Optimization of the Separation Efficiency of Buckwheat Seeds and Wild Radish Siliques in a Grader with Indented Pockets

Abstract

:1. Introduction

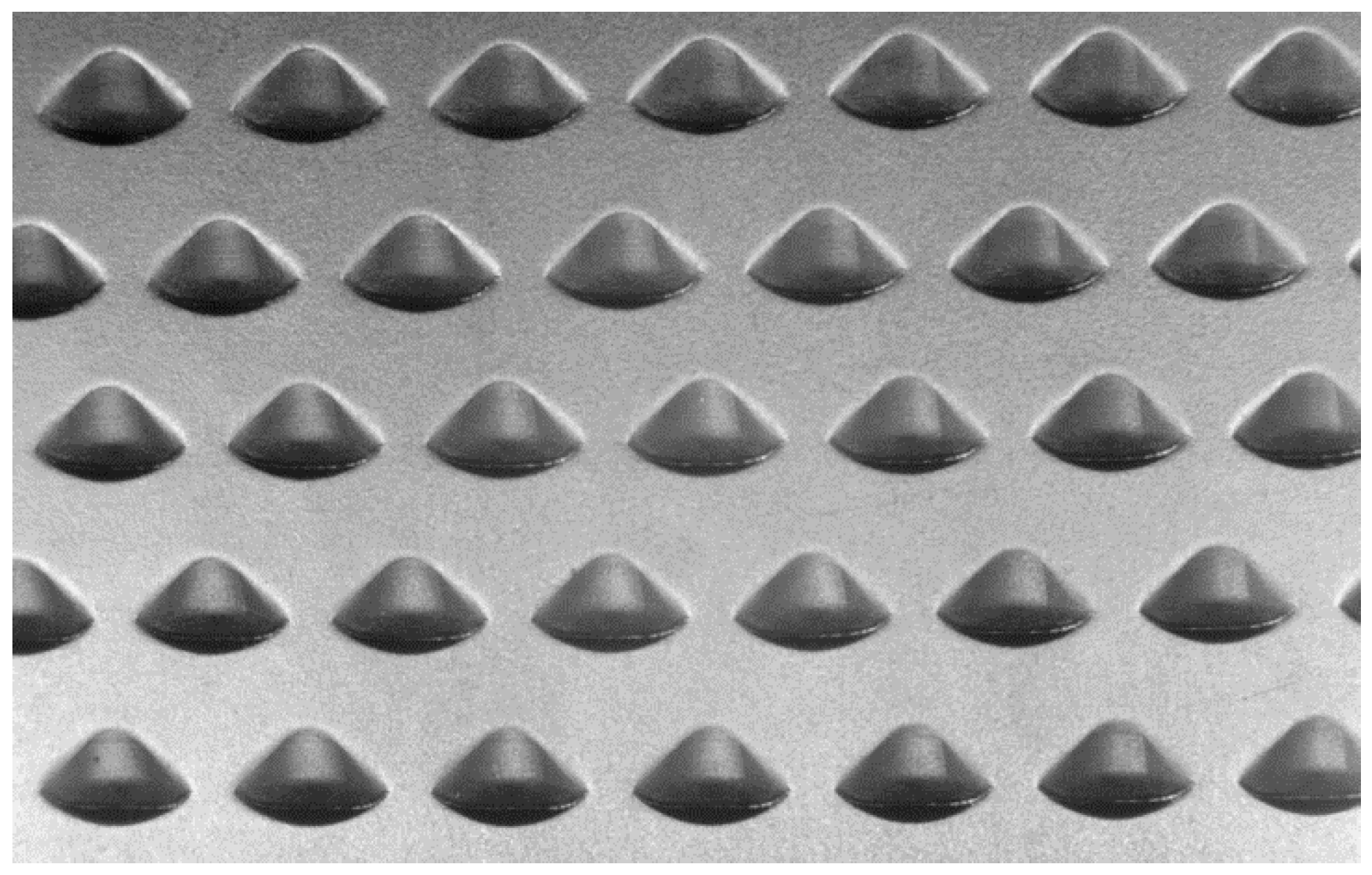

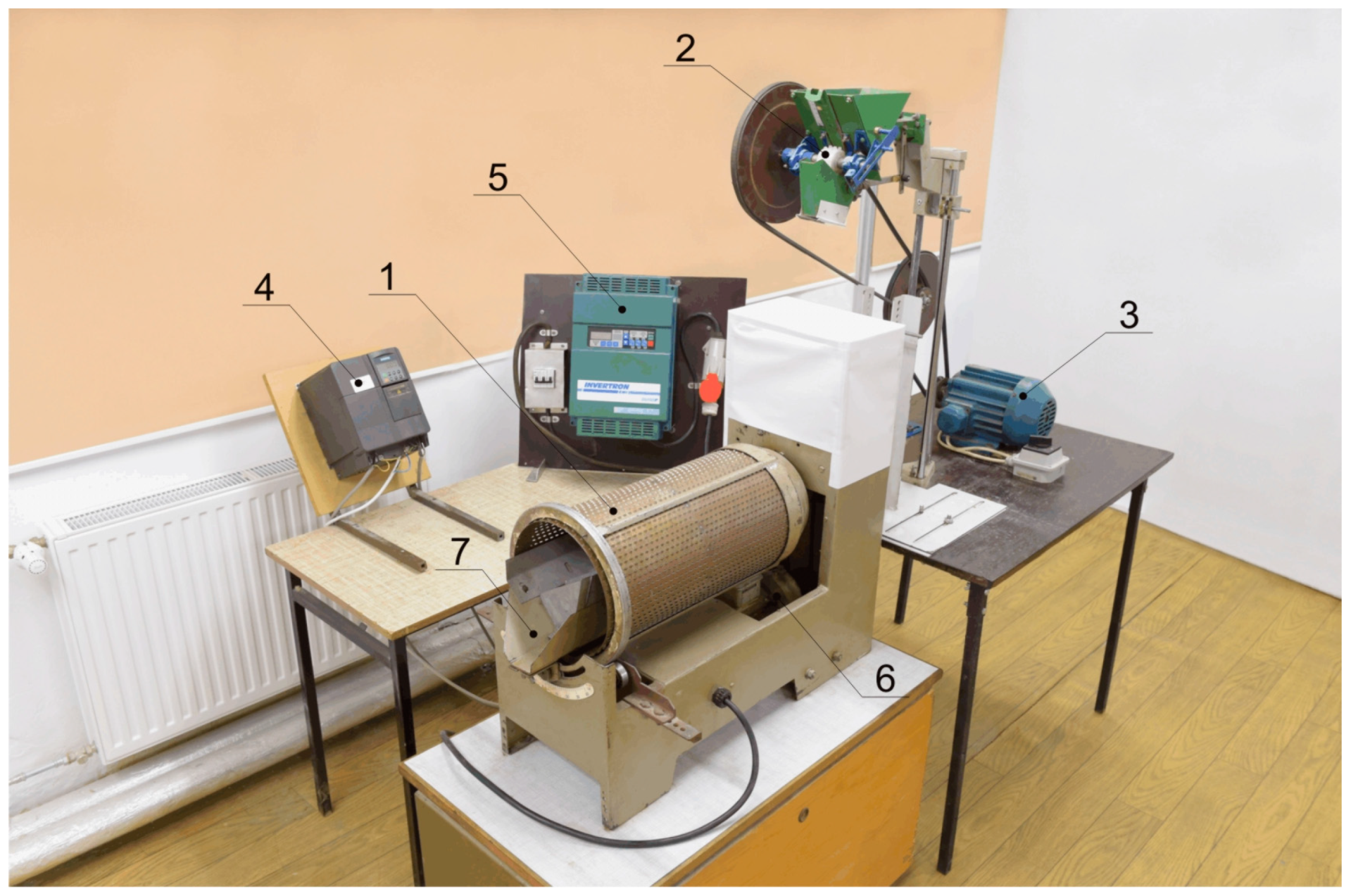

2. Materials and Methods

- (a)

- Constant parameters:

cylinder length 480 mm, cylinder’s internal diameter 240 mm, inclination angle of the cylinder’s horizontal axis 2°, inclination angle of an indented surface relative to its base 60°, distance between the working edge of the trough and cylinder surface 6 mm, content of wild radish siliques in the seed mixture 20%, - (b)

- Variable parameters (working parameters):

- –

- depth of indented pocket (s)—from 2.0 to 3.6 mm, changed in steps of 0.4 mm (interchangeable cylinders),

- –

- kinematic index (k)—from 0.15 to 0.45, changed in steps of 0.1,

- –

- static load rating of a cylinder (q)—from 0.1 to 0.4, changed in steps of 0.1,

- –

- inclination angle of the working edge of the trough (α)—from 10° to 40° relative to the cylinder’s horizontal axis, changed in steps of 10°.

- –

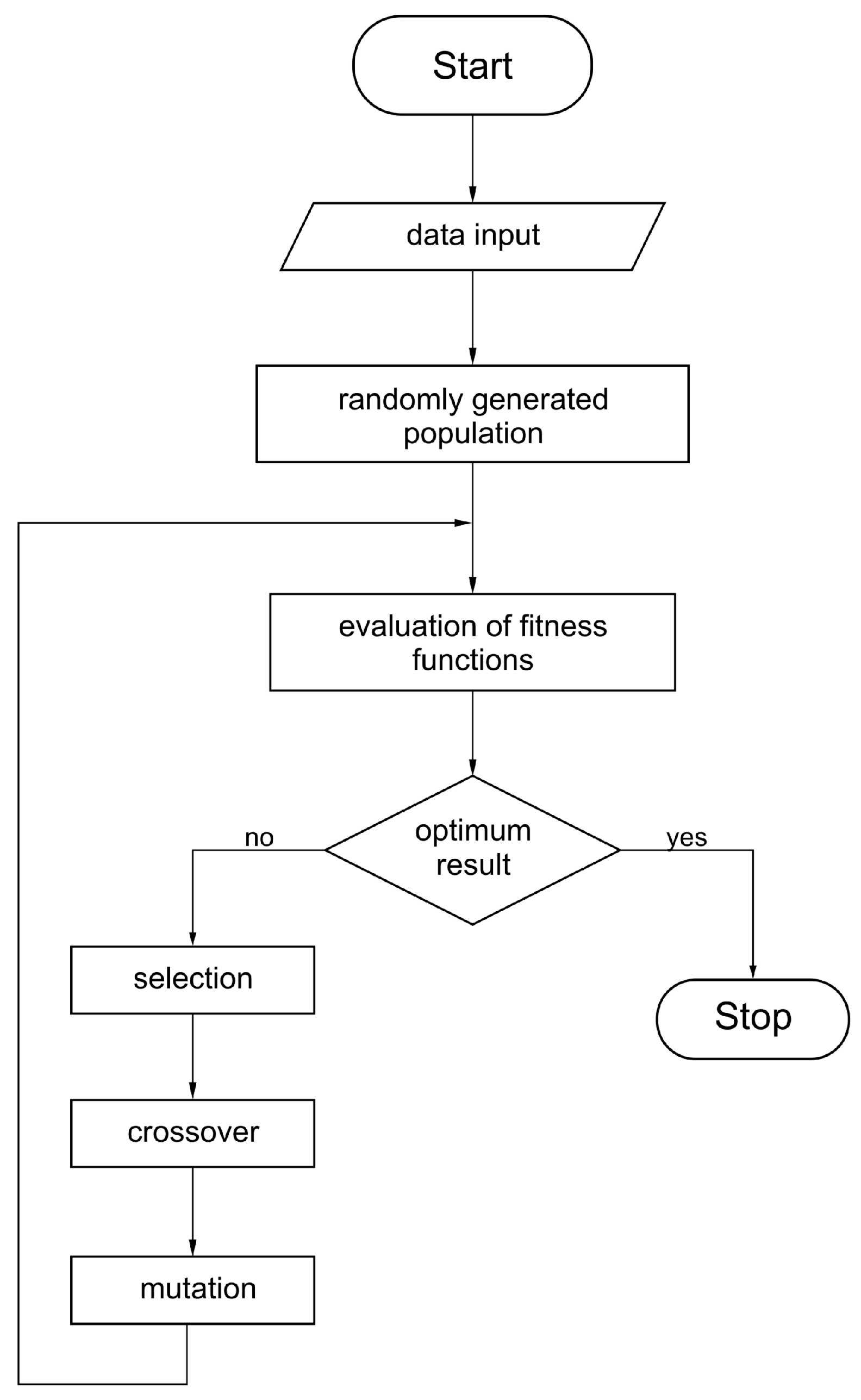

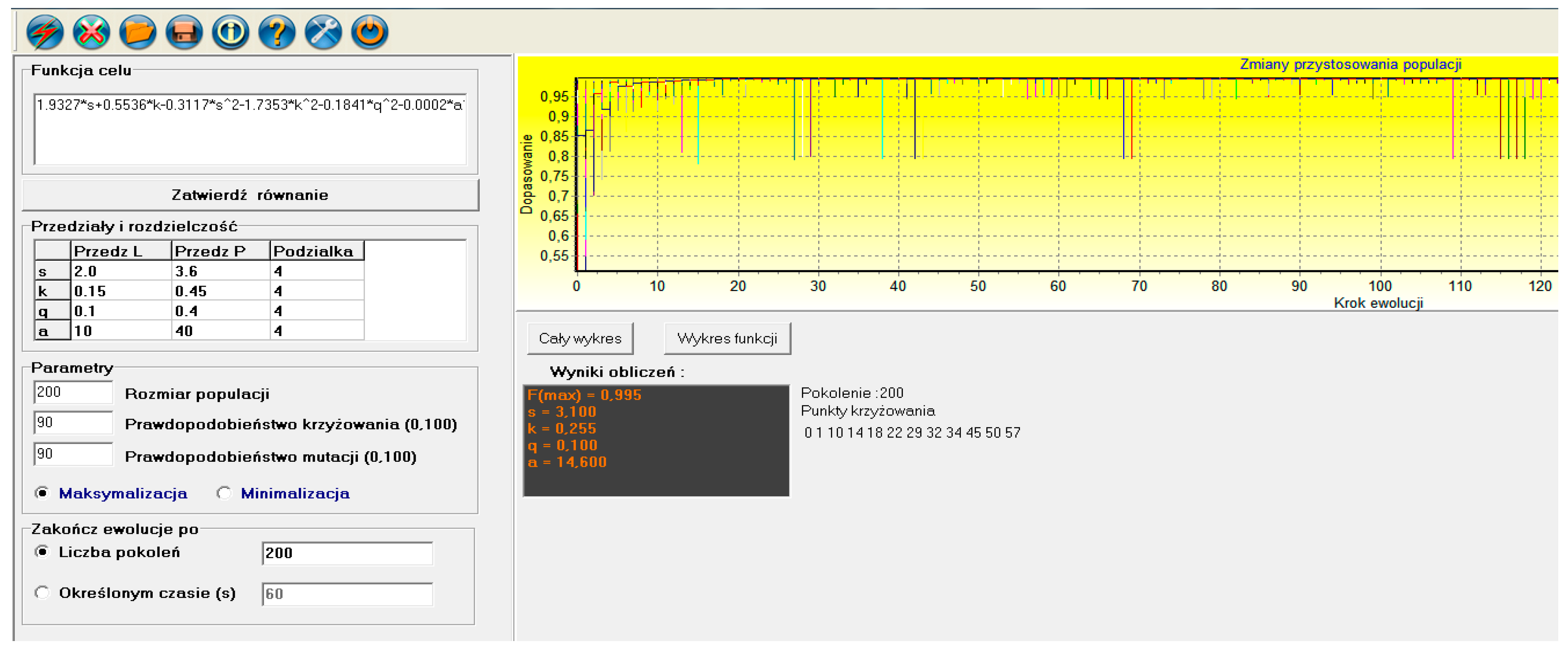

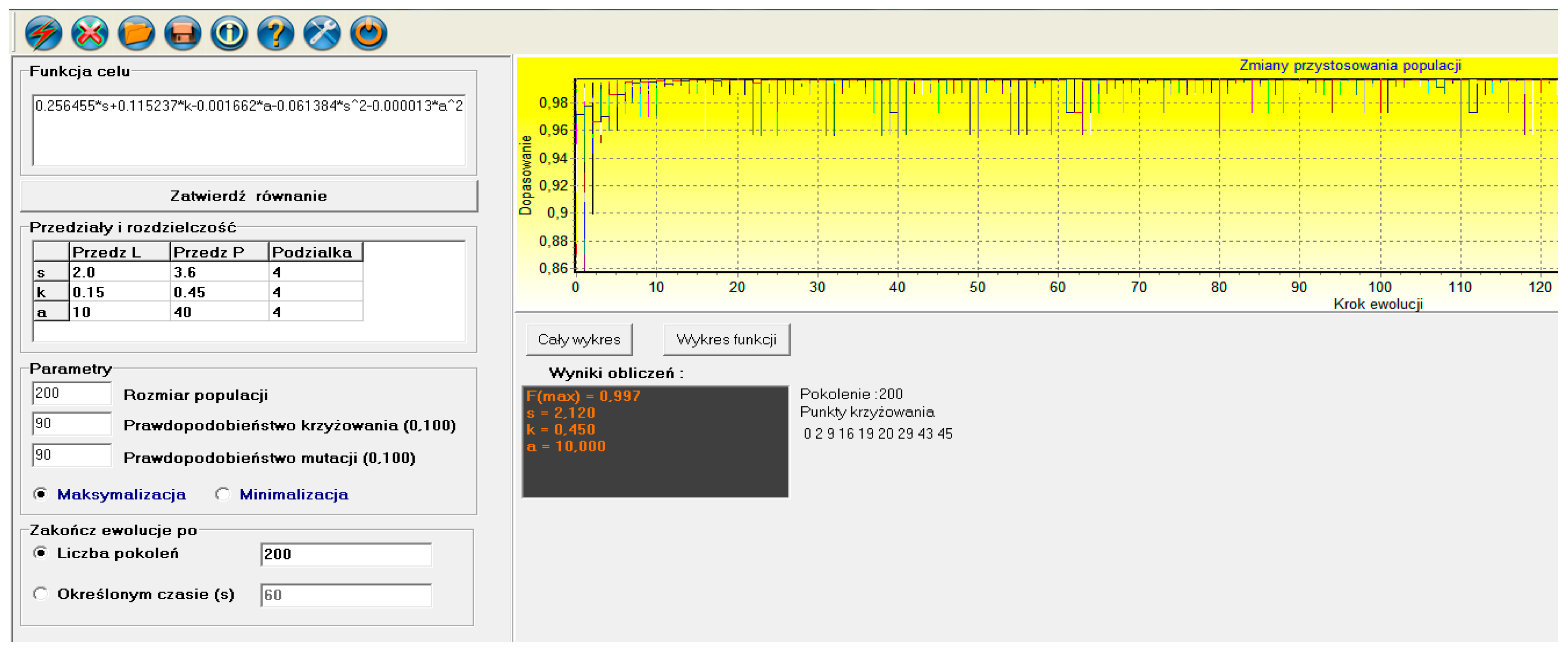

- The appropriate forms of the objective function (stochastic models) for optimization were found (Equations (1)–(3)).

- –

- The search intervals (range of parameters) for the task were defined at s <2.0; 3.6>, k <0.15; 0.45>, q <0.1; 0.4> and α <10°; 40°>.

- –

- The direction of the optimization process was selected.

- –

- Constraint functions (the number of generations was limited to 200) were defined.

3. Results and Discussion

- –

- ε1 = 0.995 at s = 3.10 mm; k = 0.255; q = 0.1 and α = 14.6°.

- –

- ε2 = 0.997 at s = 2.12 mm; k = 0.45 and α = 14.6°.

- –

- ε = 0.993 at s = 2.93 mm; k = 0.254; q = 0.1 and α = 12.0°.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ohnishi, O. On the origin of cultivated buckwheat. In Proceedings of the 9th International Symposium on Buckwheat, Prague, Czech Republic, 18–22 August 2004; pp. 16–21. [Google Scholar]

- Wang, L.; Yin, F. The geography distribution of wild buckwheat resources of Yunnan province of China. In Proceedings of the 9th International Symposium on Buckwheat, Prague, Czech Republic, 18–22 August 2004; pp. 265–270. [Google Scholar]

- Jacquemart, A.L.; Cawoy, V.; Kinet, J.M.; Ledent, J.F.; Quinet, M. Is buckwheat (Fagopyrum esculentum Moench) still a valuable crop today? Eur. J. Plant Sci. Biotechnol. 2012, 6, 1–10. [Google Scholar]

- Halbrecq, B.; Romedenne, P.; Ledent, J.F. Evolution of flowering, ripening and seed set in buckwheat (Fagopyrum esculentum Moench): Quantitative analysis. Eur. J. Agron. 2005, 23, 209–224. [Google Scholar] [CrossRef]

- Japhet, W.; Zhou, D.; Zhang, H.; Zhang, H.; Yu, T. Evidence of phenotypic plasticity in the response of Fagopyrum esculentum to population density and sowing date. J. Plant Biol. 2009, 52, 303–311. [Google Scholar] [CrossRef]

- Jacquemart, A.L.; Gillet, C.; Cawoy, V. Floral visitors and importance of honey bee on buckwheat (Fagopyrum esculentum Moench) in central Belgium. J. Hortic. Sci. Biotechnol. 2007, 82, 104–108. [Google Scholar] [CrossRef]

- Taki, H.; Okabe, K.; Makino, S.; Yamaura, Y.; Sueyoshi, M. Contribution of small insects to pollination of common buckwheat, a distylous crop. Ann. Appl. Biol. 2009, 155, 121–129. [Google Scholar] [CrossRef]

- Steadman, K.J.; Burgoon, M.S.; Lewis, B.A.; Edwardson, S.E. Obendorf, RL. Buckwheat seed milling fractions: Description, macronutrient composition and dietary fibre. J. Cereal Sci. 2001, 33, 271–278. [Google Scholar] [CrossRef]

- Unal, H.; Izli, G.; Izli, N.; Asik, B.B. Comparison of some physical and chemical characteristics of buckwheat (Fagopyrum esculentum Moench) grains. CyTA-J. Food 2017, 15, 257–265. [Google Scholar] [CrossRef]

- Jiang, P.; Burczynski, F.; Campbell, C.; Pierce, G.; Austria, J.A.; Briggs, C.J. Rutin and flavonoid contents in three buckwheat species Fagopyrum esculentum, F. tataricum, and F. homotropicum and their protective effects against lipid peroxidation. Food Res. Int. 2007, 40, 356–364. [Google Scholar] [CrossRef]

- Gulpinar, A.R.; Orhan, I.E.; Kan, A.; Senol, F.S.; Celik, S.A.; Kartal, M. Estimation of in vitro neuroprotective properties and quantification of rutin and fatty acids in buckwheat (Fagopyrum esculentum Moench) cultivated in Turkey. Food Res. Int. 2012, 46, 536–543. [Google Scholar] [CrossRef]

- Lan-Sook, L.; Eun-Ji, C.; Chang-Hee, K.; Jung-Min, S.; Young-Boong, K.; Dong-Ho, S.; Hyun-Wook, C.; Yun-Sang, C.; Jun-Seok, K.; Jong-Dae, P. Contribution of flavonoids to the antioxidant properties of common and tartary buckwheat. J. Cereal Sci. 2016, 68, 181–186. [Google Scholar]

- Levent, H.; Bilgiçli, N. Enrichment of gluten-free cakes with lupin (Lupinus albus L.) or buckwheat (Fagopyrum esculentum Moench) flours. Int. J. Food Sci. Nutr. 2011, 62, 725–728. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Zhang, Q.H. Advances in the development of functional foods from buckwheat. Crit. Rev. Food Sci. 2001, 41, 451–464. [Google Scholar] [CrossRef] [PubMed]

- Bonafaccia, G.; Marocchini, M.; Kref, I. Composition and technological properties of the flour and bran from common and tartary buckwheat. Food Chem. 2003, 80, 9–15. [Google Scholar] [CrossRef]

- Christa, K.; Soral-Smietana, M. Buckwheat grains and buckwheat products—Nutritional and prophylactic value of their components—A review. Czech J. Food Sci. 2008, 26, 153–162. [Google Scholar] [CrossRef]

- Rawa, T. Studia nad skutecznością czyszczenia ziarna gryki [A study of the buckwheat grain cleaning effectivenss]. Acta Acad. Agric. Technol. Olst. Aedif. Mech. 1992, 22 (Suppl. A), 1–63. [Google Scholar]

- Kwiatkowski, J.; Szczukowski, S.; Tworkowski, J. Production of buckwheat seeds on soil of a good wheat soil suitability complex. In Proceedings of the 9th International Symposium on Buckwheat, Prague, Czech Republic, 18–22 August 2004; pp. 475–480. [Google Scholar]

- Pozeliene, A.; Lynikiene, S.; Sapailaite, I.; Sakalauskas, A. Utilization of strong electric field for special cleaning buckwheat seeds. Agron. Res. 2008, 6, 291–298. [Google Scholar]

- Pozeliene, A.; Lynikiene, S.; Sapailaite, I. Use of electroseparator in improving the quality of ecological buckwheat seeds. Žemės Ūkio Mokslai 2010, 17, 56–59. [Google Scholar]

- Codex Alimentarius Commission. Ad Hoc Working Group on the Revision of the Standard for Gluten-Free Foods. Available online: http://eagri.cz/public/web/file/3535/al30_26e_1_.pdf (accessed on 23 October 2018).

- Kaliniewicz, Z. Modelowanie tryjerów z wgłębieniami kieszonkowymi w aspekcie poprawy skuteczności czyszczenia nasion gryki [Modelling Trieurs with Pocket Pits in Aspect of Efficiency Improvement of Buckwheat Seeds Cleaning]. Ph.D. Thesis, Politechnika Warszawska, Wydział Budownictwa, Mechaniki i Petrochemii, Płock, Poland, 2000; 98p. (In Polish). [Google Scholar]

- Konopka, S. Analiza procesu separacji nasion gryki przy wykorzystaniu prętowych powierzchni roboczych tryjerów [An analysis of buckweat seed separation process using trieur bar-type working surfaces]. Inżynieria Rolnicza 2006, 8, 123. (In Polish) [Google Scholar]

- Wierzbicki, K.; Semczyszyn, M. Urządzenie do rozdzielania mieszaniny ziarnistej, zwłaszcza nasion gryki [A Device for Separating Seed Mixtures, in Particular Buckwheat Seeds]. Patent UP PRL No. P-137216, 30 November 1988. (In Polish). [Google Scholar]

- Rawa, T. Cylinder do maszyny czyszczącej, zwłaszcza do czyszczenia ziarna gryki [Cleaning Cylinder in Particular for A Buckwheat Cleaning Machine]. Patent Application No. P-290419, 23 May 1991. (In Polish). [Google Scholar]

- Rawa, T.; Semczyszyn, M. Oddzielacz nasion trójgraniastych, zwłaszcza nasion gryki [Separator of Three-sided Seeds, especially Buckwheat Seeds]. Patent UP PRL No. P-160088, 26 February 1993. (In Polish). [Google Scholar]

- Konopka, S. Skuteczność czyszczenia gryki przeznaczonej do siewu i przetwórstwa [The Efficiency of Cleaning Buckwheat Seeds for Planting and Food Processing]. Ph.D. Thesis, Akademia Rolniczo-Techniczna, Olsztyn, Poland, 1995. (In Polish). [Google Scholar]

- Kaliniewicz, Z.; Rawa, T. Analiza cech geometrycznych nasion gryki pod kątem określenia kształtu i wymiarów wgłębień tryjera cylindrycznego [Analysis of geometrical characteristics of buckwheat seeds with respect to determining shape and dimensions of cylindrical trieur pits]. Problemy Inżynierii Rolniczej 2001, 1, 21–28. (In Polish) [Google Scholar]

- Rawa, T.; Kaliniewicz, Z. Cylinder tryjera do czyszczenia nasion gryki [Trieur Cylinder for Cleaning Buckwheat Seeds]. Patent UP RP No. PL 187945, 30 November 2004. (In Polish). [Google Scholar]

- Grochowicz, J. Maszyny do Czyszczenia i Sortowania Nasion [Seed Cleaning and Sorting Machines]; Wydawnictwo Akademii Rolniczej: Lublin, Poland, 1994. [Google Scholar]

- Kaliniewicz, Z.; Rawa, T. Analiza teoretyczna skuteczności rozdzielania mieszaniny nasion gryki i łuszczyn rzodkwi świrzepy w tryjerze z wgłębieniami kieszonkowymi [Theoretical analysis of the effectiveness of separating buckwheat seeds and wild radish siliques from their mixture in scooping area of a pocket trieur]. Problemy Inżynierii Rolniczej 2002, 4, 43–49. (In Polish) [Google Scholar]

- Choszcz, D. Efektywność rozdzielania mieszaniny nasion rzepaku i przytulii czepnej w separatorze z taśmą pętelkową [Separation efficiency for mixture of rape and cleavers seeds in a separator with looped belt]. Inżynieria Rolnicza 2009, 7, 106. (In Polish) [Google Scholar]

- Ahmed, S.G. Automatic generation of basis test paths using variable length genetic algorithm. Elsevier B.V. 2014, 114, 304–316. [Google Scholar]

- Konopka, S.; Choszcz, D.J.; Markowski, P. Optimization of the separation parameters and indicators of separation efficiency of buckwheat seeds. Sustainability 2017, 9, 2134. [Google Scholar] [CrossRef]

- Kaliniewicz, Z.; Konopka, S.; Rawa, T.; Wierzbicki, K. Propozycje nowych maszyn do czyszczenia ziarna gryki [Proposals of new machines to dry-cleaning of buckwheat grain]. Zeszyty Problemowe Postępów Nauk Rolniczych 2002, 486, 333–340. (In Polish) [Google Scholar]

- Choszcz, D.; Konopka, S.; Wierzbicki, K. Wyniki badań wstępnych skuteczności czyszczenia nasion gryki w fotoelektrycznym separatorze [Preliminary test results of the efficiency of buckwheat seed cleaning in a photoelectric separator]. Inżynieria Rolnicza 2003, 7, 17–22. (In Polish) [Google Scholar]

| Physical Parameter | Species | |

|---|---|---|

| Buckwheat Seeds | Wild Radish Siliques | |

| Thickness (mm) | 3.35 ± 0.28 | 3.61 ± 0.65 |

| 2.61–4.14 | 2.00–5.50 | |

| Width (mm) | 3.86 ± 0.36 | 3.82 ± 0.65 |

| 2.99–4.84 | 2.25–5.70 | |

| Length (mm) | 6.08 ± 0.52 | 5.88 ± 1.02 |

| 4.89–7.15 | 4.04–9.26 | |

| Angle of external friction (°) | 29.4 ± 4.97 | 18.8 ± 5.35 |

| 17–43 | 8–37 | |

| 1000-seed weight (g) | 22.9 ± 5.20 | 14.8 ± 6.63 |

| 7.0–35.8 | 4.5–39.5 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konopka, S.; Markowski, P.; Kaliniewicz, Z.; Choszcz, D.J.; Lipiński, A.J.; Kusińska, E. Optimization of the Separation Efficiency of Buckwheat Seeds and Wild Radish Siliques in a Grader with Indented Pockets. Sustainability 2018, 10, 3870. https://doi.org/10.3390/su10113870

Konopka S, Markowski P, Kaliniewicz Z, Choszcz DJ, Lipiński AJ, Kusińska E. Optimization of the Separation Efficiency of Buckwheat Seeds and Wild Radish Siliques in a Grader with Indented Pockets. Sustainability. 2018; 10(11):3870. https://doi.org/10.3390/su10113870

Chicago/Turabian StyleKonopka, Stanisław, Piotr Markowski, Zdzisław Kaliniewicz, Dariusz Jan Choszcz, Adam Józef Lipiński, and Elżbieta Kusińska. 2018. "Optimization of the Separation Efficiency of Buckwheat Seeds and Wild Radish Siliques in a Grader with Indented Pockets" Sustainability 10, no. 11: 3870. https://doi.org/10.3390/su10113870

APA StyleKonopka, S., Markowski, P., Kaliniewicz, Z., Choszcz, D. J., Lipiński, A. J., & Kusińska, E. (2018). Optimization of the Separation Efficiency of Buckwheat Seeds and Wild Radish Siliques in a Grader with Indented Pockets. Sustainability, 10(11), 3870. https://doi.org/10.3390/su10113870