Design and Experimental Research on a New Integrated EBS with High Response Speed

Abstract

1. Introduction

2. New EBS Structure and Function Design

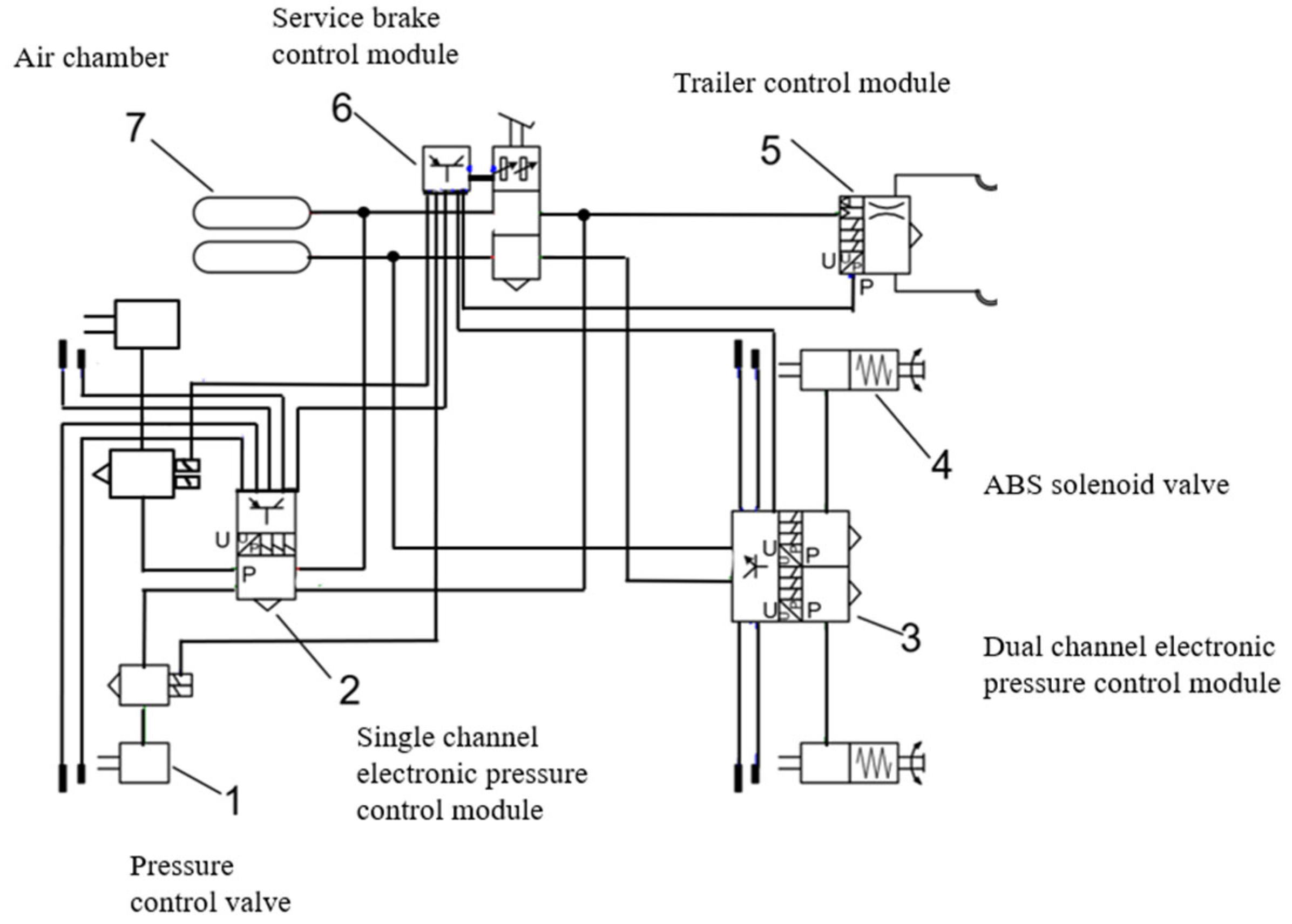

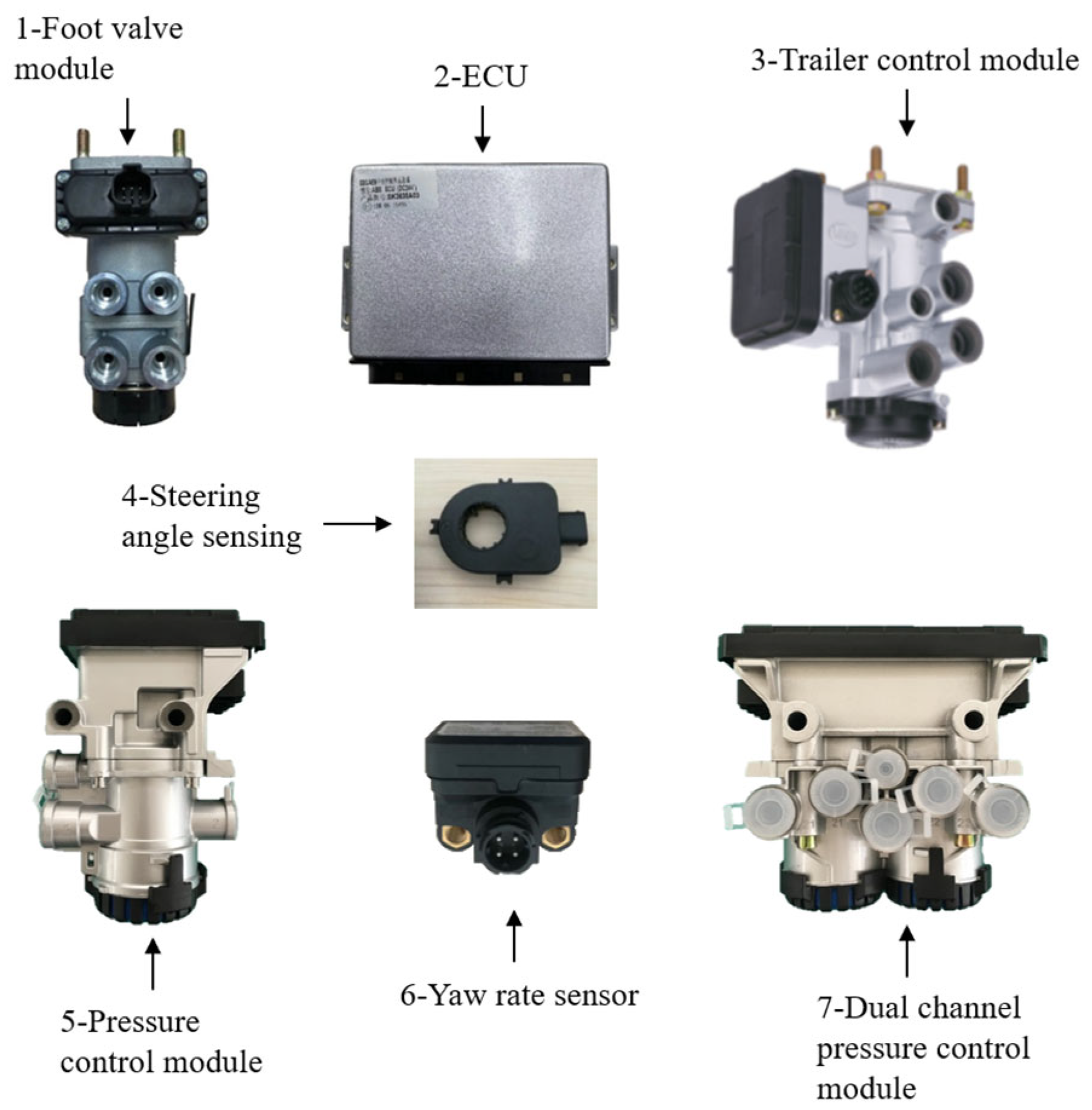

2.1. EBS Structure

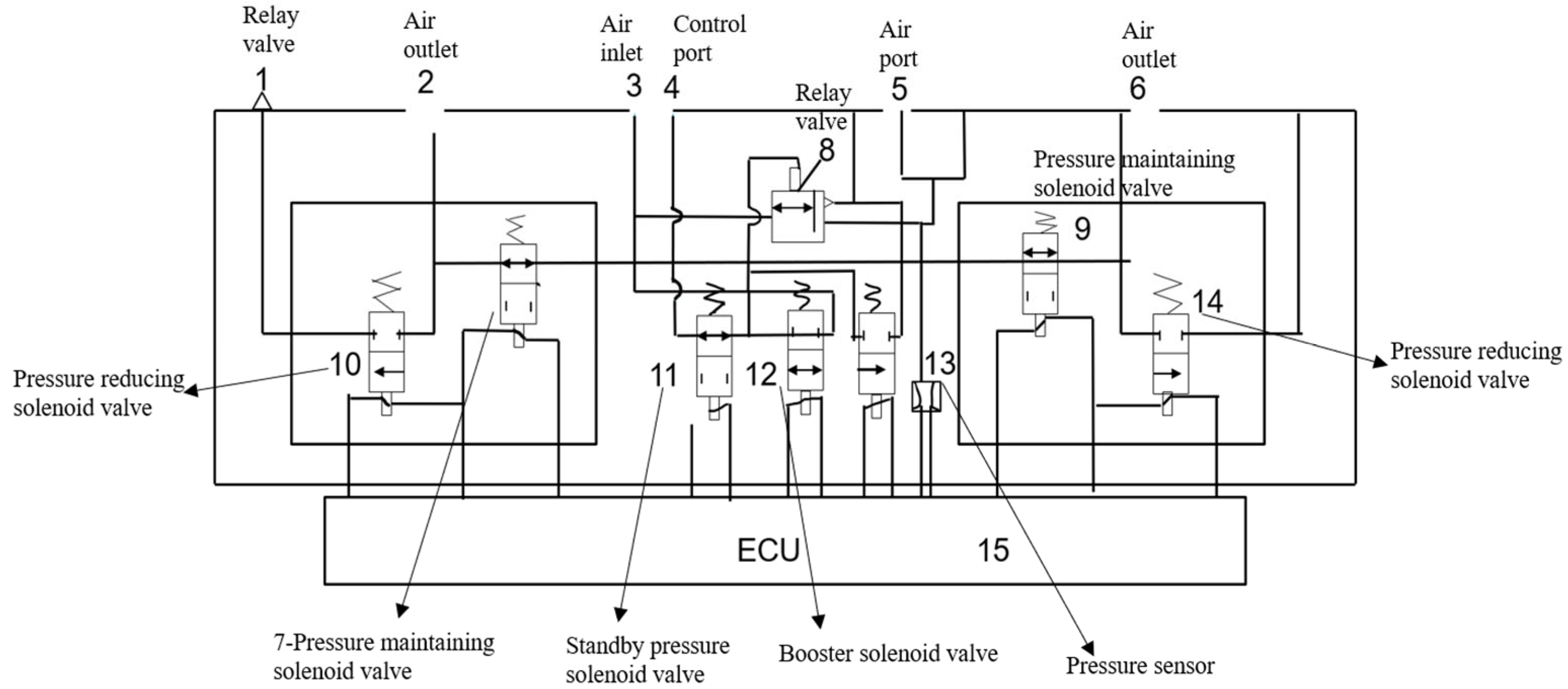

2.2. EBS Rear Axle Control Module Assembly

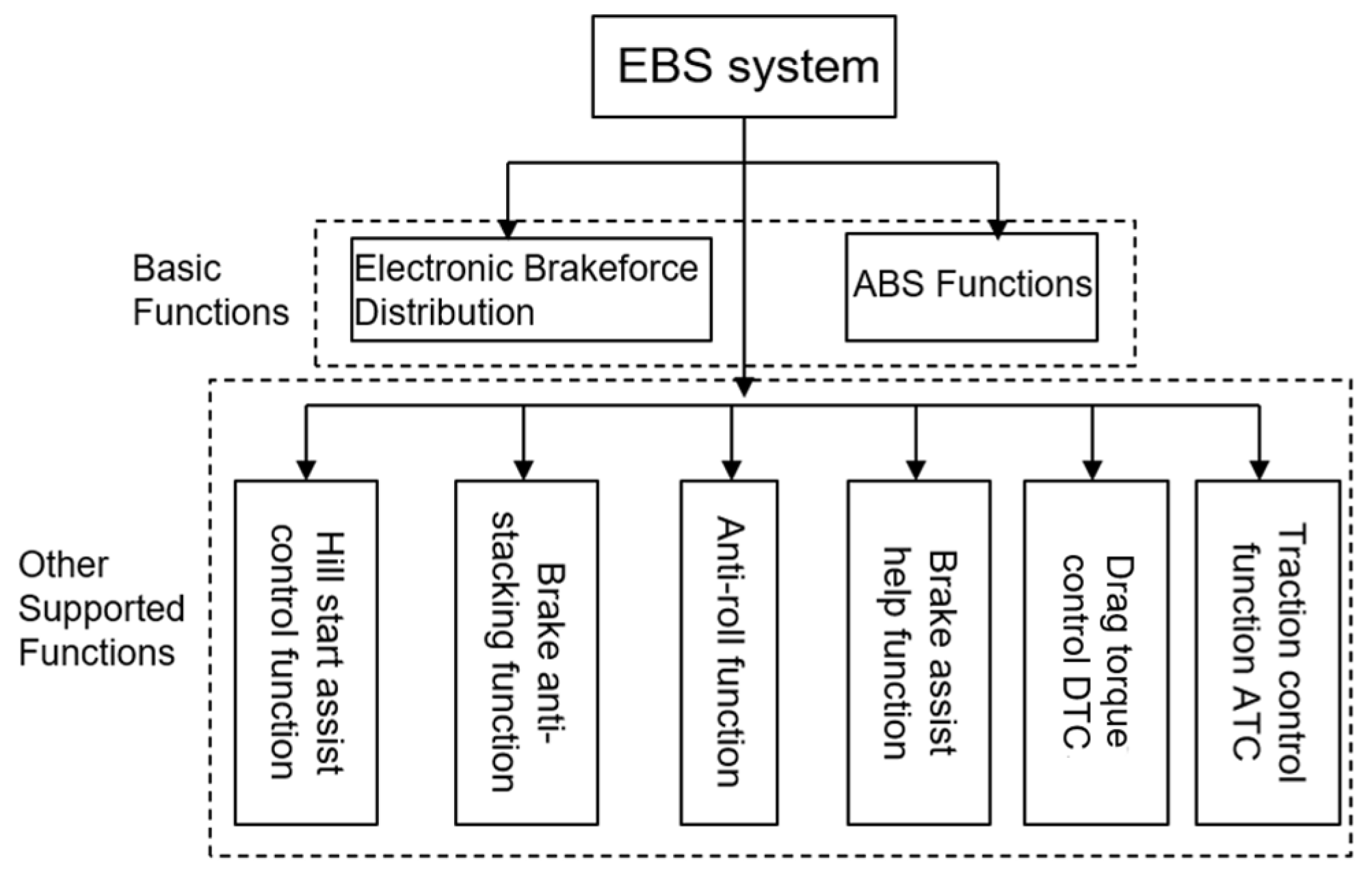

2.3. Main Function

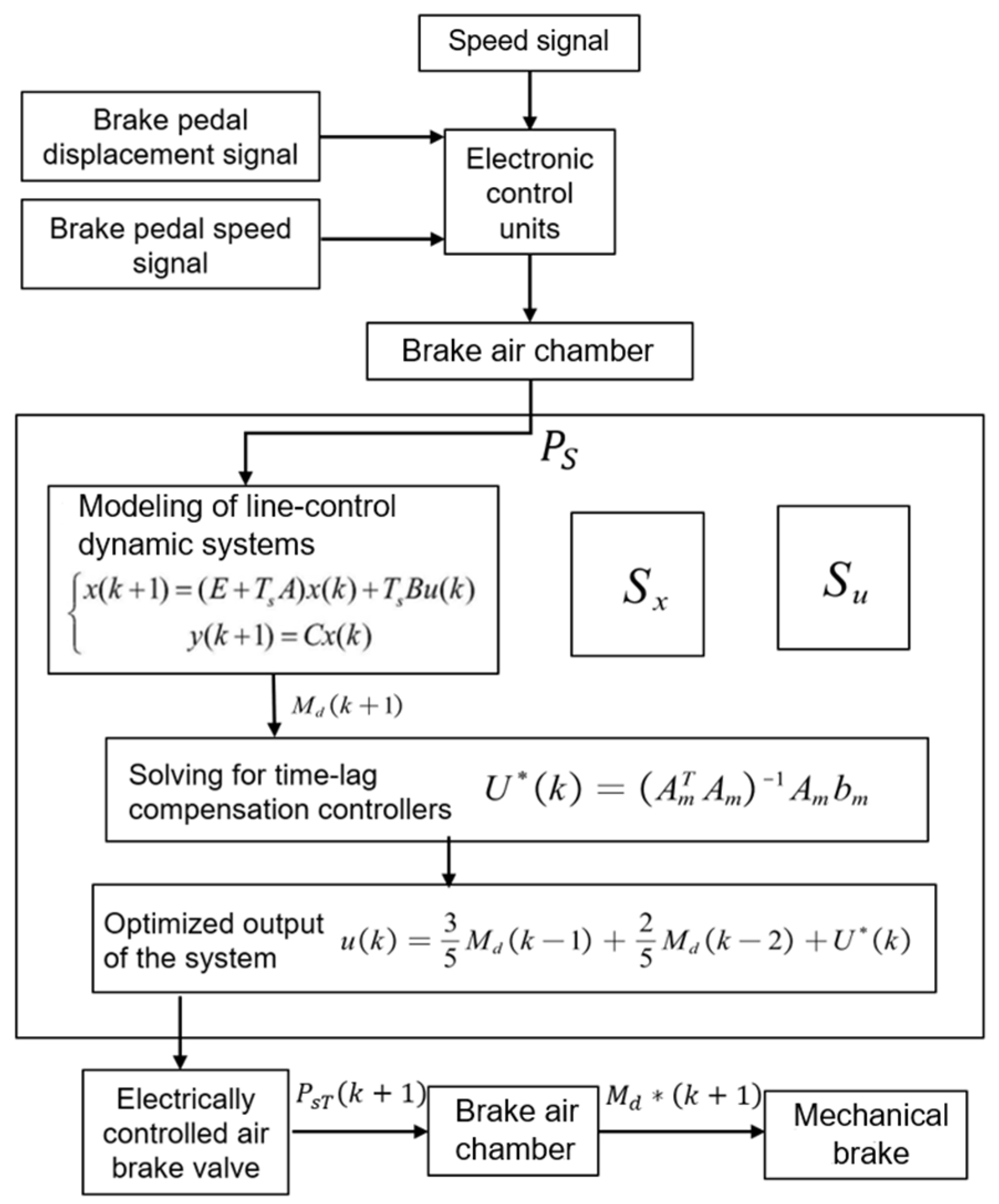

3. Control Strategy and Modeling of EBS

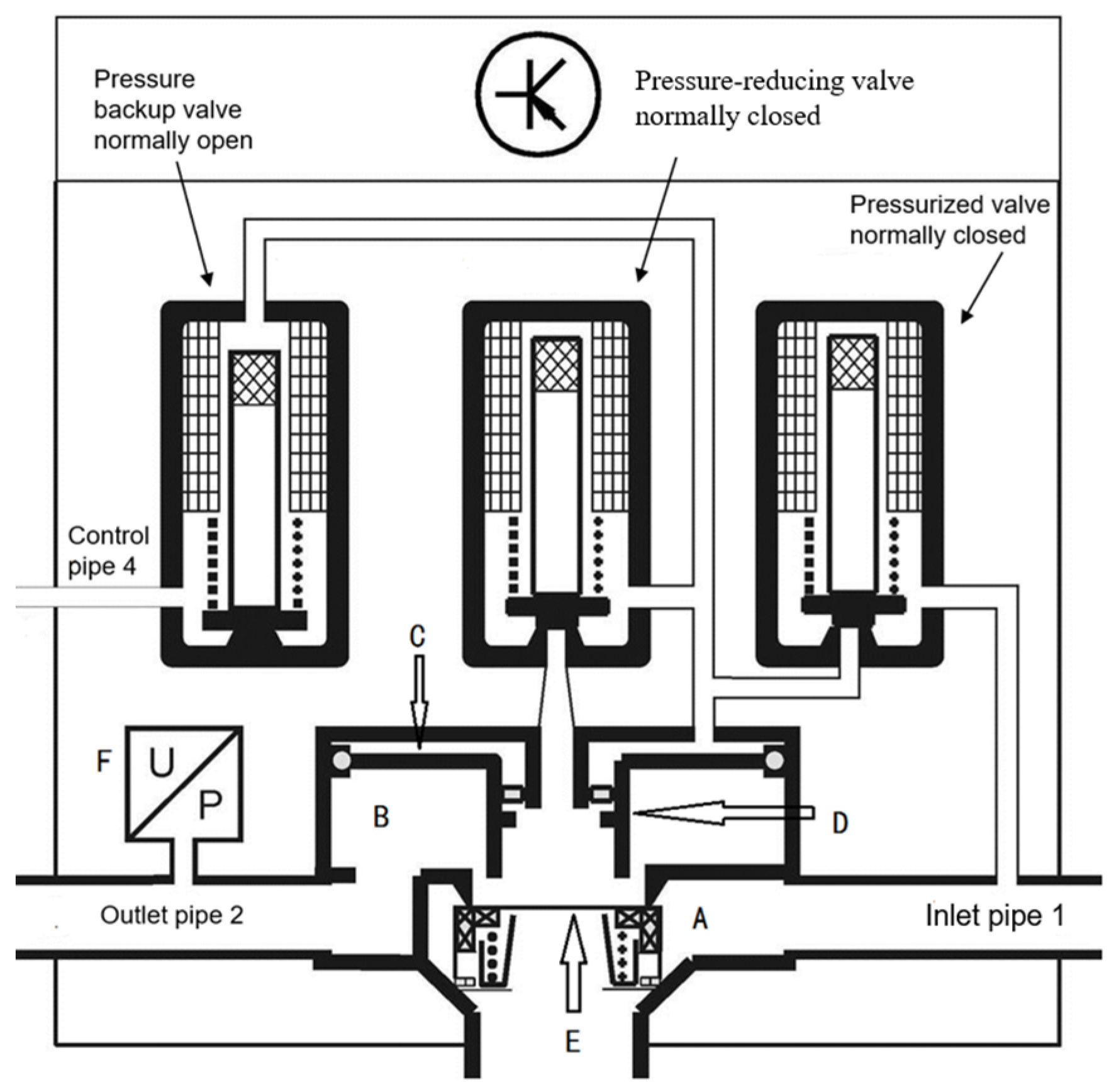

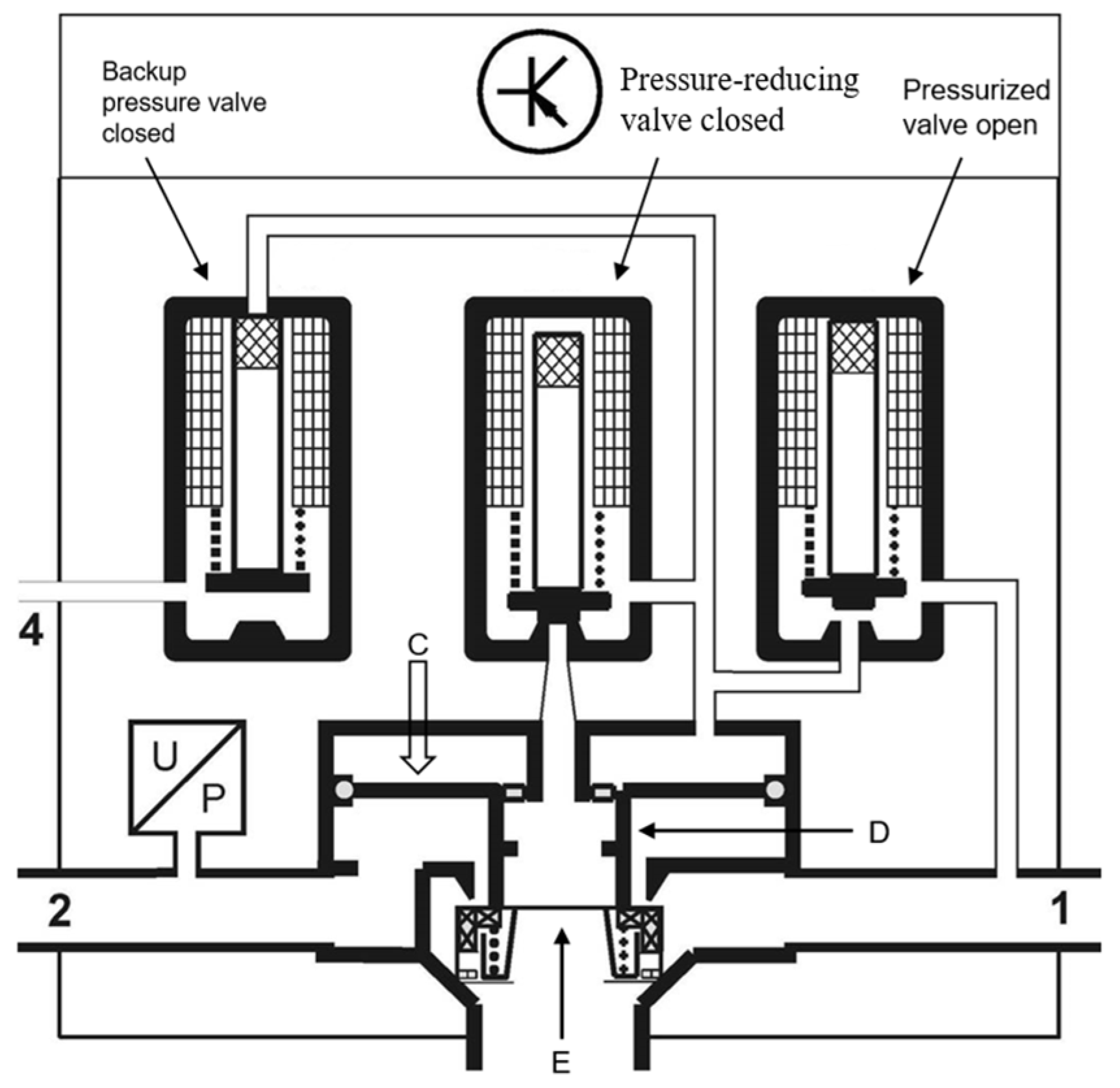

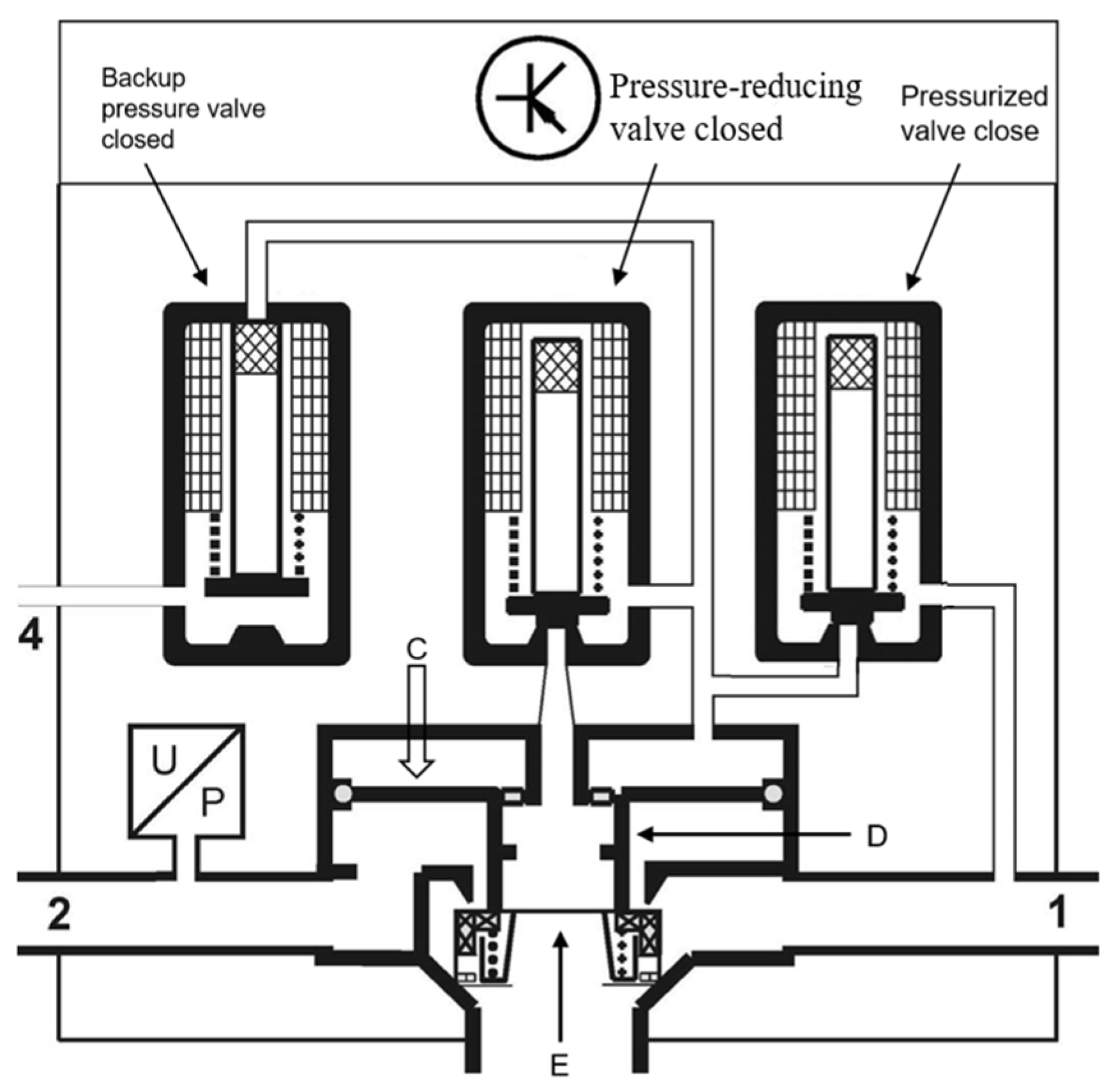

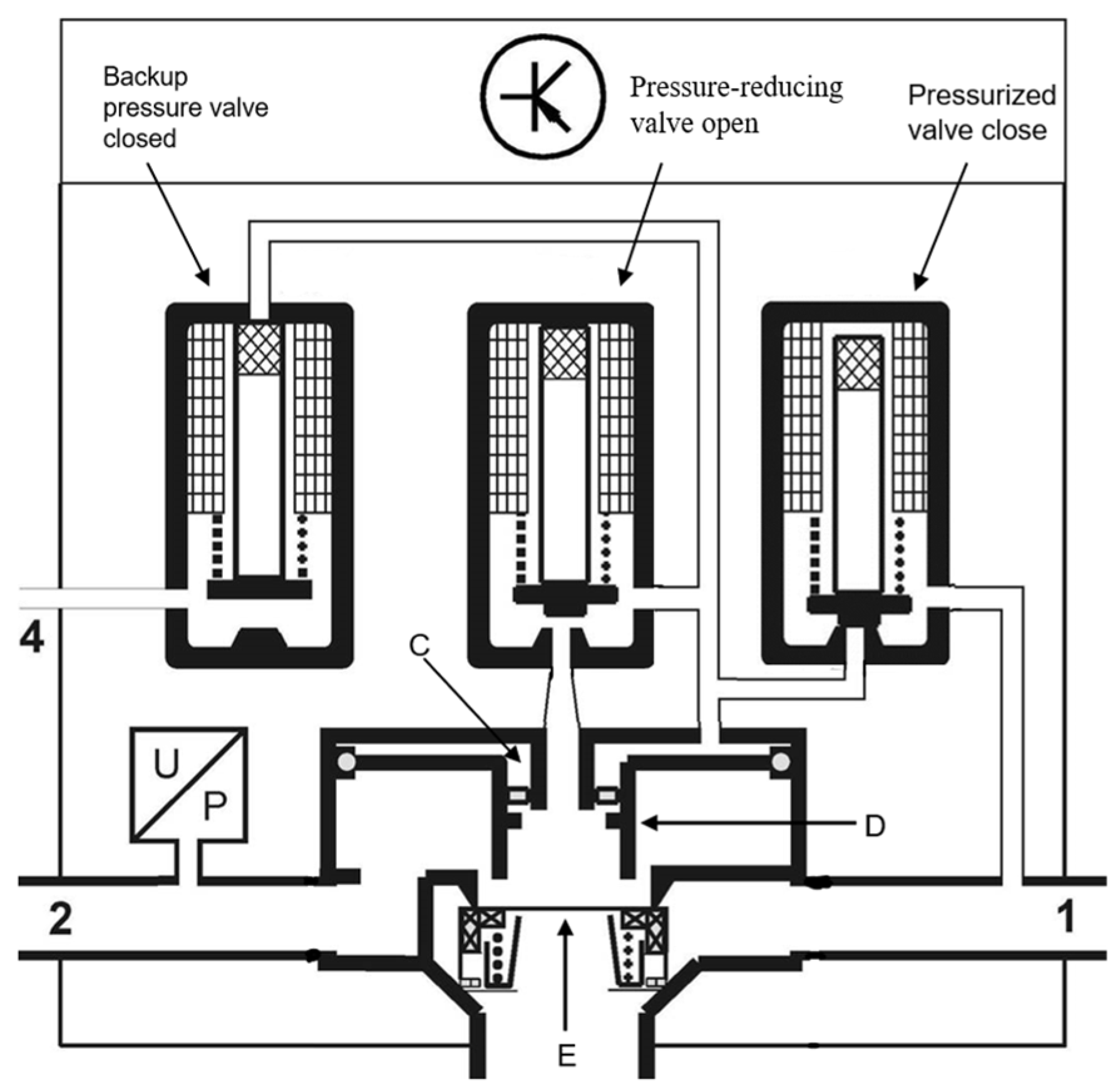

3.1. Working State and Control Mechanism

3.1.1. Multimodal Operating State Analysis

3.1.2. Electric Control Dynamic Stress Management Mechanisms

3.2. Control System Model

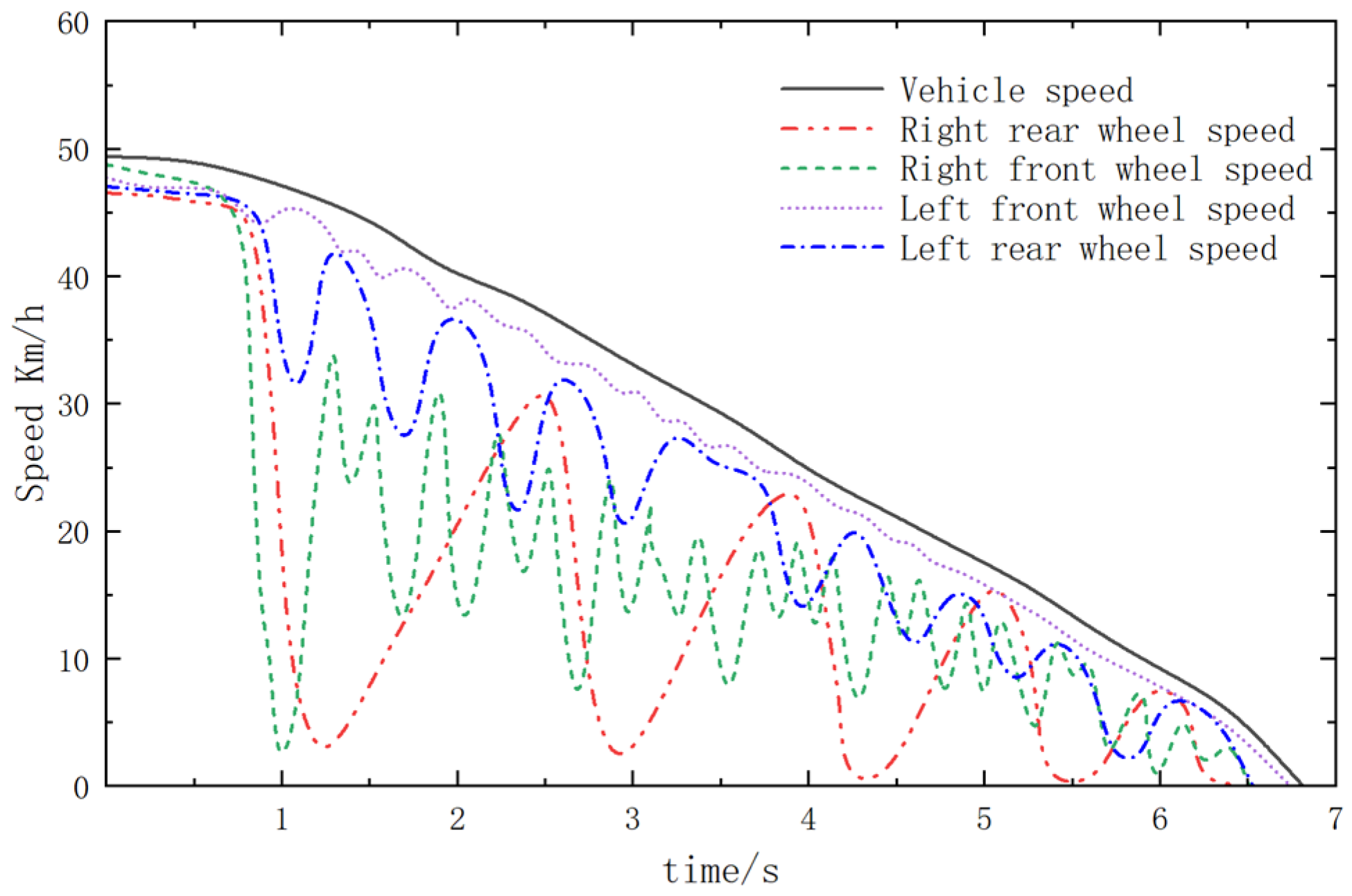

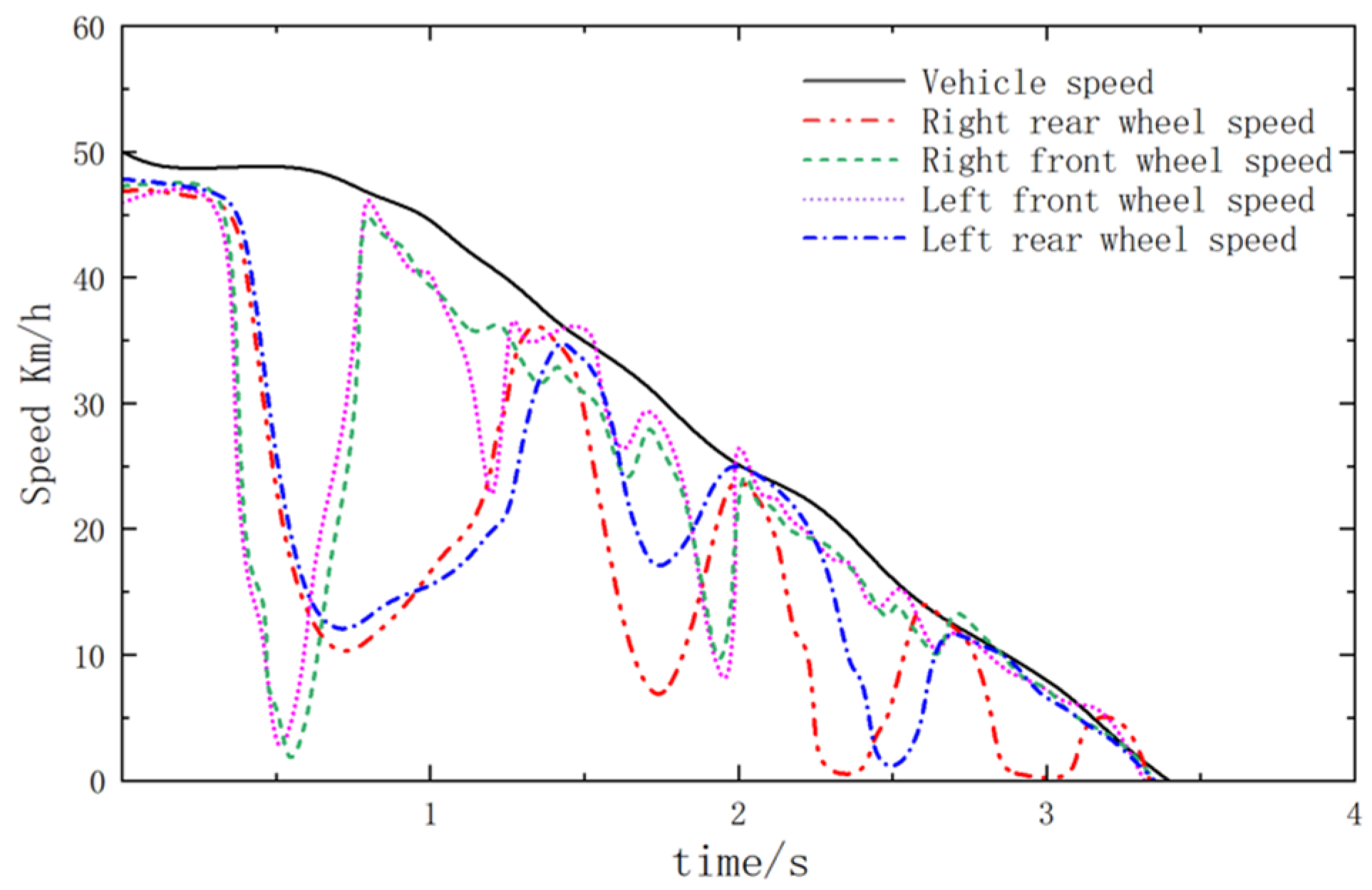

3.3. Simulation Analysis of EBS

4. EBS Experimental Testing Analysis

4.1. Experimental Testing System

4.2. Test Results

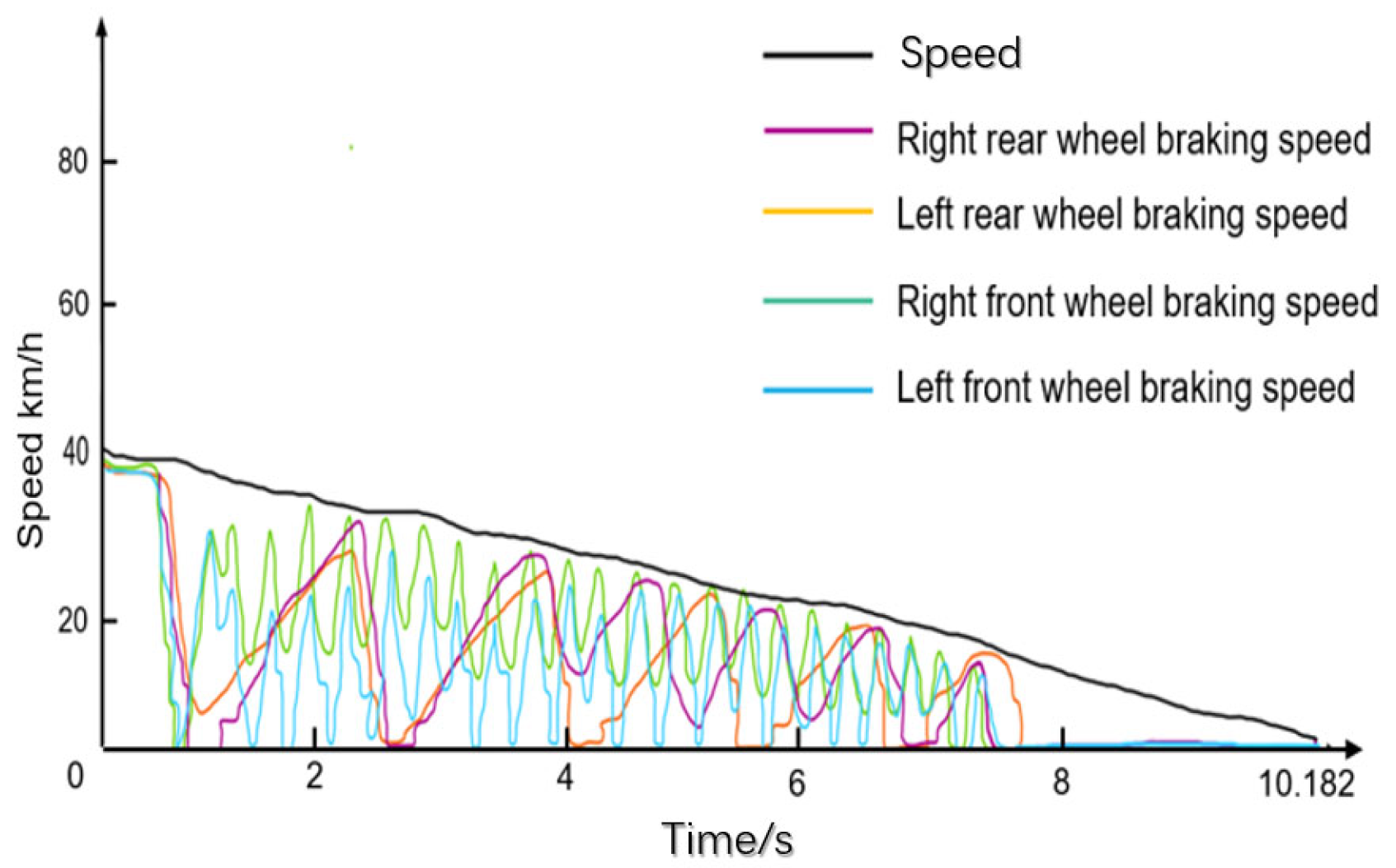

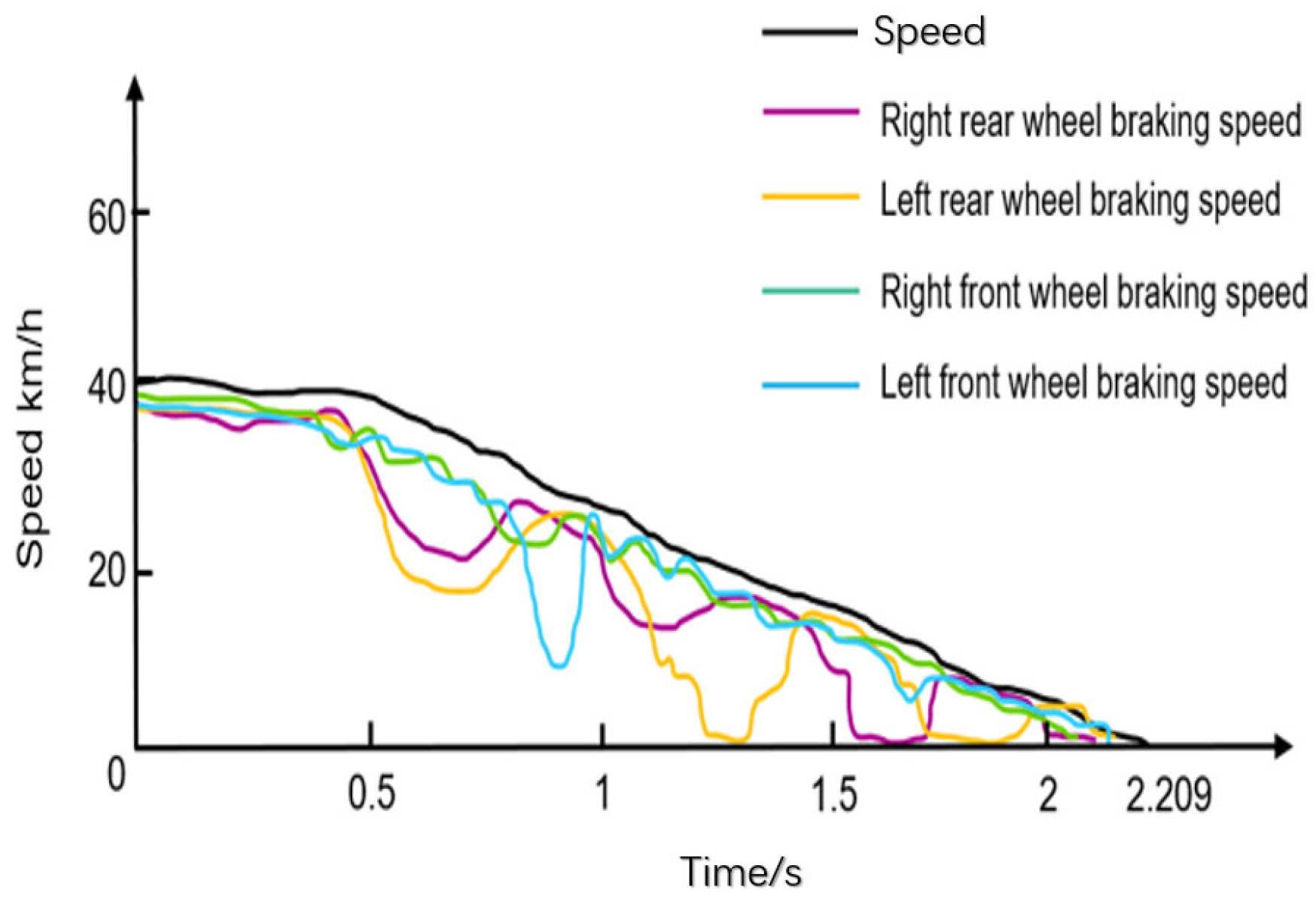

4.2.1. Experimental Analysis of Braking on Low-Adhesion Road

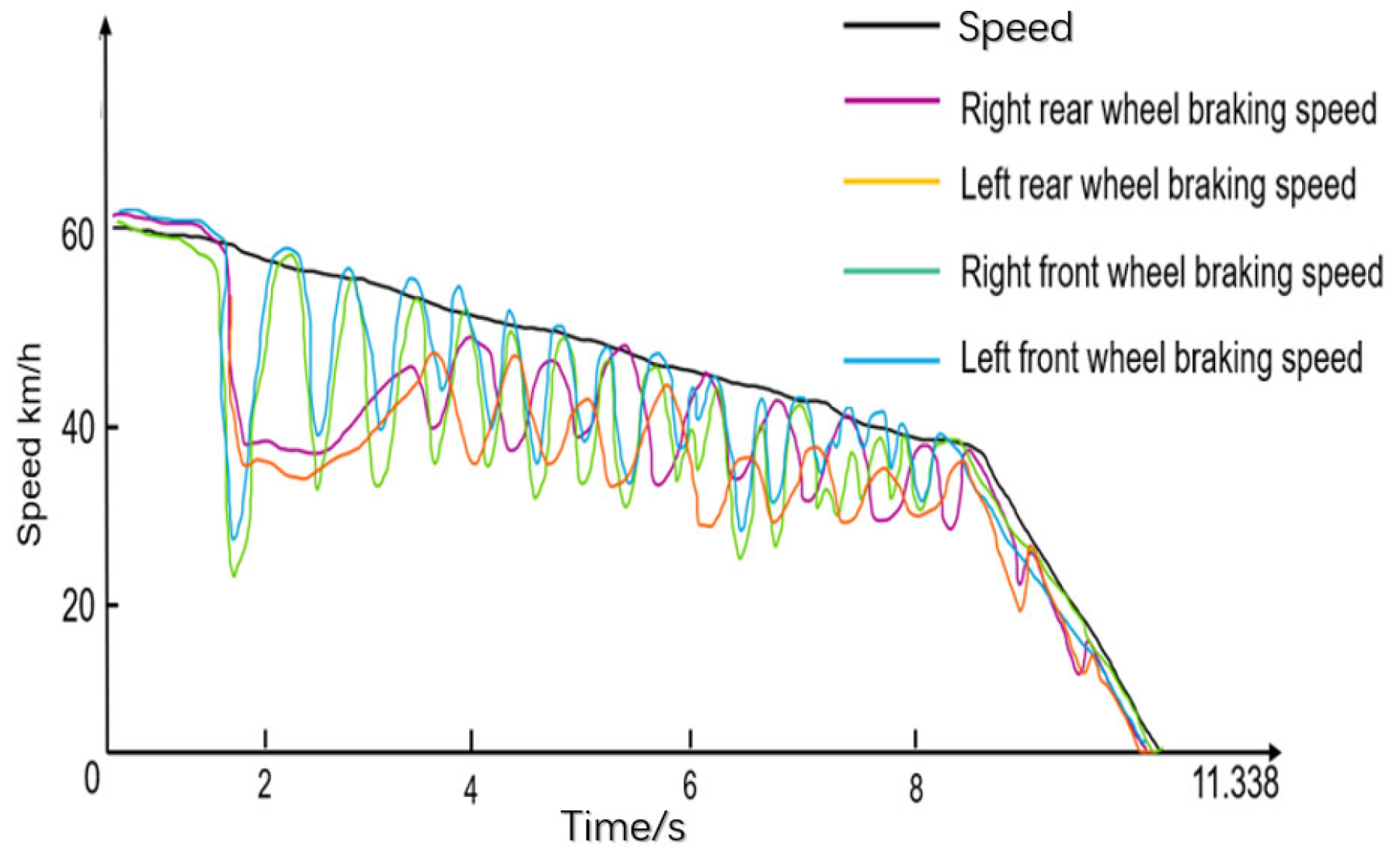

4.2.2. Experimental Analysis of Braking on High-Adhesion Road

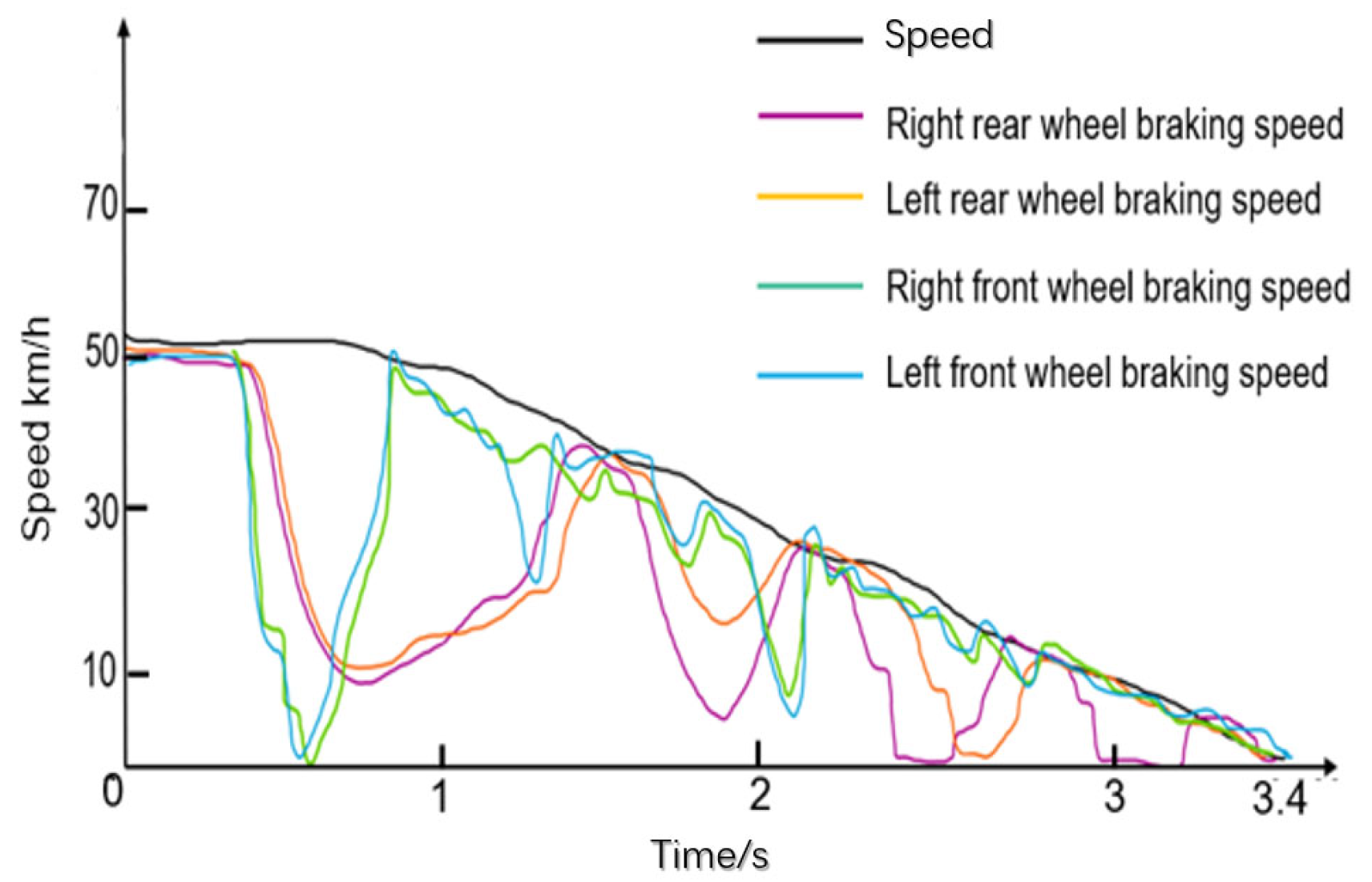

4.2.3. Experimental Analysis of Split and Docking Road Braking

4.2.4. Comparison of Experimental Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, L.P.; Shang, Y.X. Introduction of EBS electronic braking system. Automob. Technol. 2017, 12801, 139–141. [Google Scholar]

- Zhao, Y.; Wang, W.Y. Application of Electronic Brake System (EBS) for Heavy Truck. Auto Electr. Parts 2022, 6, 86–91. [Google Scholar]

- Li, J.; Hu, Y.W.; Shi, Q.J.; Zhu, W.W. Research on Simulation Control of Proportional Relay Valve in Electric Bus. Mach. Des. Manuf. 2017, 9, 1–4. [Google Scholar]

- Zhang, L.J.; Yan, Y.; Zhu, Q.W.; Zhao, G.; Feng, D.; Wu, J. A Pneumatic Control Method for Commercial Vehicle Electronic Brake System Based on EPV Module. Actuators 2022, 11, 316. [Google Scholar] [CrossRef]

- Zhang, Z.S.; Wang, L.F.; Zhang, J.Z.; Ma, R. Study on Requirements for Load Emulation of the Vehicle with an Electric Braking System. IEEE Trans. Veh. Technol. 2017, 66, 9638–9653. [Google Scholar] [CrossRef]

- Mara, T.; Roberto, S.; Sergio, M.S. Combining Slip and Deceleration Control for Brake-by-wire Control Systems: A Sliding-mode Approach. Eur. J. Control 2007, 13, 593–611. [Google Scholar]

- Wang, J.C. Hierarchical braking accurate control of electrohydraulic composite braking system for electric vehicles. ISA Trans. 2025, 158, 594–608. [Google Scholar] [CrossRef]

- Zheng, H.Y.; Liu, Z.Y.; Xu, K.W. Integrated Braking Algorithm Based on Brake Temperature and Wear Loss Control. J. South China Univ. Technol. 2013, 132–136, 142. [Google Scholar]

- Zhong, C.F.; Wang, Y.; Zhao, W.Q.; Feng, D.; Wu, J. Development of simulation platform and hysteresis control strategy of pneumatic electronic braking system for commercial vehicles. J. Jilin Univ. (Eng. Technol. Ed.) 2016, 46, 711–717. [Google Scholar]

- Xia, W.Y.; Wu, H.P. Application of electronic brake system (EBS) on Trailer. Auto Expo 2021, 16, 37–38. [Google Scholar]

- Li, W.J.; Wang, X.H.; Wang, F.; Pu, J.J.; Yan, J.H. Application of electronic braking system in new energy commercial vehicle. Automob. Technol. 2020, 24, 4–5. (In Chinese) [Google Scholar]

- Yu, B.; Zhao, R.; Yang, F.; Li, G.Y. Function and system design of pneumatic EBS for dangerous goods semitrailer. Highw. Automot. Appl. 2021, 2, 1–6. [Google Scholar]

- Jamal, E.; Hamid, O.; Abdallah, S. Adaptive Neuro Fuzzy Inference System Based controller for Electric Vehicle’s hybrid ABS braking. IFAC-PapersOnLine 2022, 55, 371–376. [Google Scholar]

- Yang, M.; Hu, Z.X. Application of EBS in Trailer. Commer. Veh. 2019, 12, 101–103. [Google Scholar]

- Song, Y.L.; Xie, K.C. Application of EBS in heavy truck. Heavy Truck. 2015, 5, 29–31. [Google Scholar]

- Salaani, M.K.; Rao, S.; Every, J.L.; Mikesell, D.R.; Barickman, F.; Elsasser, D.; Martin, J. Hardware-in-the-Loop Pneumatic Braking System for Heavy Truck Testing of Advanced Electronic Safety Interventions. SAE Int. J. Passeng. Cars Mech. Syst. 2016, 9, 912–923. [Google Scholar] [CrossRef]

- Morrison, G.; Cebon, D. Combined emergency braking and turning of articulated heavy vehicles. Veh. Syst. Dyn. Int. J. Veh. Mech. Mobil. 2017, 55, 725–749. [Google Scholar] [CrossRef]

- Halilović, A.; Zimmerschitt-Halbig, P. ISO 26262 for Electronic Brake Systems Software. Auto Tech Rev. 2014, 3, 42–47. [Google Scholar] [CrossRef]

- Hakan, K.; Ersin, T. Experimental study on braking and stability performance during low speed braking with ABS under critical road conditions. Eng. Sci. Technol. 2021, 24, 1224–1238. [Google Scholar]

- van der Merwe, N.A.; Els, P.S.; Žuraulis, V. ABS braking on rough terrain. J. Terramech. 2018, 80, 49–57. [Google Scholar] [CrossRef]

- Bao, H.W.; Wang, K.Y.; Wei, X.X.; Cheng, Y.; Zhao, M.; Li, G. Highly Redundant Safety Scheme and Its Experimental Validation for the Electronic-Controlled Pneumatic Braking System of Commercial Vehicle for Autonomous Driving. IEEE Access 2024, 12, 138201–138210. [Google Scholar] [CrossRef]

- Bao, H.W.; Li, G.Y.; Du, S.Y.; Liu, Y.; Liu, Y. Research on the Influence of Commercial Vehicle Electronic Control Pneumatic Braking Pressure Change Rate on Braking Ride Comfort. Integr. Ferroelectr. 2021, 271, 265–278. [Google Scholar] [CrossRef]

- GB/T 13594-2003; Antilock Braking Performance and Test Procedure for Motor Vehicles and Their Trailers. The Standardization Administration of the People’s Republic of China: Beijing, China, 2023.

- GB/T 12676-2014; Technical Requirements and Testing Methods for Commercial Vehicle and Trailer Braking Systems. The Standardization Administration of the People’s Republic of China: Beijing, China, 2014.

- Soliman, A.M.; Kaldas, M.; Soliman, A.M.; Huzayyin, A.S. Vehicle Braking Performance Improvement via Electronic Brake Booster. SAE Int. J. Veh. Dyn. Stab. NVH 2024, 8, 63–79. [Google Scholar] [CrossRef]

| Size parameter(mm) | Wheelbase | No-load centroid height | Full-load centroid height |

| 3300 + 1350 | 900 | 1325 | |

| No load and axle load (kg) | No load | Front axle load | Rear axle load |

| 7960 | 3600 | 4360 | |

| Full load and axle load (kg) | Full load | Front axle load | Rear axle load |

| 25,250 | 6650 | 4980 |

| Test Scenario | Results of this EBS | Conventional Pneumatic Brakes | Enhancement Effect |

|---|---|---|---|

| 40 km/h no-load braking time | 10.182 s | 12.1–13.5 s | 15–20% reduction |

| 60 km/h no-load braking time | 11.338 s | 14.2–15.8 s | 20–25% reduction |

| Directional stability | No lane departure | Common offsets > 1 m | 30%+ improvement in control accuracy |

| Test Conditions | Braking Time | Steering Wheel Correction | Key Phenomena |

|---|---|---|---|

| Split road | 6.68 s | <120° in the initial 2 s Total turning angle <240° | Maintaining trajectory stability after a short hold |

| Docking road | 3.4 s | No significant amendments triggered | Sudden increase in deceleration when connecting to highways |

| Braking System Type | Working Condition | Initial Speed | Braking Time |

|---|---|---|---|

| Traditional pneumatic braking system | Low-adhesion road | 40 km/h | 12.1–13.5 s |

| Traditional pneumatic braking system | High-adhesion road | 40 km/h | 4–6 s |

| New integrated EBS | Low-adhesion road | 40 km/h | 10.182 s |

| New integrated EBS | High-adhesion road | 40 km/h | 2.209 s |

| Traditional pneumatic braking system | Split road | 50 km/h | 8–12 s |

| New integrated EBS | Split road | 50 km/h | 6.68 s |

| Traditional pneumatic braking system | Docking road | 50 km/h | 5–7 s |

| New integrated EBS | Docking road | 50 km/h | 3.4 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Fu, Z.; Qiu, B.; Song, X.; Chen, G.; Li, Z.; He, Q.; Lu, G.; Sun, X. Design and Experimental Research on a New Integrated EBS with High Response Speed. World Electr. Veh. J. 2025, 16, 446. https://doi.org/10.3390/wevj16080446

Chen F, Fu Z, Qiu B, Song X, Chen G, Li Z, He Q, Lu G, Sun X. Design and Experimental Research on a New Integrated EBS with High Response Speed. World Electric Vehicle Journal. 2025; 16(8):446. https://doi.org/10.3390/wevj16080446

Chicago/Turabian StyleChen, Feng, Zhiquan Fu, Baoxiang Qiu, Xiaoyi Song, Gangqiang Chen, Zhanming Li, Qijiang He, Guo Lu, and Xiaoqing Sun. 2025. "Design and Experimental Research on a New Integrated EBS with High Response Speed" World Electric Vehicle Journal 16, no. 8: 446. https://doi.org/10.3390/wevj16080446

APA StyleChen, F., Fu, Z., Qiu, B., Song, X., Chen, G., Li, Z., He, Q., Lu, G., & Sun, X. (2025). Design and Experimental Research on a New Integrated EBS with High Response Speed. World Electric Vehicle Journal, 16(8), 446. https://doi.org/10.3390/wevj16080446