1. Introduction

Countries around the world were faced with varying degrees of housing shortage problems after World War II [

1]. At the moment of rapid housing re-building, short delivery time, control of building process, narrow and clear specialized job, as well as avoiding complexity were considered as the main issues of building strategy [

2], thus a large number of standardized and unified buildings were set up to meet the quantity requirement. In the mid-70s, when the number of houses surpassed the number of households, a shift occurred from focusing on quantity to quality [

3]. A large number of standardized and unified housing are facing the predicament of fixed internal layouts greatly limiting users’ abilities to reflect their own style and reconstruct their homes during different stages of housing life. Therefore, the fixed buildings face the eventuality of being demolished or destructive modification, despite the fact that their service life is far less than the design life [

4], resulting in an enormous waste of resources and a series of environmental problems [

5].

1.1. Definition of SI Housing

According to the need for flexibility and adaptability, housings have been segmented according to main building parts: load-bearing system, facade, interior walls and supply systems. That was the first transition from “closed” concrete “cast-in-site structure” where components rely on each other by mixed functions and fixed connections to “open” prefabrication through detachment and independence of different systems and components [

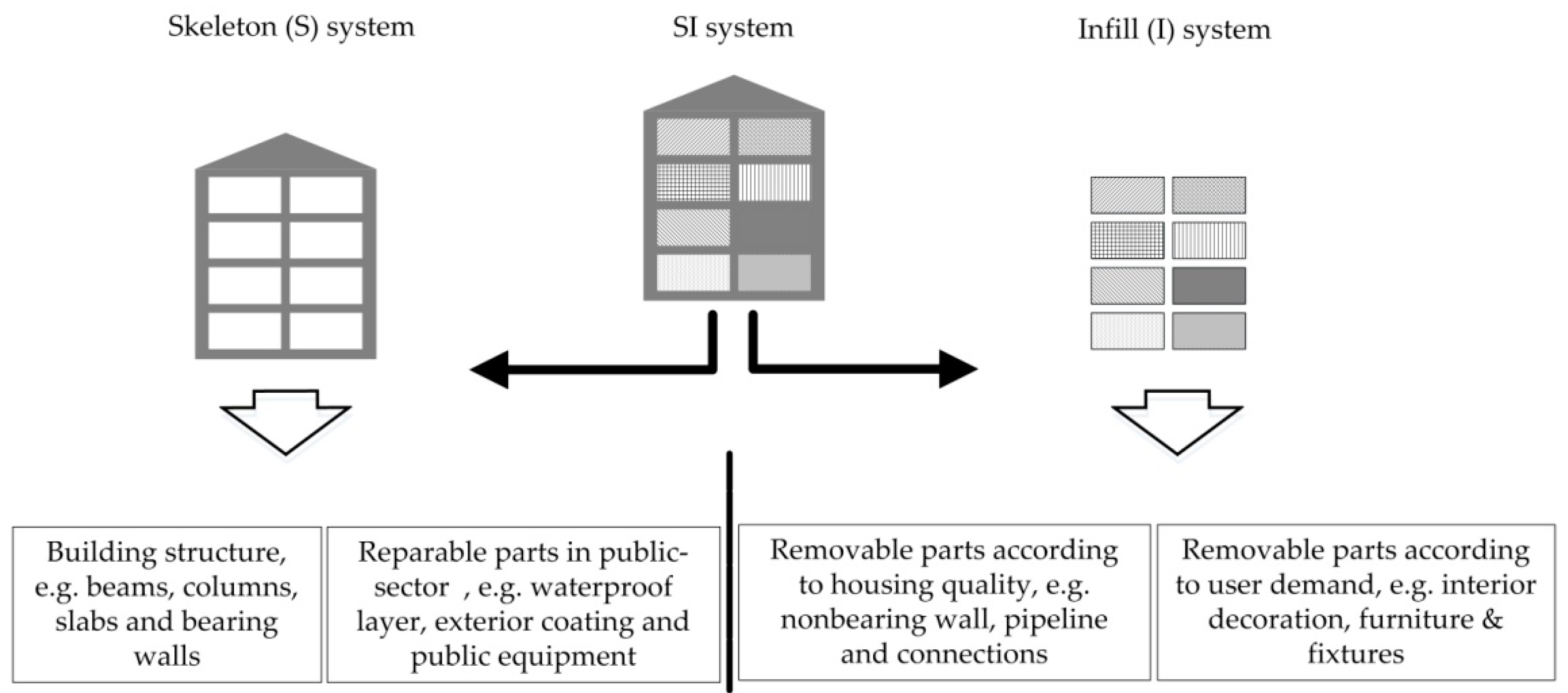

6]. In 1961, N. John Habraken originated SI housing system that consists of mutual independent Skeleton (S) system and Infill (I) system derivate from open building theory [

7]. In an SI housing system, housing structure is divided into the skeleton (S) part and infill (I) part based on the different functions and service life of the components, and connections are established between the two parts during the construction delivery process. The S part mainly contains the primary structure: beams, slabs, columns and bearing walls, and reparable parts in public sector, such as a public pipelines system, the exterior coating, and elevator equipment. The I part comprises removable parts according to housing quality: nonbearing walls and indoor pipelines, and parts used according to user demand, such as interior decorations and integrated kitchen/bathrooms [

4]. The diagrammatic sketch of SI housing system is shown in

Figure 1. The S part is fixed, while the I part could be rebuilt to satisfy updated functional demands during the service life of a SI housing, which greatly improves the variability and flexibility of building layouts. It was considered a new path for sustainably prolonging building life by improving structural durability and infill variability [

8].

The SI housing system has been extensively used in many countries to provide a building fit to current and future users in a way that allows them to carry out the diverse activities required [

9,

10]. In the Netherlands, architecture research called SAR (Stichiting Architecture Research) was funded to specialize in skeleton and infill theory, led by Habraken, which has greatly facilitated the development of the SI housing system [

11]. In 1975, Habraken worked for the department of architecture at MIT (Massachusetts Institute of Technology) and promoted the skeleton and infill theory in public housing maintenance and renovation. Hereafter, the Open House International (OHI) was founded to diffuse the skeleton and infill theory, to promote sustainable housing development in more countries [

12]. In the last decade, the SI system has been successfully disseminating into industry and become recognizable by almost all in the Japanese industry [

3] and has demonstrated advantages in both extending the housing service life through the necessary regular maintenance on skeleton parts, and meeting users’ rising demands for diversification in housing layouts through flexible functional changes in the infill parts [

13].

1.2. Dilemmas of SI Housing

With the rising demand to achieve a resource-conscious and environmentally friendly society in China, there has been an increasing interest in the sustainability of buildings [

14]. In 2006, the SI housing system was introduced in China’s building industry to help improve housing sustainability, due to its potential for promoting residential adaptability and flexibility. By learning from Japan and other countries where the SI housing system has already been widely used for years, the Chinese government developed a CSI (Chinese skeleton and infill) housing system to adapt Chinese housing needs. In support of the development of the CSI housing system, the Ministry of Housing and Urban-Rural Development of China (MOHURD) issued the CSI residential construction technical guidance document in October 2010 as a guideline to the CSI housing system at a national level [

15]. Although the advantages of the SI housing system have been proven by its successful application in some countries, its uptake in China’s building industry remains sluggish. Only a few research institutes and housing developers in China are interested in the research on the SI housing system, and most research works are confined to theoretical studies on a technology research [

16,

17,

18] and development level [

19,

20,

21]. Those studies largely demonstrate the practical technology methods and the effectiveness of SI housing in meeting users’ changeable demands within China’s housing industry. However, studies on management methods and stakeholder cooperation in the SI housing system are insufficient.

In the traditional cast-in-site construction mode in China, only developers, designers and contractors are the major players in the building construction process. Designers complete engineering drawings and blueprints according to developers’ requirements and deliver them to contractors to implement the building and realize its complex functional requirements. In this process, developers, designers and contractors perform their duties in strict accordance with their respective mandates. The collaborative process among the three major players is relatively simple. Compared to traditional housing delivery process, the application of a SI housing system involves two new characteristics: components production in factories and site construction are carried out simultaneously; the S part and the I part are constructed in parallel phases, which increase enormous parallel works. Iterations and rework would increase with the improper handling of parallel works, which lead to higher construction cost and lower participant willingness of stakeholders in SI housing construction delivery process. SI housing formation heavily relies on integration of more complicated technologies and involves more interactive procedures, including extensive planning, components customization and manufacturing, and S part and I part connections. Moreover, researchers, manufacturers and suppliers are considered as important as developers, designers and contractors for implementing an SI housing project. As the stakeholders increase, the demand for communication and coordination among different stakeholders is consequently augmented. The SI housing system encourages cooperation among different stakeholders, not only in design phase, but also in the components production and supply phase and construction and assembly phase. The SI housing system is witnessing an increasing demand for cooperation and coordination among different professions, leading to a synergy of design integration, construction processes, and supply chain management in order to fully achieve optimal results. Therefore, the traditional cooperation mode cannot be directly transferred to the SI housing construction delivery process. It is necessary to establish a new collaborative process and optimize the coupling works and iterations among the stakeholders to increase project delivery efficiency and further to take full advantage of the SI housing system.

In this research, two key points are explored: (1) defining the major cooperative work items of different stakeholders and recognizing the complex dependencies and inner logical relationships among them; (2) identifying parallel work sets to optimize the execution sequences by reducing repetition and iteration and to promote collaborative efficiency.

2. Methodology

The design structure matrix (DSM), which is also called the dependency structure matrix (DSM), has been proven to be an effective method in visualizing information transfer among works and optimizing work scheduling [

22]. In the DSM, the dependencies—including serial relationships, parallel relationships and iteration among work items in a complex project—are described using a mathematical matrix [

23]. It can play a role in improving information transfer, decreasing rework and re-engineering [

24,

25]. DSM is proven to be an effective method in illustrating dependency relationships among buildings’ product architecture. Schmidt, Deamer and Austin [

26,

27] proposed a DSM model with the capacity to compactly model a new buildings’ product architecture, hence illustrating how well a proposed design can respond to change, through the clustering of modules and observing of dependency relationships in and outside a module. Schmidt, Deamer and Austin [

28] applied DSM to identify all variant components to create a work breakdown structure and classify the components relationships. Schmidt, Vibaek and Austin [

29] verified DSM could visualize the relationships between elements within a system and reveal about the capacity for an industrialized building to accommodate change, through clustering and impact analyses. In this paper, DSM is introduced to describe and optimize the dependencies of the main cooperative work items from different stakeholders, in order to reduce iteration and rework, so as to improve the collaborative efficiency and realize optimized resource configuration during the SI housing construction delivery process.

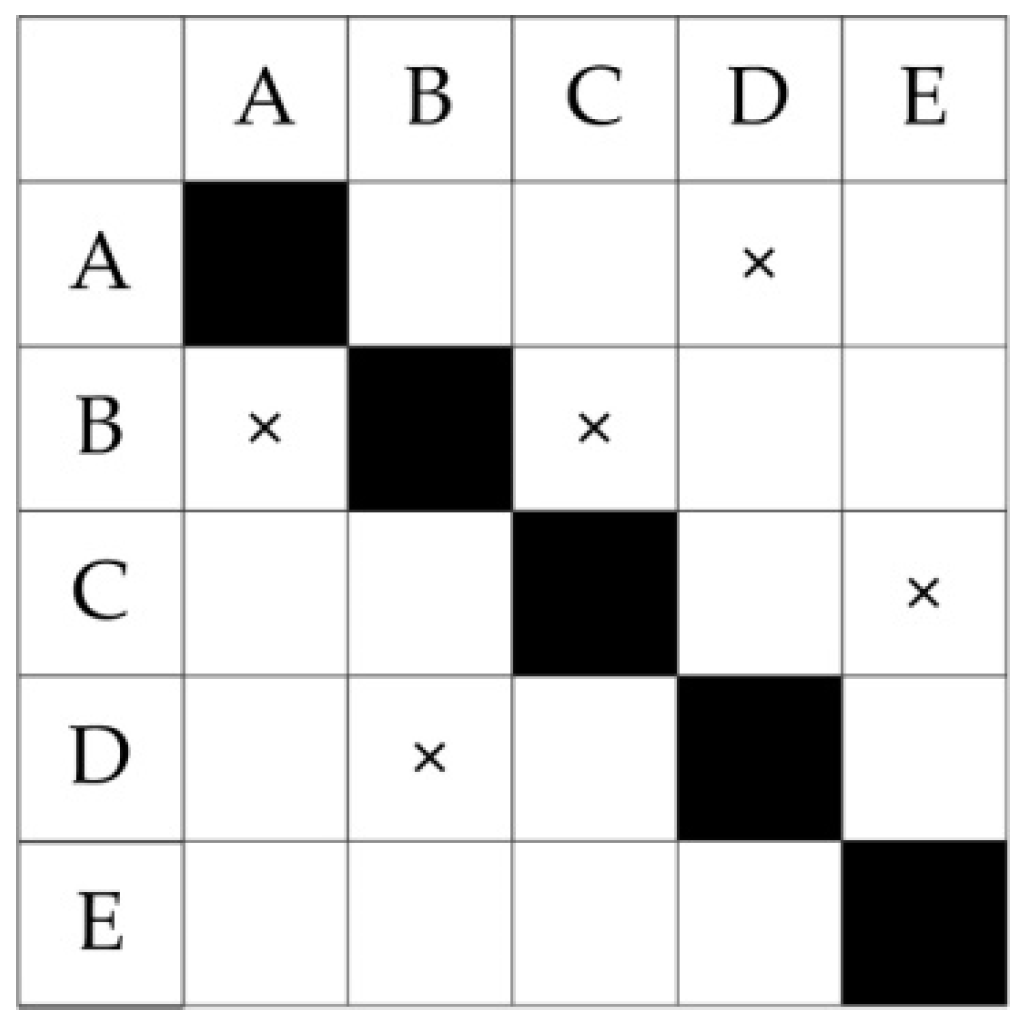

A DSM is a square matrix with identical row and column labels in which the diagonal represents the elements in row or column and the off-diagonal mark signifies the dependency of one element on another. The mark positioned in the lower left portion of the diagonal is the relationship or information provided by the element in the corresponding row to other elements in the column; the mark positioned in the upper right portion of the diagonal is the relationship or information that the element in the corresponding column depends on from other elements in the row. As illustrated in

Figure 2, Element A provides something to Element D, and depends on something from Element B. Initially, the DSM is a binary DSM, also called a Boolean DSM [

30,

31], in which the relationship or information between elements can only be represented by two values, “0” and “1”, or “×”and blank, as shown in

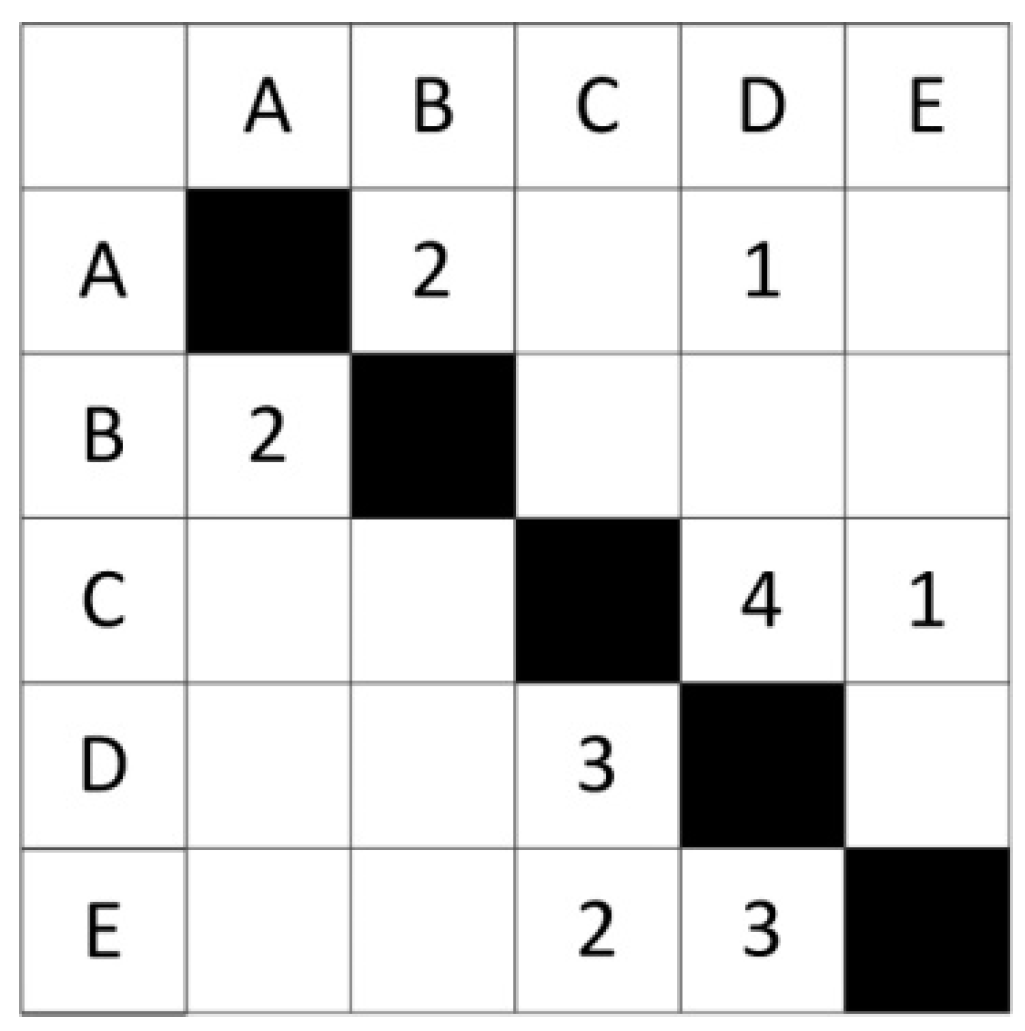

Figure 2. In a Boolean DSM, the values can only indicate whether there is dependency between elements but cannot reflect the strength of the dependency. In order to overcome such a defect in the Boolean DSM, Smith and Eppinger [

32] proposed the NDSM (numeric design structure matrix) based on the Boolean DSM and used specific digital quantification to describe the relationship or information strength of elements between rows and columns in the matrix. The schematic of the NDSM is shown in

Figure 3.

In the SI housing construction delivery process, a certain number of building components in both the S part and I part are manufactured in a factory using prefabrication technology [

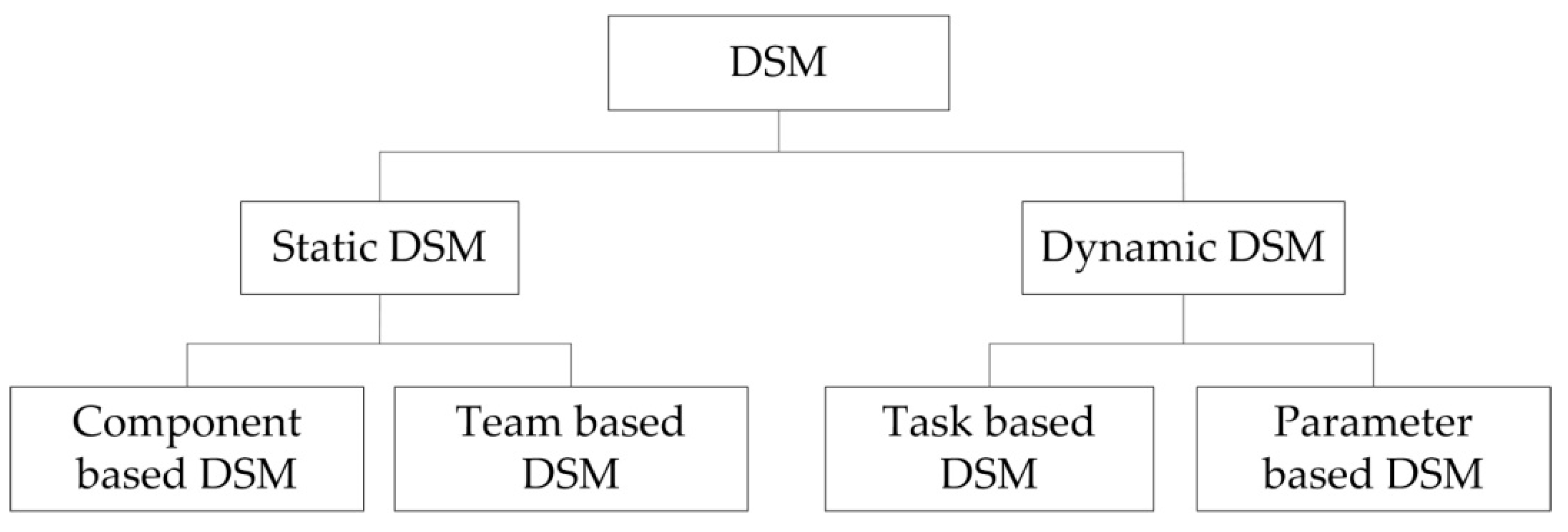

33]. This changes the working sequence from that in traditional housing construction, and brings many successor activities forward after foundation construction, resulting in increased parallel works and cross works for the SI housing construction delivery process. The increased parallel works and cross works are prone to increased rework at the risk of wasting of resources and additional cost, which brings a notable challenge to the working team of different stakeholders with different skills to for work together deliver a persuasive SI project. The DSM is introduced to find out the relationships among different works, breakdown the SI housing construction delivery process according to work categories, optimize parallel works and cross works, and finally recombine the work procedure in a more efficient way using matrix operations in order for the stakeholders to reduce conflict and improve productivity in the cooperation process, and thereby improve implementation efficiency. Browning [

22] reviewed the application of DSMs in two main categories: static DSMs and dynamic DSMs including four distinct areas: component-based DSM, team-Based DSM, task-Based DSM and parameter-Based DSM. The taxonomy of DSMs is shown in

Figure 4.

In a component-based DSM, the constituents of a system are expressed as the elements of rows and columns in the matrix, and the system is optimized by defining and studying the relationship between the sub-system and the constituents. In a team-based DSM, stakeholders of a system are considered the elements of rows and columns in the matrix, and the system is optimized by studying the relationship of information interactions among different stakeholders. In a task-based DSM, tasks of a system are regarded as the elements of rows and columns in the matrix, and the system is optimized by analyzing the relationship and information among tasks. In a parameter-based DSM, systematic parameters are considered as the elements of rows and columns in the matrix, and the system is optimized by analyzing the mutual relationship between systematic parameters.

This paper aimed to reduce the complexity and uncertainty of tasks in the SI housing construction delivery process and establish a more efficient work procedure for the stakeholders. Therefore, the task-based DSM was selected to identify the execution sequence and correlative dependence relationship between the main cooperative works, in order to decrease rework and unnecessary iterations, and thus optimize the SI housing construction delivery process.

3. Work Items and Dependency Identification in the SI Housing Construction Delivery Process

3.1. Decomposition of the SI Housing Construction Delivery Process

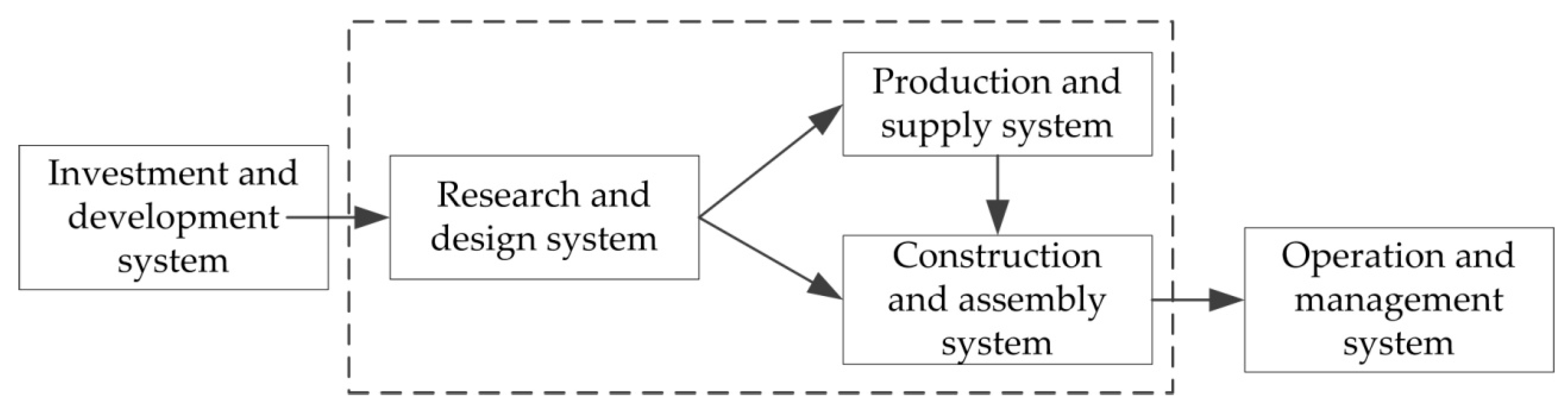

The total work of the SI housing system is divided into five sub-systems: the investment and development system, research and design system, production and supply system, construction and assembly system, and operation and management system, according to the normal process of housing and the specific features of SI housing. The five sub-systems and the relationships among them are shown in

Figure 5.

Considering that the work in the investment and development system is more partial to the enterprise of strategic decision-making, it is generally implemented only by the participant-investor, rather than specific construction works cooperated on by several stakeholders from different fields. Similarly, the works in SI housing operations and the management stage are implemented by the property management company, and other stakeholders, such as designers, contractors, and material/equipment manufacturers and suppliers rarely participate in this stage. The main purpose of this paper is to explore an optimized implementation procedure for different stakeholders to promote collaborative efficiency during the SI housing delivery process; therefore, the research scope is confined to the research and design system, production and supply system, and construction and assembly system (hereinafter referred to as the three major sub-systems).

Twenty-eight semi-structured interviews with researchers, designers, housing developers, contractors, material/equipment manufacturers, and suppliers that participate in the SI housing construction delivery process (eight with researchers, five with designers, five with developers, four with contractors, and six with manufacturers/suppliers) were conducted to develop an in-depth understanding of the three major sub-systems. Most of interviewees participated in the SI demonstration projects in Beijing and Shanghai, which are the most representative SI projects so far in China. Overall, the average work experience length related to the SI housing system of the interviewees was 2.3 years. Details are listed in

Table 1.

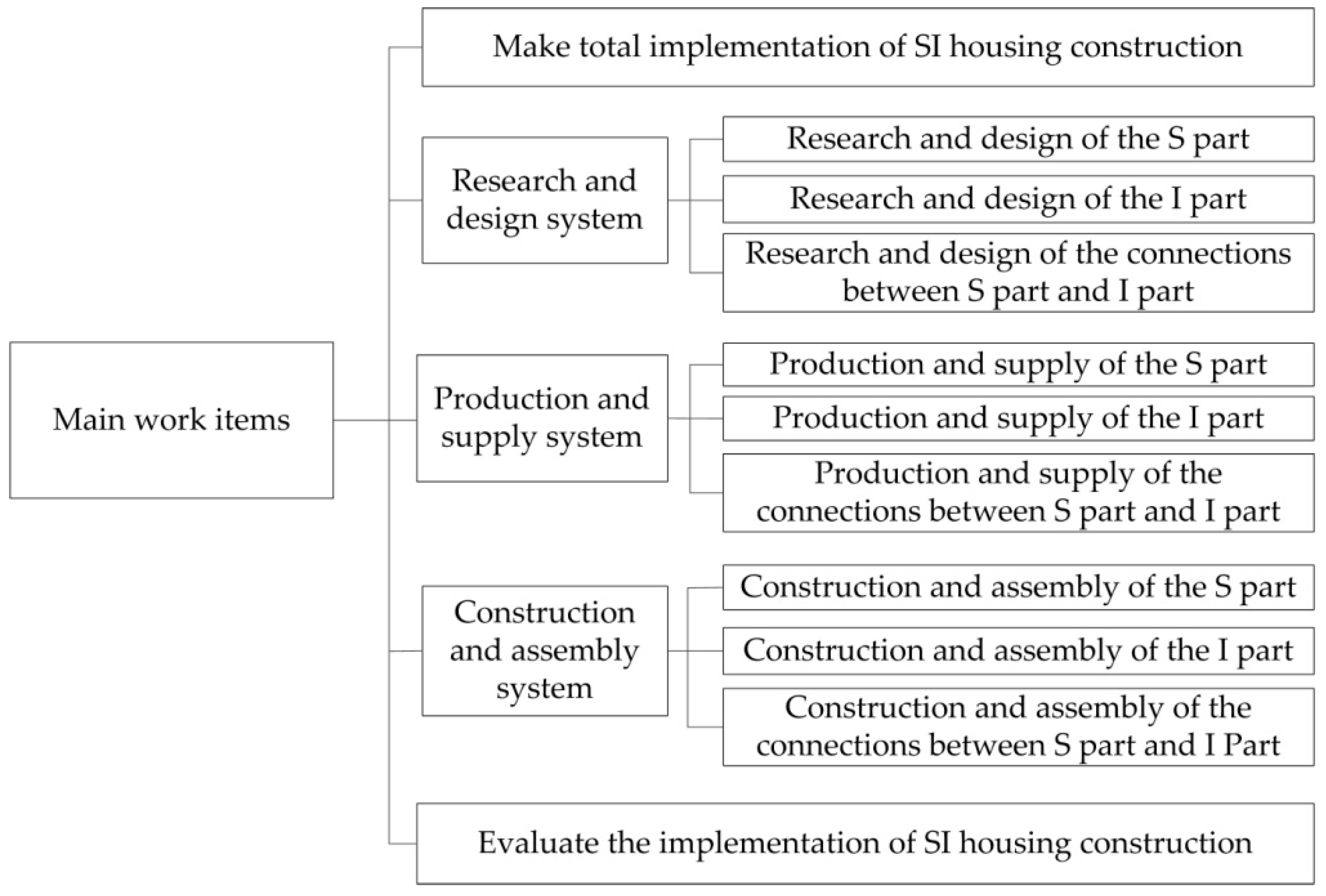

Finally, 11 main work items that cover the three major sub-systems were elicited by scrutinizing the processes through which the SI housing system was adopted and utilized in residential projects by the interviewees. The 11 main work items are shown in

Figure 6.

3.2. Identification of the Relationships Among the Main Work Items

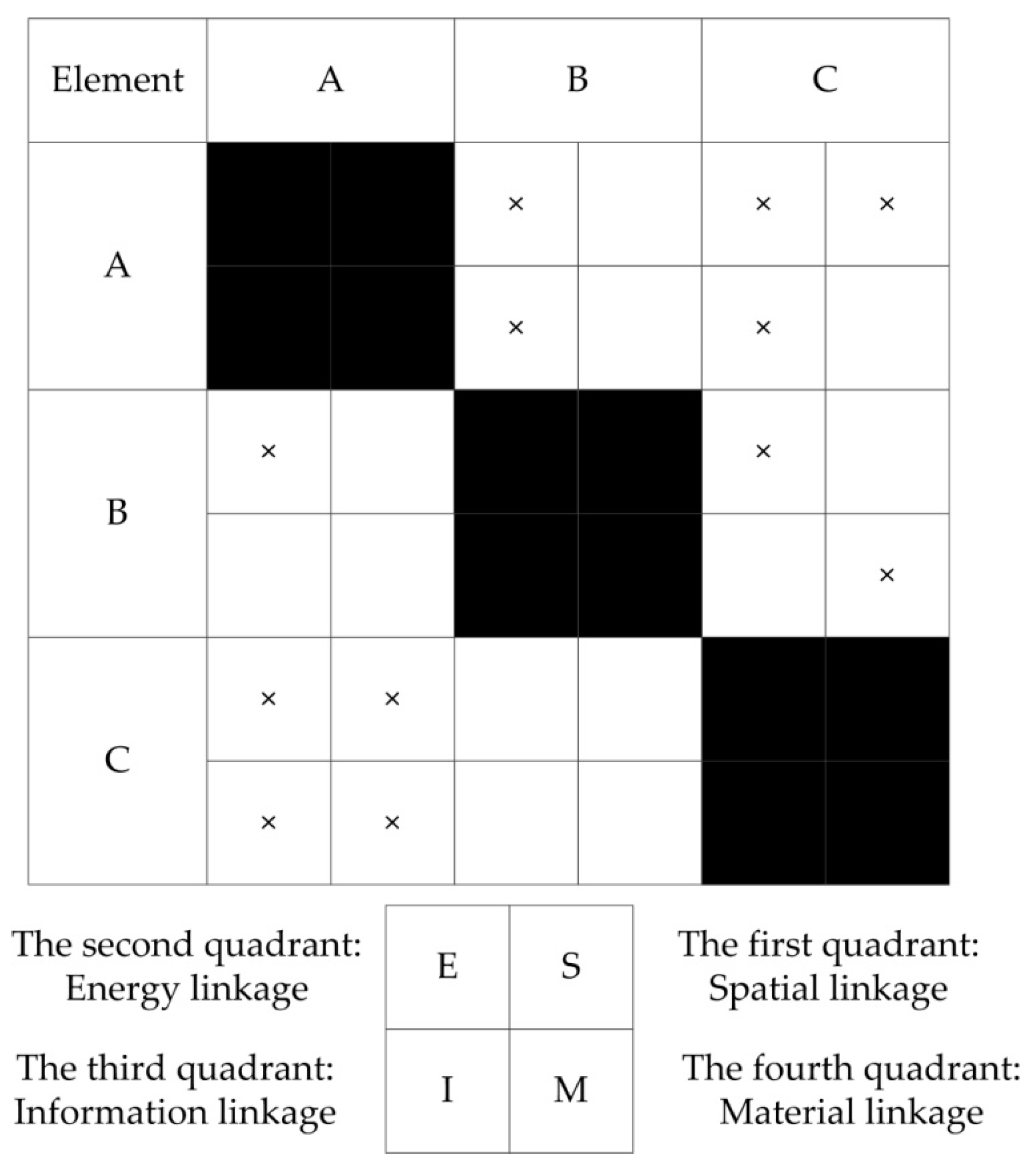

Sharman and Yassine [

34] divided the relationships of the elements between ranks and lines in the NDSM into four categories: spatial linkage, energy linkage, information linkage and material linkage.

Four quadrants were used to refer to the four linkages between elements: The first quadrant is the spatial linkage; the second quadrant is the energy linkage; the third quadrant is the information linkage, and the fourth quadrant is the material linkage, as shown in

Figure 7.

Tang, Qian and Liu [

35] used a four-point scale to express the relationship strength of corresponding linkages between elements on a scale from 0 to 3, where “3” represents “high degree of contact”, “2” represents “middle degree of contact”, “1” represents “low degree of contact”, and “0” or blankness represents “no contact”. Furthermore, a comprehensive weight method is introduced for dimensionality reduction of the four-vector matrix, as shown in Equation (1). The linkage strength in different quadrants is expressed by the product of the figure and its weight, and the sum of the products in the four quadrants represents the comprehensive relationship strength between the elements in corresponding rows and columns.

—the comprehensive relationship strength between the elements in row and column ;

—the spatial linkage strength between the elements in row and column ;

—the energy linkage strength between the elements in row and column ;

—the information linkage strength between the elements in row and column ;

—the material linkage strength between the elements in row and column ;

—the weight of spatial linkage strength in the comprehensive relationship strength;

—the weight of energy linkage strength in the comprehensive relationship strength;

—the weight of information linkage strength in the comprehensive relationship strength;

—the weight of material linkage strength in the comprehensive relationship strength.

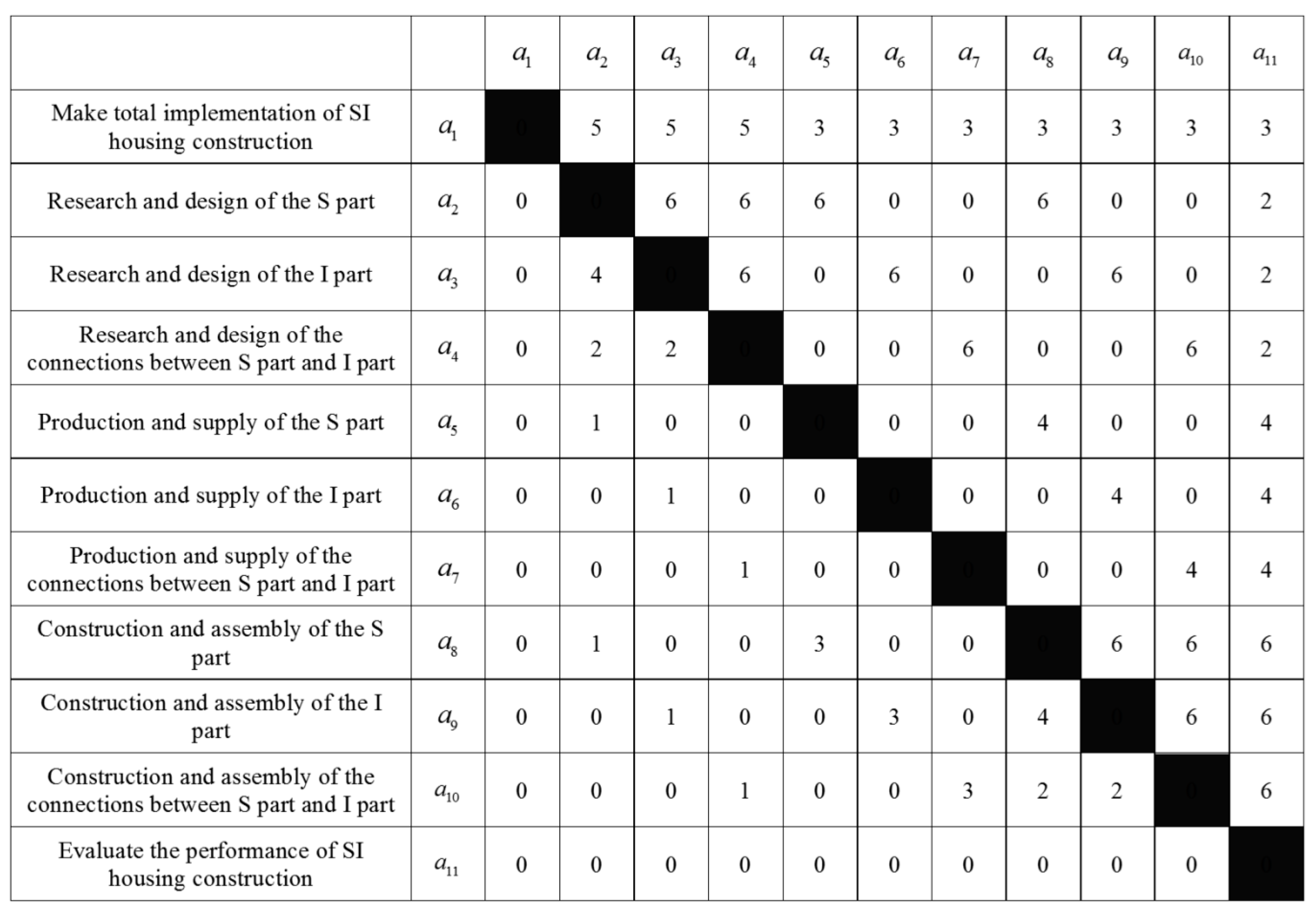

Twenty-eight semi-structured interviews with the stakeholders in

Table 1 were conducted in an attempt to understand the weight of the four linkages and the relationship strength among the main work items. The results of interviews included the following:

- (1)

The weights of the four linkages are made equally important in the initial stage of SI housing development in China: = = = = 1.

- (2)

The work item provides guidance and reference information for all subsequent work items, but subsequent work items exert no influence on , thus the row of is full of different values that represent varying degrees of linkage strength with other elements, and all the column values of are 0. The work investments, marketing positioning, and product modeling that contribute to exert a direct influence on the work items , and in the research and design system, the linkage strength values for , and are higher than the values for , , in the production and supply system, and , , in the construction and assembly system, respectively.

- (3)

The work item refers to evaluation of the implementation and performance of the whole SI housing construction delivery process, to verify whether it realizes the initial target. All previous work items exert an influence on , but exerted no influence on previous work items, thus the column of is full of different values that represent varying degrees of linkage strength with other elements, and all the row values of are 0. Considering that the work items , , in the construction and assembly system are the core steps of the whole SI housing construction delivery process and determine the final realization of SI housing, the linkage strength values with the three work items are higher than that with other items. The work items , , in the production and supply system define material and component production and manufacturing techniques, and have a superior influence on . The work items , and in the research and design system provide design guidance for SI housing construction, and exert no direct influence on , thus the linkage strength values for , and are smaller than that for other items.

- (4)

The information communication and feedback among , and realize the design of the SI housing together. However, is superior to in space from the perspective of housing functions in the S part and I part, as well as the implemented subsequence. A suitable adjustment for could be conducted in accordance with feedback from . The work items and determine the implementation of together. Simultaneously, subtle adjustments will be conducted in line with the technical level and suitable conditions of . The relationships among , , and are similar to the relationships among , and .

- (5)

From the longitudinal angle of the cooperation process, determines the implementation of and , and and interact with each other. The production and supply scheme of is adjusted in accordance with planning, schedule and site construction conditions, and construction and assembly planning of is adjusted in accordance with production schedules and supply situations of simultaneously. Moreover, conflicts and low feasibility in the implementation of and feed back to , and is modified in line with the feedback information. The relationship among , and , as well as , and , respectively, is equal to the relationships among , and .

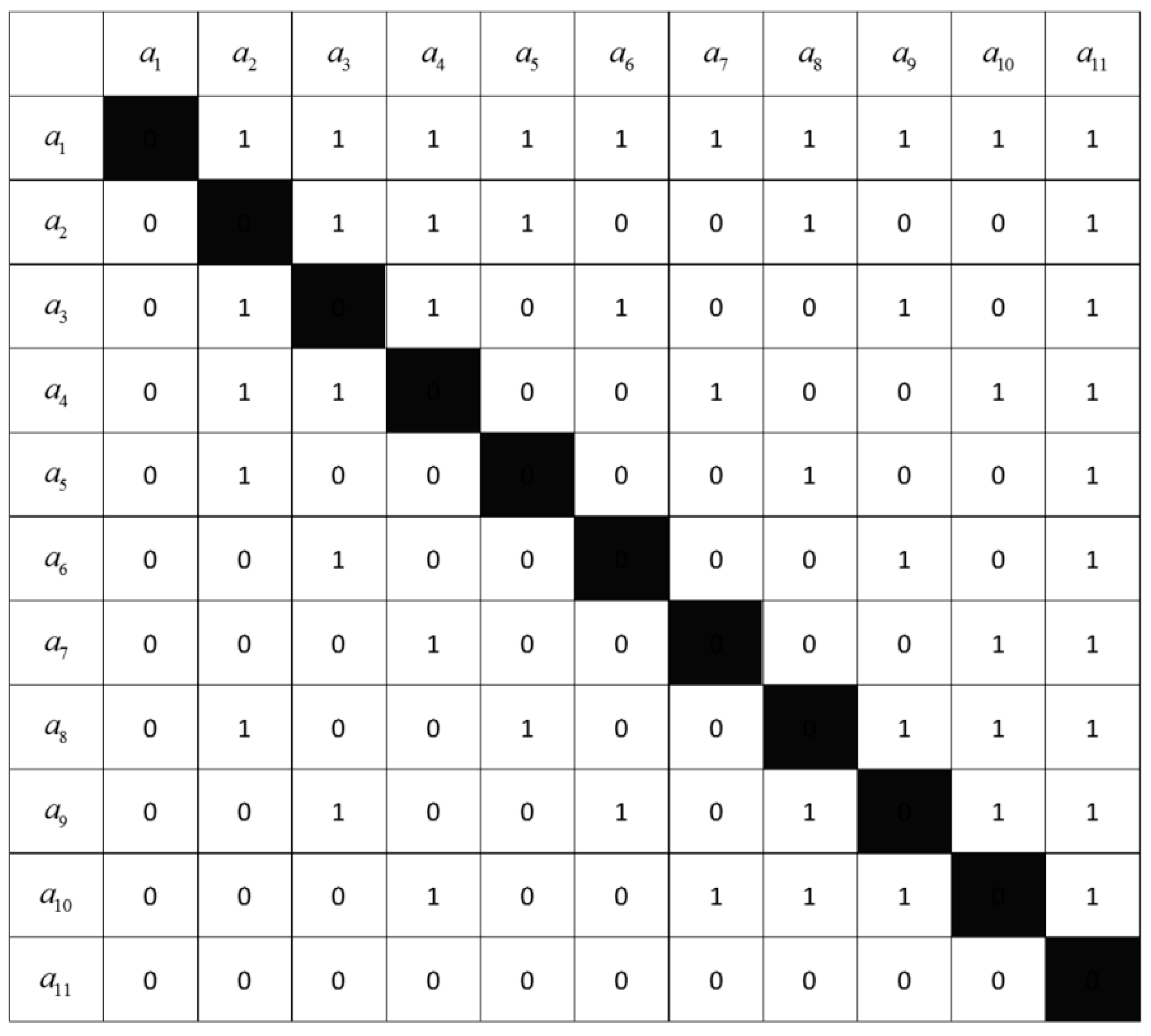

A comprehensive DSM of the main work items and the dependencies among them in the SI housing construction delivery process is established according to the results of interviews, as shown in

Figure 8.

4. SI Housing Construction Delivery Process Optimization

4.1. Optimization Methods of the DSM

Liu, Hu and Li [

36] divided the optimization methods of the DSM into three categories: optimization based on graph theory [

37,

38], optimization based on fuzzy relations [

39,

40], and optimization based on intelligent methods [

41,

42], as shown in

Table 2. There are only 11 main work items in the DSM and identification and reconstitution of parallel contact in this research is low complexity, therefore optimization based on graph theory can acquire an exact solution within a reasonable time. For this reason, optimization based on graph theory is employed for the DSM operation in this research.

The essence of parallel contact identification is the process of searching for information circuits using graph theory. The graph is the set of knots and directed arcs linking the knots. A graph in this case is an ordered couple, marked as Graph , in which:

- (1)

is a finite and nonempty set of knots, called the knots set. is a knot.

- (2)

is a set of finite edges, called the edge set. is an edge.

- (3)

Element in corresponds to the knot in .

- (4)

If there is an access from knot

to knot

, it is considered reachable between

and

. Graph

is considered a strongly connected graph when any knot is reachable by other knots in it [

43].

Assuming that there is a certain order for knot to knot in , the n-order matrix is the adjacent matrix of . The n-order matrix is the reachable matrix of , in which:

- (1)

=1, 2, …, ; =1, 2, …, ;

- (2)

If , = 1; otherwise = 0.

- (3)

If there is at least one non-zero access from to , = 1; otherwise = 0.

The relationship between matrix

and matrix

is shown in Equation (2).

where

is the n-degree power matrix of

; ∨ is the “Boolean sum”; and ∧ is the “Boolean product”. The algorithms of the “Boolean sum” and “Boolean product” are shown in

Table 3.

is the transposed matrix of the reachable matrix

. The algorithm of

is defined in Equation (3).

If knot

is reachable from knot

in a graph,

= 1; if it is reachable from

to

,

= 1. Therefore, if and only if

·

= 1, can

and

be mutually reachable. According to the rule above, if a non-zero element in row

is in column

simultaneously, knots

,

are on the same strongly connected branch, that is the sub-graph derived from {

,

} is a strongly connected component in Graph

[

44].

4.2. Optimization Result of the DSM

The major operation of process optimization is conducting concurrent engineering structure identified coupling work sets and eliminating repetition and iterations caused by an improper work execution sequence, so as to promote executive efficiency. The rules of process optimization based on the DSM are described as follows:

In the DSM, if all elements in one row are zero, it indicates that the work in this row will not output information to other works, thus it will be executed last.

In the DSM, if all elements in one column are zero, it indicates that the work in this column has no need for inputting information from other activities, thus it will be executed at the beginning.

The work items in a coupling work set mean that relationships among these works are close. Therefore, the work items in a coupling work set should operate as a single holistic work.

Work items should be divided by priority ranking first and reconstructed according to the priority ranking. The method for dividing priority ranking is described as follows:

Coupling work sets in the reachable matrix are normalized as single holistic works respectively. Matrix is the reduced matrix of matrix after reducing the dimension of matrix .

; n-dimensional column vector , ; When , = 0; When {0,1}, = 1. Therefore, the necessary and sufficient condition for work to be an m-level element is = 1.

In this research, the SI housing construction delivery process is considered as Graph . The work items in the SI housing construction delivery process are knots in , and the relationships among work items are limited edge in , thus the Boolean DSM of the SI housing construction delivery process is the adjacent matrix of . According to this rule, coupling work identification in the SI housing construction delivery process is transferred into solving strongly connected components of the graph.

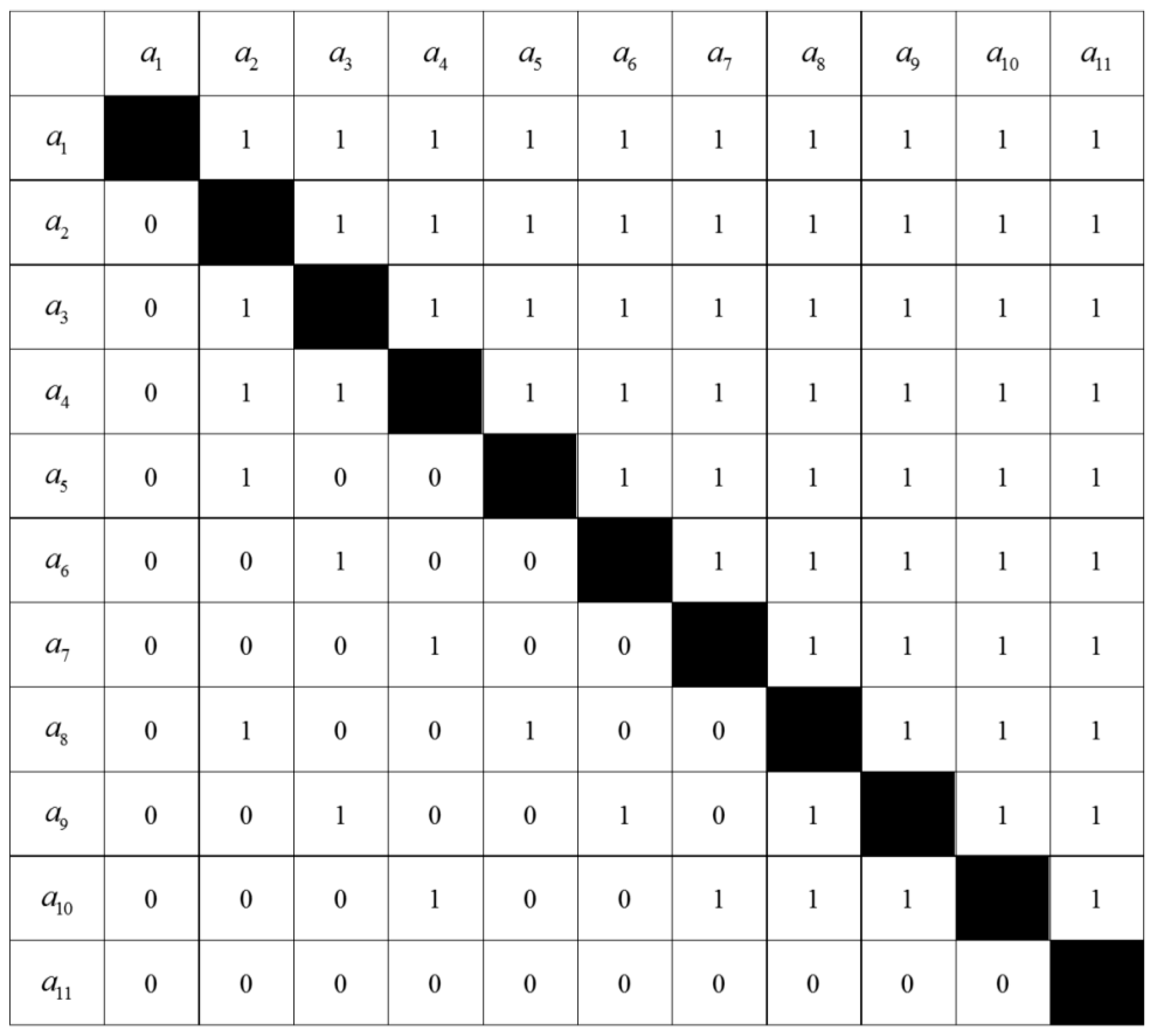

The DSM of the SI housing construction delivery process established in

Section 3 is transferred into a Boolean DSM, as shown in

Figure 9. Thus, its corresponding reachable matrix

can be obtained by the algorithm of Formula 2, as shown in

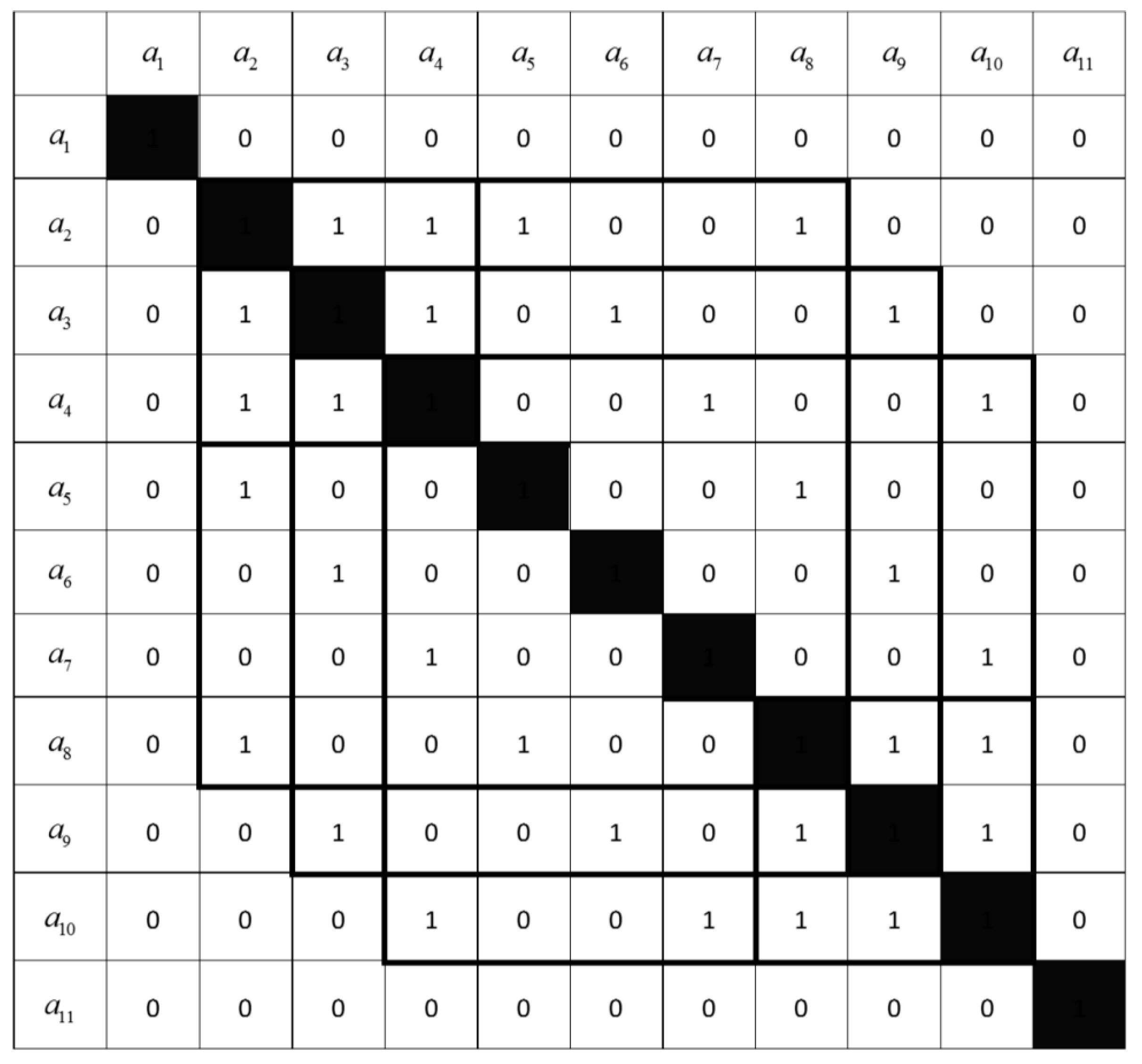

Figure 10. The operation result of

based on the algorithm of Formula 3 is show in

Figure 11.

According to the results of

in

Figure 11 and the algorithm of coupling work identification in

Section 4.1, five parallel work sets of the SI housing construction delivery process are obtained, including {

,

,

}, {

,

,

}, {

,

,

}, {

,

,

} and {

,

}. Every coupling work set is marked with a bold wireframe in

Figure 11. The method confirmed in

Section 4.1 is applied to optimize the SI housing construction delivery process. The work items

,

,

in the research and design system and

,

,

in the construction and assembly system belong to two coupling work sets, respectively. In the SI housing construction delivery process, the research and design system is prior to the construction and assembly system in the implementation sequence. Therefore,

,

,

and

,

,

are normalized as a whole entirety during the parallel work sets normalizing operation. Finally, the reduced matrix

of

is calculated and shown in Equation (4).

The method confirmed in

Section 4.1 is applied to identify the work execution sequence. The operation process is shown in follows:

According to the work execution sequence above, as well as the dependencies among work items in practical projects, {, , }, {, , } and {, , } are also considered new coupling work sets, which provides a guide for stakeholders to make intensive management program and appropriate cooperation strategies to reduce repetition and iteration in the implement of these parallel work sets.

5. Discussion

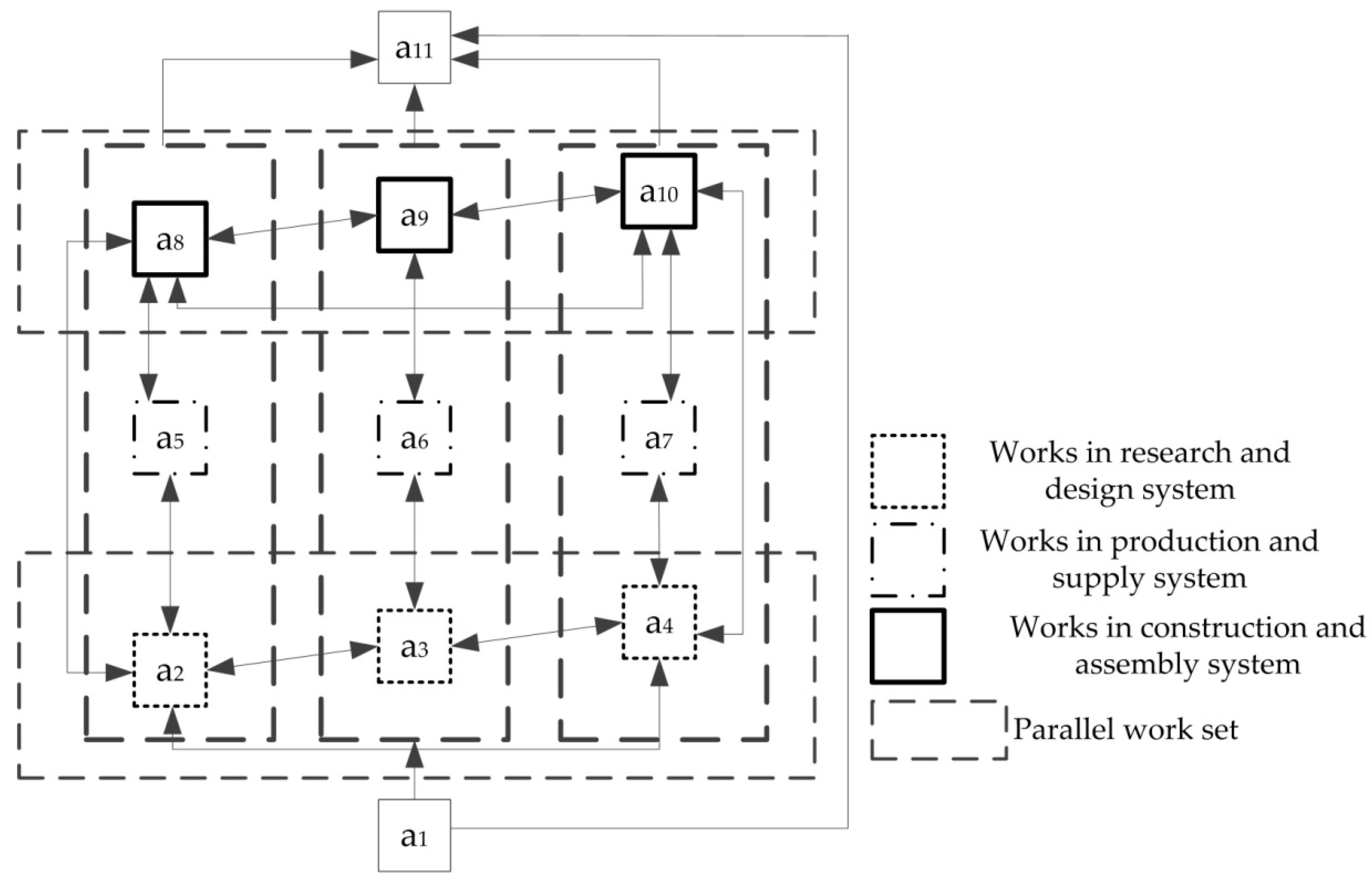

An optimized SI housing construction delivery process is established in

Figure 12 according to the optimization result. From the optimization model in

Figure 12, three significant changes in the SI housing construction delivery process compared to the cast-in-site housing construction delivery process can be seen. The changes are analyzed as follows:

The housing design work of cast-in-site housing construction is divided according to specialties, such as building design, structural design, water and electricity supply design, and equipment design. However, that of the SI housing construction delivery process is divided according to different parts, including design of the S part, design of the I part, and design of the connections between the S part and I part. Designers with different specialties participate in each part of the design, which increases the communication and cooperation between designers. Meanwhile, the traditional serial design mode of building design → structural design → water and electricity supply design → equipment design is changed into the concurrent design mode in SI housing, in which the S part and I part can be designed simultaneously by the collaboration of designers with different specialties, significantly promoting design efficiency. In addition, the S part, I part and connections between them could be produced independently without disturbing each other, which reduces the waiting time between different works and improves production efficiency and supply efficiency.

In the traditional serial construction mode, works in different specialties are implemented in a rigorous precedence order of main structure construction → secondary structure construction → refined decoration construction, with water and electricity supply construction and equipment construction inserted within this chain. Contractors with different specialties seldom collaborate together. Contractors in pre-works generally ignore their influence on follow-up works. When the follow-up workers encounter problems inhibiting their works arising from the pre-works, they have to do some repair or even rework on the pre-works, which is hugely wasteful because the pre-workers have possibly already left the construction site when their work finished and could not communicate with the follow-up workers in the parallel construction mode. In the SI housing construction delivery process, different parts of the housing are constructed and assembled in a parallel mode. Constructors for the S part, I part and connections between them create an integrated construction and assembly by planning together in a way that adequately considers the works in every part before starting. During the construction and assembly process, workers for different parts communicate with each other and solve the problems together whenever necessary. The parallel mode could reduce waste caused by conflicts and rework, and improve constructive efficiency.

In the traditional housing construction delivery process, when constructors encounter unreasonable or inconvenient works caused by design problems, they feed back the information to the designers in the corresponding specialty. However, design work that is divided into different specialties increases difficulties for communication. When the unreasonable or inconvenient works are in the cross-specialty, it is especially possible for different designers to pass the buck, which could increase communication costs and cause delays in the construction schedule. In SI housing, design work, production work and construction work are divided into the S part, I part, and connections between them, and workers with different specialties participate in each part, which increases the communication and cooperation between designers, producers and contractors. Therefore, problems caused by design in the production and supply process or in the construction and assembly process could be fed back to designers in a timely manner to acquire accurate corrections and adjustments, which not only ensures the smoothness of the current project, but also provides reference and guidance for the design of new SI housing projects.

6. Conclusions

SI housing has brought about a great deal of cooperative works among different stakeholders during the whole construction delivery process. Therefore, the traditional serial cooperation mode cannot be directly transferred to the SI housing construction. It is necessary to establish a new collaborative process to optimize the coupling works and iterations among the stakeholders in order to take full advantage of the SI housing system compared to the traditional housing construction.

A comprehensive DSM was established to measure the strength of the logical relationships among the main cooperation works, which provides a basis for the optimization of the SI housing construction delivery process. Furthermore, graph theory was applied to identify coupling work sets and eliminate repetition and iterations, so as to provide an optimized parallel construction delivery process for SI housing.

According to the results obtained from the optimized SI housing construction delivery process, the optimized parallel construction delivery process plays a significant role in promoting design efficiency. The design work of SI housing is divided into three functional parts: the S part, I part and connections between them. The S part and I part can be designed simultaneously by the collaboration of designers with different specialties, which increases the communication and cooperation between stakeholders. In addition, the S part, I part and connections between them could be produced independently without disturbing each other, which reduces the waiting time between different works and improves production efficiency and supply efficiency. Moreover, the parallel cooperation mode provides immediate feedback of design defects from the product process or assembly process to designers in order to acquire accurate correction and adjustment, which could promote efficiency in the whole construction delivery process, reduce time, and save construction costs.

There are some limitations in this paper: (1) SI housing construction delivery process was divided into three major sub-systems and only eleven main cooperative work items affiliated to the three major sub-systems, which could not cover all the cooperative works and their complex inner logic relationships in different delivery levels among all the stakeholders. (2) Graph theory which is generally applied to small or medium-sized project was employed for the DSM, therefore the significant characteristic of SI housing- adaptability analysis was not fully demonstrated in this research. As a consequence, the parallel cooperation model in this study only provides a reference for stakeholders in the macroscopic aspects. Therefore, additional research must be conducted to identify the cooperative works at a more specific level, and provide a more effective cooperative construction sequence. Future research will continue to focus on:

- (1)

Constructing a comprehensive DSM that covers the components and their complex inner logic relationships in different layers considering for system design, service life, adaptability and stakeholders in line with the characteristics of SI housing.

- (2)

Upgrading the DSM optimization based on intelligent methods to provide greater clarity of components organization and to optimize the parallel works and cross works in a more efficient way.

- (3)

Exploring the underlying cause as well as the transmission mechanism of iterations to predict rework risk and minimize building delivery duration and construction cost.

Author Contributions

Data curation, Y.Y.; Formal analysis, X.C.; Investigation, Y.Y. and X.Y.; Methodology, X.C.; Project administration, X.L.; Resources, X.C.; Software, X.C.; Supervision, X.L.; Writing–original draft, X.C.; Writing–review & editing, X.L.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 51868016.

Acknowledgments

The authors also would like to thank Miss Xiaoshu Lu in Southeast University for her assistance in date collection and Miss Mingfang Yang in Dalian University of Technology for her assistance in figure processing.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nikolic, J. Building “with the systems” vs. building “in the system” of IMS open technology of prefabricated construction: Challenges for new “infill” industry for massive housing retrofitting. Energies 2018, 11, 1128. [Google Scholar] [CrossRef]

- Jovanovic, J.; Grbic, J.; Petrovic, D. Prefabricated Construction in Former Yugoslavia. Visual and Aesthetic Features and Technology of Prefabrication. In Proceedings of the Post War Modern Architecture in Europe, Berlin, Germany, 22–24 July 2011. [Google Scholar]

- Schmidt, R., III; Eguchi, T.; Austin, S. Lessons from Japan: A look at century housing system. In Proceedings of the 12th International Dependency and Structure Modelling Conference, DSM’10, Cambridge, UK, 22–23 July 2010; pp. 361–373. [Google Scholar]

- Cao, X.; Li, Z.; Liu, S. Study on factors that inhibit the promotion of SI housing system in China. Energy Build. 2014, 88, 384–394. [Google Scholar] [CrossRef]

- Paduart, A.; Debacker, W.; Henrotay, C.; Temmerman, N.D.; Wilde, W.P.; Hendtrickx, H. Transforming cities: Introducing adaptability in existing residential buildings through reuse and disassembly strategies for retrofitting. Lifecycle Des. Build. Syst. Mater. 2009, 18–23. [Google Scholar]

- Nikolic, J. New challenging approach for analysis and upgrading of massive building structure: Case study of New Belgrade post-war mega blocks. In CESB 2013 Prague—Central Europe towards Sustainable Building 2013: Sustainable Building and Refurbishment for Next Generations; Grada for Faculty of Civil Engineering; Czech Technical University in Prague: Prague, Czech Republic, 2013; pp. 1–10. [Google Scholar]

- Slaughter, E.S. Design strategies to increase building flexibility. Build. Res. Inf. 2001, 29, 208. [Google Scholar] [CrossRef]

- Rahim, A.A.; Hamid, Z.A.; Zen, I.H.; Ismail, Z.; Kamar, K.A.M. Adaptable housing of precast panel system in Malaysia. Procedia-Soc. Behav. Sci. 2012, 50, 369–382. [Google Scholar] [CrossRef]

- Li, Y.; Xue, D.; Gu, P. Design for product adaptability. Concurr. Eng. 2008, 16, 220. [Google Scholar] [CrossRef]

- Nikolic, J. Industrialized housing transformation capacity: Case study of post-war massive housing in Beograd. In CESB2016 Prague—Central Europe Towards Sustainable Building 2016: Innovation for Sustainable Future; Czeech Technical University in Prague: Prague, Czech Republic, 2016; pp. 229–236. [Google Scholar]

- Hao, F.; Fan, Y.; Qin, P.; Cheng, L. Green building concept of SI housing system in Japan. Housing Ind. 2008. Available online: http://kns.cnki.net/kns/detail/detail.aspx?FileName=ZZCY2008Z1036&DbName=CJFQ2008 (accessed on 20 March 2008).

- Fan, Y.; Cheng, Y. Past and present of sustainable open-house. Architect 2008, 6, 90–94. [Google Scholar]

- Fukao, S. The history of developments toward open building in Japan. New Archit. 2011, 6, 14–17. [Google Scholar] [CrossRef]

- Cao, X.; Li, X.; Zhu, Y.; Zhang, Z. A comparative study of environmental performance between prefabricated and traditional residential buildings in China. J. Clean. Prod. 2015, 109, 131–143. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of China (MOHURD). The Technical Guideline for Construction of China-Skeleton-Infill Housing; China Architecture & Building Press: Beijing, China, 2010; ISBN 1511217938.

- Li, Z.; Han, X. Study on interface types and interface methods of the SI system. J. Eng. Manag. 2017, 31, 87–91. [Google Scholar] [CrossRef]

- Shao, Y.; Zhao, S. Study on SI separation system of multi-story residential buildings in cities in northeast China. J. Hum. Settl. West China 2018, 6–13. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, L.; Yang, Y. Built-in industrialization evaluation of SI-system housing based on improved F-AHP. Constr. Econ. 2018, 102–107. [Google Scholar] [CrossRef]

- Qin, S.; Jiang, H.; Wang, S. Public housing practice based on SI housing sustainable building theory in Japan. Constr. Technol. 2014, 20, 62–66. [Google Scholar] [CrossRef]

- Xie, X.; Liu, H. Customized design strategy for SI residence with internet thinking—Thoughts inspired from the development of a century residential demonstration project. Hous. Sci. 2018, 6, 33–37. [Google Scholar] [CrossRef]

- Yuan, M.; Li, Z.; Li, L. SI system housing virtual enterprise partners selection based on vector angle cosine. J. Civ. Eng. Manag. 2018, 35, 117–122. [Google Scholar] [CrossRef]

- Browning, T.R. Applying the design structure matrix to system decomposition and integration problems: A review and new directions. IEEE Trans. Eng. Manag. 2001, 48, 292–306. [Google Scholar] [CrossRef]

- Unger, D.; Eppinger, S. Improving product development process design: A method for managing information flows, risks, and iterations. J. Eng. Des. 2011, 22, 689–699. [Google Scholar] [CrossRef]

- Danilovic, M.; Sandkull, B. The use of dependence structure matrix and domain mapping matrix in managing uncertainty in multiple project situations. Int. J. Project Manag. 2005, 23, 193–203. [Google Scholar] [CrossRef]

- Danilovic, M.; Browning, T.R. Managing complex product development projects with design structure matrices and domain mapping matrices. Int. J. Project Manag. 2007, 25, 300–314. [Google Scholar] [CrossRef]

- Schmidt, R.I.; Deamer, J.; Austin, S. Understanding Adaptability Through Layer Dependencies; Design Society: Leicestershire, UK, 2011; pp. 1–12. [Google Scholar]

- Schmidt, R., III; Eguchi, T.; Austin, S.; Gibb, A. What Is the Meaning of Adaptability in the Building Industry? In Open and Sustainable Building; Labein-TECNALIA: Derio, Spain, 2010; pp. 233–242. [Google Scholar]

- Robert, S., III; Jason, D.; Simon, A. Understanding adaptability through layer dependencies. In Proceedings of the International Conference on Engineering Design, ICED11, Lyngby, Denmark, 15–18 August 2011., 15–18 August 2011. [Google Scholar]

- Robert, S., III; Kasper, S.V.; Simon, A. Evaluating the adaptability of an industrialized building using dependency structure matrices. Constr. Manag. Econ. 2014, 32, 160–182. [Google Scholar] [CrossRef]

- Smith, R.P.; Eppinger, S.D. A predictive model of sequential iteration in engineering design. Manag. Sci. 1997, 43, 1104–1120. [Google Scholar] [CrossRef]

- Smith, R.P.; Eppinger, S.D. Identifying controlling features of engineering design iteration. Manag. Sci. 1997, 43, 276–293. [Google Scholar] [CrossRef]

- Smith, R.P.; Eppinger, S.D. Deciding between sequential and concurrent tasks in engineering design. Concurr. Eng. Res. Appl. 1998, 6, 15–25. [Google Scholar] [CrossRef]

- Zhang, X.; Skitmore, M.; Peng, Y. Exploring the challenges to industrialized residential building in China. Habitat Int. 2014, 41, 176–184. [Google Scholar] [CrossRef]

- Sharman, D.M.; Yassine, A.A. Characterizing complex product architectures. Syst. Eng. 2004, 7, 35–60. [Google Scholar] [CrossRef]

- Tang, D.; Qian, X.; Liu, J. Product Design and Development Based on Design Structure Matrix; Science Press: Beijing, China, 2009; ISBN 9787030228291. [Google Scholar]

- Liu, L.; Hu, D.; Li, B. Survey of optimal algorithm of design process model based on DSM. Comput. Eng. Appl. 2009, 45, 22–25. [Google Scholar] [CrossRef]

- Gebala, D.A.; Eppinger, S.D. Methods for analyzing design procedures. In Proceedings of the International Conference on Design Theory & Methodology, Scottsdale, Arizona, 13–16 September 1991. [Google Scholar]

- Wang, Y.; Xing, Y.; Ruan, X. Information modeling and re-engineering for Design Process. Comput. Integr. Manuf. Syst. 2002, 8, 111–114. [Google Scholar] [CrossRef]

- Yassine, A. Engineering design management: An information structure approach[C]// Innovation in Technology Management-the Key to Global Leadership Picmet 97. In Proceedings of the Portland International Conference on Management & Technology, Portland, OR, USA, 31–31 July 1999. [Google Scholar] [CrossRef]

- Whitfield, R.I.; Duffy, A.H.B.; Gartzia-Etxabe, L.K. Identifying and evaluating parallel design activities using the design structure matrix. In Proceedings of the 15th International Conference on Engineering Design (ICED’05), Melbourne, Australia, 15–18 August 2005. [Google Scholar]

- Yao, Y. Product development process intelligent analysis and improvement technology in PDM. China Mech. Eng. 2004, 15, 1857–1861. [Google Scholar] [CrossRef]

- Abdelsalam, H.M.E.; Bao, H.P. A simulation-based optimization framework for product development cycle time reduction. Eng. Manag. IEEE Trans. 2006, 53, 69–85. [Google Scholar] [CrossRef]

- Mcculley, C.; Bloebaum, C.L. A genetic tool for optimal design sequencing in complex engineering systems. Struct. Multidiscip. Optim. 1996, 12, 186–201. [Google Scholar] [CrossRef]

- Kenneth, H.R. Discrete Mathematics and Its Applications; China Machine Press: Beijing, China, 2015; ISBN 9787111453826. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).