Gaps between Awareness and Activities on Green Construction in China: A Perspective of On-Site Personnel

Abstract

1. Introduction

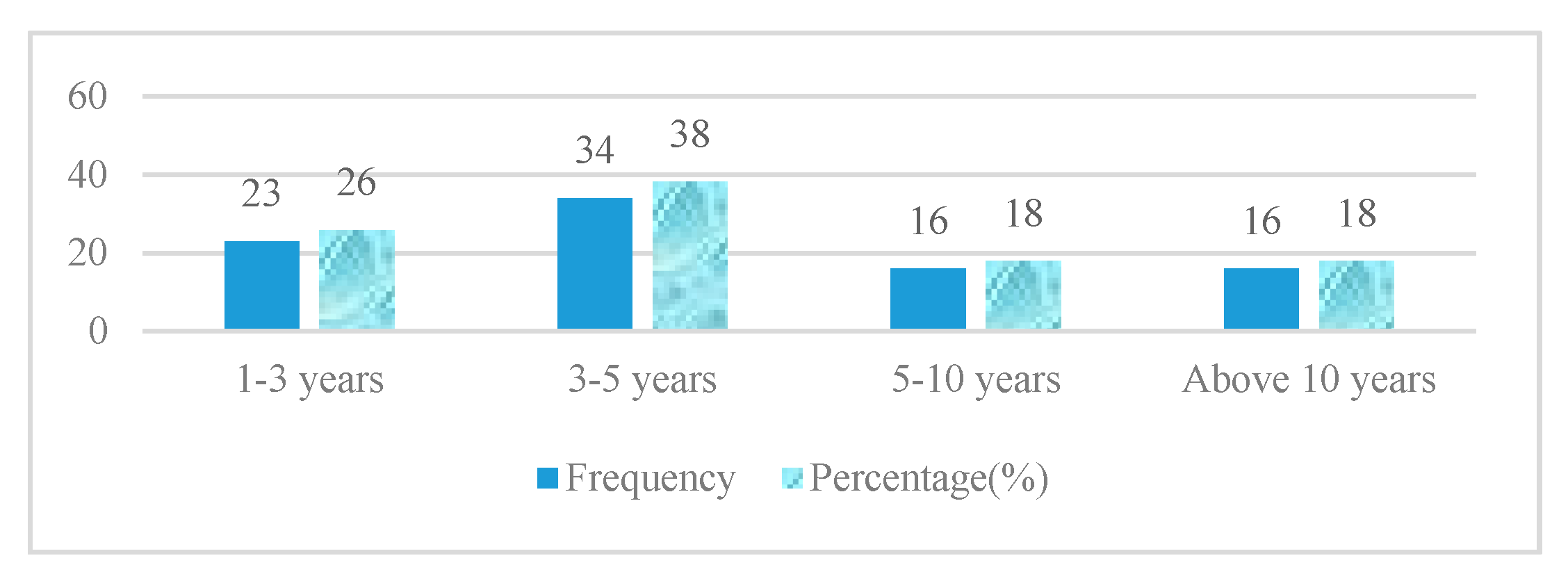

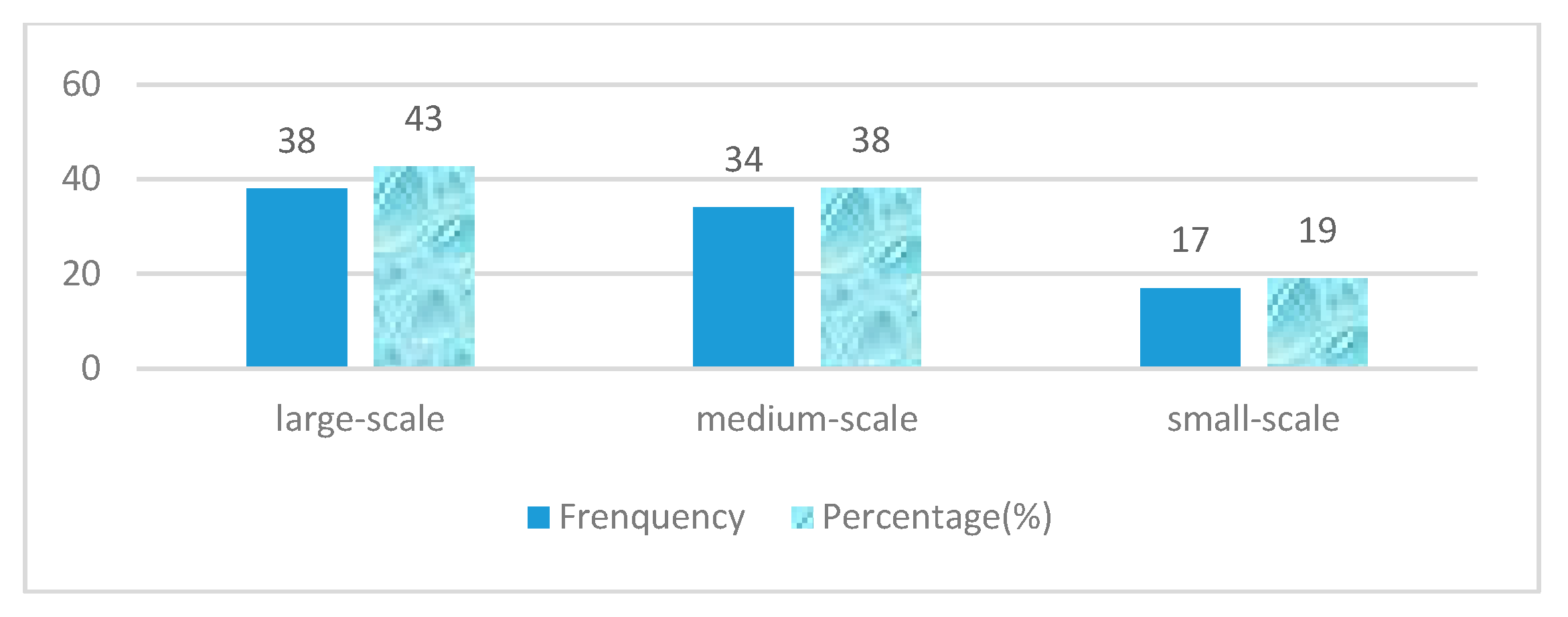

2. Factors and Activities for Green Construction

2.1. Environmental Protection

2.2. Material Saving

2.3. Water Saving

2.4. Energy Saving

2.5. Sustainable Land Usage

3. Research Methodologies

4. Results and Discussion

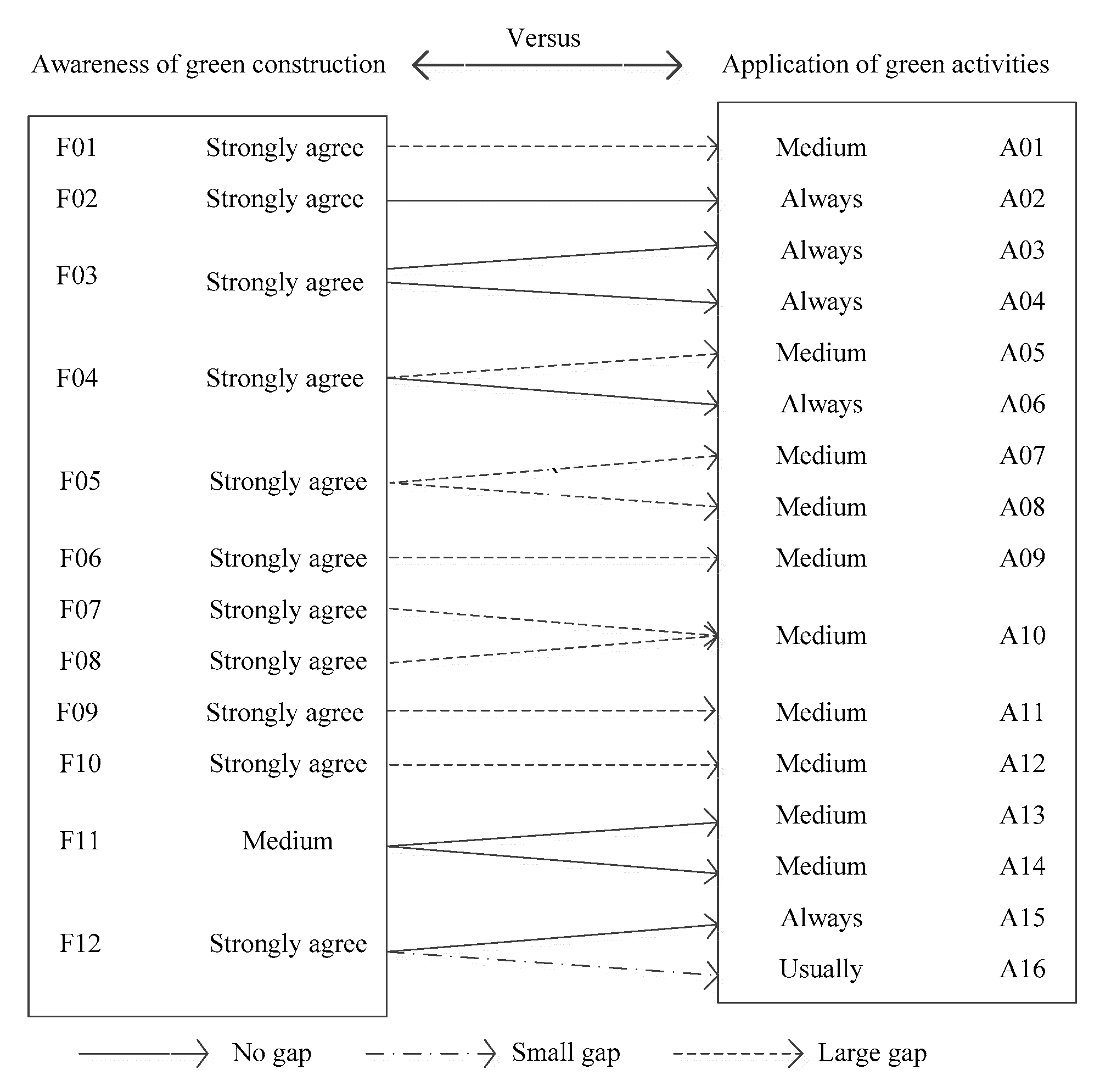

4.1. Awareness of On-Site Personnel on Green Construction

4.2. The Implementation Level of On-Site Green Construction Activities

4.3. Gaps between the Level of Awareness and Implementation

5. Implications

5.1. Narrow the Gaps between Green Awareness and Activities

5.2. Strengthen Financial and Technical Support

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Serpell, A.; Vera, J.K.S. Awareness, actions, drivers and barriers of sustainable construction in Chile. Technol. Econ. Dev. Econ. 2013, 19, 272–288. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, Y.; Shen, L. Embedding “green” in project-based organizations: The way ahead in the construction industry? J. Clean. Prod. 2015, 107, 420–427. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, K. Life-cycle energy analysis of prefabricated building components: An input–output-based hybrid model. J. Clean. Prod. 2015, 112, 2198–2207. [Google Scholar] [CrossRef]

- Sev, A. How can the construction industry contribute to sustainable development? A conceptual framework. Sustain. Dev. 2009, 17, 161–173. [Google Scholar] [CrossRef]

- Berardi, U. A cross-country comparison of the building energy consumptions and their trends. Resour. Conserv. Recycl. 2017, 123, 230–241. [Google Scholar] [CrossRef]

- Van Bueren, E.; De Jong, J. Establishing sustainability: Policy successes and failures. Build. Res. Inf. 2007, 35, 543–556. [Google Scholar] [CrossRef]

- Son, H.; Kim, C.; Chong, W.K.; Chou, J.S. Implementing sustainable development in the construction industry: Constructors’ perspectives in the US and Korea. Sustain. Dev. 2011, 19, 337–347. [Google Scholar] [CrossRef]

- Sharrard, A.L.; Matthews, H.S.; Roth, M. Environmental implications of construction site energy use and electricity generation. J. Constr. Eng. Manag. 2007, 133, 846–854. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Cheng, S.Y.; Tian, G.; Guo, X.; Wang, H. Construction fugitive dust pollution and control in Beijing. J. Beijing Univ. Technol. 2007, 10, 1086–1090. [Google Scholar]

- Cole, R.J. Building environmental assessment methods: Assessing construction practices. Constr. Manag. Econ. 2000, 18, 949–957. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Shen, L.; Tang, L. Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy Build. 2013, 66, 165–176. [Google Scholar] [CrossRef]

- Li, D.H.W.; Yang, L.; Lam, J.C. Zero energy buildings and sustainable development implications—A review. Energy 2013, 54, 1–10. [Google Scholar] [CrossRef]

- Abuzeinab, A.; Arif, M.; Qadri, M.A. Barriers to MNEs green business models in the UK construction sector: An ISM analysis. J. Clean. Prod. 2017, 160, 27–37. [Google Scholar] [CrossRef]

- Ofori, G.; Kien, H.L. Translating Singapore architects’ environmental awareness into decision making. Build. Res. Inf. 2004, 32, 27–37. [Google Scholar] [CrossRef]

- Silman, R.; Meryman, H. Sustainable Engineering–Using Specifications to Make it Happen. Struct. Eng. Int. 2004, 14, 216–219. [Google Scholar]

- Hoffman, A.J.; Henn, R. Overcoming the Social and Psychological Barriers to Green Building. Organ. Environ. 2008, 21, 390–419. [Google Scholar] [CrossRef]

- Shi, Q.; Zuo, J.; Huang, R.; Huang, J.; Pullen, S. Identifying the critical factors for green construction—An empirical study in China. Habitat Int. 2013, 40, 1–8. [Google Scholar] [CrossRef]

- Bohari, A.A.M.; Skitmore, M.; Xia, B.; Teo, M.; Zhang, X.; Adham, K.N. The path towards greening the Malaysian construction industry. Renew. Sustain. Energy Rev. 2015, 52, 1742–1748. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C.; Gyamfi, S.; Olanipekun, A.O.; He, B.J.; Yu, Y. Driving forces for green building technologies adoption in the construction industry: Ghanaian perspective. Build. Environ. 2017, 125, 206–215. [Google Scholar] [CrossRef]

- Lam, P.T.I.; Chan, E.H.W.; Poon, C.S.; Chau, C.K.; Chun, K.P. Factors affecting the implementation of green specifications in construction. J. Environ. Manag. 2010, 91, 654–661. [Google Scholar] [CrossRef] [PubMed]

- Yong, H.A.; Chan, W.J.; Suh, M.; Jeon, M.H. Integrated Construction Process for Green Building. Procedia Eng. 2016, 145, 670–676. [Google Scholar]

- Ametepey, S.O.; Gyadu-Asiedu, W.; Assah-Kissiedu, M. Sustainable Construction Implementation In Ghana: Focusing On Awareness And Challenges. Civ. Environ. Res. 2015, 7, 109–119. [Google Scholar]

- Shen, L.Y.; Zhang, Z.H. China’s urbanization challenging sustainable development. Int. J. Hous. Sci. Appl. 2002, 26, 181–193. [Google Scholar]

- Tan, Y.; Shen, L.; Yao, H. Sustainable construction practice and contractors’ competitiveness: A preliminary study. Habitat Int. 2011, 35, 225–230. [Google Scholar] [CrossRef]

- Jia, S.Y.; Tao, S.M. Discussion on Ecological Impact Assessment of Construction Projects in Natural Reserves. Sichuan Environ. 2008, 51, 153. [Google Scholar]

- Čulo, K.; Skendrović, V.; Gracin, P. Impact of environmental costs and benefits on project economics. People Build. Environ. 2010, 54, 1236–1239. [Google Scholar]

- Virji, M.A.; Bello, D.; Woskie, S.R.; Liu, X.M.; Kalil, A.J. Analysis of quartz by FT-IR in air samples of construction dust. Appl. Occup. Environ. Hyg. 2002, 17, 165–175. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Zhang, X.; Wu, M. Mitigating construction dust pollution: State of the art and the way forward. J. Clean. Prod. 2016, 112, 1658–1666. [Google Scholar] [CrossRef]

- Poon, C.S.; Ann, T.W.; Ng, L.H. On-site sorting of construction and demolition waste in Hong Kong. Resour. Conserv. Recycl. 2001, 32, 157–172. [Google Scholar] [CrossRef]

- Esin, T.; Cosgun, N. A study conducted to reduce construction waste generation in Turkey. Build. Environ. 2007, 42, 1667–1674. [Google Scholar] [CrossRef]

- Cass, D.; Mukherjee, A. Calculation of greenhouse gas emissions for highway construction operations by using a hybrid life-cycle assessment approach: Case study for pavement operations. J. Constr. Eng. Manag. 2011, 137, 1015–1025. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Feng, Y.; Lau, W.S.; Mao, C. Greenhouse gas emissions during the construction phase of a building: A case study in China. J. Clean. Prod. 2015, 103, 249–259. [Google Scholar] [CrossRef]

- Turk, A.M. The benefits associated with ISO 14001 certification for construction firms: Turkish case. J. Clean. Prod. 2009, 17, 559–569. [Google Scholar] [CrossRef]

- Zutshi, A.; Creed, A. An international review of environmental initiatives in the construction sector. J. Clean. Prod. 2015, 98, 92–106. [Google Scholar] [CrossRef]

- Telichenko, V.; Benuzh, A.; Eames, G.; Orenburova, E.; Shushunova, N. Development of Green Standards for Construction in Russia. Procedia Eng. 2016, 153, 726–730. [Google Scholar] [CrossRef]

- MHURD. The Evaluation Standard for Green Construction of Building; China Building Industry Press: Beijing, China, 2010. [Google Scholar]

- Vieira, C.S.; Pereira, P.M. Use of recycled construction and demolition materials in geotechnical applications: A review. Resour. Conserv. Recycl. 2015, 103, 192–204. [Google Scholar] [CrossRef]

- González, M.J.; Navarro, J.G. Assessment of the decrease of CO2 emissions in the construction field through the selection of materials: Practical case study of three houses of low environmental impact. Build. Environ. 2006, 41, 902–909. [Google Scholar] [CrossRef]

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Alaka, H.A.; Owolabi, H.A. Optimising material procurement for construction waste minimization: An exploration of success factors. Sustain. Mater. Technol. 2017, 11, 38–46. [Google Scholar] [CrossRef]

- European, C. A Project under the Framework Contract ENV.G.4/FRA/2008/0112. Service Contract on Management of Construction and Demolition Waste—SR1 Final Report Task 2. 2011. Available online: https://www.adelphi.de/en/publication/service-contract-management-construction-and-demolition-waste (accessed on 1 June 2018).

- UE Directive, E. Directive, 2008/98/EC of the European Parliamentand of the Council of 19 November on waste and repealing certain Directives. Off. J. Eur. Union (L312/3 of 22 November 2008) 2008, 34, 99–126. [Google Scholar]

- Stavenhagen, M.; Buurman, J.; Tortajada, C. Saving water in cities: Assessing policies for residential water demand management in four cities in Europe. Cities 2018, 79, 187–195. [Google Scholar] [CrossRef]

- Kiyanets, A.V. Resource-saving Construction Technologies. Procedia Eng. 2016, 150, 2124–2127. [Google Scholar] [CrossRef]

- Gu, A.; Teng, F.; Wang, Y. China energy-water nexus: Assessing the water-saving synergy effects of energy-saving policies during the eleventh Five-year Plan. Energy Convers. Manag. 2014, 85, 630–637. [Google Scholar] [CrossRef]

- Tang, X.; Huang, Z. Water-saving Scheme for Construction site of National Indoor Station. China Water Wastewater 2007, 23, 79–81. [Google Scholar]

- Liu, B.; Ping, Y. Water Saving Retrofitting and Its Comprehensive Evaluation of Existing Residential Buildings. Energy Procedia 2012, 14, 1780–1785. [Google Scholar] [CrossRef]

- Cole, R.J. Energy and greenhouse gas emissions associated with the construction of alternative structural systems. Build. Environ. 1998, 34, 335–348. [Google Scholar] [CrossRef]

- Devi, L.P.; Palaniappan, S. A study on energy use for excavation and transport of soil during building construction. J. Clean. Prod. 2017, 164, 543–556. [Google Scholar] [CrossRef]

- Lewis, M.P. Estimating Fuel Use and Emission Rates of Nonroad Diesel Construction Equipment Performing Representative Duty Cycles. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 18 March 2009. [Google Scholar]

- Marshall, S.K.; Rasdorf, W.; Lewis, P.; Frey, H.C. Methodology for Estimating Emissions Inventories for Commercial Building Projects. J. Archit. Eng. 2012, 18, 251–260. [Google Scholar] [CrossRef]

- Carmichael, D.G.; Williams, E.H.; Kaboli, A.S. Minimum Operational Emissions in Earthmoving. In Proceedings of the Construction Research Congress, West Lafayette, IN, USA, 21–23 May 2012; pp. 1869–1878. [Google Scholar]

- Fang, J. BIM-Based Building Energy Consumption Estimation and Energy Conservation Modification Mechanism. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2017. [Google Scholar]

- Liu, Y.; Zhang, Z.; Zhou, Y. Efficiency of construction land allocation in China: An econometric analysis of panel data. Land Use Policy 2018, 74, 261–272. [Google Scholar] [CrossRef]

- Patrick, C. Construction Project Planning and Scheduling; Pearson Schweiz Ag: Zug, Switzerland, 2003. [Google Scholar]

- Goestch, L.D. Project Management for Construction: Quality Control and Safety during Construction; Pearson Publishing Company: London, UK, 2013. [Google Scholar]

- Hegazy, T.; Elbeltagi, E. EvoSite: Evolution-Based Model for Site Layout Planning. J. Comput. Civ. Eng. 1999, 13, 198–206. [Google Scholar] [CrossRef]

- Sanad, H.M.; Ammar, M.A.; Ibrahim, M.E. Optimal Construction Site Layout Considering Safety and Environmental Aspects. J. Constr. Eng. Manag. 2008, 134, 536–544. [Google Scholar] [CrossRef]

- Said, H.; El-Rayes, K. Performance of global optimization models for dynamic site layout planning of construction projects. Autom. Constr. 2013, 36, 71–78. [Google Scholar] [CrossRef]

- MHURD. Green Construction Guideline; China Building Industry Press: Beijing, China, 2007. [Google Scholar]

- MHURD. Code for Green Construction of Building; China Building Industry Press: Beijing, China, 2014. [Google Scholar]

- Song, X.; Xu, J.; Shen, C.; Peñamora, F.; Zeng, Z. A Decision Making System for Construction Temporary Facilities Layout Planning in Large-Scale Construction Projects. Int. J. Civ. Eng. 2017, 15, 1–21. [Google Scholar] [CrossRef]

- Said, H.; Elrayes, K. Optimizing Material Procurement and Storage on Construction Sites. J. Constr. Eng. Manag. 2011, 137, 421–431. [Google Scholar] [CrossRef]

- Dittrich, R.; Francis, B.; Hatzinger, R.; Katzenbeisser, W. A paired comparison approach for the analysis of sets of Likert-scale responses. Stat. Model. 2007, 7, 3–28. [Google Scholar] [CrossRef]

- Croasmun, J.T.; Ostrom, L. Using Likert-type scales in the social sciences. J. Adult Educ. 2011, 40, 19–22. [Google Scholar]

- Abidin, N.Z. Investigating the awareness and application of sustainable construction concept by Malaysian developers. Habitat Int. 2010, 34, 421–426. [Google Scholar] [CrossRef]

- Azarmi, F.; Kumar, P.; Marsh, D.; Fuller, G. Assessment of the long-term impacts of PM10 and PM2.5 particles from construction works on surrounding areas. Environ. Sci. Process. Impacts 2015, 18, 208–221. [Google Scholar] [CrossRef] [PubMed]

- Zhan, H.; Li, Q.; Zhao, K.; Zhang, L.; Zhang, Z.; Zhang, C.; Xiao, L. Evaluating PM2.5 at a Construction Site Using Terahertz Radiation. IEEE Trans. Terahertz Sci. Technol. 2015, 5, 1028–1034. [Google Scholar] [CrossRef]

- Chang, N.B.; Rivera, B.J.; Wanielista, M.P. Optimal design for water conservation and energy savings using green roofs in a green building under mixed uncertainties. J. Clean. Prod. 2011, 19, 1180–1188. [Google Scholar] [CrossRef]

- Lou, C.; Duforestel, T.; Roux, J.J.; Rusaouën, G. Energy saving and environmental resources potentials: Toward new methods of building design. Build. Environ. 2012, 58, 199–207. [Google Scholar]

- Ye, H.; Zhang, Y. Trend Analysis of the Labor Supply and Demand in China’s Construction Industry: 2016–2025; Springer: Singapore, 2018. [Google Scholar]

- Wang, B.C.; Chou, F.Y.; Lee, Y.J. Awareness of Residents Regarding the Construction of a Sustainable Urban Community: A Case Study of Action Research in Taiwan. Syst. Pract. Action Res. 2010, 23, 157–172. [Google Scholar] [CrossRef]

- Chan, I.Y.S.; Liu, A.M.M.; Chen, B. Management Strategies for 5D-BIM Adoption in Hong Kong; Springer: Singapore, 2018. [Google Scholar]

- Santi, E.N.L.A. A Review of Application Building Information Modeling (BIM) During Pre-Construction Stage: Retrospective and Future Directions. IOP Conf. Ser. Earth Environ. Sci. 2018, 143, 12050. [Google Scholar]

- Ries, R.; Bilec, M.M.; Gokhan, N.M.; Needy, K.L. The economic benefits of green buildings: A comprehensive case study. Eng. Econ. 2006, 51, 259–295. [Google Scholar] [CrossRef]

| Categories | Factors/Awareness | Activities |

|---|---|---|

| Environmental protection | F01 Protection of water resources F02 Healthy construction environment F03 Control of dust and construction waste F04 Emissions of exhaust gas and wastewater F05 Control of light pollution and noise | A01 Don’t pump groundwater A02 Separate living area from operation area and disinfect regularly A03 Close or cover vehicles carrying earth and works generating dust A04 Collect construction waste separately and recycle it A05 Don’t burn wooden scraps A06 Set a drain and discharge sewage and rainwater separately A07 Take measures to prevent strong light from leaking A08 Take measures to absorb sound and to reduce noise |

| Material saving | F06 Adoption of green materials F07 Control of amount of usage and wastage F08 Cyclic utilization of materials | A09 Give high priority to green and sustainable materials A10 Optimize the material plan and utilize remnants properly |

| Water saving | F09 Cyclic utilization of water | A11 Adopt water saving devices and water recycling devices |

| Energy saving | F10 Adoption of energy-saving machines F11 Utilization of natural resources | A12 Adopt energy efficient machines and monitor the data of energy utilization A13 Adopt facilities of natural light and ventilation A14 Adopt construction technology with less energy consumption |

| Sustainable land usage | F12 Economical layout of construction site | A15 Arrange the general layout of construction site compactly A16 Take measures to prevent soil erosion and restore the vegetation after completion |

| Code | All Respondents | Large Scale | Medium Scale | Small Scale | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | SD | Rank | -Value | Mean | SD | Rank | Mean | SD | Rank | Mean | SD | Rank | |

| F01 | 4.34 | 0.88 | 4 | 0.000 ** | 4.26 | 1.00 | 8 | 4.38 | 0.85 | 4 | 4.41 | 0.62 | 2 |

| F02 | 4.65 | 0.68 | 1 | 0.000 ** | 4.63 | 0.75 | 3 | 4.65 | 0.69 | 1 | 4.71 | 0.47 | 1 |

| F03 | 4.56 | 0.71 | 3 | 0.000 ** | 4.66 | 0.67 | 2 | 4.59 | 0.50 | 2 | 4.29 | 1.05 | 4 |

| F04 | 4.58 | 0.64 | 2 | 0.000 ** | 4.74 | 0.50 | 1 | 4.53 | 0.61 | 3 | 4.35 | 0.86 | 3 |

| F05 | 4.33 | 0.72 | 6 | 0.000 ** | 4.37 | 0.79 | 4 | 4.29 | 0.68 | 6 | 4.29 | 0.69 | 4 |

| F06 | 4.26 | 0.73 | 8 | 0.000 ** | 4.26 | 0.79 | 8 | 4.29 | 0.76 | 6 | 4.18 | 0.53 | 9 |

| F07 | 4.28 | 0.72 | 7 | 0.000 ** | 4.29 | 0.84 | 7 | 4.29 | 0.63 | 6 | 4.24 | 0.66 | 7 |

| F08 | 4.34 | 0.77 | 4 | 0.000 ** | 4.37 | 0.79 | 4 | 4.32 | 0.81 | 5 | 4.29 | 0.69 | 4 |

| F09 | 4.26 | 0.9 | 8 | 0.000 ** | 4.34 | 0.85 | 6 | 4.24 | 0.99 | 9 | 4.12 | 0.86 | 11 |

| F10 | 4.16 | 0.8 | 11 | 0.000 ** | 4.18 | 0.83 | 11 | 4.12 | 0.84 | 11 | 4.18 | 0.64 | 9 |

| F11 | 3.57 | 1.08 | 12 | 0.523 | 3.55 | 1.13 | 12 | 3.62 | 1.18 | 12 | 3.53 | 0.72 | 12 |

| F12 | 4.20 | 0.84 | 10 | 0.000 ** | 4.21 | 0.93 | 10 | 4.18 | 0.83 | 10 | 4.24 | 0.66 | 8 |

| Code | All Respondents | Large Scale | Medium Scale | Small Scale | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | SD | Rank | -value | Mean | SD | Rank | Mean | SD | Rank | Mean | SD | Rank | |

| A01 | 3.40 | 1.28 | 15 | 0.482 | 3.29 | 1.43 | 16 | 3.62 | 1.16 | 13 | 3.24 | 1.15 | 14 |

| A02 | 3.94 | 1.04 | 3 | 0.000 ** | 3.95 | 1.11 | 2 | 4.09 | 0.90 | 3 | 3.65 | 1.11 | 2 |

| A03 | 4.04 | 0.96 | 1 | 0.000 ** | 4.03 | 1.03 | 1 | 4.32 | 0.84 | 1 | 3.53 | 0.87 | 5 |

| A04 | 3.82 | 1.11 | 5 | 0.008 * | 3.76 | 1.22 | 5 | 3.88 | 1.04 | 6 | 3.82 | 1.07 | 1 |

| A05 | 3.49 | 1.12 | 13 | 0.962 | 3.39 | 1.24 | 14 | 3.70 | 1.02 | 10 | 3.29 | 0.99 | 12 |

| A06 | 3.96 | 0.98 | 2 | 0.000 ** | 3.95 | 1.04 | 2 | 4.18 | 0.94 | 2 | 3.53 | 0.80 | 5 |

| A07 | 3.43 | 1.08 | 14 | 0.523 | 3.45 | 1.16 | 13 | 3.50 | 1.11 | 16 | 3.24 | 0.83 | 14 |

| A08 | 3.67 | 0.99 | 8 | 0.099 | 3.71 | 1.09 | 7 | 3.68 | 0.98 | 12 | 3.59 | 0.80 | 4 |

| A09 | 3.67 | 1.03 | 9 | 0.115 | 3.68 | 1.09 | 8 | 3.79 | 0.98 | 8 | 3.41 | 1.00 | 10 |

| A10 | 3.76 | 0.95 | 6 | 0.011 * | 3.76 | 1.02 | 5 | 3.91 | 0.90 | 5 | 3.47 | 0.87 | 8 |

| A11 | 3.62 | 1.01 | 11 | 0.271 | 3.66 | 1.05 | 9 | 3.74 | 1.02 | 10 | 3.29 | 0.85 | 12 |

| A12 | 3.39 | 1.04 | 16 | 0.336 | 3.34 | 1.15 | 15 | 3.53 | 1.02 | 15 | 3.24 | 0.83 | 14 |

| A13 | 3.60 | 1.00 | 12 | 0.369 | 3.66 | 1.05 | 10 | 3.62 | 1.04 | 13 | 3.41 | 0.80 | 10 |

| A14 | 3.65 | 0.92 | 10 | 0.123 | 3.61 | 1.00 | 12 | 3.76 | 0.89 | 9 | 3.53 | 0.80 | 5 |

| A15 | 3.89 | 0.95 | 4 | 0.000 ** | 3.95 | 0.98 | 2 | 3.94 | 0.95 | 4 | 3.65 | 0.86 | 2 |

| A16 | 3.70 | 1.04 | 7 | 0.077 | 3.66 | 1.19 | 10 | 3.85 | 0.93 | 7 | 3.47 | 0.87 | 8 |

| Code | Diff. (L−M) | Diff. (L−S) | Diff. (M−S) | ANOVA |

|---|---|---|---|---|

| F01 | −0.12 | −0.15 | −0.03 | 0.79 |

| F02 | −0.02 | −0.08 | −0.06 | 0.93 |

| F03 | 0.07 | 0.37 | 0.3 | 0.20 |

| F04 | 0.21 | 0.39 | 0.18 | 0.10 |

| F05 | 0.08 | 0.08 | 0.00 | 0.89 |

| F06 | −0.03 | 0.08 | 0.11 | 0.87 |

| F07 | 0.00 | 0.05 | 0.05 | 0.96 |

| F08 | 0.05 | 0.08 | 0.03 | 0.94 |

| F09 | 0.10 | 0.22 | 0.12 | 0.69 |

| F10 | 0.06 | 0.00 | −0.06 | 0.94 |

| F11 | −0.07 | 0.02 | 0.09 | 0.95 |

| F12 | 0.03 | −0.03 | −0.06 | 0.97 |

| Code | Diff. (L−M) | Diff. (L−S) | Diff. (M−S) | ANOVA |

|---|---|---|---|---|

| A01 | −0.33 | 0.05 | 0.38 | 0.47 |

| A02 | −0.14 | 0.3 | 0.44 | 0.36 |

| A03 | −0.29 | 0.5 | 0.79 | 0.02 |

| A04 | −0.12 | −0.06 | 0.06 | 0.90 |

| A05 | −0.31 | 0.1 | 0.41 | 0.30 |

| A06 | −0.23 | 0.42 | 0.65 | 0.08 |

| A07 | −0.05 | 0.21 | 0.26 | 0.71 |

| A08 | 0.03 | 0.12 | 0.09 | 0.92 |

| A09 | −0.11 | 0.27 | 0.38 | 0.46 |

| A10 | −0.15 | 0.29 | 0.44 | 0.30 |

| A11 | −0.08 | 0.37 | 0.45 | 0.32 |

| A12 | −0.19 | 0.1 | 0.29 | 0.59 |

| A13 | 0.04 | 0.25 | 0.21 | 0.69 |

| A14 | −0.15 | 0.08 | 0.23 | 0.64 |

| A15 | 0.01 | 0.3 | 0.29 | 0.51 |

| A16 | −0.19 | 0.19 | 0.38 | 0.45 |

| Awareness | Percentage of Awareness (%) | n | Frequency of Implementation (%) | Activities | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 4 | 3 | 2 | 1 | 5 | 4 | 3 | 2 | 1 | |||

| F01 | 55 | 28 | 13 | 2 | 1 | 89 | 26 | 22 | 27 | 16 | 9 | A01 |

| F02 | 74 | 19 | 4 | 2 | 0 | 89 | 39 | 25 | 29 | 4 | 2 | A02 |

| F03 | 64 | 31 | 2 | 1 | 1 | 89 | 44 | 21 | 30 | 4 | 0 | A03 |

| 89 | 38 | 19 | 31 | 9 | 2 | A04 | ||||||

| F04 | 65 | 29 | 4 | 1 | 0 | 89 | 26 | 19 | 38 | 13 | 3 | A05 |

| 89 | 37 | 28 | 29 | 4 | 1 | A06 | ||||||

| 89 | 21 | 19 | 45 | 10 | 4 | A07 | ||||||

| F05 | 47 | 38 | 15 | 0 | 0 | 89 | 26 | 26 | 39 | 8 | 1 | A08 |

| F06 | 43 | 40 | 17 | 0 | 0 | 89 | 28 | 24 | 37 | 10 | 1 | A09 |

| F07 | 44 | 40 | 16 | 0 | 0 | 89 | 28 | 27 | 39 | 4 | 1 | A10 |

| F08 | 52 | 30 | 18 | 0 | 0 | 89 | ||||||

| F09 | 52 | 26 | 20 | 1 | 1 | 89 | 24 | 27 | 39 | 8 | 2 | A11 |

| F10 | 40 | 35 | 25 | 0 | 0 | 89 | 18 | 22 | 45 | 10 | 4 | A12 |

| F11 | 25 | 26 | 34 | 13 | 2 | 89 | 21 | 30 | 37 | 9 | 2 | A13 |

| 89 | 21 | 30 | 42 | 6 | 1 | A14 | ||||||

| F12 | 45 | 33 | 20 | 2 | 0 | 89 | 34 | 27 | 34 | 6 | 0 | A15 |

| 89 | 26 | 33 | 29 | 10 | 2 | A16 | ||||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Tam, V.W.Y.; Qin, Y. Gaps between Awareness and Activities on Green Construction in China: A Perspective of On-Site Personnel. Sustainability 2018, 10, 2266. https://doi.org/10.3390/su10072266

Zhou J, Tam VWY, Qin Y. Gaps between Awareness and Activities on Green Construction in China: A Perspective of On-Site Personnel. Sustainability. 2018; 10(7):2266. https://doi.org/10.3390/su10072266

Chicago/Turabian StyleZhou, Jingyang, Vivian W. Y. Tam, and Yanjun Qin. 2018. "Gaps between Awareness and Activities on Green Construction in China: A Perspective of On-Site Personnel" Sustainability 10, no. 7: 2266. https://doi.org/10.3390/su10072266

APA StyleZhou, J., Tam, V. W. Y., & Qin, Y. (2018). Gaps between Awareness and Activities on Green Construction in China: A Perspective of On-Site Personnel. Sustainability, 10(7), 2266. https://doi.org/10.3390/su10072266