Integration of 3D Printing and Industry 4.0 into Engineering Teaching

Abstract

:1. Introduction

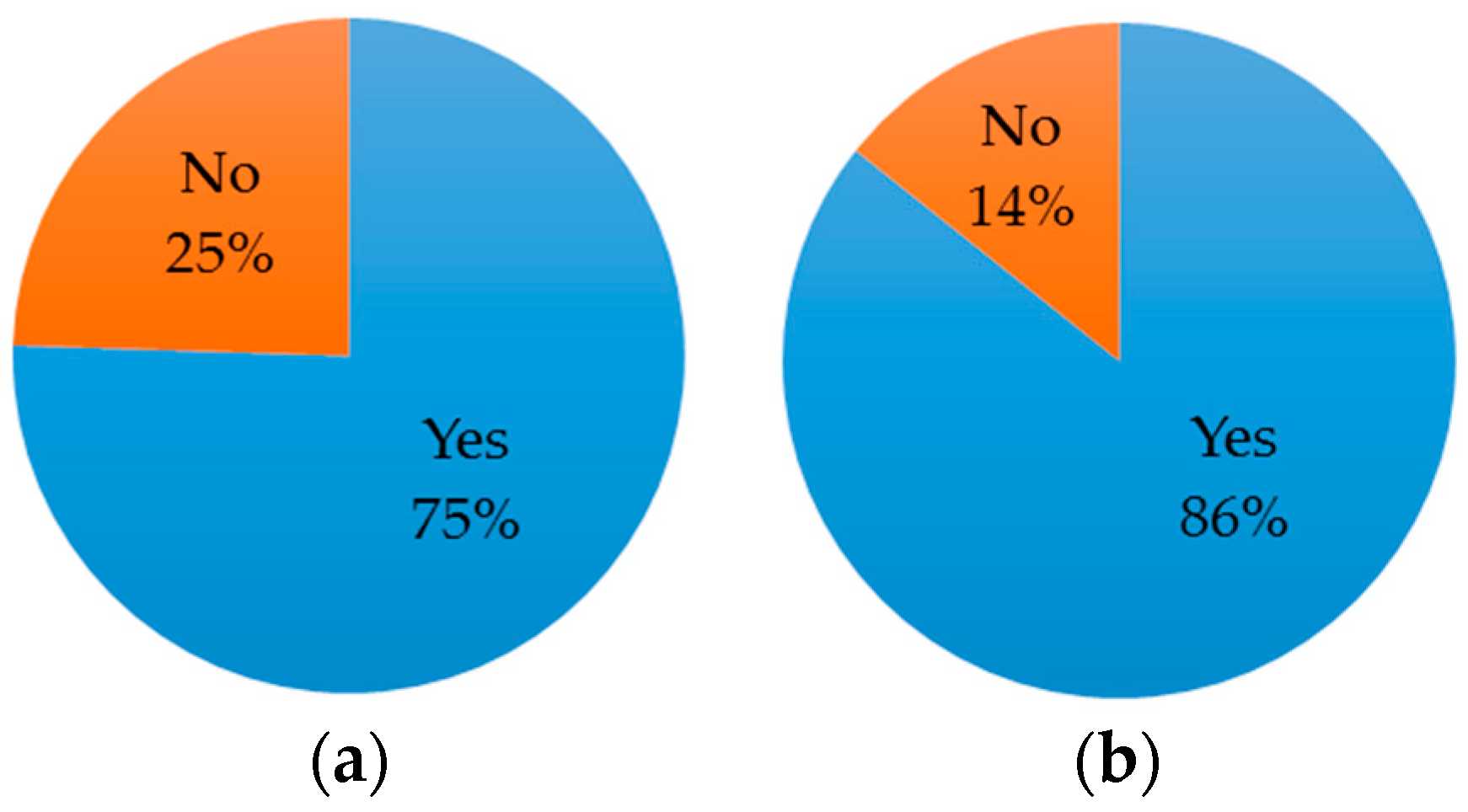

2. Surveys

3. Results and Discussion

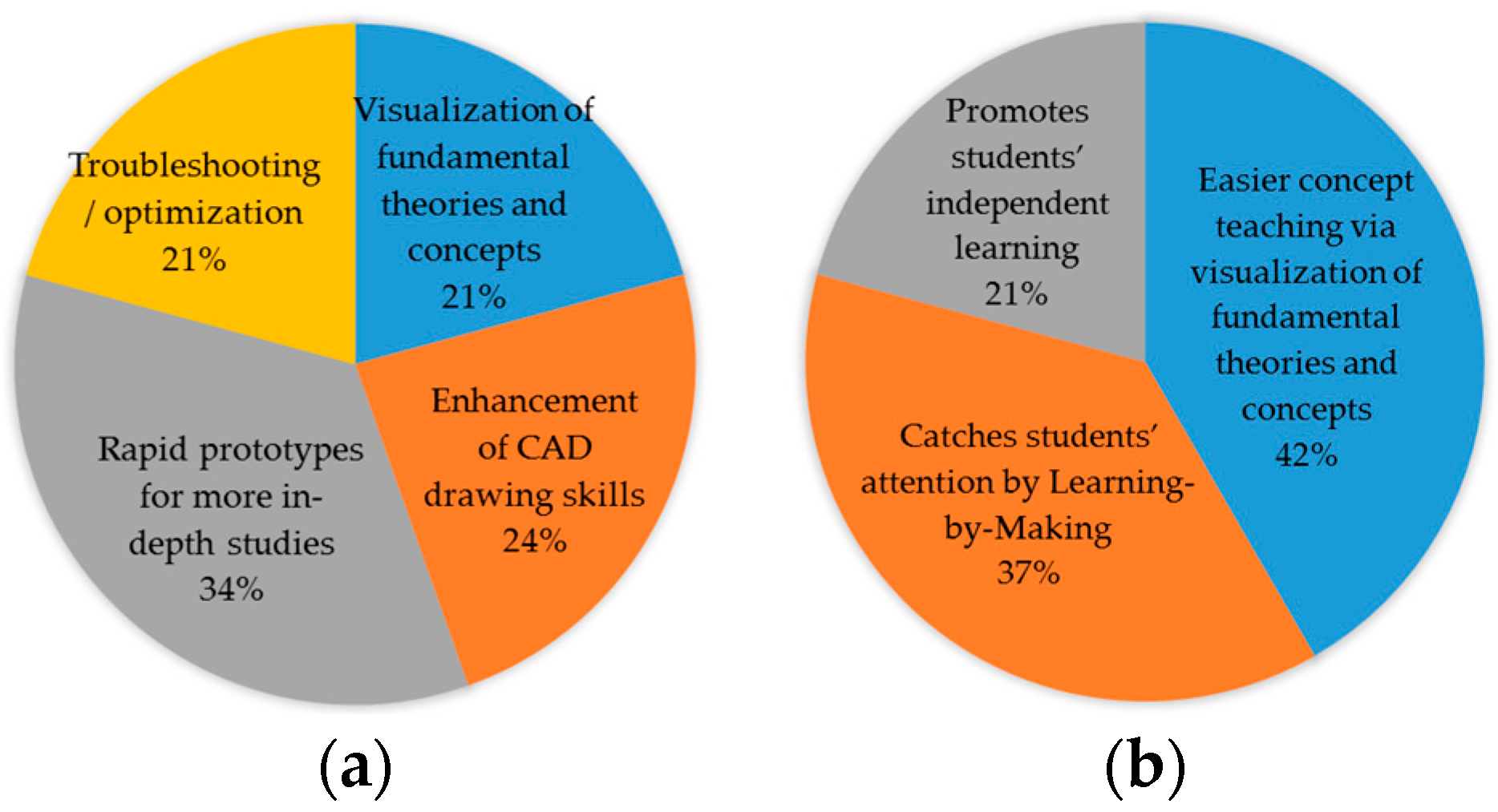

3.1. Fields of Application in Teaching and Learning

3.2. Impacts on Teaching and Learning

3.2.1. Tangible Models for Theoretical and Conceptual Teaching

3.2.2. Enhancement of CAD Drawing Skills

3.2.3. Improvement of Troubleshooting and Optimization Skills

- Integration of technologies—processing, mining and quarry, etc.

- Utility—power generation, water treatment, waste management, etc.

- Factory and manufacturing—automation, production machinery, packaging, raw material, transportation, maintenance, logistics, etc.

- Sustainability and ethics—product/material design, environmental and human health regulations.

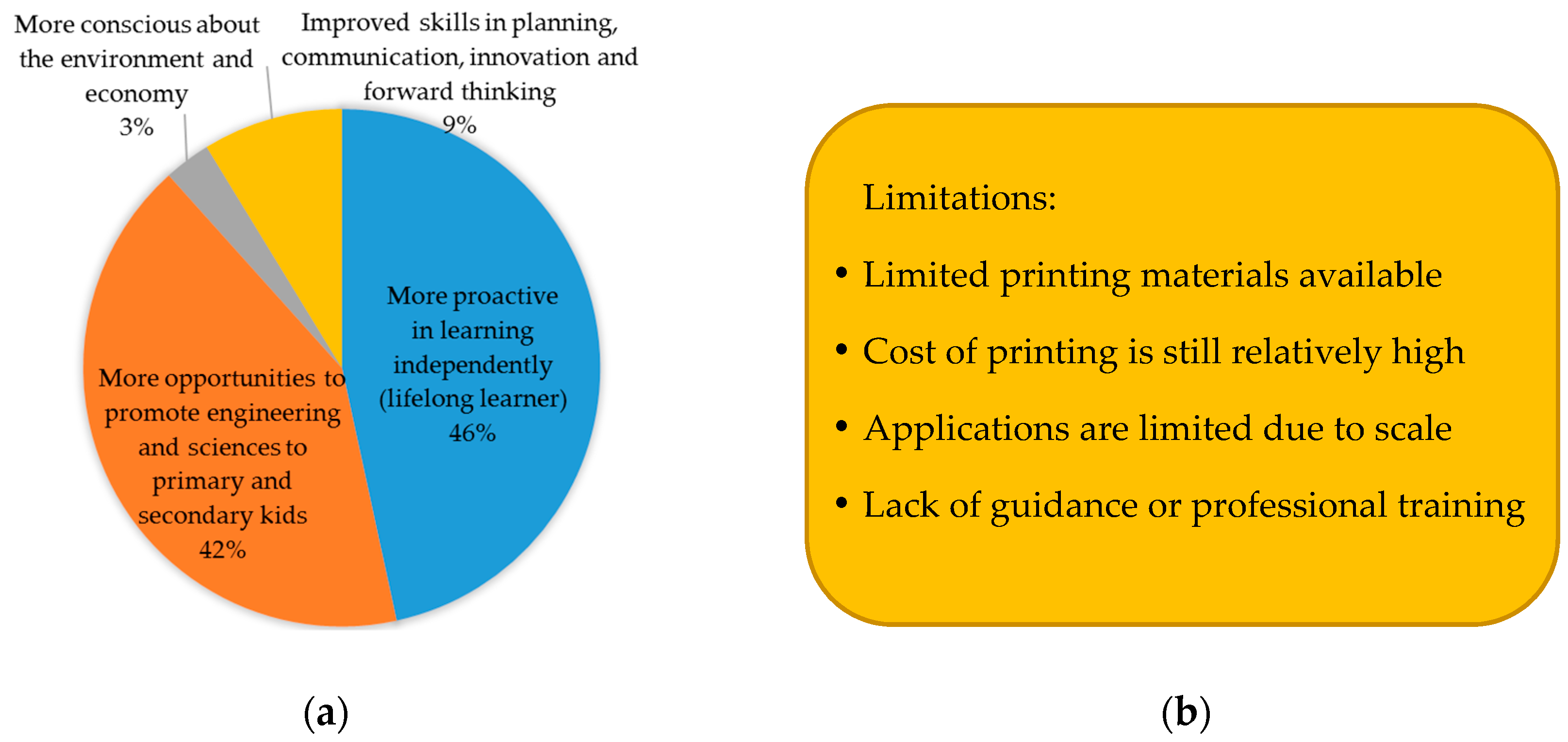

3.2.4. Improvement of Lifelong Learning Skills

3.2.5. Increase of Consciousness on the Community and Environment

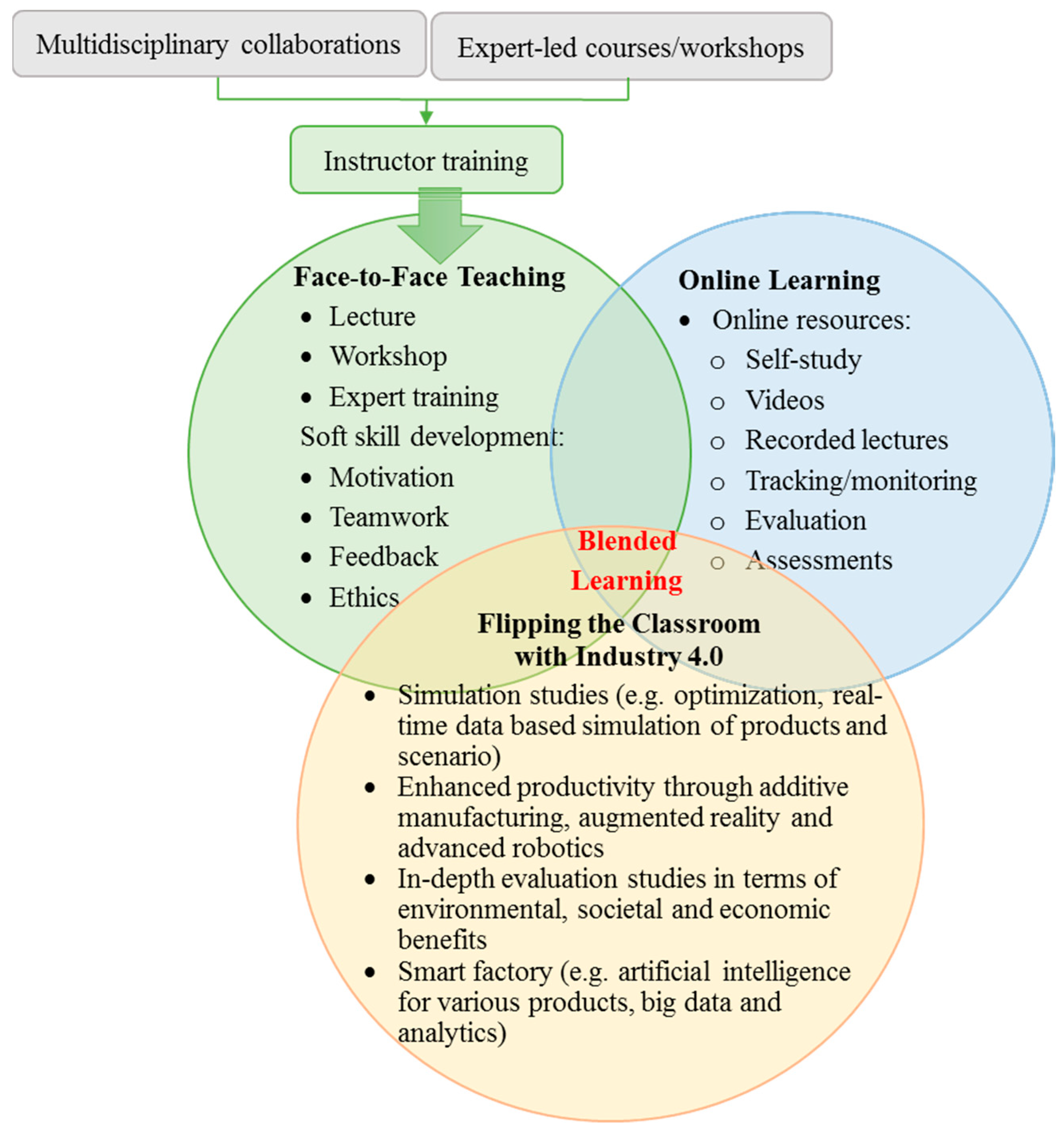

4. Recommendations for Integrating Industry 4.0 into Engineering Teaching

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cheung, C.L.; Saber, N.R. Chapter 9—Application of 3d printing in medical simulation and education. In Bioengineering for Surgery; Chandos Publishing: Oxford, UK, 2016; pp. 151–166. [Google Scholar]

- AbouHashem, Y.; Dayal, M.; Savanah, S.; Štrkalj, G. The application of 3d printing in anatomy education. Med. Educ. Online 2015, 20. [Google Scholar] [CrossRef] [PubMed]

- Adams, J.W.; Paxton, L.; Dawes, K.; Burlak, K.; Quayle, M.; McMenamin, P.G. 3d printed reproductions of orbital dissections: A novel mode of visualising anatomy for trainees in ophthalmology or optometry. Br. J. Ophthalmol. 2015, 99, 1162–1167. [Google Scholar] [CrossRef] [PubMed]

- Emerging Objects. Big Ideas About 3D Printing & 3D Printing Big. Available online: http://www.emergingobjects.com/ (accessed on 22 April 2018).

- Gillett, J.E. Chemical engineering education in the next century. Chem. Eng. Technol. 2001, 24, 561–570. [Google Scholar] [CrossRef]

- Schelly, C.; Anzalone, G.; Wijnen, B.; Pearce, J.M. Open-source 3-d printing technologies for education: Bringing additive manufacturing to the classroom. J. Visual Lang. Comput. 2015, 28, 226–237. [Google Scholar] [CrossRef]

- Loy, J. Elearning and emaking: 3d printing blurring the digital and the physical. Educ. Sci. 2014, 4, 108–121. [Google Scholar] [CrossRef]

- Verner, I.; Merksamer, A. Digital design and 3d printing in technology teacher education. Procedia CIRP 2015, 36, 182–186. [Google Scholar] [CrossRef]

- Tibbits, S. The Emergence of “4D Printing”. Available online: https://www.ted.com/talks/skylar_tibbits_the_emergence_of_4d_printing (accessed on 30 October 2018).

- Momeni, F.; Liu, X.; Ni, J. A review of 4d printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Choi, J.; Kwon, O.-C.; Jo, W.; Lee, H.J.; Moon, M.-W. 4d printing technology: A review. 3D Pr. Addit. Manuf. 2015, 2, 159–167. [Google Scholar] [CrossRef]

- Bakarich, S.E.; Gorkin, R.; Spinks, G.M. 4d printing with mechanically robust, thermally actuating hydrogels. Macromol. Rapid Commun. 2015, 36, 1211–1217. [Google Scholar] [CrossRef] [PubMed]

- Nadgorny, M.; Xiao, Z.; Chen, C.; Connal, L.A. Three-dimensional printing of ph-responsive and functional polymers on an affordable desktop printer. ACS Appl. Mater. Interfaces 2016, 8, 28946–28954. [Google Scholar] [CrossRef] [PubMed]

- Campbell, T.A.; Tibbits, S.; Garrett, B. The programmable world. Sci. Am. 2014, 311, 60–65. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.-W.; Lin, T.-K.; Kuo, S.-Y.; Huang, T.-H. Integration of high-resolution laser displacement sensors and 3d printing for structural health monitoring. Sensors 2017, 18, 19. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Wu, X.; Guo, X.; Kong, B.; Zhang, M.; Qian, X.; Mi, S.; Sun, W. The boom in 3d-printed sensor technology. Sensors 2017, 17, 1166. [Google Scholar] [CrossRef] [PubMed]

- Kuksenok, O.; Balazs, A.C. Stimuli-responsive behavior of composites integrating thermo-responsive gels with photo-responsive fibers. Mater. Horiz. 2016, 3, 53–62. [Google Scholar] [CrossRef]

- Zhou, Y.; He, B.; Yan, Z.; Shang, Y.; Wang, Q.; Wang, Z. Touch locating and stretch sensing studies of conductive hydrogels with applications to soft robots. Sensors 2018, 18, 569. [Google Scholar] [CrossRef] [PubMed]

- Martinez, B.; Vilajosana, X.; Kim, I.H.; Zhou, J.; Tuset-Peiró, P.; Xhafa, A.; Poissonnier, D.; Lu, X. I3mote: An open development platform for the intelligent industrial internet. Sensors 2017, 17, 986. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, N.; Chaim, O.; Cazarini, E.; Gerolamo, M. Manufacturing in the fourth industrial revolution: A positive prospect in sustainable manufacturing. Procedia Manuf. 2018, 21, 671–678. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Ali, S.M.; Kusi-Sarpong, S.; Shaikh, M.A.A. Assessing challenges for implementing industry 4.0: Implications for process safety and environmental protection. Process Saf. Environ. Prot. 2018, 117, 730–741. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- i-Scoop. Industry 4.0: The Fourth Industrial Revolution—Guide to Industrie 4.0. Available online: https://www.i-scoop.eu/industry-4-0/ (accessed on 15 October 2018).

- Ministry of International Trade and Industry (MITI), Malaysia. Industry 4.0. Available online: http://www.miti.gov.my/index.php/pages/view/industry4.0 (accessed on 15 August 2018).

- Tsai, W.-H.; Lu, Y.-H. A framework of production planning and control with carbon tax under industry 4.0. Sustainability 2018, 10, 3221. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What drives the implementation of industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Simons, S.; Abé, P.; Neser, S. Learning in the autfab—The fully automated industrie 4.0 learning factory of the university of applied sciences darmstadt. Procedia Manuf. 2017, 9, 81–88. [Google Scholar] [CrossRef]

- Madsen, O.; Møller, C. The aau smart production laboratory for teaching and research in emerging digital manufacturing technologies. Procedia Manuf. 2017, 9, 106–112. [Google Scholar] [CrossRef]

- The Boston Consulting Group. Sprinting to Value in Industry 4.0, Perspectives from and Implications for U.S. Manufacturers. Available online: https://www.slideshare.net/TheBostonConsultingGroup/sprinting-to-value-in-industry-40 (accessed on 30 October 2018).

- Lipson, H.; Kurman, M. Fabricated: The New World of 3d Printing; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Prinz, C.; Morlock, F.; Freith, S.; Kreggenfeld, N.; Kreimeier, D.; Kuhlenkötter, B. Learning factory modules for smart factories in industrie 4.0. Procedia CIRP 2016, 54, 113–118. [Google Scholar] [CrossRef]

| Pillars of Industry 4.0 | Description | |

|---|---|---|

| 1 | Advanced Robotics |

|

| 2 | Additive Manufacturing |

|

| 3 | Augmented Reality |

|

| 4 | Simulation |

|

| 5 | Horizontal/Vertical Integration |

|

| 6 | Industrial Internet |

|

| 7 | Cloud |

|

| 8 | Cybersecurity |

|

| 9 | Big Data and Analytics |

|

| Participants’ Background | ||||||

|---|---|---|---|---|---|---|

| Type | Mechanical, Materials, and Manufacturing Engineering | Chemical and Environmental Engineering | Electrical, Electronic, and Mechatronics Engineering | Civil Engineering and other streams | Total number of participants | |

| Academics | 2 | 7 | 3 | 2 | 14 | |

| Students | 16 | 20 | 8 | 9 | 54 | |

| Students’ questionnaire | ||||||

| Part A: Fields of application | ||||||

| A1 | Have you heard of Industry 4.0? | |||||

| A2 | Which modules that you enrolled in made use of 3D printing/Industry 4.0? | |||||

| A3 | What models/elements of Industry 4.0 have you been exposed to? | |||||

| Part B: Impacts | ||||||

| B1 | How do you think 3D printing/Industry 4.0 helps your learning? | |||||

| B2 | What non-academic aspects of 3D printing/Industry 4.0 have an impact on you? | |||||

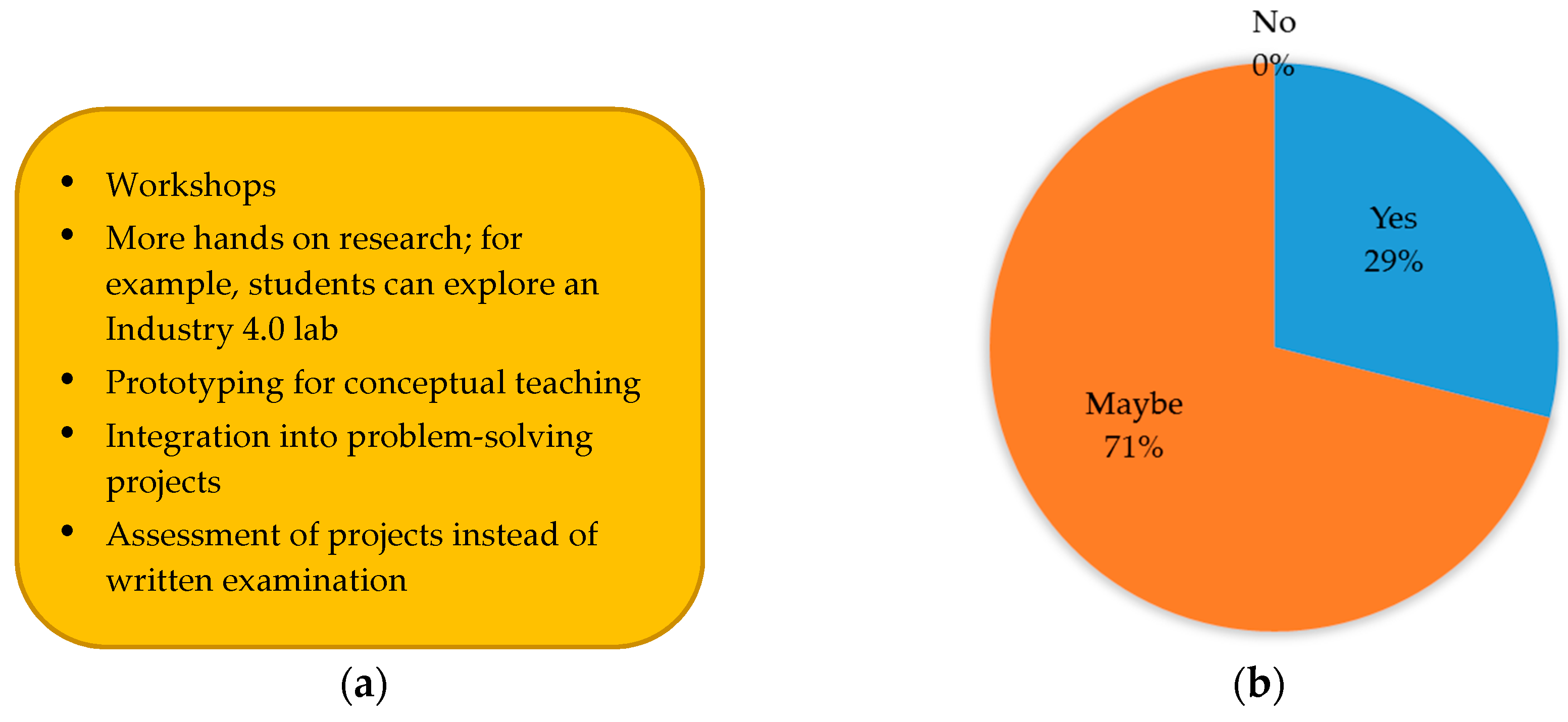

| Part C: Recommendation | ||||||

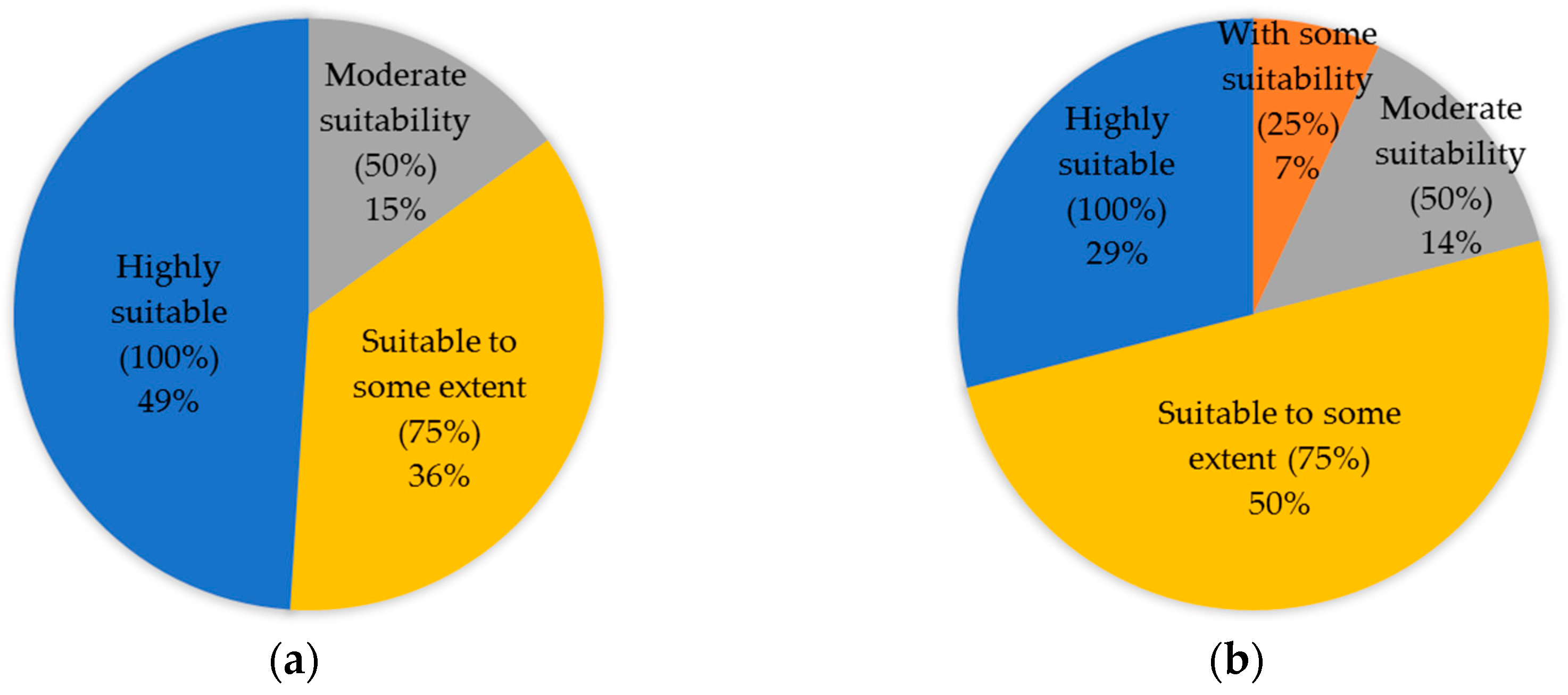

| C1 | How would you rate the suitability of 3D printing/Industry 4.0 in engineering education? | |||||

| C2 | How should lecturers adopt Industry 4.0 (3D or 4D printing, smart systems, cloud, big data, etc.) into their teaching? | |||||

| Academics’ questionnaire | ||||||

| Part A: Fields of application | ||||||

| A1 | Have you heard of Industry 4.0? | |||||

| A2 | In which modules did you make use of 3D printing/Industry 4.0? | |||||

| A3 | What models/elements of Industry 4.0 have you used for teaching purposes? | |||||

| Part B: Impacts | ||||||

| B1 | How do you think 3D printing/Industry 4.0 helps your teaching? | |||||

| B2 | Do you think there are disadvantages of this technology? | |||||

| Part C: Recommendation | ||||||

| C1 | How would you rate the suitability of 3D printing/Industry 4.0 in engineering education? | |||||

| C2 | Do you plan to use these technologies in your future modules? | |||||

| Question | Summary of the Responses from Students and Lecturers |

|---|---|

| A2 | % of students involved in 3D printing/Industry 4.0 modules and curriculum: 63% Curriculum (28%): Group/individual design projects, applied mechatronic construction projects, building information modeling, applied electrical and electronic engineering, materials and manufacturing, air-land robot team, design and manufacturing, and process engineering laboratories Clubs and activities (35%): Nott’s Makers, Institution of Engineers (IEM) student chapters, Robotics Society, and some education talks and competitions |

| A3 | Prototype (46%): Demo house, sensor holders, some mechanical parts, BIM models for simulation of structures, holder for a pneumatic cylinder, robotic arm, propeller models, artificial limbs, and embossing for RFID system Method (7%): Automation in setting layers of carbon fiber reinforced polymer Decorative object (36%): Butterfly, keychain, name tag, Dota2 logo on keychain, rotating stand, Minecraft sword, book rack organizer, camera holder, sprockets, motor brackets, battery holder, and cases Intelligent items (11%): Automated machines, sensor-based lighting, line-following sensor, and setting up of algorithms to respond to changes during a process |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chong, S.; Pan, G.-T.; Chin, J.; Show, P.L.; Yang, T.C.K.; Huang, C.-M. Integration of 3D Printing and Industry 4.0 into Engineering Teaching. Sustainability 2018, 10, 3960. https://doi.org/10.3390/su10113960

Chong S, Pan G-T, Chin J, Show PL, Yang TCK, Huang C-M. Integration of 3D Printing and Industry 4.0 into Engineering Teaching. Sustainability. 2018; 10(11):3960. https://doi.org/10.3390/su10113960

Chicago/Turabian StyleChong, Siewhui, Guan-Ting Pan, Jitkai Chin, Pau Loke Show, Thomas Chung Kuang Yang, and Chao-Ming Huang. 2018. "Integration of 3D Printing and Industry 4.0 into Engineering Teaching" Sustainability 10, no. 11: 3960. https://doi.org/10.3390/su10113960

APA StyleChong, S., Pan, G.-T., Chin, J., Show, P. L., Yang, T. C. K., & Huang, C.-M. (2018). Integration of 3D Printing and Industry 4.0 into Engineering Teaching. Sustainability, 10(11), 3960. https://doi.org/10.3390/su10113960