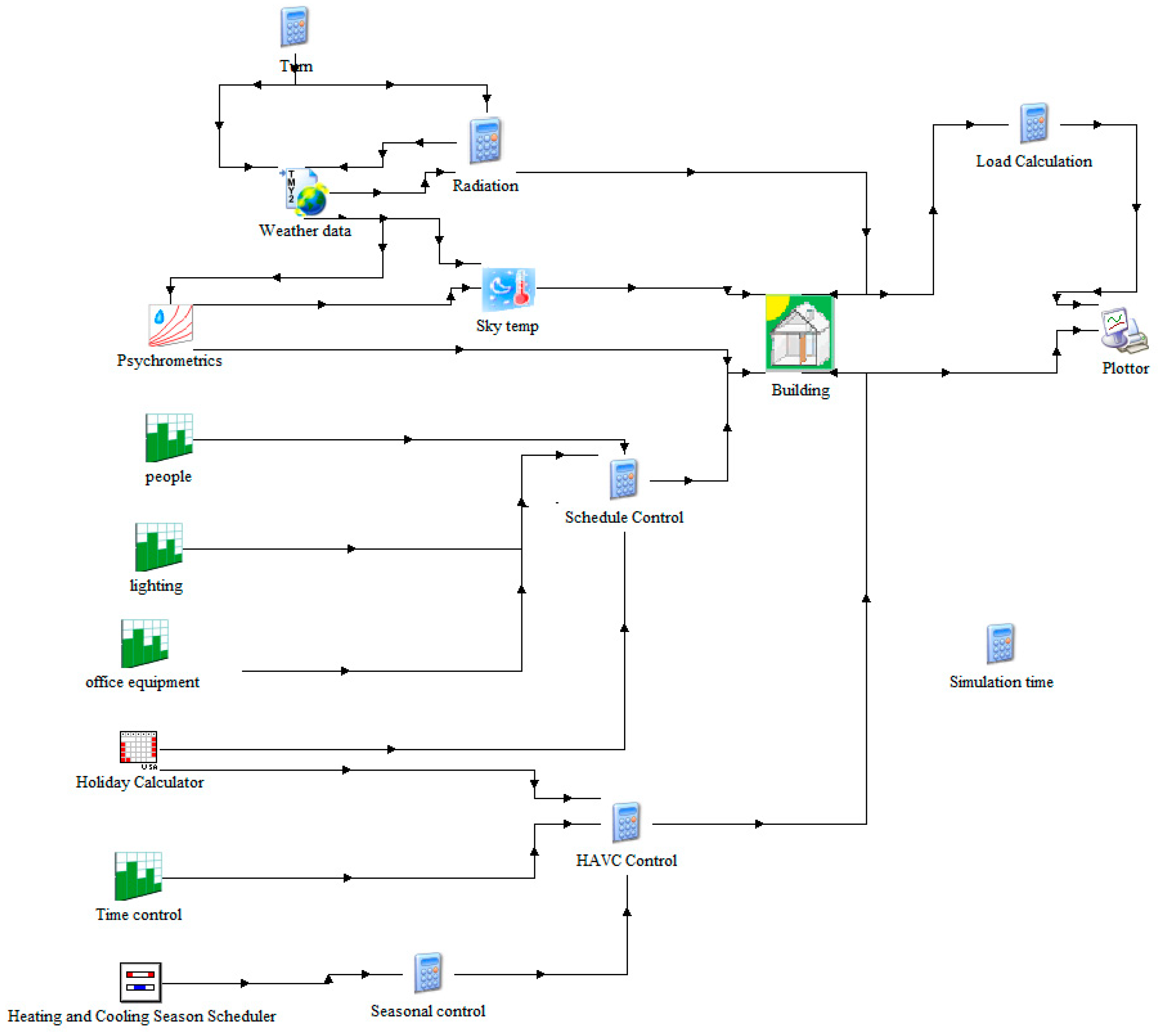

39]. The system model for calculating the heating and cooling load for the office building is created in TRNSYS simulation model, as illustrated in

Figure 2. The necessary components are added and linked in the model. Component Type 56 (Building) represents the office building and the building’s data is set up within it [

36].

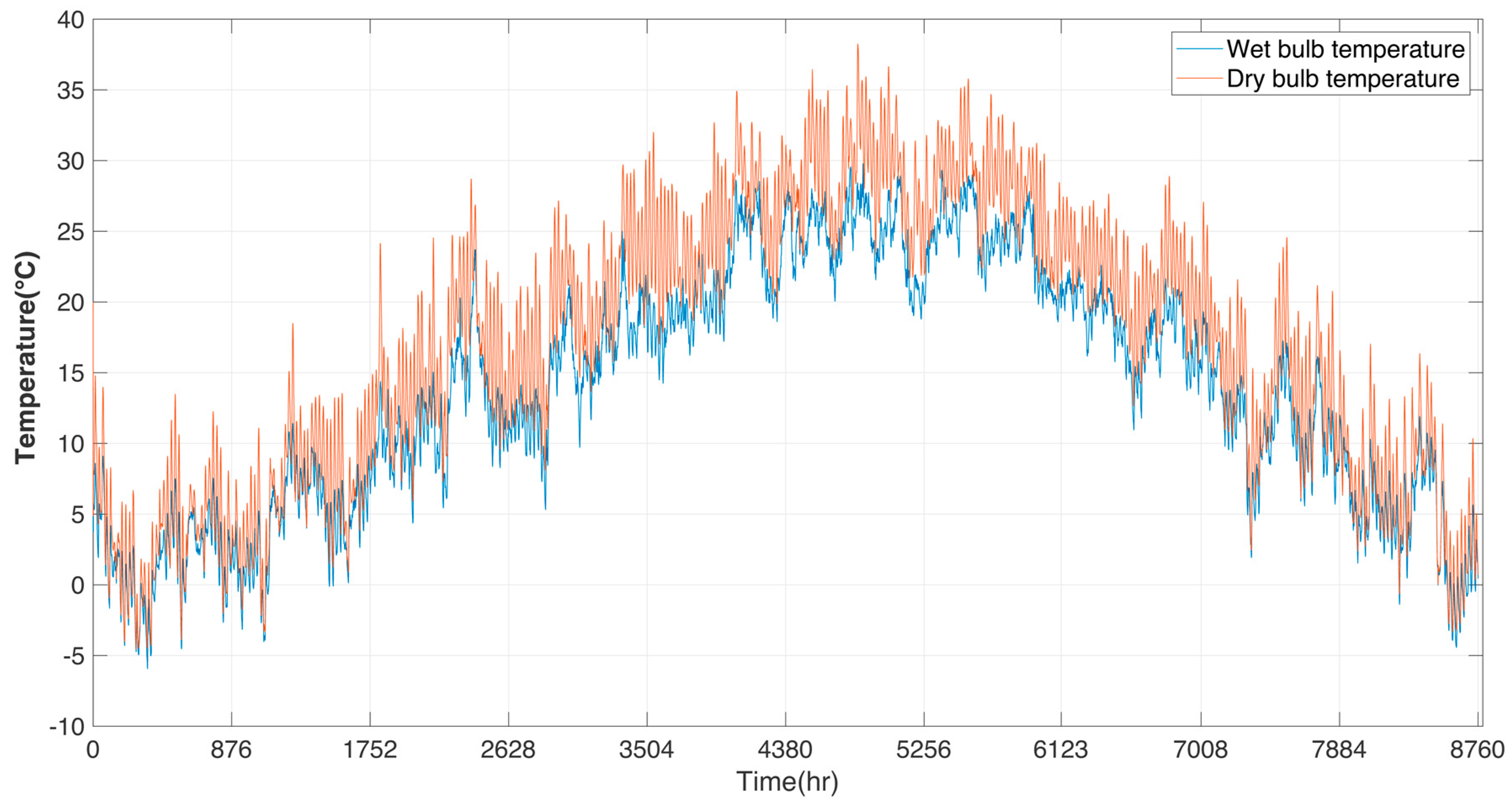

The Suzhou weather data of a typical meteorological year is imported by Meteonorm 7.0 through the Type 15-2 (weather data) component of the TRNSYS simulation model [

36]. A typical meteorological year for Suzhou is illustrated in

Figure 3, which shows typical air temperature characteristics for a hot summer and cold winter climate region of China.

According to the weather conditions in Suzhou, the cooling supply usually starts from the middle of May and goes through to the end of September and the heating supply usually starts from the beginning of December and goes through to the middle of March. People usually use natural ventilation during transition seasons. The cooling and heating seasonal schedules are set to component Type 515 (Cooling and heating seasonal schedule) of the TRNSYS simulation model [

36]. In addition, according to GB50189-2015 [

32], the air-conditioning control for the office building model is set at 26 °C in the summer and 18 °C in the winter [

32].

According to GB 50189-2015 [

32] for an office building, the personal occupancy density is 0.1 person/m

2, fresh air per person is 30 m

3/h, the lighting power density is 9 W/ m

2, and the equipment power density is 13 W/m

2. All these parameters are set in the TRNSYS simulation model. For the office building, people normally work 8 hours a day from 9:00 am to 5:00 pm except weekends and holidays, so the lighting and office equipment working schedules are set accordingly in the TRNSYS simulation model.

Other components necessary for processing data and information to calculate the load include: Type 33 (Psychometrics) for calculating the corresponding wet bulb temperature and percent relative humidity in order to obtain the dry bulb temperature and relative humidity from weather data; Type 69 (Sky Temp) for calculating the effective sky temperature of long-wave radiation exchange; and Type 24 (Integrator) for calculating the accumulated energy demand of different zones as well as the total accumulated energy demand of the building [

36,

40].

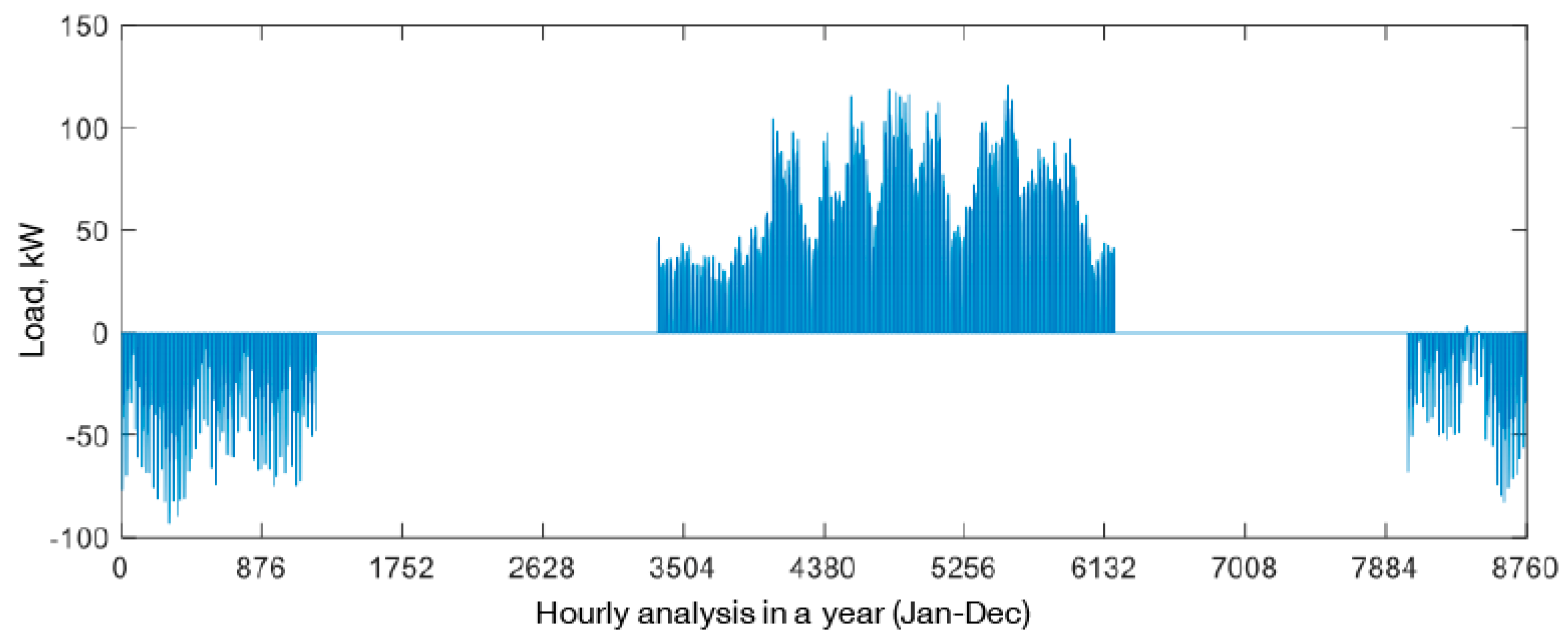

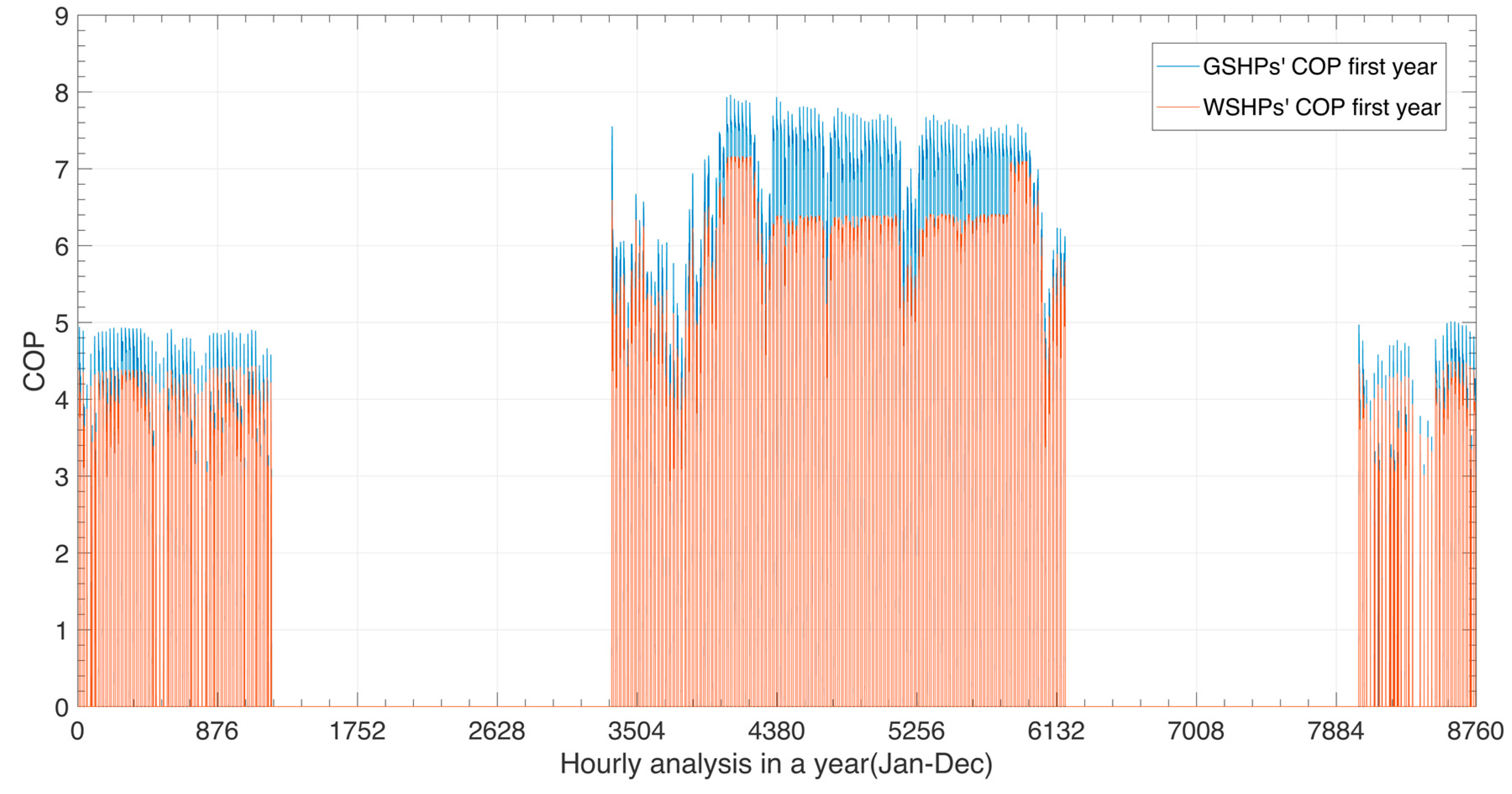

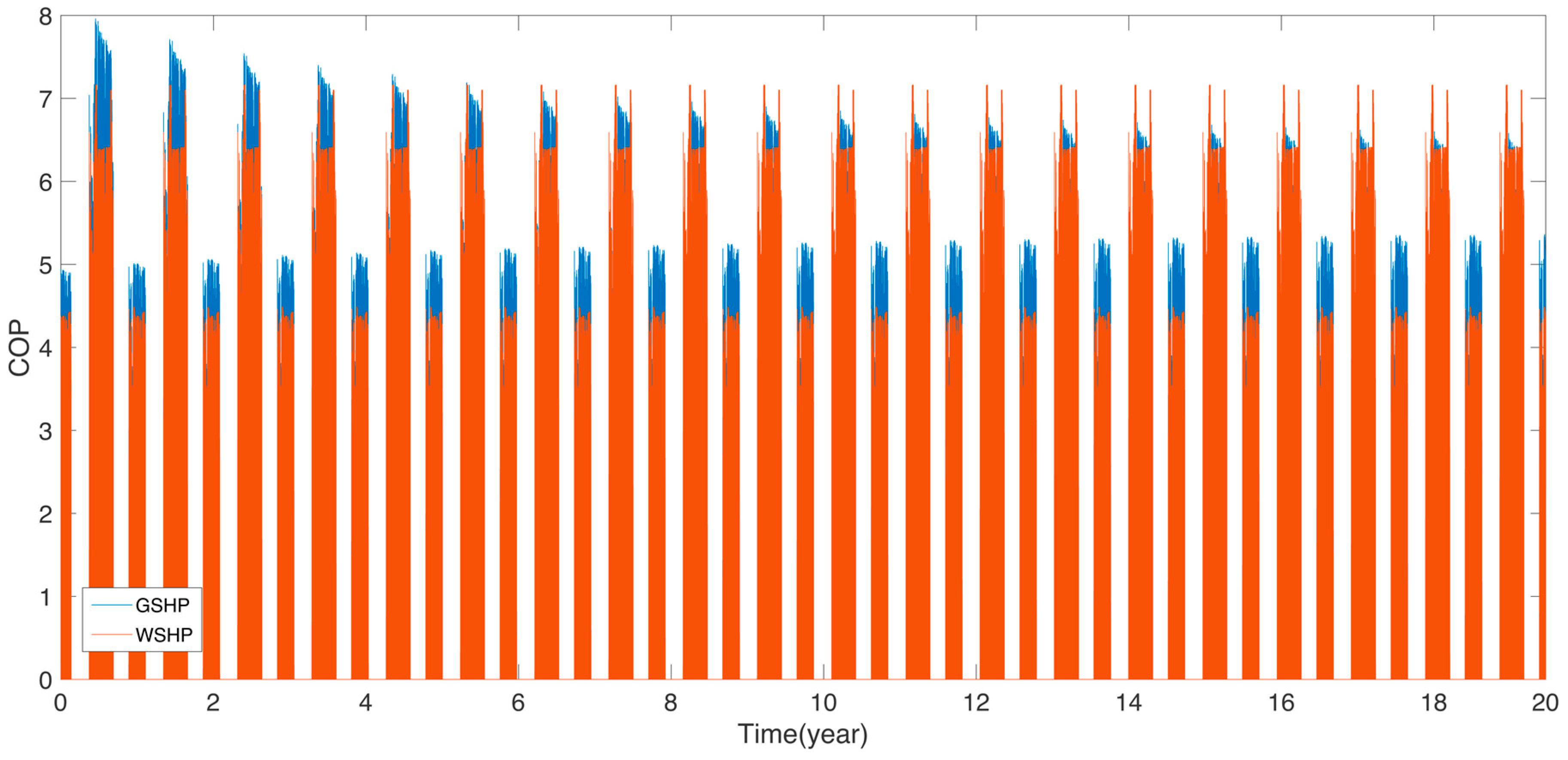

The yearly dynamic heating and cooling load of the office building is calculated and results are shown in

Figure 4 and

Table 3. As can be seen, the yearly accumulated cooling load is 70,673 kwh, and heating load is 24,735 kwh. By calculating the simulation result, it is found that the heating and cooling load imbalance ratio is about 65% in this case.

2.2. TRNSYS Simulation Model of the GSHP System

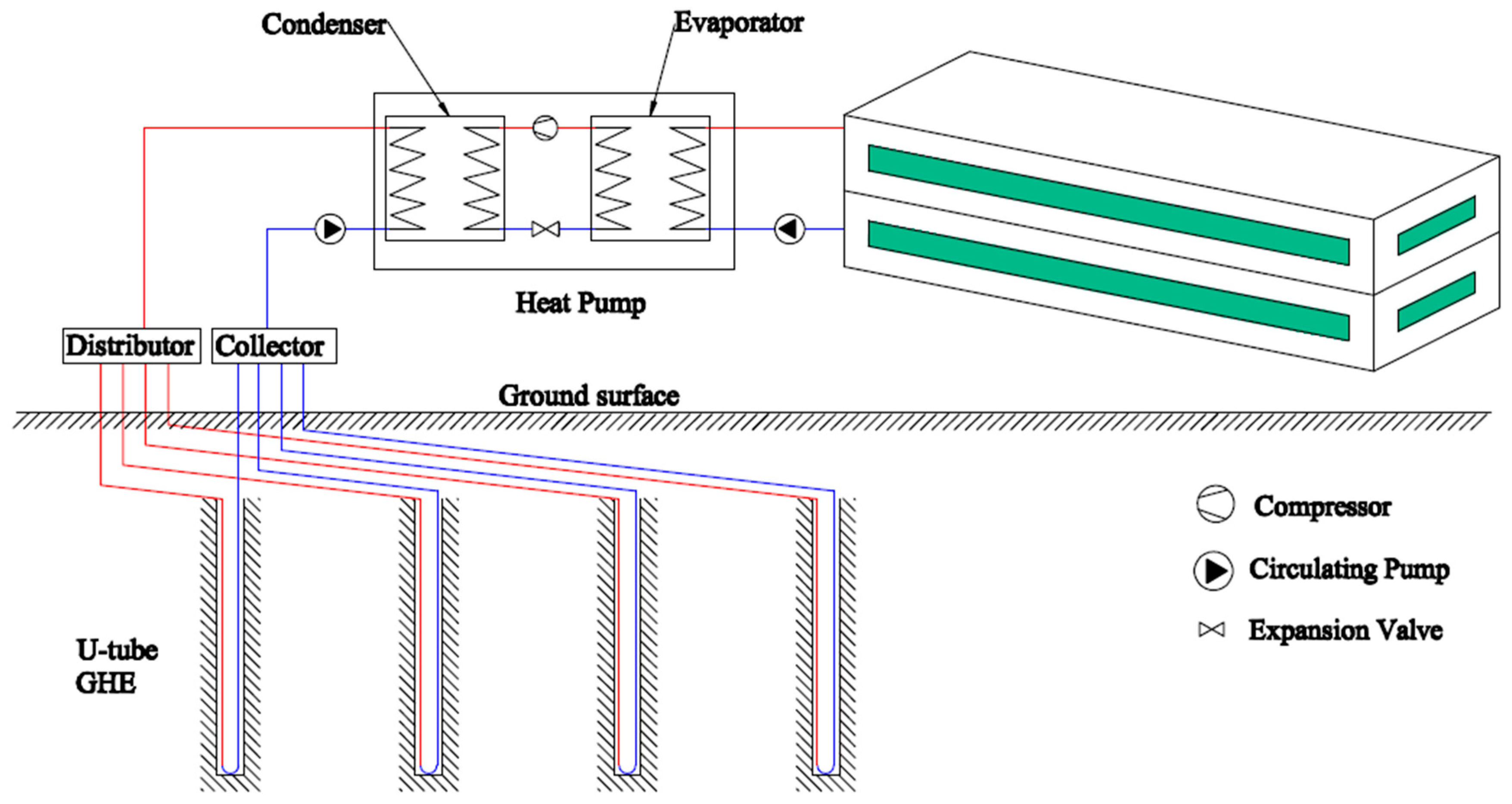

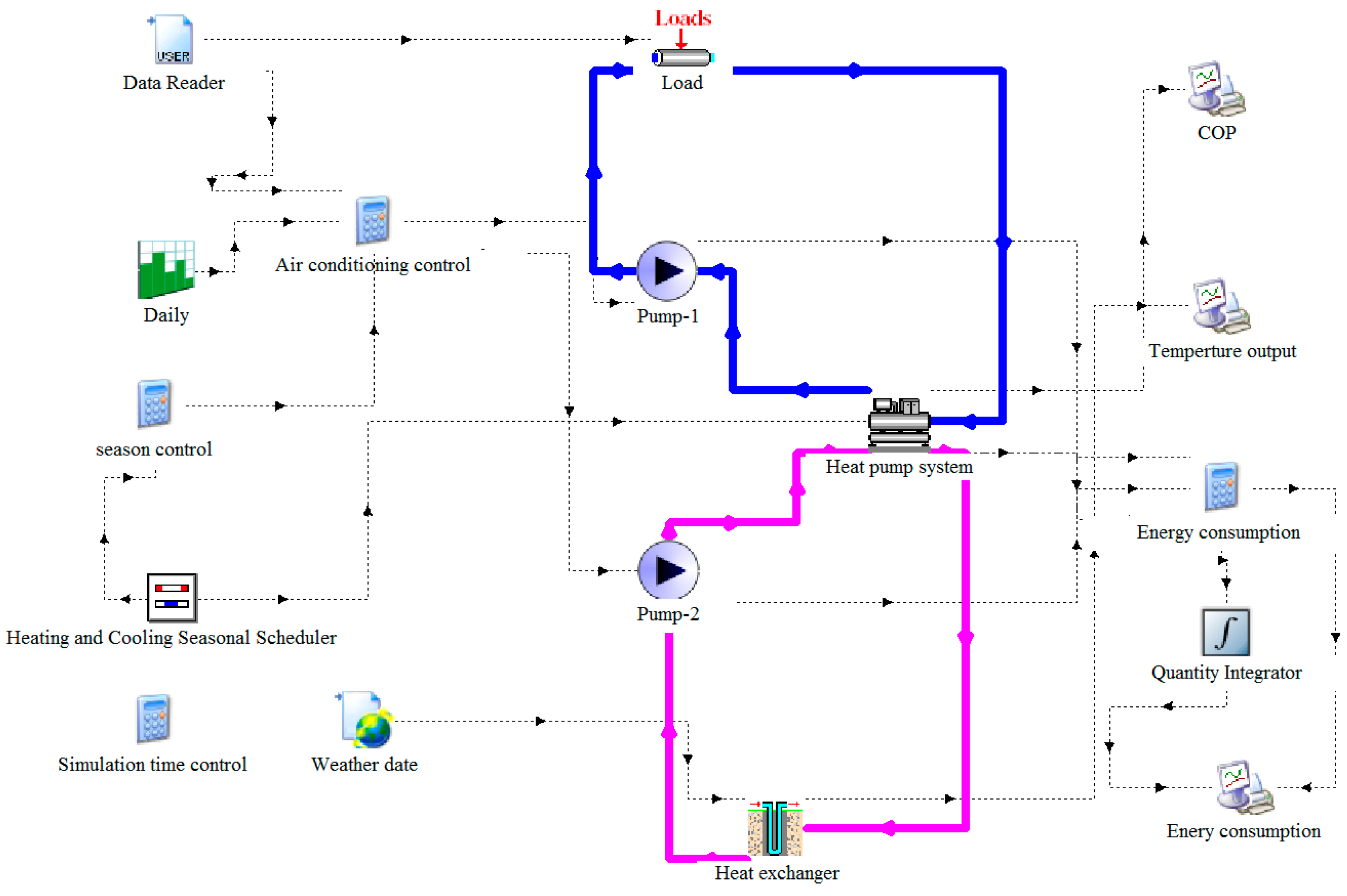

The TRNSYS simulation model of the GSHP system is designed to supply space cooling and heating of the office building. Since the maximum cooling load is more than the maximum heating load, the GSHP system is designed based on the cooling load in order to fulfill the cooling demand. According to the schematic of the GSHP system’s design shown in

Figure 5, the simulation model of the GSHP system is created in TRNSYS as shown in

Figure 6.

The heat pump is selected based on the value of the maximum calculated cooling load. The main parameters of the heat pump are listed in the

Table 4 and the component Type-225 (Heat Pump system) represents the water-water heat pump in the TRNSYS simulation model [

36].

Two single speed pumps component Type114 (Water pump) are designed in both load side and source side to model a constant speed pump capable of maintaining a constant fluid outlet mass flow rate [

35]. The main parameters of the pumps are shown in

Table 5.

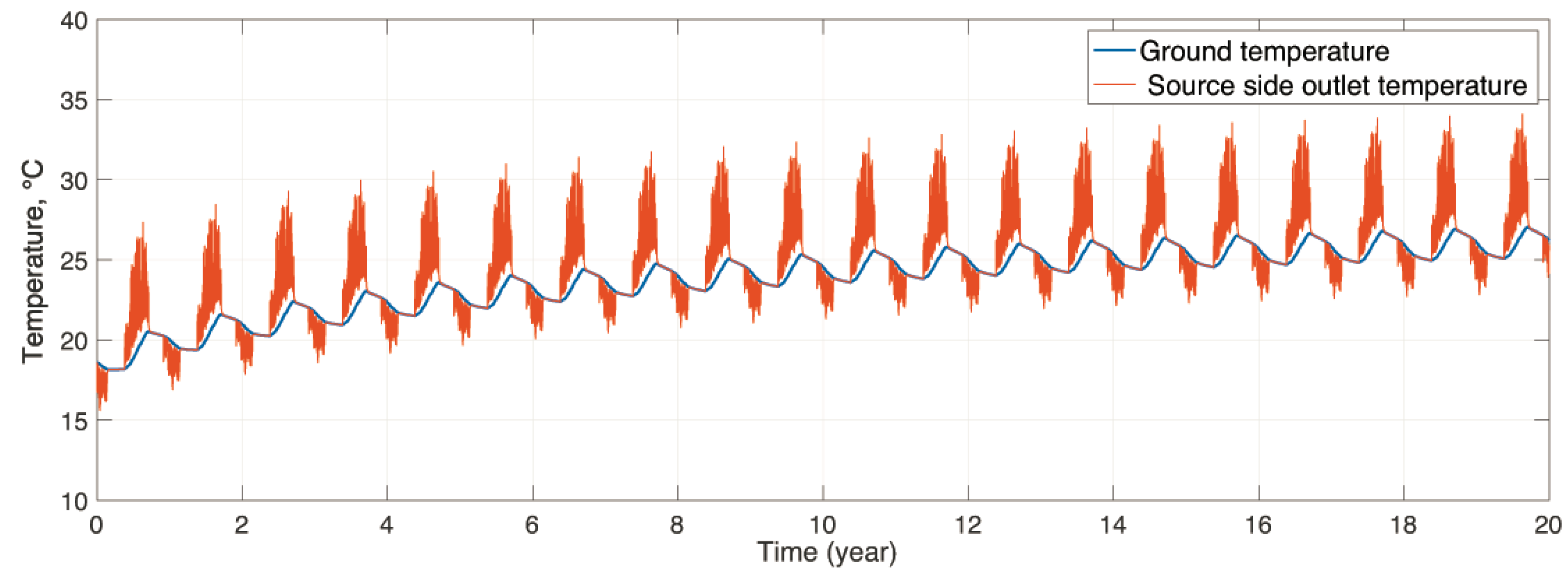

The GSHP system’s heat exchangers are designed to fulfill the need for the cooling load. To represent a heat exchanger, component Type 557 (Heat Exchanger) is used in this model to be thermally connected to the ground [

36]. This component, described as the vertical U-tube, is compiled using a Duct Ground Heat Storage (DST) calculation model developed by Hellstrom, which is able to exchange heat with a heat transfer medium within the ground and give a very accurate analysis calculation [

41]. The ground thermal properties data of the heat exchanger design of this model are obtained from an in-situ thermal response test (TRT) of the ground thermal properties conducted in Suzhou. The TRT of the ground thermal property results can be found in the

Appendix A. The main heat exchanger design parameters are listed in

Table 6.

The in-ground heat exchange is calculated by the equation according to the Chinese national standard “The Technical Code of Ground Source Heat Pump System for Engineering Design, GB50366-2009” [

42], the equation is expressed as follows:

where:

is heat released to the ground, kW

is heat pump cooling capacity, kW

EER is the heat pump’s energy efficiency ratio of cooling

The borehole length is calculated using the following equation [

32]:

The storage volume is calculated in TRNSYS according to the following equation [

36]:

Component Type 682 (Load) represents the building’s heating and cooling load calculated for the system; and component Type 15-2 (Weather Data) serves the purpose of reading Suzhou weather data imported by Meteonorm 7.0 and making it available to other components. Some other necessary components for the calculation, controlling and processing of data are created and connected in the TRNSYS simulation model of the GSHP system shown above.

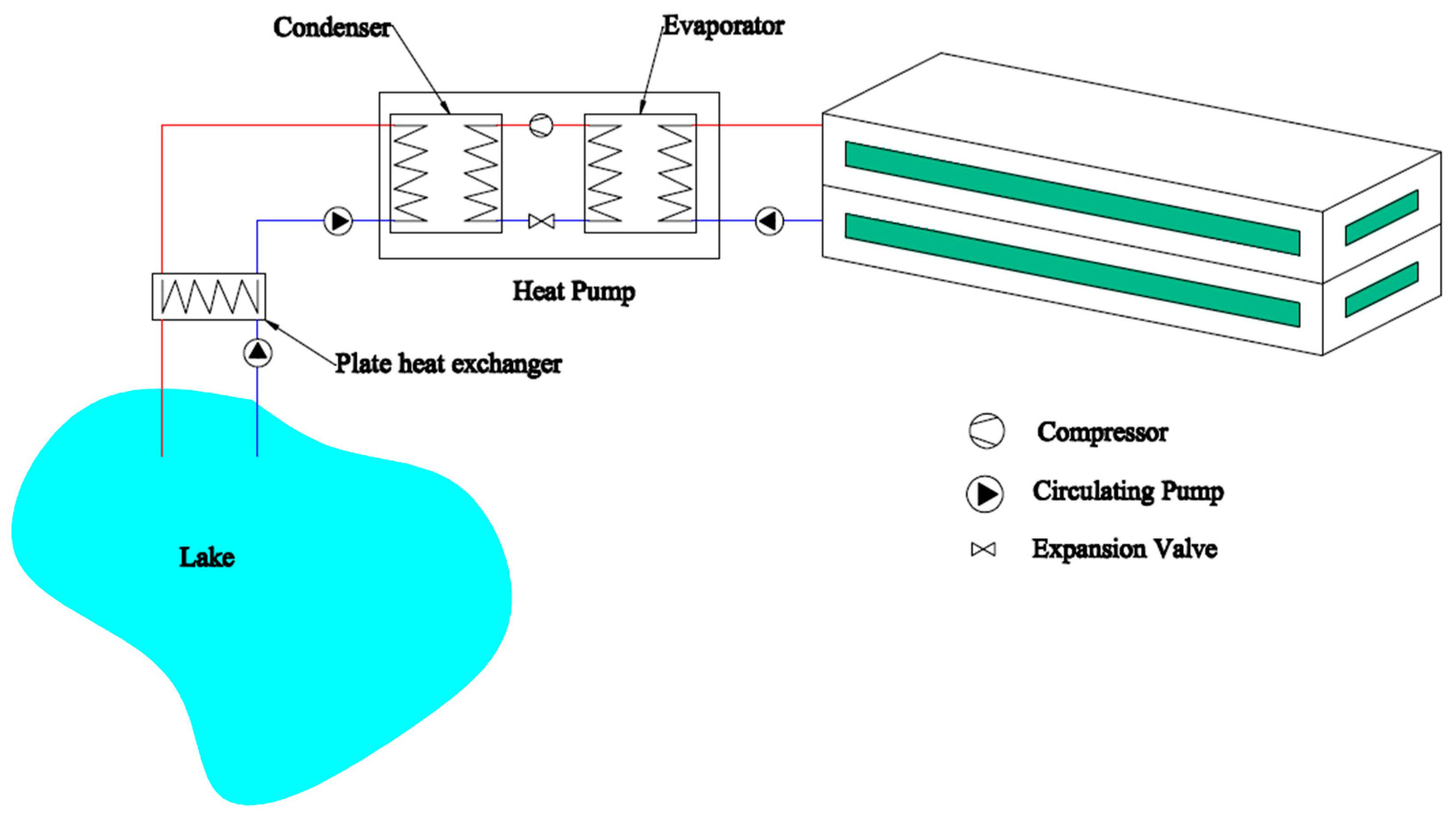

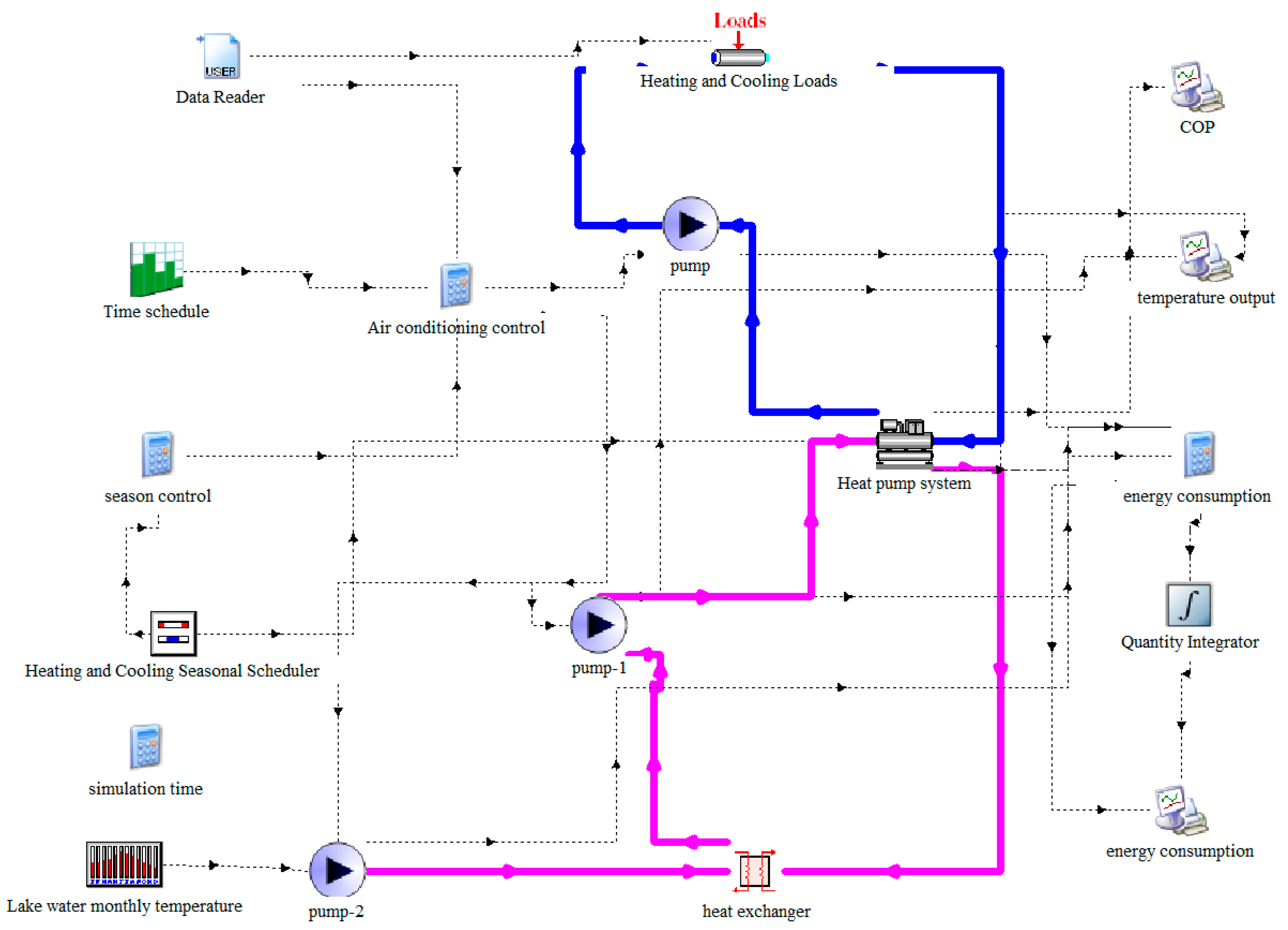

2.3. TRNSYS Simulation Model of the WSHP System

TRNSYS simulation model of the WSHP system is designed to supply space cooling and heating to the office building. The cooling load is more than the heating load, so the WSHP system is designed based on the cooling load in order to fulfill the cooling demand. According to the schematic design of the WSHP system as shown in

Figure 7, the simulation model of the WSHP system is created in TRNSYS, as shown in

Figure 8.

The heat pump is selected based on the value of the maximum cooling load calculated from the building calculation model. Component Type-225 (Heat Pump System) represents the water-water heat pump in the TRNSYS simulation model [

35]. The main parameters of the heat pump unit are listed in

Table 7.

Three single speed pumps component Type114 (water pump) are designed: one on the load side, one on the source side, and one for pumping the water from the lake. The pumps’ main parameters are shown in

Table 8.

The counter flow plate heat exchanger component Type 5 (heat exchanger) is designed in the lake side of the WSHP simulation model in TRNSYS [

36]. The coefficient of heat transfer of the plate heat exchanger is 6500 W/k. The design of the plate heat exchanger based on logarithmic mean temperature difference (LMTD) is expressed as [

43,

44]:

where:

is the log mean temperature °C

is the hot fluid inlet temperature °C

is the hot fluid outlet temperature °C

is the cold fluid inlet temperature °C

is the cold fluid outlet temperature °C

is the heat exchange area m2

is the coefficient of heat transfer of the plate heat exchanger W/m2K

is the heat load of heat exchanger W

is the volume flow rate m3

is water specific heat capacity

is the mass flow rate kg/h

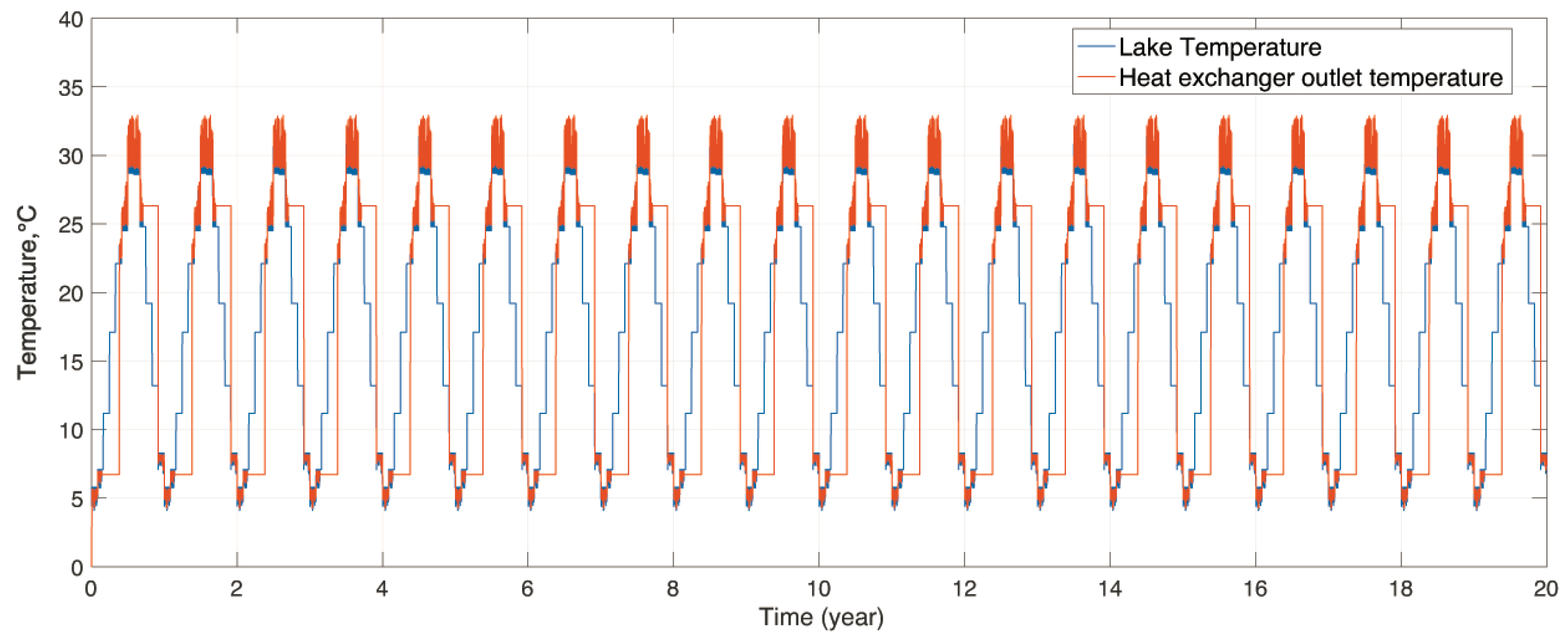

Suzhou’s Tai lake was selected as the water heat source of the WSHP system for the simulation model. The lake is located in the west of Suzhou, the water area is about 2358 km

2, and the average depth is about 1.89 m. The data of the lake’s annual monthly temperature at a depth of 0.5 m is reported by Jiangsu Water Resources [

45]. The water temperature at a depth of 0.55 m, 1.00 m, 1.45 m, and 1.90 m were tested throughout the year [

46]. In the winter and the spring, the water temperature at 0.55 m deep is about 1 °C lower than at 1.45 m deep, while in the summer and autumn the water temperature at 0.55 m is about 0.5 °C lower than at 1.45 m [

46]. The water heat exchangers are therefor designed to be 1.45 m under the water for the WSHP simulation model. The lake’s monthly temperatures at 1.45 m are adjusted accordingly and shown in

Table 9.

The monthly water temperature of the lake is imported to the simulation model by component Type 518 (Water Monthly Temperature). Component Type 682 (Load) represents the building’s heating and cooling load calculated for the system [

36]; other necessary components for calculating, controlling, and processing data are created and connected in the WSHP simulation model.