Application of Hybrid-Electric Propulsion to ‘Large-Cabin’ Business Aircraft

Abstract

1. Introduction

- 1.

- The range achievable with varying degrees of energy hybridization for series and parallel HEP architectures;

- 2.

- The weight and volume of the batteries required to achieve a given range with different architectures;

- 3.

- An optimal architecture for large-cabin business aircraft, enabling further research in the future.

2. Background

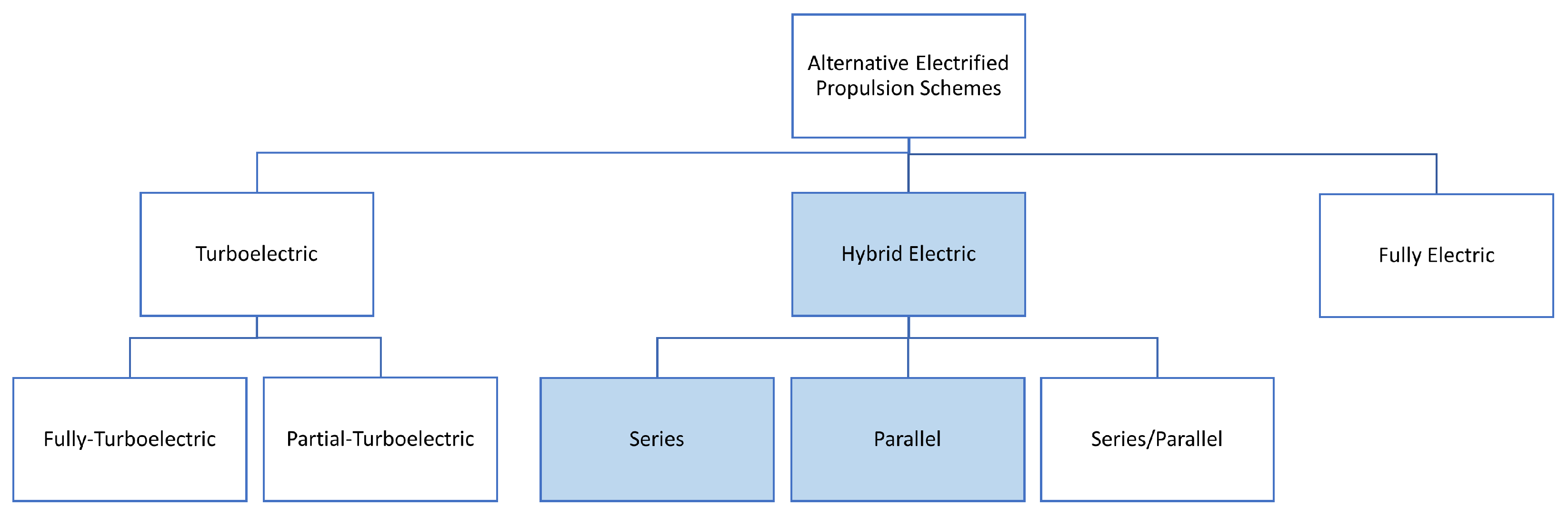

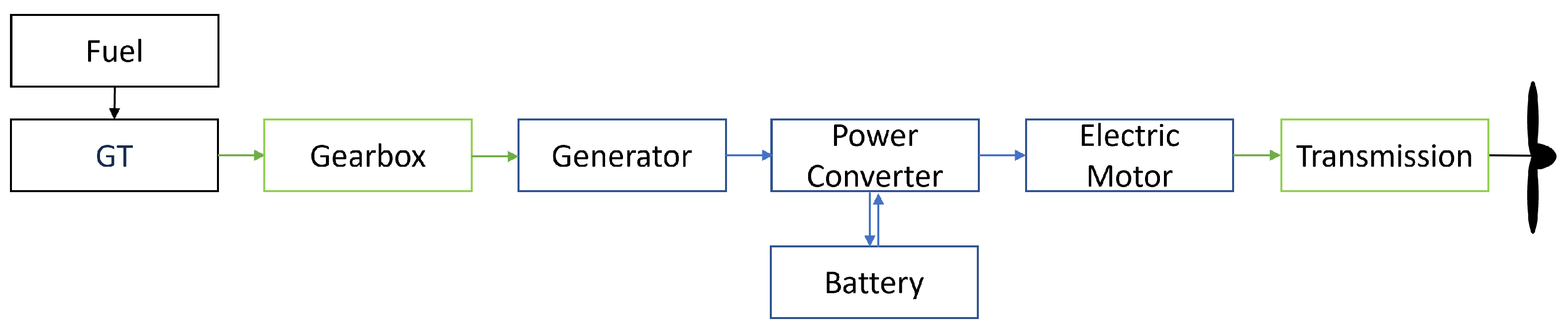

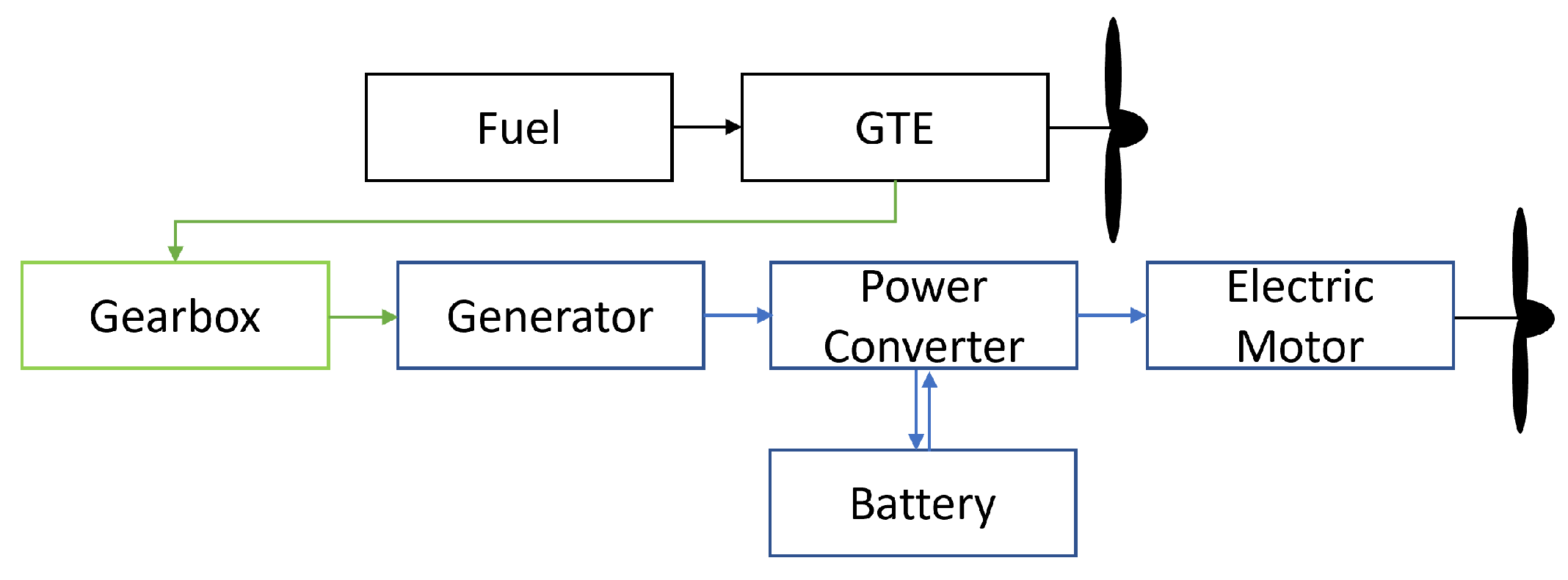

2.1. Serial Architectures

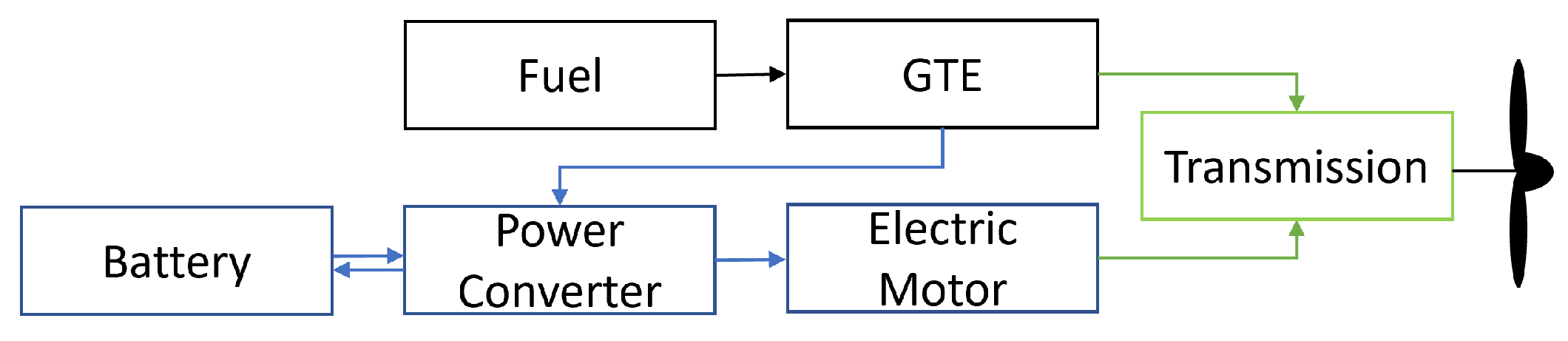

2.2. Parallel Architectures

2.3. Series/Parallel Architectures

2.4. Energy Storage Technology

2.5. Power Electronics, Motor, and Generator Technology

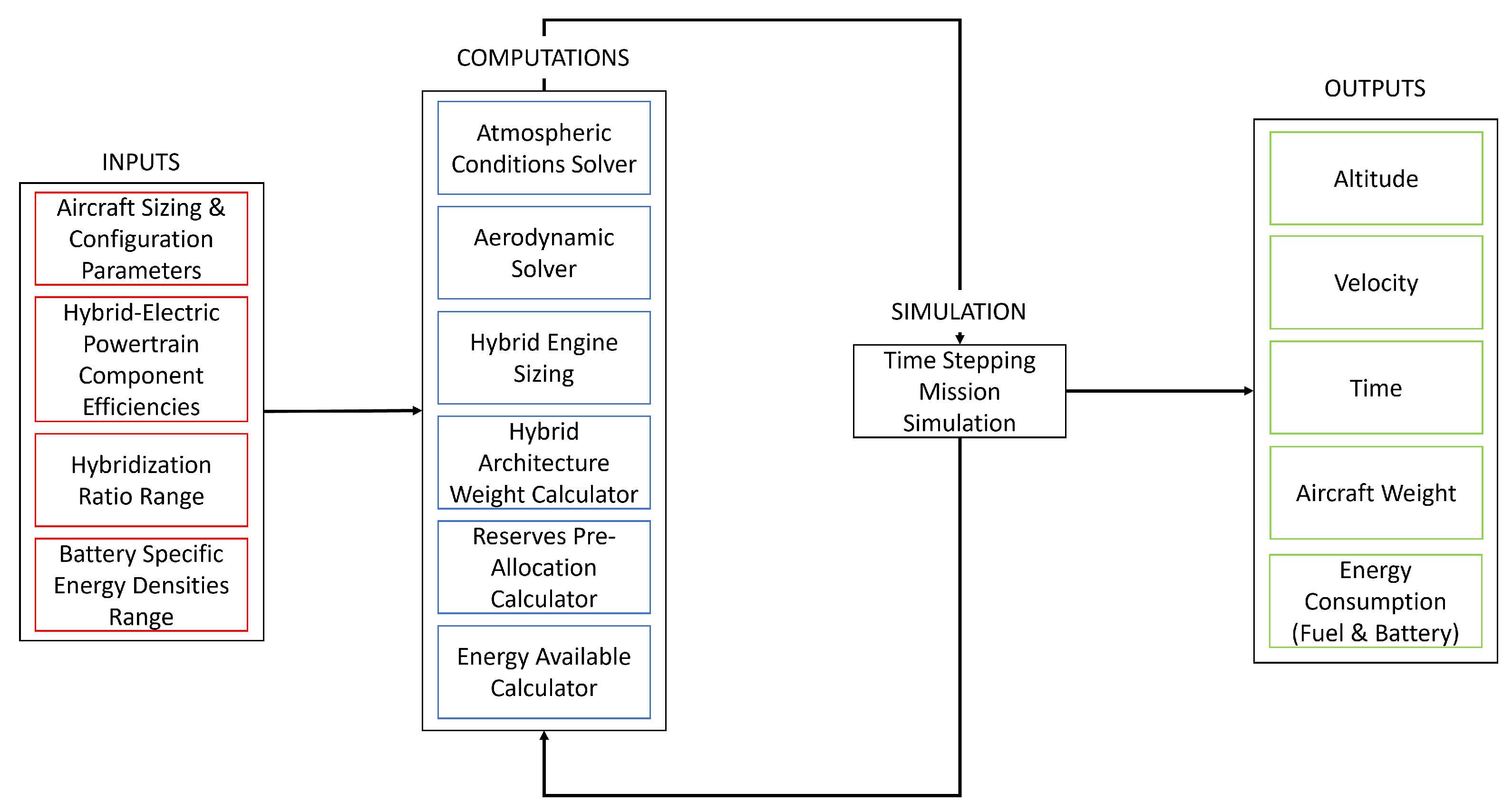

3. Methodology

3.1. Baseline Aircraft Aerodynamic Model

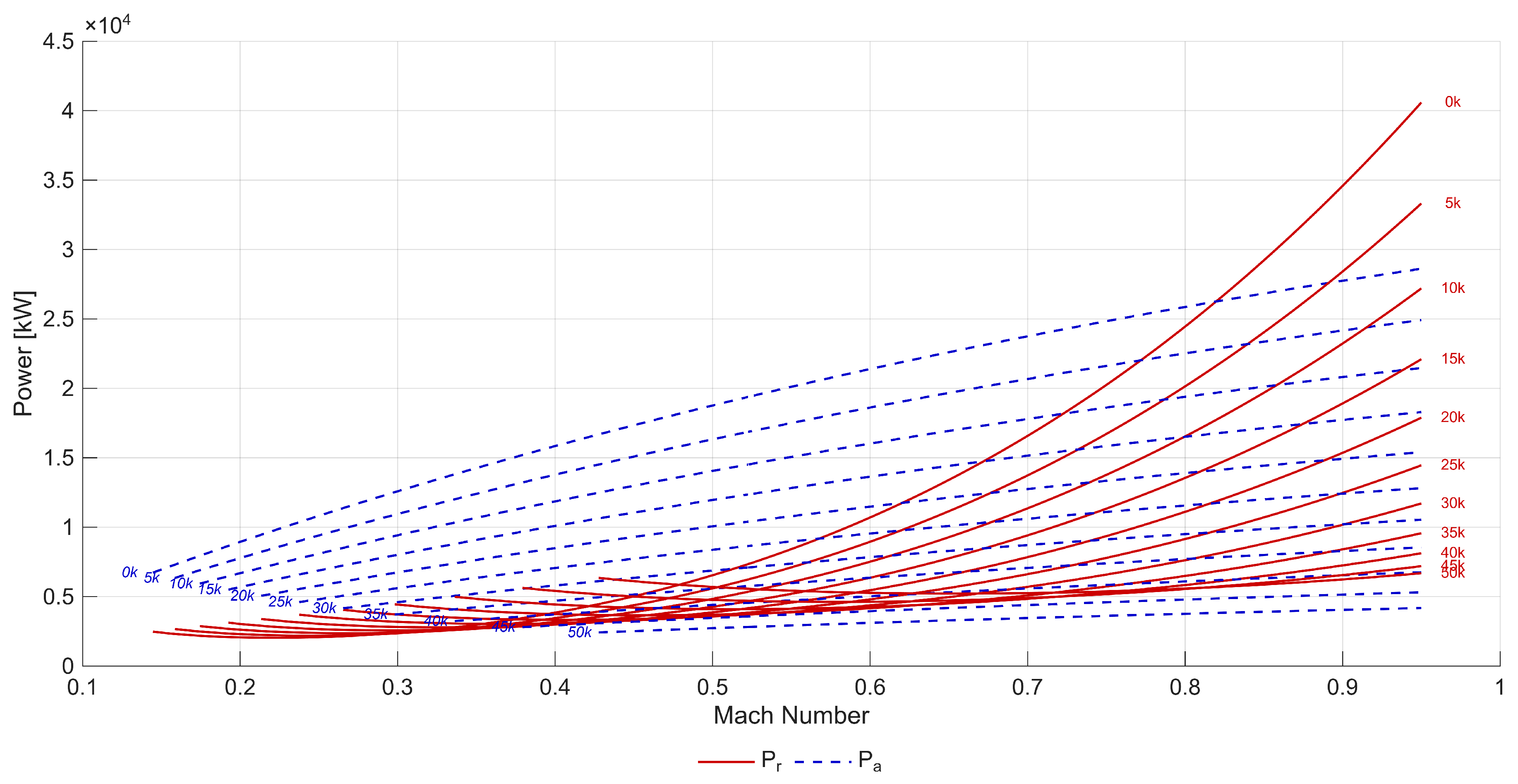

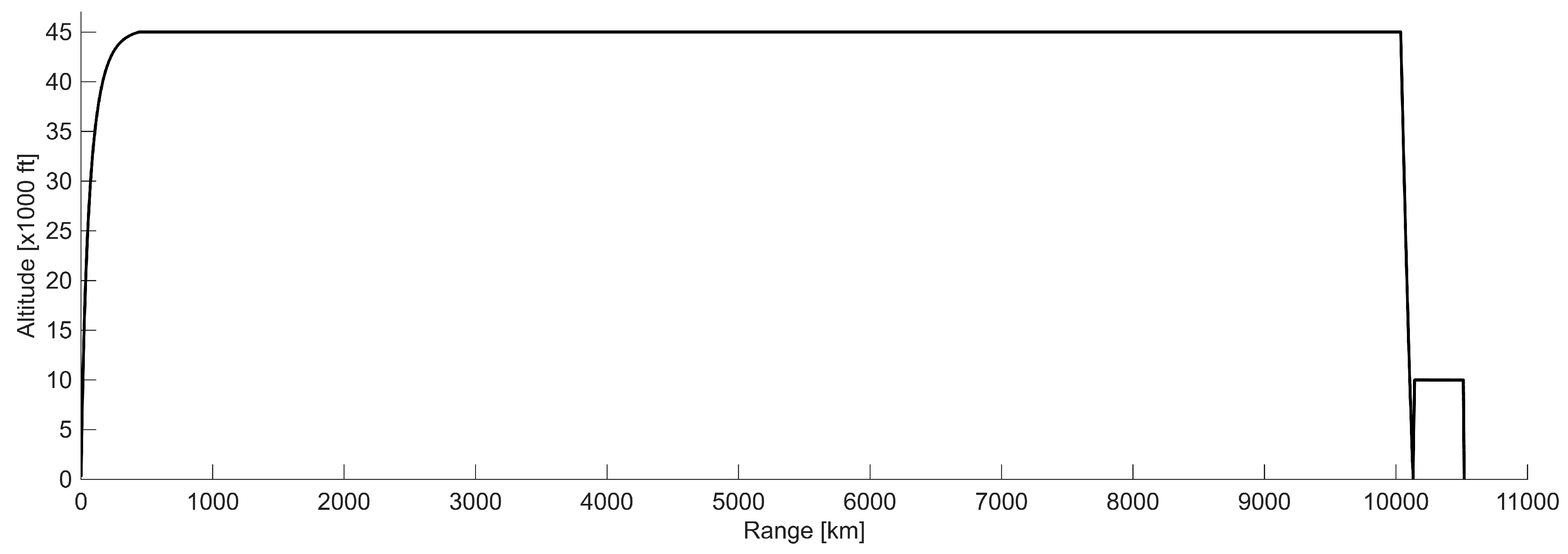

3.2. Performance Simulation

3.3. Conventional Turbofan Performance

3.3.1. Power Curves

3.3.2. Turbofan Weight

3.3.3. Turbofan Range

3.4. Hybrid-Electric Drivetrain Performance

3.4.1. Energy Hybridization

3.4.2. Motor Power Hybridization

3.4.3. Hybrid-Electric Drivetrain Sizing and Weight

3.4.4. Hybrid-Electric Range

3.5. Validation of Aircraft Performance Model

4. Results & Discussion

4.1. Turbofan Baseline Range

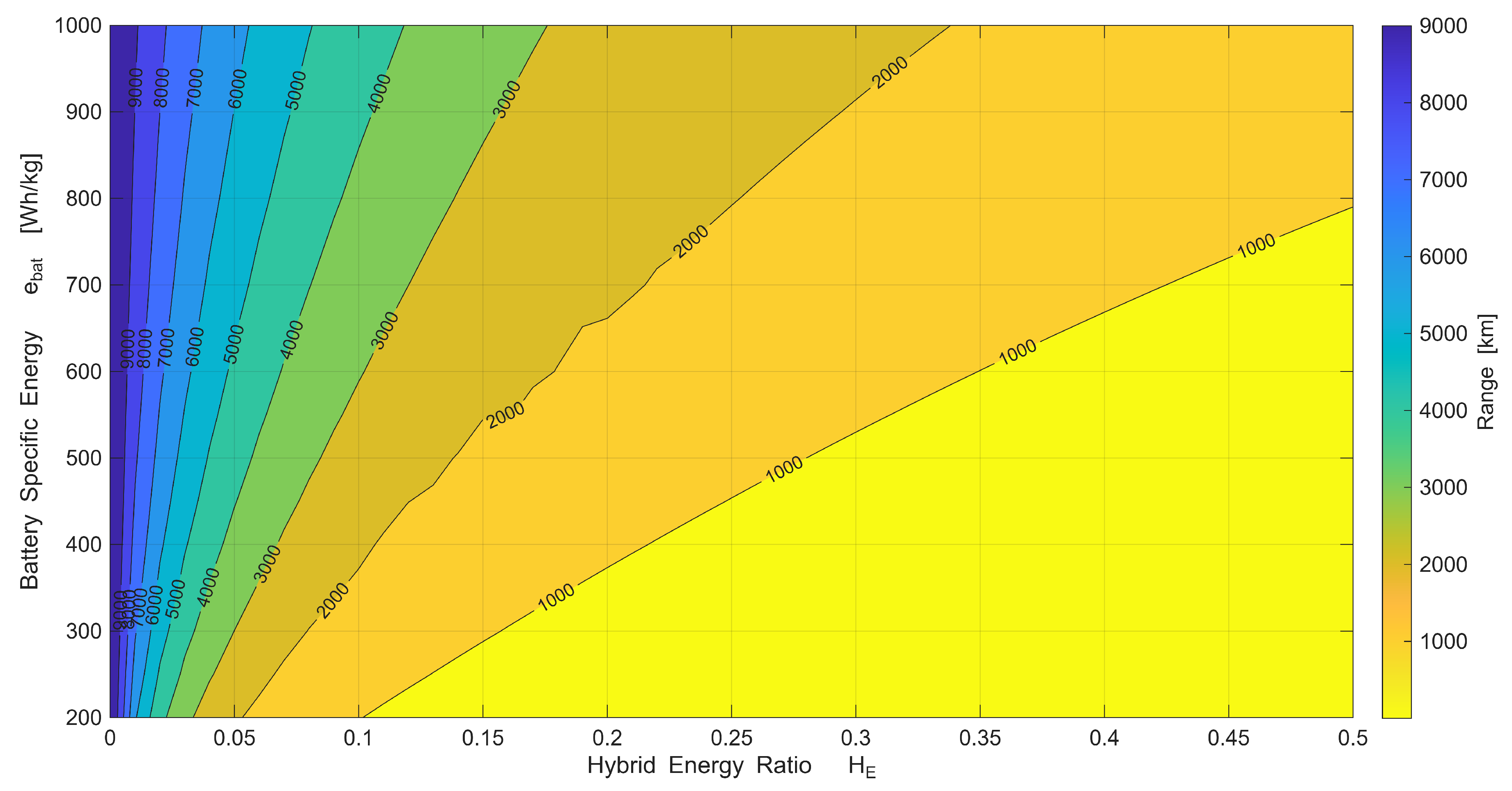

4.2. Hybrid-Electric Performance

Range

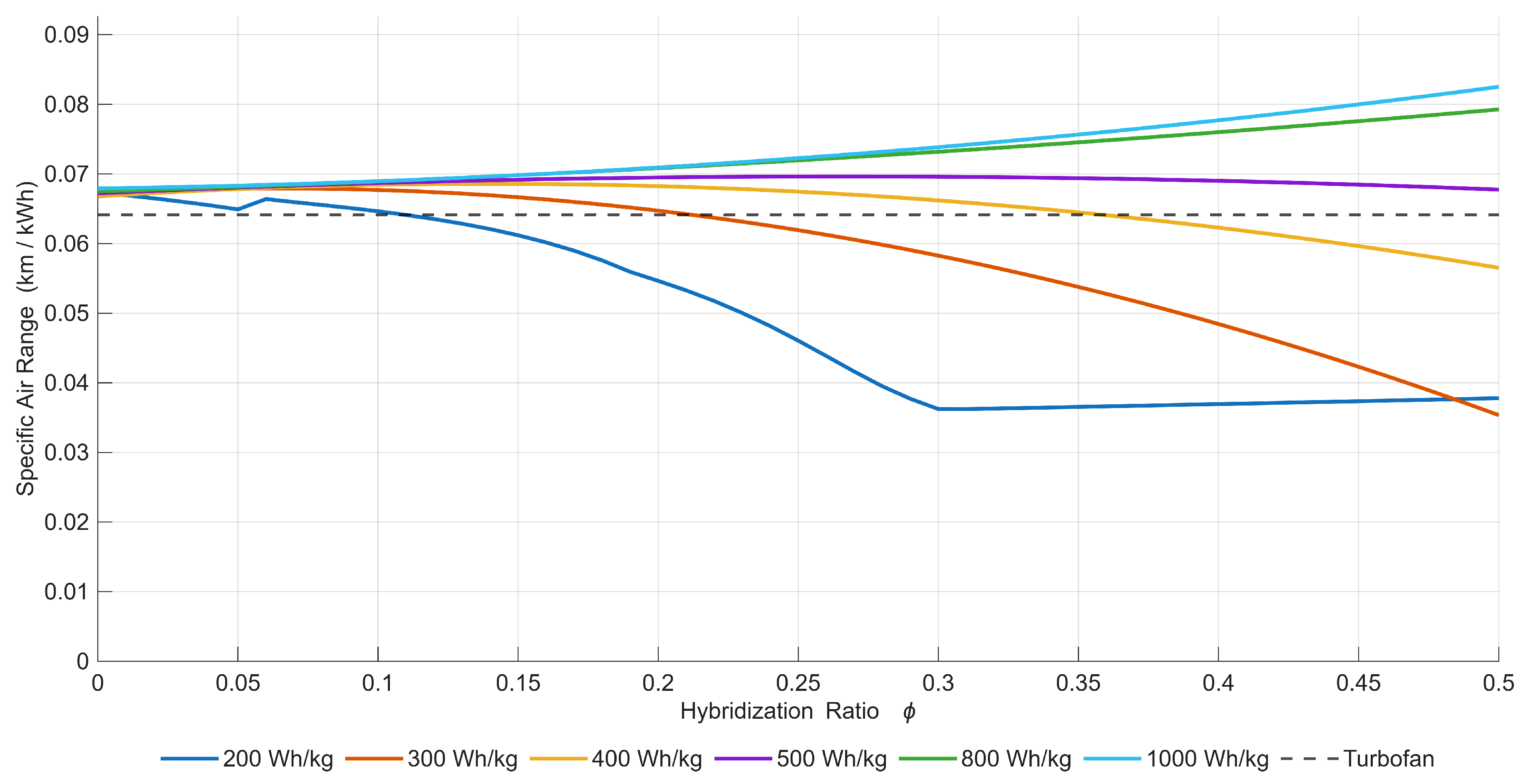

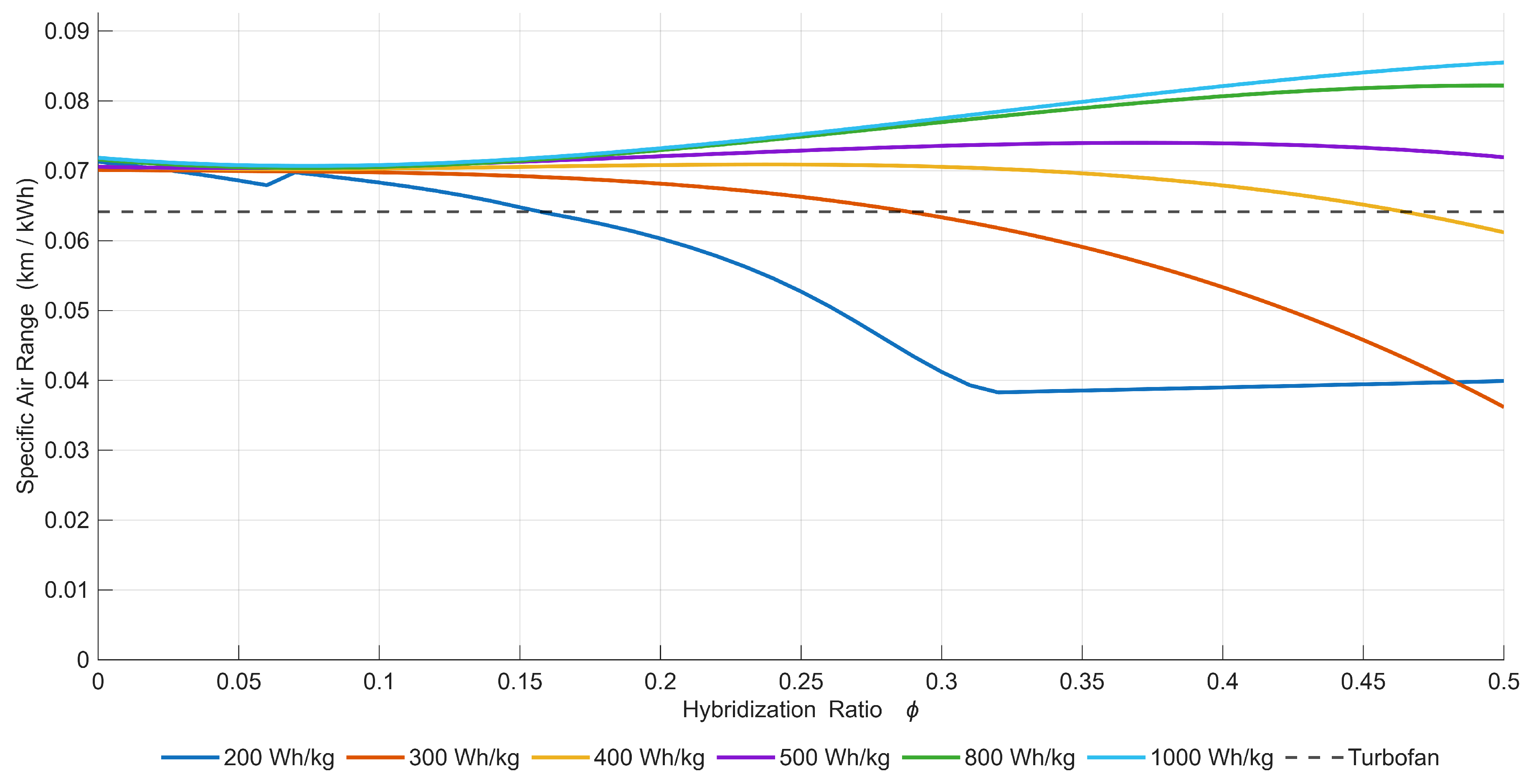

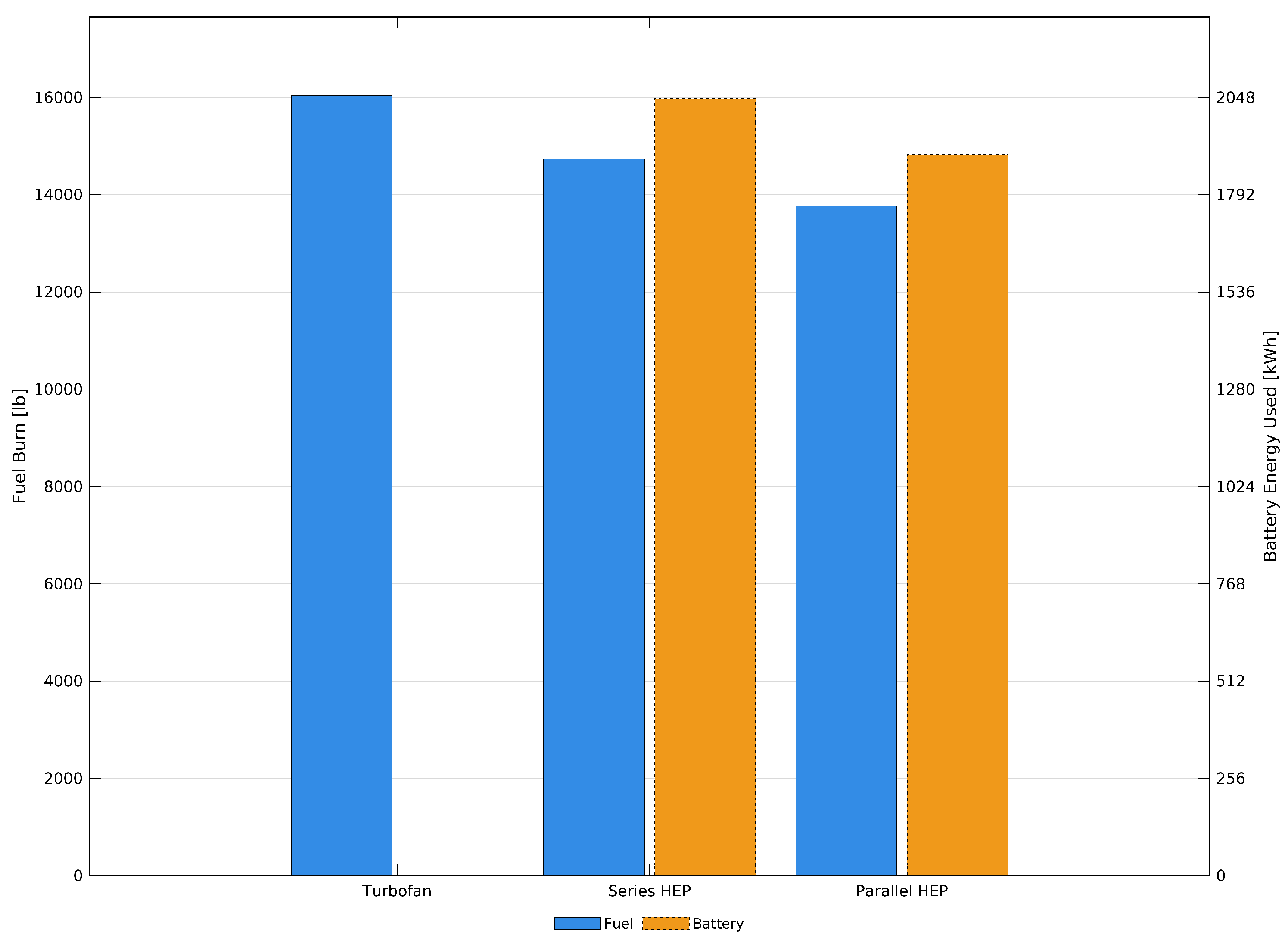

4.3. Energy Consumption

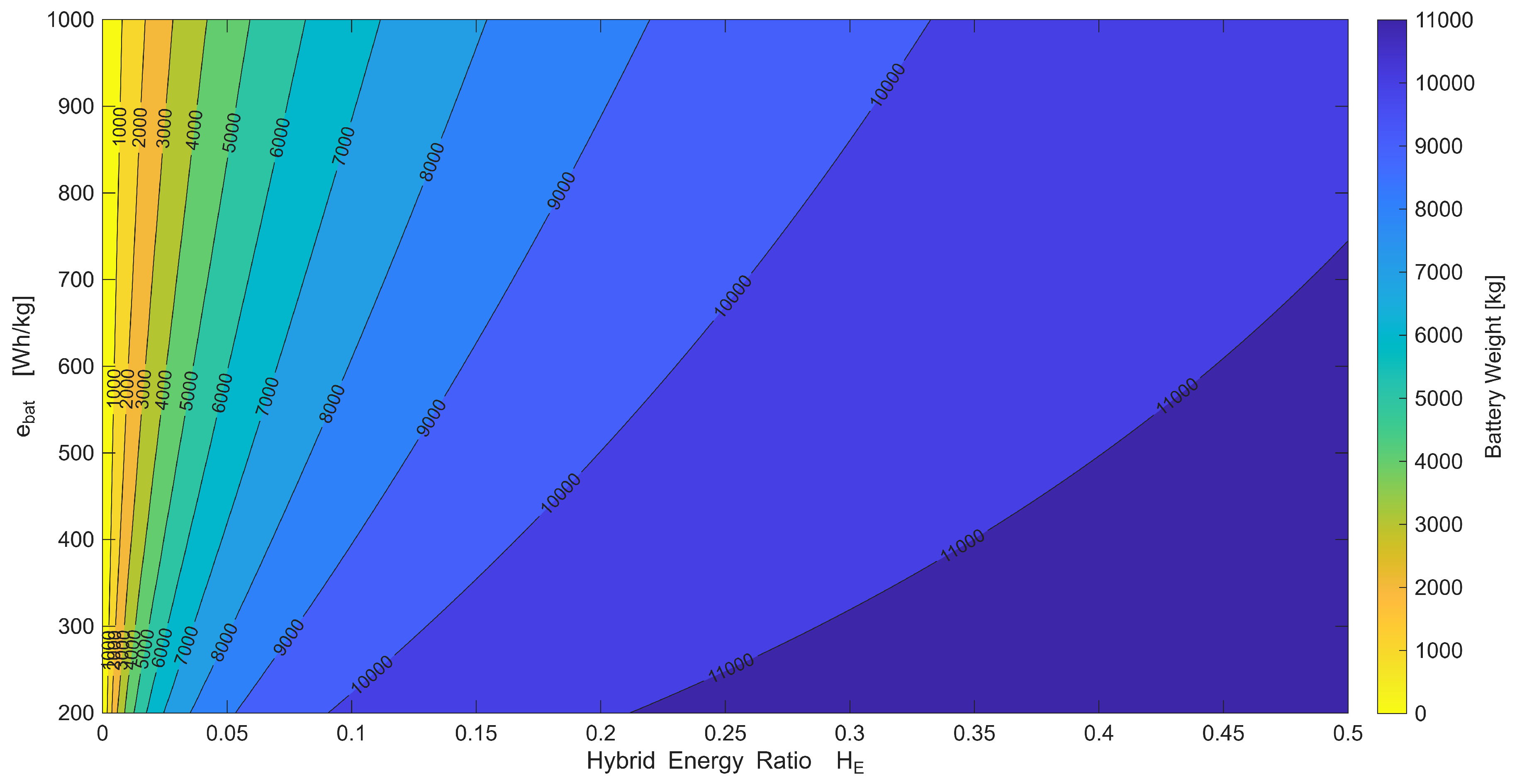

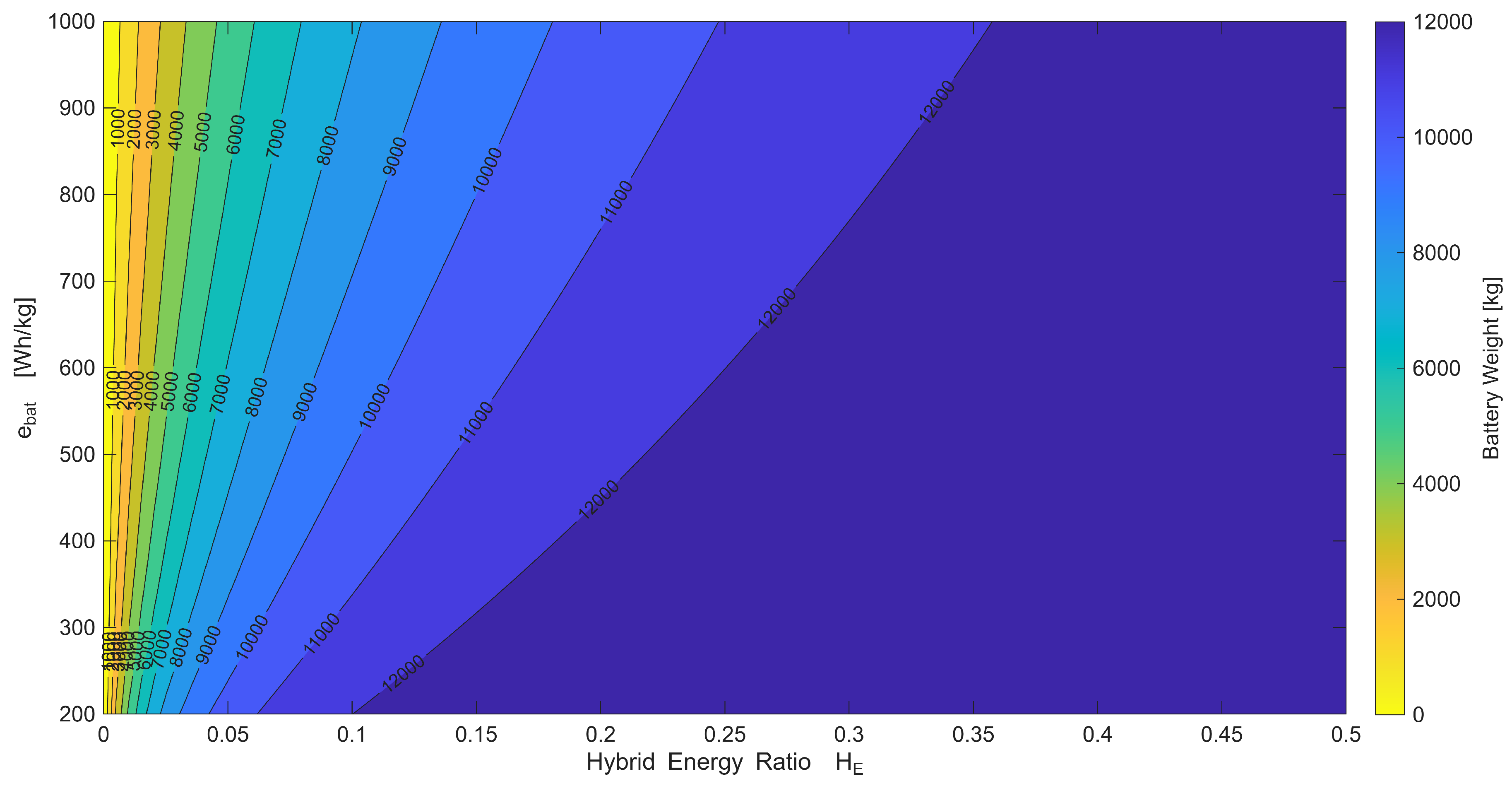

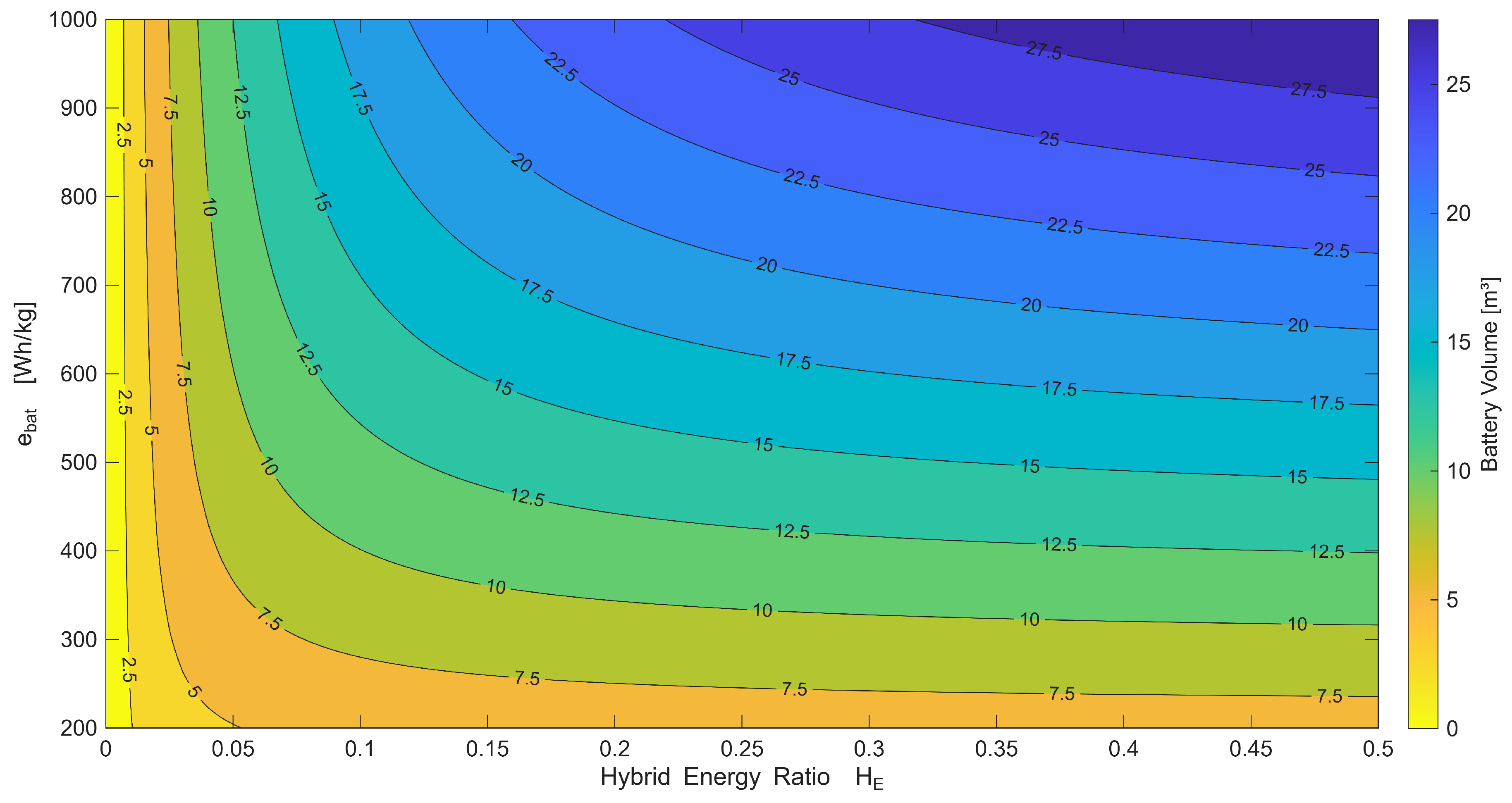

Battery Weight and Volume

4.4. Typical Mission

5. Conclusions

6. Future Research

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Alternating Current |

| BPR | Bypass Ratio |

| DC | Direct Current |

| ESAR | Energy Specific Air Range |

| FADEC | Full Authority Digital Engine Controller |

| GAMA | General Aviation Manufacturers Association |

| HEP | Hybrid-Eclectic Propulsion |

| IBAC | International Business Aviation Council |

| ICAO | International Civil Aviation Organization |

| MTOW | Maximum Takeoff Weight |

| NBAA | National Business Aviation Association |

| SP | Specific Power |

| TSFC | Thrust Specific Fuel Consumption |

| TR | Throttle Ratio |

References

- Contribution of the Global Aviation Sector to Achieving Paris Agreement Climate Objectives, United Nations Framework Convention on Climate Change—Climate Action Network (CAN) and International Coalition for Sustainable Aviation (ICSA), 2022. Available online: https://unfccc.int/sites/default/files/resource/156_CAN20ICSA20Aviation20TD20submission.pdf (accessed on 10 May 2025).

- Business Aviation Commitment on Climate Change, General Aviation Manufacturers Assosciation, 2020. Available online: https://gama.aero/wp-content/uploads/GAMA-IBAC-Joint-Position-on-Business-Aviation-Tackling-Climate-Change-1.pdf (accessed on 10 May 2025).

- National Academies of Sciences, Engineering, and Medicine; Division on Engineering and Physical Sciences; Aeronautics and Space Engineering Board; Committee on Propulsion and Energy Systems to Reduce Commercial Aviation Carbon Emissions. Commercial Aircraft Propulsion and Energy Systems Research: Reducing Global Carbon Emissions; The National Academies Press: Washington, DC, USA, 2016. [Google Scholar] [CrossRef]

- Yeung, T.H. Optimal Battery Weight Fraction for Serial Hybrid Propulsion System in Aircraft Design. Master’s Thesis, Embry-Riddle Aeronautical University, Daytona Beach, FL, USA, 2019. [Google Scholar]

- Vincent, R. JETNET IQ Pulse Issue # 41, 2022. Available online: https://www.jetnet.com/documents/iq-pulse/JETNET%20iQ%20Pulse%20-%20May%2012%202022.pdf (accessed on 1 June 2025).

- Shay, L.A.; McMillin, M.; Carey, B. Business & Commercial Aviation—Q2 2023, Aviation Week, 2023. Available online: https://aviationweek.com/sites/default/files/2023-05/BCA_2023_Q2.pdf (accessed on 20 May 2025).

- Spangler, T. Business Aviation Aircraft Categories, Jetcraft, 2021. Available online: https://www.jetcraft.com/jetstream/2021/11/business-aviation-aircraft-categories/ (accessed on 1 June 2025).

- Aircraft Guide—Private Jets, Aircraft Partner. Available online: https://www.airpartner.com/en/aircraft-guide/private-jets/ (accessed on 1 July 2025).

- Private Jet Comparison, Jet Advisors, 2022. Available online: https://jetadvisors.com/private-jet-comparison/ (accessed on 1 July 2025).

- Rendón, M.A.; Sánchez R., C.D.; Gallo M., J.; Anzai, A.H. Aircraft Hybrid-Electric Propulsion: Development trends, challenges and opportunities. J. Control. Autom. Electr. Syst. 2021, 32, 1244–1268. [Google Scholar] [CrossRef]

- Sahoo, S.; Zhao, X.; Kyprianidis, K. A Review of Concepts, Benefits, and Challenges for Future Electrical Propulsion-Based Aircraft. Aerospace 2020, 7, 44. [Google Scholar] [CrossRef]

- Bowman, C. Establishing Electrified Aircraft Propulsion Concepts: How AATT identified viable propulsion concepts and established foundational technologies. In Proceedings of the ARMD Technical Seminar 2018, Cleveland, OH, USA, 11 August 2018. [Google Scholar]

- Xie, Y.; Savvarisal, A.; Tsourdos, A.; Zhang, D.; Gu, J. Review of Hybrid Electric Powered Aircraft, its Conceptual Design and Energy Management Methodologies. Chin. J. Aeronaut. 2021, 34, 432–450. [Google Scholar] [CrossRef]

- de Vries, R.; Hoogreef, M.F.; Vos, R. Range Equation for Hybrid-Electric Aircraft with Constant Power Split. J. Aircr. 2020, 57, 552–557. [Google Scholar] [CrossRef]

- Chapman, J.W. Considering Turbofan Operability in Hybrid Electric Aircraft Propulsion System Design. In Proceedings of the AIAA SCITECH 2023 Forum, National Harbor, MD, USA, 23–27 January 2023. [Google Scholar] [CrossRef]

- Gong, K. A Comparative Study on the Design and Challenges for All-Electric and Hybrid-Electric Aircraft. E3S Web Conf. 2024, 553, 04009. [Google Scholar] [CrossRef]

- Ludowicy, J.; Rings, R.; Finger, D.; Braun, C. Sizing Studies of Light Aircraft with Serial Hybrid Propulsion Systems; Deutsche Gesellschaft für Luft-und Raumfahrt-Lilienthal-Oberth eV: Bonn, Germany, 2018. [Google Scholar] [CrossRef]

- Bills, A.; Sripad, S.; Fredericks, W.; Singh, M.; Viswanathan, V. Performance Metrics Required of Next-Generation Batteries to Electrify Commercial Aircraft. ACS Energy Lett. 2020, 5, 663–668. [Google Scholar] [CrossRef]

- Janovec, M.; Čerňan, J.; Škultéty, F.; Novák, A. Design of Batteries for a Hybrid Propulsion System of a Training Aircraft. Energies 2021, 15, 49. [Google Scholar] [CrossRef]

- Dever, T.; Duffy, K.P.; Provenza, A.; Loyselle, P.L.; Choi, B.B.; Morrison, C.R.; Lowe, A.M. Assessment of Technologies for Noncryogenic Hybrid Electric Propulsion; National Aeronautics and Space Administration: Cleveland, OH, USA, 2015. [Google Scholar]

- Christen, T.; Carlen, M.W. Theory of Ragone plots. J. Power Sources 2000, 91, 210–216. [Google Scholar] [CrossRef]

- Rheaume, J.M.; Lents, C. Energy Storage for Commercial Hybrid Electric Aircraft; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2016. [Google Scholar] [CrossRef]

- Misra, A. Summary of 2017 NASA Workshop on Assessment of Advanced Battery Technologies for Aerospace Applications. In Proceedings of the AIAA SciTech Forum and Exposition, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar]

- Hepperle, M. Electric Flight—Potential and Limitations. In Proceedings of the Energy Efficient Technologies and Concepts of Operation, Lisbon, Portugal, 22–24 October 2012. [Google Scholar]

- Johnson, L. The Viability of High Specific Energy Lithium Air Batteries. In Symposium on Research Opportunities in Electrochemical Energy Storage-Beyond Lithium Ion: Materials Perspectives; 7 October 2010; Available online: https://rexresearch.com/johnsonliairbatty/Session4-350-Johnson.pdf (accessed on 10 May 2025).

- Nagata, H.; Chikusa, Y. All-Solid-State Lithium-Sulfur Battery with High Energy and Power Densities at the Cell Level. Energy Technol. 2015, 4, 484–489. [Google Scholar] [CrossRef]

- Hall, C.; Pastra, C.L.; Burrell, A.; Gladin, J.; Mavris, D.N. Projecting Power Converter Specific Power Through 2050 for Aerospace Applications. In Proceedings of the 2022 IEEE Transportation Electrification Conference & Expo (ITEC), Anaheim, CA, USA, 15–17 June 2022; pp. 760–765. [Google Scholar] [CrossRef]

- Hall, D.; Greitzer, E.; Dowdle, A.; Gonzalez, J.; Hoburg, W.; Lang, J.; Sabnis, J.; Spakovszky, Z.; Yutko, B.; Courtin, C.; et al. Feasibility of Electrified Propulsion for Ultra-Efficient Commercial Aircraft Final Report; Technical Report; NASA: Washington, DC, USA, 2019. [Google Scholar]

- Zhang, X.; Bowman, C.L.; O’Connell, T.C.; Haran, K.S. Large electric machines for aircraft electric propulsion. IET Electr. Power Appl. 2018, 12, 767–779. [Google Scholar] [CrossRef]

- Granger, M.; Anderson, A.; Maroli, J.M.; Tallerico, T.; Scheidler, J.J. Combined Analysis of NASA’s High Efficiency Megawatt Motor and Its Converter. In Proceedings of the 2021 AIAA/IEEE Electric Aircraft Technologies Symposium (EATS), Denver, CO, USA, 11–13 August 2021; pp. 1–13. [Google Scholar] [CrossRef]

- Tallerico, T.; Scheidler, J.J.; Lee, D.; Haran, K.S. Electromagnetic Redesign of NASA’s High Efficiency Megawatt Motor. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Virtual Event, 24–28 August 2020. [Google Scholar] [CrossRef]

- 1 Megawatt (MW) Power Gnerator, Honeywell, 2025. Available online: https://prod-edam.honeywell.com/content/dam/honeywell-edam/aero/en-us/products/power-and-propulsion/electric-power/honeywell-1-megawatt-mw-turbogenerator/documents/hon-aero-n61-2229-000-000-1mw-generator-brochure-en.pdf (accessed on 1 June 2025).

- Spakovszky, Z.S.; Chen, Y.; Greitzer, E.M.; Cordero, Z.C.; Lang, J.H.; Kirtley, J.L.; Perreault, D.J.; Andersen, H.N.; Qasim, M.M.; Cuadrado, D.G.; et al. Technology Demonstration of a Megawatt-Class Integrated Motor Drive for Aircraft Propulsion. In Proceedings of the AIAA AVIATION 2023 Forum, San Diego, CA, USA, 12–16 June 2023. [Google Scholar] [CrossRef]

- Jansen, R.; Bowman, C.; Jankovsky, A.; Dyson, R.; Felder, J. Overview of NASA Electrified Aircraft Propulsion (EAP) Research for Large Subsonic Transports. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017. [Google Scholar] [CrossRef]

- Al Khoury, J.; Bou Nader, W. Design and simulation of turbogenerators for series hybrid electric vehicles. Energy Convers. Manag. 2021, 236, 114078. [Google Scholar] [CrossRef]

- McCormick, B.W. Aerodynamics, Aeronautics, and Flight Mechanics, 2nd ed.; Wiley: Hoboken, NJ, USA, 1995. [Google Scholar]

- Raymer, D.P. Aircraft Design: A Conceptual Approach, 2nd ed.; The American Institute of Aeronautics and Astronautics, Inc.: Reston, VA, USA, 1992. [Google Scholar]

- Gudmundsson, S. General Aviation Aircraft Design: Applied Methods and Procedures, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Wroblewski, G.E.; Ansell, P.J. Mission Analysis and Emissions for Conventional and Hybrid-Electric Commercial Transport Aircraft. J. Aircr. 2019, 56, 1200–1213. [Google Scholar] [CrossRef]

- Pornet, C.; Gologan, C.; Vratny, P.C.; Seitz, A.; Schmitz, O.; Isikveren, A.T.; Hornung, M. Methodology for sizing and performance assessment of Hybrid Energy Aircraft. J. Aircr. 2015, 52, 341–352. [Google Scholar] [CrossRef]

- Wroblewski, G.E.; Ansell, P.J. Mission analysis and emissions for conventional and hybrid-electric regional jet aircraft. In Proceedings of the 2018 AIAA/IEEE Electric Aircraft Technologies Symposium, Cincinnati, OH, USA, 12–14 July 2018. [Google Scholar] [CrossRef]

- Majka, A.; Muszyńska-Pałys, J. Analysis of the performance of an aircraft powered by hybrid propulsion. Combust. Engines 2023, 193, 45–51. [Google Scholar] [CrossRef]

- Antcliff, K.R.; Guynn, M.D.; Marien, T.; Wells, D.P.; Schneider, S.J.; Tong, M.J. Mission Analysis and Aircraft Sizing of a Hybrid-Electric Regional Aircraft. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016. [Google Scholar]

- Gulfstream G550 (GV-SP) Sample Analysis, 2022. Available online: https://www.lissys.uk/samp2/index.html (accessed on 15 May 2025).

- Roskam, J. Some Comments on Trim Drag. In Proceedings of the NASA, Industry, University, General Aviation Drag Reduction Workshop, Lawrence, KS, USA, 14–16 July 1975; pp. 295–305. [Google Scholar]

- Jackson, P.; Peacock, L.; Bushell, S.; Willis, D.; Winchester, J. Jane’s All the World’s Aircraft: Development and Production, 2018–2019; IHS Markit: London, UK, 2018. [Google Scholar]

| Jet Size Class | Max. MTOW | Avg. NBAA IFR Range | Pax. Seats |

|---|---|---|---|

| Very Light Jets | <5670 kg (12,500 lbs) | 1852 km (1000 nmi) | 4–6 |

| Light Jets | ≈9072 kg (20,000 lbs) | 3704 km (2000 nmi) | 5–6 |

| Midsize Jets | ≈13,608 kg (30,000 lbs) | 4630 km (2500 nmi) | 7–8 |

| Super-Midsize Jets | ≈18,144 kg (40,000 lbs) | 5556 km (3000 nmi) | 8–10 |

| Large-Cabin Jets | ≈36,287 kg (80,000 lbs) | 8334 km (4500 nmi) | 10–18 |

| Ultra Long-Range Jets | >41,957 kg (92,500 lbs) | 12,038 km (6500 nmi) | 12–20 |

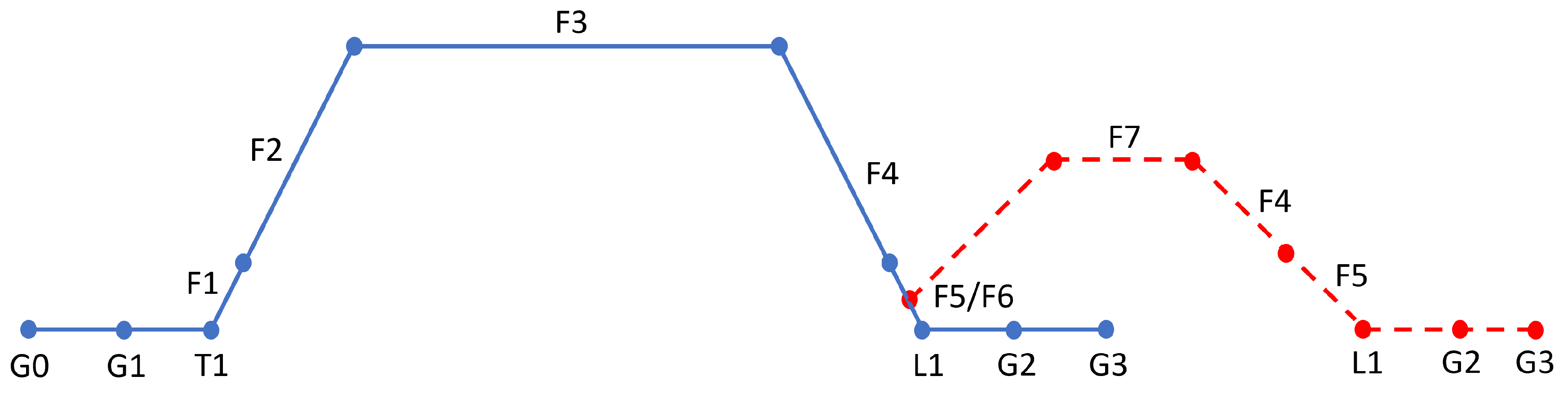

| Phase | Phase Name | Phase Description | Typical Values |

|---|---|---|---|

| G0 | Engine Start | Engine start | - |

| G1 | Taxi | Ramp to runway | 10 min at ground idle |

| T1 | Takeoff | Roll to rotation | Approximately 5500 ft TOFL @ MTOW |

| F1 | Initial Climb | Climb to departure altitude | Surface to between 2500 ft AGL & 4500 ft MSL |

| F2 | Climb | Climb to cruise altitude | From 2500/4500 ft AGL to 30,000 ft MSL |

| F3 | Cruise | Cruise climb and cruise | 30,000 ft MSL to 50,000 ft MSL @ Mach 0.85 to Mach 0.9 |

| F4 | Descent | Descent to approach altitude | Cruise altitude to between 4500 ft AGL & 2500 ft AGL |

| F5 | Approach | Descent to runway threshold | From 4500/2500 ft AGL to approximately 50 ft AGL |

| L1 | Landing | Touchdown to full stop | Approximately 914 m (3000 ft) LFL |

| G2 | Taxi | Taxi to ramp | - |

| G3 | Engine Shutoff | Engine Shutoff | - |

| F6 | Missed Approach | Missed approach procedure | Including 5 min of holding time |

| F7 | Cruise/Reserves | IFR reserves | Cruise 370 km (200 nmi) + reserves (VFR/IFR: 30/45 min) |

| Energy Storage Type | Specific Energy [Wh/kg] | Specific Power [W/kg] | Vol. Energy Density [Wh/L] | Cycle Life [#] | ||

|---|---|---|---|---|---|---|

| Current | Future | Current | Future | Current | Current | |

| Jet A-1 | 11,950 | 9500 | ||||

| Lead-Acid | 50 a | 150–300 a | 50–100 a | 1200–1800 a | ||

| Ni-Cd | 60 a | 150–200 a | 75–150 a | 2000–3000 a | ||

| Li-ion | 80–200 a,h | 400 b,c 300 d 250 e | 1800 a | 200–300 a | 3000 a | |

| Li-po | 130–200 a | 3000 a | 250 a | 1000+ a | ||

| Li-air | 400–800 a | 600–750 b 900–1000 d 800–1750 e | 400–640 f | 180–250 a | 10–50 a,b | |

| Li-S | 200–700 a | 500–650 b 600–700 b 500–1250 e | 750 a | 1000 g | 180–250 a | 100 a |

| Weights | Miscellaneous | ||

|---|---|---|---|

| Max. Takeoff Weight [kg] | 34,019 | Installed Thrust (×2) [kN] | 68.95 |

| Operating Empty Weight [kg] | 18,461 | TSFC [g/kN-s] | 15.0 |

| Max. Fuel Weight [kg] | 14,742 | Bypass Ratio | 5.5 |

| Max. Payload [kg] | 2722 | Ceiling [ft] | 50,000 |

| Payload at Max. Fuel [kg] | 816 | Cabin Volume [m3] | 49.55 |

| Baggage Volume [m3] | 4.96 | ||

| Wings | Vertical Stabilizer | ||

|---|---|---|---|

| Wing Ref. Area, [m2] | 111.48 | V. Stab. Wet. Area, [m2] | 29.26 |

| Wing Wet. Area, [m2] | 185.81 | Mean V. Stab. Chord, [m] | 3.81 |

| Mean Wing Chord, [m] | 3.73 | Chordwise Max. Thick., | 0.50 |

| Chordwise Max. Thickness, | 0.50 | Thickness to Chord Ratio, | 0.09 |

| Thickness to Chord Ratio, | 0.10 | Max.-Thick. Line Sweep, [] | 33 |

| Max.-Thick. Line Sweep, [] | 35 | ||

| Winglet Wet. Area, [m2] | 2.04 | Fuselage | |

| Wing L.E. Sweep, [] | 38 | Fuselage Wet. Area, [m2] | 162.58 |

| Wingspan [m] | 27.43 | Length, L [m] | 24.38 |

| Aspect ratio, | 6.75 | Diameter, d [m] | 2.44 |

| Horizontal Stabilizer | Single-Engine Nacelle | ||

| H. Stab. Wet. Area, [m2] | 48.77 | Nacelle Wet. Area, [m2] | 23.23 |

| Mean H. Stab. Chord, [m] | 2.29 | Length, L [m] | 4.88 |

| Chordwise Max. Thick., | 0.50 | Diameter, d [m] | 1.75 |

| Thickness to Chord Ratio, | 0.095 | ||

| Flight Condition | Power [kW] |

|---|---|

| Sea Level at | 3473 |

| Sea Level at | 13,129 |

| Ceiling at | 2920 |

| Drivetrain Path | Series | Parallel |

|---|---|---|

| Fuel to Shaft, | ||

| Battery to Shaft, | ||

| Shaft to Thrust, |

| Component | Efficiency | Sp. Power [kW/kg] |

|---|---|---|

| Turbogenerator, | 0.49 | 13.0 |

| Turbofan, | 0.43 | * |

| Power Converter, | 0.99 | 12.0 |

| Electric Motor, | 0.98 | 9.0 |

| Gearbox, | 0.99 | 100.0 |

| Propulsor Fan, | 0.85 | 30.0 |

| Component | Power [kW] | Weight [kg] |

|---|---|---|

| Propulsor Fan | 13,129 | 266 |

| Transmission Gearbox | 15,445 | 94 |

| Electric Motor | 15,601 | 1054 |

| Power Converter | 15,919 | 807 |

| Turbogenerator | 16,081 | 752 |

| Total Weight | - | 2973 |

| Component | Power [kW] | Weight [kg] |

|---|---|---|

| Transmission Gearbox | 3281 | 67 |

| Electric Motor | 3315 | 224 |

| Power Converter | 3403 | 171 |

| Turbofan | 13,129 | 1449 |

| Total Weight | - | 1911 |

| Architecture | Weight [kg] | Weight [kg] | Energy Weight [kg] |

|---|---|---|---|

| Turbofan | 2894 | 0 | 14,742 |

| Series | 5947 | 3053 | 11,689 |

| Parallel | 3823 | 929 | 13,813 |

| Distance Profile | Simulation | Piano Data | Difference |

|---|---|---|---|

| Distance for Climb [km] | 276 | 267 | 3.37% |

| Distance for Cruise [km] | 11,931 | 12,045 | 0.95% |

| Distance for Descent [km] | 195 | 187 | 4.27% |

| Block Range [km] | 12,403 | 12,497 | 0.75% |

| Time Profile | Simulation | Piano Data | Difference |

| Time to Climb [mins] | 23 | 22 | 4.54% |

| Time for Cruise [mins] | 834 | 850 | 1.89% |

| Time for Descent [mins] | 20 | 17 | 17.7% |

| Block Time [mins] | 877 | 889 | 1.35% |

| Fuel Profile | Simulation | Piano Data | Difference |

| Fuel for Climb [kg] | 1058 | 1076 | 1.67% |

| Fuel for Cruise [kg] | 16,043 | 15,914 | 0.81% |

| Fuel for Descent [kg] | 115 | 104 | 10.58% |

| Block Fuel [kg] | 17,216 | 17,094 | 0.71% |

| Hybridization Ratio | Series Range [km (nmi)] | Reduction [%] | Parallel Range [km (nmi)] | Reduction [%] |

|---|---|---|---|---|

| 0.025 | 7819 (4222) | 23.17% | 8823 (4764) | 13.31% |

| 0.050 | 6271 (3386) | 38.39% | 7082 (3824) | 30.43% |

| 0.100 | 4443 (2399) | 56.36% | 5024 (2713) | 50.64% |

| 0.200 | 2700 (1458) | 73.48% | 3063 (1654) | 69.90% |

| 0.300 | 2211 (1194) | 78.28% | 2522 (1362) | 75.21% |

| 0.400 | 1729 (934) | 83.01% | 1982 (1070) | 80.52% |

| 0.500 | 1415 (764) | 86.10% | 1630 (880) | 83.99% |

| Weights | Series | Parallel | Volumes | Series | Parallel |

|---|---|---|---|---|---|

| Battery Weight [kg] | 4499 | 5317 | Battery Volume [m3] | 12.50 | 14.77 |

| Fuel Weight [kg] | 7190 | 8496 | Fuel Volume [m3] | 9.00 | 10.63 |

| Energy Weight [kg] | −3053 | −929 | Energy Volume [m3] | 6.87 | 10.77 |

| Parameter | Turbofan | Series | Parallel |

|---|---|---|---|

| Fuel Mass Consumption [kg] | 7281 | 6685 | 6434 |

| Battery Energy Consumption [kWh] | - | 2049 | 1901 |

| Total Energy Consumption [kWh] | 86,555 | 81,524 | 78,388 |

| Energy SAR [km/kWh] | 0.0642 | 0.0682 | 0.0709 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarup, A. Application of Hybrid-Electric Propulsion to ‘Large-Cabin’ Business Aircraft. World Electr. Veh. J. 2025, 16, 530. https://doi.org/10.3390/wevj16090530

Sarup A. Application of Hybrid-Electric Propulsion to ‘Large-Cabin’ Business Aircraft. World Electric Vehicle Journal. 2025; 16(9):530. https://doi.org/10.3390/wevj16090530

Chicago/Turabian StyleSarup, Ambar. 2025. "Application of Hybrid-Electric Propulsion to ‘Large-Cabin’ Business Aircraft" World Electric Vehicle Journal 16, no. 9: 530. https://doi.org/10.3390/wevj16090530

APA StyleSarup, A. (2025). Application of Hybrid-Electric Propulsion to ‘Large-Cabin’ Business Aircraft. World Electric Vehicle Journal, 16(9), 530. https://doi.org/10.3390/wevj16090530