Data Analysis of Shipment for Textiles and Apparel from Logistics Warehouse to Store Considering Disposal Risk

Abstract

:1. Introduction

2. Literature Review

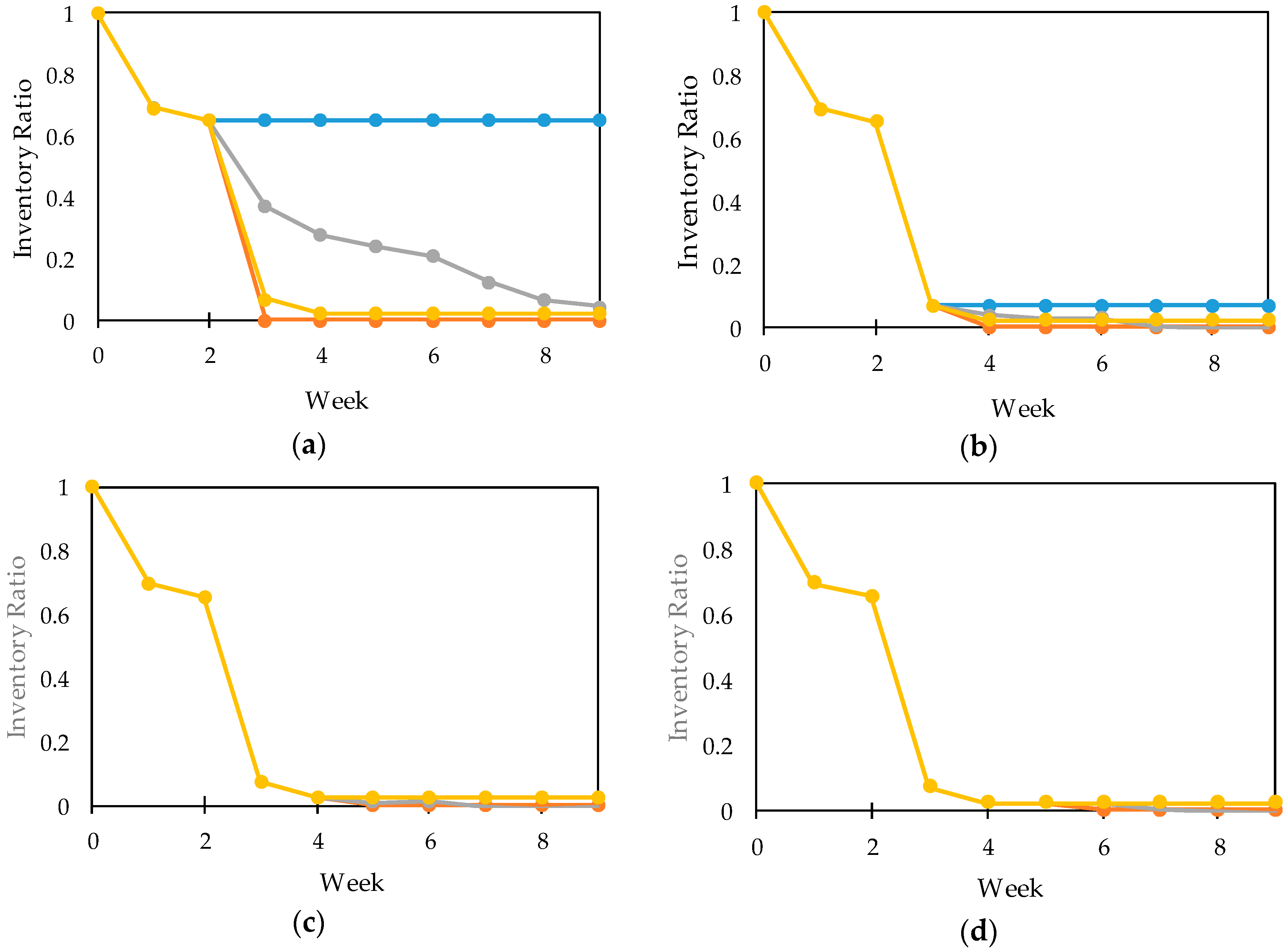

3. Status of Products

4. Methods

4.1. Assumptions, Parameters, and Variables

- Products are sold in the same period

- The total arrival quantity of each product is known

- Product movement among stores is not considered

- The period in which products are sold at the fixed price is nine weeks

- Since products are sold up for nine weeks, the sales period is nine weeks

- If the product did not sell for nine weeks, the product is discarded

- N: number of products

- T: sales period [weeks]

- t: elapsed periods [weeks] (t = 1, …, T)

- i: product number (i = 1, …, N)

- di (t): shipping amount of product i in week t

- Di: total delivery amount of product i

- ui (t): shipping rate in week t of product i

- K: number of clusters

- T’: investigated sales period

- : inventory ratio of product i in week t

- : random variable representing the realized inventory ratio of product i

- : random variable representing the predicted inventory ratio of product i

- : conditional expectation

- : average of

- : average of

- ρ: correlation coefficient

- : variance of

- : variance of

- : variance in conditional probability

4.2. Decision-Making Process for Shipping Personnel

- Step 1.

- Product i arrives at the logistics warehouse from a plant, and its quantity is Di.

- Step 2.

- Shipping personnel practice first shipment of product i based on a sales policy which is given by manufactures and its quantity is di (1).

- Step 3.

- Shipping personnel recognize sales information of product i for one week.

- Step 4.

- Shipping personnel consider and decide whether to ship additional product during the next week. At this time, they refer not only to sales quantity of product i but also to sales information of similar products sold last year and current trends.

- Step 5.

- Based on shipping personnel decision, product i is shipped whose quantity is di (t) at t-th week. In the determination of the quantity, the inventory of the store and the scale of the store are taken into consideration. Then, if personnel decide not to make an additional shipment, shipping quantity of the product di (t) is zero.

- Step 6.

- If the next week, t + 1, is end of sales period T, go to Step 7. Otherwise, shipping personnel return to Step 3 and repeat from Step 3 to Step 5 until they fulfill Step 6.

- Step 7.

- Shipping personnel finish their decision.

4.3. Product Data Extraction

4.4. Forecasting Inventory Ratios

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Baumgartner, R.J.; Ebner, D. Corporate sustainability strategies: Sustainability profiles and maturity levels. Sustain. Dev. 2010, 18, 76–89. [Google Scholar] [CrossRef]

- Norman, W.; MacDonald, C. Getting to the bottom of “triple bottom line”. Bus. Ethics Q. 2004, 14, 243–262. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. Measuring social issues in sustainable supply chains. Meas. Bus. Excell. 2015, 19, 33–45. [Google Scholar] [CrossRef]

- Markley, M.J.; Davis, L. Exploring future competitive advantage through sustainable supply chains. Int. J. Phys. Distrib. Logist. Manag. 2007, 37, 763–774. [Google Scholar] [CrossRef]

- Bruce, M.; Daly, L.; Towers, N. Lean or agile: A solution for supply chain management in the textiles and clothing industry? Int. J. Oper. Prod. Manag. 2004, 24, 151–170. [Google Scholar] [CrossRef]

- Iyer, A.V.; Bergen, M.E. Quick response in manufacturer-retailer channels. Manag. Sci. 1997, 43, 559–570. [Google Scholar] [CrossRef]

- Tanaka, R.; Ishigaki, A.; Suzuki, T.; Hamada, M.; Kawai, W. Shipping plan for apparel products using shipping record and just-in-time inventory at a logistics warehouse. In Proceedings of the 7th International Congress on Advanced Applied Informatics, Yonago, Tottori, Japan, 8–13 July 2018. [Google Scholar]

- Kim, H.S. A bayesian analysis on the effect of multiple supply options in a quick response environment. Nav. Res. Logist. (NRL) 2003, 50, 937–952. [Google Scholar] [CrossRef]

- Liu, N.; Ren, S.; Choi, T.M.; Hui, C.L.; Ng, S.F. Sales forecasting for fashion retailing service industry: A review. Math. Probl. Eng. 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Mostard, J.; Teunter, R.; De Koster, R. Forecasting demand for single-period products: A case study in the apparel industry. Eur. J. Oper. Res. 2011, 211, 139–147. [Google Scholar] [CrossRef]

- Gurnani, H.; Tang, C.S. Note: Optimal ordering decisions with uncertain cost and demand forecast updating. Manag. Sci. 1999, 45, 1456–1462. [Google Scholar] [CrossRef]

- Moore, S.B.; Ausley, L.W. Systems thinking and green chemistry in the textile industry: Concepts, technologies and benefits. J. Clean. Prod. 2004, 12, 585–601. [Google Scholar] [CrossRef]

- Larney, M.; Van Aardt, A.M. Case study: Apparel industry waste management: A focus on recycling in South Africa. Waste Manag. Res. 2010, 28, 36–43. [Google Scholar] [CrossRef] [PubMed]

- Briga-Sa, A.; Nascimento, D.; Teixeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile waste as an alternative thermal insulation building material solution. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar] [CrossRef]

- Tseng, M.L.; Tan, R.R.; Siriban-Manalang, A.B. Sustainable consumption and production for Asia: Sustainability through green design and practice. J. Clean. Prod. 2013, 40, 1–5. [Google Scholar] [CrossRef]

- Kuo, T.C.; Hsu, C.W.; Huang, S.H.; Gong, D.C. Data sharing: A collaborative model for a green textile/clothing supply chain. Int. J. Comput. Integr. Manuf. 2014, 27, 266–280. [Google Scholar] [CrossRef]

- Wang, F.; Zhuo, X.; Niu, B. Sustainability analysis and buy-back coordination in a fashion supply chain with price competition and demand uncertainty. Sustainability 2016, 9, 25. [Google Scholar] [CrossRef]

- Caniato, F.; Caridi, M.; Crippa, L.; Moretto, A. Environmental sustainability in fashion supply chains: An exploratory case based research. Int. J. Prod. Econ. 2012, 135, 659–670. [Google Scholar] [CrossRef]

- Choi, T.M.; Chiu, C.H. Mean-downside-risk and mean-variance newsvendor models: Implications for sustainable fashion retailing. Int. J. Prod. Econ. 2012, 135, 552–560. [Google Scholar] [CrossRef]

- Brun, A.; Castelli, C. Supply chain strategy in the fashion industry: Developing a portfolio model depending on product, retail channel and brand. Int. J. Prod. Econ. 2008, 116, 169–181. [Google Scholar] [CrossRef]

- Čiarnienė, R.; Vienažindienė, M. Management of contemporary fashion industry: Characteristics and challenges. Procedia-Soc. Behav. Sci. 2014, 156, 63–68. [Google Scholar] [CrossRef]

- Mehrjoo, M.; Pasek, Z.J. Risk assessment for the supply chain of fast fashion apparel industry: A system dynamics framework. Int. J. Prod. Res. 2016, 54, 28–48. [Google Scholar] [CrossRef]

- Patil, R.; Avittathur, B.; Shah, J. Supply chain strategies based on recourse model for very short life cycle products. Int. J. Prod. Econ. 2010, 128, 3–10. [Google Scholar] [CrossRef]

- Choi, T.M.; Sethi, S. Innovative quick response programs: A review. Int. J. Prod. Econ. 2010, 127, 1–12. [Google Scholar] [CrossRef]

- Fisher, M.; Raman, A. Reducing the cost of demand uncertainty through accurate response to early sales. Oper. Res. 1996, 44, 87–99. [Google Scholar] [CrossRef]

- Choi, T.M. Quick response in fashion supply chains with retailers having boundedly rational managers. Int. Trans. Oper. Res. 2017, 24, 891–905. [Google Scholar] [CrossRef]

- Choi, T.M.; Zhang, J.; Cheng, T.E. Quick response in supply chains with stochastically risk sensitive retailers. Decis. Sci. 2018, 49, 932–957. [Google Scholar] [CrossRef]

- Tsukagoshi, Y.; Ishigaki, A.; Sandoh, H. Effective Quick Response in a Supply Chain. In Proceedings of the 17th Asia Pacific Industrial Engineering and Management Systems, Taipei, Taiwan, 7–10 December 2016. [Google Scholar]

- Sun, Z.L.; Choi, T.M.; Au, K.F.; Yu, Y. Sales forecasting using extreme learning machine with applications in fashion retailing. Decis. Support Syst. 2008, 46, 411–419. [Google Scholar] [CrossRef]

- Thomassey, S. Sales forecasts in clothing industry: The key success factor of the supply chain management. Int. J. Prod. Econ. 2010, 128, 470–483. [Google Scholar] [CrossRef]

- Fan, Z.P.; Che, Y.J.; Chen, Z.Y. Product sales forecasting using online reviews and historical sales data: A method combining the Bass model and sentiment analysis. J. Bus. Res. 2017, 74, 90–100. [Google Scholar] [CrossRef]

- Frank, C.; Garg, A.; Sztandera, L.; Raheja, A. Forecasting women’s apparel sales using mathematical modeling. Int. J. Cloth. Sci. Technol. 2003, 15, 107–125. [Google Scholar] [CrossRef]

| Change in Inventory in Each Week | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Product | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| A | 2884 | 291 | 266 | 240 | 198 | 154 | 123 | 80 | 44 | 36 |

| B | 2078 | 1151 | 1038 | 347 | 221 | 171 | 122 | 0 | 0 | 0 |

| C | 293 | 249 | 248 | 220 | 220 | 220 | 191 | 116 | 94 | 32 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tanaka, R.; Ishigaki, A.; Suzuki, T.; Hamada, M.; Kawai, W. Data Analysis of Shipment for Textiles and Apparel from Logistics Warehouse to Store Considering Disposal Risk. Sustainability 2019, 11, 259. https://doi.org/10.3390/su11010259

Tanaka R, Ishigaki A, Suzuki T, Hamada M, Kawai W. Data Analysis of Shipment for Textiles and Apparel from Logistics Warehouse to Store Considering Disposal Risk. Sustainability. 2019; 11(1):259. https://doi.org/10.3390/su11010259

Chicago/Turabian StyleTanaka, Rina, Aya Ishigaki, Tomomichi Suzuki, Masato Hamada, and Wataru Kawai. 2019. "Data Analysis of Shipment for Textiles and Apparel from Logistics Warehouse to Store Considering Disposal Risk" Sustainability 11, no. 1: 259. https://doi.org/10.3390/su11010259

APA StyleTanaka, R., Ishigaki, A., Suzuki, T., Hamada, M., & Kawai, W. (2019). Data Analysis of Shipment for Textiles and Apparel from Logistics Warehouse to Store Considering Disposal Risk. Sustainability, 11(1), 259. https://doi.org/10.3390/su11010259