1. Introduction

According to data provided by the International Energy Agency, buildings consume over a third of the worldwide energy produced, and represent a major source of carbon dioxide-related emissions [

1]. Indeed, it is expected that, if no measures are adopted to enhance the sector’s energy efficiency, energy consumption will increase up to more than 50% by 2050. Buildings in the European Union account for 40% of total primary energy consumption and 36% of total CO

2 emissions. A large part of the energy demand of buildings (up to 70%) is for heating and cooling, 75% of which is met by fossil fuels and only 18% by renewable sources [

1]. To promote energy saving measures and reduce the power consumption to heat and cool European buildings, the European Commission launched a strategy of engagement to cut down the huge quantity of energy used in heating and cooling. This is in line with the Energy Efficiency Directive (EED-2012/27/EU) through which a common framework is established to promote energy efficiency within members states [

2,

3].

Furthermore, almost zero energy consumption will be a legal requirement in the construction of buildings by the end of 2018. Nearly Zero-Energy Buildings (NZEB) should not be the buildings of the future, but of the present. In this regard, the European directive 2010/31/EU determines that from 31 December 2018 all new public buildings will be NZEB, and in 2020 the rest will be NZEB [

4,

5]. A NZEB is a very highly energy-efficient building, so the nearly null or minimal quantity of requested energy must be largely satisfied by clean energy sources, whether produced on site or in the surrounding environment [

6].

The European Union has as one of its major objectives to promote energy saving and energy efficiency measures, so that compared to the 1990 levels, the European Union’s commitments to achieve this are to reduce Greenhouse Gas (GHG) emissions by 20%; to save 20% of energy consumption through greater energy efficiency; to cover in each country 10% of transport needs must by biofuels; and to promote renewable energies so that they account for 20% of the energy mix [

7].

To increase the share of renewables in the energy mix, as well as energy efficiency, new innovative sources of renewable energy should be researched and promoted. Biomass is a high-energy, clean source with a high degree of sustainable growth due to its carbon neutral status and high availability worldwide, as it can be obtained from a wide variety of agro-industrial and livestock waste. It accounts for between 9% and 14% of total primary energy consumption in industrialized countries, while in developing countries bioenergy accounts for approximately a fifth to a third of total consumption [

8,

9,

10]. However, despite its potential as environmentally friendly energy source, biomass is largely discarded without making any energy use of it.

In the meantime, the transformation towards energy sustainability needs measures [

11] such as the promotion of efficiency [

12], the provision of energy services [

13], cooperation for energy development [

14], or the incorporation into legislation of the most innovative technologies and procedures for efficiency [

15]. Among these measures, it should not be forgotten to help finance efficiency improvements [

14]. This means for governments to invest in a more sustainable and productive economy over the long term [

16]; however, for households, it is necessary to have short-term results to assume the costs of the required investments [

17]. Then, the key is to encourage energy efficiency and savings of households [

18], and within these highlights the residential use of energy, which must take into account both the combination of obtaining energy with an efficient and clean technology [

19] and maintenance operations of the same [

20].

Biomass is the set of organic matter, of vegetable or animal origin, and the materials that come from their natural or artificial transformation. Directive 2009/28/EC on the promotion of the use of energy from renewable sources, defines biomass as “the biodegradable fraction of products, disposals and residues of biological origin coming from agricultural activities (including substances of plant and animal origin), of forestry and related industries, including fisheries and aquaculture, as well as the biodegradable fraction of industrial and municipal waste”. That is, biomass is a very broad concept that includes from the waste coming from the forestry, agricultural and livestock activities up to the organic fraction of domestic and industrial waste, including the by-products of the agri-food and wood processing industries [

21,

22,

23].

Biomass, from an environmental point of view, could be seen as a straightforward alternative to fossil fuels, especially coal, as it burns or gasifies in a similar way to coal and, similar to coal, produces greenhouse gas emissions, mainly CO

2. Nevertheless, there are important differences. The biomass of the plant as it grows captures carbon dioxide out of the atmosphere through photosynthesis process [

13]. Therefore, throughout the cycle of growth, harvest and combustion, there is a net balance between the addition and subtraction of CO

2 into the atmosphere. However, the major distinction between biomass and coal is that biomass does not contain sulphides and therefore biomass gas power plants do not require treatment to remove sulphur dioxide before releasing emissions into the atmosphere.

The main fuels obtained from biomass are firewood, wood chips, pellets, olive stone and fruit shells. Firewood cut and chopped, ready for use in domestic combustion appliances such as stoves or chimneys, is the least elaborate of them, and they have traditionally been used in single-family homes. Chips are the product resulting from the crushing of biomass of woody origin, both agricultural and forestry, and have a variable size depending on the degree of crushing to which they have been subjected. The pellets are the most elaborated product, and they are small cylinders of 6–12 mm in diameter and 10–30 mm in length made with sawdust, splinters or other compressed waste that can be used as fuel [

24,

25].

Fruit stones and seeds as well as fruit husks, although used in smaller quantities than firewood, wood chips and pellets, also are a fuel that is increasingly used. In recent years, as the exploitation of the immense potential available and a market for biomass has been consolidated, increasing the agents involved and the volumes commercialized, efforts have been increased to standardize and certify the quality of this type of fuels, mainly chips and pellets (ISO 17225 standards), having even studios recent (BIOMASUD) and specific standards intended for biomass waste such as olive stone and fruit shells (standards UNE-164003 and UNE-164004, respectively) [

26,

27].

The sunflower (

Helianthus annuus) is a large herbaceous crop of the Asteraceae family, widely cultivated worldwide due to its relatively short growth cycle, high resistance to drought and adaptation to different soil conditions. The top producers’ countries of sunflower and sunflower derivatives are the Russian Federation, Ukraine and Argentina, which produce roughly half of the world’s sunflower seed production.

Figure 1 shows world production of sunflower.

Sunflower is currently planted in six continents (

Figure 1), with the cultivated world surface of 26.2 million hectares with a total production of 47.34 million tons. In other words, the world average yield of this oleaginous species is 18,067 hg/ha. On the European continent, 18.07 million hectares (70% of the world surface) are harvested, of which 16.31 million are in the Eastern Countries. In Spain, the area sown with sunflower is stabilized at 700,000 hectares (4% of the European continent), being the eighth country in terms of sunflower seed production [

28].

Figure 2 depicts the trend in the world’s sunflower production over the course of 20 years.

Sunflower husk represents a weight percentage of 45–60% of the seed depending on the sunflower variety, and is separated from the kernel in the grinding process, to obtain a better pressing of the seed and a higher oil yield. Therefore, sunflower seed husk is a by-product of the sunflower oil industry, which, although widely used for the production of animal feed, its energy use is very scarce [

29]. The high energy content of this biomass-by-product makes it optimal for use as a heating fuel. However, currently, a large share of it is disposed of and sent to landfills without eco-friendly use. It should be borne in mind that, because of its carbon-neutral potential, this by-product can help mitigate the effects of climate change.

The objectives of this study were to evaluate the properties and suitability of the sunflower husk as a solid biofuel to produce heat and to evaluate the viability of a thermal installation that uses this fuel, from an energy, environmental, economic and operational point of view.

This paper presents the results on energy efficiency and economic viability, obtained from a heat generation system fed by sunflower seed husks, which would serve to cover part of the thermal energy demand in buildings of the residential sector. To meet the proposed objectives, we analysed the energy properties of sunflower husk as a solid biofuel. To evaluate the viability of a thermal installation that uses this fuel, a five-storey, sixty-room hotel located in the south of Spain was chosen, with a thermal installation consisting of a 430 kW fuel oil boiler.

2. Materials and Methods

2.1. Materials

First, an energy audit of the building was carried out to check the real situation regarding the energy management of the installations, and served as a technical basis for the feasibility study.

Once the installation was executed, to obtain the data related to its operation, each of the components of the system was introduced in the hotel’s preventive maintenance plan, assigning a specific time to each of the maintenance tasks. The daily time devoted to the maintenance work of the biomass boiler and its complementary facilities, as well as the one devoted to the location and repair of faults, was timed. In addition, the data related to the overall performance of the installation was monitored by using the remote management system of the boiler, monitoring the operating parameters and automatically recording the operating status and the value of its control parameters. The data acquisition procedure was enhanced with the data obtained from the historical archive of the hotel’s maintenance service.

To validate the results obtained during the analysed period, the values have been contrasted by means of a second energy audit. The data collection methodology is described in

Figure 3.

As far as fuel analysis is concerned, 2000 g of sunflower seed husks were gathered for subsequent analysis coming from sunflower oil industries in the area (

Figure 4).

2.2. Determination of Quality Parameters and Equipment

The quality parameters were set by the UNE-EN 14961-1 standard “Solid biofuels–Specifications and fuel classes—Part 1: General requirements”, developed by the Spanish Association for Standardisation and Certification (AENOR).

Table 1 shows the standards and the measuring equipment used. The samples were characterized by their dry weight content.

2.2.1. Physical Parameters: Humidity

To determine the moisture percentage of the sample, it was dried at 105 ± 2 °C using an oven (MEMMERT UFE 700) and performing 3–5 full air exchanges per hour. The mass loss of the sample indicates the percentage of humidity, but considering the increase in mass of the trays produced by the heat expansion effect.

The moisture content of a solid biofuel is a key factor in its energy efficiency, because it is necessary to evaporate the water it contains before the heat is released. Therefore, the higher the moisture content of the fuel, the poorer its combustion power will be. Most heat transfers require fuels with a moisture content below 30%, achieving optimum yields at 10% humidity. With low moisture content, the combustion is complete, reducing both the emission of tars that tend to accumulate in the exhaust fumes and the problems of corrosion and clogging in the chimneys [

30].

2.2.2. Chemical Parameters: Elemental Composition

Carbon (C), Hydrogen (H) and Nitrogen (N) determine the elemental composition of the biomass. For the calculation of the total content of carbon, hydrogen and nitrogen, the UNE-EN 15104:2011 standard was applied and the LECO TruSpec CHN 620-100-400 analyser, which works in accordance with the Dumas combustion method, was used as measuring equipment.

To calculate the elemental composition of the biomass, a certain mass of the sample was burned in atmosphere containing oxygen or a mixture of a carrier gas and oxygen in such a way that ashes and combustion gases (carbon dioxide, water vapour, elemental nitrogen and/or nitrogen oxides, sulphur oxides and hydrogen halides) were obtained. The mass fractions of carbon dioxide, water vapour and nitrogen in the gas stream were determined quantitatively by using instrumental techniques. A drift correction with pattern EDTA was necessary before entering the sample quantity (0.1–0.25 grams) into the LECO Tru Spec CHN 620-100-400 analyser for combustion at 950 °C to quantify the proportion of carbon, hydrogen and nitrogen in the instrumentation.

A proper ultimate analysis of the biomass, i.e., the precise determination of the percentage mass contents of carbon, hydrogen and oxygen, was necessary to determine the quality of the biofuel and its Higher Heating Value (HHV). It also served to evaluate its possible environmental impact, as nitrogen is mostly converted into N

2 gas and NOx, the latter being one of the gases that contributes to the greenhouse effect. The carbon content would also allow CO

2 emissions to be assessed [

9].

2.2.3. Chemical Parameters: Sulphur and Chlorine Content

As reflected in

Table 1, the determination of the chlorine and sulphur content was carried out in accordance with the UNE-EN 15289 standard, which sets out various techniques for its quantification. In our case, we opted for a procedure similar to the one used to determine calorific value according to the UNE-EN 14918 standard, but using digestion in a calorimetric pump. In this case, by means of potentiometry (TITRATOR METTLER TOLEDO G20), the existing chlorine in the washing water generated during combustion was quantified by using silver nitrate.

For sulphur, a procedure similar to that used for the determination of the elemental chemical composition (C, H, and N) was followed using in this case a LECO TruSpec S 630-100-700 elemental analyser where the sample was combusted at 1350 °C and the gaseous combustion products formed were quantified [

9].

2.2.4. Chemical Parameters: Non-Combustible Inorganic Fraction (Ashes)

Ashes are considered the inorganic and non-flammable part of biomass that is formed as a result of its content in minerals such as potassium, chlorine, sodium and phosphorus. The ash content is an indicative parameter of biofuel quality, where the higher the ash content, the worse the fuel quality. This is because this by-product of combustion can cause clogging and corrosion problems in various elements of the thermal installation due to the formation of sulphur oxide and molten potassium ash [

31].

To calculate the ash content, the remaining residual mass was quantified after the sample was burned in a muffle furnace (NABERTHERM LVT 15/11) under strictly controlled weight, time and temperature conditions.

2.2.5. Chemical Parameters: Total Oxygen

The UNE-EN 15296 standard “Solid biofuels–Conversion of analytical results from one base to another” was used to indirectly determine the oxygen content as the percentage left after subtracting the percentage of the other elements plus the ashes [

31].

2.2.6. Energy Parameters: HHV and LHV

The calorific value of a fuel is the amount of energy released in the combustion reaction, referred to the unit of fuel mass (e.g., J/Kg), i.e., the amount of heat delivered by 1 kg, or 1 m3 of fuel when completely oxidised.

The calorific value is defined as the total amount of energy that can be released by the bonding of the fuel to the oxidant, and is calculated by subtracting the energy used to form additional molecules in the gases generated during combustion from the energy that keeps the atoms together in the fuel molecules.

The magnitude of the calorific value can vary according to how it is measured. Depending on the method of measurement, the expressions Higher Heating Value (HHV) and Lower Heating Value (LHV) are used. HHV, also known as Gross Heating Value (GHV), is the total amount of heat emitted in the complete combustion of 1 kg of fuel when the water vapour produced by the combustion is condensed and the heat emitted in this phase change is therefore accounted for. The LHV, or Net Heating Value (NHV), is the overall quantity of thermal output from the complete burning of 1 kg of fuel, excluding the latent heat portion of the combustion water vapour, as there is no phase-shift and it is released as steam [

9].

The UNE-EN 14918 standard establishes the procedure for the determination of the HHV of a solid biofuel at a steady volume and 25 °C, by the use of a calorimetric pump (PARR 6300) gauged by the combustion of benzoic acid. The ultimate result is HHV at constant volume with the water from the combustion remaining liquid. The UNE-EN 14918 standard was also used to determine the LHV from the HHV by deducting the energy losses associated with the evaporation of water and the formation of other gases. For our case study, the moisture-free LHV (dry basis) was calculated from the constant volume HHV and the elemental chemical composition by using the following equation:

Hdb%, Odb%, and Ndb% represent the elemental hydrogen, oxygen and nitrogen contents of biofuel (dry basis), respectively.

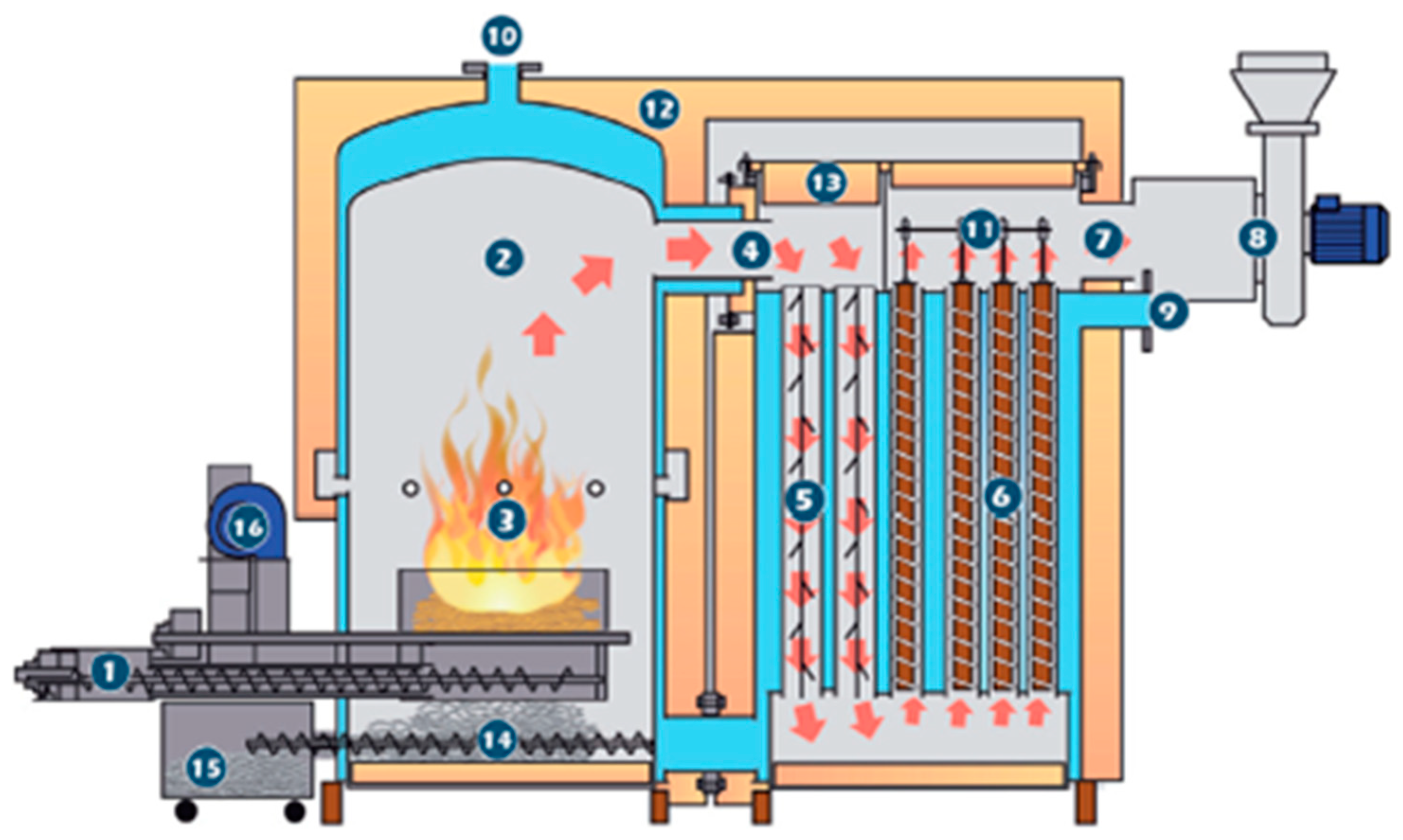

2.3. Boiler

The biomass boiler, which was installed for space heating and sanitary hot water, works in conjunction with existing boilers, maintaining the previous boiler in reserve mode to automatically start up redundantly in the case of failure. It is the Oliva-430 model of the manufacturer Hergom Industries, has a power of 430 kW, and complies with the UNE-EN 303/5 standard (heating boilers–special boilers for solid fuels) [

32]. The operation of the Oliva 430 boiler is fully automatic and is equipped with an adjustable electronic panel. It is made of a steel body that guarantees maximum heat transmission of the combustion products to the water, thus achieving high performance. The high-capacity fuel tank guarantees long-lasting autonomous operation. The generated ashes are deposited in the bottom of the chamber, being very easy to remove.

The operating pressure of the system is 6 bar and the power can be regulated according to demand, as the burner is electronically adjusted by means of proportional, integral and derivative (PID) controller. In addition, the boiler has automatic ignition control, an automatic cleaning system as well as an automatic ash collection system by means of a worm screw. The boiler replaced, which used fuel oil as fuel, had a nominal power similar to the installed.

A worm screw is used to transport the fuel from the storage silo to the boiler, in whose combustion chamber the fuel is introduced by gravity and the transfer of energy in the form of heat to the water of the primary circuit occurs. The operating diagram of the boiler is shown in

Figure 5.

In addition, the boiler has a remote management system, connected to a programmable logic controller (PLC) that is integrated into the boiler itself that allows to regulate its operation, monitor and at the same time control all the operating variables of the installation, obtaining information in real time of temperatures, pressures, consumption and possible breakdowns that may occur. To achieve greater efficiency by regulating the thermal demand, an inertia tank of 2000 L was provided, which acts as a heat deposit that avoids multiple burner starts, optimizing burner performance and extending the life of the installation.

The working temperature was regulated at 84 °C and the operating hours were set uninterrupted.

Figure 6 is the operating diagram of the biomass thermal power plant.

2.4. Biofuels

In Spain, the types of biomass that can be used are conditioned by the availability of the market, the most common being the olive bone, the pruning of the olive grove and fruit trees to make chips, the wood cuttings coming from industries, the husk of nuts, forest residues, vine concentrates and “pellets” [

33].

For the start-up of the installation, the economic cost per kilowatt hour relative to the use of different fuels has been evaluated, considering the costs derived from transport to the point of supply, and comparing them with the costs of non-renewable fuels (fuel oil and natural gas), considering the market prices (March 2018) for a consumption equivalent to that expected annually in the hotel.

Figure 7 shows the final costs of different fuels expressed in euro cents per kWh unit of heat energy produced, showing how renewable fuels are more economical. In particular, the sunflower husk is 43% cheaper than elaborate chip, 64% than the “pellet”, 71% than natural gas and 75% than fuel oil, assuming that the efficiency of solid fuel boilers is 10% lower than the other boilers [

34].

However, the cost of fossil fuels is taxed at a high rate. In particular, heating oil increases the final price by up to 32.3%. On the other hand, biomass derived from agri-food resources has important subsidies derived from the European Union’s agrarian policy. These facts alter the real price of commercialization of both types of fuels in such a way that, from a purely economic perspective, it even equals them.

In the medium to long term, the trend of increasing production costs of hydrocarbons and their derivatives, clearly upwards, will increase the price difference with respect to biofuels, whose cost tends to stabilize as the industries dedicated to the transformation of by-products.

Among the different types of existing biomass, it was decided to use crushed sunflower husk as fuel, whose physical characteristics are specified in

Table 2.

The axial dimensions of the grains were determined from samples of 10 randomly selected seeds. The length (L), width (W) and thickness (T) of the seeds and husk thickness were obtained using a 0.001 mm resolution outside micrometer (DP-1HS, Digimatic Mini-Processor, Mitutoyo, Japan).

The true density (ρt), defined as the ratio of the mass of the sample to its true volume, was determined by using pycnometry; for each test, the 10 grain husk was used and xylene was used as the liquid to be displaced. The apparent density (ρb), the ratio of the mass of a grain sample to its total volume, was calculated using a standardized weight-hectolitre scale. Physical properties are reported as averages of ten repetitions.

Bed porosity (

ε), defined as the fraction of space in bulk seed that is not occupied by grains, was calculated using Equation (2) [

35].

The difference between the true density of 644.4 ± 28.3 kg/m3 and the apparent density of 95 ± 1 kg/m3 shows the main problem with this waste, large volumes of light weight. Residual biomass, in general, presents low energy density and it is essential to increase density to reduce problems and logistic costs for its use. Densification, which consists of compacting small pieces of biomass (wood sawdust, stubble, rice residues, coffee, sugar cane, etc.) into pieces of similar shape and size, becomes necessary for the use of this biofuel. The products formed (pellets and briquettes) have a constant density and moisture content, which makes the calorific value more homogeneous and improves the combustion efficiency of the equipment. With compaction, the density can be reduced up to 10 times. If the density is higher, the energy/volume ratio is also higher.

As already mentioned, this biofuel is obtained from the grinding process of the sunflower seeds in the mills, and it is considered a by-product of the oil sunflower extractor industries. Its size and low moisture content (usually below 10%) ensures the proper performance of the installation, thus proper combustion of all particles.

The high availability of this type of fuel means that it can be used throughout the year, as world sunflower production is around 47.34 million tons, of which 72% corresponds to Europe, with Spain being the eighth largest producer country within the European continent [

28]. Therefore, sunflower husks are a renewable biomass resource, although limited to the production of the basic industry from which they are derived.

3. Results and Discussion

Energy properties of the sunflower seed husk were analysed and compared with other biomass residues and the energy, environmental, economic and operational balance of the biomass thermal installation was calculated.

3.1. Sunflower Seed Husk Quality Parameters

To quantify and assess the quality parameters, samples of sunflower husk from the sunflower oil industry were analysed.

Table 3 lists the mean, median, standard deviation, and maximum and minimum values that define the parameters distribution.

One of the most interesting properties of sunflower husks as biofuel is their low moisture content, below 10%. This means that no lengthy pre-drying processes will be required, as is the case with other wood biofuels, and that energy losses due to water evaporation during combustion are therefore minimal.

As the ash content of the sunflower husk is within the range of 1.98–2.22%, in comparison with the ash concentration of other solid biofuels currently used such as almond shell pellets (3.35%), olive pellets (4.79%) and oak pellets (3.32%), it is observed that, despite having a high ash content, its value is below those of other standardized fuels.

The physicochemical parameters obtained from the analysis were compared with those of other standardized solid biofuels currently in use to establish the suitability of this waste by-product for the generation of thermal energy.

Table 4 compares the quality parameters of various biofuels (pine pellets, olive stone, and almond shell) with those of the sunflower husk.

In view of the data obtained, it could be concluded that the ash percentage is clearly greater compared to some of the most widely used biofuels, which means that plant produces more residuum, and therefore corrosion problems and maintenance cost may increase.

Ash constitutes the inorganic constituent fraction of biomass and is produced as a consequence of its content in potassium, chlorine, phosphorus, silica and calcium. The inorganic elements that contain biomass might adopt three forms: uniformly spread in the biofuel, as independent granules of inorganic matter, or as impurities provided by the fuel in its collection, transport and subsequent treatment process. The chemical make-up of the ashes is mainly SiO2 and CaO, and to a lesser extent the oxides of magnesium, aluminium, potassium and phosphorus.

In practice, ash-related issues in the burners and boilers of biomass combustion systems are linked to:

- –

The partially melted ashes tend to form agglomerates on the grid walls as well as to form slag deposits on the installation.

- –

Ash deposits formation at moderate temperature zones or exchangers in convection heat boilers.

- –

Rapid corrosion and abrasion of the metal body of the installation at its most critical points.

- –

Ash aerosol emission.

- –

Removal of ash waste from boilers.

Overall, it can be concluded that the efficiency of the plant is strongly dependent on the properties of the fuel (ash content, elemental composition and calorific value) as well as on the design and reliability of the installation.

As far as calorific value is concerned, the values of HHV and LHV are roughly similar to those of olive stone and a little inferior to those of almond shells, which demonstrates the high energy potential of this residual biomass. The last row of

Table 4 shows a comparison of the HHV in per cent, ranging from 0.2% to 11%.

With regard to chlorine and sulphur, their proportion varies according to the biofuel chosen, and, once it is consumed, they are generally transformed into sulphur and chlorine oxides. These combustion by-products increase the corrosion problems of the installation, while also emitting greenhouse gases into the atmosphere as SOx. In the case of sunflower husk, the sulphur content is 0.24%, which is double that of olive stones and five times higher than that of almond shells, indicating that SOx emissions are higher than those of other solid biofuels, but lower than those of fossil fuels.

The chlorine content, which depends on the soil composition, has a significant effect on the corrosiveness of the installation. Chlorine has been shown in many scientific investigations to have a dissociative catalytic effect on steel pipe materials in heat exchangers, also at low temperatures (100–150 °C). This problem is greater in fuels with a molar ratio of Cl:S higher than 2, because the absence of sulphides leads to the chlorides formation, resulting in a catalytic effect on corrosion. The sunflower husk has an average chlorine content of 0.08%, which is below that of other biofuels such as almond shell (0.20%), wood material (0.1%) and cereal residues (0.4%), which implies that corrosion problems could be diminished if this biofuel is used.

3.2. Energy Balance

The energy balance of the biomass installation has been made based on the historical demand of the last five years, both hot water for heating and domestic hot water. The energy demand that the biomass boiler must meet annually has been estimated and it has been assumed that the performance of the biomass heating system is 10% lower than the previous diesel boiler. In

Table 5, the parameters are detailed.

The calculations of the thermal demand considered that the use of hot water for heating is carried out in the months of October–April, while the boiler is only used to produce domestic hot water in the remaining months. According to the calorific value (LHV) of sunflower seed husk, 223 tonnes of this by-product are needed to meet the annual thermal demand of the installation.

3.3. Environmental Balance

The main advantage of biomass as an energy source is its renewable nature, since it uses organic waste from agricultural activities or garbage from cities as its primary source. Whether in the form of unprocessed waste, pellets, biogas or biodiesel, biomass is unlimited, as living beings can never stop producing waste. The use of biomass energy to generate thermal and electrical energy—due to the burning of the same or its derived fuels—is considered as a neutral emission activity. This is because it takes advantage of the carbon that was initially in the plants and therefore was part of the natural CO2 cycle. Then, once these fuels are burned, the CO2 produced returns to the forests or sources of vegetation and is used in photosynthesis, being the carbon neutral balance throughout the cycle. In addition, the use of biomass boilers generates lower emissions than conventional fuel boilers, reducing emissions of sulphur and particles and pollutants such as CO, HC and NOx.

Other advantages associated with the biomass use are its contribution to the reduction of forest fire and pest risks, the cleanliness of forests, the use of by-products from industries and the generation of local employment.

However, the greatest advantage of using biomass as an energy source is its contribution to mitigating the effects of climate change. Biomass emits CO

2, but in the same proportion that the plant absorbed during its growth process, so this CO

2 is considered zero. In addition, the emission of other greenhouse gases (NOx and SOx) is significantly lower compared to fossil fuels. To carry out an environmental analysis, assessing possible reductions in greenhouse gases emissions regarding to the suggested scenario, an estimated installation level of direct greenhouse gases emissions linked to the existing fuel oil boiler was worked out, in accordance with Well to tank Report, v 4.0, submitted by the Joint Research Institute [

41].

Table 6 presents the emission coefficients considered in this work.

Assuming that the plant retains more CO

2 in the growing cycle than it releases when it is burned, the emissions of this gas are zero [

43]. As can be seen in

Table 7, the biomass thermal installation for the case study would produce annual reductions of 254.09 tonnes of carbon dioxide (CO

2), 438.24 tonnes of sulphur dioxide (SO

2), and 209.97 tonnes of nitrous oxide (N

2O) emissions, compared to the conventional fuel oil installation.

During the first year, carbon dioxide emissions to the atmosphere would be lowered by 254.09 tons, corresponding to the annual CO

2 sequestration of roughly 5092 adult trees [

44].

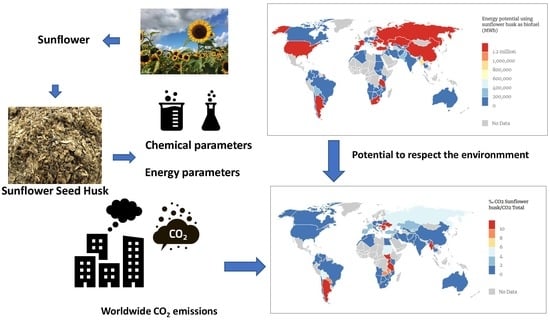

It is interesting to carry out a worldwide study of the energy potential of sunflower husks as biofuel, and its effect on reducing CO

2 emissions. First, after determining the calorific value of the sunflower husk and knowing the annual production of each country [

28], it is possible to calculate the energy production that can be generated by the combustion of this biomass using Equation (3):

where

Ec is the energy expressed in MWh that could be generated using all the sunflower husks produced in a selected country;

Pc is the production of sunflower seeds from a specific country (kg), taking data for the year 2016;

fs is the factor of husk in a whole sunflower seed (45%);

LHV is the previously determined Lower Heating Value (16.507 MJ/kg); and

Uc is the conversion unit (0.000277778 Wh/J).

In the case of Spain, sunflower seed production was 755,050 t in 2016, which means the possibility of generating 1557.952 GWh or 133.960 ktoe (kilo tons of oil equivalent), with 1 toe being 11.63 MWh. Therefore, considering that the world production of sunflower seed was 47.34 million tons in the same year, the total bioenergy that could be produced with this biomass is estimated at 97.69 TWh or 8.40 Mtoe.

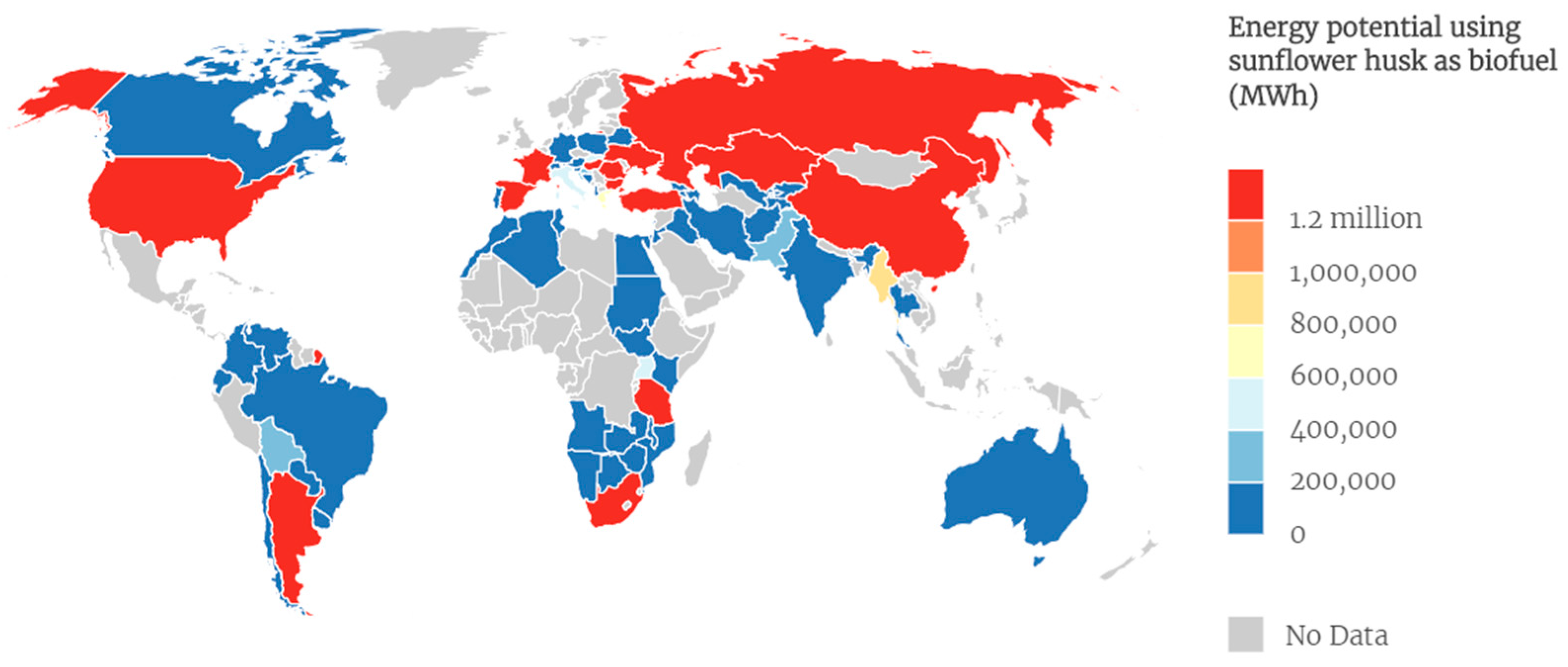

If the potential for power generation of each country is worked out using Equation (3), the world map in

Figure 8, which relates energy production to the different sunflower seed producing countries is obtained. As can be seen on the European continent, countries such as the Russian Federation, Ukraine, Romania and, to a lesser extent, Spain, stand out for their energy potential. In Asia, China concentrates the largest energy production capacity, while, in the Americas, the United States and Argentina are particularly noteworthy.

To evaluate the potential of the sunflower husk in CO2 reduction, it is necessary to consider the related fossil fuel CO2 emissions data provided by the world data bank, which converts the emissions of other greenhouse gases into CO2 equivalent. Therefore, if the equivalent energy of using sunflower husks as fuel came from fossil fuels, 0.357 tons of CO2 would be released into the atmosphere for every MWh generated.

As expected, the main countries producing sunflower seeds are those that would have the greatest potential for energy production and therefore also the greatest potential in reducing CO2 emissions. The ten main countries are: Ukraine (10 million tonnes), Russia (8.11 million tonnes), Argentina (2.21 million tonnes), China (1.9 million tonnes), Romania (1.49 million tonnes), Bulgaria (1.38 million tonnes), Turkey (1.23 million tonnes), Hungary (1.13 million tonnes) and the United States (0.88 million tonnes).

However, if we compare the total CO

2 emissions generated by each country (world data bank) with the CO

2 emissions savings associated with the use of the sunflower husk as fuel (

Figure 9), we observe that a large part of Central Africa (Tanzania, Uganda, and South Sudan) and Eastern Europe (Ukraine, Hungary, Romania and Bulgaria) would obtain emissions savings greater than ten per thousand.

3.4. Economical Balance

The market for decentralised biomass boilers is largely conditioned by regional fossil fuel prices, and is increasing, especially in countries where high taxes are levied on fossil fuels. The economic balance was carried out by means of a comparative study between the old fuel-oil installation and the new biomass-based installation, calculating the annual cost necessary to meet the thermal energy demand of the building with each of the fuels.

Table 8 shows both the annual fuel oil consumption of the former installation and the actual cost of heating, considering 0.91 €/L as the value of the fuel oil. As can be seen, the total annual cost with fuel oil was 81,700 €.

The amount of fuel required in both scenarios (fuel oil boiler and biomass boiler) can easily be calculated by dividing the annual thermal energy demand of the installation by the lower heating value of the fuel, but taking into account the boiler efficiency. That is to say,

With the new biomass boiler, 222,615.80 kg of sunflower husks were consumed, and considering a price of this by-product already treated of 0.09 €/kg, the annual cost associated with the new biomass installation is 20,035.42 €, which translates into an economic saving of 61,664.58 € for a 430 kW installation. This represents a cost saving of 75.47% of the present yearly expenditure.

These calculations were made for an operating time of 1900 h per year, considering that the use of hot water for heating is made in the months from October to April, while only the boiler is used to produce sanitary hot water in the remaining months. However, it must be borne in mind that, due to the existence of an inertial tank, the number of operating hours could be reduced.

The investment was 193,000 €, and considering the annual savings of 61,664.58 € produced, a return period of 3.13 years is obtained, which is lower than that obtained in other types of installations based on solar collection. Therefore, during the first ten years of operation, the total savings obtained with the use of this biofuel would be greater than 400,000 €. On the other hand, the purchase value of an equivalent amount of CO

2 avoided in the emissions rights market (reference August 2018), would mean an additional saving of 4800 €/year [

45].

The 223 tons of sunflower husks can be easily obtained from the sunflower oil industries in the area, which sell their surplus waste once their energy demands from the manufacturing processes have been met, contributing on the one hand to a better use and environmental management of this agro-industrial by-product, and on the other hand to an enhancement of the local economy.

3.5. Operating Balance

The security and continuity in the supply of any thermal power plant is essential to guarantee an acceptable quality of the installation. In the case of residential buildings, they become critical facilities in terms of the aforementioned factors, making it essential to carry out a detailed study on their reliability, availability and maintainability.

For this, a survival function is implemented, defined as the probability that the moment of a failure is later than a specified time, and that mathematically corresponds to the expression:

where

R(

t) is the survival function,

t is time,

T is a random variable that denotes the moment of failure, and

Pr is the probability. For the analysis of reliability in time-bound processes, the concept of failure rate has been used, which is defined as follows:

The failure rate over time is defined as the failure probability of the equipment that remains in good condition during time

t, and is represented by λ(

t), according to Equation (7):

The failure rate is of particular interest, since its inverse represents the mean time between failures (MTBF), at least when

λ(

t) remains constant in time [

33]. Its mathematical expression is as follows:

To analyse the reliability of the biomass installation over time, that is, the probability that the installation is in an operational state throughout its useful life, the trend of the failure rate as a function of the number of accumulated hours of operation is plotted in

Figure 10.

It can be observed how the failure rate is high during the first 500 h of operation, which implies that redundant complementary measures must be available to ensure the continuity of supply. However, after 1000 operation hours, the system stabilizes and evolves constantly over time.

It has been proven that the technology applied to biomass boilers has a lower reliability than natural gas and diesel boilers, especially in the first stage of operation, mainly due to the calibration and start-up processes of the installation.

On the other hand, the preventive maintenance tasks of the biomass installation have increased by 100% with regard to similar thermal energy production installations using diesel and/or natural gas, due to cleaning, regulation and emptying operations of the ashtray, which implies an average additional task of 45 min/day.

4. Conclusions

The energy model of the last 150 years is unsustainable for environmental, economic and social reasons. Its transformation involves the widespread of renewable energies, efficiency and energy saving. This paper highlights the benefits of using biomass as fuel to reduce the energy consumed by buildings to meet heating demands. In concrete, it is performed an energy, environmental, economic and operational balance of a thermal installation powered by sunflower husk. For this purpose, an analysis of this residual biomass is first carried out to determine its calorific value as well as its elemental chemical analysis. The higher calorific value (17.844 MJ/kg) is similar to that of other commercially available solid biofuels, which demonstrates its potential for thermal energy generation. However, due to its low volume/energy ratio, it is necessary to pellet this biofuel to reduce transport costs.

The analysed scenario shows that, if a 430 kW boiler of fuel oil is replaced by a boiler of the same power fed by sunflower husk, 209.97 tons of NO2, 438.24 tons of SO2 and 254.09 tons of CO2 could be stopped emitting annually. In addition, the annual saving would be 75% regarding the former fuel oil installation, obtaining a return period of 3.13 years of the necessary investment.

The environmental benefit of this biomass is due to its carbon neutral condition. When comparing the possible CO2 savings of a country using this biofuel, in relation to the total CO2 emitted, it is observed how a large part of Central Africa (Tanzania, Uganda, and South Sudan) and Eastern Europe (Ukraine, Hungary, Romania and Bulgaria) would obtain savings higher than 10 per thousand, considering the total sunflower seed production of these countries.

The findings of this work help improve the energy sustainability of residential buildings while highlighting the environmental and economic benefits of the sunflower husk as a fuel, which has thus far been scarcely used. Therefore, in helping to achieve sustainable energy development, the use of local resources such as biomass for heating systems must be facilitated. As has been demonstrated, these systems make it possible to move towards a low-carbon economy, fulfilling the long-term global objective of sustainability but also that of households in the short term, as their economic viability has been seen, including maintenance costs.

As future work, it is expected to apply this methodology in other public buildings such as universities and colleges, in addition to exploring other renewable sources such as biofuel.