Apple Cubes Drying and Rehydration. Multiobjective Optimization of the Processes

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Drying Process

2.3. Rehydration Process

2.4. Mass and Volume Measurements

2.5. Color Determination

2.6. Quality Parameters

- Water absorption capacity index (WAC) calculated from the formula [45]:where, M—the mass (g), s—the dry matter content, and subscripts 0, d, and r refer to before drying, dry, and rehydrated, respectively. Discussed index WAC gives information on the ability of the material to absorb water.

- The volume ratio (VR) is formulated aswhere, Vd—volume of dried apple cube (after drying) and Vr—volume after rehydration in m3.

- Color difference (CD) between the fresh and rehydrated samples determined as [46]where: SL, SC, and SH are the weight functions adjusting internal non-uniform structure of CIELab and , , and whereas KL, KC, and KH (equal to 1) describe the variation from the reference conditions, and describe the difference between tested (T) and standard (S) samples in hue, luminance, and chroma, respectively. , and

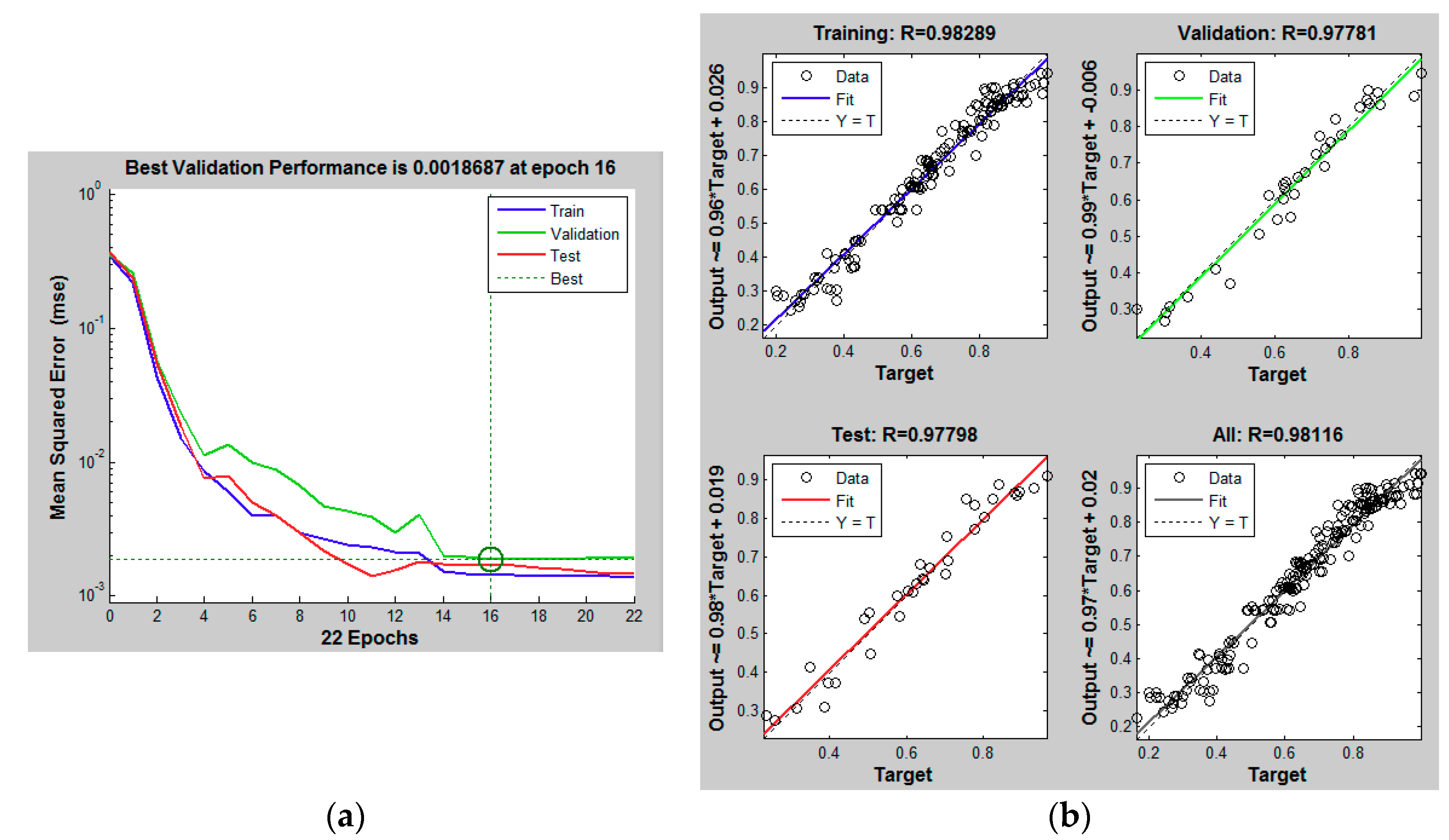

2.7. Quality Parameters Modeling Using ANN

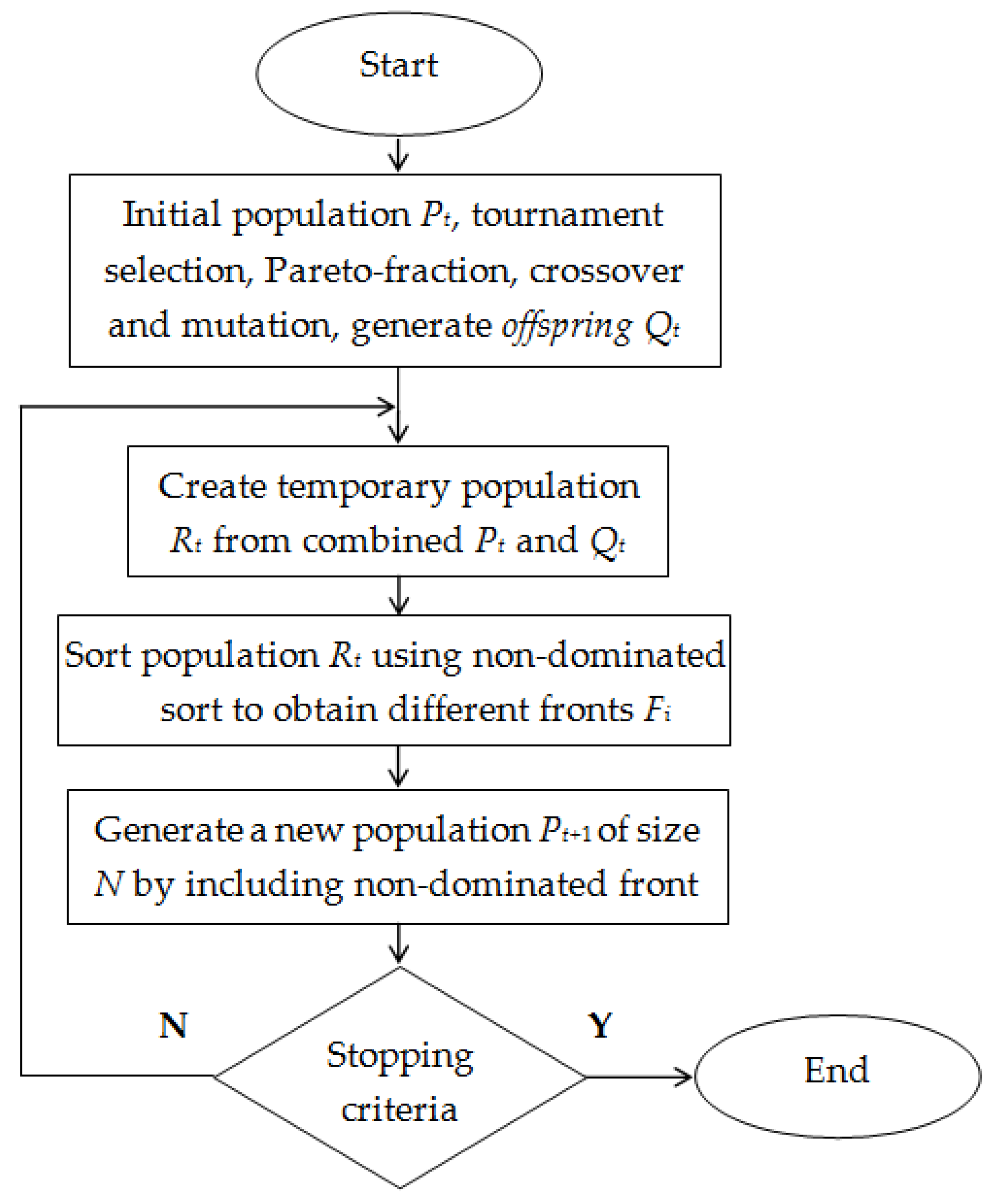

2.8. Multiobjective Optimization (MOO) Problem

3. Results and Discussion

3.1. ANN

3.2. Mathematical Formulations

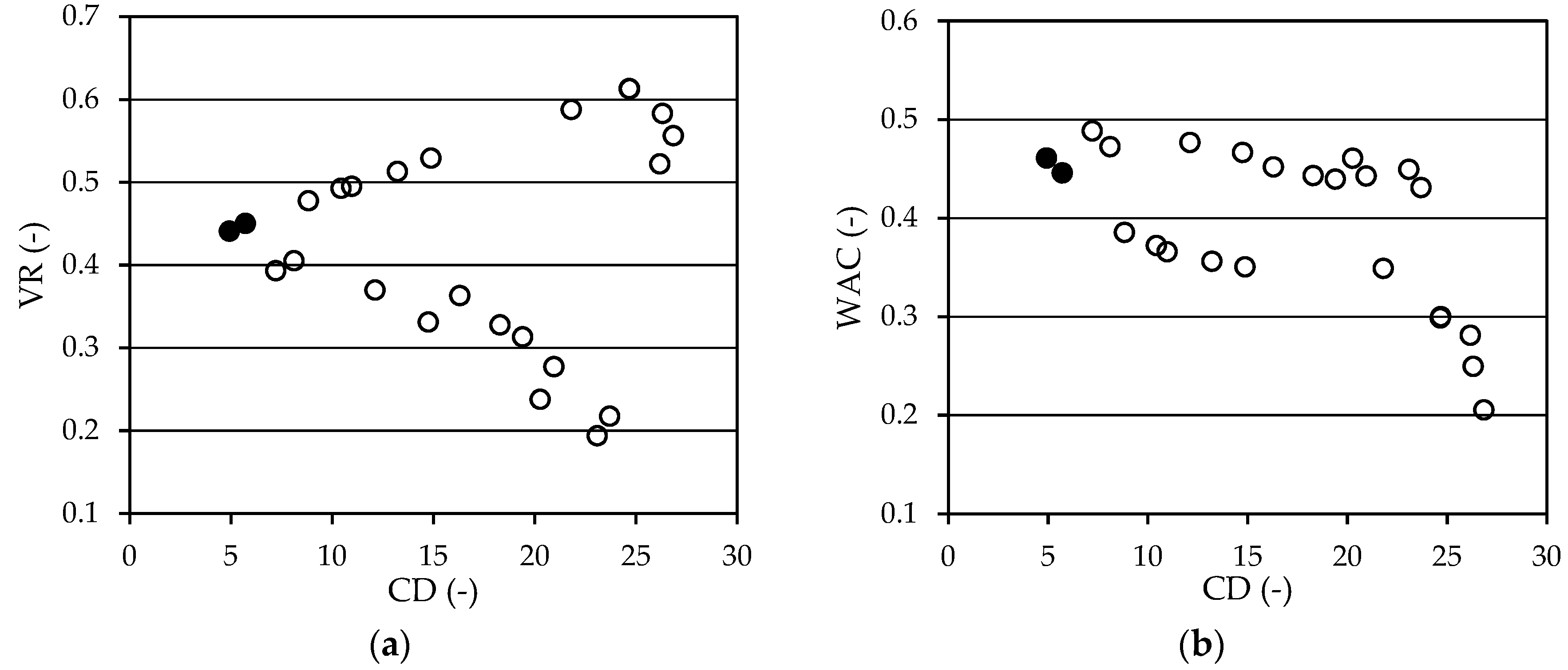

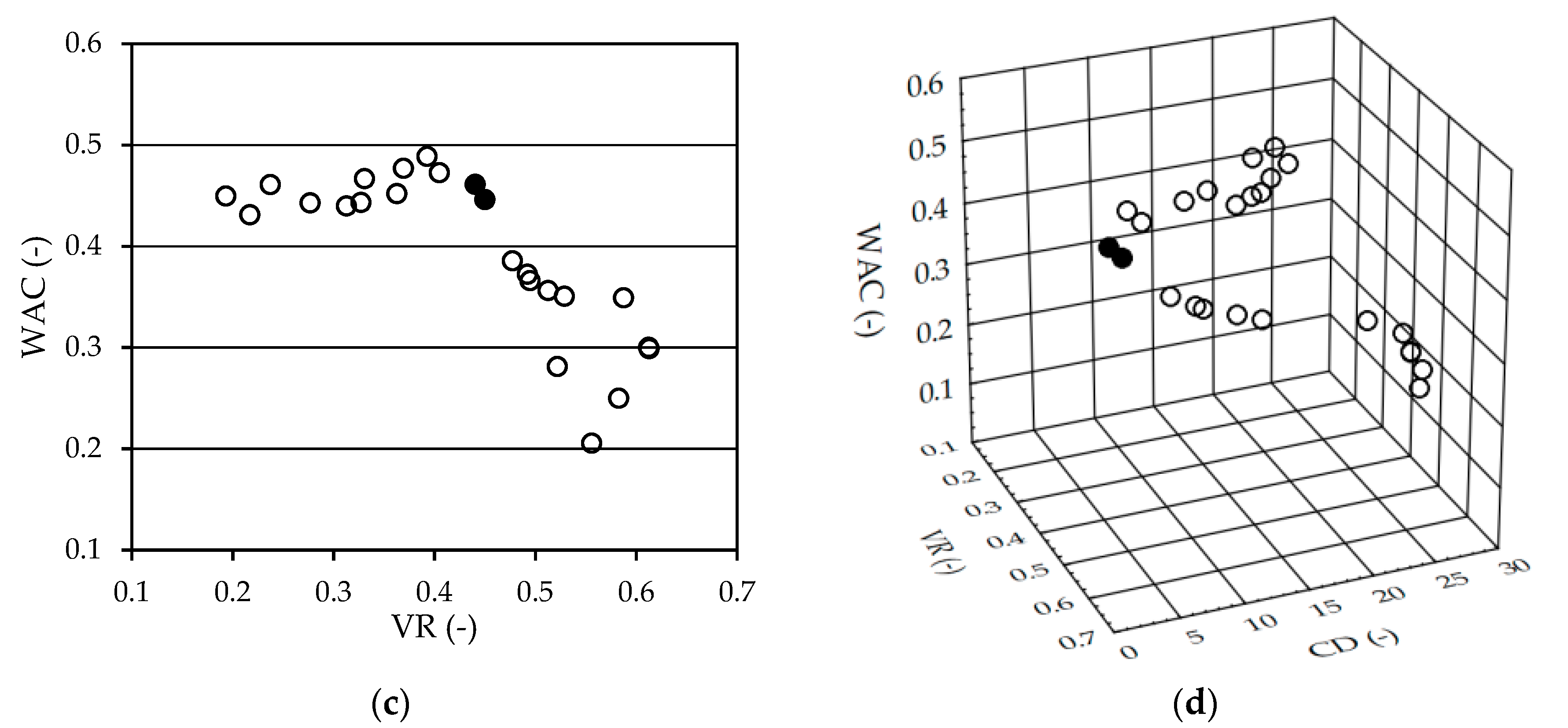

3.3. MOO

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dincer, I.; Dost, S. A modelling study for moisture diffusivities and moisture transfer coefficients in drying of solid objects. Int. J. Energy Res. 1996, 20, 531–539. [Google Scholar] [CrossRef]

- Raponi, F.; Moscetti, R.; Monarca, D.; Colantoni, A.; Massantini, R. Monitoring and optimization of the process of drying fruits and vegetables using computer vision: A Review. Sustainability 2017, 9, 2009. [Google Scholar] [CrossRef]

- Koszela, K.; Otrzasek, J.; Zaborowicz, M.; Boniecki, P.; Mueller, W.; Raba, B.; Lewicki, A.; Przybyl, K. Quality assessment of microwave-vacuum dried material with the use of computer image analysis and neural model. In Proc. SPIE 9159, Sixth International Conference on Digital Image Processing (ICDIP 2014), Athens, Greece, April 5-6, 2014; Falco, C.M., Chang, C.-C., Jiang, X., Eds.; SPIE: Bellingham, WA, USA, 2014; Volume 915913, pp. 1–9. [Google Scholar]

- Nindo, C.I.; Sun, T.; Wang, S.W.; Tang, J.; Powers, J.R. Evaluation of drying technologies for retention of physical quality and antioxidants in asparagus (Asparagus officinalis, L.). LWT—Food Sci. Technol. 2003, 36, 507–516. [Google Scholar] [CrossRef]

- Sacilik, K.; Elicin, A.K. The thin layer drying characteristics of organic apple slices. J. Food Eng. 2006, 73, 281–289. [Google Scholar] [CrossRef]

- Deng, Y.; Luo, Y.; Wang, Y.; Yue, J.; Liu, Z.; Zhong, Y.; Zhao, Y.; Yang, H. Drying-induced protein and microstructure damages of squid fillets affected moisture distribution and rehydration ability during rehydration. J. Food Eng. 2014, 123, 23–31. [Google Scholar] [CrossRef]

- Maldonado, S.; Arnau, E.; Bertuzzi, M.A. Effect of temperature and pretreatment on water diffusion during rehydration of dehydrated mangoes. J. Food Eng. 2010, 96, 333–341. [Google Scholar] [CrossRef]

- Giraldo, G.; Vázquez, R.; Martín-Esparza, M.E.; Chiralt, A. Rehydration kinetics and soluble solids lixiviation of candied mango fruit as affected by sucrose concentration. J. Food Eng. 2006, 77, 825–834. [Google Scholar] [CrossRef]

- Marabi, A.; Livings, S.; Jacobson, M.; Saguy, I.S. Normalized Weibull distribution for modeling rehydration of food particulates. Eur. Food Res. Technol. 2003, 217, 311–318. [Google Scholar] [CrossRef]

- Nayak, C.A.; Suguna, K.; Rastogi, N.K. Combined effect of gamma-irradiation and osmotic treatment on mass transfer during rehydration of carrots. J. Food Eng. 2006, 74, 134–142. [Google Scholar] [CrossRef]

- Wangler, J.; Kohlus, R. Development and validation of methods to characterize rehydration behavior of food hydrocolloids. Food Hydrocoll. 2018, 82, 500–509. [Google Scholar] [CrossRef]

- Rojas, M.L.; Augusto, P.E.D. Microstructure elements affect the mass transfer in foods: The case of convective drying and rehydration of pumpkin. LWT—Food Sci. Technol. 2018, 93, 102–108. [Google Scholar] [CrossRef]

- Ricce, C.; Rojas, M.L.; Miano, A.C.; Siche, R.; Augusto, P.E.D. Ultrasound pre-treatment enhances the carrot drying and rehydration. Food Res. Int. 2016, 89, 701–708. [Google Scholar] [CrossRef] [PubMed]

- Rojas, M.L.; Augusto, P.E.D. Ethanol pre-treatment improves vegetable drying and rehydration: Kinetics, mechanisms and impact on viscoelastic properties. J. Food Eng. 2018, 233, 17–27. [Google Scholar] [CrossRef]

- Benseddik, A.; Azzi, A.; Zidoune, M.N.; Khanniche, R.; Besombes, C. Empirical and diffusion models of rehydration process of differently dried pumpkin slices. J. Saudi Soc. Agric. Sci. 2018. [Google Scholar] [CrossRef]

- Link, J.V.; Tribuzi, G.; Laurindo, J.B. Improving quality of dried fruits: A comparison between conductive multi-flash and traditional drying methods. LWT—Food Sci. Technol. 2017, 84, 717–725. [Google Scholar] [CrossRef]

- Doymaz, İ.; Sahin, M. Effect of temperature and pre-treatment on drying and rehydration characteristics of broccoli slices. J. Food Meas. Charact. 2016, 10, 364–373. [Google Scholar] [CrossRef]

- Giri, S.K.; Prasad, S. Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J. Food Eng. 2007, 78, 512–521. [Google Scholar] [CrossRef]

- Atarés, L.; Chiralt, A.; González-Martínez, C. Effect of solute on osmotic dehydration and rehydration of vacuum impregnated apple cylinders (cv. Granny Smith). J. Food Eng. 2008, 89, 49–56. [Google Scholar] [CrossRef]

- Saguy, I.S.; Marabi, A.; Wallach, R. Liquid imbibition during rehydration of dry porous foods. Innov. Food Sci. Emerg. Technol. 2005, 6, 37–43. [Google Scholar] [CrossRef]

- Aral, S.; Beşe, A.V. Convective drying of hawthorn fruit (Crataegus spp.): Effect of experimental parameters on drying kinetics, color, shrinkage, and rehydration capacity. Food Chem. 2016, 210, 577–584. [Google Scholar] [CrossRef] [PubMed]

- Markowski, M.; Zielińska, M. Kinetics of water absorption and soluble-solid loss of hot-air-dried carrots during rehydration: Rehydration kinetics and soluble-solid loss of carrots. Int. J. Food Sci. Technol. 2011, 46, 1122–1128. [Google Scholar] [CrossRef]

- Ergün, K.; Çalışkan, G.; Dirim, S.N. Determination of the drying and rehydration kinetics of freeze dried kiwi (Actinidia deliciosa) slices. Heat Mass Transf. 2016, 52, 2697–2705. [Google Scholar] [CrossRef]

- Cagnoni, S.; Lutton, R.; Olague, G. Genetic and Evolutionary Computation for Image Processing and Analysis; EURASIP Book Series on Signal Processing and Communications; Hindawi Publishing Corporation: New York, NY, USA, 2007; ISBN 978-977-454-001-1. [Google Scholar]

- Morimoto, T.; De Baerdemaeker, J.; Hashimoto, Y. An intelligent approach for optimal control of fruit-storage process using neural networks and genetic algorithms. Comput. Electron. Agric. 1997, 18, 205–224. [Google Scholar] [CrossRef]

- Abakarov, A.; Sushkov, Y.; Almonacid, S.; Simpson, R. Multiobjective optimization approach: Thermal food processing. J. Food Sci. 2009, 74, E471–E487. [Google Scholar] [CrossRef] [PubMed]

- Ma, F.; Yin, H.; Wei, L.; Tian, G.; Gao, H. Design and optimization of IPM motor considering flux weakening capability and vibration for electric vehicle applications. Sustainability 2018, 10, 1533. [Google Scholar] [CrossRef]

- Yin, L.; Li, X.; Lu, C.; Gao, L. Energy-efficient scheduling problem using an effective hybrid multi-objective evolutionary algorithm. Sustainability 2016, 8, 1268. [Google Scholar] [CrossRef]

- Han, Y.; Yu, H.; Sun, C. Simulation-based multiobjective optimization of timber-glass residential buildings in severe cold regions. Sustainability 2017, 9, 2353. [Google Scholar] [CrossRef]

- Sleesongsom, S.; Bureerat, S. Vibration suppression of a single-cylinder engine by means of multi-objective evolutionary optimisation. Sustainability 2018, 10, 2067. [Google Scholar] [CrossRef]

- Shahraki, M.H.; Ziaiifar, A.M.; Kashaninejad, S.M.; Ghorbani, M. Optimization of pre-fry microwave drying of french fries using response surface methodology and genetic algorithms. J. Food Process. Preserv. 2014, 38, 535–550. [Google Scholar] [CrossRef]

- Winiczenko, R.; Górnicki, K.; Kaleta, A.; Martynenko, A.; Janaszek-Mańkowska, M.; Trajer, J. Multi-objective optimization of convective drying of apple cubes. Comput. Electron. Agric. 2018, 145, 341–348. [Google Scholar] [CrossRef]

- Sendín, J.O.H.; Alonso, A.A.; Banga, J.R. Efficient and robust multi-objective optimization of food processing: A novel approach with application to thermal sterilization. J. Food Eng. 2010, 98, 317–324. [Google Scholar] [CrossRef]

- Thakur, M.; Wang, L.; Hurburgh, C.R. A multi-objective optimization approach to balancing cost and traceability in bulk grain handling. J. Food Eng. 2010, 101, 193–200. [Google Scholar] [CrossRef]

- Hadiyanto, H.; Boom, R.M.; Van Straten, G.; Van Boxtel, A.J.B.; Esveld, D.C. Multi-objective optimization to improve the product range of baking systems. J. Food Process. Eng. 2009, 32, 709–729. [Google Scholar] [CrossRef]

- Goñi, S.M.; Salvadori, V.O. Model-based multi-objective optimization of beef roasting. J. Food Eng. 2012, 111, 92–101. [Google Scholar] [CrossRef]

- Białobrzewski, I.; Danowska-Oziewicz, M.; Karpińska-Tymoszczyk, M.; Nalepa, B.; Markowski, M.; Myhan, R. Turkey breast roasting—Process optimization. J. Food Eng. 2010, 96, 394–400. [Google Scholar] [CrossRef]

- Górnicki, K.; Kaleta, A. Drying curve modelling of blanched carrot cubes under natural convection condition. J. Food Eng. 2007, 82, 160–170. [Google Scholar] [CrossRef]

- Kaleta, A.; Górnicki, K. Evaluation of drying models of apple (var. McIntosh) dried in a convective dryer. Int. J. Food Sci. Technol. 2010, 45, 891–898. [Google Scholar] [CrossRef]

- Kaleta, A.; Górnicki, K.; Winiczenko, R.; Chojnacka, A. Evaluation of drying models of apple (var. Ligol) dried in a fluidized bed dryer. Energy Convers. Manag. 2013, 67, 179–185. [Google Scholar] [CrossRef]

- Horwitz, W. Official Methods of Analysis of the Association of Official’s Analytical Chemists; Association of Official Analytical Chemists (AOAC): Arlington, VA, USA, 2003. [Google Scholar]

- Mazza, G. Dehydration of carrots. Effects of pre-drying treatments on moisture transport and product quality. Int. J. Food Sci. Technol. 1983, 18, 113–123. [Google Scholar] [CrossRef]

- Colorimetry, 3rd ed.; International Commission on Illumination; Technical Report CIE15:2004; CIE Central Bureau: Vienna, Austria, 2004. Available online: https://archive.org/details/gov.law.cie.15.2004 (accessed on 2 June 2017).

- Schanda, J. CIE Colorimetry. In Colorimetry: Understanding the CIE System; Schanda, J., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; pp. 25–78. ISBN 978-0-470-17563-7. [Google Scholar]

- Lewicki, P.P. Some remarks on rehydration of dried foods. J. Food Eng. 1998, 36, 81–87. [Google Scholar] [CrossRef]

- Witt, K. CIE Color Difference Metrics. In Colorimetry: Understanding the CIE System; Schanda, J., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; pp. 79–100. ISBN 978-0-470-17563-7. [Google Scholar]

- Okuyucu, H.; Kurt, A.; Arcaklioglu, E. Artificial neural network application to the friction stir welding of aluminum plates. Mater. Des. 2007, 28, 78–84. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Behnagh, R.A.; Akbari, M.; Givi, M.K.B.; Farhani, F. Modelling and Pareto optimization of mechanical properties of friction stir welded AA7075/AA5083 butt joints using neural network and particle swarm algorithm. Mater. Des. 2013, 44, 190–198. [Google Scholar] [CrossRef]

- Rutkowski, L. Computational Intelligence; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-76287-4. [Google Scholar]

- Winiczenko, R.; Górnicki, K.; Kaleta, A.; Janaszek-Mańkowska, M. Optimisation of ANN topology for predicting the rehydrated apple cubes colour change using RSM and GA. Neural Comput. Appl. 2018, 30, 1795–1809. [Google Scholar] [CrossRef] [PubMed]

- Gevrey, M.; Dimopoulos, I.; Lek, S. Review and comparison of methods to study the contribution of variables in artificial neural network models. Ecol. Model. 2003, 160, 249–264. [Google Scholar] [CrossRef]

- Winiczenko, R.; Górnicki, K.; Kaleta, A.; Janaszek-Mańkowska, M.; Trajer, J. Multi-objective optimization of the apple drying and rehydration processes parameters. Emir. J. Food Agric. 2018, 30, 1–9. [Google Scholar] [CrossRef]

| i | D1i | D2i | D3i | D4i | D5i |

|---|---|---|---|---|---|

| 1 | −11.1588 | −7.7592 | −0.6697 | 1.5380 | 18.4940 |

| 2 | −1.0835 | −0.1818 | −9.6281 | −3.8191 | 10.5589 |

| 3 | −15.0529 | −4.9146 | 8.6942 | −2.8797 | 17.9134 |

| 4 | −8.7055 | −0.6294 | 4.3391 | −14.9923 | 17.1001 |

| 5 | −11.8990 | −18.2054 | −1.8929 | 2.3569 | 9.2392 |

| 6 | −3.6760 | 1.6062 | −17.8052 | −5.5386 | 11.8517 |

| Pareto ID | WAC (−) | VR (−) | CD (−) | Td (°C) | v (m/s) | pH (−) | Tr (°C) |

|---|---|---|---|---|---|---|---|

| 1 * | 0.4610 | 0.4406 | 4.9339 | 50.0726 | 4.0269 | 2.1231 | 20.0787 |

| 2 | 0.2496 | 0.5829 | 26.3198 | 59.1482 | 0.3961 | 2.1268 | 84.6113 |

| 3 | 0.3505 | 0.5290 | 14.8788 | 56.8466 | 1.4085 | 2.5738 | 67.7296 |

| 4 | 0.2987 | 0.6130 | 24.6705 | 60.4821 | 2.1437 | 2.3132 | 91.4555 |

| 5 | 0.3560 | 0.5128 | 13.2246 | 56.9539 | 1.3443 | 2.4292 | 63.7404 |

| 6 | 0.3490 | 0.5876 | 21.8093 | 57.4686 | 1.5863 | 2.9835 | 81.2848 |

| 7 | 0.4427 | 0.2771 | 20.9616 | 53.2569 | 0.1899 | 4.6265 | 72.0360 |

| 8 | 0.4767 | 0.3696 | 12.1261 | 52.1816 | 0.7663 | 4.9951 | 75.2174 |

| 9 | 0.3854 | 0.4775 | 8.8345 | 53.1772 | 3.4738 | 2.8495 | 33.9584 |

| 10 | 0.4395 | 0.3129 | 19.4062 | 53.5391 | 0.2951 | 4.4393 | 71.1104 |

| 11 | 0.4607 | 0.2376 | 20.2743 | 50.6788 | 0.1718 | 5.4014 | 66.2427 |

| 12 | 0.4494 | 0.1935 | 23.0974 | 50.0522 | 0.0151 | 5.3859 | 66.7517 |

| 13 | 0.4884 | 0.3929 | 7.2222 | 61.1844 | 1.9569 | 5.4500 | 59.5787 |

| 14 | 0.4310 | 0.2173 | 23.7054 | 52.1683 | 0.0145 | 4.7001 | 71.9461 |

| 15* | 0.4459 | 0.4501 | 5.7222 | 51.7956 | 3.3349 | 2.2060 | 31.0002 |

| 16 | 0.4519 | 0.3629 | 16.3099 | 55.2706 | 0.4085 | 4.4603 | 72.3659 |

| 17 | 0.3722 | 0.4924 | 10.4412 | 55.9213 | 1.7468 | 2.3832 | 57.1886 |

| 18 | 0.3659 | 0.4950 | 10.9728 | 56.3231 | 1.6107 | 2.4896 | 58.2014 |

| 19 | 0.4725 | 0.4049 | 8.1156 | 55.7922 | 1.1456 | 4.8176 | 57.8621 |

| 20 | 0.4665 | 0.3310 | 14.7560 | 53.9473 | 0.4089 | 4.8891 | 69.1178 |

| 21 | 0.3001 | 0.6125 | 24.6999 | 60.7488 | 2.4932 | 2.3504 | 92.8243 |

| 22 | 0.2810 | 0.5220 | 26.1803 | 57.1793 | 0.2308 | 2.8994 | 81.7101 |

| 23 | 0.2053 | 0.5559 | 26.8543 | 60.0454 | 0.0122 | 2.1271 | 91.4352 |

| 24 | 0.4432 | 0.3274 | 18.2983 | 53.5391 | 0.3576 | 4.4393 | 71.1104 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Winiczenko, R.; Górnicki, K.; Kaleta, A.; Janaszek-Mańkowska, M.; Choińska, A.; Trajer, J. Apple Cubes Drying and Rehydration. Multiobjective Optimization of the Processes. Sustainability 2018, 10, 4126. https://doi.org/10.3390/su10114126

Winiczenko R, Górnicki K, Kaleta A, Janaszek-Mańkowska M, Choińska A, Trajer J. Apple Cubes Drying and Rehydration. Multiobjective Optimization of the Processes. Sustainability. 2018; 10(11):4126. https://doi.org/10.3390/su10114126

Chicago/Turabian StyleWiniczenko, Radosław, Krzysztof Górnicki, Agnieszka Kaleta, Monika Janaszek-Mańkowska, Aneta Choińska, and Jędrzej Trajer. 2018. "Apple Cubes Drying and Rehydration. Multiobjective Optimization of the Processes" Sustainability 10, no. 11: 4126. https://doi.org/10.3390/su10114126

APA StyleWiniczenko, R., Górnicki, K., Kaleta, A., Janaszek-Mańkowska, M., Choińska, A., & Trajer, J. (2018). Apple Cubes Drying and Rehydration. Multiobjective Optimization of the Processes. Sustainability, 10(11), 4126. https://doi.org/10.3390/su10114126