Design of an Optimal Enhanced Quadratic Controller for a Four-Wheel Independent Driven Electric Vehicle (4WID-EV) Under Failure Cases

Abstract

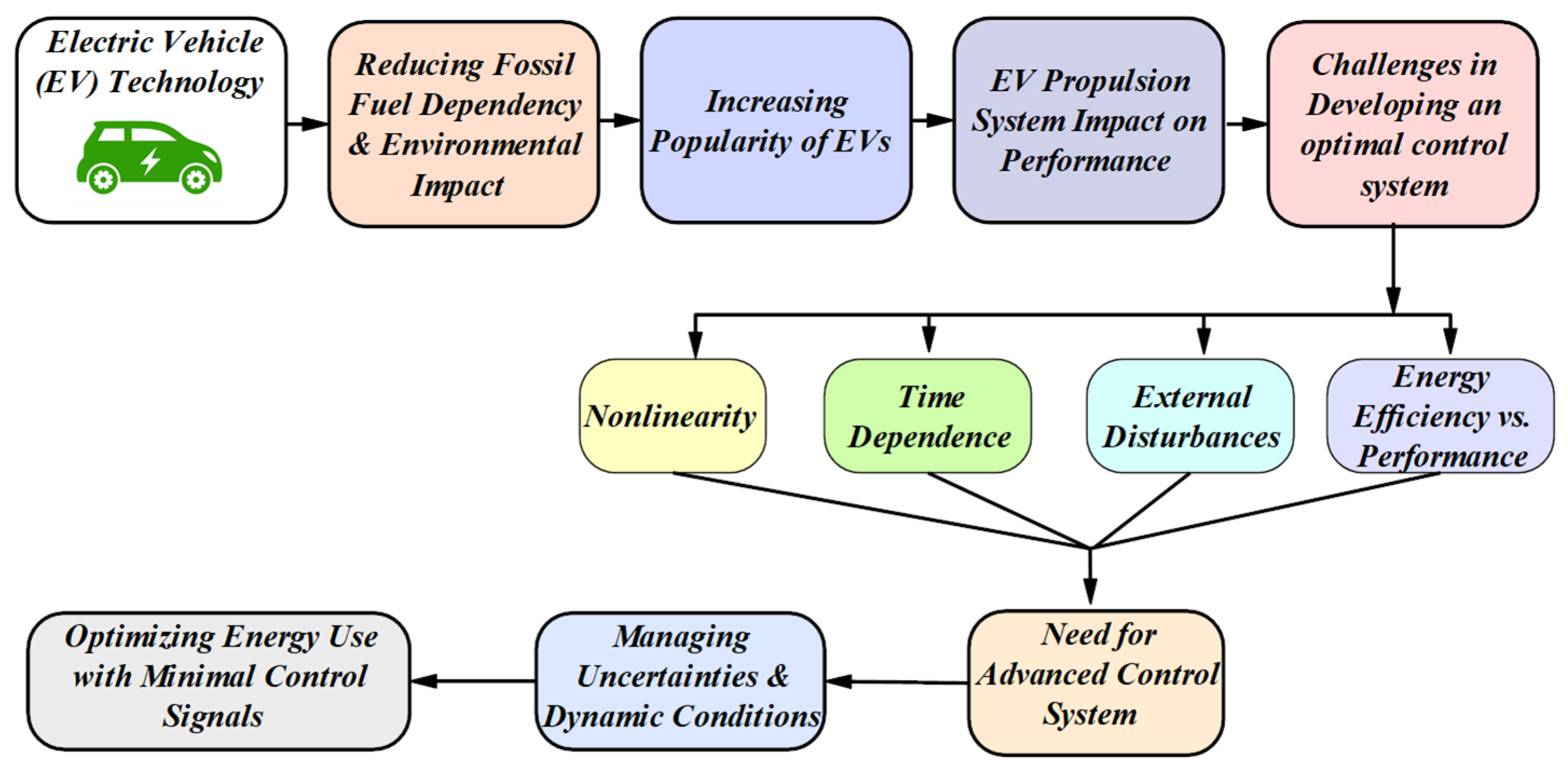

1. Introduction

- The optimal LQR controller was developed as an advanced control strategy to optimize the system’s performance. The controller employs state-space models to represent the system dynamics and calculates the optimal control inputs to achieve the desired output.

- PID and optimal LQR controllers are implemented to control the velocity of the 4WID-EV. PID controllers offer a simple design approach with proven effectiveness, whereas optimal LQR controllers provide significant control performance but require a more complex design.

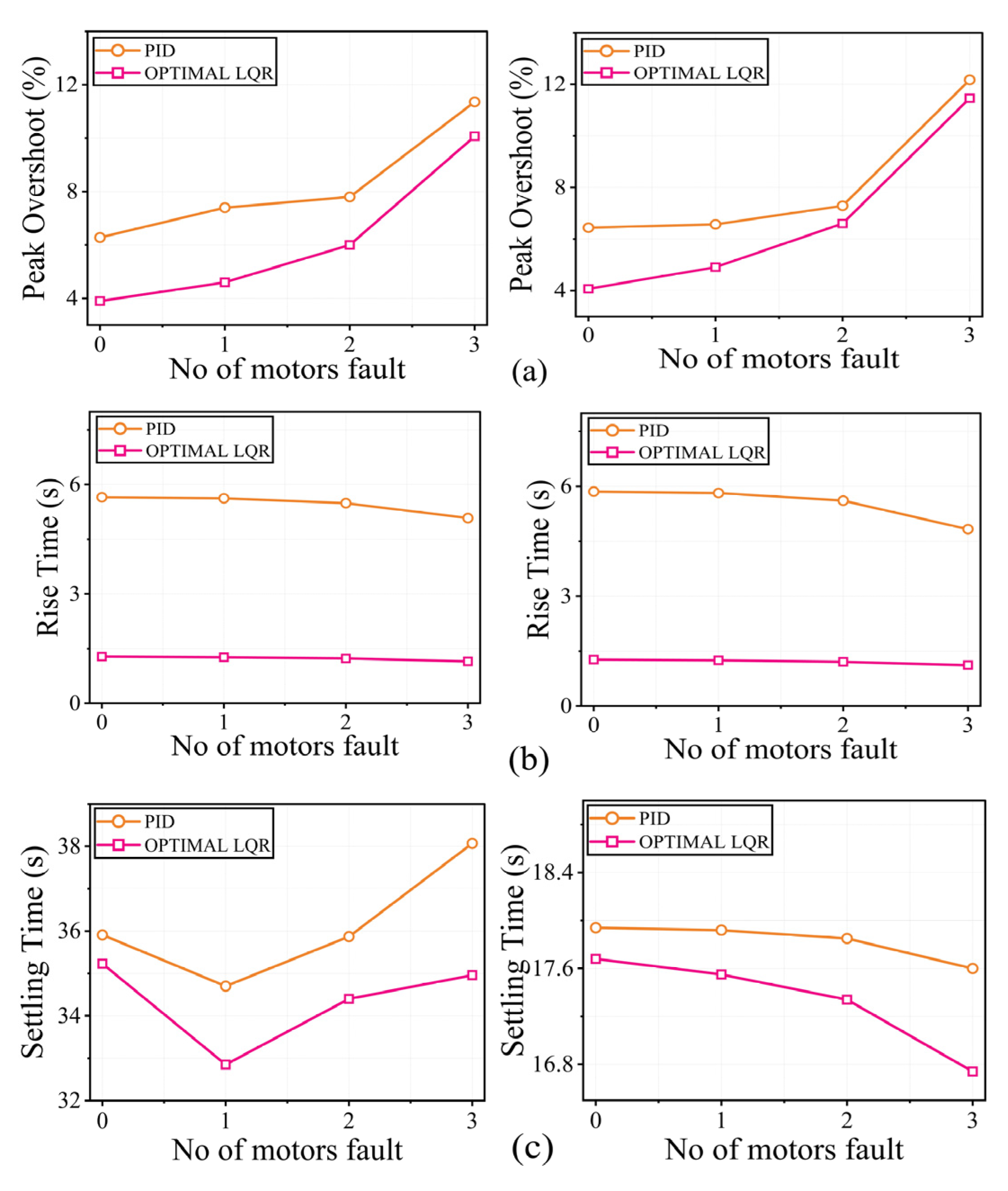

- A comparative analysis indicated that the rise time, settling time, and overshoot, particularly under fault scenarios predicted by the optimal LQR controller, are better than those of the PID controller.

2. Methods

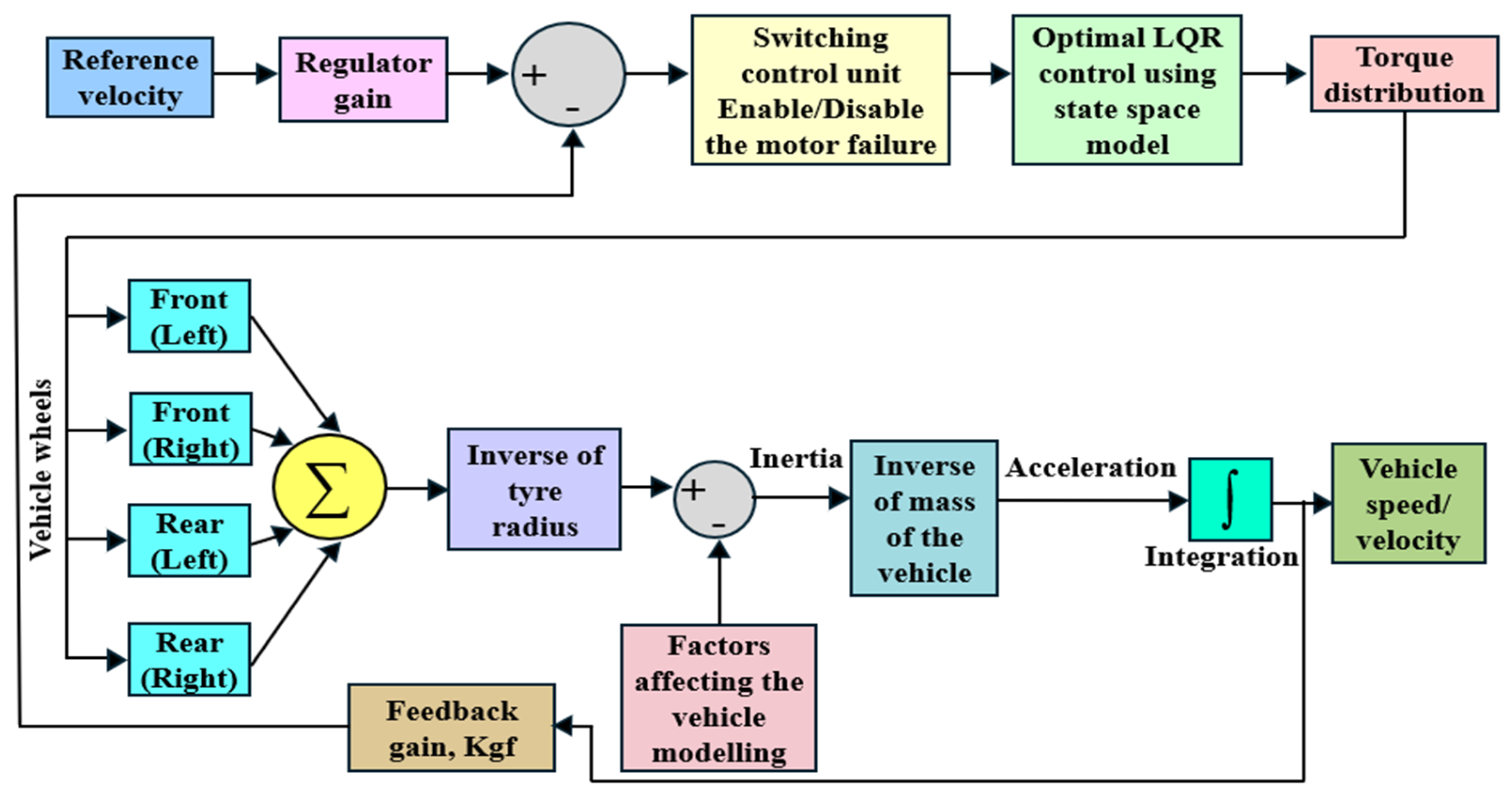

2.1. Modeling of 4WID-EV

2.1.1. Controlling Parameters and Assumptions

2.1.2. Governing Equation

2.2. Modeling of Motor Using PID Controller

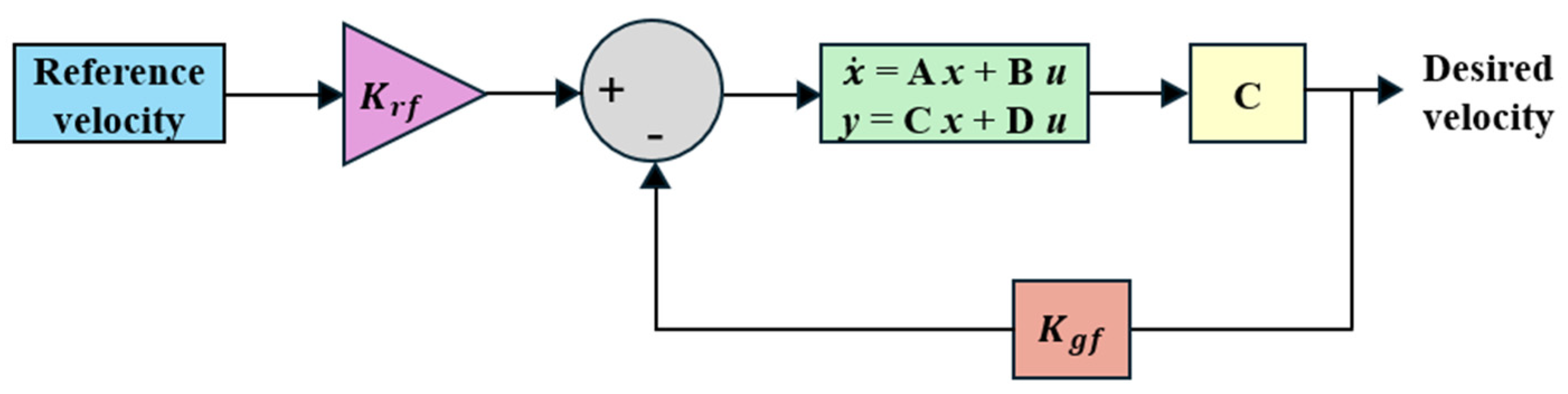

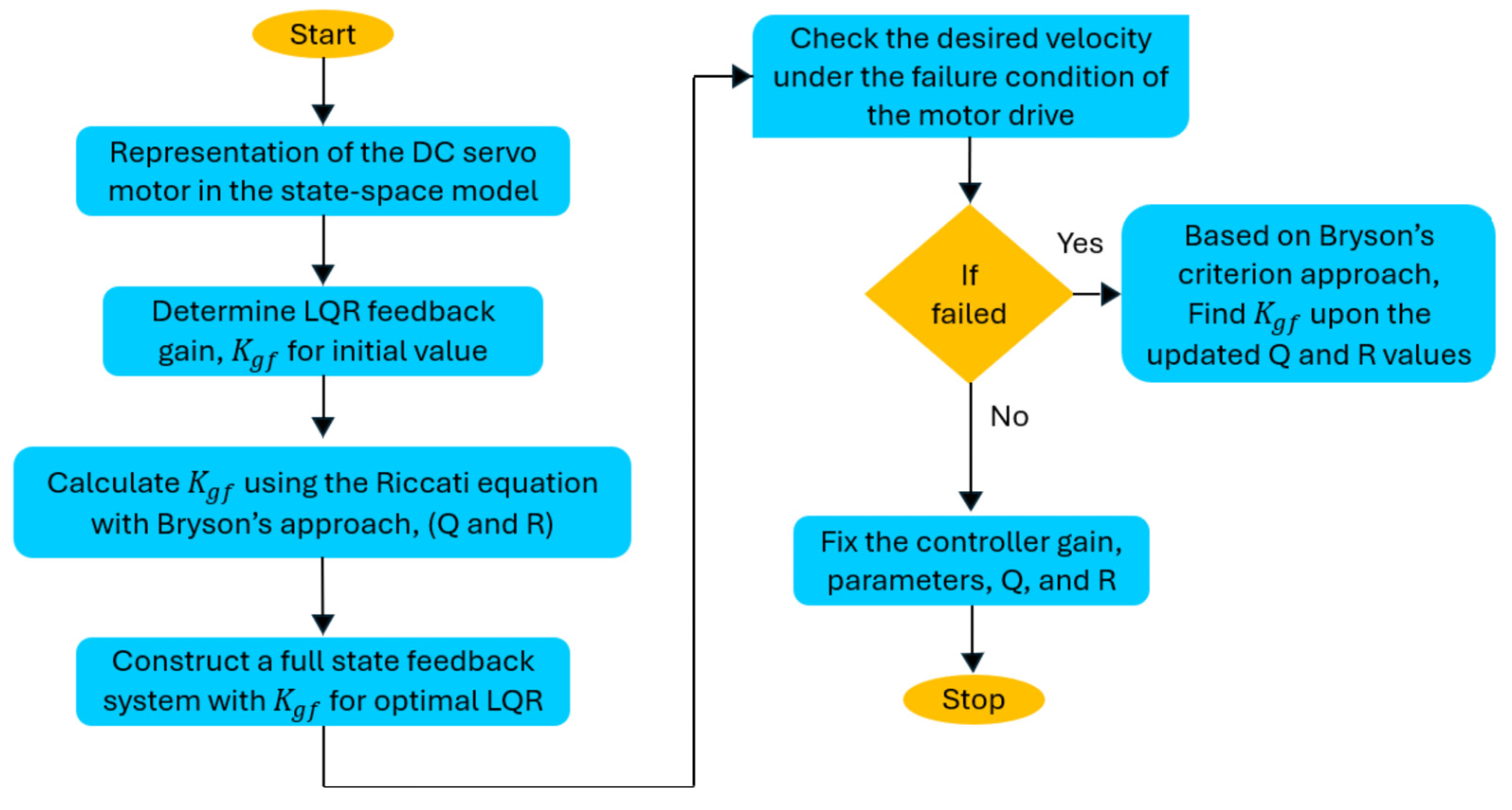

2.3. Proposed Methodology for the Optimal Linear Quadratic Regulator

2.4. Implementation of the Proposed Methodology

2.4.1. Proposed System-Level Architecture Model

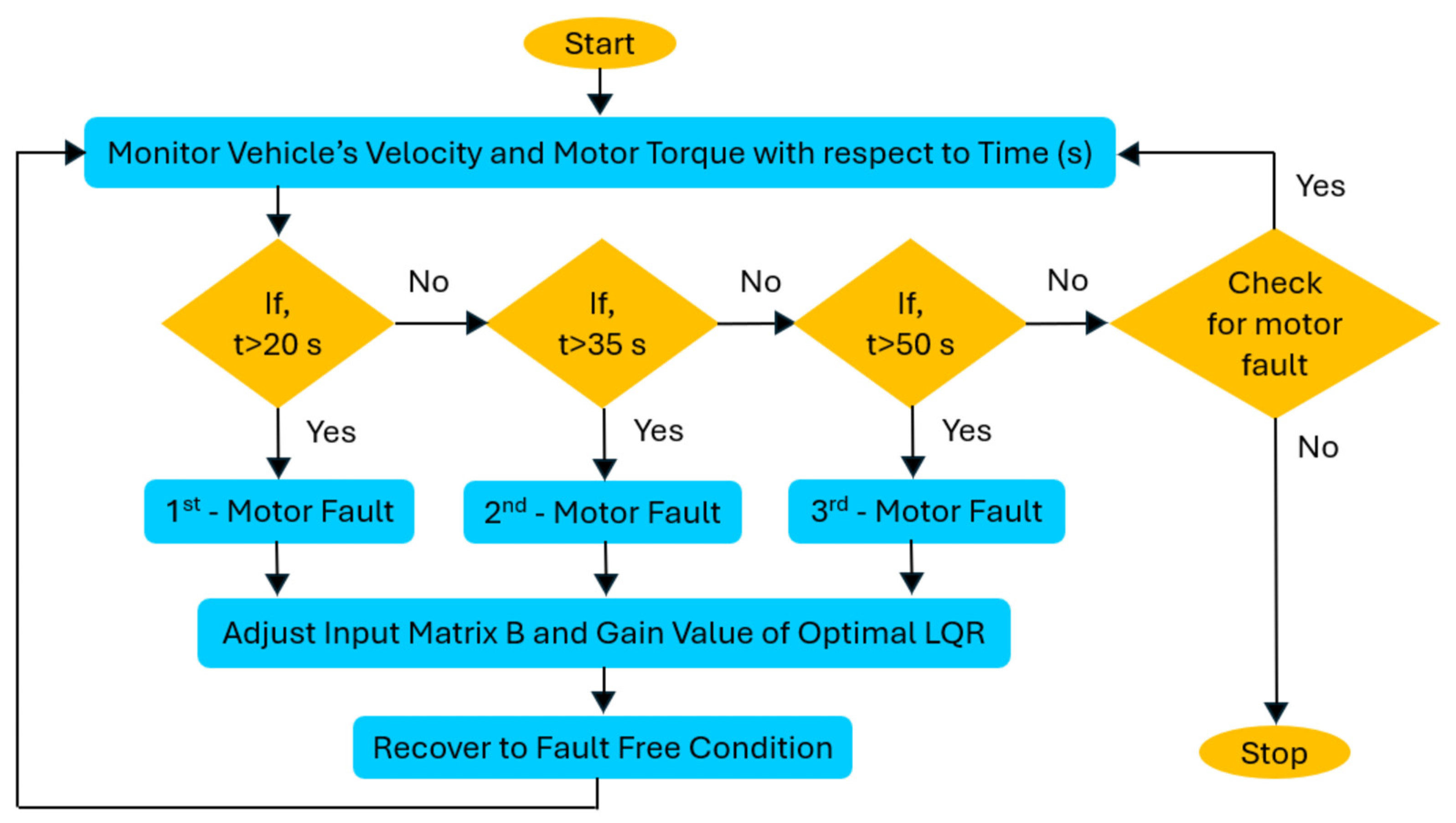

2.4.2. Operation and Flow Diagram of Switching Control Unit

3. Results and Discussion

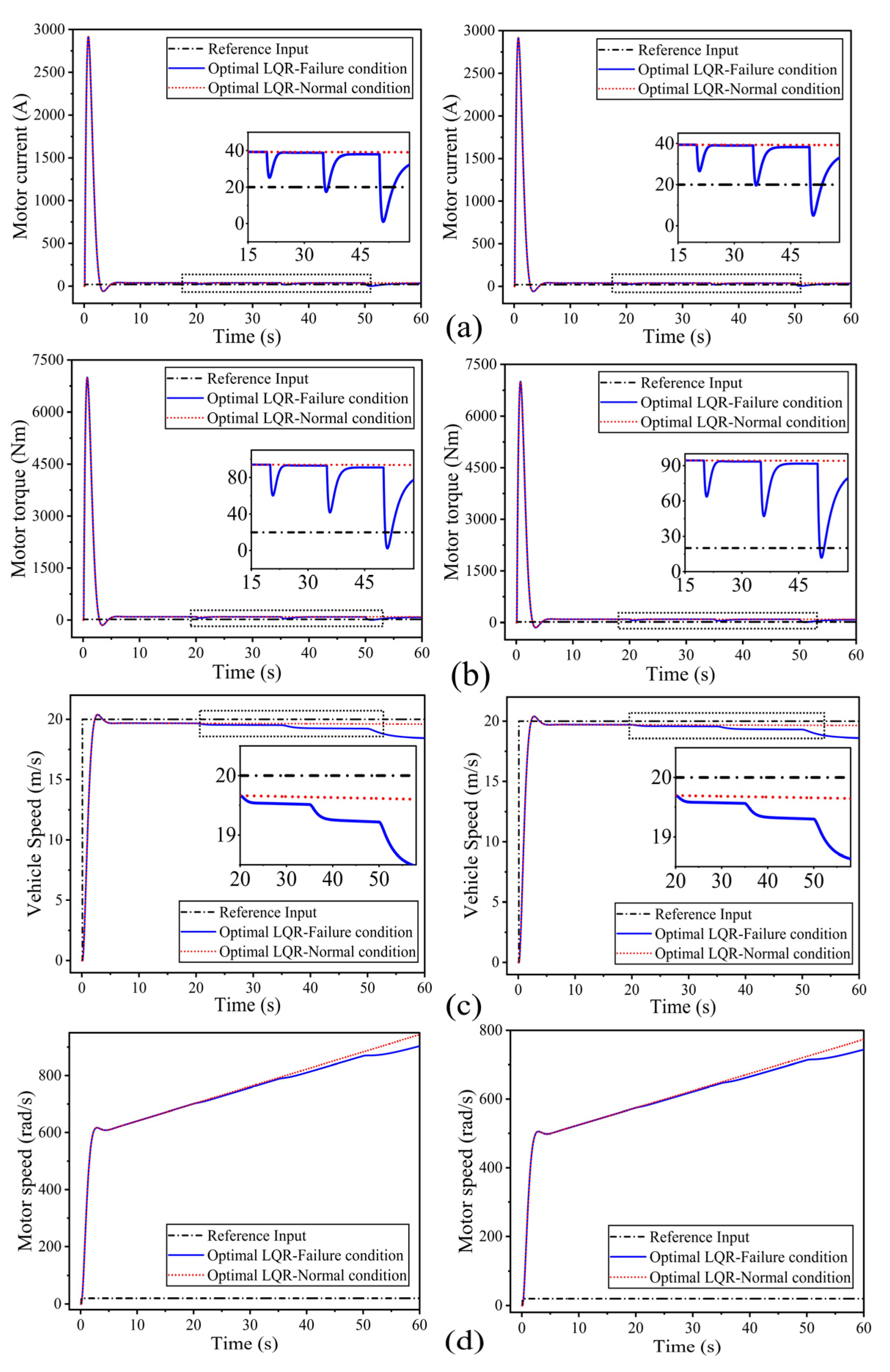

3.1. Performance Analysis of the Model for Varying Reference Input (20 m/s)

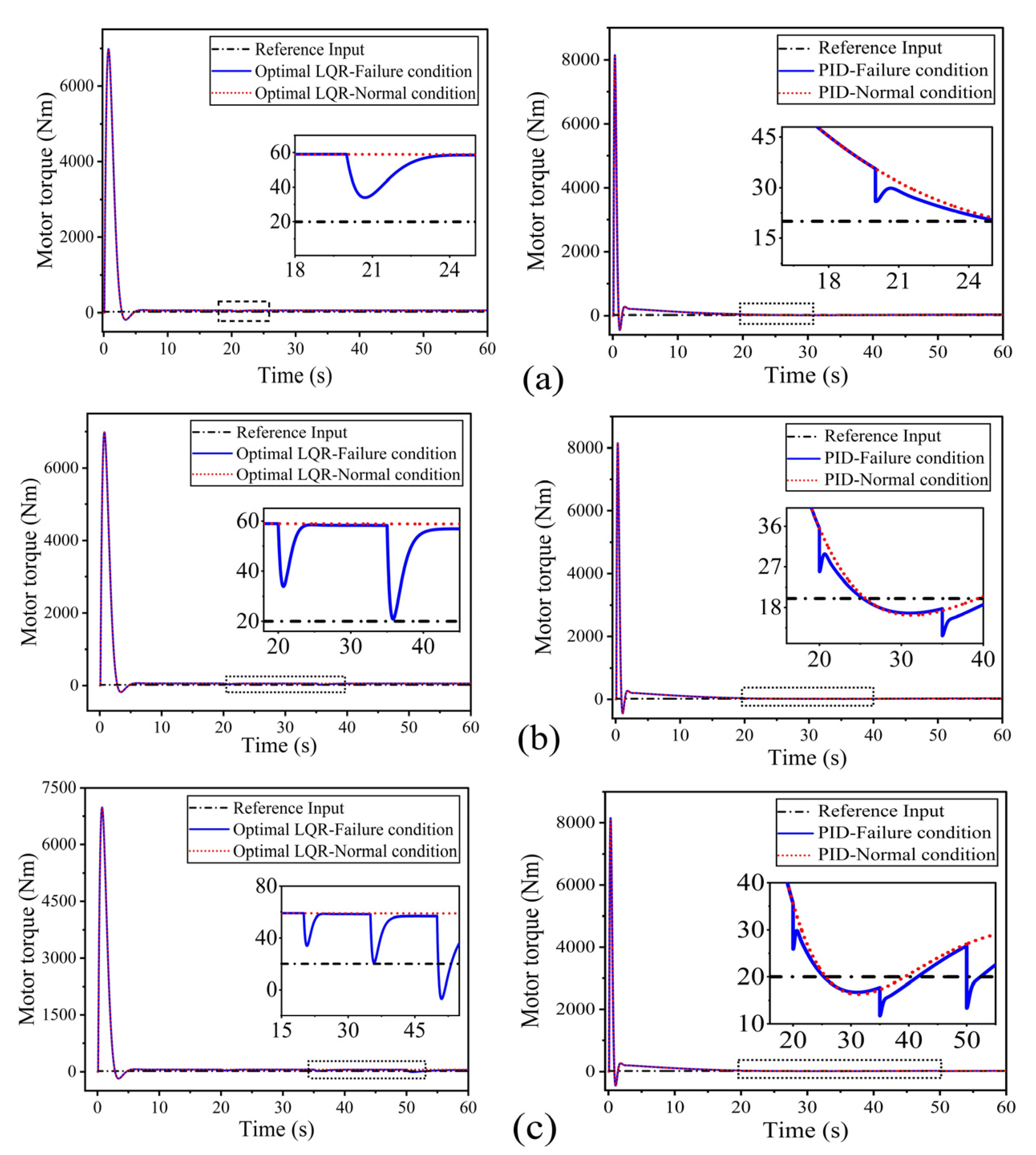

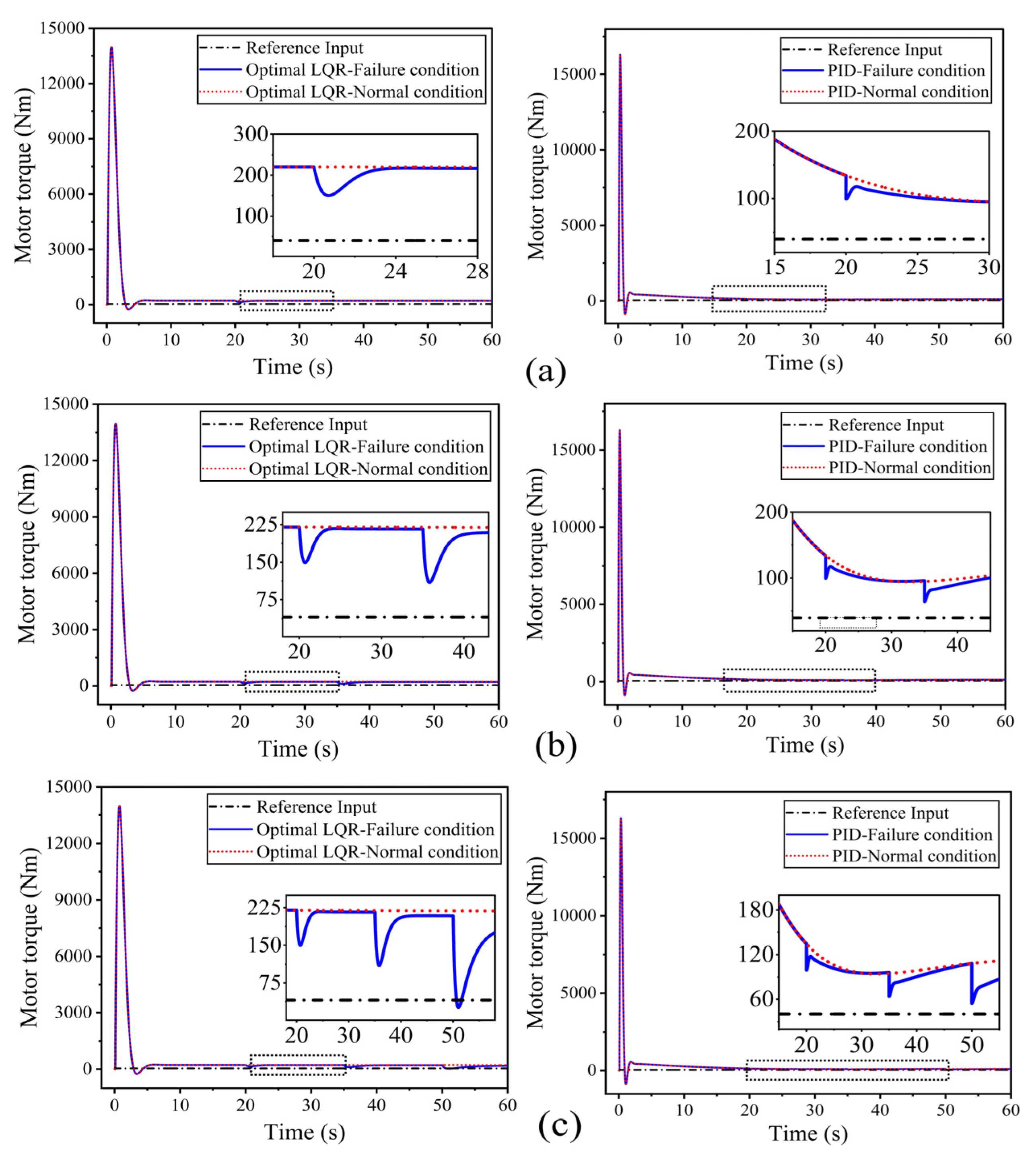

3.1.1. Motor Torque

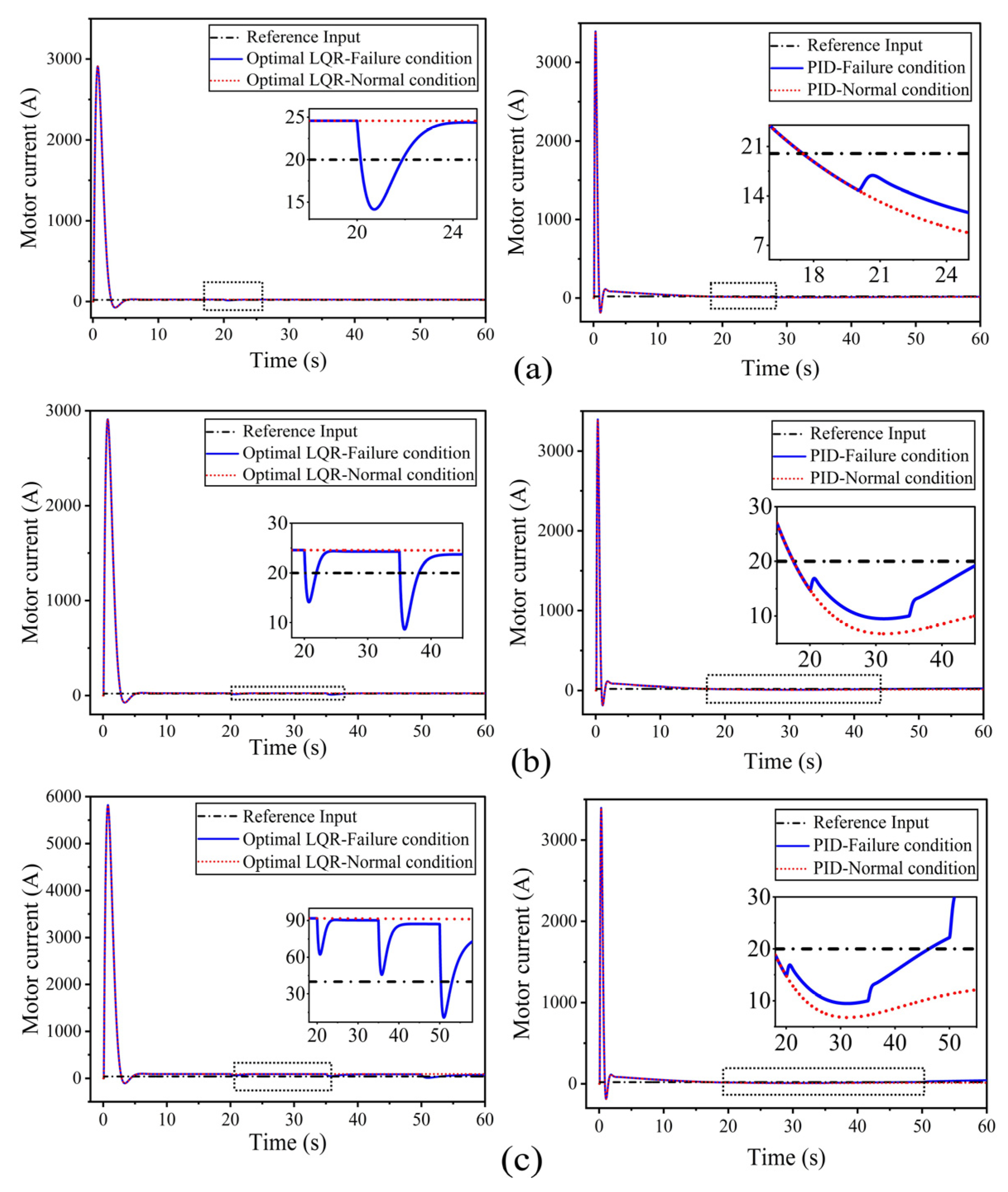

3.1.2. Motor Current

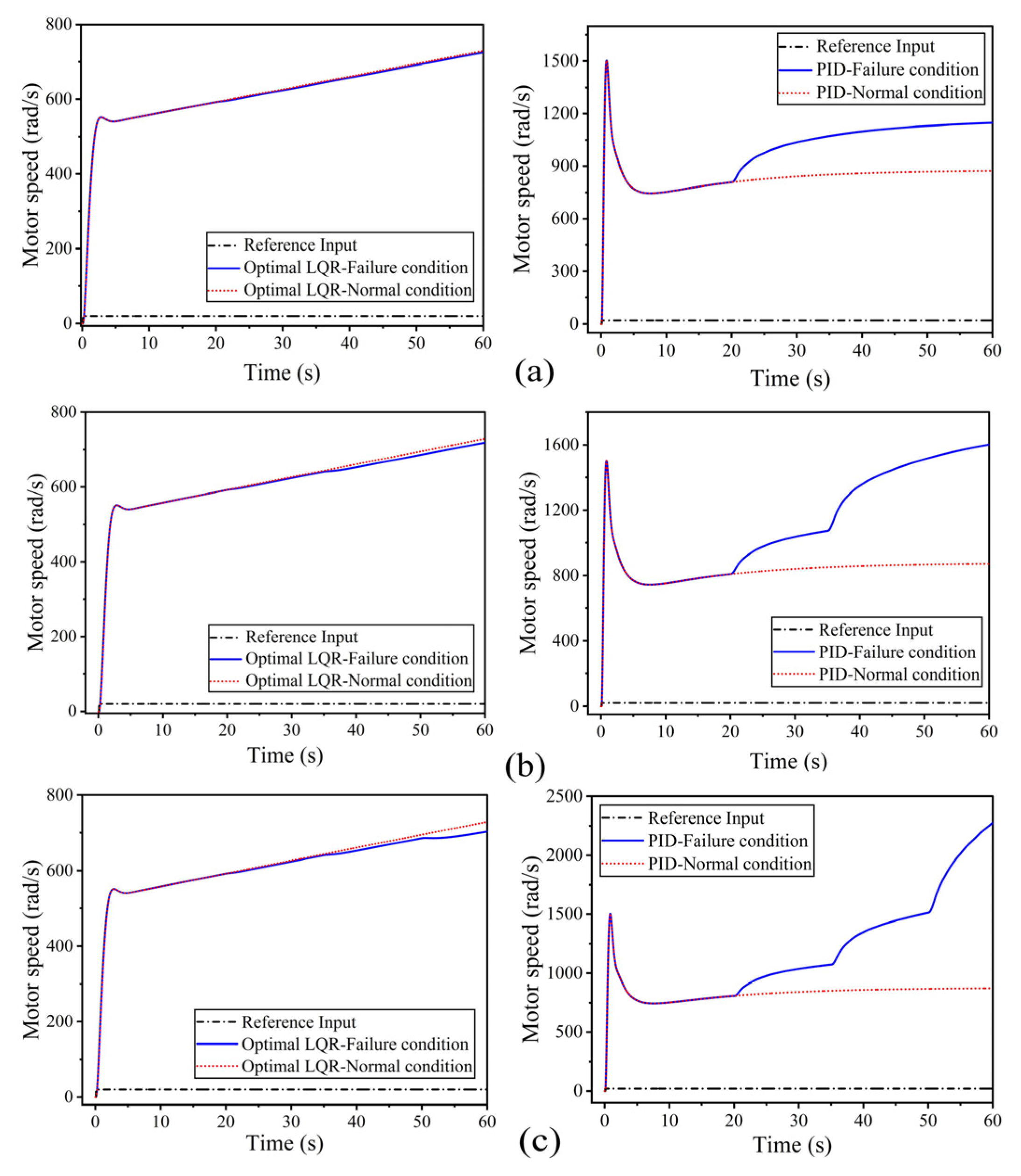

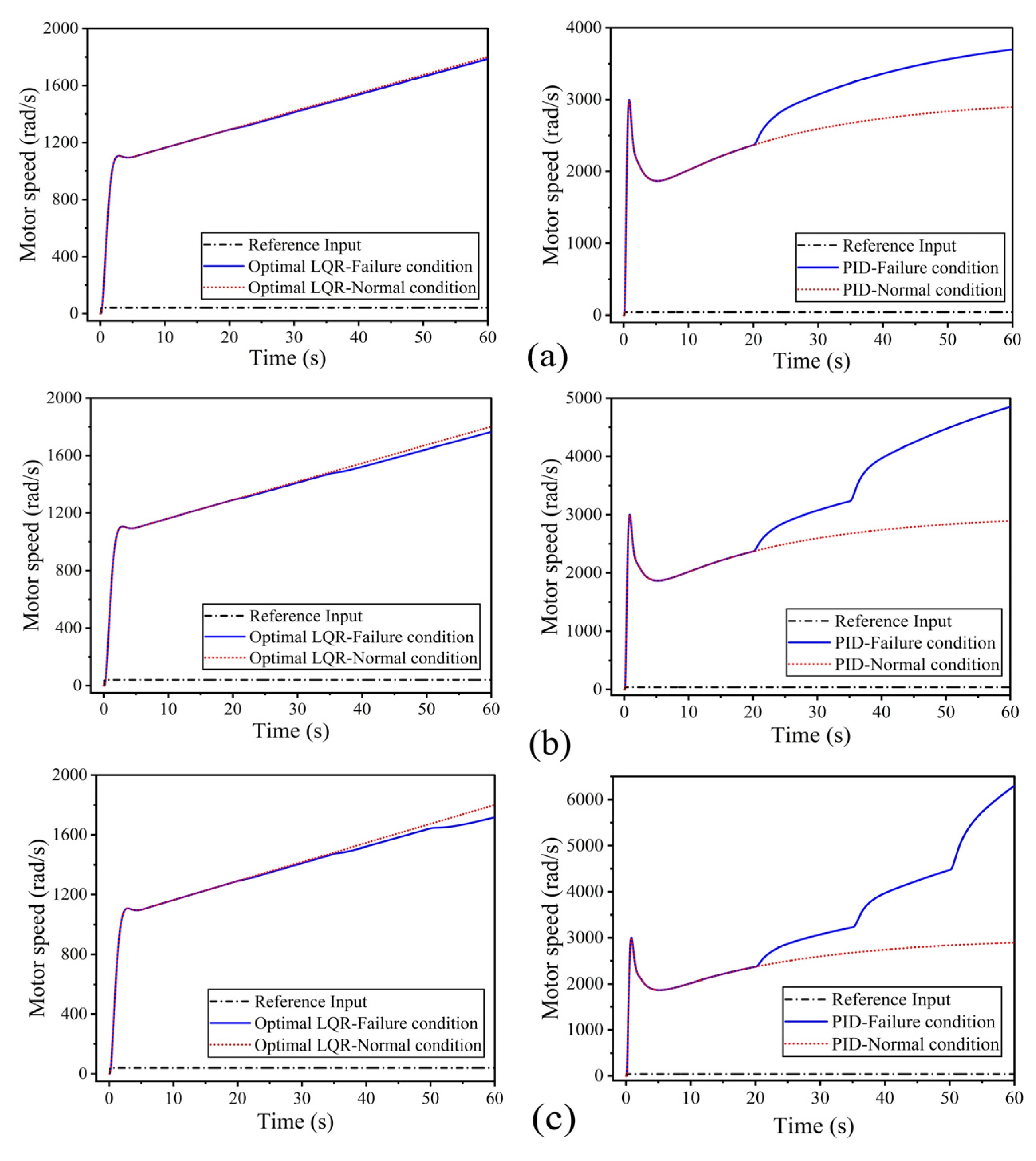

3.1.3. Motor Speed

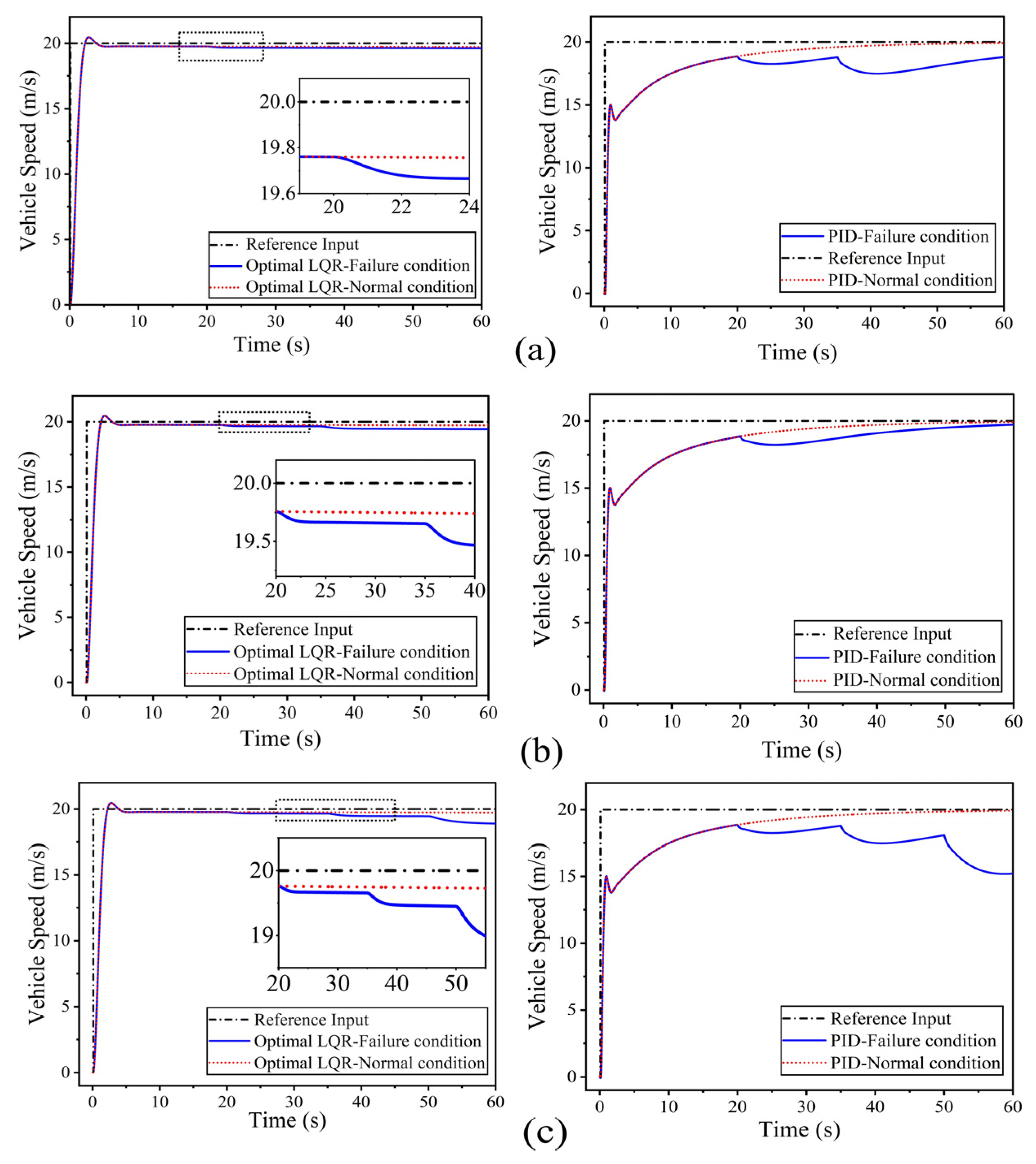

3.1.4. Vehicle Speed

3.2. Performance Analysis of the Model for Varying Reference Input (40 m/s)

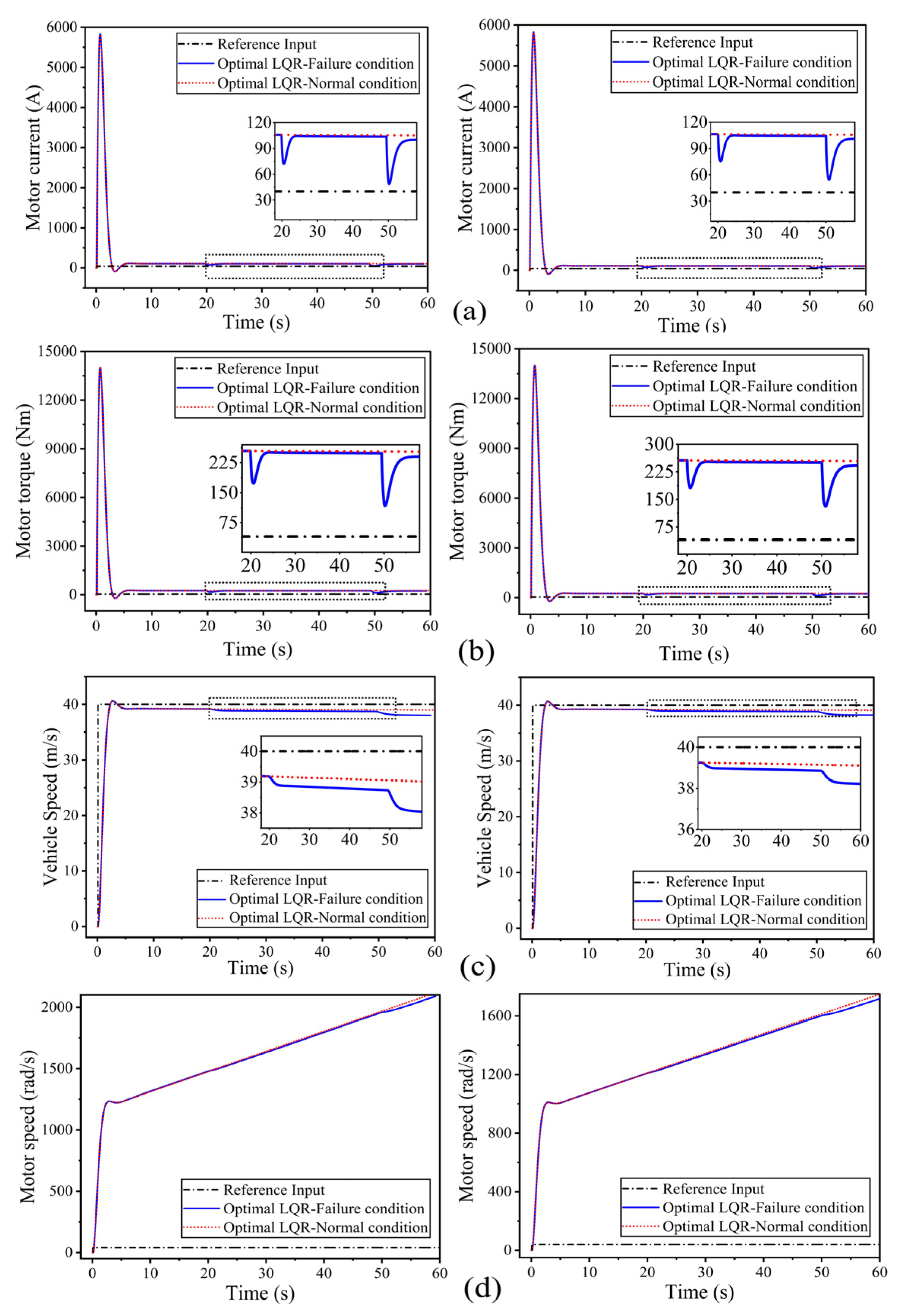

3.2.1. Motor Torque

3.2.2. Motor Current

3.2.3. Motor Speed

3.2.4. Vehicle Speed

3.3. Time Domain Analysis of PID vs. Optimal LQR in 4WID-EV Under 0–3 Motor Fault at Reference Speeds of 20 and 40 m/s

3.4. Sensitivity Analysis of the Model for Various Reference Input (20 and 40 m/s)

3.4.1. Response of a Proposed Optimal LQR Controller for Coupled In-Wheel Motor Fault Conditions at a Reference Speed, 20 m/s, and 40 m/s

3.4.2. Response of a Proposed Optimal LQR Controller for Three In-Wheel Motor Fault Conditions at a Reference Speed, 20 m/s, and 40 m/s

4. Conclusions and Future Work

4.1. Conclusions

- The controller was designed explicitly for 4WID electric vehicles, and the modeling environment was developed and tested under various conditions.

- The proposed optimal LQR controller demonstrated better tracking performance, accurately following the desired speed profile across varying trajectories. A comparative analysis with a conventional PID controller revealed that the optimal LQR consistently outperformed PID in terms of maximum attainable speed, stability, and responsiveness, particularly at elevated speeds.

- During the transient phases for step inputs at 20 m/s and 40 m/s, the system exhibited short-duration peaks in motor torque (up to 6900 Nm and 14,200 Nm) and current (up to 5580 A and 5800 A), respectively. Despite these transient peaks, the system remained stable and quickly settled to nominal operating ranges (approximately 60–100 Nm and 50–90 A).

- The proposed controller predictions are better in terms of settling time, overshoot, mean error, and MSE than the conventional PID controller, indicating enhanced stability and accuracy.

4.2. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 4WID-EV | Four-wheel independent drive electric vehicle |

| PMSM | Permanent magnet synchronous motor |

| BLDC | Brushless direct current |

| LQR | Linear quadratic regulator |

| PID | Proportional integral derivative |

| MRAC | Model reference adaptive control |

| SMC | Sliding mode control |

| PSO | Particle swarm optimization |

| SBW | Steer-by-wire |

| CR-GWO-PID | Chaotic random grey-wolf-optimization-based proportional integral derivative |

| IGBT | Insulated gate bipolar transistor |

| EVs | Electric vehicles |

| ICEVs | Internal combustion engine vehicles |

| PI | Proportional integral |

| MPC | Model predictive control |

| DC | Direct current |

| ARE | Algebraic Riccati equation |

References

- Wahid, M.R.; Budiman, B.A.; Joelianto, E.; Aziz, M. A Review on Drive Train Technologies for Passenger Electric Vehicles. Energies 2021, 14, 6742. [Google Scholar] [CrossRef]

- Hossain, M.d.; Kumar, L.; Islam, M.; Selvaraj, J. A Comprehensive Review on the Integration of Electric Vehicles for Sustainable Development. J. Adv. Transp. 2022, 2022, 3868388. [Google Scholar] [CrossRef]

- Lulhe, A.M.; Date, T.N. A technology review paper for drives used in electrical vehicle (EV) & hybrid electrical vehicles (HEV). In Proceedings of the 2015 International Conference on Control, Instrumentation, Communication and Computational Technologies (ICCICCT), Kumaracoil, India, 18–19 December 2015; pp. 632–636. [Google Scholar] [CrossRef]

- Khurana, A.; Kumar, V.V.; Sidhpuria, M. A Study on the Adoption of Electric Vehicles in India: The Mediating Role of Attitude. Vision J. Bus. Perspect. 2020, 24, 23–34. [Google Scholar] [CrossRef]

- Singh, A.P.; Kumar, Y.; Sawle, Y.; Alotaibi, M.A.; Malik, H.; Márquez, F.P.G. Development of artificial Intelligence-Based adaptive vehicle to grid and grid to vehicle controller for electric vehicle charging station. Ain Shams Eng. J. 2024, 15, 102937. [Google Scholar] [CrossRef]

- Baidya, D.; Dhopte, S.; Bhattacharjee, M. Sensing system assisted novel PID controller for efficient speed control of DC motors in electric vehicles. IEEE Sens. Lett. 2023, 7, 1–4. [Google Scholar] [CrossRef]

- Ahmed, I.; Adnan, M.; Ali, M.; Kaddoum, G. Supertwisting sliding mode controller for grid-to-vehicle and vehicle-to-grid battery electric vehicle charger. J. Energy Storage 2023, 70, 107914. [Google Scholar] [CrossRef]

- Vignesh, R.; Ashok, B.; Kumar, M.S.; Szpica, D.; Harikrishnan, A.; Josh, H. Adaptive neuro fuzzy inference system-based energy management controller for optimal battery charge sustaining in biofuel powered non-plugin hybrid electric vehicle. Sustain. Energy Technol. Assess. 2023, 59, 103379. [Google Scholar] [CrossRef]

- Mathesh, G.; Saravanakumar, R. A novel intelligent controller-based power management system with instantaneous reference current in hybrid energy-fed electric vehicle. IEEE Access 2023, 11, 137849–137865. [Google Scholar] [CrossRef]

- Charest-Finn, M.; Pejhan, S. Model Predictive Control Used in Passenger Vehicles: An Overview. Machines 2024, 12, 773. [Google Scholar] [CrossRef]

- Wang, W.; Yuan, S.; Yang, C.; Zhang, Y. A robust MPC-based vehicle stability control strategy for four-wheel independent drive electric vehicles considering IGBT thermal effect. Nonlinear Dyn. 2025, 113, 6893–6906. [Google Scholar] [CrossRef]

- Peng, H.; Wang, W.; Xiang, C.; Li, L.; Wang, X. Torque coordinated control of four in-wheel motor independent-drive vehicles with consideration of the safety and economy. IEEE Trans. Veh. Technol. 2019, 68, 9604–9618. [Google Scholar] [CrossRef]

- Xu, X.; Wang, M.; Xiao, P.; Ding, J.; Zhang, X. In-wheel motor control system for four-wheel drive electric vehicle based on CR-GWO-PID control. Sensors 2023, 23, 8311. [Google Scholar] [CrossRef]

- Guo, M.; Bao, C.; Cao, Q.; Xu, F.; Miao, X.; Wu, J. Fault-Tolerant Control Study of Four-Wheel Independent Drive Electric Vehicles Based on Drive Actuator Faults. Machines 2024, 12, 450. [Google Scholar] [CrossRef]

- Lu, Y.; Liang, J.; Zhuang, W.; Yin, G.; Feng, J.; Zhou, C. Four-wheel independent Drive Vehicle Fault Tolerant Strategy Using Stochastic Model Predictive Control with Model Parameter Uncertainties. IEEE Trans. Veh. Technol. 2023, 73, 3287–3299. [Google Scholar] [CrossRef]

- Shen, Y.; Zhao, Y.; Deng, H.; Lin, F.; Shen, H. Coordinated control of stability and economy of distributed drive electric vehicle based on Lyapunov adaptive theory. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2024, 238, 1535–1549. [Google Scholar] [CrossRef]

- Han, Q.; Liu, C.; Zhao, J.; Liu, H. The Fault-Tolerant Control Strategy for the Steering System Failure of Four-Wheel Independent By-Wire Steering Electric Vehicles. World Electr. Veh. J. 2025, 16, 183. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, G.; Chen, M. A Fault-Tolerant Control Strategy for Distributed Drive Electric Vehicles Based on Model Reference Adaptive Control. Actuators 2024, 13, 486. [Google Scholar] [CrossRef]

- Liang, Y.; Dong, H.; Li, D.; Song, Z. Adaptive eco-cruising control for connected electric vehicles considering a dynamic preceding vehicle. eTransportation 2024, 19, 100299. [Google Scholar] [CrossRef]

- Deepak, K.; Mandal, R.K.; Verma, V. Novel Aggregated Controller of Wind and PV based Grid Connected Charging Station for Electric Vehicle. Int. J. Power Electron. Drive Syst. (IJPEDS) 2023, 14, 2319–2327. [Google Scholar] [CrossRef]

- Kannan, R.; Sundharajan, V. A novel MPPT controller based PEMFC system for electric vehicle applications with interleaved SEPIC converter. Int. J. Hydrogen Energy 2023, 48, 14391–14405. [Google Scholar] [CrossRef]

- Peng, H.; Wang, W.; An, Q.; Xiang, C.; Li, L. Path tracking and direct yaw moment coordinated control based on robust MPC with the finite time horizon for autonomous independent-drive vehicles. IEEE Trans. Veh. Technol. 2020, 69, 6053–6066. [Google Scholar] [CrossRef]

- Li, Z.; Jiao, X.; Zhang, T. Robust H∞ Output Feedback Trajectory Tracking Control for Steer-by-Wire Four-Wheel Independent Actuated Electric Vehicles. World Electr. Veh. J. 2023, 14, 147. [Google Scholar] [CrossRef]

- Lu, S.; Wu, Q.; Zhang, J.; Liu, B.; Chu, Z.; Yang, W. Fault-tolerant control of electric vehicle based on integral fast terminal sliding mode. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2025, 09544070241310952. [Google Scholar] [CrossRef]

- Chen, X.; Qu, Y.; Cui, T.; Zhao, J. Nonlinear hierarchical control for four-wheel-independent-drive electric vehicle. Complex Eng. Syst. 2023, 3, 8. [Google Scholar] [CrossRef]

- Djouadi, H.; Ouari, K.; Belkhier, Y.; Lehouche, H. Real-Time HIL Simulation of Nonlinear Generalized Model Predictive-Based High-Order SMC for Permanent Magnet Synchronous Machine Drive. Int. Trans. Electr. Energy Syst. 2024, 2024, 5536555. [Google Scholar] [CrossRef]

- Naqvi, S.S.A.; Jamil, H.; Iqbal, N.; Khan, S.; Lee, D.I.; Park, Y.C.; Kim, D.H. Multi-objective optimization of PI controller for BLDC motor speed control and energy saving in Electric Vehicles: A constrained swarm-based approach. Energy Rep. 2024, 12, 402–417. [Google Scholar] [CrossRef]

- Kumar, M.; Panda, K.P.; Naayagi, R.T.; Thakur, R.; Panda, G. Comprehensive review of electric vehicle technology and its impacts: Detailed investigation of charging infrastructure, power management, and control techniques. Appl. Sci. 2023, 13, 8919. [Google Scholar] [CrossRef]

- Jassim, A.A.; Karamb, E.H.; Alic, M.M.E. Design of optimal PID controller for electric vehicle based on particle swarm and multi-verse optimization ALGORITHMS. Eng. Technol. J. 2023, 41, 446–455. [Google Scholar] [CrossRef]

- Jia, C.C.; Liu, W.; He, H.W.; Chau, K.T. Superior energy management for fuel cell vehicles guided by improved DDPG algorithm: Integrating driving intention speed prediction and health-aware control. Appl. Energy 2025, 394, 126195. [Google Scholar] [CrossRef]

- Reddy, G.S.; Premkumar, M.; Ravi, S.; Abualigah, L. An intelligent converter and controller for electric vehicle drives utilizing grid and stand-alone solar photovoltaic power generation systems. Int. J. Appl. Power Eng. (IJAPE) 2023, 12, 255–276. [Google Scholar] [CrossRef]

- Li, Y.; Cai, Y.; Sun, X.; Wang, H.; Jia, Y.; He, Y.; Chen, L.; Chao, Y. Trajectory tracking of four-wheel driving and steering autonomous vehicle under extreme obstacle avoidance condition. Veh. Syst. Dyn. 2024, 62, 601–622. [Google Scholar] [CrossRef]

- Serralvo Neto, R.; Palermo, J.B.; Giacomini, R.; Rodrigues, M.; Delatore, F.; Rossi, G.B.; Bühler, R.T. Performance Prediction of a 4WD High-Performance Electric Vehicle Using a Model-Based Torque-Vectoring Approach. World Electr. Veh. J. 2023, 14, 183. [Google Scholar] [CrossRef]

- Talbot, J.; Brown, M.; Gerdes, J.C. Shared Control Up to the Limits of Vehicle Handling. IEEE Trans. Intell. Veh. 2024, 9, 2977–2987. [Google Scholar] [CrossRef]

- Lee, K.; Lee, M. Fault-tolerant stability control for an independent four-wheel drive electric vehicle under actuator fault conditions. IEEE Access 2020, 8, 91368–91378. [Google Scholar] [CrossRef]

- Chen, Q.P.; Xu, W.H.; Lv, Z.Y.; Zeng, D.Q.; Zhong, C.P.; Zeng, X.C. Anti-slip regulation method for electric vehicles with four in-wheel motors based on the identification of slip ratio. Trans. Can. Soc. Mech. Eng. 2024, 48, 15–25. [Google Scholar] [CrossRef]

| Motor Parameters | Values | Vehicle Parameters | Values |

|---|---|---|---|

| Resistance, R1 | 0.004 Ω | Mass of the vehicle, M1 | 1530 Kg |

| Inductance, L1 | 0.0016 H | Grade angle, α | 0° |

| Moment of inertia, J1 | 4.31 Kg/m2 | Rolling resistance, Cr | 0.01 |

| Moment of inertia, J2 | 8.63 Kg/m2 | Air density, ρ | 1.225 Kg/m3 |

| Moment of inertia, J3 | 12.93 Kg/m2 | Vehicle speed, Vv | (20–40) m/s |

| Back emf, Kb1 | 0.1 | wind speed, Vw | (20–40) m/s |

| Torque constant, Kt1 | 0.042 | Air drag coefficient, CD | 0.29 m3 |

| Friction coefficient, b1 | 1 | Gravitational acceleration, g | 9.81 m/s2 |

| Maximum torque @ 20 m/s | 55 Nm | 2.1 m2 | |

| Maximum torque @ 40 m/s | 194 Nm | ||

| Maximum speed @ 20 m/s | 770 m/s | ||

| Maximum speed @ 40 m/s | 1750 m/s |

| Controller | Gain | Settling Time (s) | Overshoot (%) | Mean Error (rad/s) | MSE (rad/s2) |

|---|---|---|---|---|---|

| PID | Kp = 60, Ki = 100 | 0.13 | 0.33 | 0.0674 | 0.1050 |

| Proposed (Optimal LQR) | K1 = 60, K2 = 100 | 0.13 | 0.27 | 0.0441 | 0.0820 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durairaj, S.; Mohamed Ismail, M.R. Design of an Optimal Enhanced Quadratic Controller for a Four-Wheel Independent Driven Electric Vehicle (4WID-EV) Under Failure Cases. World Electr. Veh. J. 2025, 16, 470. https://doi.org/10.3390/wevj16080470

Durairaj S, Mohamed Ismail MR. Design of an Optimal Enhanced Quadratic Controller for a Four-Wheel Independent Driven Electric Vehicle (4WID-EV) Under Failure Cases. World Electric Vehicle Journal. 2025; 16(8):470. https://doi.org/10.3390/wevj16080470

Chicago/Turabian StyleDurairaj, Sasikala, and Mohamed Rabik Mohamed Ismail. 2025. "Design of an Optimal Enhanced Quadratic Controller for a Four-Wheel Independent Driven Electric Vehicle (4WID-EV) Under Failure Cases" World Electric Vehicle Journal 16, no. 8: 470. https://doi.org/10.3390/wevj16080470

APA StyleDurairaj, S., & Mohamed Ismail, M. R. (2025). Design of an Optimal Enhanced Quadratic Controller for a Four-Wheel Independent Driven Electric Vehicle (4WID-EV) Under Failure Cases. World Electric Vehicle Journal, 16(8), 470. https://doi.org/10.3390/wevj16080470