Application of Anticoincidence Technology to Burn-Up Measurement Systems in High-Temperature Gas-Cooled Reactors

Abstract

:1. Introduction

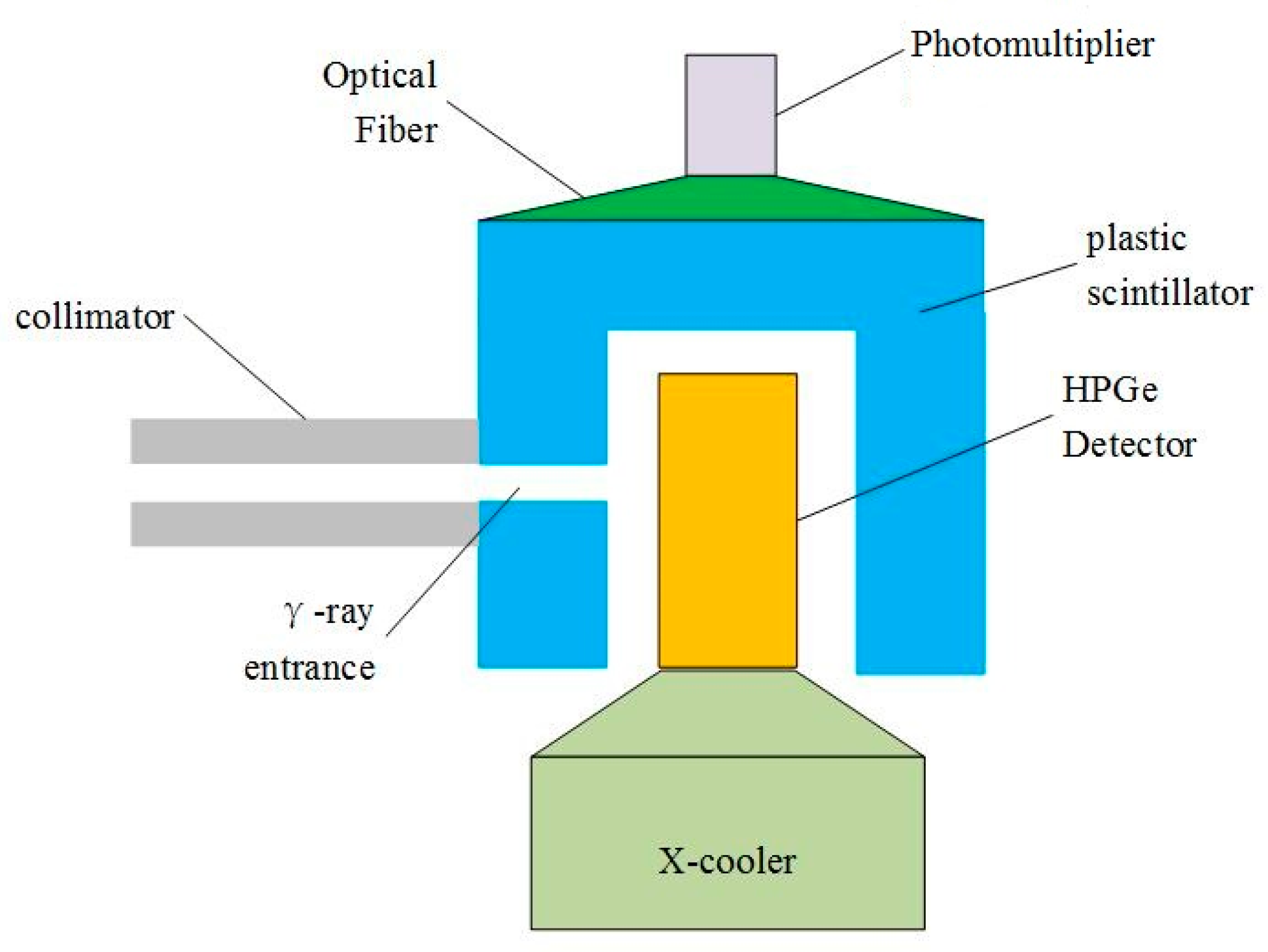

2. Materials and Methods

3. Results

3.1. Model Calculation and Parameters

3.2. Analysis Results of Two Detectors

3.2.1. Plastic Scintillator Detector Anticoincidence Effect Analysis

3.2.2. BGO Detector Anticoincidence Effect Analysis

4. Discussion

4.1. Comparative Analysis of Experimental Results and Simulation Results

4.2. Statistical Error Analysis of Simulated Data

5. Conclusions

- (1)

- As the wall and top thickness of the two annular detectors increased, the P/C of the γ-rays showed an increasing trend to varying degrees. The influence of wall thickness increases on the P/C of the system was found to be greater than that of increases in the top thickness.

- (2)

- When the wall thickness of the plastic scintillator increased from the value of 50 to 100 mm, the P/C of the system increased by 70. For every 10 mm increase in wall thickness, the mean increase of the P/C of the system was 14. After the wall thickness increased to 80 mm, the growth trend of P/C gradually leveled off. The geometric size producing the best anticoincidence effect was estimated to consist in a diameter of 260 mm and a length of 260 mm, and its P/C is 180.

- (3)

- In the detector using BGO crystals, when the wall thickness increased from 5 to 20 mm, the system showed an obvious rising trend, with the P/C increasing by a total of 414. However, after the wall thickness reached 20 mm, the P/C growth curve flattened out, with a peak of around 730. Taking into account the system’s anticoincidence effect, geometric space, material cost, and other factors, we determined the best anticoincidence BGO crystal geometry for a detector size of a diameter of 140 mm and a length of 210 mm, and it achieved a P/C of 727.

Author Contributions

Funding

Conflicts of Interest

References

- Verfondern, K.; Lensa, W.V. Past and present research in Europe on the production of nuclear hydrogen with HTGR. Prog. Nucl. Energy 2005, 47, 472–483. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Current Status and Future Development of Modular High Temperature Gas Cooled Reactor Technology; IAEA-TECDOC-1198; International Atomic Energy Agency: Vienna, Austria, 2001. [Google Scholar]

- Zhang, Z.; Yu, S. Future HTGR developments in China after the criticality of the HTR-10. Nucl. Eng. Des. 2002, 218, 249–257. [Google Scholar] [CrossRef]

- Kuijper, J.C.; Raepsaet, X.; De Haas, J.B.M.; Von Lensa, W.; Ohlig, U.; Ruetten, H.J.; Brockmann, H.; Damian, F.; Dolci, F.; Bernnat, W.; et al. HTGR reactor physics and fuel cycle studies. Nucl. Eng. Des. 2006, 236, 615–634. [Google Scholar] [CrossRef]

- Chersola, D.; Lomonaco, G.; Marotta, R. The VHTR and GFR and their use in innovative symbiotic fuel cycles. Prog. Nucl. Energy 2015, 83, 443–459. [Google Scholar] [CrossRef]

- Yan, W.H.; Zhang, L.G.; Zhang, Z.; Zhang, Y.; Xiao, Z.G. Prototype studies on the nondestructive online burnup determination for the modular pebble bed reactors. Nucl. Eng. Des. 2014, 267, 172–179. [Google Scholar] [CrossRef]

- Sawa, K.; Minato, K. An Investigation of Irradiation Performance of High Burnup HTGR Fuel. J. Nucl. Sci. Technol. 1999, 36, 781–791. [Google Scholar] [CrossRef]

- Ueta, S.; Aihara, J.; Sawa, K.; Yasuda, A.; Honda, M.; Furihata, N. Development of high temperature gas-cooled reactor (HTGR) fuel in Japan. Prog. Nucl. Energy 2011, 53, 788–793. [Google Scholar] [CrossRef]

- Sawa, K.; Ueta, S. Research and development on HTGR fuel in the HTTR project. Nucl. Eng. Des. 2004, 233, 163–172. [Google Scholar] [CrossRef]

- Lee, Y.W.; Park, J.Y.; Kim, Y.K.; Lee, Y.W.; Park, J.Y.; Kim, Y.K.; Jeong, K.C.; Kim, W.K.; Kim, B.G.; Kim, Y.M.; et al. Development of HTGR-coated particle fuel technology in Korea. Nucl. Eng. Des. 2008, 238, 2842–2853. [Google Scholar] [CrossRef]

- Tang, C.; Tang, Y.; Zhu, J.; Zou, Y.; Li, J.; Ni, X. Design and manufacture of the fuel element for the 10 MW high temperature gas-cooled reactor. Nucl. Eng. Des. 2002, 218, 91–102. [Google Scholar] [CrossRef]

- Wei-Hua, Y.; Li-Guo, Z.; Yan, Z.; Zhao, Z.; Zhi-Gang, X. Monte Carlo studies on the burnup measurement for the high temperature gas cooling reactor. Chin. Phys. C 2013, 37, 58–62. [Google Scholar]

- Zhang, L.G.; Shang, R.C. Analysis of influence of decay-cooling time on on-line burnup measurement of HTR-PM. Nucl. Eng. Des. 2009, 30, 43–46. [Google Scholar]

- Hawari, A.I.; Chen, J.; Su, B.; Zhao, Z. Assessment of on-line burnup monitoring of pebble bed reactor fuel using passive gamma-ray spectrometry. In Proceedings of the 2001 IEEE Nuclear Science Symposium Conference Record, San Diego, CA, USA, 4–10 November 2001. [Google Scholar]

- Lieder, R.M.; Jäger, H.; Neskakis, A.; Venkova, T.; Michel, C. Design of a bismuth germanate anti-Compton spectrometer and its use in nuclear spectroscopy. Nucl. Instrum. Methods Phys. Res. 1984, 220, 363–370. [Google Scholar] [CrossRef]

- Badran, H.M.; Sharshar, T. An experimental method for the optimization of anti-Compton spectrometer. Nucl. Instrum. Methods Phys. Res. 1999, 435, 423–432. [Google Scholar] [CrossRef]

- Kantele, J.; Marttila, O.J.; Hattula, J. Gamma spectrometer systems employing an anti-compton annulus. Nucl. Instrum. Methods 1966, 39, 194–216. [Google Scholar] [CrossRef]

- Bomboni, E.; Cerullo, N.; Fridman, E.; Lomonaco, G.; Shwageraus, E. Comparison among MCNP-based depletion codes applied to burnup calculations of pebble-bed HTR lattices. Nucl. Eng. Des. 2010, 240, 918–924. [Google Scholar] [CrossRef]

- Cerullo, N.; Bufalino, D.; Forasassi, G.; Lomonaco, G.; Rocchi, P.; Romanello, V. An additional performance of HTRS: The waste radiotoxicity minimisation. Radiat. Prot. Dosim. 2005, 115, 122–125. [Google Scholar] [CrossRef] [PubMed]

- Xia, B.; Li, F.; Wu, Z. Burn-Up Calibration and Error Analysis of HTR-10 Spherical Fuel Elements by Gamma Spectroscopy. In Proceedings of the International Conference on Nuclear Engineering, Xi’an, China, 17–21 May 2010; pp. 437–444. [Google Scholar]

- Xia, B. The Preliminary Simulation on the Physical Features in the Running-In Phase of the HTR-10. Ph.D. Thesis, Tsinghua University, Beijing, China, 2010. [Google Scholar]

- Agostinelli, S.; Allison, J.; Amako, K.A.; Apostolakis, J.; Araujo, H.; Arce, P.; Asai, M.; Axen, D.; Banerjee, S.; Barrand, G.; et al. Geant4-A simulation toolkit. Nucl. Instrum. Methods Phys. Res. A 2003, 506, 250–303. [Google Scholar] [CrossRef]

- Bender, S.E.; Ünlü, K.; Orton, C.R.; Schwantes, J.M. Geant4 model validation of Compton suppressed system for process monitoring of spent fuel. J. Radioanal. Nucl. Chem. 2013, 296, 647–654. [Google Scholar] [CrossRef]

- Ionicǎ, R.; Cǎta-Danil, G. Efficiency evaluation of a high resolution, low background gamma spectrometer with GEANT4. UPB Sci. Bull. 2008, 70, 75–82. [Google Scholar]

- Tsutsumi, M.; Oishi, T.; Kinouchi, N.; Sakamoto, R.; Yoshida, M. Design of an Anti-Compton Spectrometer for Low-Level Radioactive Wastes using Monte Carlo Techniques. J. Nucl. Sci. Technol. 2002, 39, 957–963. [Google Scholar] [CrossRef]

- IEEE Standard Test Procedures for Germanium Gamma-Ray Detectors; Ansi/IEEE Std.; IEEE: Piscataway, NJ, USA, 2002; pp. 1–32.

| Wall Thickness/mm | P/C of Plastic Scintillator | ||||

|---|---|---|---|---|---|

| Peak Channel | Np | Total Counts from 1040 keV to 1096 keV | Nc | P/C | |

| 50 | 6774 | 13,284 | 27,209 | 95 | 139 |

| 60 | 6774 | 13,189 | 24,364 | 85 | 154 |

| 70 | 6774 | 13,241 | 22,321 | 78 | 169 |

| 80 | 6774 | 13,174 | 20,755 | 73 | 180 |

| 90 | 6774 | 13,238 | 19,241 | 67 | 196 |

| 100 | 6774 | 13,146 | 17,926 | 63 | 209 |

| Top Thickness/mm | P/C of Plastic Scintillator | ||||

|---|---|---|---|---|---|

| Peak Channel | Np | Total Counts from 1040 keV to 1096 keV | Nc | P/C | |

| 50 | 6774 | 13,122 | 21,214 | 74 | 176 |

| 60 | 6774 | 13,174 | 20,755 | 73 | 180 |

| 70 | 6774 | 13,094 | 19,924 | 70 | 187 |

| 80 | 6774 | 13,224 | 19,792 | 69 | 190 |

| 90 | 6774 | 13,191 | 19,397 | 68 | 194 |

| Wall Thickness/mm | P/C of BGO Crystals | ||||

|---|---|---|---|---|---|

| Peak Channel | Np | Total Counts from 1040 keV to 1096 keV | Nc | P/C | |

| 5 | 6774 | 13,129 | 11,962 | 42 | 313 |

| 10 | 6774 | 13,048 | 6535 | 23 | 569 |

| 15 | 6774 | 13,005 | 5472 | 19 | 677 |

| 20 | 6774 | 13,079 | 5129 | 18 | 727 |

| 25 | 6774 | 13,028 | 5071 | 18 | 732 |

| 30 | 6774 | 13,139 | 5145 | 18 | 728 |

| Top Thickness/mm | P/C of BGO Crystals | ||||

|---|---|---|---|---|---|

| Peak Channel | Np | Total Counts from 1040 keV to 1096 keV | Nc | P/C | |

| 10 | 6774 | 13,079 | 5129 | 18 | 727 |

| 15 | 6774 | 12,942 | 5047 | 18 | 731 |

| 20 | 6774 | 13,054 | 4980 | 17 | 747 |

| 25 | 6774 | 13,012 | 5033 | 18 | 737 |

| 30 | 6774 | 13,171 | 4996 | 18 | 751 |

| Peak Channel | Np | Total Counts from 1040 keV to 1096 keV | Nc | P/C |

|---|---|---|---|---|

| 6774 | 13,109 | 53,767 | 189 | 69 |

| 6774 | 13,039 | 53,685 | 188 | 69 |

| 6774 | 13,038 | 53,792 | 189 | 69 |

| Detector Type | Statistical Error/% | Wall Thickness/mm | |||||

|---|---|---|---|---|---|---|---|

| 50/5 | 60/10 | 70/15 | 80/20 | 90/25 | 100/30 | ||

| Plastic scintillator | Np error | 0.87 | 0.87 | 0.87 | 0.87 | 0.87 | 0.87 |

| Background error | 0.61 | 0.64 | 0.67 | 0.69 | 0.72 | 0.75 | |

| BGO crystals | Np error | 0.87 | 0.87 | 0.88 | 0.87 | 0.88 | 0.87 |

| Background error | 0.91 | 1.24 | 1.35 | 1.40 | 1.40 | 1.39 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, C.; Liu, Y.-B.; Zhang, L.-G. Application of Anticoincidence Technology to Burn-Up Measurement Systems in High-Temperature Gas-Cooled Reactors. Sustainability 2018, 10, 2883. https://doi.org/10.3390/su10082883

Mao C, Liu Y-B, Zhang L-G. Application of Anticoincidence Technology to Burn-Up Measurement Systems in High-Temperature Gas-Cooled Reactors. Sustainability. 2018; 10(8):2883. https://doi.org/10.3390/su10082883

Chicago/Turabian StyleMao, Cui, Yi-Bao Liu, and Li-Guo Zhang. 2018. "Application of Anticoincidence Technology to Burn-Up Measurement Systems in High-Temperature Gas-Cooled Reactors" Sustainability 10, no. 8: 2883. https://doi.org/10.3390/su10082883

APA StyleMao, C., Liu, Y.-B., & Zhang, L.-G. (2018). Application of Anticoincidence Technology to Burn-Up Measurement Systems in High-Temperature Gas-Cooled Reactors. Sustainability, 10(8), 2883. https://doi.org/10.3390/su10082883