The Effect of Firewood Moisture Content on the Atmospheric Thermal Load by Flue Gases Emitted by a Boiler

Abstract

1. Introduction

2. Model Evaluation of the Atmospheric Thermal Load by the Heat of Flue Gases

3. Dependence of Producing Flue Gases and Atmospheric Thermal Load by the Heat of Emitted Flue Gases on the Moisture Content of Combusted Firewood

4. Conclusions

- (1)

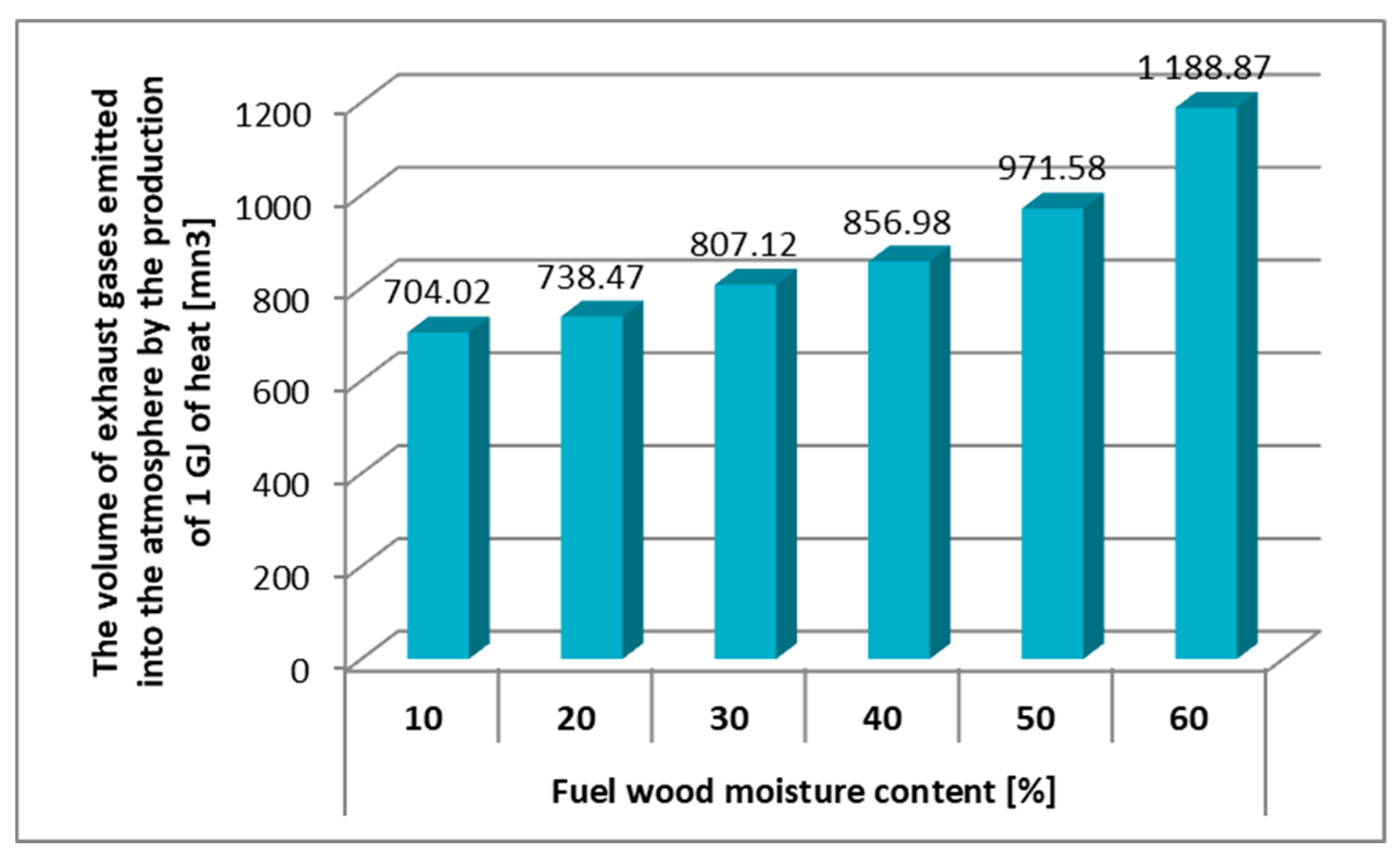

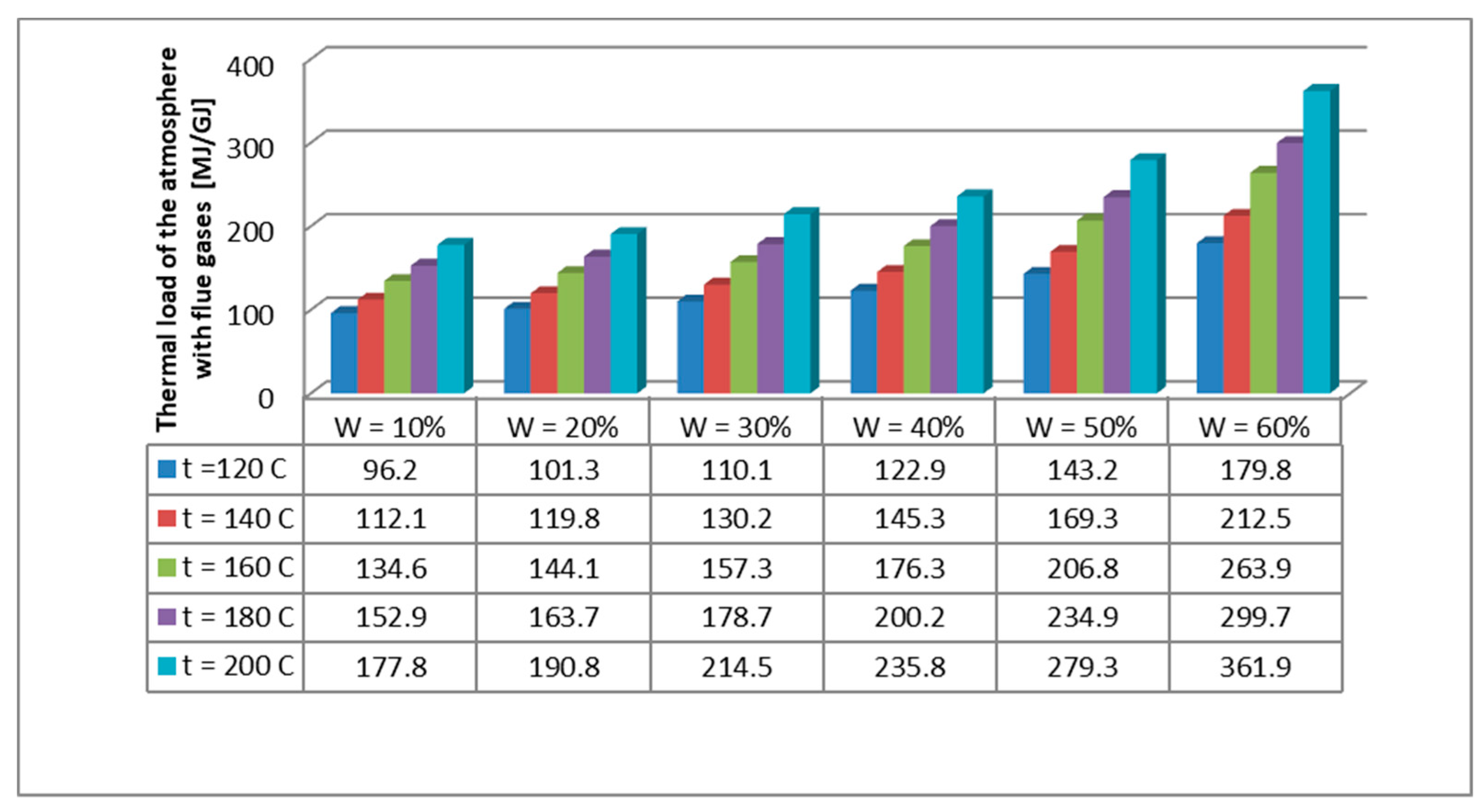

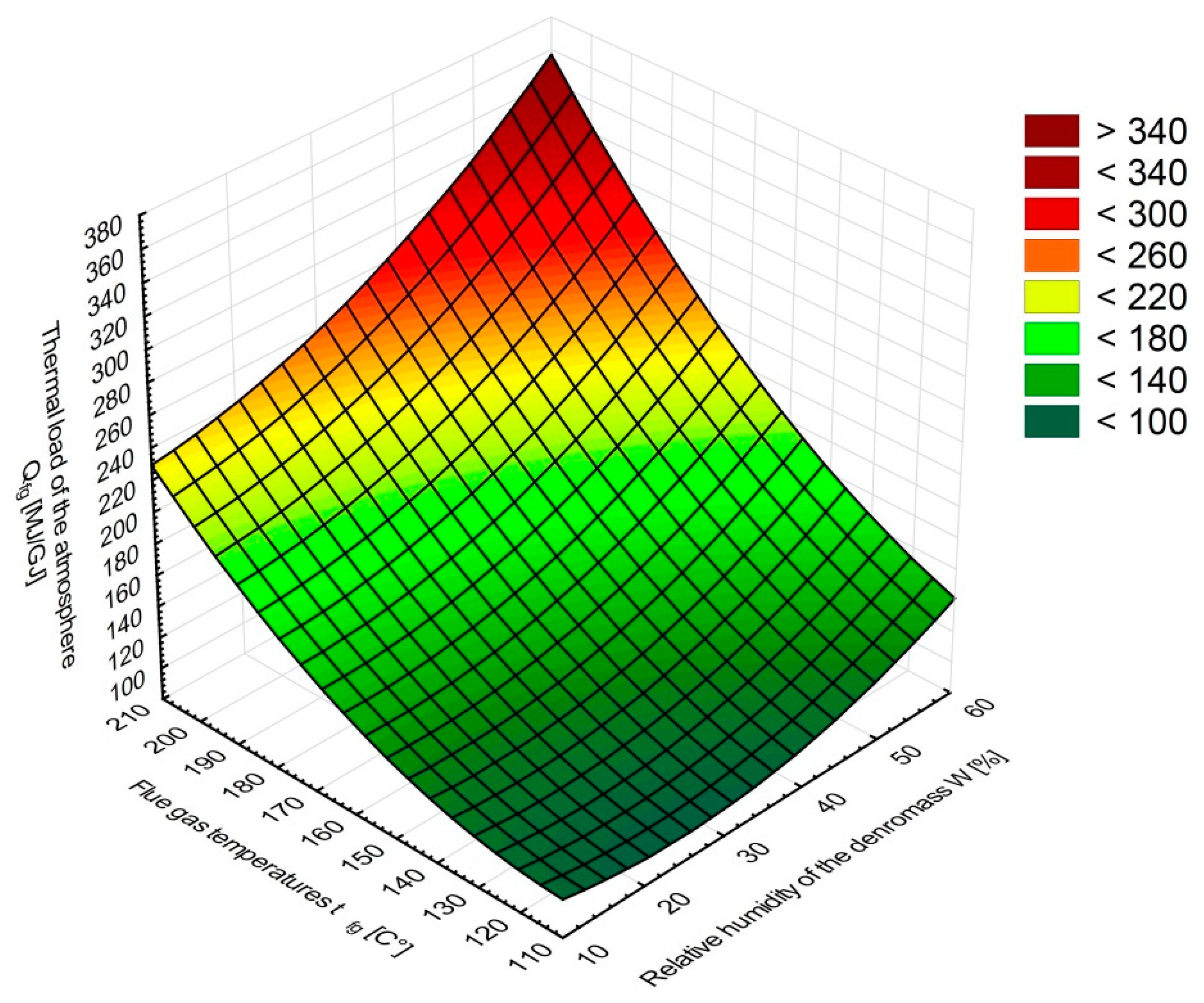

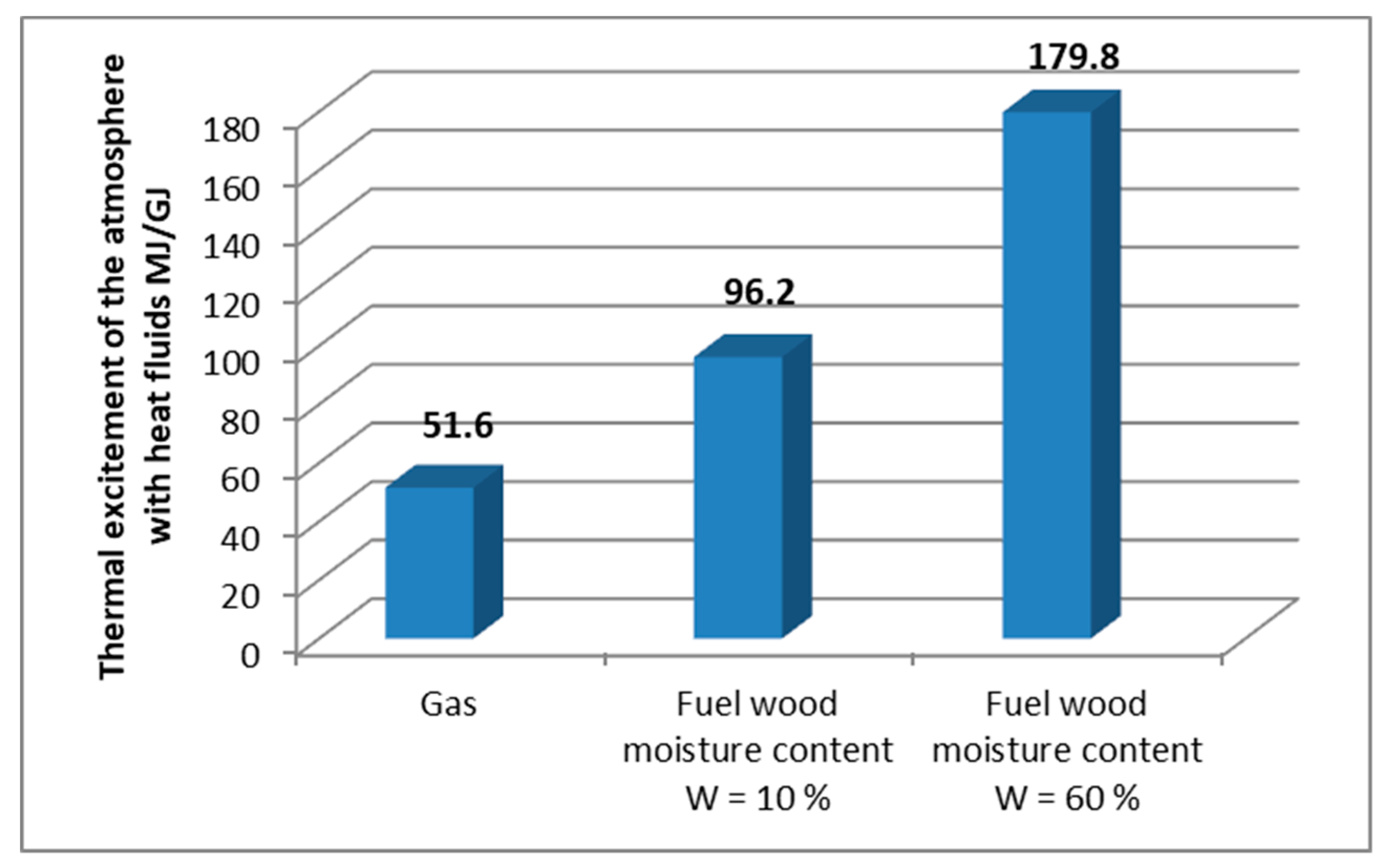

- in the production of 1 GJ of heat from dried wood with a moisture content of W = 10%, a volume of flue gases of Vfg-1GJ = 96.2–177.8 mn3 with a temperature of tfg = 120–200 °C is delivered to the atmosphere. In the combustion process of wet wood with a moisture content of W = 60%, a volume of flue gases of Vfg-1GJ = 179.8–361.9 mn3 is emitted to the atmosphere.

- (2)

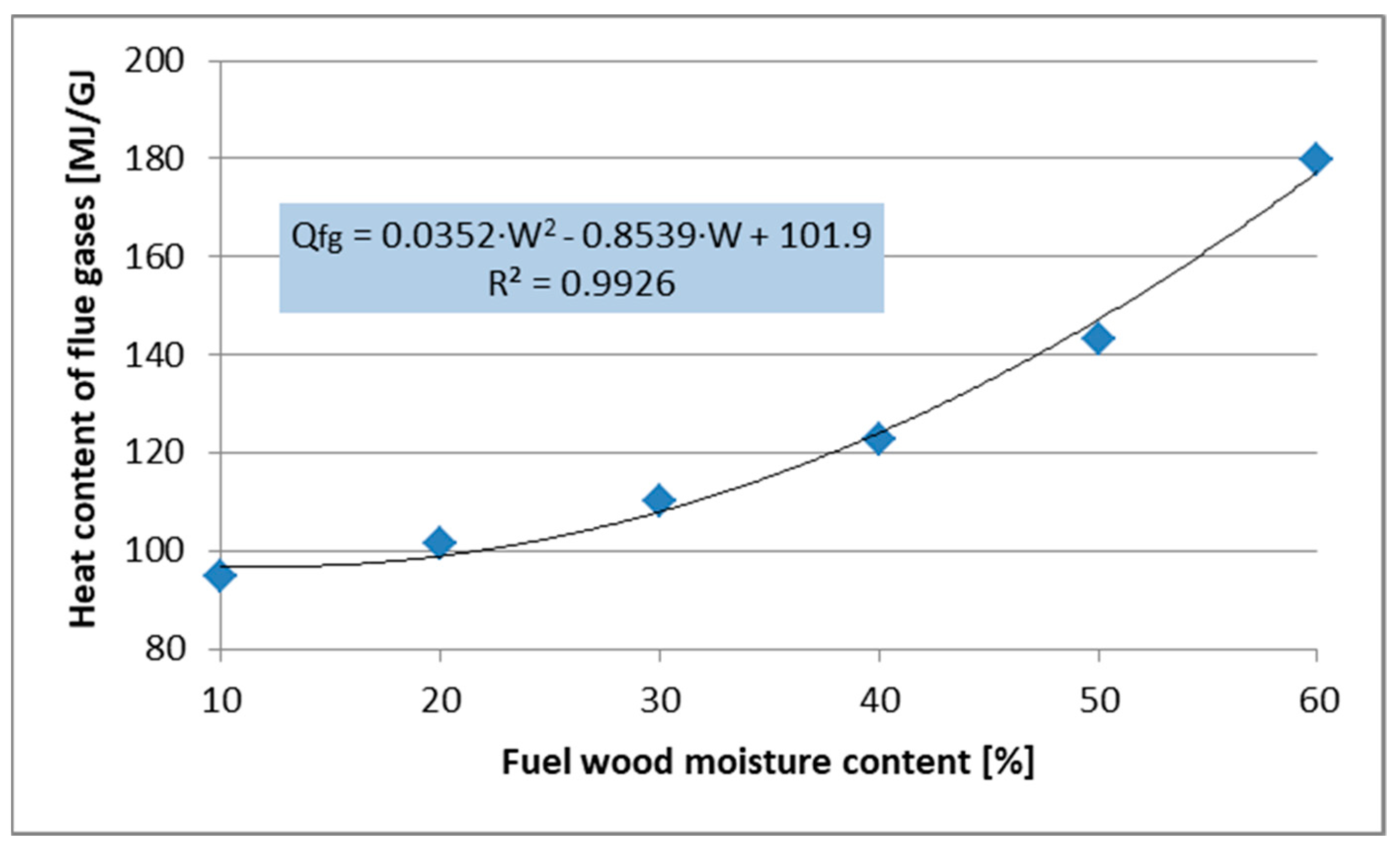

- An increase of 1% in the moisture content of firewood results in an increase in the atmospheric thermal load created by the heat of flue gases with a temperature of tfg = 120 °C of ∆Qfg = 1.7 MJ, on average. When the temperature of the flue gases is tfg = 200 °C, it increases by ∆Qfg = 3.68 MJ.

- (3)

- Comparing the values of the atmospheric thermal load created by the flue gases resulting from the combustion process of firewood to the thermal load caused by the combustion process of natural gas, we can state that the atmospheric thermal load caused by the combustion of firewood ranges from 1.8–7 times higher.

- (4)

- The heat of the water vapor from the evaporated water of the combusted wood, as well as the heat of the heated nitrogen and unoxidized oxygen in the combustion air delivered to the furnace of a boiler to dry firewood, are the reasons for the increasing volume of the flue gases. This, therefore, causes the increasing atmospheric thermal load created by the heat of the flue gases, resulting from the combustion of wood with higher moisture content.

- (5)

- Because of the effect of the moisture content of the firewood on the atmospheric thermal load created by emitted the flue gases from firewood, as well as the fact that, because of the moisture content, the energy efficiency of the boiler and the efficiency of the heat production decreases and the emission production increases. This justifies the use of economically-efficient forms of pre-drying and seasoning of firewood, such as the technology of transpiration used to dry branches and tree tops before the production of wood chips, or the natural pre-drying of stored firewood logs in a sheltered position.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| A | ash content in dried firewood, % |

| cfg | specific heat capacity 1 mn−3 of flue gases when the pressure is constant, kJ·mn−3K−1 |

| cpCO2 | specific heat capacity of carbon dioxide, kJ/m3·K |

| cpH2O | specific heat capacity of water vapor, kJ/m3·K |

| cpO2 | specific heat capacity of oxygen, kJ/m3·K |

| cpN 2 | specific heat capacity of nitrogen, kJ/m3·K |

| Cdaf | amount of carbon in flammable substance of firewood, % |

| Hdaf | amount of hydrogen in flammable substance of firewood, % |

| Ndaf | amount of nitrogen in flammable substance of firewood, % |

| Odaf | amount of oxygen in flammable substance of firewood, % |

| m | quantity of wood to produce 1 GJ of heat, kg |

| tair | temperature of combustion air, °C |

| tfg | temperature of flue gases, °C |

| tfg-e | temperature of flue gases cooled to the temperature of combustion air, °C |

| Vair | stechiometric combustion air volume, m3/kg |

| Vfg | specific volume of humid flue gases produced in the combustion of 1kg of firewood, m3/kg |

| Vfg-1MJ | flue gases produced in the firewood combustion to produce the heat of 1GJ, mn3 |

| W | moisture content of firewood, % |

| Qn | heating value, kJ/kg, or MJ/m3 |

| XCO2 | volumetric proportion of carbon dioxide in flue gases, m3/m3 |

| XCO | mass concentration of carbon monoxide (CO) in dry flue gases, kg/m3 |

| XH2O | volumetric proportion of water vapor in flue gases, m3/m3 |

| XO2 | volumetric proportion of oxygen in flue gases, m3/m3 |

| XN2 | volumetric proportion of nitrogen in flue gases, m3/m3 |

| Greek symbols | |

| λ | coefficient of the excess of combustion air, m3/m3 |

| ƞK | energy efficiency of a boiler, % |

References

- Jandačka, J.; Malcho, M.; Mikulík, M. Biomasa Ako Zdroj Energie; GEORG: Žilina, Slovakia, 2007; 241p. [Google Scholar]

- Dzurenda, L.; Geffertová, J.; Hecl, V. Energy characteristics of wood-chips produced from Salix viminalis-clone ULV. Drvna Ind. 2010, 61, 27–31. [Google Scholar]

- Hytönen, J.; Nurmi, J. Heating value and ash content of intensively managed stands. Wood Res. 2015, 60, 71–82. [Google Scholar]

- Nosek, R.; Holubcik, M.; Jandacka, J. The impact of bark content of wood biomass on biofuel properties. BioResorces 2016, 11, 44–53. [Google Scholar] [CrossRef]

- Dzurenda, L.; Pňakovič, L. The influence of combustion temperature of non-flammable woody woods on deciduous trees on ash production and its properties. Acta Fac. Xylologiae Zvolen 2016, 58, 95–104. [Google Scholar] [CrossRef]

- Simanov, V. Energetické Využívání Dříví; Terapolis: Olomouc, Czech Republic, 1995; 98p. [Google Scholar]

- Sergovskij, P.S.; Rasev, A.I. Gidrotermičeskaja Obrabotka i Konservirovanije Drevesiny; Lesnaja Promyšlennost: Moskva, Russia, 1987; 350p. [Google Scholar]

- Dzurenda, L.; Banski, A. Výroba Tepla a Energie z Dendromasy; TU vo Zvolene: Zvolen, Slovakia, 2016; 273p. [Google Scholar]

- Nosek, R.; Holubčík, M. Energy properties of air dry firewood. Acta Fac. Xylologiae Zvolen 2016, 58, 105–112. [Google Scholar] [CrossRef]

- Samuelsson, R.; Thyrel, M.; Sjostrom, M.; Lestander, T.A. Effect of biomaterial characteristics on pelletizing properties and biofuel pellet quality. Fuel Process. Technol. 2009, 90, 1129–1134. [Google Scholar] [CrossRef]

- Holubčik, M.; Nosek, R.; Jandačka, J. Effect of Time and Method of Storage on the Properties of Wood Pellets with Addition of Lignin. Wood Res. 2014, 59, 851–860. [Google Scholar]

- Marutzky, R.; Seeger, K. Energie aus Holz und Anderer Biomasse; DRD–Verlag Weinbrenner GmbH &Co.: Leinfelden-Echterdingen, Germany, 1999; 430p. [Google Scholar]

- Domanski, M.; Dzurenda, L.; Jablonski, M.; Osipiuk, J. Drewno Jako Material Energetyczny; SGGW: Warszawa, Poland, 2007; 131p. [Google Scholar]

- Rajniak, I.; Zavodnov, L.; Kučák, L. Tepelno-energetické a Emisné Merania; Ister Science: Bratislava, Slovakia, 1997; 481p. [Google Scholar]

- Holoubek, D. Spaľovacie Zariadenia, Výmenníky Tepla a Kotly; ARS LITERA: Košice, Slovakia, 2002. [Google Scholar]

- Dzurenda, L.; Banski, A. Influence of moisture content of combusted wood on the thermal efficiency of a boiler. Arch. Thermodyn. 2017, 38, 63–74. [Google Scholar] [CrossRef]

- Dzurenda, L.; Banski, A. Dependence of the boiler flue gas losses on humidity of woody biomass. Arch. Thermodyn. 2015, 36, 77–86. [Google Scholar] [CrossRef]

- Sippula, O.; Hytönen, K.; Tissari, J.; Raunemaa, T.; Jokiniemi, J. Effect of Wood Fuel on the Emissions from a Top-Feed Pellet Stove. Energy Fuels 2007, 21, 1151–1160. [Google Scholar] [CrossRef]

- Neužil, V.; Heppner, P.; Picková, H. Emisní zátež při použití různych druhů paliv. Energetika 1997, 2, 359–363. [Google Scholar]

- Chabadová, J.; Papučík, Š.; Nosek, R. Particle emissions from biomass combustion. AIP Conf. Proc. 2014, 67. [Google Scholar] [CrossRef]

- Dzurenda, L. Model of heat load on the atmosphere by flue gases. Manuf. Technol. 2015, 15, 804–808. [Google Scholar]

- Holubčík, M.; Jandačka, J. The Effect of Moisture Content of Firewood on the Energy Efficiency of Fireplace Insert and Emission Production in The Combustion Process. Acta Fac. Xylologiae Zvolen 2018, 60, 187–195. [Google Scholar] [CrossRef]

- Hroncová, E.; Ladomerský, J.; Valíček, J.; Dzurenda, L. Combustion of Biomass Fuel and Residues. Emiss. Prod. Perspect. 2016. [Google Scholar] [CrossRef]

- Horak, J.; Kubonova, L.; Krpec, K.; Hopan, F.; Kubesa, P.; Motyka, O.; Laciok, V.; Dej, M.; Ochodek, T.; Placha, D. PAH emissions from old and new types of domestic hot water boilers. Environ. Pollut. 2017, 225, 31–39. [Google Scholar] [CrossRef] [PubMed]

- Dzurenda, L.; Hroncová, E.; Ladomerský, J. Extensive Operating Experiments on the Conversion of Fuel-Bound Nitrogen into Nitrogen Oxides in the Combustion of Wood Fuel. Forests 2017, 8, 1. [Google Scholar] [CrossRef]

- Jandačka, J.; Mičieta, J.; Holubčik, M.; Nosek, R. Experimental Determination of Bed Temperatures during Wood Pellet Combustion. Energy Fuels 2017, 31, 2919–2926. [Google Scholar] [CrossRef]

- Dzurenda, L. 3D Diagram of Heat Boiler Efficiency for Combustion of Fuelwood. Acta Fac. Xylologiae Zvolen 2017, 59, 149–156. [Google Scholar] [CrossRef]

| Temperature [°C] | cp-i–Mean Specific Heat Capacity of 1 mn3 of Flue Gases When the Pressure is Constant [kJ·mn−3·K−1] | |||

|---|---|---|---|---|

| CO2 | O2 | N2 | H2O | |

| 0 | 1.620 | 1.306 | 1.302 | 1.491 |

| 100 | 1.725 | 1.319 | 1.306 | 1.499 |

| 200 | 1.817 | 1.336 | 1.310 | 1.520 |

| 300 | 1.892 | 1.357 | 1.315 | 1.537 |

| 400 | 1.955 | 1.382 | 1.327 | 1.557 |

| 500 | 2.022 | 1.403 | 1.336 | 1.583 |

| 600 | 2.077 | 1.419 | 1.348 | 1.608 |

| Fuel | Moisture Content | Heating Value | Specific Volume of Flue Gases from 1 kg of Wood | Thermal Efficiency of a Boiler | Consumption of Firewood to Produce 1 GJ of Heat | Production of Emitted Flue Gases when 1 GJ of Heat is Produced | Atmospheric Thermal Load by Flue Gases |

|---|---|---|---|---|---|---|---|

| Wr | Qn | Vfg | ηk | mp-1GJ | Vfg-1GJ | Qfg | |

| [%] | [kJ·kg−1] | [mn3] | [-] | [kg] | [mn3] | [MJ·GJ−1] | |

| Fuel wood | 10 | 16,159 | 9.34 | 0.883 | 73.38 | 704.02 | 96.2 |

| 20 | 14,075 | 8.44 | 0.878 | 87.49 | 738.47 | 101.3 | |

| 30 | 11,992 | 7.54 | 0.871 | 107.05 | 807.12 | 110.1 | |

| 40 | 9908 | 6.64 | 0.861 | 129.06 | 856.98 | 122.9 | |

| 50 | 7825 | 5.74 | 0.845 | 169.27 | 971.58 | 143.2 | |

| 60 | 5742 | 4.8 | 0.819 | 245.03 | 1188.87 | 179.8 |

| Fuel | Heating Value | Production of Emitted Flue Gases When 1 GJ of Heat is Produced | Thermal Efficiency of a Boiler | Atmospheric Thermal Load |

|---|---|---|---|---|

| [MJ·m−3] | [mn3] | [-] | [MJ·GJ−1] | |

| Natural gas | 33.9 | 297 | 0.95 | 51.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dzurenda, L.; Banski, A. The Effect of Firewood Moisture Content on the Atmospheric Thermal Load by Flue Gases Emitted by a Boiler. Sustainability 2019, 11, 284. https://doi.org/10.3390/su11010284

Dzurenda L, Banski A. The Effect of Firewood Moisture Content on the Atmospheric Thermal Load by Flue Gases Emitted by a Boiler. Sustainability. 2019; 11(1):284. https://doi.org/10.3390/su11010284

Chicago/Turabian StyleDzurenda, Ladislav, and Adrian Banski. 2019. "The Effect of Firewood Moisture Content on the Atmospheric Thermal Load by Flue Gases Emitted by a Boiler" Sustainability 11, no. 1: 284. https://doi.org/10.3390/su11010284

APA StyleDzurenda, L., & Banski, A. (2019). The Effect of Firewood Moisture Content on the Atmospheric Thermal Load by Flue Gases Emitted by a Boiler. Sustainability, 11(1), 284. https://doi.org/10.3390/su11010284