Feasibility Assessment of the Use of Recycled Aggregates for Asphalt Mixtures

Abstract

:1. Introduction

2. Available Materials

2.1. Natural Aggregates

2.2. Artificial Aggregates

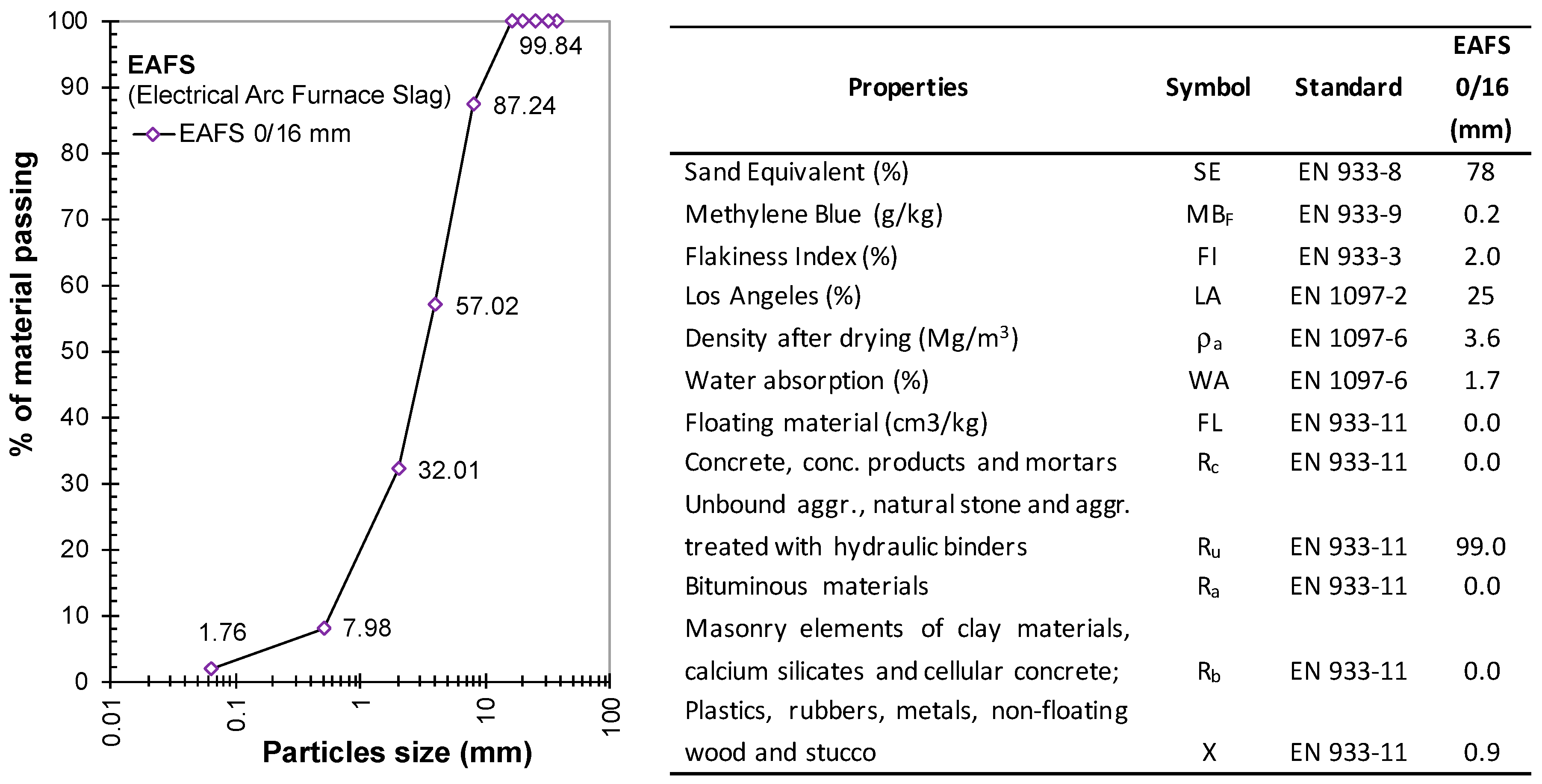

2.2.1. Electric Arc Furnace Steel Slag (EAFS)

2.2.2. Other Artificial Aggregates

2.3. Recycled Aggregates (with or without Binders)

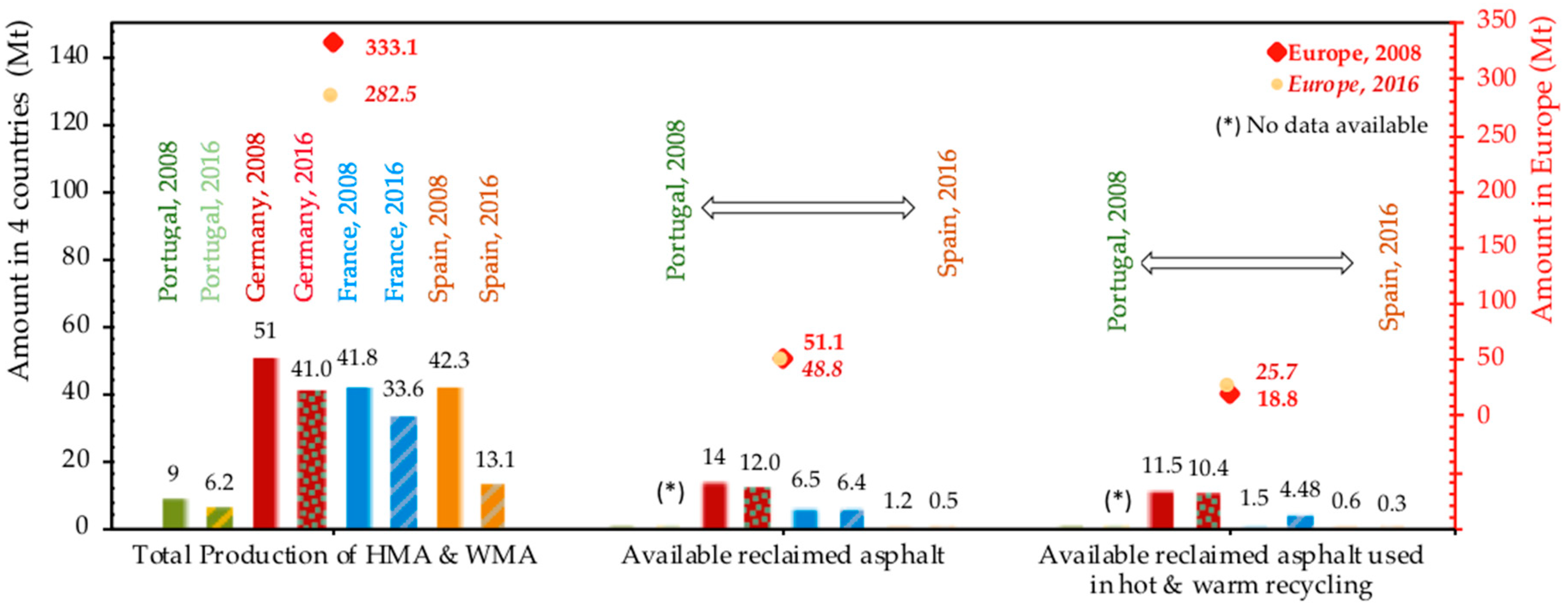

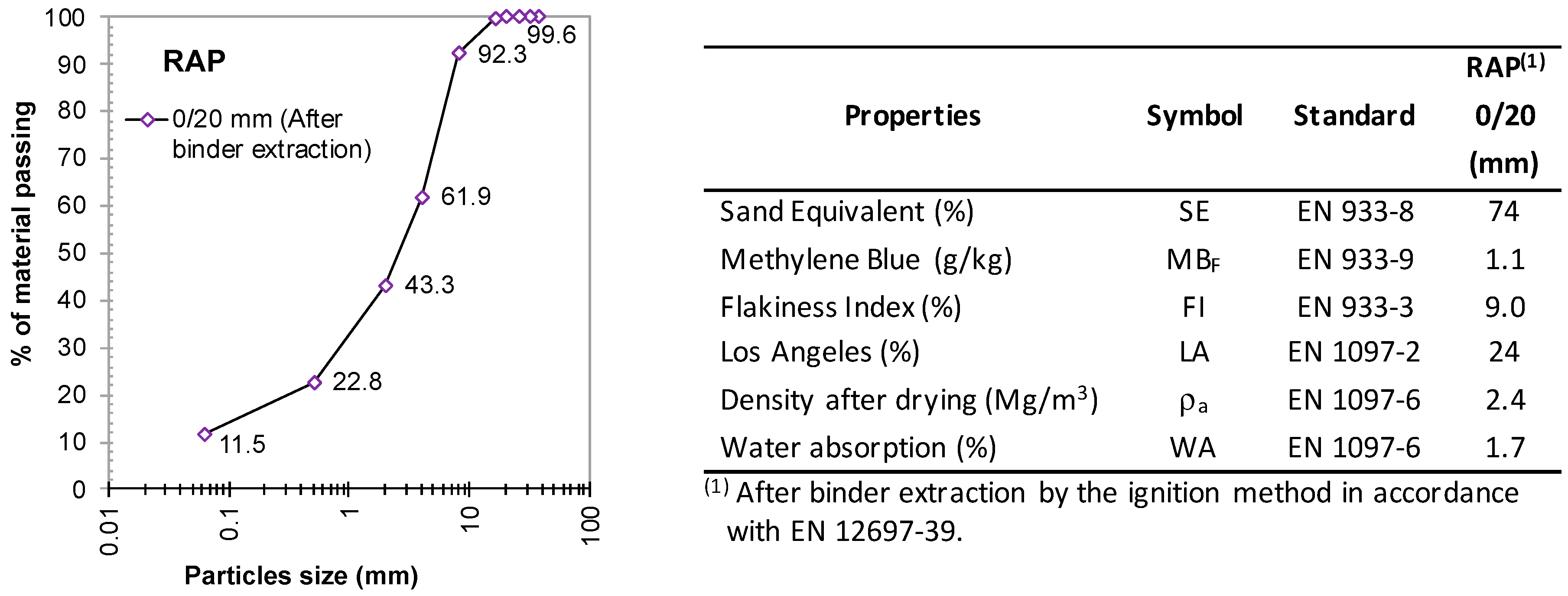

2.3.1. Reclaimed Asphalt Pavement (RAP)

- pi—Percentage of: the “final mix”, “old bitumen” or “new bitumen” (i = mix, o, n);

- mix, o, n—Indices, i, for: “mix of bitumens”, “old bitumen” or “new bitumen”, respectively;

- —Bitumen penetration @ 25 °C (i = mix, o, n);

- —Softening point, ring & ball test (i = mix, o, n).

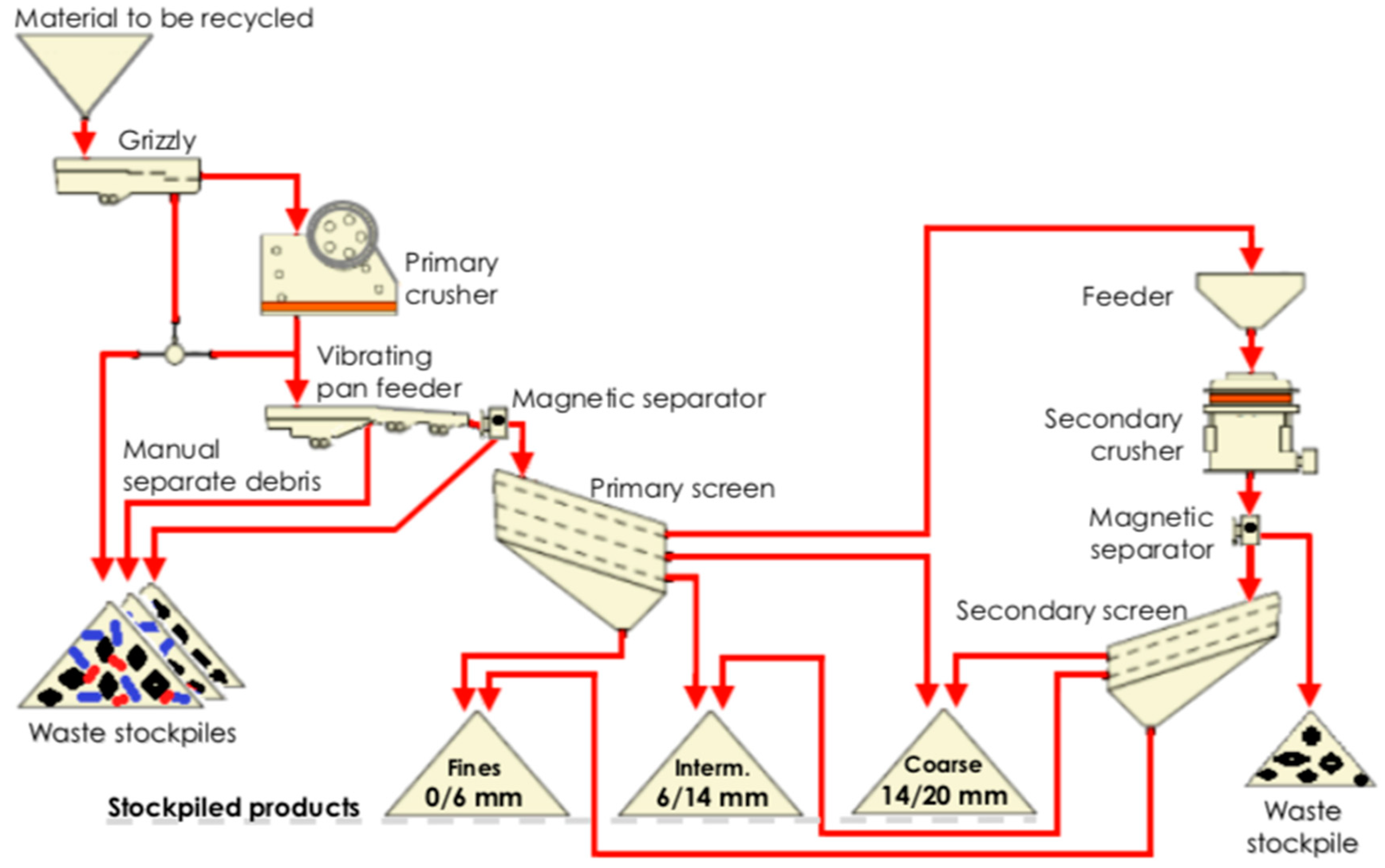

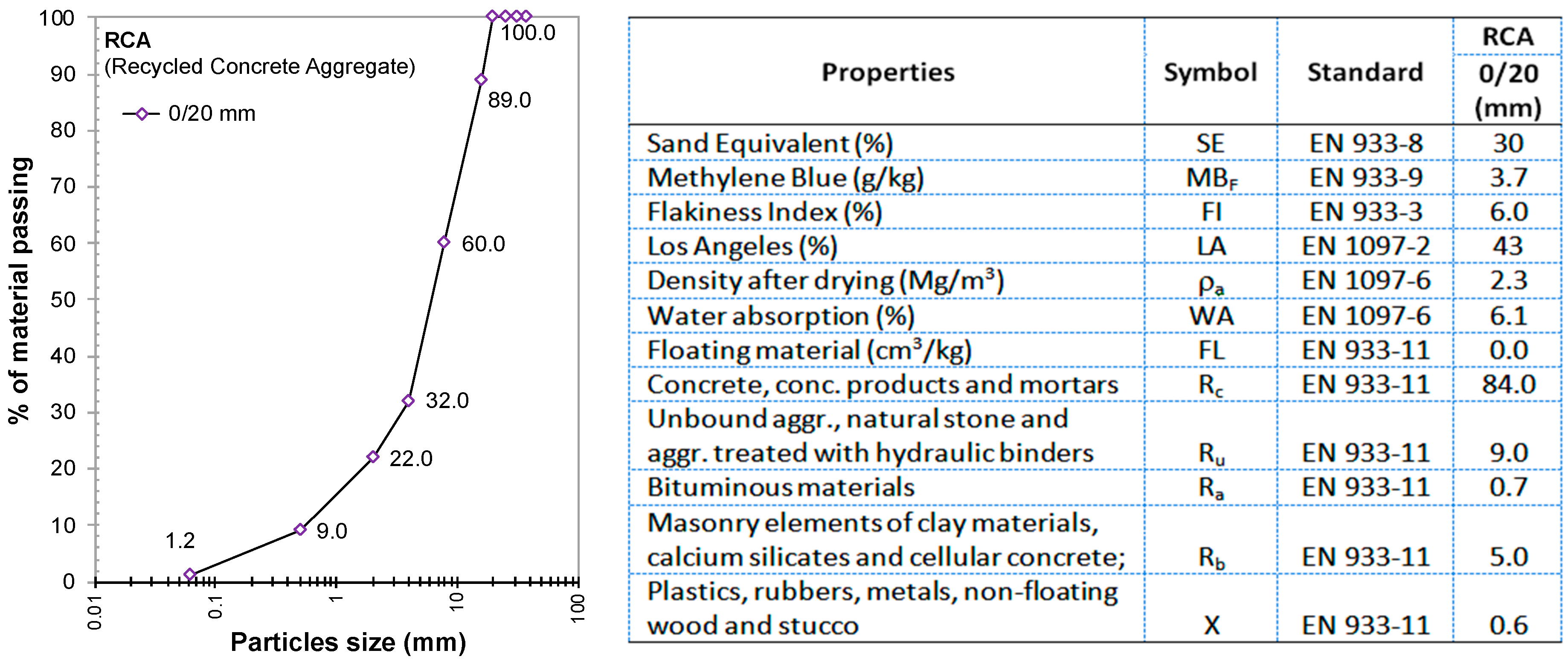

2.3.2. Recycled Concrete Aggregate (RCA)

2.3.3. Other Recycled Aggregates

2.4. Binders

3. Use of Sustainable Aggregates in Asphalt Mixtures, their Performance and Costs

3.1. Specificities in the Use of non-Traditional Aggregates

3.2. Mechanical Performance of Asphalt Mixtures with Non-Traditional Aggregates

3.2.1. Asphalt Mixtures with RAP

3.2.2. Asphalt Mixtures with RCA

3.2.3. Asphalt Mixtures with EAFS

3.2.4. Asphalt Mixtures with Other Types of Non-Conventional Aggregates

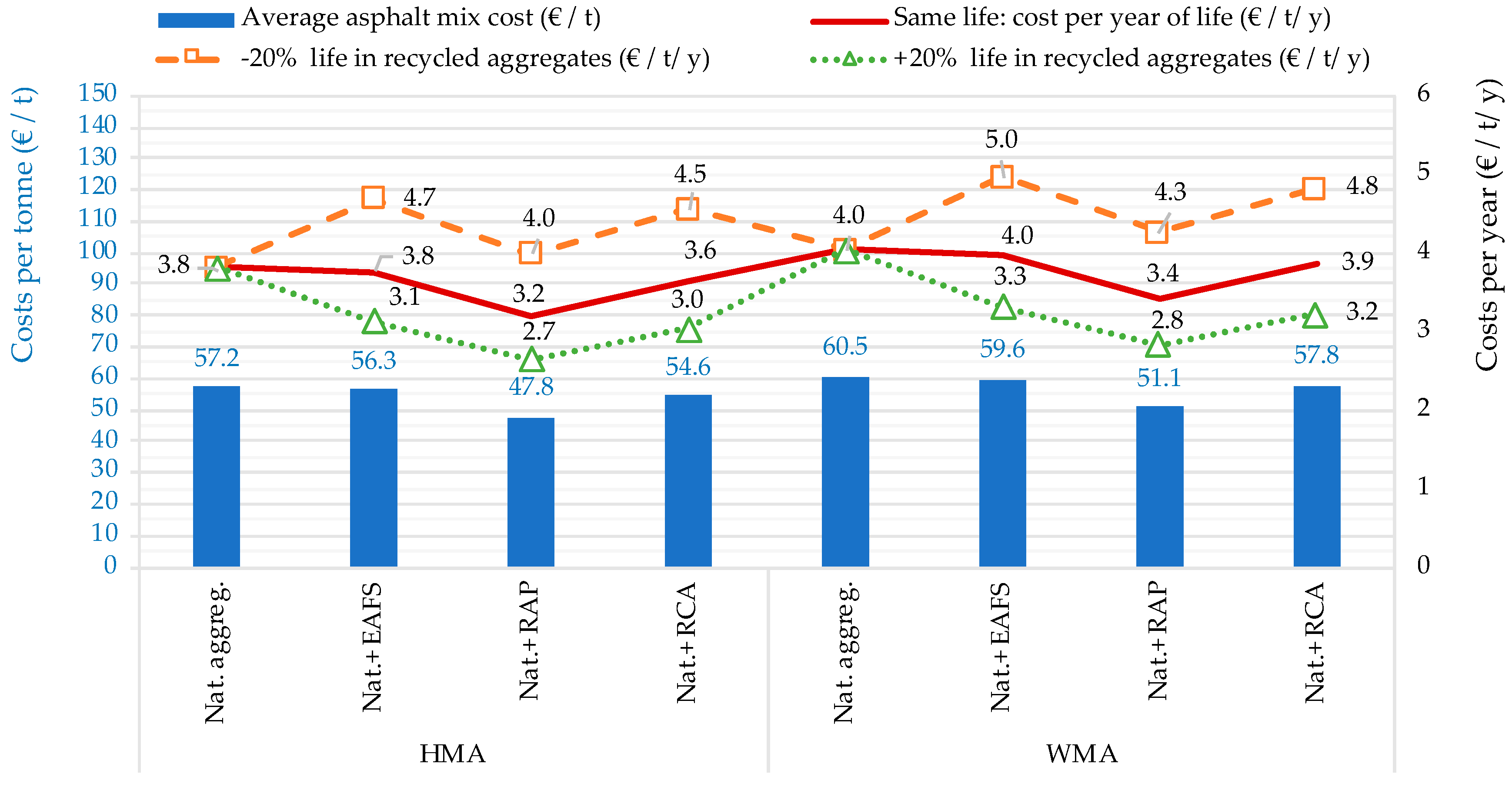

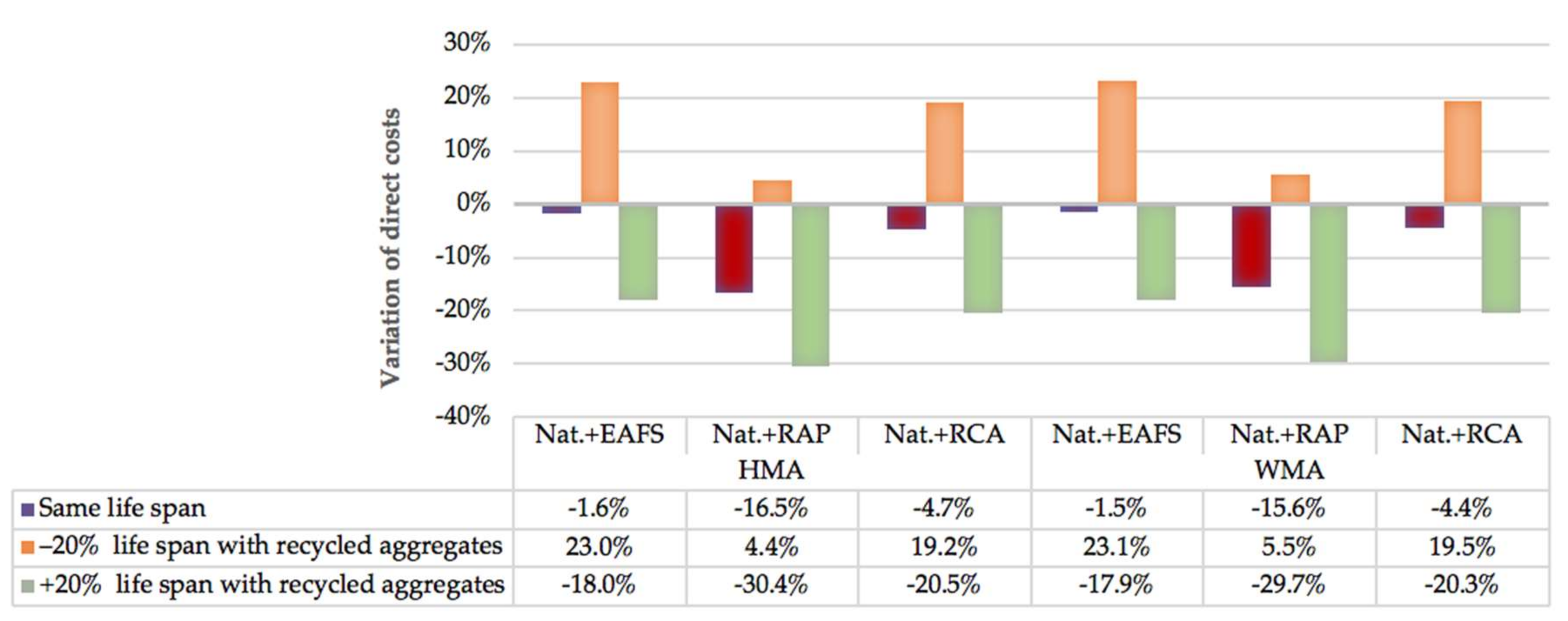

3.3. Direct Costs

4. Issues Related with Energy Consumption and Emissions

5. Summary and Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Martinho, F.; Picado-Santos, L.G.; Capitão, S. Pavement engineering materials: Review on the use of warm-mix asphalt. Constr. Build. Mater. 2012, 36, 1016–1024. [Google Scholar] [CrossRef]

- Martinho, F.; Picado-Santos, L.G.; Capitão, S. Mechanical properties of warm-mix asphalt concrete containing different additives and recycled asphalt as constituents applied in real production conditions. Constr. Build. Mater. 2017, 131, 79–89. [Google Scholar] [CrossRef]

- Feiteira, J.L.; Picado-Santos, L.; Capitão, S. Mechanical performance of dry process fine crumb rubber asphalt mixtures placed on the Portuguese road network. Constr. Build. Mater. 2014, 73, 247–254. [Google Scholar] [CrossRef]

- Rubio, M.C.; Moreno, F.; Martínez-Echevarría, M.J.; Martínez, G.; Vázquez, J.M. Comparative analysis of emissions from the manufacture and use of hot and half-warm mix asphalt. J. Clean. Prod. 2013, 41, 1–6. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.; Cheng, J.C. Comparative environmental evaluation of aggregate production from recycled waste materials and virgin sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Xiaoyu, L.; Qingbin, C.; Charles, S. Greenhouse gas emissions of alternative pavement designs: Framework development and illustrative application. J. Environ. Manag. 2014, 132, 313–322. [Google Scholar] [CrossRef]

- Martinho, F.; Picado-Santos, L.G.; Capitão, S. Influence of recycled concrete and steel slag on warm-mix asphalt properties. Constr. Build. Mater. 2018. under review. [Google Scholar]

- Baptista, A.M.; Picado-Santos, L.G.; Capitão, S. Design of hot mix recycled asphalt concrete produced in plant without preheating the reclaimed material. Int. J. Pavement Eng. 2013, 14, 95–102. [Google Scholar] [CrossRef]

- Pasandín, A.; Pérez, I. Overview of bituminous mixtures made with recycled concrete aggregates. Constr. Build. Mater. 2015, 74, 151–161. [Google Scholar] [CrossRef]

- Skaf, M.; Manso, J.M.; Aragón, Á.; Fuente-Alonso, J.; Ortega-López, V. EAF slag in asphalt mixes: A brief review of its possible re-use. Resour. Conserv. Recycl. 2017, 120, 176–185. [Google Scholar] [CrossRef]

- European Committee for Standardization. CEN EN 932-3. Tests for General Properties of Aggregates—Part 3: Procedure and Terminology for Simplified Petrographic Description; European Committee for Standardization: Brussels, Belgium, 2015. [Google Scholar]

- European Committee for Standardization. CEN EN 13043. Aggregates for Bituminous Mixtures and Surface Treatments for Roads, Airfields and Other Trafficked Areas; European Committee for Standardization: Brussels, Belgium, 2002. [Google Scholar]

- European Committee for Standardization. CEN EN 933-11. Tests for General Properties of Aggregates—Part 11: Classification Test for the Constituents of Coarse Recycled Aggregate; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- European Committee for Standardization. CEN EN 933-1. Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- European Committee for Standardization. CEN EN 933-5. Tests for Geometrical Properties of Aggregates—Part 5: Determination of Percentage of Crushed and Broken Surfaces in Coarse Aggregate Particles; European Committee for Standardization: Brussels, Belgium, 1998. [Google Scholar]

- European Committee for Standardization. CEN EN 933-9. Tests for Geometrical Properties of Aggregates—Part 9: Assessment of Fines—Methylene Blue Test; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- European Committee for Standardization. CEN EN 1097-1. Tests for Mechanical and Physical Properties of Aggregates—Part 1: Determination of the Resistance to Wear (Micro-Deval); European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- European Committee for Standardization. CEN EN 1097-2. Tests for Mechanical and Physical Properties of Aggregates—Part 2: Methods for the Determination of Resistance to Fragmentation; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- European Committee for Standardization. CEN EN 1744-1. Tests for Chemical Properties of Aggregates—Part 1: Chemical Analysis; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- Infraestruturas de Portugal. Construction Specifications, 14.03 Paving—Materials’ Characteristics. Available online: http://www.infraestruturasdeportugal.pt/sites/default/files/cet/14_03_set_2014.pdf (accessed on 26 April 2018). (In Portuguese).

- European Committee for Standardization. CEN EN 933-3. Tests for Geometrical Properties of Aggregates—Part 3: Determination of Particle Shape—Flakiness Index; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- European Committee for Standardization. CEN EN 1097-8. Tests for Mechanical and Physical Properties of Aggregates—Part 8: Determination of the Polished Stone Value; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- European Committee for Standardization. CEN EN 1097-6. Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- European Committee for Standardization. CEN EN 1097-3. Tests for Mechanical and Physical Properties of Aggregates—Part 3: Determination of Loose Bulk Density and Voids; European Committee for Standardization: Brussels, Belgium, 1998. [Google Scholar]

- European Committee for Standardization. CEN EN 12697-11. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 11: Determination of the Affinity between Aggregate and Bitumen; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- European Committee for Standardization. CEN EN 1367-2. Tests for Thermal and Weathering Properties of Aggregates—Part 2: Magnesium Sulfate Test; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- European Committee for Standardization. CEN EN 1367-5. Tests for Thermal and Weathering Properties of Aggregates—Part 5: Determination of Resistance to Thermal Shock; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- European Committee for Standardization. CEN EN 1367-3. Tests for Thermal and Weathering Properties of Aggregates—Part 3: Boiling Test for “Sonnenbrand Basalt”; European Committee for Standardization: Brussels, Belgium, 2001. [Google Scholar]

- Portuguese General Direction of Energy and Geology (DGEG). Available online: http://www.dgeg.gov.pt/ (accessed on 26 April 2018). (In Portuguese)

- Jamshidi, A.; Kurumisawa, K.; Nawa, T.; Jize, M.; White, G. Performance of pavements incorporating industrial by-products: A state-of-the-art study. J. Clean. Prod. 2017, 164, 367–388. [Google Scholar] [CrossRef]

- Tafti, M.; Khabiri, M.; Sanij, H. Experimental investigation of the effect of using different aggregate types on WMA mixtures. Int. J. Pavement Res. Technol. 2016, 9, 376–386. [Google Scholar] [CrossRef]

- Silvestre, R.; Medel, E.; García, A.; Navas, J. Utilizing recycled ceramic aggregates obtained from tile industry in the design of open graded wearing course on both laboratory and in situ basis. Mater. Des. 2013, 50, 471–478. [Google Scholar] [CrossRef]

- Wu, S.; Xue, Y.; Ye, Q.; Chen, Y. Utilization of steel slag as aggregates for stone mastic asphalt (SMA) mixtures. Build. Environ. 2007, 42, 2580–2585. [Google Scholar] [CrossRef]

- Neves, J.; Crucho, J.; Picado-Santos, L.G.; Martinho, F. The influence of processed steel slag on the performance of a bituminous mixture. In Proceedings of the Ninth International Conference on Bearing Capacity of Roads, Railways and Airfields, Trondheim, Norway, 25–27 June 2013; Akademika Publishing: Trondheim, Norway, 2013. [Google Scholar]

- Martinho, F.; Fernandes, E.; Korczak, P. The use of inert steel aggregates in the construction of embankments in road infrastructures. In Proceedings of the XIV CILA—Congresso Ibero-Latino Americano do Asfalto, La Habana, Cuba, 17–24 November 2007. (In Portuguese). [Google Scholar]

- Ferreira, S.; Correia, A.; Roque, A.; Cavalheiro, A. Mechanical and environmental behavior of granular materials. Application to national steel slag. In Proceedings of the Semana de Engenharia 2010 of University of Minho, Guimarães, Portugal, 11–15 October 2010. [Google Scholar]

- Martinho, F. Misturas Betuminosas Temperadas com Incorporação de Subprodutos Industriais: Caracterização e Validação Tecnológica (Warm Mix Asphalt with Incorporation of Industrial By-Products: Characterisation and Technological Validation). Ph.D. Thesis, Universidade de Lisboa, Lisbon, Portugal, 2014. (In Portuguese). [Google Scholar]

- Pasetto, M.; Baliello, A.; Giacomello, G.; Pasquini, E. Sustainable solutions for road pavements: A multi-scale characterization of warm mix asphalts containing steel slags. J. Clean. Prod. 2017, 166, 835–843. [Google Scholar] [CrossRef]

- Fakhri, M.; Ahmadi, A. Recycling of RAP and steel slag aggregates into the warm mix asphalt: A performance evaluation. Constr. Build. Mater. 2017, 147, 630–638. [Google Scholar] [CrossRef]

- Chen, J.-C.; Wei, S.-H. Engineering properties and performance of asphalt mixtures incorporating steel slag. Constr. Build. Mater. 2016, 128, 148–153. [Google Scholar] [CrossRef]

- Masoudi, S.; Abtahi, S.; Goli, A. Evaluation of electric arc furnace steel slag coarse aggregate in warm mix asphalt subjected to long-term aging. Constr. Build. Mater. 2017, 135, 260–266. [Google Scholar] [CrossRef]

- Ameri, M.; Hesami, S.; Goli, H. Laboratory evaluation of warm mix asphalt mixtures containing electric arc furnace (EAF) steel slag. Constr. Build. Mater. 2013, 49, 611–617. [Google Scholar] [CrossRef]

- Liapis, I.; Likoydis, S. Use of electric arc furnace slag in thin skid-resistant surfacing. Procedia Soc. Behav. Sci. 2012, 48, 907–918. [Google Scholar] [CrossRef]

- Asi, I. Evaluating skid resistance of different asphalt concrete mixes. Build. Environ. 2007, 42, 325–329. [Google Scholar] [CrossRef]

- Xu, S.; Xiao, F.; Amirkhanian, S.; Singh, D. Moisture characteristics of mixtures with warm mix asphalt technologies—A review. Constr. Build. Mater. 2017, 142, 148–161. [Google Scholar] [CrossRef]

- Behnood, A.; Ameri, M. Experimental investigation of stone matrix asphalt mixtures containing steel slag. Sci. Iran. 2012, 19, 1214–1219. [Google Scholar] [CrossRef]

- Yi, H.; Xu, G.; Cheng, H.; Wang, J.; Wan, Y.; Chen, H. An overview of utilization of steel slag. Procida Environ. Sci. 2012, 16, 791–801. [Google Scholar] [CrossRef]

- Xue, Y.; Hou, H.; Zhu, S.; Zha, J. Utilization of municipal solid waste incineration ash in stone mastic asphalt mixture: Pavement performance and environmental impact. Constr. Build. Mater. 2009, 23, 989–996. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Papadaskalopoulou, C.; Hofko, B.; Gschösser, F.; Falchetto, A.; Bueno, M.; Arraigada, M.; Sousa, J.; Ruiz, R.; Petit, C.; et al. Harvesting the unexplored potential of European waste materials for road construction. Resour. Conserv. Recycl. 2017, 116, 32–44. [Google Scholar] [CrossRef]

- EAPA. EAPA’s Position Statement on the Use of Secondary Materials, By-Products and Waste in Asphalt Mixtures. Available online: www.eapa.org (accessed on 27 April 2018).

- Pacheco-Torgal, F. Introduction to the Recycling of Construction and Demolition Waste (CDW); Woodhead Publishing Limited: Cambridge, UK, 2013. [Google Scholar]

- Prowell, B.; Hurley, G.E.; Frank, B. Warm-Mix Asphalt: Best Practices, 2nd ed.; National Asphalt Pavement Association (NAPA): Lanham, MD, USA, 2011. [Google Scholar]

- IRCOW Report Summary. Available online: https://cordis.europa.eu/result/rcn/153155_en.html (accessed on 27 April 2018).

- Abadías, A.I.; Guzmán, B. Recycling of Bituminous Materials: Conclusions of the DIRECT-MAT Project (Técnicas de Demolición y Reciclado de Materiales Para Carretera); Volume III, No. 10; Asfalto y Pavimentación: Madrid, Spain, 2013; ISSN 2174-2189. (In Spanish) [Google Scholar]

- PBL Netherlands Environmental Assessment Agency. Available online: http://www.pbl.nl/en/ (accessed on 27 April 2018).

- Anastasiou, E.; Liapis, A.; Papayianni, I. Comparative life cycle assessment of concrete road pavements using industrial by-products as alternative materials. Resour. Conserv. Recycl. 2015, 101, 1–8. [Google Scholar] [CrossRef]

- Jullien, A.; Monéron, P.; Quaranta, G.; Gaillard, D. Air emissions from pavement layers composed of varying rates of reclaimed asphalt. Resour. Conserv. Recycl. 2006, 47, 356–374. [Google Scholar] [CrossRef]

- Solaimanian, M.; Milander, S.; Boz, I.; Stoffels, S.M. Development of Guidelines for Usage of High Percent RAP in Warm-Mix Asphalt Pavements; Thomas, D., Ed.; Larson Pennsylvania Transportation Institute: Pennsylvania, PA, USA, 2011. [Google Scholar]

- Picado-Santos, L.G.; Baptista, A.M.; Capitão, S. Assessment of the use of hot mix recycled asphalt concrete in plant. ASCE J. Trasp. Eng. 2010, 136, 1159–1164. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.; Poulikakos, L.; Frank, F. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.; Frank, F. 100% recycled hot mix asphalt: A review and analysis. Resour. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- Dinis-Almeida, M.; Castro-Gomes, J.; Sangiorgi, C.; Zoorob, S.; Afonso, M. Performance of warm mix recycled asphalt containing up to 100% RAP. Constr. Build. Mater. 2016, 112, 1–6. [Google Scholar] [CrossRef]

- EAPA. Asphalt in Figures 2008. Available online: http://www.eapa.org/usr_img/asphalt/AsphaltinFigures2008.pdf (accessed on 28 April 2018).

- EAPA. Asphalt in Figures Available 2016. Available online: http://www.eapa.org/userfiles/2/Asphalt%20in%20Figures/2016/AIF_2016.pdf (accessed on 28 April 2018).

- European Committee for Standardization. CEN EN 13108-1. Bituminous Mixtures—Material Specifications—Part 1: Asphalt Concrete; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- EAPA. The Use of Warm Mix Asphalt—EAPA Position Paper. Available online: http://www.eapa.org/userfiles/2/Asphalt%20Promotion%20Tool/EAPA%20Position%20Paper%20-%20WMA%20-%20version%20October%202014.pdf (accessed on 28 April 2018).

- European Committee for Standardization. CEN EN 12697-1. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 1: Soluble Binder Content; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- European Committee for Standardization. CEN EN 1426. Bitumen and Bituminous Binders—Determination of Needle Penetration; European Committee for Standardization: Brussels, Belgium, 2015. [Google Scholar]

- European Committee for Standardization. CEN EN 1427. Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method; European Committee for Standardization: Brussels, Belgium, 2015. [Google Scholar]

- European Committee for Standardization. CEN EN 12596. Bitumen and Bituminous Binders—Determination of Dynamic Viscosity by Vacuum Capillary; European Committee for Standardization: Brussels, Belgium, 2015. [Google Scholar]

- European Committee for Standardization. CEN EN 13108-8. Bituminous Mixtures—Material Specifications—Part 8: Reclaimed Asphalt; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- European Committee for Standardization. CEN EN 12697-42. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 42: Amount of Foreign Matter in Reclaimed Asphalt; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- Martinho, F.; Capitão, S.; Picado-Santos, L.G. Incorporating industrial by-products into sustainable bituminous mixtures. In Proceedings of the CINCOS’12—Congresso de Inovação na Construção Sustentável, Aveiro, Portugal, 20–22 September 2012. (In Portuguese). [Google Scholar]

- Fernandes, G.; Capitão, S.; Picado-Santos, L.G. Use of construction and demolition waste in road pavements. In Proceedings of the 7° Congresso Rodoviário Português, Novos Desafios para a Atividade Rodoviária, Lisboa, Portugal, 10–12 April 2013. (In Portuguese). [Google Scholar]

- Pourtahmasb, M.; Karim, M. Utilization of recycled concrete aggregates in stone mastic asphalt mixtures. Adv. Mater. Sci. Eng. 2014, 2014, 1–9. [Google Scholar] [CrossRef]

- Oner, J.; Sengoz, B. Utilization of recycled asphalt concrete with warm mix asphalt and cost-benefit analysis. PLoS ONE 2015, 10, e116180. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Wu, S.; Zhong, J.; Wang, D. Investigation of asphalt mixture containing demolition waste obtained from earthquake-damaged buildings. Constr. Build. Mater. 2012, 29, 466–475. [Google Scholar] [CrossRef]

- European Committee for Standardization. CEN EN 12457-4. Characterisation of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 4: One Stage Batch Test at a Liquid to Solid Ratio of 10 I/kg for Materials with Particle Size below 10 mm (without or with Size Reduction); European Committee for Standardization: Brussels, Belgium, 2002. [Google Scholar]

- Hunter, R.; Self, A.; Read, J. The Shell Bitumen Handbook, 6th ed.; Hunter, R.N., Ed.; ICE: London, UK, 2015; ISBN 978-0727758378. [Google Scholar]

- European Committee for Standardization. CEN EN 13924-2. Bitumen and Bituminous Binders—Specification Framework for Special Paving Grade Bitumen—Part 2: Multigrade Paving Grade Bitumens; European Committee for Standardization: Brussels, Belgium, 2014. [Google Scholar]

- Mokhtari, A.; Nejad, F. Mechanistic approach for fiber and polymer modified SMA mixtures. Constr. Build. Mater. 2012, 36, 381–390. [Google Scholar] [CrossRef]

- Kedarisetty, S.; Biligiri, K.; Sousa, J. Advanced rheological characterization of reacted and activated rubber (RAR) modified asphalt binders. Constr. Build. Mater. 2016, 122, 12–22. [Google Scholar] [CrossRef]

- Cong, P.; Yu, J.; Wu, S.; Luo, X. Laboratory investigation of the properties of asphalt and its mixtures modified with flame retardant. Constr. Build. Mater. 2008, 22, 1037–1042. [Google Scholar] [CrossRef]

- LNEC E 472. Guide for the Production of Recycled HMA. Laboratório Nacional de Engenharia Civil 2009, Lisbon. Available online: http://www.lnec.pt/pt/descarregamentos/guia-para-a-reciclagem-de-misturas-betuminosas-a-quente-em-central-br-br/ (accessed on 27 April 2018). (In Portuguese).

- Azevedo, J.; Capitão, S.; Rasteiro, D.; Picado-Santos, L. Analysis of the evolution of flexible pavement conditions based on LTPP SPS-5 sections. In Proceedings of the 9th International Conference on Managing Pavement Assets (ICMPA9), Washington, DC, USA, 18–21 May 2015. [Google Scholar]

- Kandhal, P.; Mallick, R. Pavement Recycling Guidelines for State and Local Governments; Federal Highway Administration FHWA-SA-98-042; Federal Highway Administration: Washington, DC, USA, 1997. [Google Scholar]

- Pereira, P.; Oliveira, J.; Picado-Santos, L.G. Mechanical characterisation of hot mix recycled materials. Int. J. Pavement Eng. 2004, 5, 211–220. [Google Scholar] [CrossRef]

- Reyes-Ortiz, O.; Berardinelli, E.; Alvarez, A.E.; Carvajal-Muñoz, J.S.; Fuentes, L.G. Evaluation of hot mix asphalt mixtures with replacement of aggregates by reclaimed asphalt pavement (RAP) material. Procedia Soc. Behav. Sci. 2012, 53, 379–388. [Google Scholar] [CrossRef]

- Capitão, S.; Sousa, E.; Bessa, J.; Picado-Santos, L.G. Properties of warm-mix asphalt mixtures produced with terminal blend warm bitumen. In Proceedings of the CILA—Congresso Ibero-LatinoAmericano do Asfalto, Medellin, DC, USA, 27–30 November 2017. (In Portuguese). [Google Scholar]

- Zaumanis, M.; Poulikakos, L.; Partl, M. Performance-based design of asphalt mixtures and review of key parameters. Mater. Des. 2018, 141, 185–201. [Google Scholar] [CrossRef]

- Paranavithana, S.; Mohajerani, A. Effects of recycled concrete aggregates on properties of asphalt concrete. Resour. Conserv. Recycl. 2006, 48, 1–12. [Google Scholar] [CrossRef]

- Mills-Beale, J.; You, Z. The mechanical properties of asphalt mixtures with recycled concrete aggregates. Constr. Buid. Mater. 2010, 24, 230–235. [Google Scholar] [CrossRef]

- Zulkati, A.; Wong, Y.; Sun, D. Mechanistic performance of asphalt-concrete mixture incorporating coarse recycled concrete aggregate. J. Mater. Civ. Eng. 2013, 25, 1299–1306. [Google Scholar] [CrossRef]

- Pasandín, A.; Pérez, I. Effect of ageing time on properties of hot-mix asphalt containing recycled concrete aggregates. Constr. Build. Mater. 2014, 52, 284–293. [Google Scholar] [CrossRef]

- Gul, W.; Guler, M. Rutting susceptibility of asphalt concrete with recycled concrete aggregate using revised Marshall procedure. Constr. Build. Mater. 2014, 55, 341–349. [Google Scholar] [CrossRef]

- Wu, S.; Muhunthan, B.; Wen, H. Investigation of effectiveness of prediction of fatigue life for hot mix asphalt blended with recycled concrete aggregate using monotonic fracture testing. Constr. Build. Mater. 2017, 131, 50–56. [Google Scholar] [CrossRef]

- Kavussi, A.; Qazizadeh, M. Fatigue characterization of asphalt mixes containing electric arc furnace (EAF) steel slag subjected to long term aging. Constr. Build. Mater. 2014, 72, 158–166. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Fatigue performance of asphalt concretes made with steel slags and modified bituminous binders. Int. J. Pavement Res. Technol. 2013, 6, 294–303. [Google Scholar] [CrossRef]

- Chen, M.; Lin, J.; Wu, S.; Liu, C. Utilization of recycled brick powder as alternative filler in asphalt mixture. Constr. Build. Mater. 2010, 25, 1532–1536. [Google Scholar] [CrossRef]

- Hassani, A.; Ganjidoust, H.; Maghanaki, A.A. Use of plastic waste (polyethylene terephthalate) in asphalt concrete mixture as aggregate replacement. Waste Manag. Res. 2005, 23, 322–327. [Google Scholar] [CrossRef] [PubMed]

- Moghaddam, T.B.; Karim, M.R.; Syammaun, T. Dynamic properties of stone mastic asphalt mixtures containing waste plastic bottles. Constr. Build. Mater. 2012, 34, 236–242. [Google Scholar] [CrossRef]

- Rahman, W.; Wahab, A. Green pavement using recycled polyethylene terephthalate (PET) as partial fine aggregate replacement in modified asphalt. Procedia Eng. 2012, 53, 124–128. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Soltani, M.; Karim, M.R. Evaluation of permanent deformation characteristics of unmodified and Polyethylene Terephthalate modified asphalt mixtures using dynamic creep test. Mater. Des. 2013, 53, 317–324. [Google Scholar] [CrossRef]

- Costa, L.; Peralta, J.; Oliveira, J.; Silva, H. A new life for cross-linked plastic waste as aggregates and binder modifier for asphalt. App. Sci. 2017, 7, 3–16. [Google Scholar] [CrossRef]

- Lou, J.; Liu, H.; Pang, A.; Sun, H.; Yang, S.; Yang, T. The high temperature stability of asphalt composite reinforced by basalt glass powder and basalt fiber. Adv. Mater. Res. 2013, 627, 813–815. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Resistance to permanent deformation of road and airport high performance asphalt concrete base courses. Adv. Mater. Res. 2013, 723, 494–502. [Google Scholar] [CrossRef]

- Huang, RY.; Bird, R.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Santos, J.; Flintsch, G.; Ferreira, A. Environmental and economic assessment of pavement construction and management practices for enhancing pavement sustainability. Resour. Conserv. Recycl. 2017, 116, 15–31. [Google Scholar] [CrossRef]

- Santos, J.; Bryce, J.; Flintsch, G.; Ferreira, A. A comprehensive life cycle costs analysis of in-place recycling and conventional pavement construction and maintenance practices. Int. J. Pavement Eng. 2015, 18, 727–743. [Google Scholar] [CrossRef]

- EAPA. EAPA’s Position Paper on Long-Life Asphalt Pavements 2007. Available online: http://www.eapa.org/usr_img/position_paper/llp_technical2007.pdf (accessed on 27 April 2018).

- Santos, J. A Comprehensive Life Cycle Approach for Managing Pavement Systems. Ph.D. Thesis, University of Coimbra, Coimbra, Portugal, 2015. [Google Scholar]

- Thives, L.; Ghisi, E. Asphalt mixtures emission and energy consumption: A review. Renew. Sustain. Energy Rev. 2017, 72, 473–484. [Google Scholar] [CrossRef]

- Rosado, L.P.; Penteado, C.S.; Vitale, P.; Arena, U. Life cycle assessment of natural and mixed recycled aggregate production in Brazil. J. Clean. Prod. 2017, 151, 634–642. [Google Scholar] [CrossRef]

- Chen, X.; Wang, H. Life cycle assessment of asphalt pavement recycling for greenhouse gas emission with temporal aspect. J. Clean. Prod. 2018, 187, 148–157. [Google Scholar] [CrossRef]

- RTI International. Emission Factor Documentation for AP-42 Section 11.1 Hot Mix Asphalt Plants; Final Report Prepared for United States Environmental Protection Agency; RTI International: Research Triangle Park, NC, USA, 2004. [Google Scholar]

- Androjic, I.; Kaluder, G. Usage of solar aggregate stockpiles in the production of hot mix asphalt. Appl Therm. Eng 2016, 108, 131–139. [Google Scholar] [CrossRef]

- EPA. Optional Emissions from Commuting, Business Travel and Product Transport; USA Environmental Protection Agency: Washington, DC, USA, 2008.

- Ferreira, V.; Vilaplana, A.; García-Armingol, T.; Aranda-Usón, A.; Lausín-González, C.; López-Sabirón, A.; Ferreira, G. Evaluation of the steel slag incorporation as coarse aggregate for road construction: Technical requirements and environmental impact assessment. J. Clean. Prod. 2016, 130, 175–186. [Google Scholar] [CrossRef]

| Properties | Standards | Units | Base | Binder | Surface | |

|---|---|---|---|---|---|---|

| Fines quality | 3–10% | EN 933-9 [16] | g/kg | MBF10 | MBF10 | MBF10 |

| >10% | like filler | like filler | like filler | |||

| Flakiness index | EN 933-3 [21] | - | FI30 | FI25 | FI15&20 | |

| Crushed and broken surf. | EN 933-5 [15] | % | C100/0 | C100/0 | C100/0 | |

| Los Angeles abrasion | EN 1097-2 [18] | % | LA40 | LA35 | LA20 | |

| Res. to wear (m.-Deval) | EN 1097-1 [17] | % | MDE25 | MDE20 | MDE15 | |

| Polished Stone Value | EN 1097-8 [22] | % | - | - | PSV50 | |

| Particle density | EN 1097-6 [23] | Mg/m3 | DV | DV | DV | |

| Water absorption, WA | EN 1097-6 [23] | % | ≤2 | ≤2 | ≤1 | |

| Loose bulk density | EN 1097-3 [24] | Mg/m3 | DV | DV | DV | |

| Affinity aggr./bind. | EN 12697-11 [25] | - | DV | DV | DV | |

| Resistance to frost and thaw, MS 1 value | EN 1097-6 [23] EN 1367-2 [26] | % | If WA > 2, then MS35 | If WA > 2, then MS35 | If WA > 2, then MS35 | |

| Thermal shock resistance | EN 1367-5 [27] EN 1097-2 [18] | % | DV | DV | DV | |

| “Sonnenbrand” (SB) of basalt, LoMaB 2 | EN 1367-3 [28] EN 1097-2 [18] | % | LoMaB ≤ 1 & SBLA ≤ 8 | LoMaB ≤ 1 & SBLA ≤ 8 | LoMaB ≤ 1 & SBLA ≤ 8 | |

| Regions | Basalt | Granite | Greywacke | Diorite | Granodiorite | Limestone | Total |

|---|---|---|---|---|---|---|---|

| Lisbon | 3 | - | - | - | - | 14 | 17 |

| Santarém | 1 | - | - | - | - | 16 | 17 |

| Setúbal | - | - | 1 | 1 | - | 10 | 12 |

| Évora | - | 2 | - | - | 1 | 1 | 4 |

| Total | 4 | 2 | 1 | 1 | 1 | 41 | 50 |

| Properties | Units | Average properties | ||

|---|---|---|---|---|

| Limestone 1 | Basalt 2 | Granodiorite 3 | ||

| Flakiness index, FI | - | 13 | 14 | 5 |

| Crushed and broken surfaces | % | 100 | 100 | 100 |

| Los Angeles abrasion, LA | % | 27 | 12 | 15 |

| Resistance to wear (micro-Deval) | % | 12 | 7 | 12 |

| Particle density, ρ | Mg/m3 | 2.64 | 2.95 | 2.72 |

| Water absorption, WA | % | 1.1 | 1 | 0.9 |

| Polished Stone Value, PSV | % | - | 55 | 54 |

| Affinity aggregate/binder | - | - | - | 24 h = 70% |

| Thermal shock resistance | % | - | VLA = 2 | - |

| “Sonnenbrand” of basalt | % | - | SBLA = 2 | - |

| Material | Marshall Stability | Rutting Resistance | Stiffness | Fatigue Resistance | Resistance to Water |

|---|---|---|---|---|---|

| HMA with RAP 1 |  |  |  |  |  |

| WMA with RAP 2 |  |  |  |  |  |

Usually increases.

Usually increases.  usually decreases.

usually decreases.  may increase.

may increase.  may decrease.

may decrease.  usually unchanged. 1 Comparing with conventional HMA without RAP. 2 Comparing with a similar WMA blend without RAP. 3 Depends on the applied additives.

usually unchanged. 1 Comparing with conventional HMA without RAP. 2 Comparing with a similar WMA blend without RAP. 3 Depends on the applied additives.| Material | Marshall Stability | Rutting Resistance | Stiffness | Fatigue Resistance | Resistance to Water |

|---|---|---|---|---|---|

| HMA with RCA 1 |  |  |  |  |  |

| WMA with RCA 2 |  |  |  |  |  |

Usually increases.

Usually increases.  usually decreases.

usually decreases.  may increase.

may increase.  may decrease.

may decrease.  usually unchanged. 1 Comparing with conventional HMA. 2 Comparing with similar WMA blends without RCA.

usually unchanged. 1 Comparing with conventional HMA. 2 Comparing with similar WMA blends without RCA.| Material | Marshall Stability | Rutting Resistance | Stiffness | Fatigue Resistance | Resistance to Water |

|---|---|---|---|---|---|

| HMA with EAFS 1 |  |  |  |  |  |

| WMA with EAFS 2 |  |  |  |  |  |

Usually increases.

Usually increases.  usually decreases.

usually decreases.  may increase.

may increase.  may decrease.

may decrease.  usually unchanged. 1 Comparing with conventional HMA. 2 Comparing with similar WMA blends without EAFS.

usually unchanged. 1 Comparing with conventional HMA. 2 Comparing with similar WMA blends without EAFS.| Costs and Simple Resources | Average Unit Prices | HMA [1] | WMA [2] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nat. aggr. | Nat.+ EAFS | Nat.+ RAP | Nat.+ RCA | Nat. aggr. | Nat.+ EAFS | Nat.+ RAP | Nat.+ RCA | ||||

| Direct costs | Materials | Bitumen 35/50 | 350 €/t | 17.5 | 17.5 | 12.25 | 17.5 | 17.5 | 17.5 | 12.25 | 17.5 |

| Natural aggregates | 10 €/t | 9.5 | 5.5 | 5.65 | 5.5 | 9.48 | 5.48 | 5.63 | 5.48 | ||

| EAFS aggregates | 3 €/t | - | 1.2 | - | - | - | 1.2 | - | - | ||

| RAP aggregates | 5 €/t | - | - | 2.0 | - | - | - | 2.0 | - | ||

| RCA aggregates | 5 €/t | - | - | - | 2.0 | - | - | - | 2.0 | ||

| WMA additive | 2.500 €/t | - | - | - | - | 5.0 | 5.0 | 5.0 | 5.0 | ||

| Equipment [3] | Asphalt plant | 400 €/h | 7.0 | 8.0 | 7.0 | 7.0 | 6.0 | 7.0 | 6.0 | 6.0 | |

| Loader | 50 €/h | 0.9 | 1.0 | 0.9 | 0.9 | 0.8 | 0.9 | 0.8 | 0.8 | ||

| Lorries | 60 €/h | 4.5 | 5.3 | 4.5 | 4.5 | 3.8 | 4.5 | 3.8 | 3.8 | ||

| Paver | 80 €/h | 1.0 | 1.0 | 1.0 | 1.0 | 0.8 | 0.8 | 0.8 | 0.8 | ||

| Rollers | 40 €/h | 1.0 | 1.0 | 1.0 | 1.0 | 0.8 | 0.8 | 0.8 | 0.8 | ||

| Labour | Skilled workers | 12 €/h | 0.6 | 0.7 | 0.6 | 0.6 | 0.5 | 0.6 | 0.5 | 0.5 | |

| Unskilled workers | 7 €/h | 1.0 | 1.1 | 1.0 | 1.0 | 0.8 | 1.0 | 0.8 | 0.8 | ||

| Other costs and contingencies (10%) | 4.3 | 4.2 | 3.6 | 4.1 | 4.5 | 4.5 | 3.8 | 4.3 | |||

| Overhead (10%) | 4.7 | 4.7 | 3.9 | 4.5 | 5.0 | 4.9 | 4.2 | 4.8 | |||

| Profit (10%) | 5.2 | 5.1 | 4.3 | 5.0 | 5.5 | 5.4 | 4.6 | 5.3 | |||

| TOTALS (€ per ton. of mixture) | 57.2 | 56.3 | 47.8 | 54.6 | 60.5 | 59.6 | 51.1 | 57.8 | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinho, F.C.G.; Picado-Santos, L.G.; Capitão, S.D. Feasibility Assessment of the Use of Recycled Aggregates for Asphalt Mixtures. Sustainability 2018, 10, 1737. https://doi.org/10.3390/su10061737

Martinho FCG, Picado-Santos LG, Capitão SD. Feasibility Assessment of the Use of Recycled Aggregates for Asphalt Mixtures. Sustainability. 2018; 10(6):1737. https://doi.org/10.3390/su10061737

Chicago/Turabian StyleMartinho, F. C. G., L. G. Picado-Santos, and S. D. Capitão. 2018. "Feasibility Assessment of the Use of Recycled Aggregates for Asphalt Mixtures" Sustainability 10, no. 6: 1737. https://doi.org/10.3390/su10061737

APA StyleMartinho, F. C. G., Picado-Santos, L. G., & Capitão, S. D. (2018). Feasibility Assessment of the Use of Recycled Aggregates for Asphalt Mixtures. Sustainability, 10(6), 1737. https://doi.org/10.3390/su10061737