An Enhanced ABS Braking Control System with Autonomous Vehicle Stopping

Abstract

1. Introduction

2. Anti-Lock Braking System (ABS)

2.1. Subsection

2.1.1. Wheel Dynamics Model

2.1.2. Relative Slip

2.1.3. Slip Ratio

2.1.4. Slip Rate

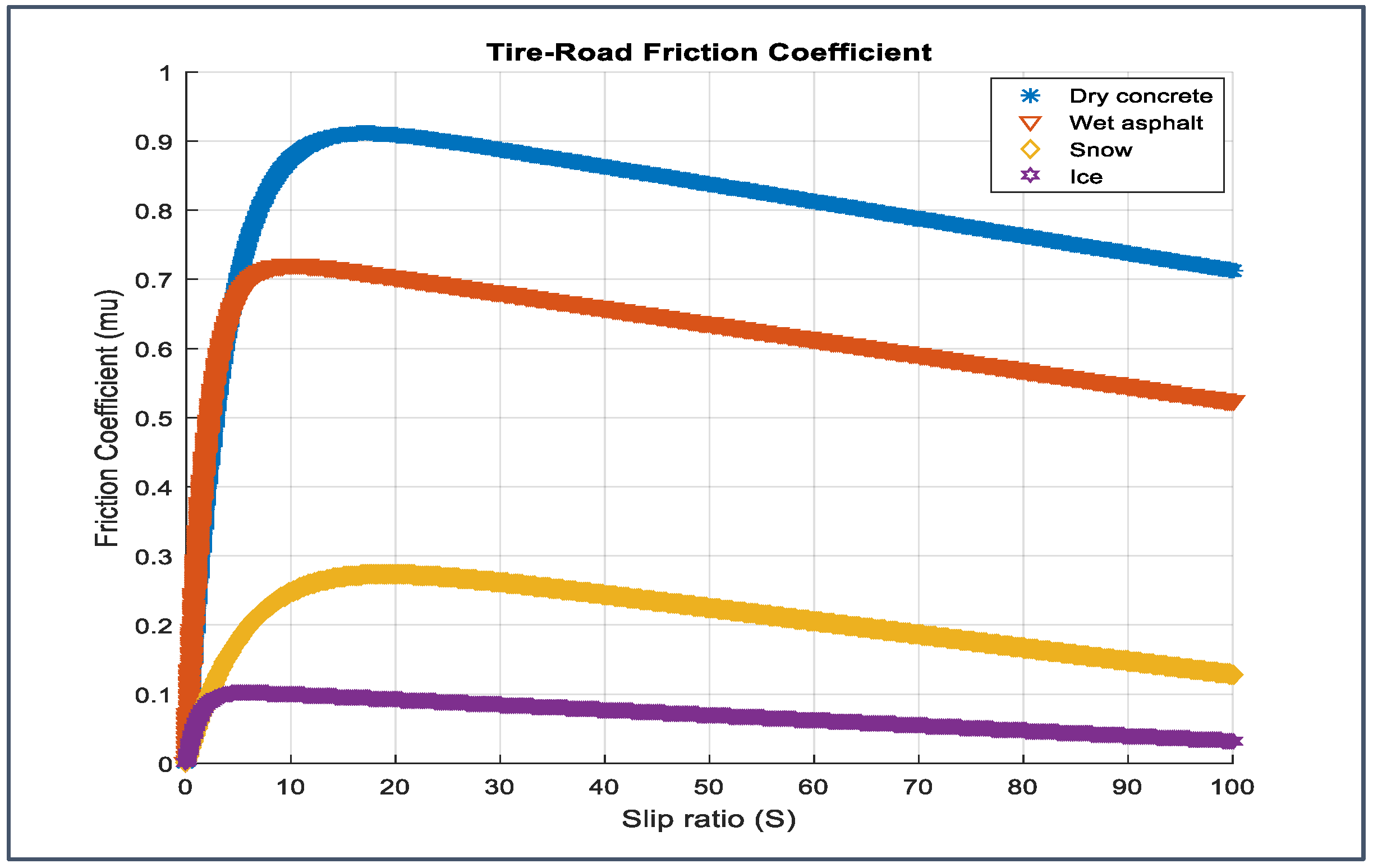

2.2. Model of Burckhardt

2.3. Parameters Used in the ABS Model

2.4. Simulation of ABS Model

2.4.1. Simulation of Wheel Model

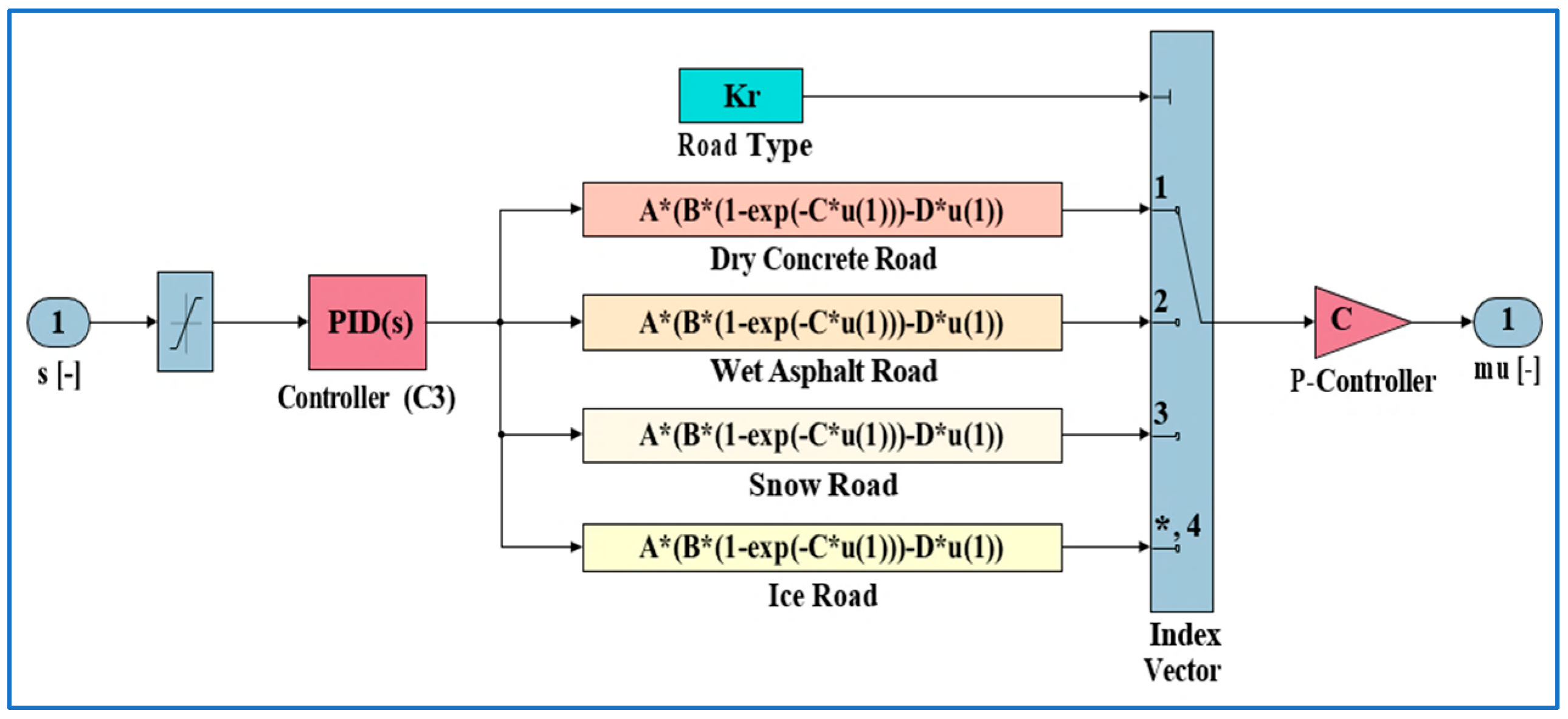

2.4.2. Simulation Model Friction

3. ABS Controller

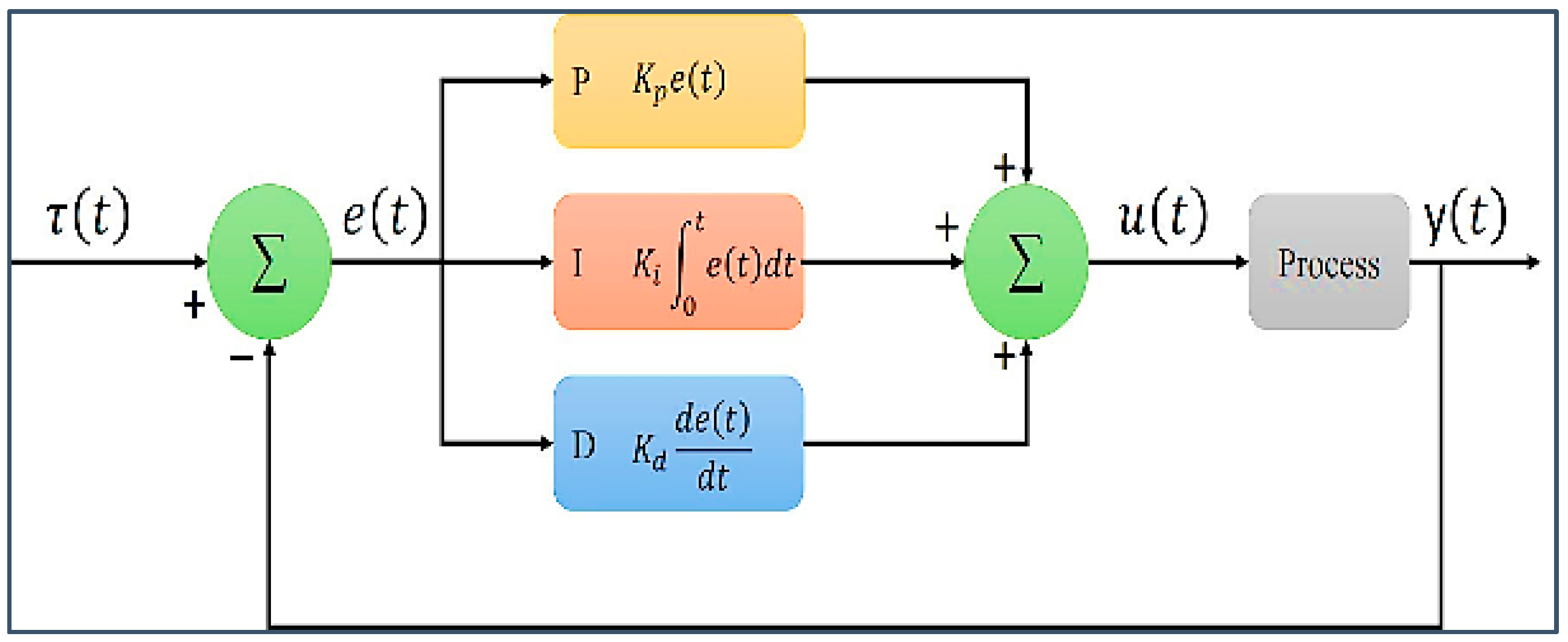

3.1. PID Controllers

Simulation of PID by MATLAB

3.2. Simulation of PID Controller by MATLAB

3.2.1. Simulation of FLC by MATLAB

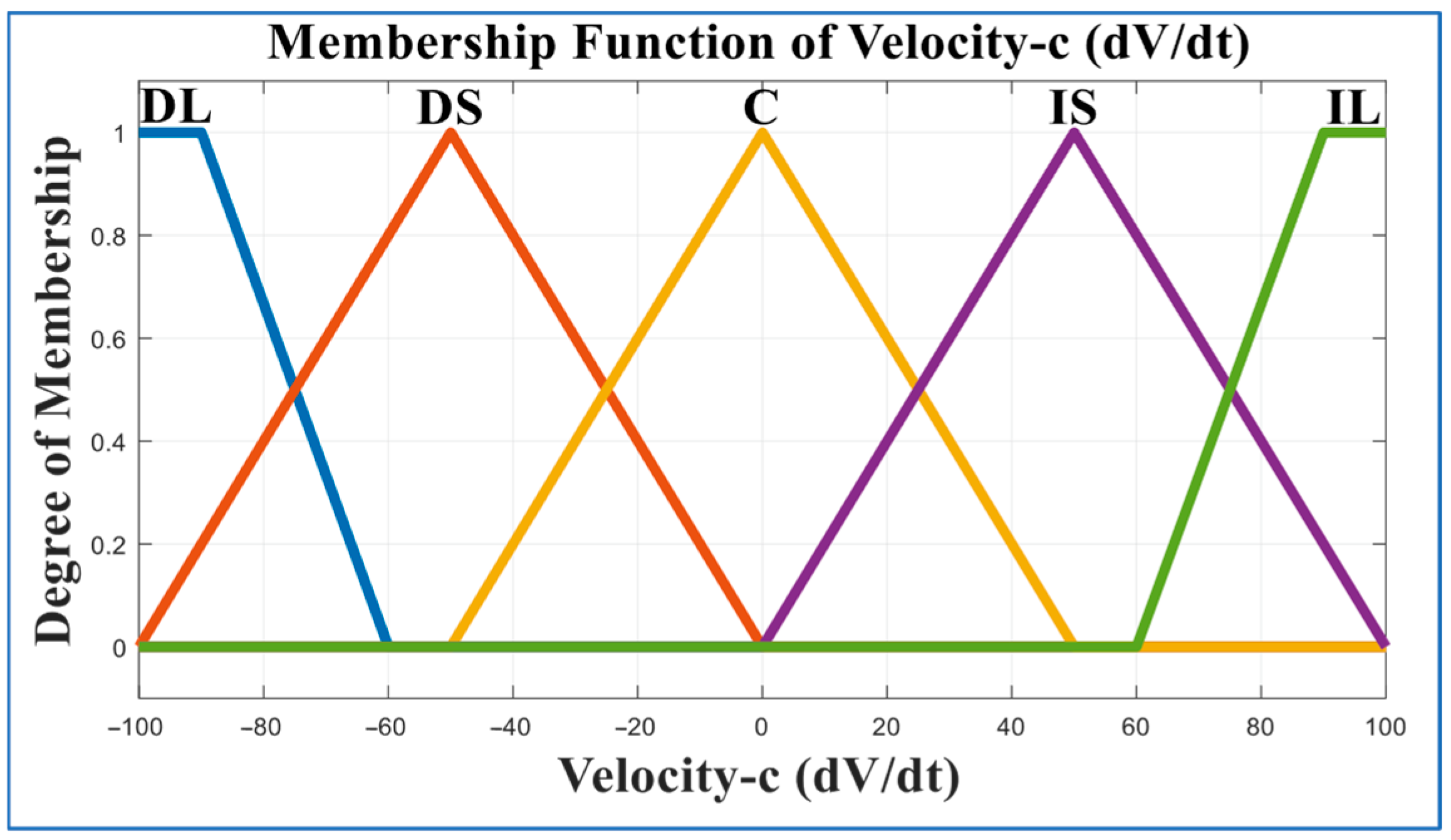

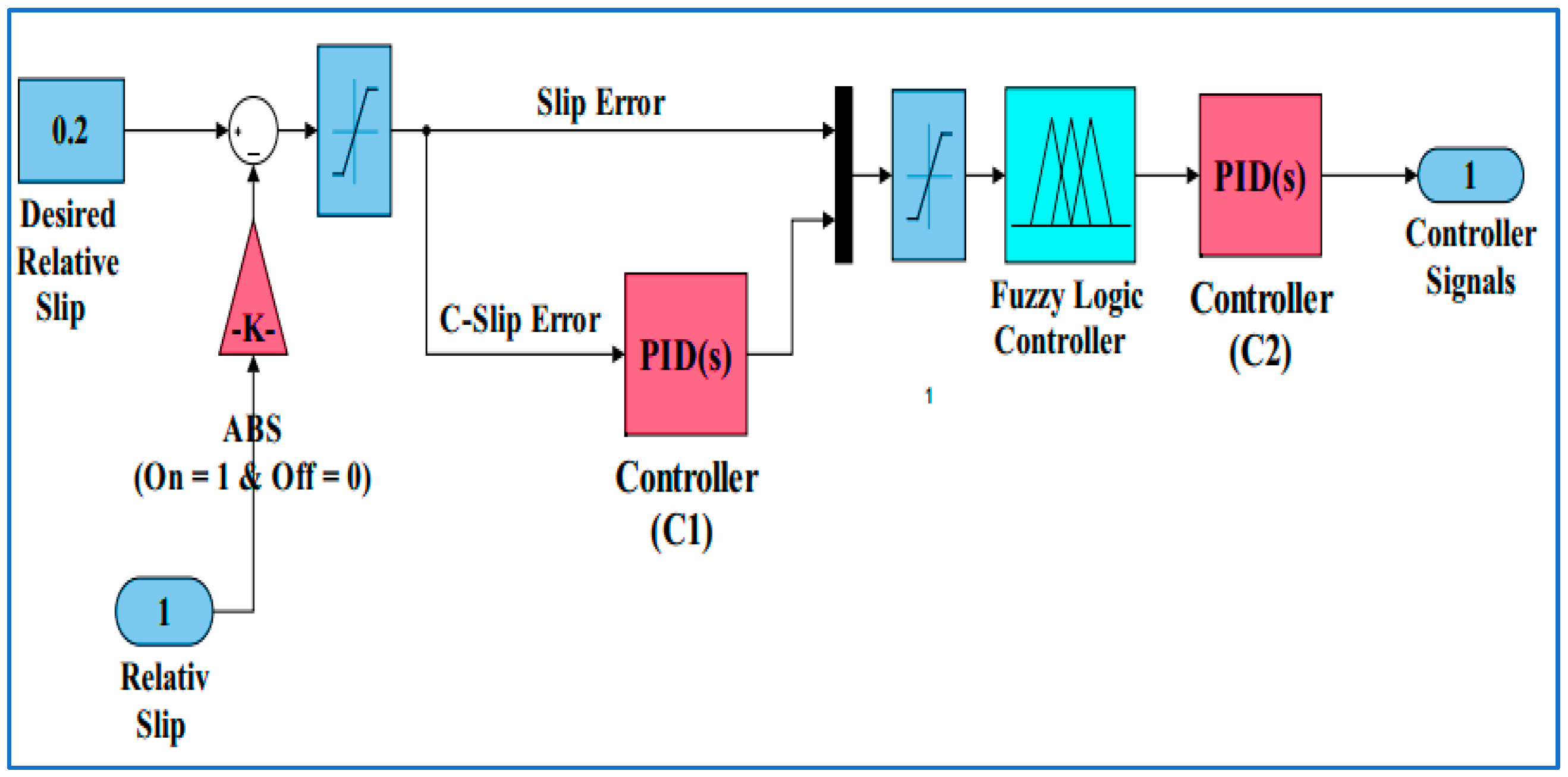

- Inputs and outputs: The inputs and outputs to the controller are as follows:

- Input 1: The error of slip between actual slip and the reference slip (error).

- Input 2: The error change ration (error-c).

- Output: The braking pressure (pressure).

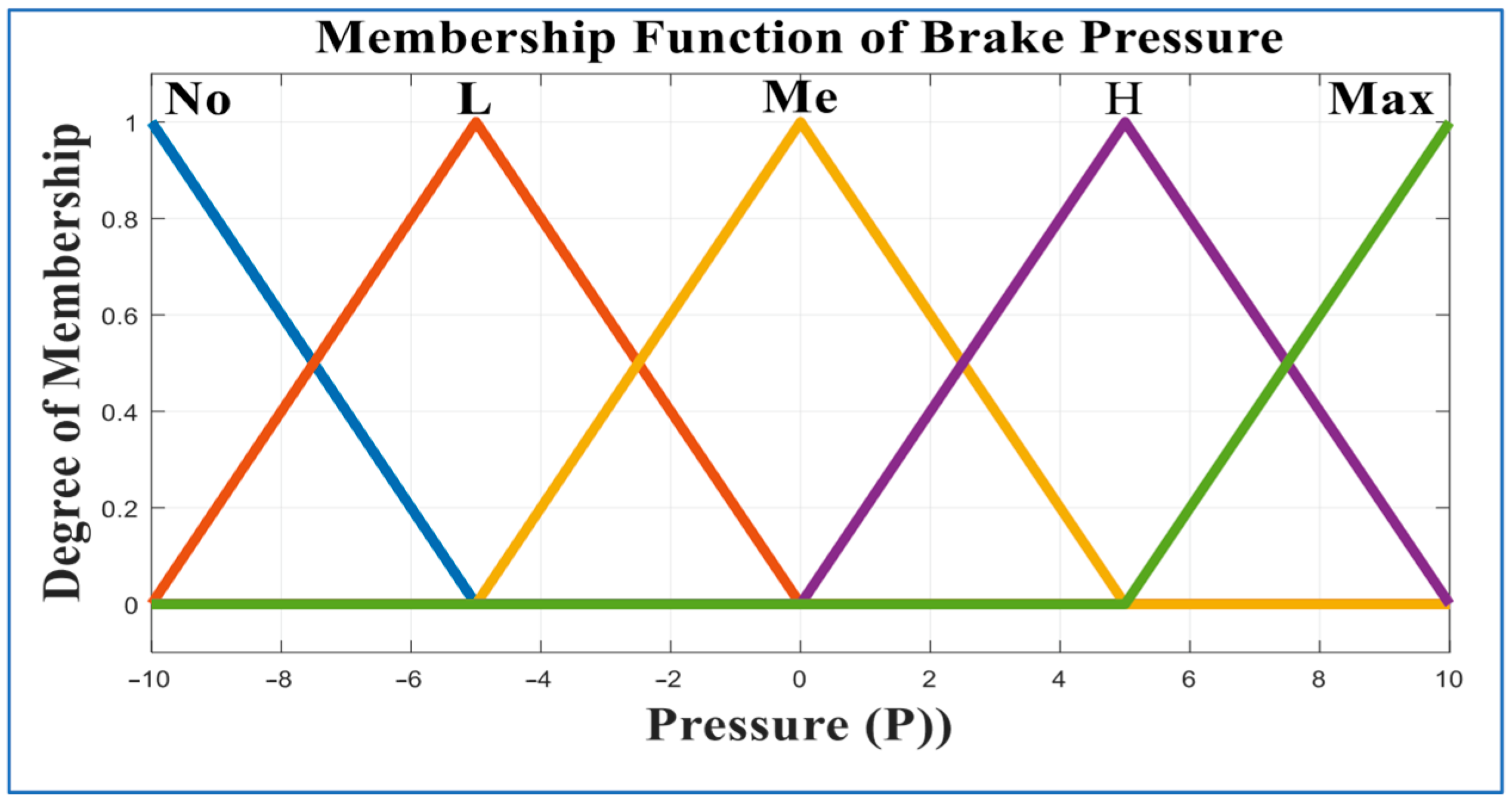

- Membership Functions: The number of membership functions (MFs) depends on the linguistic values used. In our case, for velocity (V), five categories are defined: Low (L), Medium (Me), High (H), Very High (VH), and Maximum (Max), as shown in Figure 8, Figure 9 and Figure 10. Each category describes the degree of participation for a given velocity. The velocity (V) membership function in a fuzzy logic system is shown in Figure 8.

3.2.2. Rule Table

3.3. Simulation of ABS Controller

4. Frequency Modulation Continuous Wave Radar (FMCW)

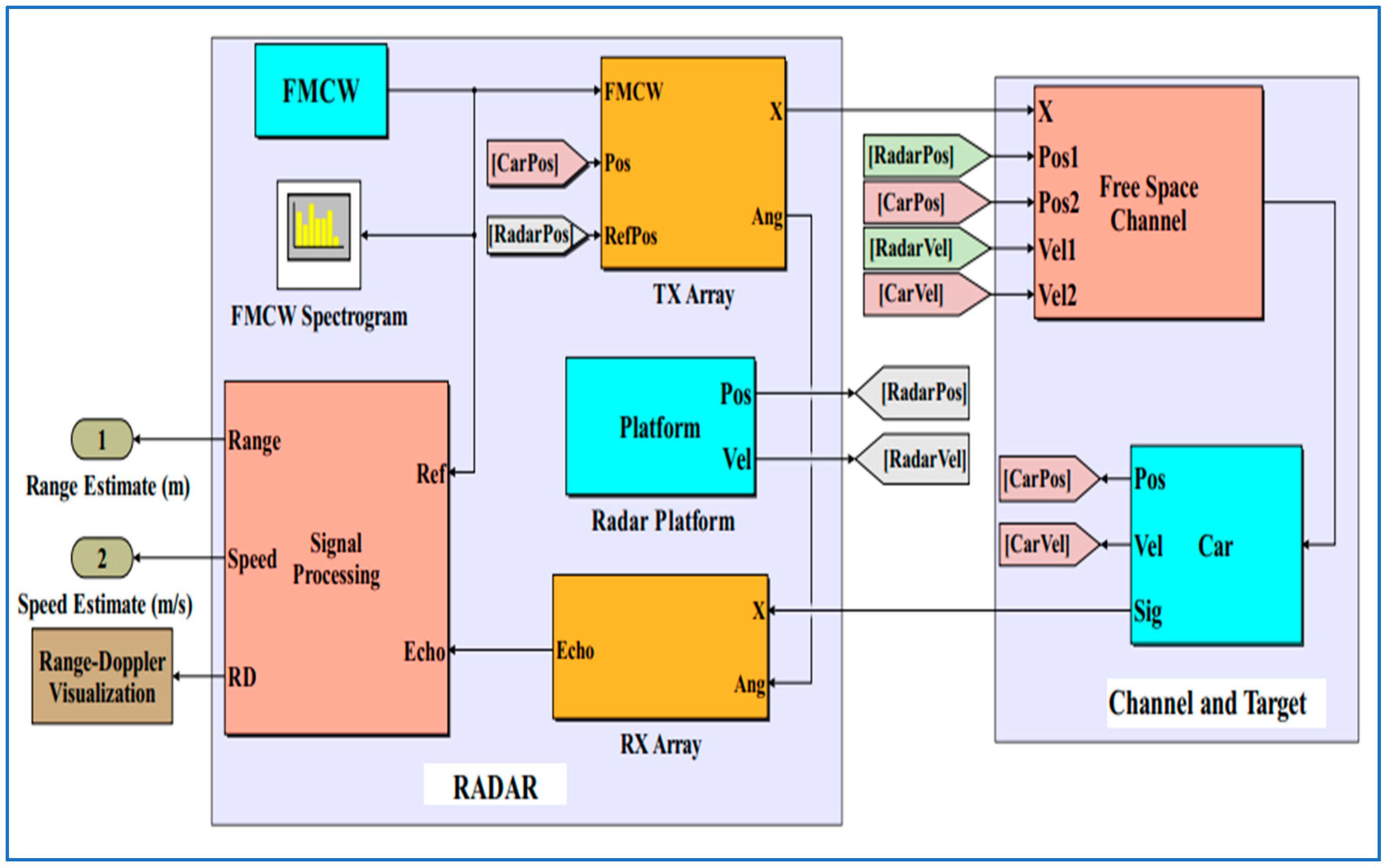

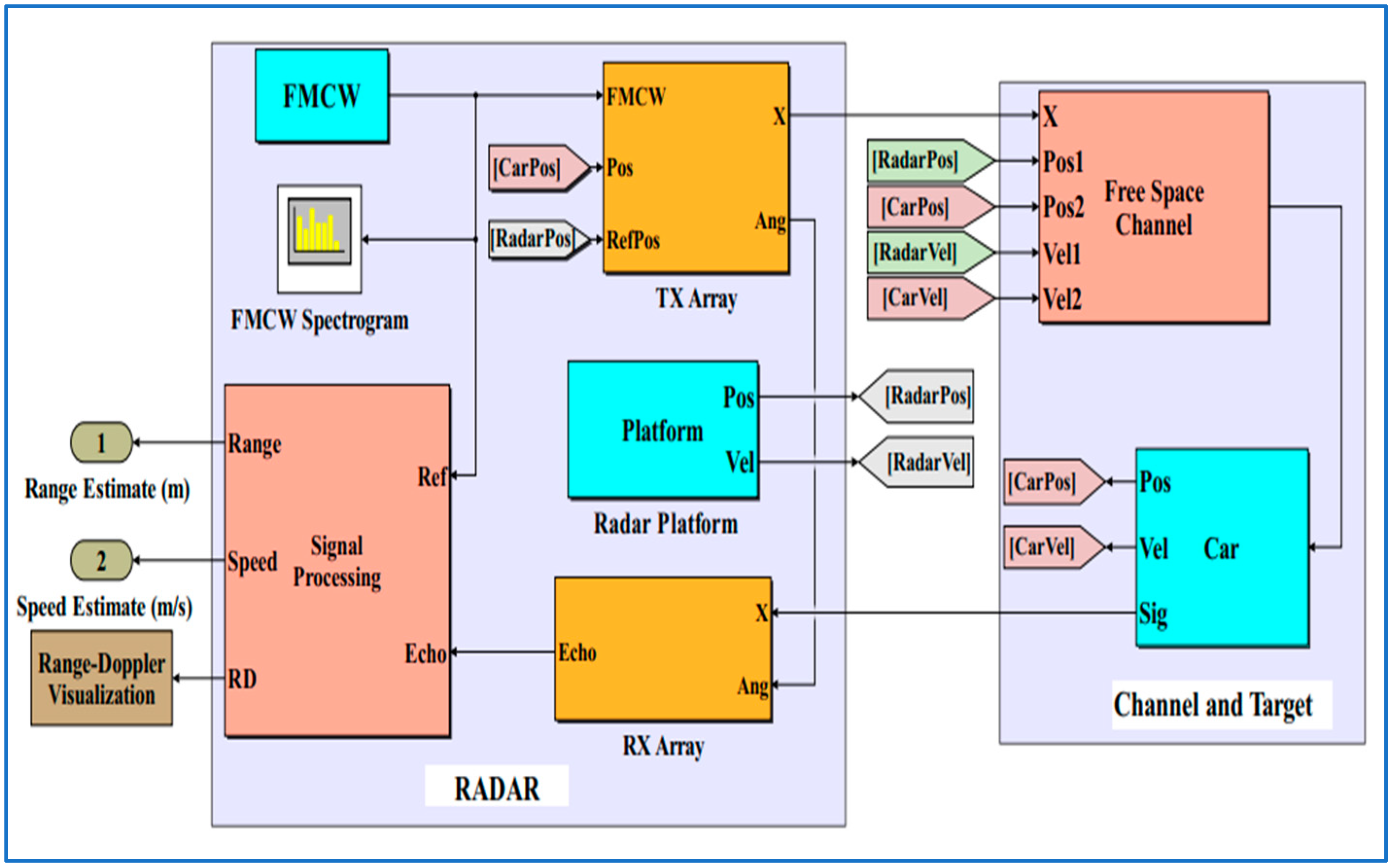

4.1. FMCW Radar Model

4.1.1. Simulation of Radar

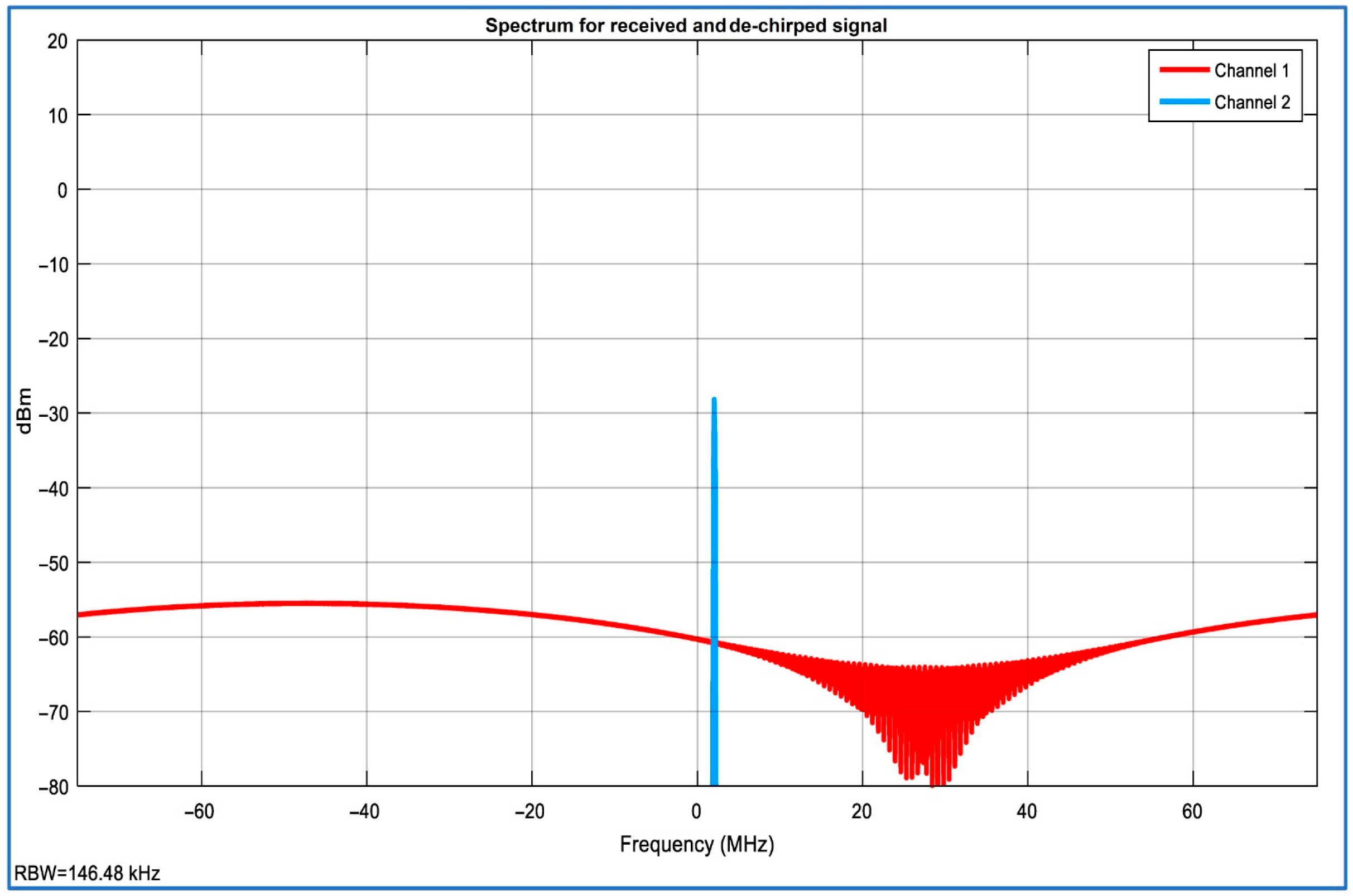

4.1.2. Signals of FMCW Radar

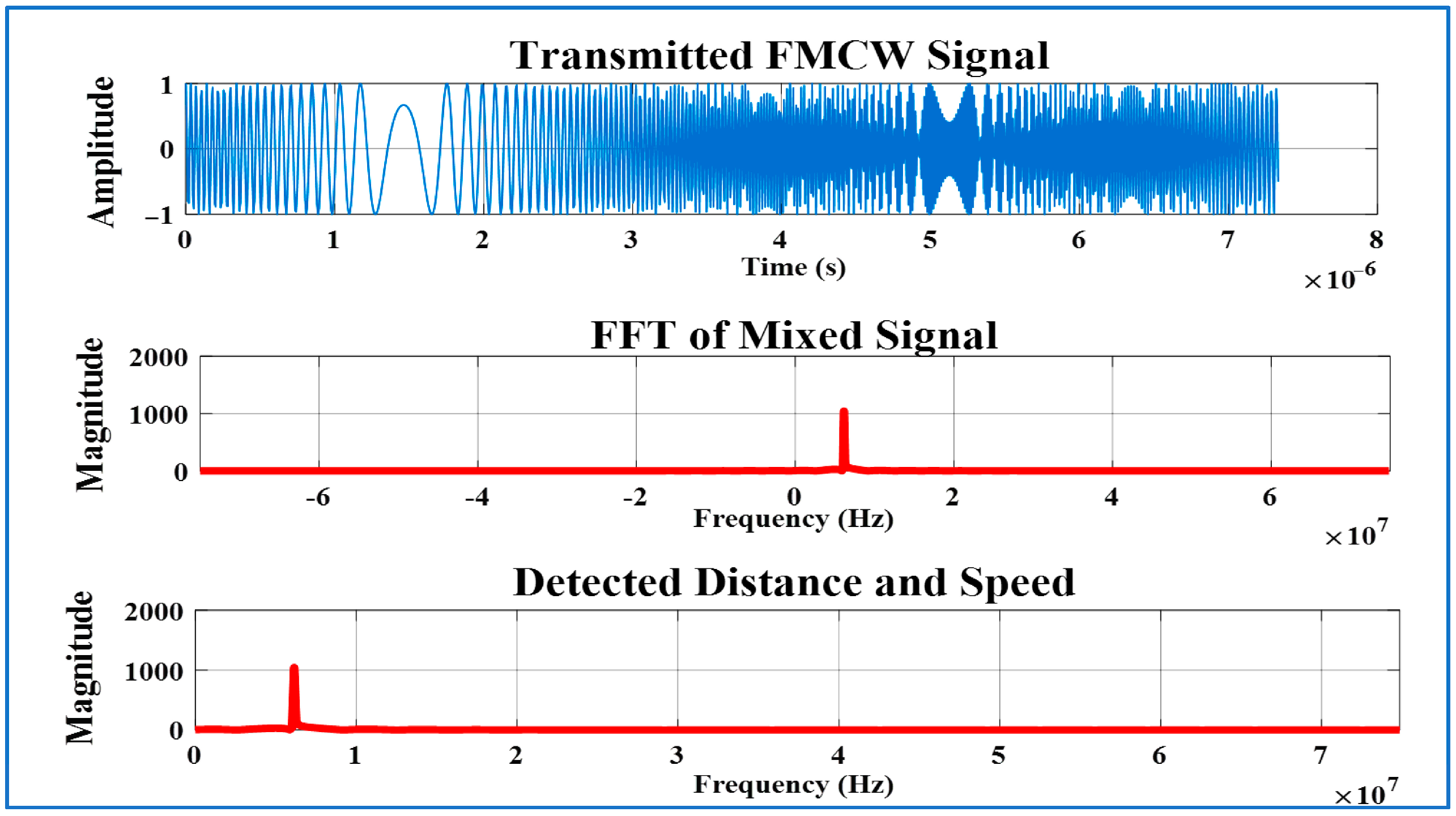

- Original FMCW Signal in Time Domain: Illustrates the signal’s amplitude evolution over time.

- Received FMCW Signal in Time Domain: Shows amplitude fluctuations after reflection from the target.

- De-chirped Signal: Displays the simplified signal for data analysis, enabling range and velocity extraction.

- FMCW Signal Spectrogram: Depicts energy distribution across frequencies over time, useful for identifying target features.

- Transmitted FMCW Signal: Shows the frequency sweep of the signal, aiding in target recognition.

- FFT of Mixed Signal: Displays the Fast Fourier Transform (FFT) of the mixed signal, crucial for calculating target range and velocity.

- Detected Distance and Speed: Shows the plot of detected distance and speed using the beat frequency to calculate target range and speed.

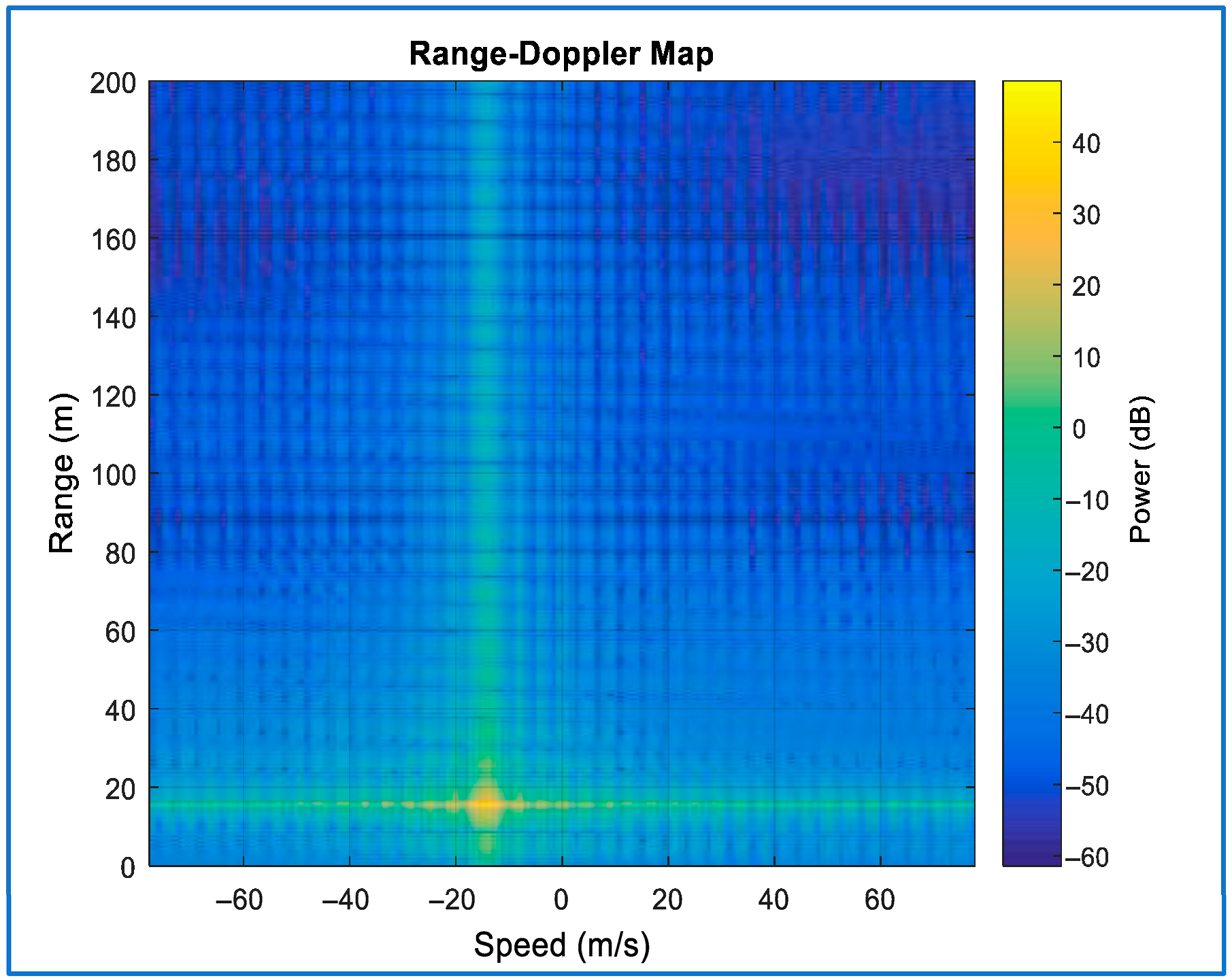

4.1.3. The Range-Doppler Map

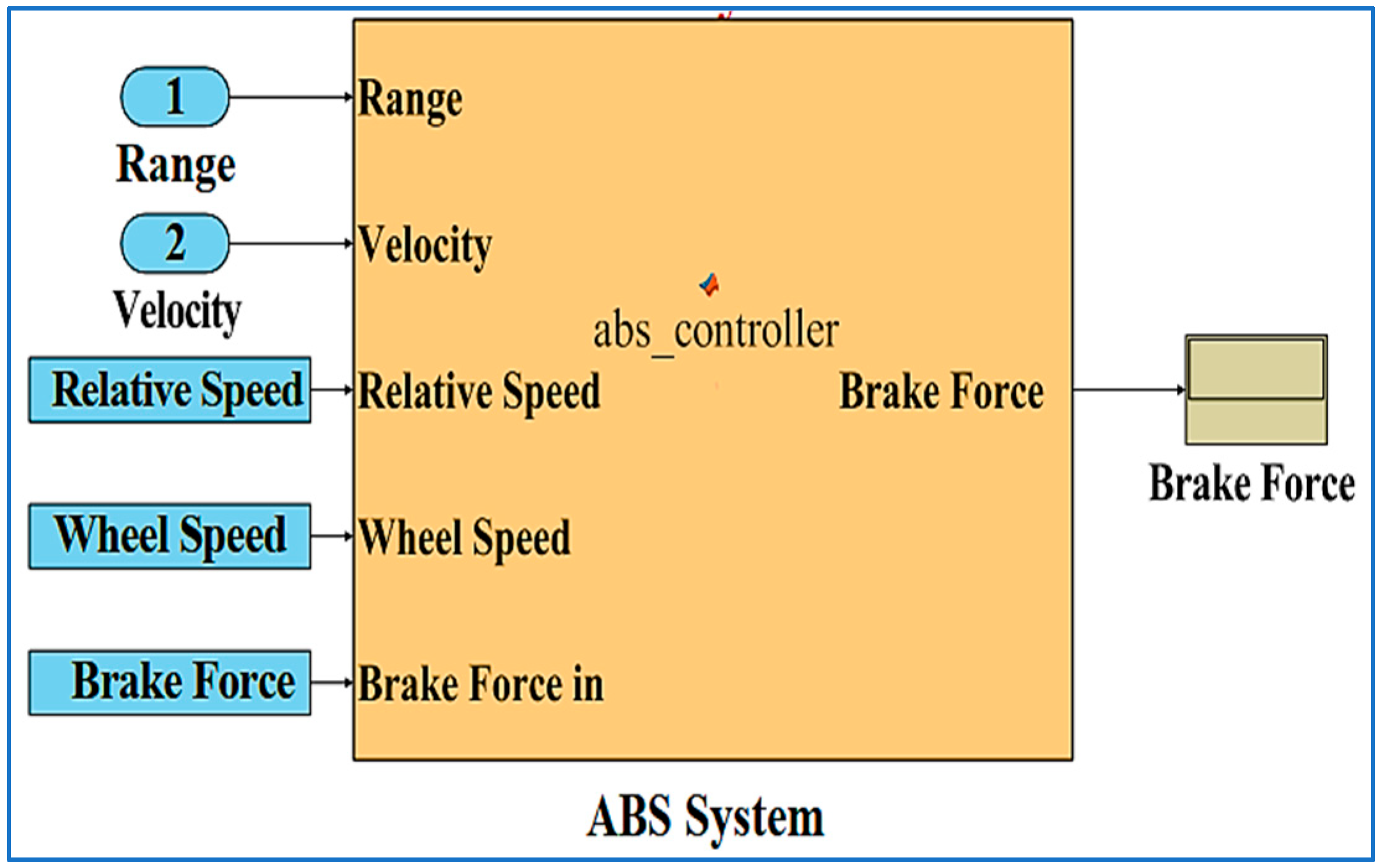

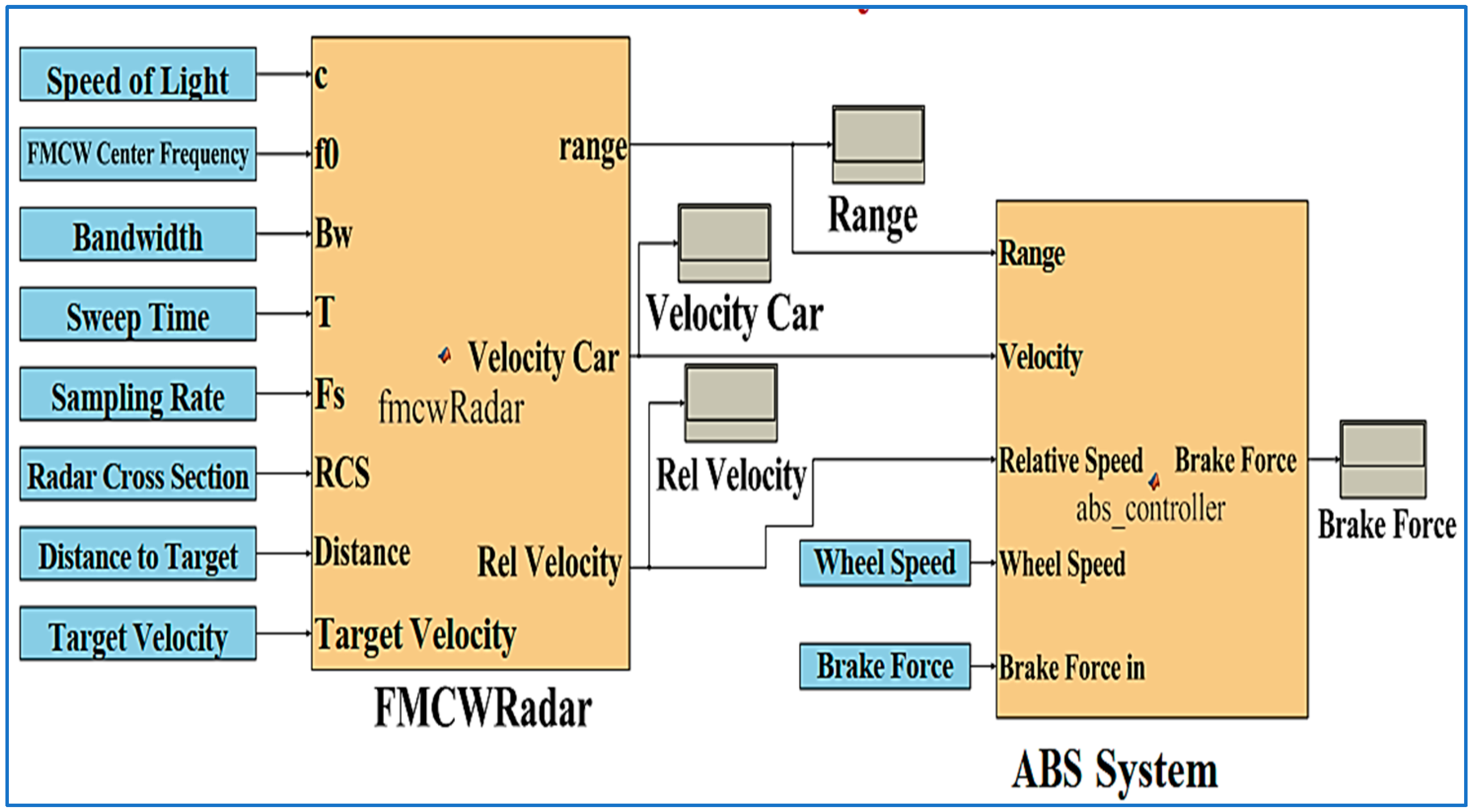

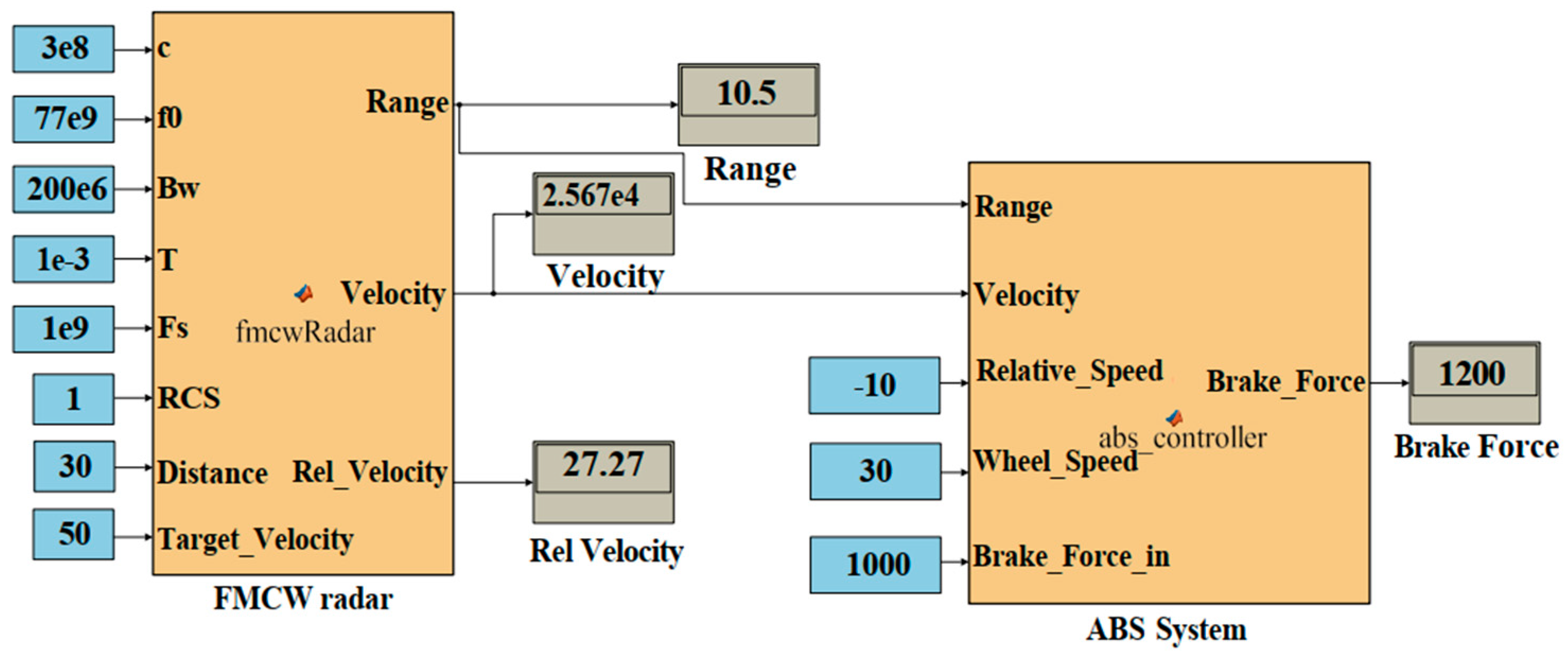

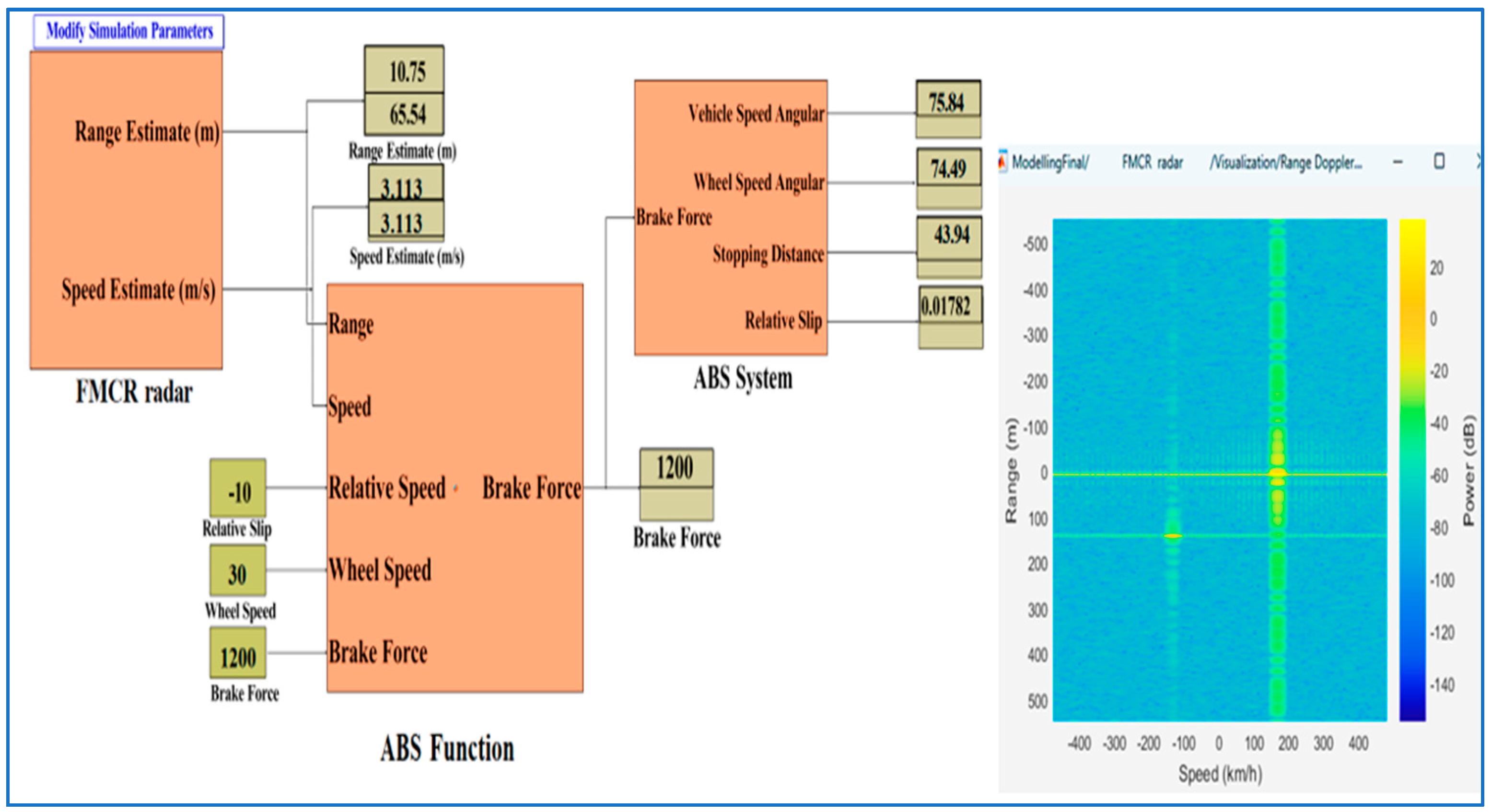

4.2. ABSFMCW System

4.2.1. ABS Function Model

4.2.2. FMCW with ABS Function

4.2.3. Programming of ABSFMCW

4.2.4. Simulation of ABSFMCW

4.2.5. Flowchart of Automatic Braking System Using FMCW Radar

4.2.6. Working Principle of Radar and System Integration

5. Results of Simulation

5.1. Range and Velocity

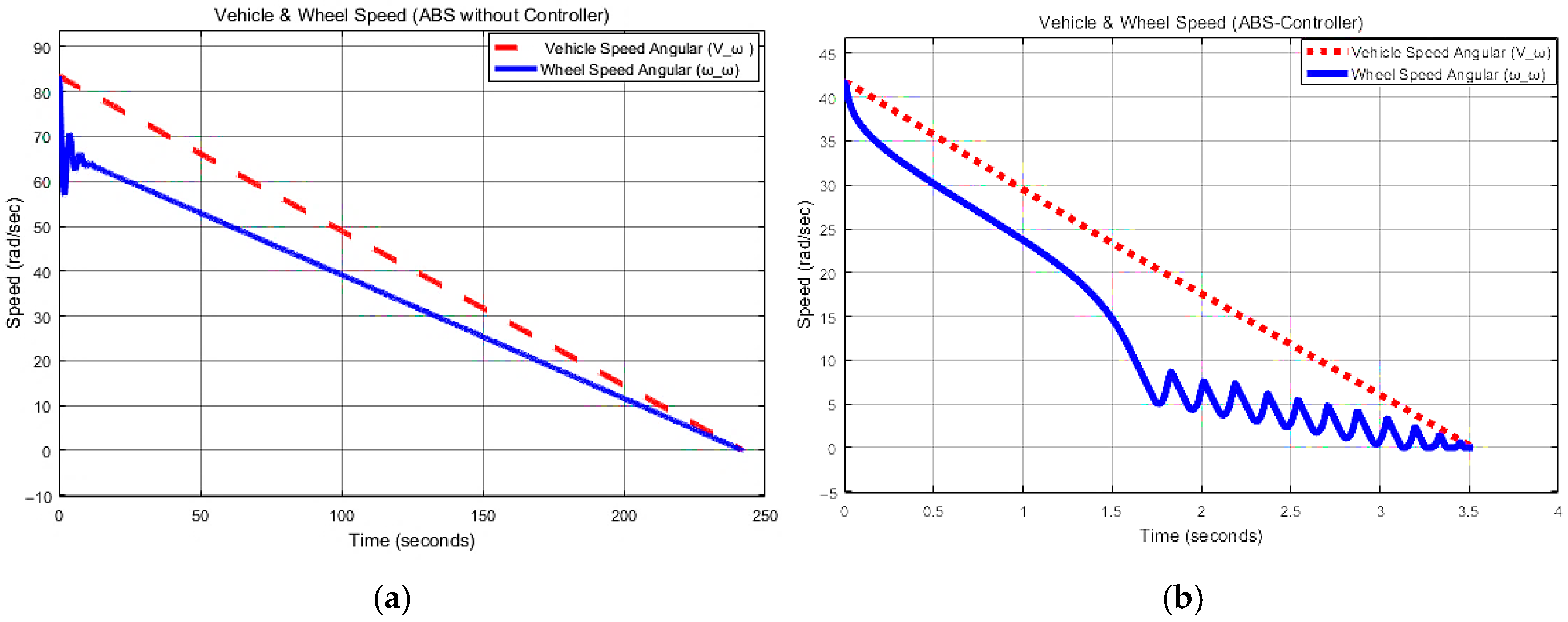

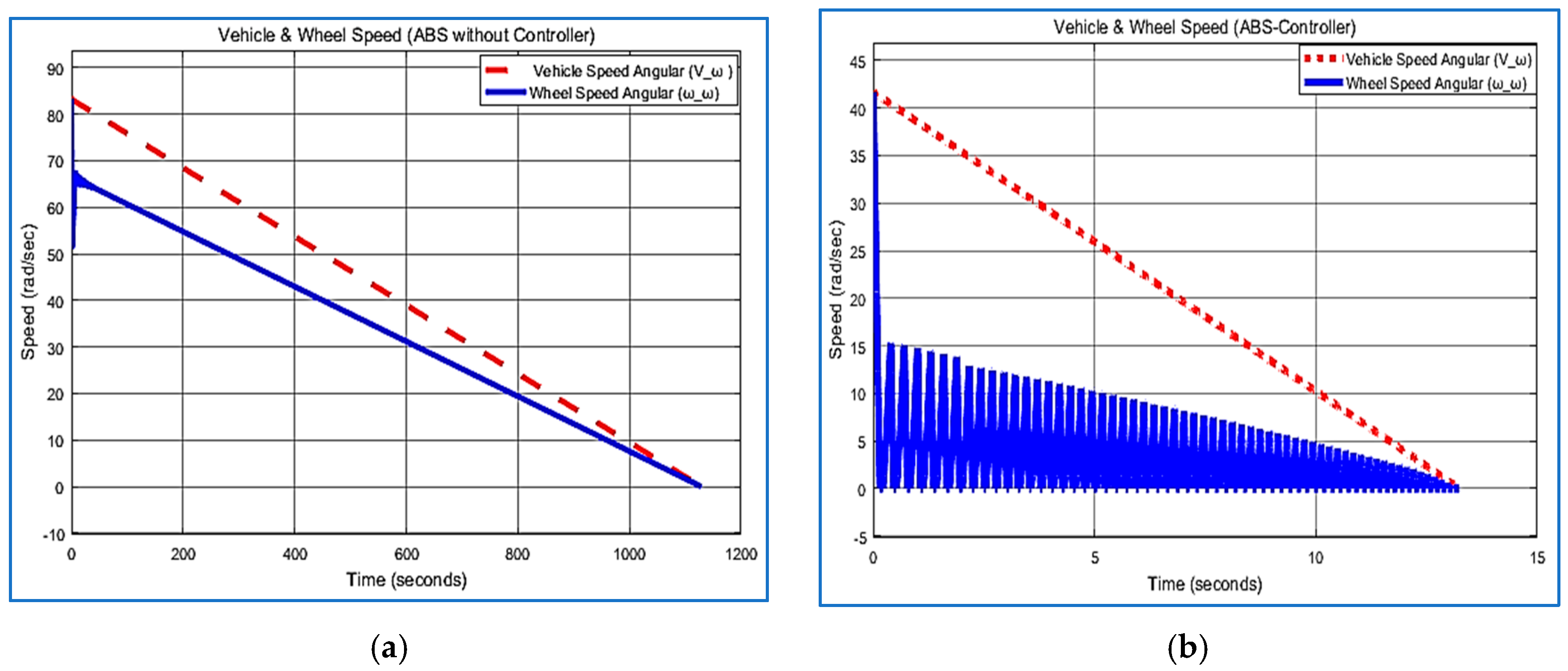

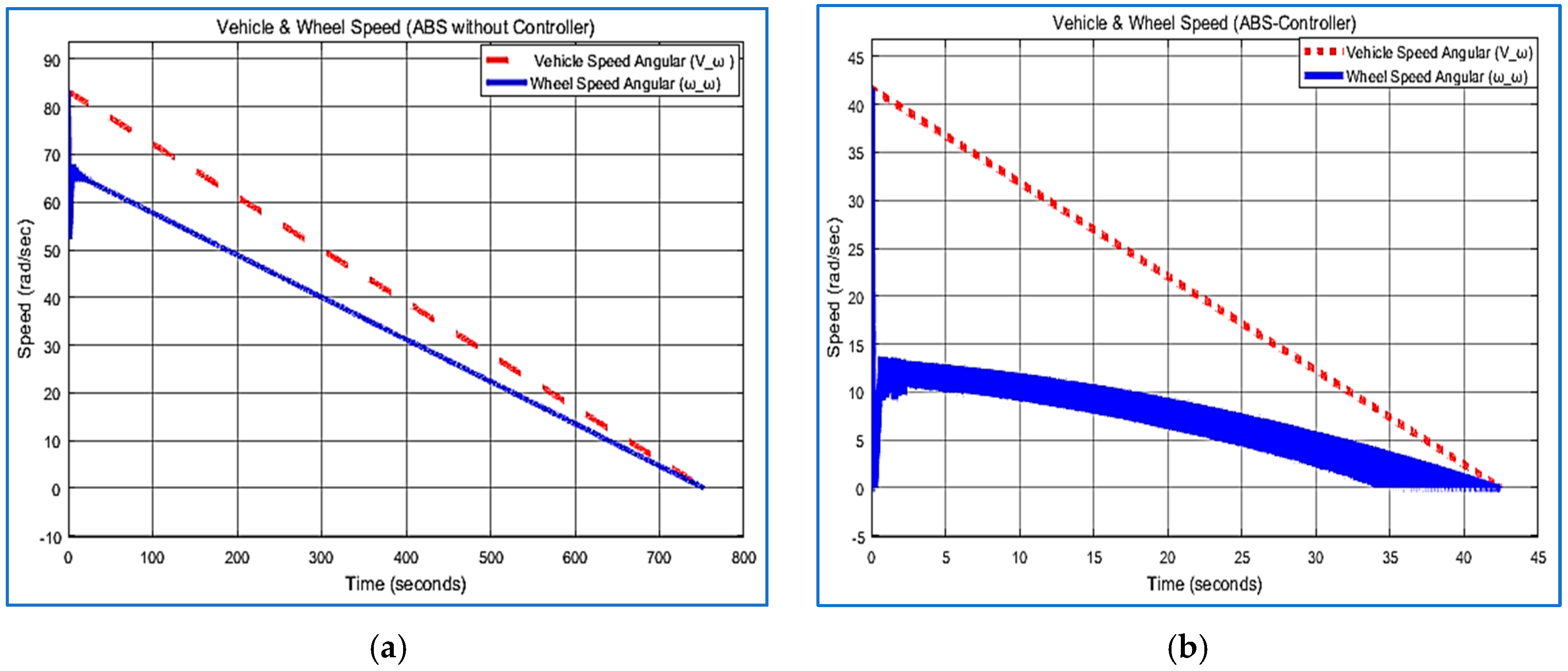

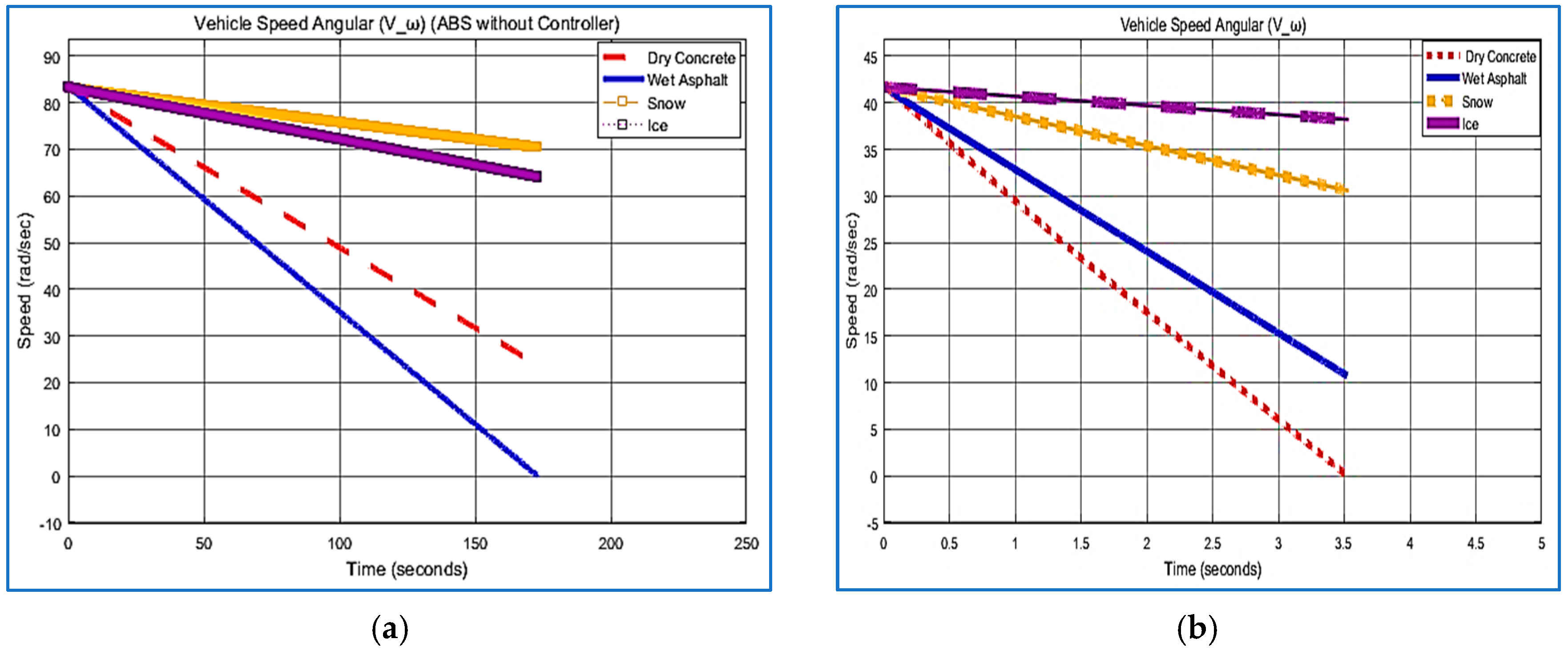

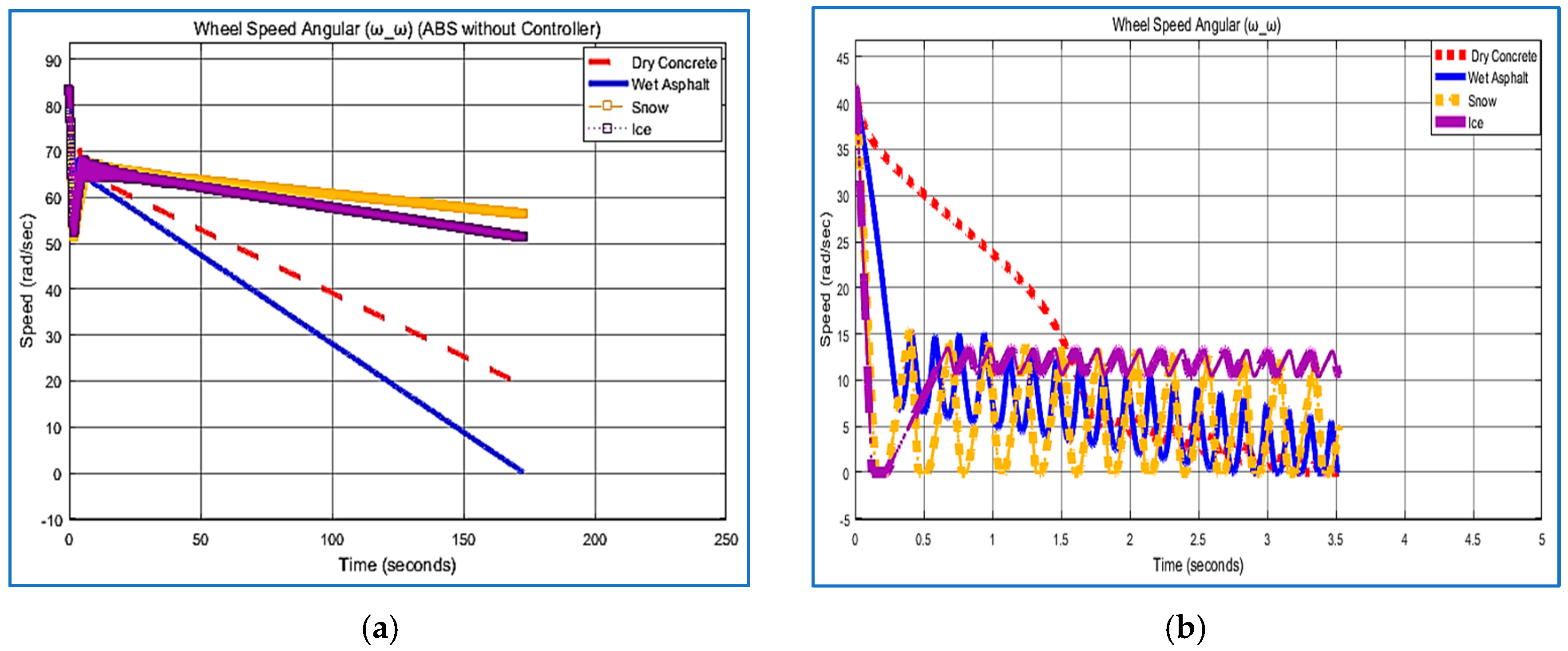

5.2. Vehicle and Wheel Speed

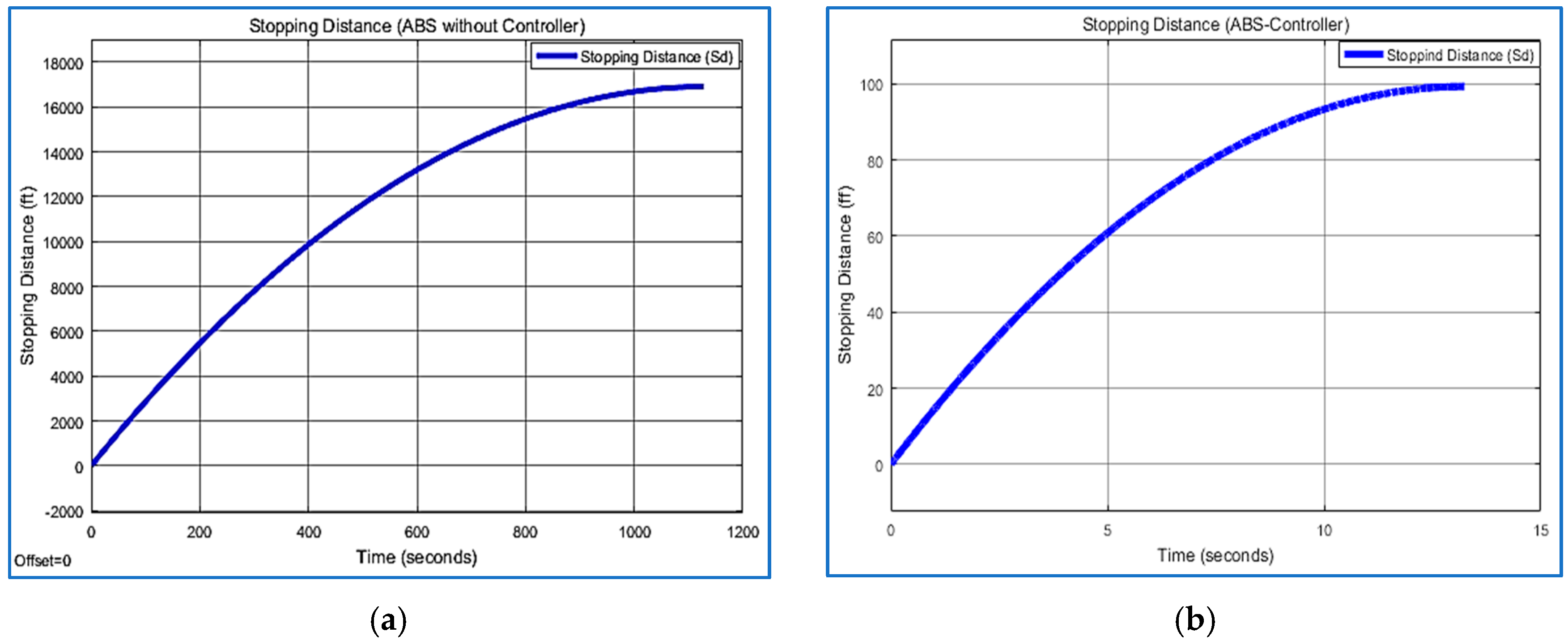

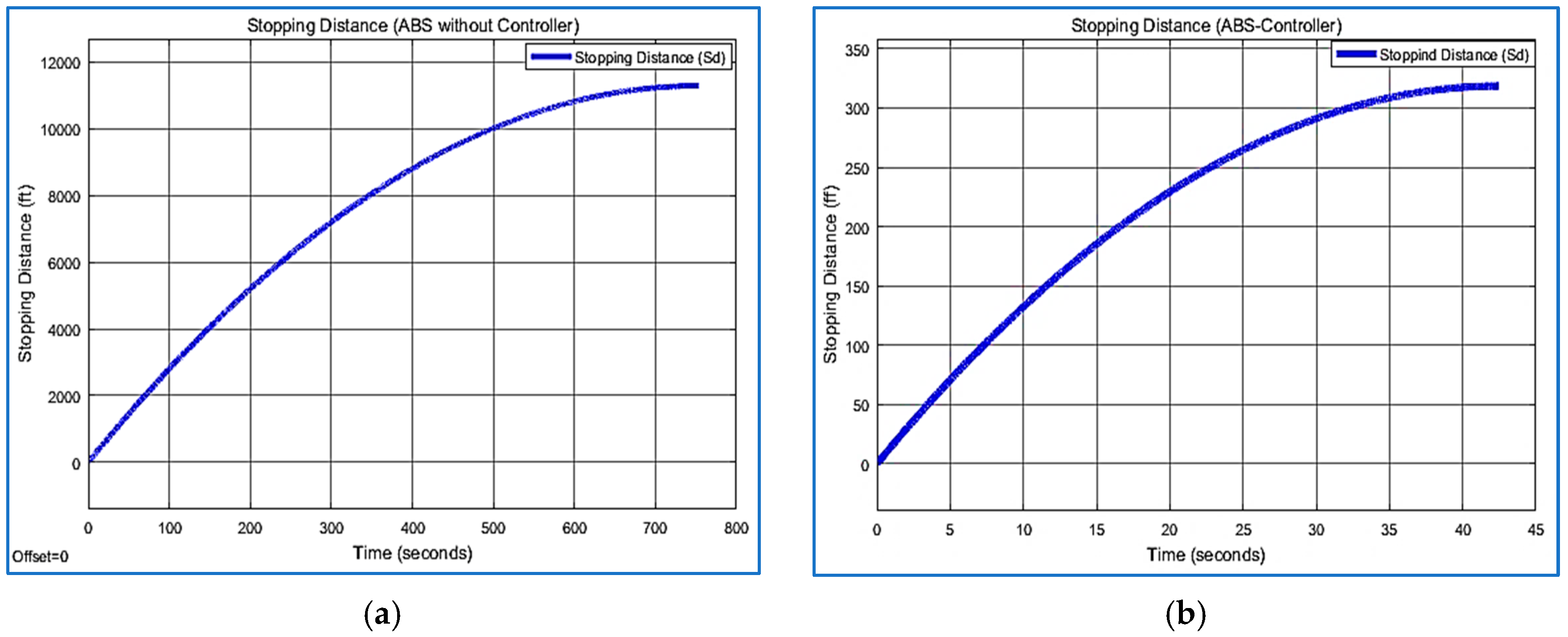

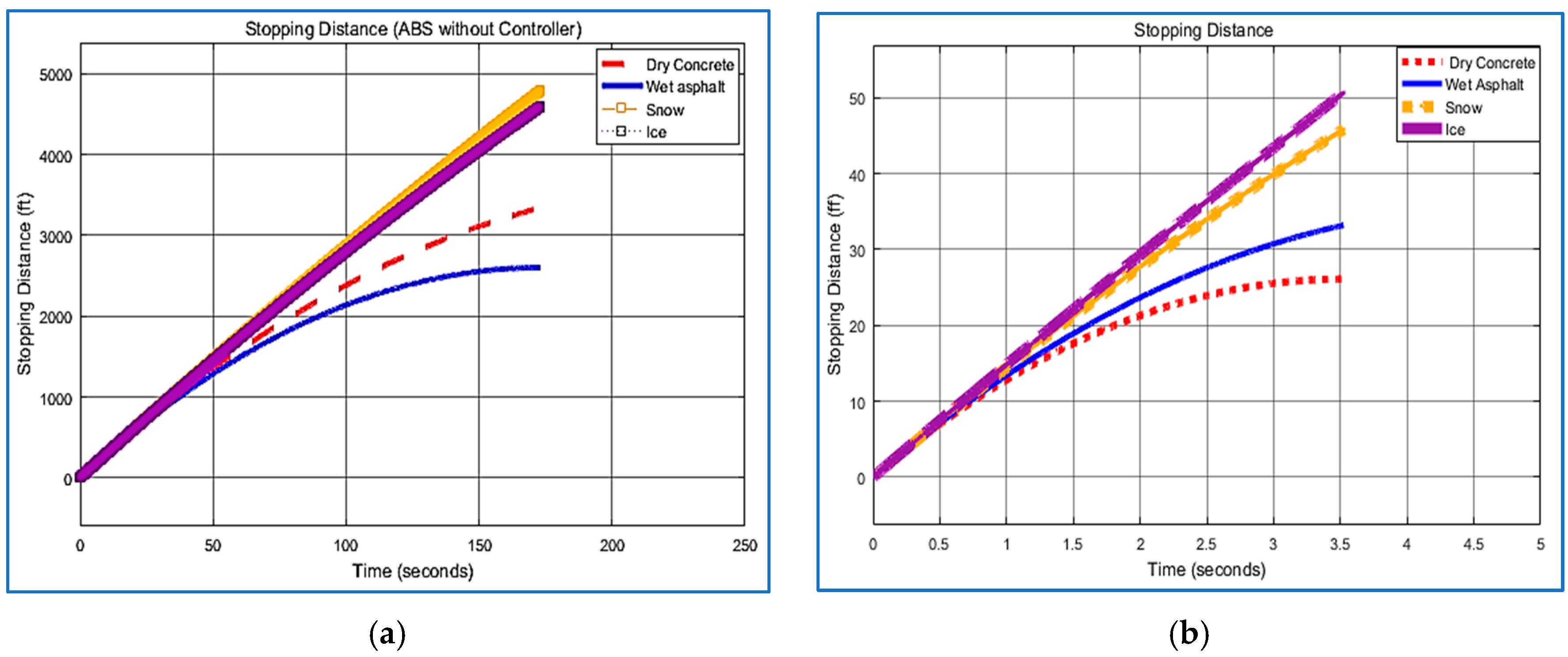

5.3. Stopping Distance

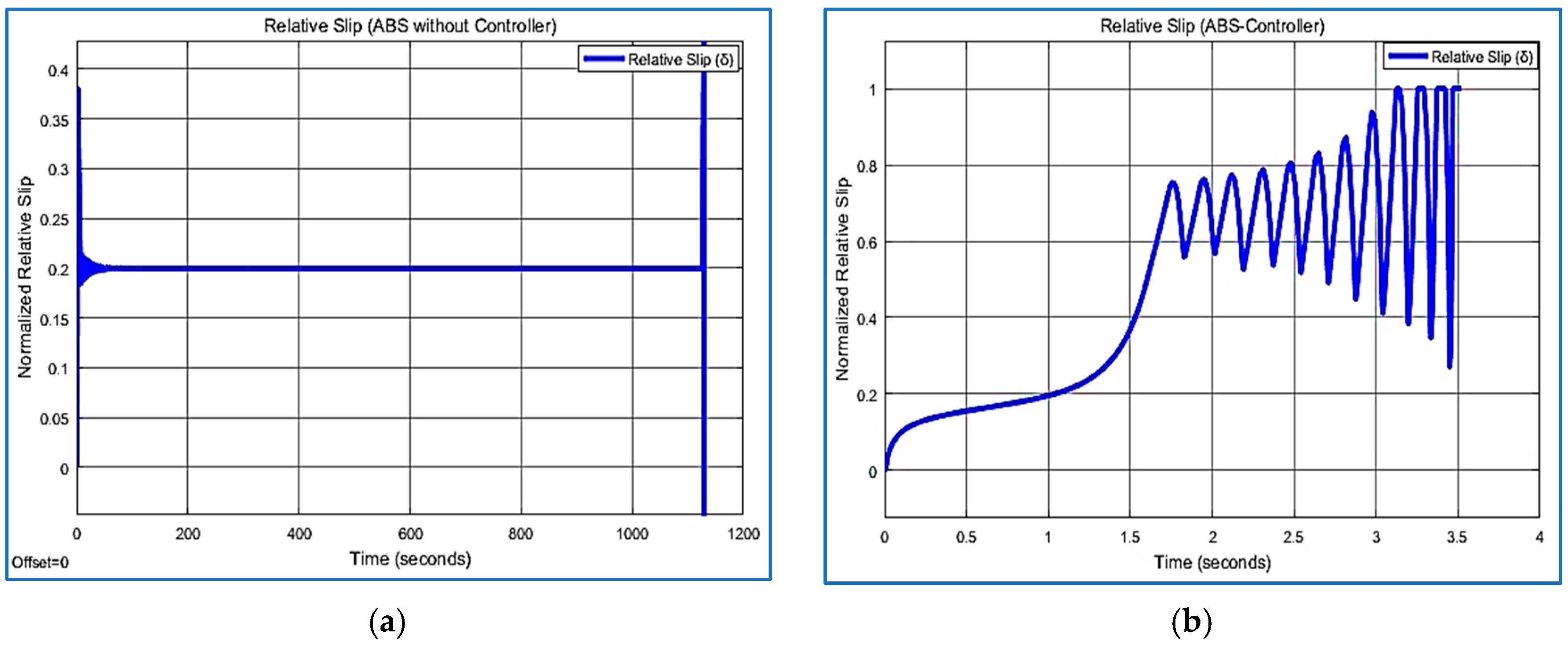

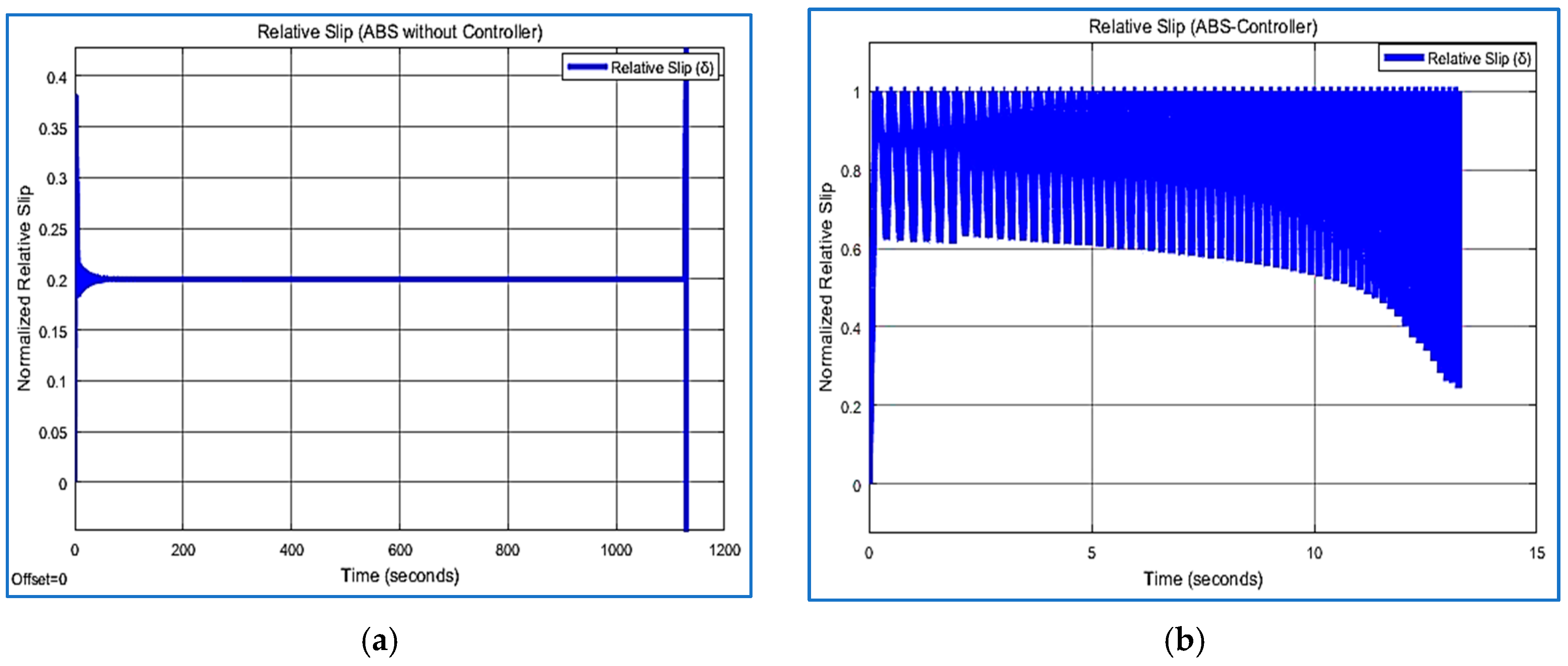

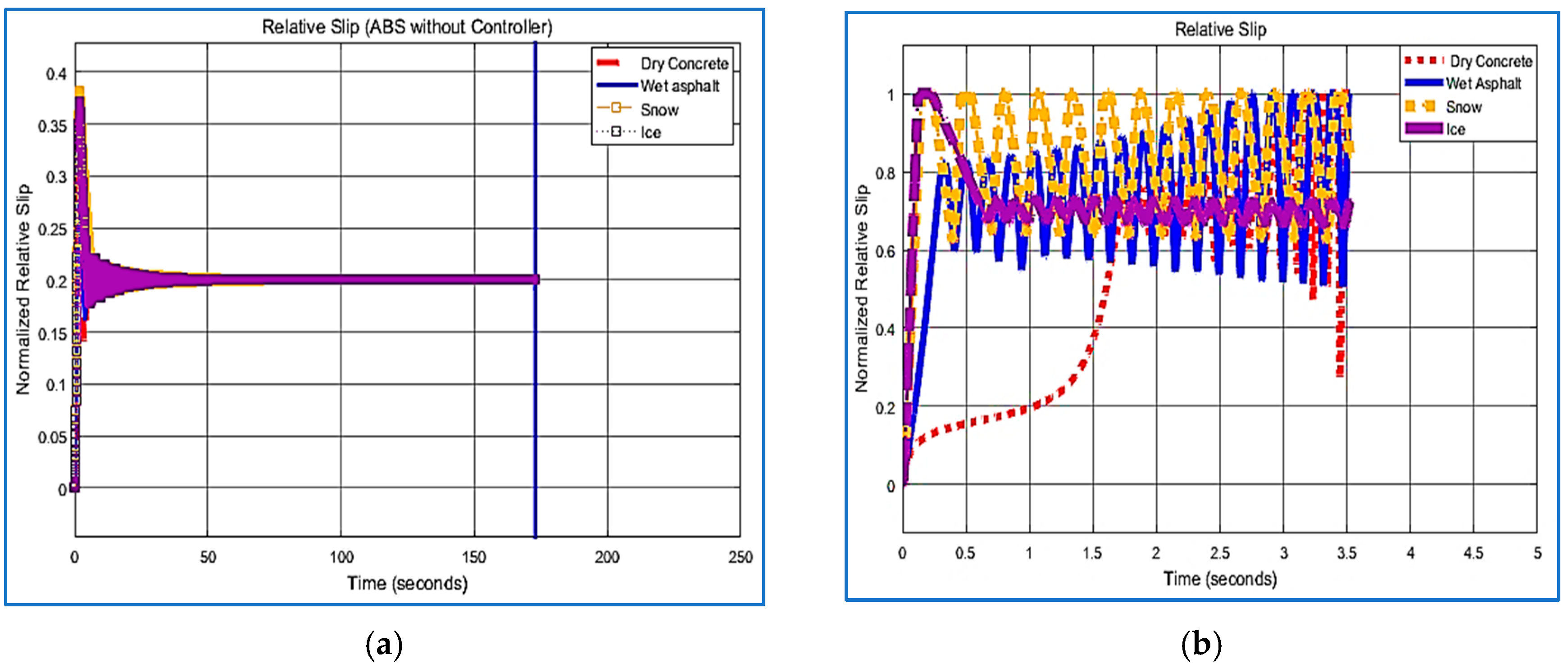

5.4. Relative Slip

5.5. Limitations and Future Work

6. Discussion of Results

6.1. Advanced Braking Systems

6.2. FMCW Technique with ABS

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Z.; Rother, C.; Chen, J. Event-Triggered Model Predictive Control for Autonomous Vehicle Path Tracking: Validation Using CARLA Simulator. IEEE Trans. Intell. Veh. 2023, 8, 3547–3555. [Google Scholar] [CrossRef]

- Zhu, Z.; Pivaro, N.; Gupta, S.; Gupta, A.; Canova, M. Safe Model-Based Off-Policy Reinforcement Learning for Eco-Driving in Connected and Automated Hybrid Electric Vehicles. IEEE Trans. Intell. Veh. 2022, 7, 387–398. [Google Scholar] [CrossRef]

- Wu, T.; Li, J.; Qin, X. Braking performance oriented multi–objective optimal design of electro–mechanical brake parameters. PLoS ONE 2021, 16, e0251714. [Google Scholar] [CrossRef] [PubMed]

- Cao, D.; Wang, X.; Li, L.; Lv, C.; Na, X.; Xing, Y.; Li, X.; Li, Y.; Chen, Y.; Wang, F. Future Directions of Intelligent Vehicles: Potentials, Possibilities, and Perspectives. IEEE Trans. Intell. Veh. 2022, 7, 7–10. [Google Scholar] [CrossRef]

- Gao, F.; Han, Y.; Li, S.E.; Xu, S.; Dang, D. Accurate Pseudospectral Optimization of Nonlinear Model Predictive Control for High-Performance Motion Planning. IEEE Trans. Intell. Veh. 2023, 8, 1034–1045. [Google Scholar] [CrossRef]

- Moloto, R.; Nyandoro, O.T.C. Review of Wheel Slip Control Design Strategies for Vehicular Anti-Lock Braking Systems; University of the Witwatersrand: Johannesburg, South Africa, 2024; Available online: https://www.researchgate.net/publication/382495607_Review_of_Wheel_Slip_Control_Design_Strategies_for_Vehicular_Anti-Lock_Braking_Systems (accessed on 10 July 2025).

- El-Bakkouri, J.; Ouadi, H.; Giri, F.; Khafallah, M.; Gheouany, S.; El Bakali, S. Extremum Seeking Based Braking Torque Distribution for Electric Vehicles’ Hybrid Anti-Lock Braking System. IFAC-PapersOnLine 2023, 56, 2546–2551. [Google Scholar] [CrossRef]

- Pérez, J.; Alcázar, M.; Sánchez, I.; Cabrera, J.A.; Nybacka, M.; Castillo, J.J. On-line learning applied to spiking neural network for antilock braking systems. Neurocomputing 2023, 559, 126784. [Google Scholar] [CrossRef]

- Chen, H.C.; Wisnujati, A.; Widodo, A.M.; Song, Y.L.; Lung, C.W. Antilock Braking System (ABS) Based Control Type Regulator Implemented by Neural Network in Various Road Conditions; Springer International Publishing: Cham, Switzerland, 2022; Volume 313. [Google Scholar] [CrossRef]

- Al-Mola, M.H.A.; Mailah, M.; Salim, M.A. Applying Active Force Control with Fuzzy Self-Tuning PID to Improve the Performance of an Antilock Braking System. Int. J. Nanoelectron. Mater. 2021, 14, 489–502. [Google Scholar]

- Haris, I.; Ahmad, F.; Hassan, M.H.C.; Yamin, A.K.M.; Nuri, N.R.M. Self Tuning PID Control of Antilock Braking System using Electronic Wedge Brake. Int. J. Automot. Mech. Eng. 2021, 18, 9333–9348. [Google Scholar] [CrossRef]

- Reitz, P.; Künzle, C. Evaluation of the Interference Performance of FMCW Radar Sensors in Dense Indoor Environments. IEEE Access 2024, 12, 46834–46850. [Google Scholar] [CrossRef]

- Guo, M.; Zhao, D.; Wu, Q.; Wu, J.; Li, D.; Zhang, P. An Integrated Real-Time FMCW Radar Baseband Processor in 40-nm CMOS. IEEE Access 2023, 11, 36041–36051. [Google Scholar] [CrossRef]

- Wang, L.; Ni, Z.; Huang, B. Extraction and Validation of Biomechanical Gait Parameters with Contactless FMCW Radar. Sensors 2024, 24, 4184. [Google Scholar] [CrossRef] [PubMed]

- Quan, V.H.; Ngoc, N.A.; Van Quynh, L.; Khoa, N.X.; Tien, N.M. Modelling and Simulation of Automatic Brake System of Vehicle. ARPN J. Eng. Appl. Sci. 2023, 18, 874–880. [Google Scholar] [CrossRef]

- Sadeghi, E.; Skurule, K.; Chiumento, A.; Havinga, P. mm-Wave FMCW Radar Vital Sign Monitoring Dataset: Diverse Physiological Scenarios. 4TU.ResearchData, Version 2. 2024. Available online: https://data.4tu.nl/datasets/48acba04-96bc-4131-b52f-9e18458ad92b (accessed on 10 July 2025).

- Rao, R.M.; Kachroo, A.; Manjunatha, K.A.; Hsu, M.; Kumar, R. Sub-Resolution mmWave FMCW radar-based touch localization using deep learning. In Proceedings of the 2024 IEEE 100th Vehicular Technology Conference (VTC2024-Fall), Washington, DC, USA, 7–10 October 2024; pp. 1–7. [Google Scholar]

- Gatti, R.V.; Cicioni, G.; Spigarelli, A.; Orecchini, G.; Saltalippi, C. A Dual-Mode FMCW-Doppler Radar with a Frequency Scanning Antenna for River Imaging Applications. IEEE Access 2024, 12, 86132–86143. [Google Scholar] [CrossRef]

- Razavi, N.; Sierpinski, G. An attempt to determine the impact of the implementation of autonomous vehicles on a larger scale on the planning of city transport systems. J. Sustain. Dev. Transp. Logist. 2024, 9, 96–120. [Google Scholar] [CrossRef]

- El-bakkouri, J.; Ouadi, H.; Giri, F.; Saad, A. Optimal control for anti-lock braking system: Output feedback adaptive controller design and processor in the loop validation test, Proceedings of the Institution of Mechanical Engineers. Part D J. Automob. Eng. 2023, 237, 3465–3477. [Google Scholar] [CrossRef]

- Unguritu, M.G.; Nichiţelea, T.C. Design and Assessment of an Anti-lock Braking System Controller. Rom. J. Inf. Sci. Technol. 2023, 26, 21–32. [Google Scholar] [CrossRef]

- Qasem, G.A.A.; Abdullah, M.F. Anti-Lock Braking Systems: A Comparative Study of Control Strategies and Their Impact on Vehicle Safety. Int. Res. J. Innov. Eng. Technol. 2024, 8, 809016. [Google Scholar] [CrossRef]

- Anti-Lock Braking System (ABS) Modeling and Simulation (Xcos). x-engineer.org. 22 May 2024. Available online: https://x-engineer.org/anti-lock-braking-system-abs-modeling-simulation-xcos/ (accessed on 10 July 2025).

- Chotikunnan, P.; Pititheeraphab, Y.; Thani, P.; Author, C.; Ziegler, A. Adaptive P Control and Adaptive Fuzzy Logic Controller with Expert System Implementation for Robotic Manipulator Application. J. Robot. Control 2023, 4, 217–226. [Google Scholar] [CrossRef]

- Chotikunnan, P.; Chotikunnan, R.; Nirapai, A.; Wongkamhang, A. Optimizing Membership Function Tuning for Fuzzy Control of Robotic Manipulators using PID-Driven Data Techniques. J. Robot. Control 2023, 4, 128–140. [Google Scholar] [CrossRef]

- Zaway, I.; Jallouli-khlif, R.; Maalej, B. Multi-objective Fractional Order PID Controller Optimization for Kid’ s Rehabilitation Exoskeleton. Int. J. Robot. Control. Syst. 2023, 3, 32–49. [Google Scholar] [CrossRef]

- Kushwah, R.; Wadhwani, S. Speed Control of Separately Excited DC Motor Using Fuzzy Logic Controller. Int. J. Eng. Trends Technol. 2013, 4, 2518–2523. [Google Scholar]

- Lindsay, M.; Emimal, M. Fuzzy logic-based approach for optimal allocation ofdistributed generation in a restructured power system Fuzzy logic-based approach for optimal allocation of distributed generation in a restructured power system. Int. J. Appl. Power Eng. 2024, 13, 123–129. [Google Scholar] [CrossRef]

- Mi, Y.; Zhang, H.; Member, S.; Fu, Y.; Wang, C. Intelligent Power Sharing of DC Isolated Microgrid Based on Fuzzy Sliding Mode Droop Control. IEEE Trans. Smart Grid 2019, 10, 2396–2406. [Google Scholar] [CrossRef]

- Sree, V.S.; Rao, C.S. Distributed power flow controller based on fuzzy-logic controller for solar-wind energy hybrid system. Int. J. Power Electron. Drive Syst. 2022, 13, 2148–2158. [Google Scholar] [CrossRef]

- Eser, D.; Member, S.; Demİr, Ş. A Compound ECCM Technique for FMCW Radars. IEEE Access 2023, 11, 62942–62954. [Google Scholar] [CrossRef]

- Tong, Z.; Reuter, R.; Fujimoto, M. Fast chirp FMCW radar in automotive applications. In Proceedings of the IET International Radar Conference 2015, Hangzhou, China, 14–16 October 2015; pp. 1–4. [Google Scholar]

- Xu, L.; Sun, S.; Mishra, K.V.; Zhang, Y.D. Automotive FMCW Radar With Difference Co-Chirps. IEEE Trans. Aerosp. Electron. Syst. 2023, 59, 8145–8165. [Google Scholar] [CrossRef]

- Gao, X.; Roy, S.; Xing, G.; Jin, S. Perception through 2d-mimo fmcw automotive radar under adverse weather. In Proceedings of the 2021 IEEE International Conference on Autonomous Systems (ICAS), Montreal, QC, Canada, 11–13 August 2021; pp. 1–5. [Google Scholar]

- Zhou, Y.; Cao, R.; Zhang, A.; Li, P. An Interference Mitigation Method for FMCW Radar Based on Time–Frequency Distribution and Dual-Domain Fusion Filtering. Sensors 2024, 24, 3288. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, S.; Sharma, A.; Khichar, S.; Meng, Y.; Malhotra, J. Enhancing autonomous vehicle navigation using SVM-based multi-target detection with photonic radar in complex traffic scenarios. Sci. Rep. 2024, 14, 17339. [Google Scholar] [CrossRef] [PubMed]

| Coefficients | A | B | C | D | |

|---|---|---|---|---|---|

| Types of Roads | |||||

| Dry concrete | 0.9 | 1.07 | 0.2723 | 0.0026 | |

| Wet asphalt | 0.7 | 1.07 | 0.5 | 0.003 | |

| Snow | 0.3 | 1.07 | 0.1773 | 0.006 | |

| Ice | 0.1 | 1.07 | 0.83 | 0.007 | |

| Symbol | Value | Description |

|---|---|---|

| 1200 [kg] | Total vehicle mass | |

| 5 [kg·m2] | Wheel inertia | |

| 0.36 [m] | Wheel radius | |

| 30 [m/s] | Initial vehicle speed | |

| F | [N] | Normal force (weight) |

| [rad/s] | Wheel speed angular | |

| g | 9.81 [m/s2] | Gravitational acceleration |

| 1 [-] | Force and Torque | |

| 2000 [N·m] | Maximum braking torque applied to the wheels | |

| TB | 0.01 [s] | Hydraulic Lag |

| 0.2 [-] | Desired slip | |

| Ctrl | 1 or 0 | With ABS and Without ABS |

| K | 1200 | Proportional gain |

| A, B, C, and D | - | The constants which depend on road conditions |

| Road type | 1, 2… N | Constant for road setting |

| e | 2.2204 × 10−16 | Division by zero protection constant |

| Velocity-c | DL | DS | C | IS | IL | |

|---|---|---|---|---|---|---|

| Velocity | ||||||

| L | No | No | No | No | L | |

| Me | No | L | Me | Me | Me | |

| H | Me | Me | H | Me | Me | |

| VH | H | Max | Max | H | H | |

| Max | Max | Max | Max | H | H | |

| Road Type | Dry Concrete | Wet Asphalt | Snow | Ice | |

|---|---|---|---|---|---|

| Cases | |||||

| Stopping Time (s) with ABS-Controller | 3.522 | 4.743 | 13.240 | 42.442 | |

| Stopping Distance with ABS-Controller (ft) | 26.12 | 35.55 | 99.35 | 318.51 | |

| Stopping Distance with ABS-Controller (m) | 7.96 | 10.33 | 30.28 | 97.08 | |

| Stopping Time (s) without ABS-Controller | 242.106 | 172.979 | 1128.494 | 753.033 | |

| Stopping Distance without ABS-Controller (ft) | 3635 | 2600 | 16,900 | 11,280 | |

| Stopping Distance without ABS-Controller (m) | 1107.95 | 792.48 | 4876.80 | 3438.14 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdullah, M.F.; Qasem, G.A.; Farid, M. An Enhanced ABS Braking Control System with Autonomous Vehicle Stopping. World Electr. Veh. J. 2025, 16, 400. https://doi.org/10.3390/wevj16070400

Abdullah MF, Qasem GA, Farid M. An Enhanced ABS Braking Control System with Autonomous Vehicle Stopping. World Electric Vehicle Journal. 2025; 16(7):400. https://doi.org/10.3390/wevj16070400

Chicago/Turabian StyleAbdullah, Mohammed Fadhl, Gehad Ali Qasem, and Mazen Farid. 2025. "An Enhanced ABS Braking Control System with Autonomous Vehicle Stopping" World Electric Vehicle Journal 16, no. 7: 400. https://doi.org/10.3390/wevj16070400

APA StyleAbdullah, M. F., Qasem, G. A., & Farid, M. (2025). An Enhanced ABS Braking Control System with Autonomous Vehicle Stopping. World Electric Vehicle Journal, 16(7), 400. https://doi.org/10.3390/wevj16070400