Environmental Impacts of Experimental Production of Lactic Acid for Bioplastics from Ulva spp.

Abstract

1. Introduction

2. Materials and Methods

2.1. System Description

2.1.1. Seaweed Cultivation

2.1.2. Seaweed Processing

2.2. Goal and Scope

2.3. System Boundaries

2.4. Multifunctionality

2.5. Data Collection and LCI Modelling

2.6. Life Cycle Impact Assessment

3. Results

3.1. Inventory of Resource Use

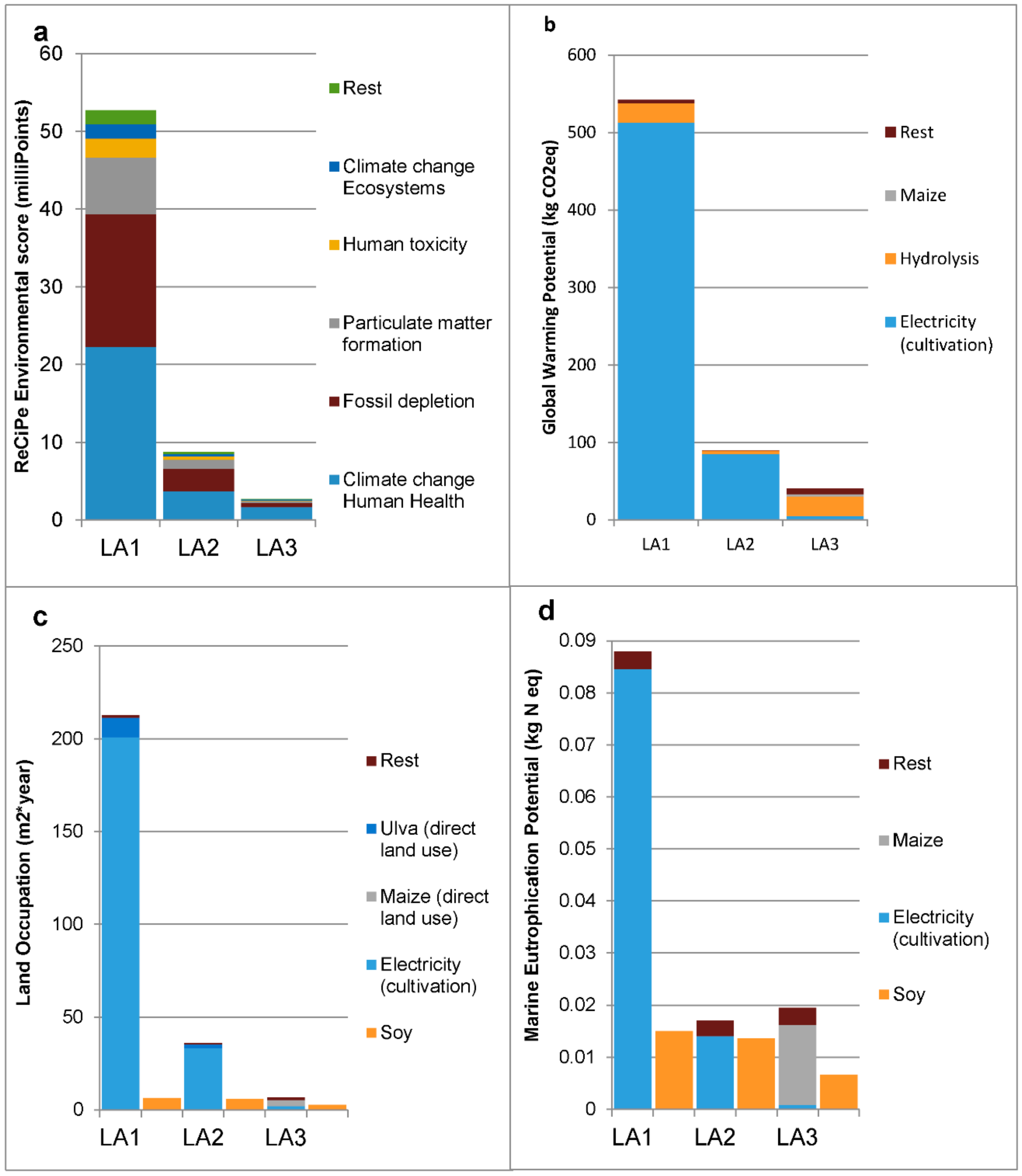

3.2. ReCiPe Environmental Score

3.3. Global Warming Potential

3.4. Land Occupation

3.5. Marine Eutrophication

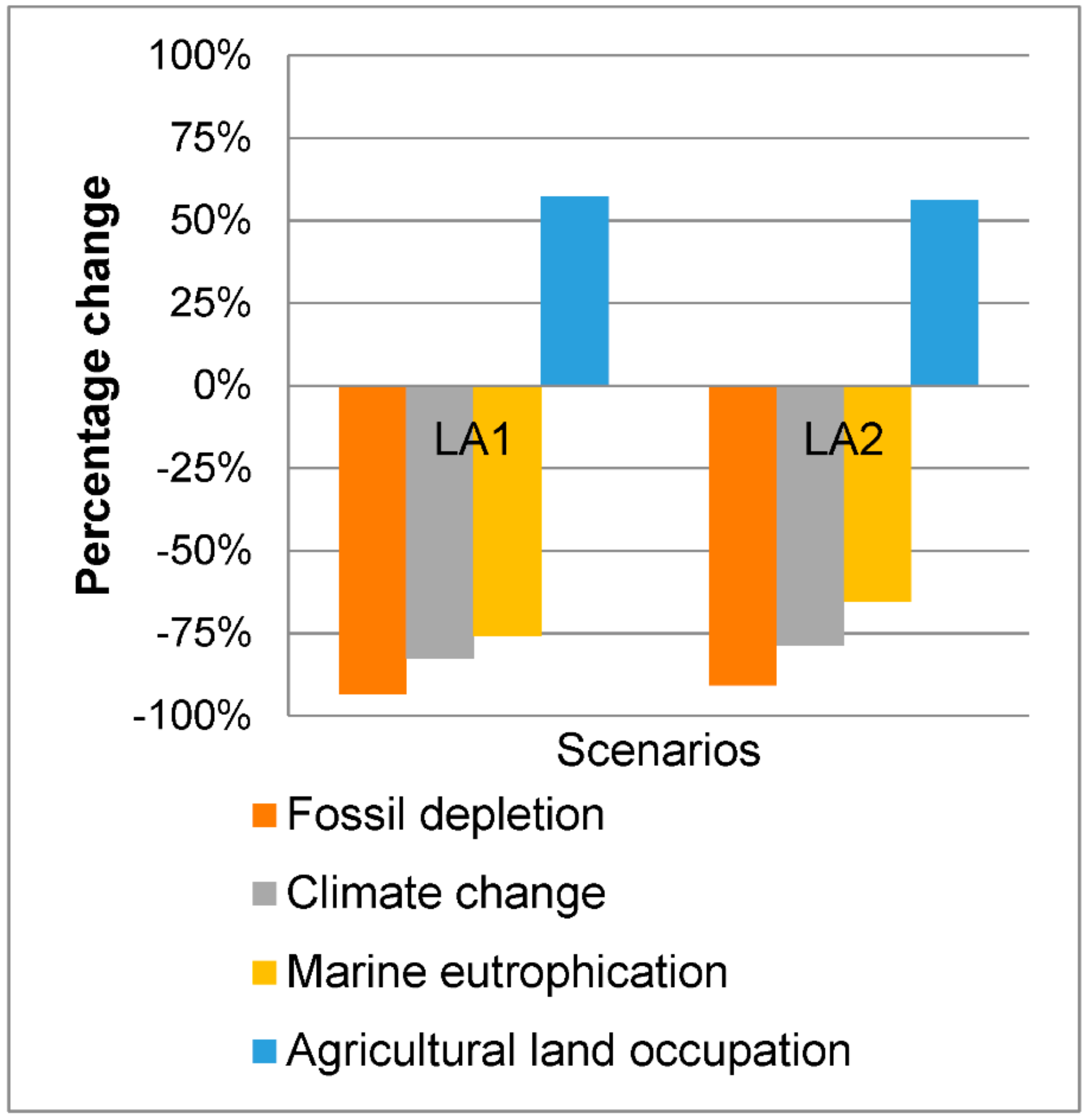

3.6. Hotspot Identification and Sensitivity Analysis

3.7. Comparison with Other Feedstocks

4. Discussion

4.1. Uncertainties and Improvements

4.2. Expected Effects of Upscaling to Industrial Production

4.3. Improvement Opportunities for Technology

4.4. Broadening the Sustainability Assessment

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- PlasticsEurope. Plastics–The Facts 2016. 2016. Available online: http://www.plasticseurope.org/application/files/4315/1310/4805/plastic-the-fact-2016.pdf (accessed on 11 March 2018).

- Belboom, S.; Léonard, A. Does biobased polymer achieve better environmental impacts than fossil polymer? Comparison of fossil HDPE and biobased HDPE produced from sugar beet and wheat. Biomass Bioenergy 2016, 85, 159–167. [Google Scholar] [CrossRef]

- Groot, W.J.; Borén, T. Life cycle assessment of the manufacture of lactide and PLA biopolymers from sugarcane in Thailand. Int. J. Life Cycle Assess. 2010, 15, 970–984. [Google Scholar] [CrossRef]

- Vink, E.T.H.; Davies, S. Life Cycle Inventory and Impact Assessment Data for 2014 Ingeo Polylactide Production. Ind. Biotechnol. 2015, 11, 167–180. [Google Scholar] [CrossRef]

- Drumright, R.E.; Gruber, P.R.; Henton, D.E. Polylactic acid technology. Adv. Mater. 2000, 12, 1841–1846. [Google Scholar] [CrossRef]

- Masutani, K.; Kimura, Y. Present Situation and Future Perspectives of Poly(lactic acid). In Synthesis, Structure and Properties of Poly(Lactic Acid); Di Lorenzo, M., Androsch, R., Eds.; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Juturu, V.; Wu, J.C. Microbial production of lactic acid: The latest development. Crit. Rev. Biotechnol. 2015, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Changwichan, K.; Silalertruksa, T.; Gheewala, S.H. Eco-Efficiency Assessment of Bioplastics Production Systems and End-of-Life Options. Sustainability 2018, 10, 952. [Google Scholar] [CrossRef]

- Holdt, S.L.; Kraan, S. Bioactive compounds in seaweed: Functional food applications and legislation. J. Appl. Phycol. 2011, 23, 543–597. [Google Scholar] [CrossRef]

- Buschmann, A.H.; Camus, C.; Infante, J.; Neori, A.; Israel, Á.; Hernández-González, M.C.; Pereda, S.V.; Gomez-Pinchetti, J.L.; Golberg, A.; Tadmor-Shalev, N.; et al. Seaweed production: Overview of the global state of exploitation, farming and emerging research activity. Eur. J. Phycol. 2017, 52, 391–406. [Google Scholar] [CrossRef]

- Kraan, S. Mass-cultivation of carbohydrate rich macroalgae, a possible solution for sustainable biofuel production. Mitig. Adapt. Strat. Glob. Chang. 2013, 18, 27–46. [Google Scholar] [CrossRef]

- Hughes, A.D.; Kelly, M.S.; Black, K.D.; Stanley, M.S. Biogas from Macroalgae: Is it time to revisit the idea? Biotechnol. Biofuels 2012, 5, 86. [Google Scholar] [CrossRef] [PubMed]

- Wei, N.; Quarterman, J.; Jin, Y.S. Marine macroalgae: An untapped resource for producing fuels and chemicals. Trends Biotechnol. 2013, 31, 70–77. [Google Scholar] [CrossRef] [PubMed]

- Van der Wal, H.; Sperber, B.L.; Houweling-Tan, B.; Bakker, R.R.; Brandenburg, W.; López-Contreras, A.M. Production of acetone, butanol, and ethanol from biomass of the green seaweed Ulva lactuca. Bioresour. Technol. 2013, 128, 431–437. [Google Scholar] [CrossRef] [PubMed]

- Korzen, L.; Abelson, A.; Israel, A. Growth, protein and carbohydrate contents in Ulva spp. and Gracilaria bursa-pastoris integrated with an offshore fish farm. J. Appl. Phycol. 2016, 28, 1835–1845. [Google Scholar] [CrossRef]

- Marinho, G.; Nunes, C.; Sousa-Pinto, I.; Pereira, R.; Rema, P.; Valente, L.M.P. The IMTA-cultivated Chlorophyta Ulva spp. as a sustainable ingredient in Nile tilapia (Oreochromis niloticus) diets. J. Appl. Phycol. 2013, 25, 1359–1367. [Google Scholar] [CrossRef]

- Aehle, W. Enzymes in Industry: Production and Applications, 3rd ed.; John Wiley & Sons: Weinheim, Germany, 2007. [Google Scholar]

- Gupta, R.; Kumar, S.; Gomes, J.; Kuhad, R.C. Kinetic study of batch and fed-batch enzymatic saccharification of pretreated substrate and subsequent fermentation to ethanol. Biotechnol. Biofuels 2012, 5, 16. [Google Scholar] [CrossRef] [PubMed]

- Nigam, P.S.; Singh, A. Production of liquid biofuels from renewable resources. Prog. Energy Combust. Sci. 2011, 37, 52–68. [Google Scholar] [CrossRef]

- Abreu, M.H.; Pereira, R.; Yarish, C.; Buschmann, A.H.; Sousa-Pinto, I. IMTA with Gracilaria vermiculophylla: Productivity and nutrient removal performance of the seaweed in a land-based pilot scale system. Aquaculture 2011, 312, 77–87. [Google Scholar] [CrossRef]

- Troell, M.; Joyce, A.; Chopin, T.; Neori, A.; Buschmann, A.H.; Fang, J.-G. Ecological engineering in aquaculture—Potential for integrated multi-trophic aquaculture (IMTA) in marine offshore systems. Aquaculture 2009, 297, 1–9. [Google Scholar] [CrossRef]

- ISO. Environmental Management: Life Cycle Assessment: Principles and Framework ISO 14040; Technical Committee ISO/TC 207; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Langlois, J.; Fréon, P.; Steyer, J.-P.; Delgenès, J.-P.; Hélias, A. Sea-use impact category in life cycle assessment: State of the art and perspectives. Int. J. Life Cycle Assess. 2014, 19, 994–1006. [Google Scholar] [CrossRef]

- EC-JRC-IES 2010. International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Detailed Guidance, 1st ed.; Publications Office of the European Union: Luxembourg, 2010; p. 417. [Google Scholar]

- Peixoto, M.J.; Svendsen, J.C.; Malte, H.; Pereira, L.F.; Carvalho, P.; Pereira, R.; Gonçalves, J.F.; Ozório, R.O. Diets supplemented with seaweed affect metabolic rate, innate immune, and antioxidant responses, but not individual growth rate in European seabass (Dicentrarchus labrax). J. Appl. Phycol. 2016, 28, 2061–2071. [Google Scholar] [CrossRef]

- Humbird, D.; Davis, R.; Tao, L.; Kinchin, C.; Hsu, D.; Aden, A.; Schoen, P.; Lukas, J.; Olthof, B.; Worley, M. Process Design and Economics for Biochemical Conversion of Lignocellulosic Biomass to Ethanol: Dilute-Acid Pretreatment and Enzymatic Hydrolysis of Corn Stover; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2011. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- IEA 2016. Energy Policies of IEA Countries: Portugal. Paris, France. Available online: https://www.iea.org/publications/freepublications/publication/Energy_Policies_of_IEA_Countries_Portugal_2016_Review.pdf (accessed on 9 July 2018).

- Nielsen, P.H.; Oxenboll, K.M.; Wenzel, H. Cradle-to-Gate Environmental Assessment of Enzyme Products Produced Industrially in Denmark by Novozymes A/S. Int. J. Life Cycle Assess. 2007, 12, 432–438. [Google Scholar] [CrossRef]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.A.J.; Schryver Ad Struijs, J.; van Zelm, R. ReCiPe 2008, A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level, Report I Characterization; Ministry of Housing, Spatial Planning and the Environment (VROM): Den Haag, The Netherlands, 2009; p. 132. [Google Scholar]

- Hansen, B. Determination of nitrogen as elementary N, an alternative to Kjeldahl. Acta Agriculturae Scandinavica 1989, 39, 113–118. [Google Scholar] [CrossRef]

- Vink, E.T.; Glassner, D.A.; Kolstad, J.J.; Wooley, R.J.; O’Connor, R.P. Original research: The eco-profiles for current and near-future NatureWorks® polylactide (PLA) production. Ind. Biotechnol. 2007, 3, 58–81. [Google Scholar] [CrossRef]

- Hottle, T.A.; Bilec, M.M.; Landis, A.E. Sustainability assessments of bio-based polymers. Polym. Degrad. Stab. 2013, 98, 1898–1907. [Google Scholar] [CrossRef]

- Taelman, S.E.; De Meester, S.; Van Dijk, W.; da Silva, V.; Dewulf, J. Environmental sustainability analysis of a protein-rich livestock feed ingredient in The Netherlands: Microalgae production versus soybean import. Resour. Conserv. Recy. 2015, 101, 61–72. [Google Scholar] [CrossRef]

- Aitken, D.; Bulboa, C.; Godoy-Faundez, A.; Turrion-Gomez, J.L.; Antizar-Ladislao, B. Life cycle assessment of macroalgae cultivation and processing for biofuel production. J. Clean. Prod. 2014, 75, 45–56. [Google Scholar] [CrossRef]

- Van Hal, J.W.; Huijgen, W.; López-Contreras, A. Opportunities and challenges for seaweed in the biobased economy. Trends Biotechnol. 2014, 32, 231–233. [Google Scholar] [CrossRef] [PubMed]

- Blunden, G. Agricultural uses of seaweeds and seaweed extracts. In Seaweed Resources in Europe: Uses and Potential; Blunden, G., Guiry, M.D., Eds.; J. Wiley: Chichester, UK, 1992; pp. 63–81. [Google Scholar]

- Chapman, V. Seaweeds and Their Uses; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Makkar, H.P.; Tran, G.; Heuzé, V.; Giger-Reverdin, S.; Lessire, M.; Lebas, F.; Ankers, P. Seaweeds for livestock diets: A review. Anim. Feed. Sci. Technol. 2016, 212, 1–17. [Google Scholar] [CrossRef]

- Bikker, P.; Krimpen, M.M.; Wikselaar, P.; Houweling-Tan, B.; Scaccia, N.; Hal, J.W.; Huijgen, W.J.; Cone, J.W.; López-Contreras, A.M. Biorefinery of the green seaweed Ulva lactuca to produce animal feed, chemicals and biofuels. J. Appl. Phycol. 2016, 28, 3511–3525. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Chai, Z.; Wang, Q.; Chen, W.; He, Z.; Jiang, S. Cultivation of seaweed Gracilaria in Chinese coastal waters and its contribution to environmental improvements. Algal Res. 2015, 9, 236–244. [Google Scholar] [CrossRef]

- Radulovich, R.; Umanzor, S.; Cabrera, R.; Mata, R. Tropical seaweeds for human food, their cultivation and its effect on biodiversity enrichment. Aquaculture 2015, 436, 40–46. [Google Scholar] [CrossRef]

- Pelletier, N.L.; Ayer, N.W.; Tyedmers, P.H.; Kruse, S.A.; Flysjo, A.; Robillard, G.; Ziegler, F.; Scholz, A.J.; Sonesson, U. Impact categories for life cycle assessment research of seafood production systems: Review and prospectus. Int. J. Life Cycle Assess. 2007, 12, 414–421. [Google Scholar] [CrossRef]

- Cottier-Cook, E.; Nagabhatla, N.; Badis, Y.; Campbell, M.; Chopin, T.; Dai, W.; Fang, J.; He, P.; Hewitt, C.; Kim, G. Safeguarding the Future of the Global Seaweed Aquaculture Industry; United Nations University (INWEH) and Scottish Association for Marine Science Policy Brief: Hamilton, ON, Canada, 2016; p. 12. [Google Scholar]

- Kousoulaki, K.; Sæther, B.S.; Albrektsen, S.; Noble, C. Review on European sea bass (Dicentrarchus labrax, Linnaeus, 1758) nutrition and feed management: A practical guide for optimizing feed formulation and farming protocols. Aquac. Nutr. 2015, 21, 129–151. [Google Scholar] [CrossRef]

| Scenario | LA1 | LA2 | LA3 |

|---|---|---|---|

| Species used (and part) | Ulva spp. (whole) | Ulva spp. (whole) | Zea mays (grains) |

| Biomass production | IMTA (experimental) | IMTA (experimental, optimized for starch enrichment) | Conventional agriculture |

| Hydrolysis and Fermentation | Experimental | Experimental | Experimental (theoretical) |

| Purification | Expert judgment | Expert judgment (optimized) | Expert judgment |

| Phase | Variables |

|---|---|

| Biomass production | Dry matter content (%WM) |

| Starch content (%WM) | |

| Starch content (%DM) | |

| Direct land occupation (m2×year) | |

| Electricity use (kWh) | |

| Diesel use (kWh) | |

| On-site use of pick-up truck (km) | |

| Biomass processing | Biomass used (kg WM) |

| Biomass used (kg DM) | |

| Hydrolysis yield (%) | |

| Fermentation yield (%) | |

| LA purification yield (%) | |

| Starch used (kg) | |

| Direct electricity use (kWh/kg LA) | |

| Sulfuric acid, concentrated (kg) | |

| Hydrochloric acid (1 M, kg) | |

| Calcium carbonate (kg) | |

| Enzyme mix for hydrolysis (kg) | |

| Monoammonium phosphate (kg) | |

| Ammonium sulfate (kg) | |

| Calcium hydroxide (kg) | |

| Purified water (also waste water, L) | |

| Biowaste produced (kg) | |

| N content in biomass (%DM) | |

| Hydrolysis byproduct | N in residue (kg) |

| N content in soy (%DM) | |

| Substituted soy (kg) | |

| Purification byproduct | Gypsum (kg) |

| Description | Data Source |

|---|---|

| Cultivation of Ulva spp. | ALGAplus |

| Hydrolysis of Ulva spp., yielding hydrolysate and residue | CEVA |

| Fermentation of hydrolysate to lactic acid | Wageningen University & Research (experimental) |

| Purification of lactic acid from fermentation broth | Wageningen University & Research (expert judgment) |

| Chemicals (cultivation operation, salts, acids, bases), maize cultivation | [27] |

| Electricity | [27,28] |

| Enzymes for hydrolysis | [29] |

| Scenario | LA1 | LA2 | LA3 | |

|---|---|---|---|---|

| Biomass production | Dry matter content (%WM) | 8.5 | 15 | 85 |

| Starch content (%WM) | 1.7 | 6.0 | 58 | |

| Starch content (%DM) | 20 | 40 | 68 | |

| Direct land occupation (m2×year/kg WM) | 0.07 | 0.07 | 0.7 | |

| Electricity use (kWh/kg WM) | 8.2 | 8.2 | 1.1 | |

| Diesel use (kWh/kg WM) | 0.012 | 0.012 | 0.022 | |

| On-site use of pick-up truck (km/kg WM) | 2.1 | 0.33 | n.a. | |

| Biomass processing | Biomass used (kg WM) | 158 | 25 | 4.6 |

| Biomass used (kg DM) | 13 | 3.7 | 3.9 | |

| Hydrolysis yield (%) | 75 | 75 | 75 | |

| Fermentation yield (%) | 90 | 90 | 90 | |

| LA purification yield (%) | 56 | 99 | 56 | |

| Starch used (kg) | 2.0 | 1.2 | 2.0 | |

| Direct electricity use (kWh/kg LA) | 13.7 | 13.5 | 13.7 | |

| Sulfuric acid, concentrated (kg) | 5.0 | 1.7 | 5.0 | |

| Hydrochloric acid (1 M, kg) | 1.7 | 0.27 | 1.7 | |

| Calcium carbonate (kg) | 57 | 9.0 | 57 | |

| Enzyme mix for hydrolysis (kg) | 0.38 | 0.060 | 0.38 | |

| Monoammonium phosphate (kg) | 0.058 | 0.033 | 0.058 | |

| Ammonium sulfate (kg) | 0.10 | 0.057 | 0.10 | |

| Calcium hydroxide (kg) | 1.47 | 0.83 | 1.47 | |

| Purified water (also waste water, L) | 21 | 18 | 21 | |

| Biowaste produced (kg) | 20 | 20 | 20 | |

| N content in biomass (%DM) | 1.5 | 4.9 | 2.3 | |

| Hydrolysis byproduct | N in residue (kg) | 0.20 | 0.19 | 0.089 |

| N content in soy (%DM) | 7.5 | 7.5 | 7.5 | |

| Substituted soy (kg) | 2.7 | 2.4 | 1.2 | |

| Purification byproduct | Gypsum (kg) | 0.95 | 0.95 | 0.95 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Helmes, R.J.K.; López-Contreras, A.M.; Benoit, M.; Abreu, H.; Maguire, J.; Moejes, F.; Burg, S.W.K.v.d. Environmental Impacts of Experimental Production of Lactic Acid for Bioplastics from Ulva spp. Sustainability 2018, 10, 2462. https://doi.org/10.3390/su10072462

Helmes RJK, López-Contreras AM, Benoit M, Abreu H, Maguire J, Moejes F, Burg SWKvd. Environmental Impacts of Experimental Production of Lactic Acid for Bioplastics from Ulva spp. Sustainability. 2018; 10(7):2462. https://doi.org/10.3390/su10072462

Chicago/Turabian StyleHelmes, Roel J. K., Ana M. López-Contreras, Maud Benoit, Helena Abreu, Julie Maguire, Fiona Moejes, and Sander W. K. van den Burg. 2018. "Environmental Impacts of Experimental Production of Lactic Acid for Bioplastics from Ulva spp." Sustainability 10, no. 7: 2462. https://doi.org/10.3390/su10072462

APA StyleHelmes, R. J. K., López-Contreras, A. M., Benoit, M., Abreu, H., Maguire, J., Moejes, F., & Burg, S. W. K. v. d. (2018). Environmental Impacts of Experimental Production of Lactic Acid for Bioplastics from Ulva spp. Sustainability, 10(7), 2462. https://doi.org/10.3390/su10072462