Lumber Recovery Rate of Cupressus lusitanica in Arsi Forest Enterprise, Ethiopia

Abstract

:1. Introduction

2. Methods

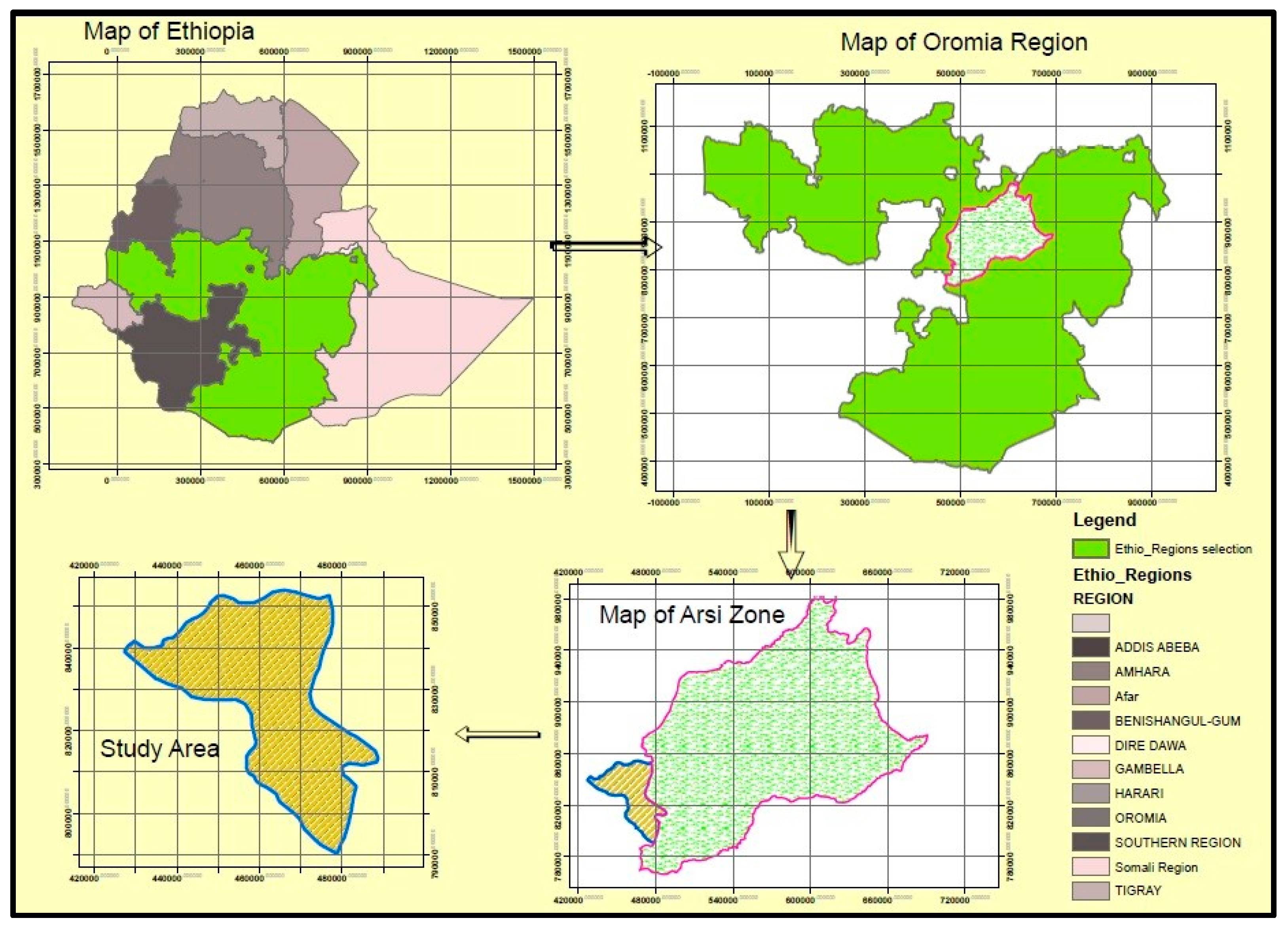

2.1. Description of the Study Area

2.2. Topography and Soil

2.3. Climate

2.4. Vegetation and Wildlife Resources

2.5. Survey and Sampling

2.6. Sawn Logs Selection and Sample Size

2.7. Data Collection, Processing and Analysis

3. Results and Discussion

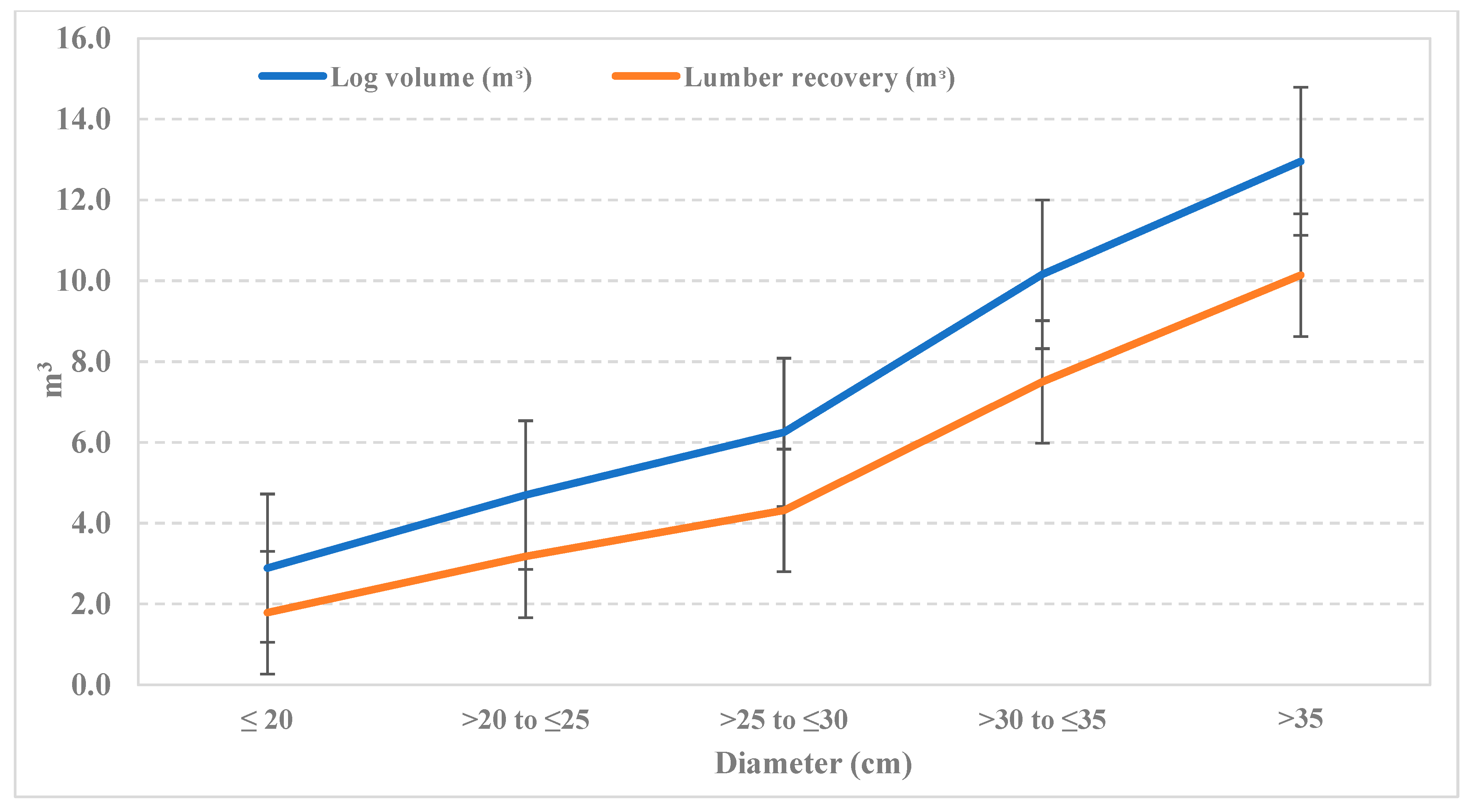

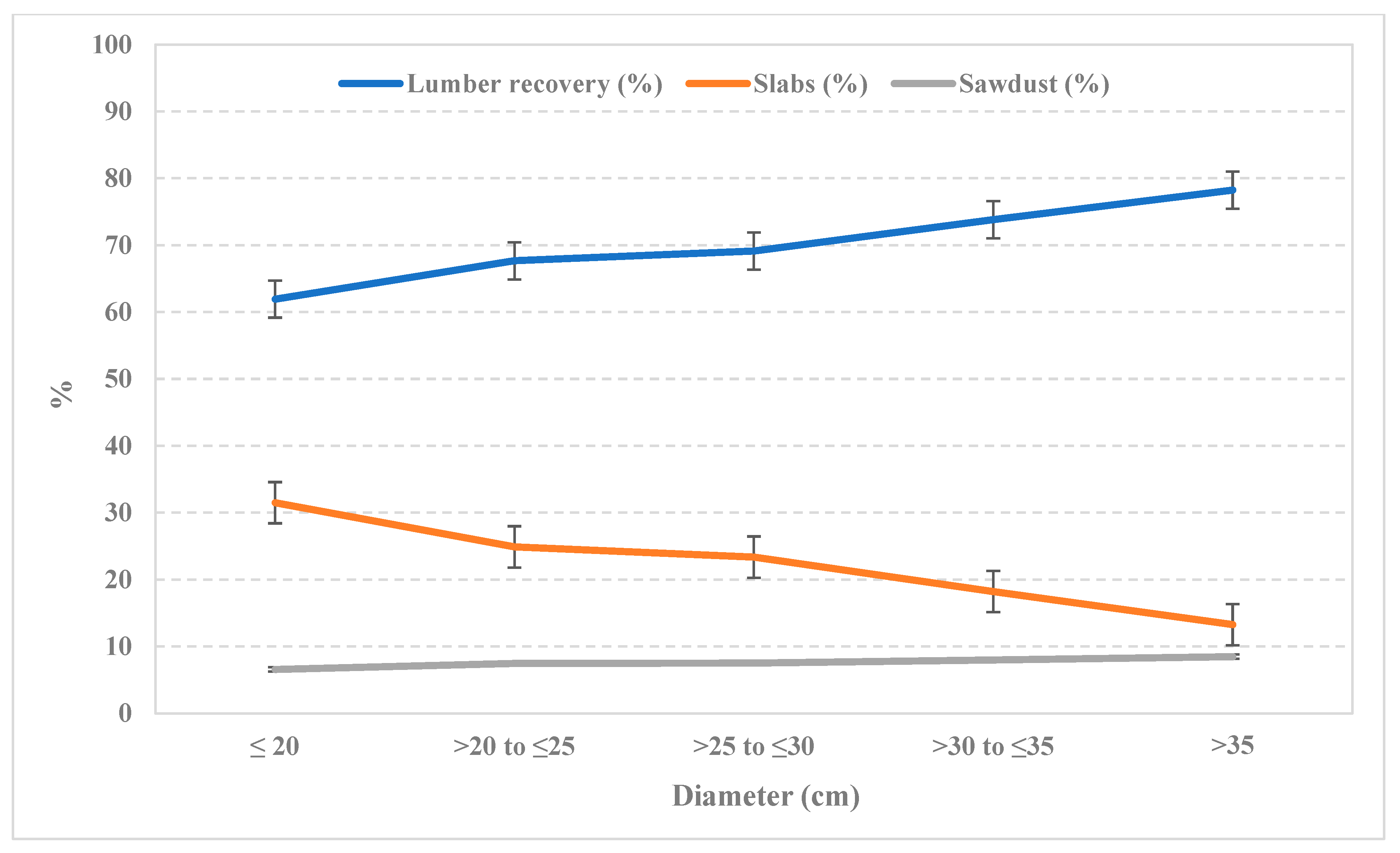

3.1. Lumber Recovery Rate

3.2. Percentage Volume of the By-Products of Sawdust and Slabs

3.3. Factors That Affect the Lumber Recovery Rate

3.3.1. Log Taper

3.3.2. Decision Making of Sawmill Operator

3.3.3. Age and Type of the Sawmills

3.3.4. Log Defects

3.3.5. Capacity Building and Training

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Omoniyi, T.E.; Fatoki, J.G. Lumber Recovery Efficiency of Some Selected Sawmills in Ibadan Metropolis, Oyo state, Nigeria. In Proceedings of the 36th Annual Conference of the Forestry Association of Nigeria, Uyo, Nigeria, 4–9 November 2013; pp. 393–400. [Google Scholar]

- Kassahun, A. Modeling of Lumber Recovery and Grade of Cupressus lusitanica Boards Produced at Adola and Zenbaba Sawmills, in Gujii Zone, Oromia Regional State, Ethiopia. Master’s Thesis, Hawassa University, Awasa, Ethiopia, 2014. [Google Scholar]

- Lin, W.; Wang, J.; Wu, J.; DeVallance, D. Log Sawing Practices and Lumber Recovery of Small Hardwood Sawmills in West Virginia. For. Prod. J. 2011, 61, 216–224. [Google Scholar] [CrossRef]

- Söderholm, P. The green economy transition: The challenges of technological change for sustainability. Sustain. Earth 2020, 3, 6. [Google Scholar] [CrossRef]

- Rawat, Y.S.; Tekleyohannes, A.T. Sustainable Forest Management and Forest Products Industry Development in Ethiopia. Int. For. Rev. 2021, 23, 197–218. [Google Scholar] [CrossRef]

- Liang, C.J. Exploring the “Green” Transformation Planning of Industrial Parks in the Era of Low Carbon Economy. World J. Eng. Technol. 2021, 09, 747–754. [Google Scholar] [CrossRef]

- Neumann, M. Participatory Forest Management in Oromia Region of Ethiopia: A Review of Experiences, Constraints and Implications for Forest Policy. In Policies to Increase Forest Cover in Ethiopia, Proceedings of a Policy Workshop, Addis Ababa, Ethiopia, 18–19 September 2007; Bane, J., Nune, S., Mekonnen, A., Blueffstone, R., Eds.; 2008; Available online: https://www.efdinitiative.org/sites/default/files/forest_workshop_proceedings_080227_am.pdf (accessed on 15 July 2021).

- Limenih, M.; Kassa, H. Re-greening Ethiopia, History, Challenges and Lessons. Forests 2014, 5, 1896–1909. [Google Scholar] [CrossRef]

- Eshetu, A.A. Forest Resource Management Systems in Ethiopia: Historical Perspective. Int. J. Biodivers. Conserv. 2014, 6, 121–131. [Google Scholar]

- Kebede, G.; Dejene, T. Indicator Land Use and Land-Use Change Related to Bioenergy Feedstock Production. In Sustainability of Biogas and Solid Biomass Value Chains in Ethiopia; Technical Report for the Global Bioenergy Project, United Nations Environment Program; UNEP: Nairobi, Kenya, 2019. [Google Scholar]

- Indufor. Ethiopia Commercial Plantation Forest Industry Investment Plan; International Finance Corporation/World Bank Group: New York, NY, USA, 2016; p. 237. [Google Scholar]

- Ministry of Environment, Forest and Climate Change (MEFCC). Ethiopia Forest Sector Review, Focus on Commercial Forestry and Industrialization; Technical Report; MEFCC: Addis Ababa, Ethiopia, 2018. [Google Scholar]

- Ministry of Environment, Forest and Climate Change (MEFCC). National Forest Sector Development Program, Ethiopia, Volume I: Situation Analysis; MEFCC: Addis Ababa, Ethiopia, 2018; 152p. [Google Scholar]

- Missanjo, E.; Magodi, F. Impact of Taper and Sawing Methods on Lumber Volume Recovery for Pinus kesiya and Pinus patula Logs in Circular Sawmills. J. For. Prod. Ind. 2015, 4, 12–16. [Google Scholar]

- Anderson, J.O.; Westerlund, L. Improved Energy Efficiency in Sawmill Drying System. Appl. Energy 2014, 113, 891–901. [Google Scholar] [CrossRef]

- Wit, M.; van Dam, J. (Eds.) Chainsaw Milling: Supplier to Local Markets; European Tropical Forest Research Network; Tropenbos International: Wageningen, The Netherlands, 2010; Volume 52, 226p. [Google Scholar]

- Tesfaye, M.A.; Gardi, O.; Anbessa, T.B.; Blaser, J. Aboveground biomass, growth and yield for some selected introduced tree species, namely Cupressus lusitanica, Eucalyptus saligna, and Pinus patula in Central Highlands of Ethiopia. J. Ecol. Environ. 2020, 44, 3. [Google Scholar] [CrossRef] [Green Version]

- Elazki, O.T.; Khider, T.O. Physical and Mechanical Properties of Cupressus lusitanica as a Potential Timber Tree for Sudan. J. For. Prod. Ind. 2013, 2, 43–46. [Google Scholar]

- Omoniyi, T.E.; Amiandamhen, S.O.; Amoo, K. Generation and Potentials of Sawmill Wood Waste of two OSUN State. For. Assoc. Niger. FAN Conf. 2013, 1, 183–190. [Google Scholar]

- U.S Food and Drug Administration. Recovery or Recycling of Products; U.S. Department of Agriculture Forest Products Laboratory: Madison, WI, USA, 2014. [Google Scholar]

- Mitchell, P.; Wiedenback, J.; Ammerman, B. Rough Mill Improvement Guide for Managers and Supervisors; General Technical Report NE-329; United States Department of Agriculture Forest Service: Delaware, OH, USA, 2005. [Google Scholar]

- Schuler, A.; Buehlmann, U. Identifying Future Competitive Business Strategies for the U.S. Residential Wood Furniture Industry: Benchmarking and Paradigm Shift; General Technical Report for U.S. Department of Agriculture, Forest Service; Northeastern Research Station: Newton Square, PA, USA, 2003. [Google Scholar]

- Huber, H.A.; McMillian, C.W.; McKinney, J.P. Lumber Defect Detection Abilities of Furniture Rough Mill Employees. For. Prod. J. 1985, 35, 79–82. [Google Scholar]

- Liu, C.; Ruel, J.C.; Groot, A.; Zhang, S.Y. Model Development for Lumber Volume Recovery of Natural Balsam Fir Trees in Quebec, Canada. For. Chron. 2009, 85, 870–877. [Google Scholar] [CrossRef] [Green Version]

- Chaffey, D.R. South-West Ethiopia Forest Inventory Project. A Reconnaissance Inventory of Forest in South-West Ethiopia; Project Report 31; Land Resource Development Center: Surbiton, UK, 1979. [Google Scholar]

- Eba, M.; Bekele, T.; Kelemwork, S. The Effects of Seasoning Defects on the Lumber quality of Cupressus lusitanica grown in Arsi Forest Enterprise, Degaga, Ethiopia. Ethiop. J. Nat. Resour. 2012, 12, 220–238. [Google Scholar]

- Lundgren, B. Soil Studies in a Montane Forest in Ethiopia; Royal College Forestry Research Notes No. 11; Department of Forest Ecology and Forest Soils: Stockholm, Sweden, 1971. [Google Scholar]

- Kedir, N. Isolation and Identification of Fungi Associated with Needle Blight and Death of Pinus patula Trees in Forest Plantations of Arsi Forest Enterprise, Ethiopia. Master’s Thesis, Awassa Univeristy Wondo Genet College of Forestry and Natural Resource, Wondo Genet, Ethiopia, 2009. [Google Scholar]

- Hambisa, M.; Rawat, Y.S.; Nebiyu, M.; Eba, M.; Tekleyohannes, A.T. Assessment of the Rate of Lumber Recovery of Eucalyptus saligna at Gefere Sawmill in Gimbi area, Ethiopia. J. Indian Acad. Wood Sci. 2023, 20. [Google Scholar] [CrossRef]

- Rongrong, L.; Pingxiang, C.; Xiaolei, G. Novel Sawing Method For Ssmall-Diameter Log. Wood Res. 2015, 60, 293–300. [Google Scholar]

- Cown, D.J.; Mcconchie, D.L.; Treloar, C. Timber Recovery from Pruned Pinus radiata Butt Logs at Mangatu: Effect of Log Sweep. N. Z. J. For. Sci. 1984, 14, 109–123. [Google Scholar]

- Muthike, G.; Kanali, C.; Shitanda, D. Comparative Analysis of On-Farm Timber Conversion Systems in Kenya. J. Hortic. For. 2013, 5, 74–80. [Google Scholar]

- United Nations Economic Commission for Europe Food and Agriculture Organization of the United Nations. Forest Product Conversion Factors for the UNECE (United Nations Economic Commission for Europe) Region; Geneva Timber and Forest Discussion Paper 49; United Nations Publication: Geneva, Switzerland, 2010; pp. 1–25. [Google Scholar]

- Christensen, G.A.; Christensen, E.A.; Ross, R.J.; Willits, S. Volume Recovery, Grade Yield, and Properties of Lumber from Young-Grouth Sitka Spruce and Western Hemlock in Southeast Alaska. For. Prod. J. 2002, 52, 81–86. [Google Scholar]

- Gligoras, D.; Borz, S.A. Factors Affecting the Effective Time Consumption, Wood Recovery and Feeding Speed When Manufacturing Lumber Usind Afbo-02 Cut Mobile Band Saw. Wood Res. 2015, 60, 329–338. [Google Scholar]

- Olufemi, B.; Akindeni, J.O.; Olaniran, S.O. Lumber Recovery Efficiency among Selected Sawmills in Akure, Nigeria. Drv. Ind. 2012, 63, 15–18. [Google Scholar] [CrossRef]

- Fonseca, M. The Drivers of Product Recovery. Presented at Timber Measurement Society Central Meeting, Medford, OR, USA, 18–19 October 2006. Available online: https://www.timbermeasure.com/medford_2006/10Drivers-of-Product-Recovery.pdf (accessed on 16 June 2022).

- Kilborn, K.A. Lumber Recovery Studies of Alaska Sawmills, 1997 to 1999; General Technical Report PNW-GTR-544; U.S. Department of Agriculture, Forest Service, Pacific Northwest Research Station: Portland, OR, USA, 2002; pp. 4–12. [Google Scholar]

- Malik, J.; Hopewell, G.P. Sawing Recovery of Several Sawmills in Jepara. J. Penelit. Has. Hutan 2011, 29, 331–342. [Google Scholar] [CrossRef] [Green Version]

- Faruwa, F.A.; Ekwugha, U.E. Operational Efficiency of Selected Sawmills in Akure Metropolis, Ondo State. J. Sustain. Environ. Manag. 2017, 9, 67–83. [Google Scholar]

- Ayarkwa, J.; Addae, A.M. Processing of Small Diameter Logs: Effect of Log Diameter, Sawing Pattern and Some Bole Variables on Lumber Recovery. Ghana J. For. 1999, 8, 43–52. [Google Scholar]

- Bennett, N. Sawing Methods for Improving Lumber Yield Recovery of out-of-Shape Hardwood Saw Logs; General Technical Report NRS-130; U.S. Department of Agriculture, Forest Service, Northern Research Station: Newtown Square, PA, USA, 2014. [Google Scholar]

- Asamoah, O.; Kuittinen, S.; Danquah, J.A.; Quartey, E.T.; Bamwesigye, D.; Boateng, C.M.; Pappinen, A. Assessing Wood Waste by Timber Industry as a Contributing Factor to Deforestation in Ghana. Forests 2020, 11, 939. [Google Scholar] [CrossRef]

- Keegan, C.E.; Morgan, T.A.; Blatner, K.A. Trends in Lumber Processing in the Western United States. Part II: Overrun and Lumber Recovery Factors. For. Prod. Soc. 2010, 60, 140–143. [Google Scholar] [CrossRef]

- ITTO. Code of Practice for Wood Processing Facilities (Sawmills & Lumberyards); Version 2; Guyana Forestry Commission: Georgetown, Guyana, 2012; pp. 13–14. [Google Scholar]

- Ogunsanwo, O.Y.; Adeleye, I.G.; Anjah, G.M. Technical Efficiency of Chain Sawmilling in Ogun State, South-West Nigeria. Int. J. Biol. Chem. Sci. 2011, 5, 34–41. [Google Scholar]

- Ogunwusi, A. Wood Waste Generation in the Forest Industry in Nigeria and Prospects for its Industrial Utilization. Civ. Environ. Res. 2014, 6, 62–69. [Google Scholar]

- Brown, H.P.; Panshin, A.J.; Forsaith, C.C. Textbook of Wood Technology; McGraw- Hill Book Co.: New York, NY, USA, 1994; pp. 40–43, 283–309. [Google Scholar]

- Nawaz, M.S.; Hassan, M.; Hassan, S.; Shaukat, S.; Asadullah, M.A. Impact of Employee Training and Empowerment on Employee Creativity through Employee Engagement: Empirical Evidence from the Manufacturing Sector of Pakistan. Middle-East J. Sci. Res. 2014, 19, 593–601. [Google Scholar]

- Maurice, J.; Le Crom, M.; Bouyer, O.; Pesce, F.; Cielo, P.; Gachanja, M.; Bull, L. Improving Efficiency in Forestry Operations and Forest Product Processing in Kenya: A Viable REDD+ Policy and Measure; Mulder, I., Webbe, J., Eds.; UN-REDD Programme; United Nations Environment Programme (UNEP): Nairobi, Kenya, 2016; pp. 1–74. [Google Scholar]

| Log Classification | Number of Logs | Mean Log Taper (cm) | Mean Diameter in cm | Log Volume in m3 | Recoveries | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lumber Recovery | Sawdust | Slabs | ||||||||

| Volume (m3) | (%) | Volume (m3) | (%) | Volume (m3) | (%) | |||||

| ≤20 cm in diameter | 30 | 0.39 | 26.83 | 2.89 | 1.79 | 61.94 | 0.19 | 6.57 | 0.91 | 31.49 |

| >20 to ≤25 cm in diameter | 30 | 0.34 | 34.02 | 4.70 | 3.18 | 67.66 | 0.35 | 7.45 | 1.17 | 24.89 |

| >25 to ≤30 cm in diameter | 30 | 0.27 | 38.87 | 6.25 | 4.32 | 69.12 | 0.47 | 7.52 | 1.46 | 23.36 |

| >30 to ≤35 cm in diameter | 30 | 0.24 | 49.72 | 10.16 | 7.50 | 73.82 | 0.81 | 7.97 | 1.85 | 18.21 |

| >35 cm in diameter | 30 | 0.19 | 55.85 | 12.96 | 10.14 | 78.24 | 1.10 | 8.49 | 1.72 | 13.27 |

| Overall and Mean | 150 | 0.29 | 41.06 | 36.96 | 26.93 | 72.86 | 2.92 | 7.90 | 7.11 | 19.24 |

| Log Volume (m3) | Lumber Recovery (%) | Slabs (%) | Sawdust (%) | Taper (cm) | Mean Diameter (cm) | ||

|---|---|---|---|---|---|---|---|

| Log volume (m3) | Pearson Correlation | 1 | |||||

| Sig. (two-tailed) | |||||||

| Recovery (%) | Pearson Correlation | 0.983 ** | 1 | ||||

| Sig. (two-tailed) | 0.003 | ||||||

| Slabs (%) | Pearson Correlation | −0.980 ** | −1.000 ** | 1 | |||

| Sig. (two-tailed) | 0.003 | 0.000 | |||||

| Sawdust (%) | Pearson Correlation | 0.952 * | 0.992 ** | −0.994 ** | 1 | ||

| Sig. (two-tailed) | 0.013 | 0.001 | 0.001 | ||||

| Taper (cm) | Pearson Correlation | −0.962 ** | −0.972 ** | 0.971 ** | −0.957 * | 1 | |

| Sig. (two-tailed) | 0.009 | 0.006 | 0.006 | 0.011 | |||

| Mean Diameter (cm) | Pearson Correlation | 0.995 ** | 0.991 ** | −0.989 ** | 0.967 ** | −0.976 ** | 1 |

| Sig. (two-tailed) | 0.000 | 0.001 | 0.001 | 0.007 | 0.005 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rawat, Y.S.; Eba, M.; Nebiyu, M. Lumber Recovery Rate of Cupressus lusitanica in Arsi Forest Enterprise, Ethiopia. Sustainability 2023, 15, 1046. https://doi.org/10.3390/su15021046

Rawat YS, Eba M, Nebiyu M. Lumber Recovery Rate of Cupressus lusitanica in Arsi Forest Enterprise, Ethiopia. Sustainability. 2023; 15(2):1046. https://doi.org/10.3390/su15021046

Chicago/Turabian StyleRawat, Yashwant Singh, Misganu Eba, and Moti Nebiyu. 2023. "Lumber Recovery Rate of Cupressus lusitanica in Arsi Forest Enterprise, Ethiopia" Sustainability 15, no. 2: 1046. https://doi.org/10.3390/su15021046