Scaling Trends of Electric Vehicle Performance: Driving Range, Fuel Economy, Peak Power Output, and Temperature Effect

Abstract

1. Introduction

2. Vehicle Data Collection

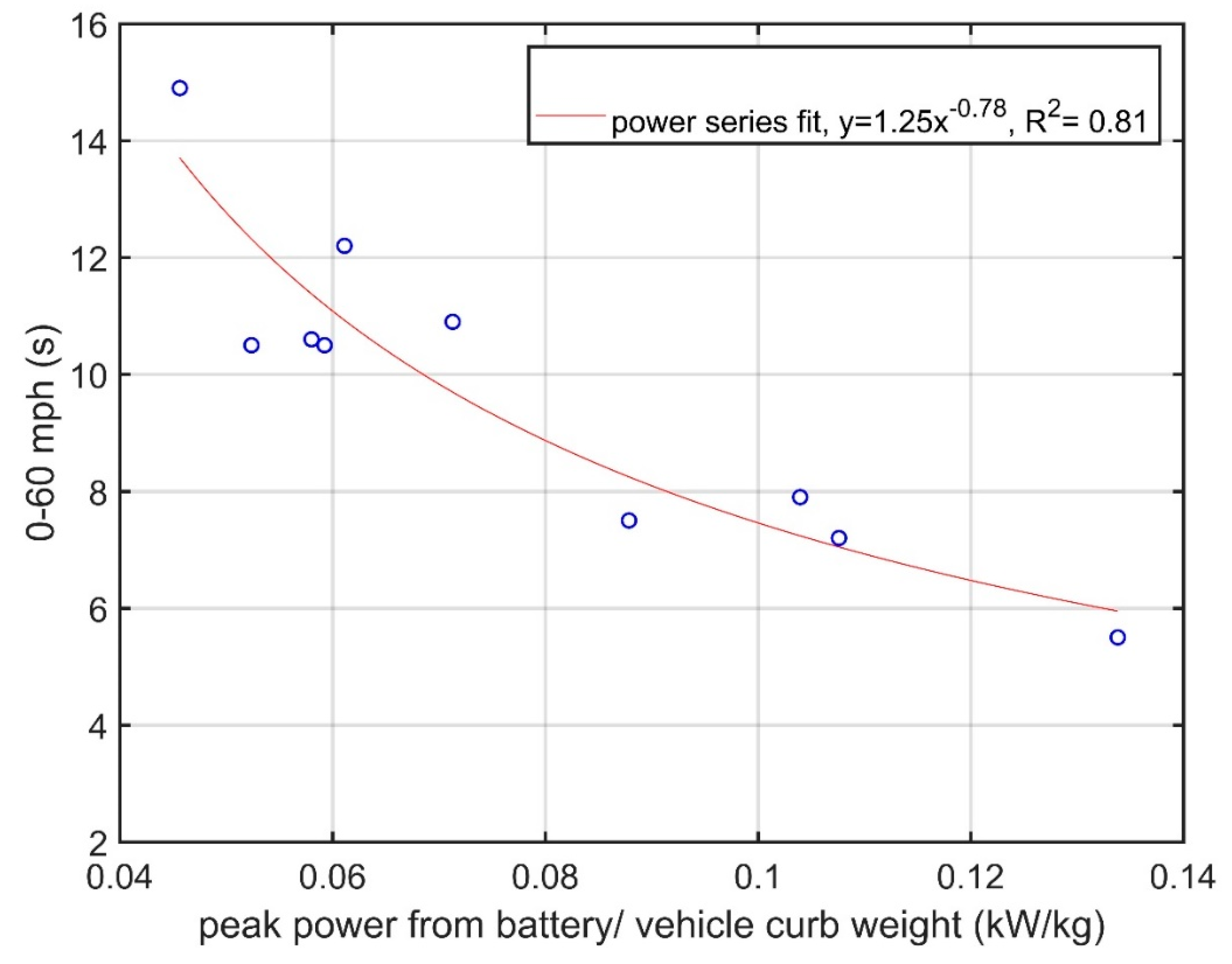

3. Results

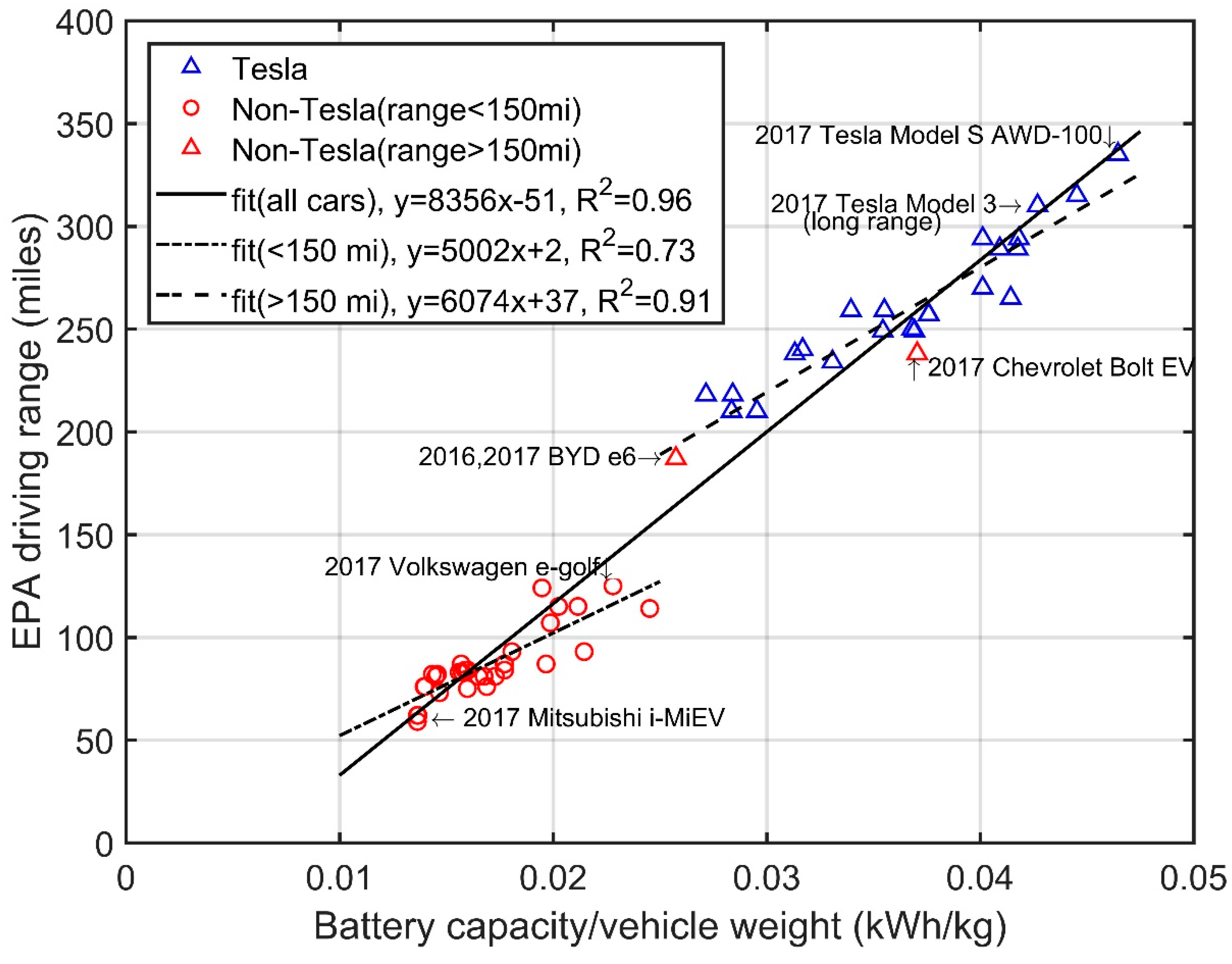

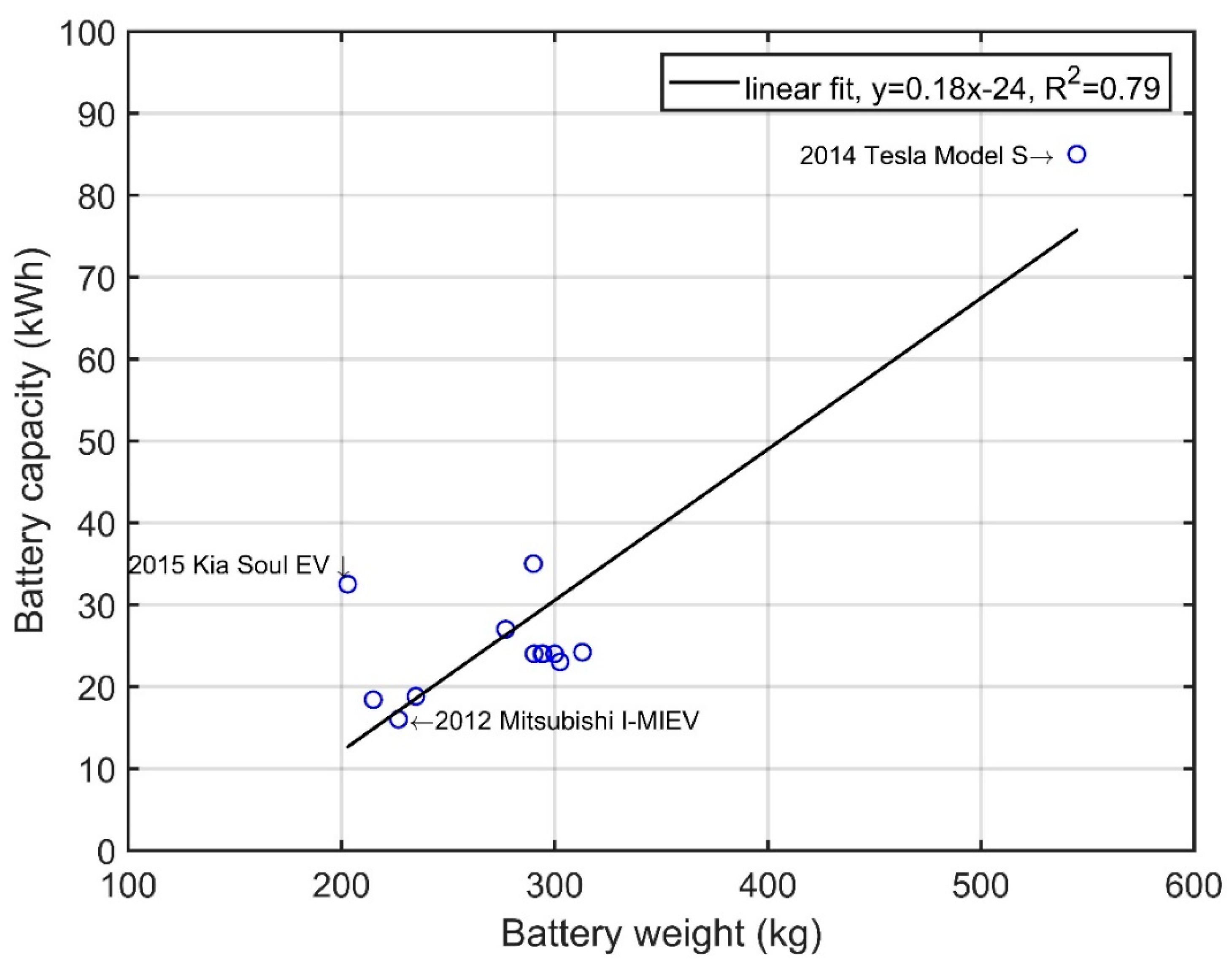

3.1. Scaling Trend of Driving Range

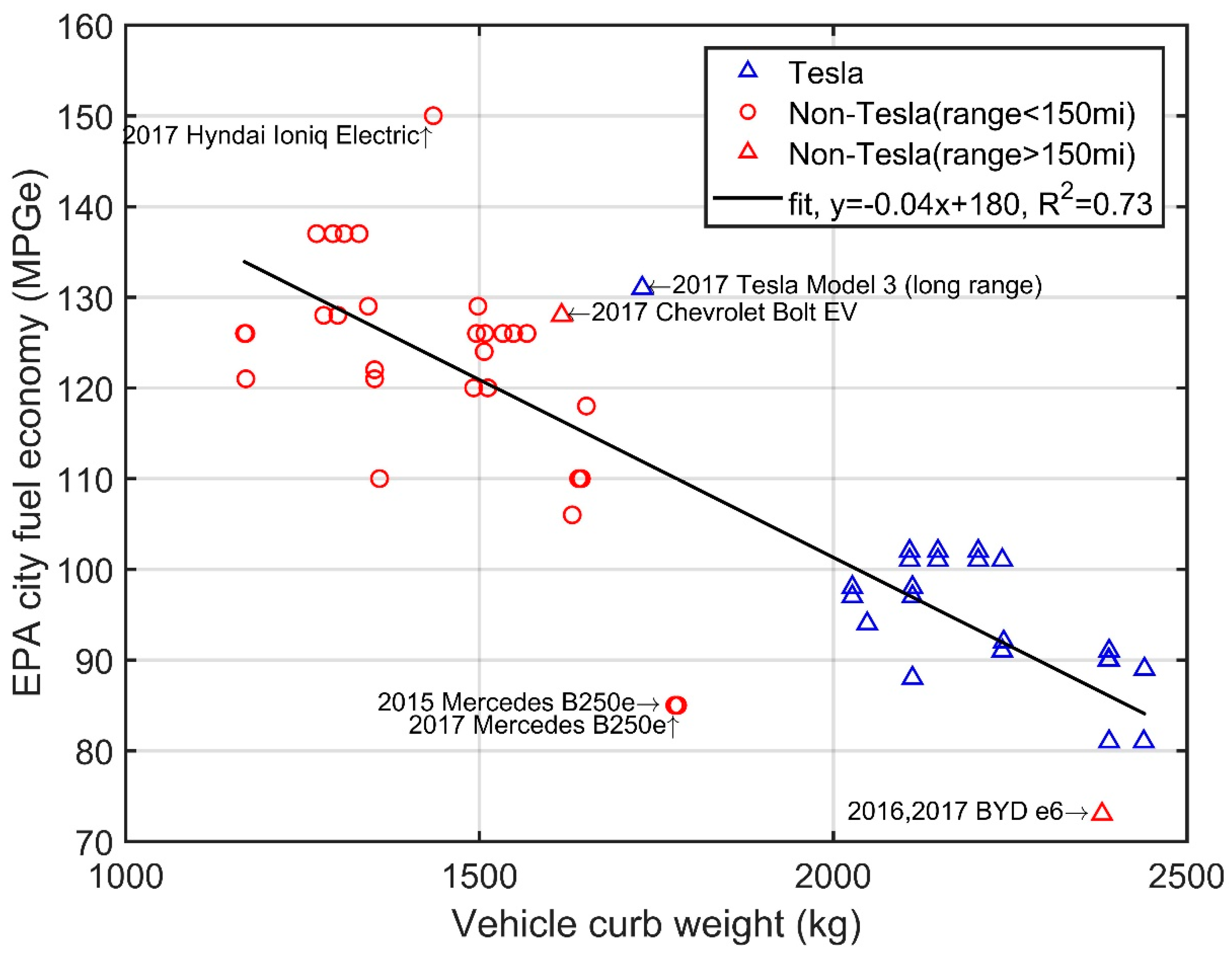

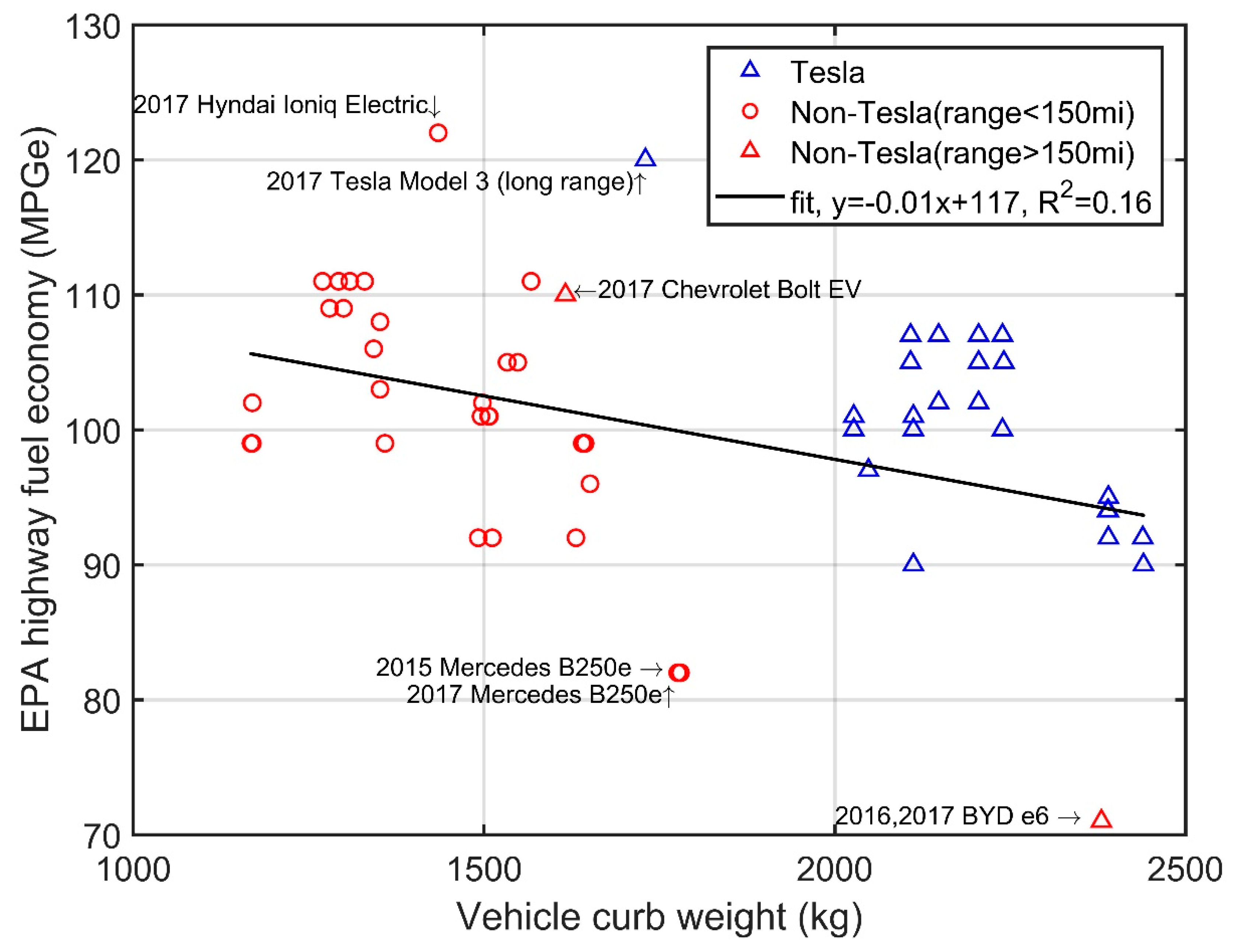

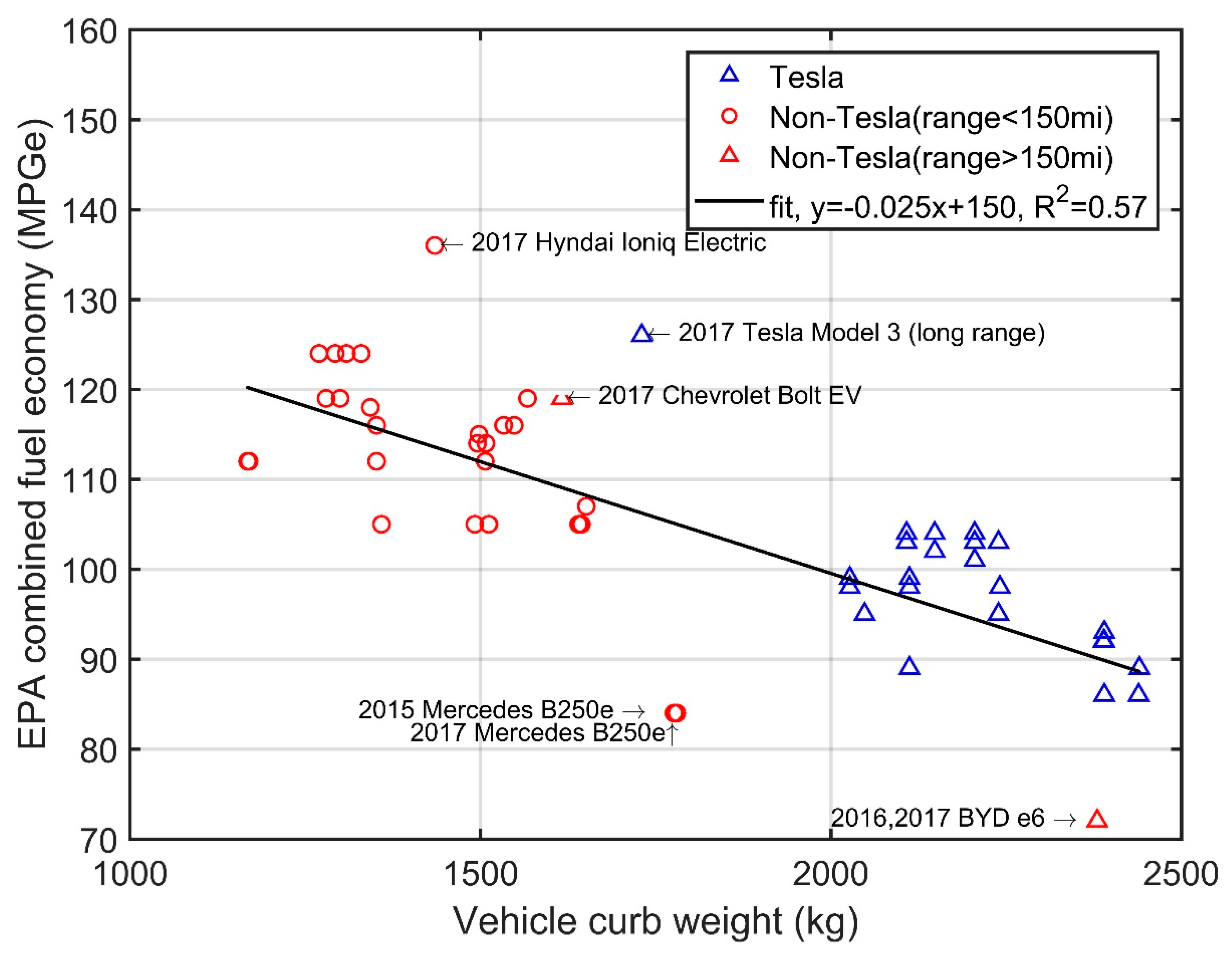

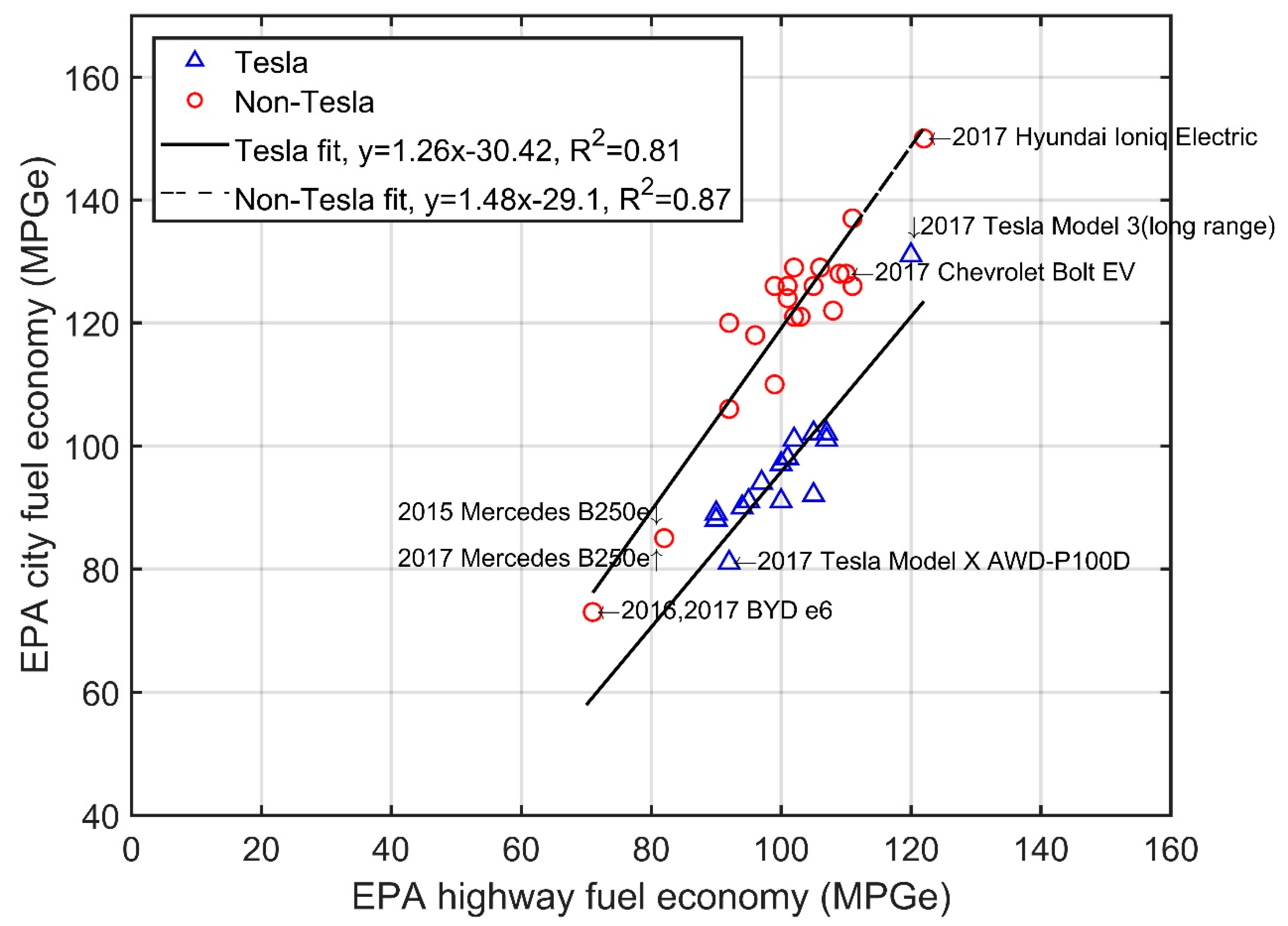

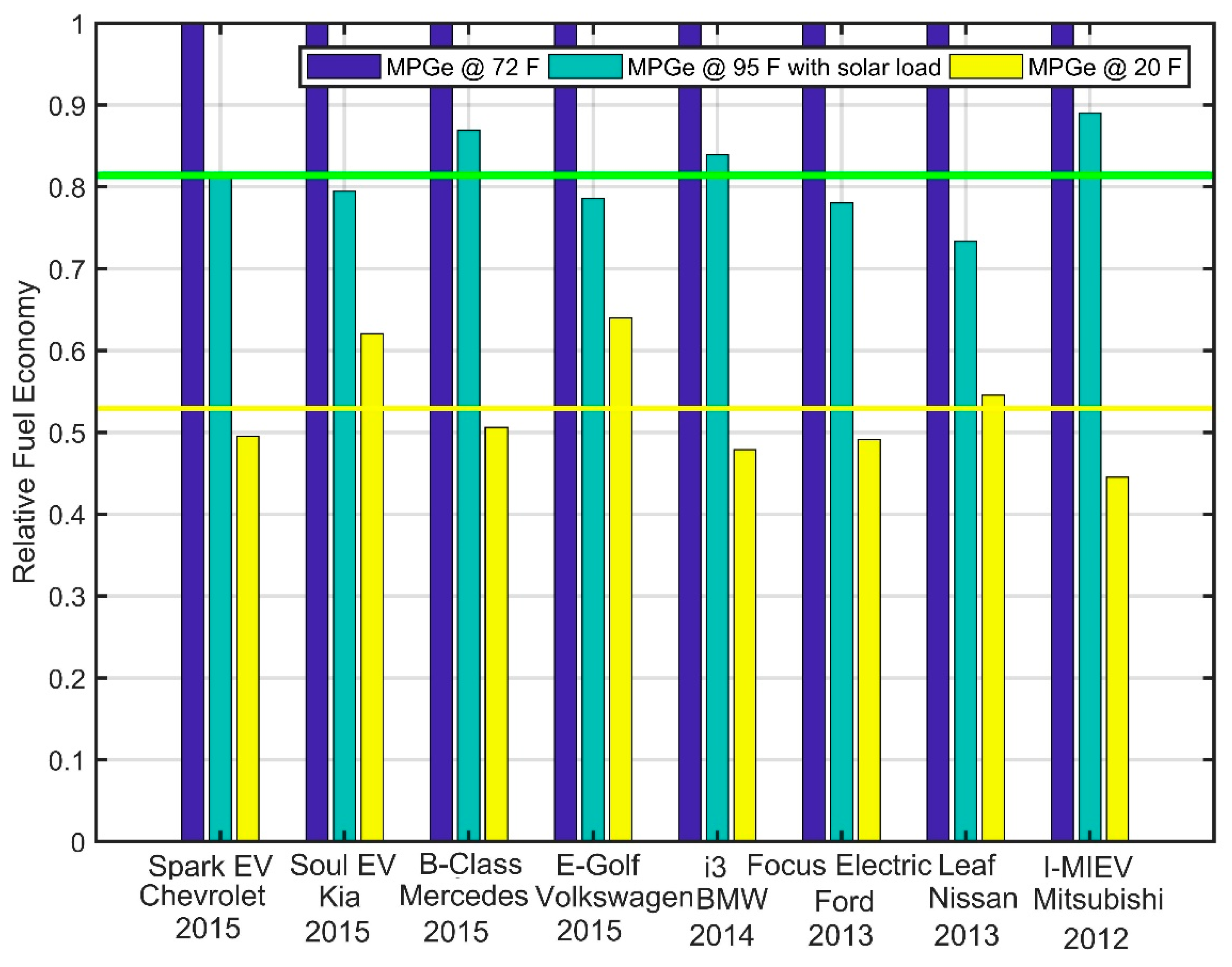

3.2. Scaling Trend of Fuel Economy

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Data Source | MY | Make | Model | Batt. Capacity (kWh) | EPA Range (miles) | EPA City (MPGe) | EPA Highway (MPGe) | EPA Combined (MPGe) | Battery Type | |

|---|---|---|---|---|---|---|---|---|---|---|

| INL | 2014 | BMW | i3 | 18.8 | 81 | 137 | 111 | 124 | Li-ion | 2850 |

| Internet | 2014 | BMW | i3 | 22 | 81 | 137 | 111 | 124 | Li-ion | 2635 |

| Internet | 2015 | BMW | i3 | 22 | 81 | 137 | 111 | 124 | Li-ion | 2932 |

| Internet | 2016 | BMW | i3 | 22 | 81 | 137 | 111 | 124 | Li-ion | 2799 |

| FE | 2017 | BMW | i3 (60 A-hr) | 22 | 81 | 137 | 111 | 124 | Li-ion | 2886 |

| FE | 2017 | BMW | i3 (94 A-hr) | 33 | 114 | 129 | 106 | 118 | Li-ion | 2961 |

| FE | 2016 | BYD | e6 | 61.4 | 187 | 73 | 71 | 72 | Li-ion | 5247 |

| FE | 2017 | BYD | e6 | 61.4 | 187 | 73 | 71 | 72 | Li-ion | 5247 |

| INL | 2015 | Chevrolet | Spark EV | 18.4 | 82 | 128 | 109 | 119 | Li-ion | 2821 |

| FE | 2016 | Chevrolet | Sprark EV | 19 | 82 | 128 | 109 | 119 | Li-ion | 2866 |

| FE | 2017 | Chevrolet | Bolt EV | 60 | 238 | 128 | 110 | 119 | Li-ion | 3563 |

| INL | 2013 | Ford | Focus Electric | 23 | 76 | 110 | 99 | 105 | Li-ion | 3616 |

| Internet | 2014 | Ford | Focus Electric | 23 | 76 | 110 | 99 | 105 | Li-ion | 2995 |

| Internet | 2015 | Ford | Focus Electric | 23 | 76 | 110 | 99 | 105 | Li-ion | 3624 |

| FE | 2016 | Ford | Focus Electric | 23 | 76 | 110 | 99 | 105 | Li-ion | 3622 |

| FE | 2018 | Ford | Focus Electric | 35 | 115 | 118 | 96 | 107 | Li-ion | 3640 |

| FE | 2017 | Ford | Focus Electric | 33.5 | 115 | 118 | 96 | 107 | Li-ion | 3640 |

| Internet | 2014 | Fiat | 500e | 24 | 87 | 122 | 108 | 116 | Li-ion | 2980 |

| Internet | 2016 | Fiat | 500e | 24 | 84 | 121 | 103 | 112 | Li-ion | 2980 |

| FE | 2017 | Fiat | 500e | 24 | 84 | 121 | 103 | 112 | Li-ion | 2980 |

| FE | 2017 | Hyundai | Ioniq Electric | 28 | 124 | 150 | 122 | 136 | Li-ion | 3164 |

| INL | 2015 | Kia | Soul Electric | 32.5 | 93 | 120 | 92 | 105 | Li-ion | 3334 |

| FE | 2016 | Kia | Soul Electric | 27 | 93 | 120 | 92 | 105 | Li-ion | 3289 |

| FE | 2017 | Kia | Soul Electric | 27 | 93 | 120 | 92 | 105 | Li-ion | 3289 |

| INL | 2015 | Mercedes | B-Class | 35 | 87 | 85 | 82 | 84 | Li-ion | 3916 |

| FE | 2016 | Mercedes | B250e | 28 | 87 | 85 | 82 | 84 | Li-ion | 3924 |

| Internet | 2017 | Mercedes | B250e | 28 | 87 | 85 | 85 | 84 | Li-ion | 3924 |

| INL | 2012 | Mitsubishi | I-MIEV | 16 | 62 | 126 | 99 | 112 | Li-ion | 2574 |

| FE | 2016 | Mitsubishi | i-MiEV | 16 | 62 | 126 | 99 | 112 | Li-ion | 2579 |

| FE | 2017 | Mitsubishi | i-MiEV | 16 | 59 | 121 | 102 | 112 | Li-ion | 2579 |

| INL | 2011 | Nissan | Leaf | 24 | 73 | 106 | 92 | Li-ion | 3595 | |

| INL | 2013 | Nissan | Leaf | 24 | 75 | 129 | 102 | 115 | Li-ion | 3302 |

| Internet | 2014 | Nissan | Leaf | 24 | 84 | 126 | 101 | 114 | Li-ion | 3298 |

| Internet | 2015 | Nissan | Leaf | 24 | 84 | 126 | 101 | 114 | Li-ion | 3298 |

| Internet | 2016 | Nissan | Leaf (24 kwh) | 24 | 84 | 126 | 101 | 114 | Li-ion | 3324 |

| FE | 2016 | Nissan | Leaf (30 kWh) | 30 | 107 | 124 | 101 | 112 | Li-ion | 3323 |

| FE | 2017 | Nissan | Leaf | 30 | 107 | 124 | 101 | 112 | Li-ion | 3323 |

| INL | 2015 | VW | e-Golf | 24.2 | 83 | 126 | 105 | 116 | Li-ion | 3412 |

| Internet | 2015 | VW | e-Golf | 24.2 | 83 | 126 | 105 | 116 | Li-ion | 3380 |

| FE | 2017 | VW | e-Golf | 35.8 | 125 | 126 | 111 | 119 | Li-ion | 3455 |

| FE | 2016 | VW | e-Golf | 24.2 | 83 | 126 | 105 | 116 | Li-ion | 3380 |

| INL | 2014 | Tesla | S | 85 | 265 | 94 | 97 | 95 | Li-ion | 4514 |

| FE | 2016 | Tesla | S AWD-60D | 60 | 218 | 101 | 107 | 104 | Li-ion | 4861 |

| FE | 2016 | Tesla | S AWD-75D | 75 | 259 | 102 | 105 | 103 | Li-ion | 4861 |

| FE | 2016 | Tesla | S AWD-90D | 90 | 294 | 101 | 107 | 103 | Li-ion | 4936 |

| FE | 2016 | Tesla | S AWD-70D | 70 | 240 | 101 | 102 | 101 | Li-ion | 4861 |

| FE | 2016 | Tesla | S (60 kWh) | 60 | 210 | 98 | 101 | 99 | Li-ion | 4656 |

| FE | 2016 | Tesla | S (70 kWh) | 70 | 234 | 88 | 90 | 89 | Li-ion | 4656 |

| FE | 2016 | Tesla | S (75 kWh) | 75 | 249 | 97 | 100 | 98 | Li-ion | 4656 |

| FE | 2016 | Tesla | S AWD-P90D | 90 | 270 | 91 | 100 | 95 | Li-ion | 4936 |

| FE | 2016 | Tesla | X AWD-75D | 75 | 238 | 91 | 95 | 93 | Li-ion | 5269 |

| FE | 2016 | Tesla | X AWD-90D | 90 | 257 | 90 | 94 | 92 | Li-ion | 5269 |

| FE | 2016 | Tesla | X AWD-P90D | 90 | 250 | 89 | 90 | 89 | Li-ion | 5379 |

| FE | 2016 | Tesla | X AWD-P100D | 100 | 289 | 81 | 92 | 86 | Li-ion | 5269 |

| FE | 2017 | Tesla | S AWD-90D | 90 | 294 | 102 | 107 | 104 | Li-ion | 4736 |

| FE | 2017 | Tesla | S AWD-60D | 60 | 218 | 101 | 107 | 104 | Li-ion | 4647 |

| FE | 2017 | Tesla | S AWD-75D | 75 | 259 | 102 | 105 | 103 | Li-ion | 4647 |

| FE | 2017 | Tesla | S AWD-100D | 100 | 335 | 101 | 102 | 102 | Li-ion | 4736 |

| FE | 2017 | Tesla | S (60 kWh) | 60 | 210 | 98 | 101 | 99 | Li-ion | 4469 |

| FE | 2017 | Tesla | S (75 kWh) | 75 | 249 | 97 | 100 | 98 | Li-ion | 4469 |

| FE | 2017 | Tesla | S AWD-P100D | 100 | 315 | 92 | 105 | 98 | Li-ion | 4941 |

| FE | 2017 | Tesla | X AWD-90D | 90 | 257 | 90 | 94 | 92 | Li-ion | 5267 |

| FE | 2017 | Tesla | X AWD-P100D | 100 | 289 | 81 | 92 | 86 | Li-ion | 5377 |

| FE | 2017 | Tesla | 3 (long range) | 74 | 310 | 131 | 120 | 126 | Li-ion | 3814 |

| Model Year | Make | Model | Acceleration (0–60 mph) (s) | Peak Power from Battery (kW) |

|---|---|---|---|---|

| 2015 | Chevrolet | Spark EV | 7.9 | 133.3 |

| 2015 | Kia | Soul EV | 10.5 | 89.8 |

| 2015 | Mercedes | B-Class | 7.5 | 156.4 |

| 2015 | Volkswagen | E-Golf | 12.2 | 94.8 |

| 2014 | BMW | i3 | 7.2 | 139.4 |

| 2014 | Tesla | Model S | 5.5 | 274.6 |

| 2013 | Ford | Focus Electric | 10.9 | 117.2 |

| 2013 | Nissan | Leaf | 10.6 | 87.1 |

| 2012 | Mitsubishi | I-MIEV | 14.9 | 53.4 |

| 2011 | Nissan | Leaf | 10.5 | 85.6 |

| Model Year | Make | Model | MPGe @72F | MPGe @95F with Solar Load | MPGe @20F |

|---|---|---|---|---|---|

| 2015 | Chevrolet | Spark EV | 1 | 0.82 | 0.5 |

| 2015 | Kia | Soul EV | 1 | 0.79 | 0.62 |

| 2015 | Mercedes | B-Class | 1 | 0.87 | 0.51 |

| 2015 | Volkswagen | E-Golf | 1 | 0.79 | 0.64 |

| 2014 | BMW | i3 | 1 | 0.84 | 0.48 |

| 2013 | Ford | Focus Electric | 1 | 0.78 | 0.49 |

| 2013 | Nissan | Leaf | 1 | 0.73 | 0.55 |

| 2012 | Mitsubishi | I-MIEV | 1 | 0.89 | 0.45 |

| Average | 1 | 0.81 | 0.53 | ||

| Standard deviation | 0.05 | 0.07 |

| Model Year | Make | Model | Battery Capacity (kWh) | Battery Weight (kg) | Battery Type |

|---|---|---|---|---|---|

| 2017 | Kia | Soul Electric | 27 | 277 | Li-ion |

| 2015 | Kia | Soul EV | 32.5 | 203 | Li-ion |

| 2015 | Chevrolet | Spark EV | 18.4 | 215 | Li-ion |

| 2015 | Mercedes | B250e | 35 | 290 | Li-ion |

| 2015 | Volkswagen | E-Golf | 24.2 | 313 | Li-ion |

| 2015 | Nissan | Leaf | 24 | 295 | Li-ion |

| 2014 | Nissan | Leaf | 24 | 300 | Li-ion |

| 2014 | BMW | i3 | 18.8 | 235 | Li-ion |

| 2014 | Tesla | Model S | 85 | 545 | Li-ion |

| 2013 | Ford | Focus Electric | 23 | 303 | Li-ion |

| 2013 | Nissan | Leaf | 24 | 290 | Li-ion |

| 2012 | Mitsubishi | I-MIEV | 16 | 227 | Li-ion |

| 2011 | Nissan | Leaf | 24 | 294 | Li-ion |

References

- Trenberth, K.E.; Jones, P.D.; Ambenje, P.; Bojariu, R.; Easterling, D.; Klein, T.; Parker, D.; Rahimzadeh, F.; Renwick, J.A.; Rusticucci, M.; et al. Observations: Surface and atmospheric climate change. In Climate Change 2007; Cambridge University Press: Cambridge, NY, USA, 2007; pp. 235–336. [Google Scholar]

- Schleussner, C.-F.; Rogelj, J.; Schaeffer, M.; Lissner, T.; Licker, R.; Fischer, E.M.; Knutti, R.; Levermann, A.; Frieler, K.; Hare, W.J.N.C.C. Science and policy characteristics of the Paris Agreement temperature goal. Nat. Clim. Chang. 2016, 6, 827–835. [Google Scholar] [CrossRef]

- Administration, U.E.I. How Much Carbon Dioxide Is Produced from Burning Gasoline and Diesel Fuel? Available online: https://www.eia.gov/tools/faqs/faq.php?id=307&t=10 (accessed on 19 May 2018).

- Chan, C.C. The state of the art of electric, hybrid, and fuel cell vehicles. Proc. IEEE 2007, 95, 704–718. [Google Scholar] [CrossRef]

- CARB. California’s Advanced Clean Cars Midterm Review: Appendix C: Zero Emission Vehicle and Plug-in Hybrid Electric Vehicle Technology Assessment. Available online: https://www.arb.ca.gov/msprog/acc/acc-mtr.htm (accessed on 8 November 2018).

- John, W.; Brennan, T.E.B. Battery Electric Vehicles vs. Internal Combustion Engine Vehicles: A United States-Based Comprehensive Assessment. Arthur D Little. 2016. Available online: http://www.adlittle.com (accessed on 9 November 2018).

- Hunt, T. Is There Enough Lithium to Maintain the Growth of the Lithium-Ion Battery Market? Available online: https://www.greentechmedia.com/articles/read/Is-There-Enough-Lithium-to-Maintain-the-Growth-of-the-Lithium-Ion-Battery-M#gs.2gLDboM (accessed on 2 June 2018).

- Shahan, Z. US Electric Car Sales up 59% in January 2017. Available online: https://cleantechnica.com/2017/02/04/us-electric-car-sales-59-january-2017 (accessed on 4 February 2017).

- Draft Technical Assessment Report: Midterm Evaluation of Light-Duty Vehicle Greenhouse Gas. Emission Standards and Corporate Average Fuel Economy Standards for Model Years 2022–2025; EPA-420-D-16-900; U.S. Environmental Protection Agency: Research Triangle Park, NC, USA, 2016.

- EV Everywhere Grand Challenge Blueprint; U.S. Department of Energy: Washington, DC, USA, 2013.

- An, F.; Santini, D.J. Mass Impacts on Fuel Economies of Conventional vs. Hybrid Electric Vehicles; SAE Technical Paper 2004–01-0572; Argonne National Laboratory: Lemont, IL, USA, 2004. [Google Scholar] [CrossRef]

- Quong, S.; Duoba, M.; Larsen, R.; LeBlanc, N.; Gonzales, R.; Bultrago, C. Electric Vehicle Performance in 1994 DOE Competitions; SAE Technical Paper 950178; Argonne National Laboratory: Lemont, IL, USA, 1995. [Google Scholar] [CrossRef]

- Raslavičius, L.; Starevičius, M.; Keršys, A.; Pilkauskas, K.; Vilkauskas, A.J.E. Performance of an all-electric vehicle under UN ECE R101 test conditions: A feasibility study for the city of Kaunas, Lithuania. Energy 2013, 55, 436–448. [Google Scholar] [CrossRef]

- Jimenez-Palacios, J.L. Understanding and Quantifying Motor Vehicle Emissions with Vehicle Specific Power and TILDAS Remote Sensing. Ph.D. Thesis, Massachusetts Institute of Technology, Department of Mechanical Engineering, Cambridge, MA, USA, 1999. [Google Scholar]

- Qu, L.; Li, M.; Chen, D.; Lu, K.; Jin, T.; Xu, X.J.A.E. Multivariate analysis between driving condition and vehicle emission for light duty gasoline vehicles during rush hours. Atmos. Environ. 2015, 110, 103–110. [Google Scholar] [CrossRef]

- Kuhns, H.D.; Mazzoleni, C.; Moosmüller, H.; Nikolic, D.; Keislar, R.E.; Barber, P.W.; Li, Z.; Etyemezian, V.; Watson, J.G. Remote sensing of PM, NO, CO and HC emission factors for on-road gasoline and diesel engine vehicles in Las Vegas, NV. Sci. Total Environ. 2004, 322, 123–137. [Google Scholar] [CrossRef] [PubMed]

- Sripad, S.; Viswanathan, V. Performance metrics required of next-generation batteries to make a practical electric semi truck. ACS Energy Lett. 2017, 2, 1669–1673. [Google Scholar] [CrossRef]

- Light-Duty Automotive Technology, Carbon Dioxide Emissions, and Fuel Economy Trends: 1975 through 2017; EPA-420-R-18-001; U.S. Environmental Protection Agency: Research Triangle Park, NC, USA, 2018.

| Vehicle Weight (kg) | Highway Fuel Economy (MPGe) | City Fuel Economy (MPGe) | Battery Capacity (kWh) | Battery Weight (kg) |

|---|---|---|---|---|

| 1000 | 108 | 141 | 54 | 437 |

| 1500 | 103 | 121 | 81 | 593 |

| 2000 | 98 | 101 | 108 | 749 |

| 2500 | 93 | 81 | 135 | 905 |

| 3000 | 88 | 61 | 162 | 1061 |

| 3500 | 83 | 41 | 189 | 1217 |

| 4000 | 78 | 21 | 217 | 1373 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, H.; Silva, R.; Han, M. Scaling Trends of Electric Vehicle Performance: Driving Range, Fuel Economy, Peak Power Output, and Temperature Effect. World Electr. Veh. J. 2018, 9, 46. https://doi.org/10.3390/wevj9040046

Jung H, Silva R, Han M. Scaling Trends of Electric Vehicle Performance: Driving Range, Fuel Economy, Peak Power Output, and Temperature Effect. World Electric Vehicle Journal. 2018; 9(4):46. https://doi.org/10.3390/wevj9040046

Chicago/Turabian StyleJung, Heejung, Rebecca Silva, and Michael Han. 2018. "Scaling Trends of Electric Vehicle Performance: Driving Range, Fuel Economy, Peak Power Output, and Temperature Effect" World Electric Vehicle Journal 9, no. 4: 46. https://doi.org/10.3390/wevj9040046

APA StyleJung, H., Silva, R., & Han, M. (2018). Scaling Trends of Electric Vehicle Performance: Driving Range, Fuel Economy, Peak Power Output, and Temperature Effect. World Electric Vehicle Journal, 9(4), 46. https://doi.org/10.3390/wevj9040046