Abstract

In this paper, a detailed review of electric vehicle (EV) charging station architectures is first presented, and then an optimal architecture suitable for a large MW-scale EV fast-charging station (EVFS) with multiple fast chargers is proposed and evaluated. The study examines various EVFS architectures, including those currently deployed in commercial sites. Most EVFS implementations use either a common AC-bus or a common DC-bus configuration, with DC-bus architectures being slightly more predominant. The paper analyzes the EV charging and battery energy storage system (BESS) requirements for future large-scale EVFSs and identifies key implementation challenges associated with the full adoption of the common DC-bus approach. To overcome these limitations, a novel multi-zone EVFS architecture is proposed that employs an optimal combination of isolated and non-isolated DC-DC converter topologies while maintaining galvanic isolation for EVs. The system efficiency and total power converter capacity requirements of the proposed architecture are evaluated and compared with those of other EVFS models. A major feature of the proposed design is its multi-zone division and zonal isolation capabilities, which are not present in conventional EVFS architectures. These advantages are demonstrated through a scaled-up model consisting of 156 EV fast chargers. The analysis highlights the superior performance of the proposed multi-zone EVFS architecture in terms of efficiency, total power converter requirements, fault tolerance, and reduced grid impacts, making it the best solution for reliable and scalable MW-scale commercial EVFS systems of the future.

1. Introduction

For large-scale adoption of electric vehicles, it is critical to have large-scale EV charging infrastructure with fast-charging capability. Faster charging at powers of 150–350 kW is already commercially available, and researchers are working toward an ambitious DOE goal, which is to charge EVs in 15 min or less [1]. There are over 100,000 public charging outlets available across the USA [1]. Companies are developing more high-power (>300 kW) fast chargers, even up to 1 MW with higher voltage [2]. For a given high charging power level (>300 kW), a higher charging voltage of 800 V and above will reduce the charging current. Hence, more charging power can be achieved by the same charging ports without overheating the charging cables and their associated hardware. As of fall 2024, Tesla had more than 27,000 individual Superchargers in the United States, and it has over 55,000 Global Superchargers with over 6500 Supercharger stations that can recharge up to 200 miles in 15 min [2]. Electrify America announced that it now has over 600 charging stations in operation in the US, and it is planning new locations in the US [3]. The company now has 2600 fast chargers at those 600 stations. Those chargers can charge at power levels of up to 150 kW (metro stations) and 350 kW. Automobile manufacturers are launching long-distance battery-powered vehicles worldwide that can recharge a range of 500 km in 10 to 15 min (charging like refueling) [4].

According to recent trends in EV charging technology, a 1 MW ultra-fast flash charger has achieved a driving range of 250 miles in just 5 min [5], which brings EV charging time close to internal-combustion-engine-based vehicle (ICV) refueling time. In sync with the charging power levels, the individual capacities of commercial EVFSs are also increasing. Several large-scale EVFSs, such as the Mount Vernon station with 200 charging stalls [6] and the Oasis Tesla supercharging station with 168 stalls [7], have been announced in recent years. Estimates for the next decade indicate that the US requires at least 20 times more EV chargers than are currently available [8]. Therefore, EV charging service providers are making extensive efforts to meet future EV power demands [1,2,3].

Despite this progress, the internal electrical architecture used in EVFSs requires further improvement and optimization. Therefore, this paper primarily focuses on analyzing the modern requirements of EVFSs and proposing a feasible and optimal architecture suitable for implementation in a large MW-scale charging station. The EVFS architectures proposed by various researchers are reviewed and categorized into three types: common AC-bus, common DC-bus, and medium-voltage (MV) AC-bus architectures. Additionally, the architecture currently adopted in commercial EVFS sites is analyzed based on the specifications and configurations of the power converter units used at these sites.

Subsequently, this paper discusses both current and anticipated future requirements of EVFS systems and identifies optimal DC-DC converter topologies to enhance system efficiency and cost-effectiveness. To meet these needs, a new multi-zone DC network structure for grouping EV chargers is proposed for a 156-stall EVFS layout. This structure provides a highly reliable charging framework that remains operational even during zonal isolation events caused by local DC-bus faults. The proposed EVFS architecture is then compared with other configurations based on key parameters, such as structural power stage differences, estimated system efficiencies, and total power converter rating requirements. In addition, the benefits of zonal grouping and vertical interconnection DC-links are demonstrated through operational case studies of an EVFS serving 120 active EV chargers during a zonal fault. The analysis covers the impact of such faults on load sharing among AC-DC units, power flow redistribution under fault conditions, and the resulting effects on the grid. Finally, the key advantages of the proposed multi-zonal EVFS structure, which are not addressed in existing EVFS designs, are summarized.

Overall, this paper is organized as follows: Section 2 describes the details of various EVFS architecture models presented in the literature. Section 3 presents the common structure of EVFSs implemented in present-day commercial EVFS facilities. Section 4 discusses the requirements of a modern EVFS facility, considering upcoming EV models in the US market. In Section 5, a detailed explanation of the proposed EVFS architecture is presented, along with the selection of DC-DC stages and the multi-zonal structuring. Section 6 presents the evaluation of the proposed EVFS model. Section 7 concludes this paper.

2. Evolution of EVFS Architectures in the Literature

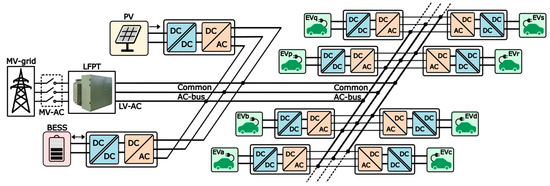

In the literature, various types of architectures have been proposed by different researchers for EVFSs. The primary classification is based on the type of common bus connection used in the EVFS architecture, which can be either an AC bus or a DC bus. In early public charging stations, a common AC-bus EVFS was developed by grouping multiple EV chargers that incorporate both AC-DC and DC-DC power stages, as shown in Figure 1. The power demand for an EVFS supporting multiple EV fast chargers is substantial, making it challenging for a low-voltage (LV) grid to handle. Consequently, large-demand EVFSs are supported by an MV-grid connection, where a grid-side low-frequency power transformer (LFPT) is required to integrate all LV-rated EV chargers with the high-voltage MV grid. The integration of additional BESSs ensures reliable charging support during peak demand hours. Early installations of commercial EVFSs and regular public charging stations are typical examples of the common AC-bus architecture. The AC-bus architecture represents the initial implementation phase in EVFS technology, termed Phase-I EVFS architecture in this paper.

Figure 1.

Traditional common AC-bus EVFS architecture.

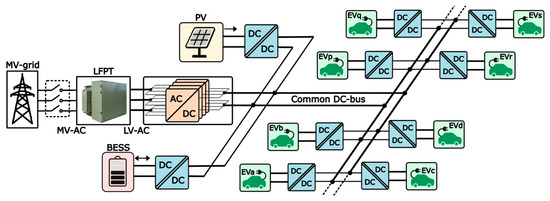

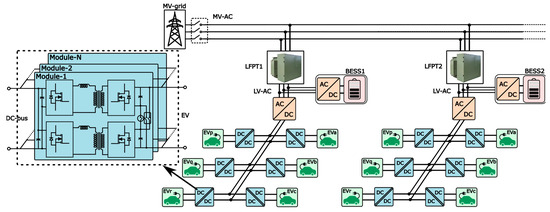

The Phase-I architecture has multiple power stages in each EV charger, which require optimization to improve the economics and efficiency of the overall EVFS. Therefore, researchers have proposed an EVFS with a common DC-bus architecture [9], as shown in Figure 2. In a DC-bus EVFS, all DC systems, such as EVs, BESSs, and PV, are connected to a common DC bus via separate DC-DC stages, and the grid connection to the common DC bus is provided through an AC-DC stage at the grid side, as shown in Figure 2. Thus, the individual AC-DC stages at each EV charger are eliminated, simplifying the overall EVFS structure. In this paper, the common DC-bus architecture is termed the Phase-II evolution of EVFSs, which is prominent in most subsequent EVFS architectures.

Figure 2.

Typical common DC-bus EVFS architecture [9], 2010.

Based on the Phase-II structure, various EVFS architectures were proposed by different authors in [10,11,12,13]. In [10], a modified DC-bus architecture replaces both the LFPT and grid-side AC-DC stage with a single solid-state transformer (SST) stage connected to the MV grid. The authors of [10] proposed SST isolation to improve the overall efficiency and power density of the EVFS. Using similar SST-based isolation, the authors of [11] proposed a common DC-bus EVFS architecture with non-isolated partial power converters (PPCs) for the DC-DC stages. These power-dense PPCs further improved the DC-DC stage efficiency and the EVFS economics. The structure of an EVFS with SST isolation and PPCs is shown in Figure 3. In this architecture, the PPCs cannot ensure isolation between EV chargers. Therefore, in practice, an additional DC protection system must be employed to mitigate the influence of the DC bus and ground faults. In contrast to the two-port DC-DC stages of [10,11], some researchers have proposed the adoption of multi-port DC-DC stages for the Phase-II EVFS structure. The authors of [12] proposed a multi-port PPC that integrates a BESS and a grid-powered DC bus with an EV through a single DC-DC topology. Similarly, the multi-port full-power converter topology proposed in [13] includes a PV integration port.

Figure 3.

Partial-power DC-DC converter EVFC [11], 2018.

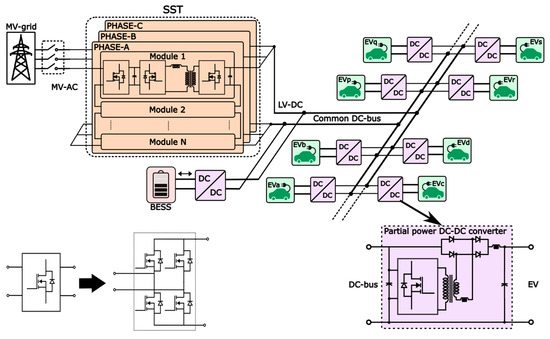

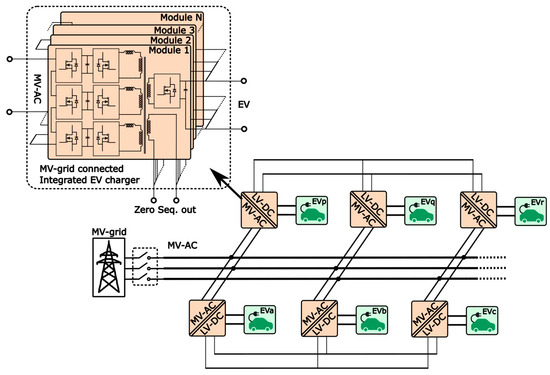

Later, several types of direct MV-grid-connected EV chargers were proposed by researchers [14,15,16,17,18,19,20]. This is termed the Phase-III evolution of EVFS architecture in this paper. Recent trends in SST technology applied to future transportation and smart grids [14] are key components for Phase-III EVFS architectures. In [15], the AC-DC isolated outputs from each of the three phases are fed to three different EV charging ports, as shown in Figure 4. However, an additional interconnection port is required for zero sequence current circulation during unbalanced loading of the three phases. A 4.2 kV MV-grid EVFS architecture is proposed in [16] using a seven-level inverter and series-connected isolated DC-DC converters to obtain LV for EV charging, which resembles the dual active bridge (DAB) SST architecture. To further enhance the SST design, the DAB DC-DC stages are replaced by quad active bridges (QABs), and their corresponding merits are presented in [17]. Different types of SST architectures applied to EVFSs are compared in [18]. The MW-scale MV-connected heavy-duty EV charger in [19] used a cascaded H-bridge (CHB) and DAB-like SST isolation, but the PV, BESSs, and EVs are interconnected by additional DABs to a 2 kV common DC bus. In the MV EVFS architecture in [20], a multi-port charger design is proposed, where a BESS is integrated between the CHB (AC-DC) and the isolated DC-DC.

Figure 4.

MV-grid-connected EV charger architecture [15], 2021.

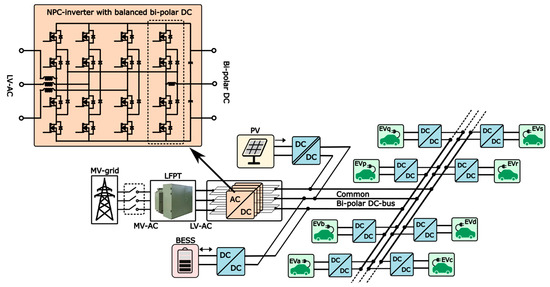

In contrast to the unipolar common DC-bus EVFS discussed previously, a bipolar DC-bus architecture is proposed in [21]. A typical bipolar EVFS architecture is shown in Figure 5, where an NPC converter is used to produce bipolar DC. EV chargers are evenly distributed between the two DC-bus pairs. Since the random arrival of EVs and the varying total demand on each DC-bus pair can create unbalanced loading between the DC-bus pairs, a voltage-balancing system is proposed in [22,23,24]. However, this voltage-balancing requirement increases the component size and complexity for the EVFS.

Figure 5.

Common bipolar DC-bus EVFS architecture [21], 2016.

3. Architecture of Existing EVFSs with High-Power Fast Chargers

Apart from previously discussed EVFS architectures from the literature, the actual architecture used in most of the EVFS sites is traditional and has yet to be optimized. Considering the current EV market, the Tesla V4 supercharger, ChargePoint Express Plus, Electrify America hyper-fast charger, EVgo high-power charger, ABB Terra 360, and Tritium PK350 are among the high-power-rating chargers (≥350 kW). Multiple units of these high-power chargers are integrated into a common EVFS facility. Actual EVFS sites, such as Tesla Supercharging stations (Mountain View, CA) [25] and Mercedes-Benz HPC sites (Atlanta, GA), are built by integrating various power conversion units. Reviewing the structure and specifications of power equipment used in 350 kW charger EV sites, it is observed that major EV charging providers such as ChargePoint and Tesla use a typical EVFS architecture, as shown in Figure 6. The input and output specifications for the Tesla V4 stalls and Tesla power cabinets can be found in [26].

Figure 6.

Typical architecture used in present commercial EVFSs.

In Figure 6, the EV ports are powered by DC-DC converter units, which are termed charging stalls in Tesla station and power link stalls at ChargePoint stations. Inside the charger units, the DC-DC circuits are reconfigured into series and parallel combinations to achieve a wide output voltage rating (reconfiguration switches are shown on the EV side of the DC-DC stage topology in Figure 6). For example, fast charger architectures such as those of Porsche and ENERCON use a switching matrix at the output side to reconfigure the output connections [27]. Similarly, a wide charging voltage range of 150 V–920 V is achieved in the ABB Terra 360. Multiple modules of isolated power electronic building blocks (PEBBs) are integrated in parallel, forming a high-output-power-rated charging unit. These individual charging units are grouped and connected to a common DC bus powered by AC-DC converter units. In Figure 6, six charging units are grouped and connected to an AC-DC unit. The AC-DC units are then connected to the MV grid via an LFPT, as shown in Figure 6. Note that these AC-DC power units are unidirectional and are typically built from active-boost power factor correction (PFC) rectifier modules [27].

For additional energy support, the solar power required for an MW-scale EVFS with 350 kW chargers cannot be satisfied by traditional canopy solar panels. It requires a large solar farm, demanding significant space, such as the upcoming Tesla solar farm supercharging station to be constructed at Oasis. Thus, solar integration support is not feasible in all cases for a future MW-scale EVFS with over 50 EV chargers when each charger is rated for 350 kW. For the rapid adoption of 350 kW charging, BESS-supported EVFSs are practically viable at charging sites. Consequently, BESS-integrated EVFSs are the most common. For example, the Tesla supercharging stations use Tesla Megapack BESS units. These three-phase AC-terminal Tesla Megapack BESS systems [28] support high charging demand during peak load hours. Most other charging service providers also follow a similar approach for BESS support. Thus, these AC-terminal BESS units are shown integrated at the LV-side output of the grid-side LFPTs in Figure 6.

In the current EVFS architecture used by EV charging providers, the common DC-bus adoption is limited to EV charging stalls. The BESS is still integrated through multiple power conversion stages to reach EV ports, following a long path via AC-bus links. Although AC-terminal BESS units are easy to deploy, the multiple power conversion stages involved introduce considerable power and energy losses, especially in MW-scale EVFS systems with large BESS capacity. The AC-bus linking of BESSs makes the commercial EVFS power path structure resemble that of a common AC-bus architecture, which will be explained further in Section 6.2. As a result, both the performance and the total power converter rating requirements of these systems remain similar to those of the common AC-bus EVFSs, as will be demonstrated through estimated calculations in Section 6.2. To enhance both performance and cost-effectiveness, it is essential to integrate the BESS directly onto the common DC bus. Furthermore, optimizing the DC-DC stages by adopting high-efficiency topologies is necessary to maintain the overall efficiency and economic viability of EVFSs. These and other requirements for a modern, MW-scale EVFS are discussed in the following sections.

4. Requirements of a Modern MW-Scale EVFS

Every year, various new EV models are released into the US market. This section discusses the diverse charging requirements of EV batteries from a wide variety of EV models, estimating future demand on EVFS. Similarly, the BESS system requirements are reviewed, and possible aspects for system optimization are identified.

4.1. Requirements at the EV-Charging Side

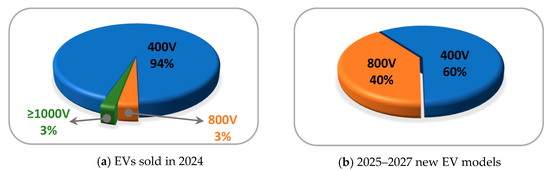

Although there is no standardized nominal battery voltage for EVs in the market from different suppliers, they can still be primarily classified into two categories: first-generation EVs with about 400 V DC architectures and second-generation EVs with about 800 V architectures. The percentage share of EVs sold in 2024 and the percentage share of the voltage levels of upcoming EV models to be released from 2025 to 2027 in the USA are shown in Figure 7 [29,30,31,32]. As shown in Figure 7b, although 400 V EVs hold a majority share among the deployed EVs, the share of 800 V EVs in upcoming new models is increasing. To achieve higher charging voltage levels of 800 V and above, isolated PEBBs are reconfigured into a series connection at the charging side, as discussed in Section 3. In fact, this series reconfiguration is a simple method that effectively maintains the efficiency of the DC-DC stage over the wide output voltage range. The requirement for a wide charging voltage range for the EV-side DC-DC stage will become mandatory for future EVFSs to meet the demands of a wide variety of EVs.

Figure 7.

EV market structure in the USA [29,30,31,32].

4.2. Requirements for BESS Integration

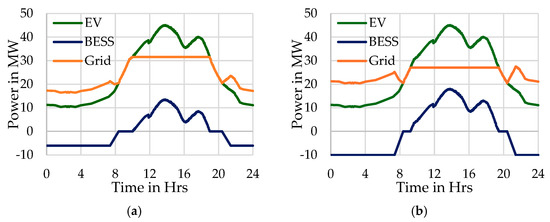

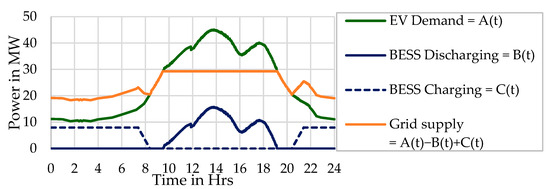

The need for BESS support in EVFSs is determined by the total charging demand, grid connection stability, and electricity price variations at the EVFS location. A BESS integrated into an EVFS is aimed at peak load shaving of the total charging station demand during peak hours to avoid penalties from the grid operators. For example, several high-traffic Tesla supercharging stations are supported by the Tesla Megapack BESS [33] for peak load support. The total BESS capacity is determined based on the daily total charging power demand trace, the probability distribution of EV arrivals at the location, and the amount of peak power demand compensation required in the EVFS. A typical weekend power demand trace from [34] is scaled up for a 50 MW EVFS, as shown in Figure 8. The net load demand on the grid corresponding to two different BESS capacities is shown in Figure 8. As shown in Figure 8, a higher BESS capacity results in greater flattening of the grid power demand near peak hours. Since BESS capacity significantly impacts the overall capital cost of an EVFS involving both the battery units and DC-DC conversion units, the total BESS size must be optimally chosen, as described in [34,35,36].

Figure 8.

Power traces for a typical EVFS integrated with BESS support: (a) with ~30% peak load shaving; (b) with ~40% peak load shaving (Note: The BESS trace is in terms of power output from the BESS).

In addition to optimizing BESS capacity, the optimization of power conversion stages between BESSs and EVs is equally important. The existing EVFS architecture discussed in Section 3 still uses AC-bus-connected BESS units due to their traditionally established industry standards practiced for BESS usage in grid support. Considering the large BESS capacity required for an MW-scale EVFS, DC-DC-stage-integrated optimal BESS systems will be in high demand in the future. Thus, existing AC-terminal BESSs must be modified into newly optimized DC-bus BESSs suitable for EVFS integration before the massive deployment of BESS units occurs across multiple EVFS facilities in the upcoming decade. This will enable a full implementation of the common DC-bus architecture in future EVFSs, improving their efficiency and cost-effectiveness.

For DC-bus integration of BESSs, a wide variety of DC-DC topologies are available in the literature. However, an optimal choice for the DC-DC stage must be determined based on the output voltage range and the isolation requirements for the BESS. Unlike the EV battery voltage, which can be in either the 400 V or 800 V group, a BESS unit has a fixed battery (typically Li-ion types) with a predefined nominal voltage rating. Since the operational voltage variation for Li-ion batteries remains within 30 percent of the maximum voltage limit [37], DC-DC for BESS integration does not require a wide output range like the EV-charging-side DC-DC stages. Moreover, in all common DC-bus EVFS architectures discussed in Section 2, galvanic isolation between the common DC bus and the grid is ensured either by an LFPT or an SST. Thus, a non-isolated power-dense DC-DC stage is a more suitable choice than a bulky isolated DC-DC topology. Therefore, an optimal choice of a non-isolated DC-DC stage is required for the integration of a BESS with an EVFS.

5. Proposed Architecture for a MW-Scale EVFS

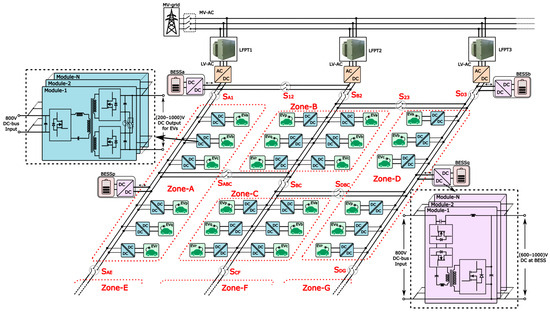

The proposed EVFS architecture is shown in Figure 9. Considering the practical implementation factors and requirements of the MW-scale EVFS discussed in Section 3 and Section 4, respectively, an optimal multi-zone common DC-bus architecture is proposed with a feasible structure suitable for large-scale EVFS facilities. Since solar integration demands significant space at an EVFS site, such special cases are excluded from the proposed model. The proposed architecture includes key aspects such as grid isolation, an optimal choice of DC-DC stages, and the structuring of an EVFS layout with a protective zonal network of EV chargers.

Figure 9.

Structure of the proposed EVFS architecture.

The total EVFS demand is supplied by multiple LFPTs connected to the incoming MV-grid feeder. Each LFPT is followed by an AC-DC stage, which is a traditional active-boost PFC unit employed in existing EVFS models, such as the power cabinets of a Tesla EVFS mentioned in Section 3. However, the DC-DC stage at the EV side is built from a compact reconfigurable isolated LLC resonant topology with a three-winding high-frequency transformer (HFT), as shown in Figure 9. The BESS is connected to the common DC bus via bidirectional CLLC resonant buck–boost PPC modules in Figure 9, which makes the BESS DC-DC stage efficient, cost-effective, and power-dense. An explanation related to the choice of LFPT and DC-DC stage topologies is provided in Section 5.1 and Section 5.2, respectively (Note: The LLC and CLLC are the resonant types in the DC-DC topology; refer to [38]).

In Figure 9, the common DC-bus voltage is mentioned along with the input- and output-side voltage ratings for DC-DC stages. Depending on the LVAC and BESS voltage ratings, an 800 V common DC-bus voltage rating is specified in the proposed EVFS architecture. The corresponding discussion related to the voltage ratings of the proposed EVFS architecture is given in Section 5.3. Additionally, the proposed EVFS architecture layout is divided into several interconnecting zones (six EV chargers per zone) using isolated DC circuit breaker switches, as shown in Figure 9. An example EVFS layout with 156 charging stalls is presented in Section 5.4. The proposed arrangement of EV chargers into charging zones helps in zonal fault isolation without disturbing the operations of adjacent charging zones. The operational advantages of this meshed network of EV chargers are demonstrated with examples in Section 6.3.

5.1. Choice of Grid Isolation and AC-DC Stages for the Proposed EVFS Architecture

To meet the high MW-scale charging demand, the EVFS facility is powered from an MV grid connection. For grid isolation from the common DC bus, some Phase-II architectures have proposed SST isolation as a power-dense option to replace the bulky LFPT. For a large EVFS site with more than 50 ultra-fast 350 kW chargers, the area occupied by the service transformer is not a constraint compared to the adoption challenges of costly SST isolation. However, SST isolation is more beneficial for high-power, small-sized EVFS facilities built within cities, where space constraints are a major concern. Thus, the proposed architecture uses LFPT isolation, which is simple and feasible for all MW-scale EVFS sites situated outside urban areas.

As mentioned previously, the proposed EVFS architecture uses regular active-boost PFC topologies, such as that in [39], similar to Tesla power cabinets in existing commercial EVFSs. On the other hand, inverter configurations, such as those in [40,41], are an efficient option for MW-scale grid support with bidirectional power flow requirements. However, the BESS capacity of an MW-scale EVFS is limited to supporting the peak shaving of high EVFS demand. Hence, the unidirectional PFC topology is a relevant choice for AC-DC stages.

5.2. Choice of Optimal Topologies for the DC-DC Stages of the Proposed EVFS Architecture

To address the wide voltage requirements of both 400 V and 800 V EVs, researchers have proposed various reconfigurable topologies [42,43,44,45,46,47,48]. The topologies of [42,43,44,45] use two separate two-winding HFTs, whereas the topologies in [46,47,48] optimize this into a single three-winding HFT circuit. For power conversion within the circuit, different operating principles are adopted in various HFT isolated DC-DC topologies. Among them, the most common types are the phase-shifted full bridge (PSFB) [47], DAB [48,49], and resonant topologies [42,43,44,45,46,50]. Typically, the unidirectional LLC resonant DC-DC has the highest efficiency due to its inherent soft-switching advantage. Therefore, the combination of a three-winding HFT with an isolated multi-mode reconfigurable LLC tank design [46] is an optimal choice for the DC-DC stage on the EV charging side. Compared to the EV-side DC-DC stage of existing EVFSs, the proposed choice of reconfiguring the DC-DC topology in Figure 9 involves the use of a single MOSFET full bridge at the primary side, making the PEBB blocks simpler and more power-dense.

On the other hand, for the DC-DC stage of the BESS, as grid isolation is ensured by the LFPT, non-isolated DC-DC topologies are a more suitable choice, as discussed in Section 4.2. Among the various non-isolated DC-DC topologies, the PPCs reviewed in [51,52] are more efficient, cost-effective, and power-dense circuits. The PPC uses a partial power-rated circuit to control the full output power of the converter, where the power rating of the PPC circuit is proportional to the difference between the input and output voltage. Therefore, by standardizing the DC-bus and BESS nominal voltage within a narrow range, the adoption of low-power-rated PPCs can be realized for an EVFS, which significantly improves the overall system efficiency and cost-effectiveness. Similarly to full-power DC-DC topologies, PPCs are also divided into buck, boost, and buck–boost types. For the 30% BESS voltage range variation mentioned in Section 4.2, the converter power rating for a buck-type PPC [53] or boost-type PPC [54] will be close to 35%, whereas buck–boost PPCs [55,56,57,58] can handle the same output within 15% to 20% of the power rating of the PPC circuit. Therefore, the proposed EVFS architecture uses a non-isolated bidirectional CLLC buck–boost PPC for the DC-DC stage at the BESS side, as shown in Figure 9.

5.3. Choice of Voltage Levels for Common DC-Bus and DC-DC Stages of the Proposed EVFS

As mentioned in Section 5.2, for the optimal adoption of PPCs, the DC-link voltage and BESS voltage range must be chosen in a close range. Considering the most widely adopted Li-ion BESS units, the typical operating voltage range for an 800 V nominal voltage battery pack is 600 V–1000 V (corresponding to the percentage voltage variation of a single Li cell [37]). Accordingly, an 800 V common DC-bus voltage is a suitable mid-point value for buck–boost PPC input. With a 480 V line voltage three-phase LV-AC input, the existing active-PFC-boost AC-DC stages can achieve a fixed 800 V supply for the common DC bus. The EV-side and BESS-side DC-DC stages are operated using this fixed 800 V DC link. Accordingly, the voltage specifications for each DC-DC stage and the common DC-bus are shown in Figure 9.

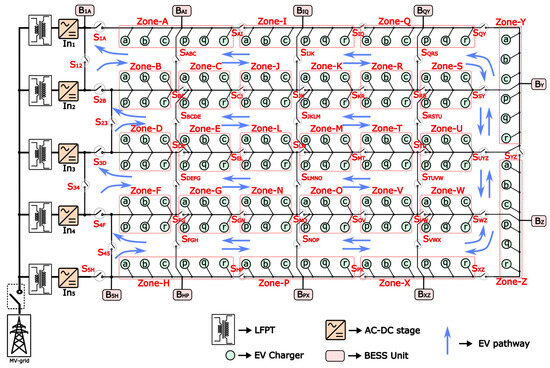

5.4. Scaled-Up EVFS Layout with 156 EV Chargers

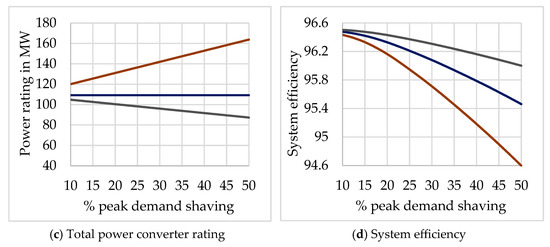

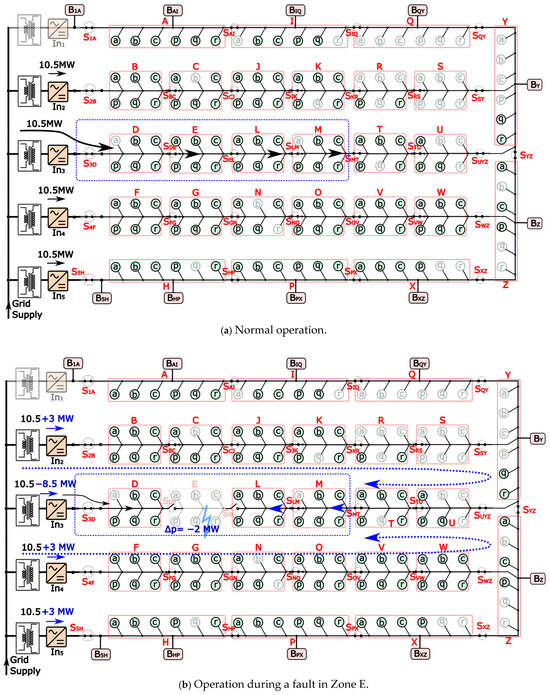

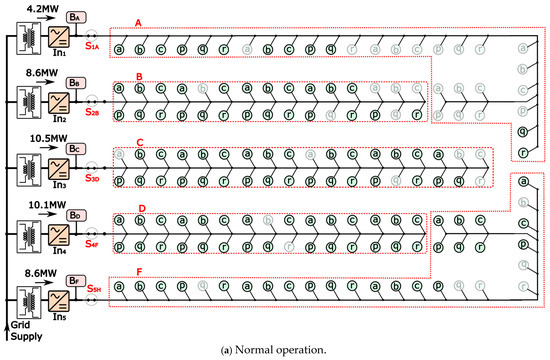

Applying the proposed EVFS structure to an MW-scale layout, an EVFS model with an interconnected mesh of 156 EV chargers divided into 26 charging zones is shown in Figure 10. Assuming a rectangular EV site area, the layout is divided into four horizontal and one vertical connecting pathway, as shown in Figure 10. The EVFS facility is powered by an MV grid through five (LFPT + AC-DC stage) units connected at five node points at the starting end of the DC network in Figure 10. For peak load support, a BESS is integrated at multiple node points along the boundary zones of the DC network, as shown in Figure 10. The BESS units placed around the boundaries maximize space for EV pathways at the actual site. In this example EVFS layout, 10 BESS units are shown for 26 zones in Figure 10. As discussed in Section 4.2, the capacity of each BESS unit can be determined based on the percentage of peak demand shaving required.

Figure 10.

EVFS layout for 156 EV chargers employing the proposed multi-zone architecture (Note: Each zone is a group of six EV-chargers named as a, b, c, p, q, and r).

To ensure reliable operation under fault conditions, each charging zone is grouped into few EV fast chargers, and each zone has isolating DC switches at both ends, as shown in Figure 10. The interconnection of EV charging zones via controllable DC switches enables isolation of the faulty zone without affecting the charging operations in other zones of the DC network. The additional arrangement of vertical cross-connector buses between the zones optimizes the power path length and improves power supply reliability for intermediate zones during fault isolation. The benefits of the multi-zonal grouping and vertical cross-connecting structure in the proposed EVFS model are demonstrated with operational examples in Section 6.3.

In Figure 9 and Figure 10, the proposed architecture incorporates an important measure in placing the vertical interconnections. The proposed DC network structure ensures that none of the cross-connectors share a common connecting node. For example, near SDE, the top-side vertical connector from SBCDE joins at Zone E, and the bottom-side vertical connector from SDEFG joins at Zone D, which are on the right and left sides of SDE, respectively. If both vertical connecting buses from SBCDE and SDEFG are joined at a common node on the Zone E side, the DC-bus fault at Zone E will isolate both of the vertical buses. Thus, the critical interconnection procedure followed in the proposed architecture ensures an optimal number of bus isolations during zonal faults and minimizes overloading on corresponding parallel buses.

Considering that each EV fast charger is rated for 350 kW, grouping six EV chargers in each zone can be rated as an approximately 2 MW load group. Due to a single zonal fault, the service for a maximum of six EVs is terminated due to the faulty zonal isolation. During the zonal isolation at a DC-bus fault instance, the total change in the DC network will be limited to 2 MW, which is 5% of the designed 55 MW capacity of an EVFS with 156 EV chargers in total. The effect of this 5% demand change will have a minimal impact on the overall stability of the 55 MW DC network of the EVFS, even when operating at its full capacity. However, based on the control stability of the EVFS network, the 5% zonal size can be further optimized. Moreover, the total number of isolating DC switches and the total DC-bus cable length required are additional constraints to be considered in zonal sizing. For example, sizing each zone with eight EV fast chargers can further reduce the total count of DC switches and the vertical interconnecting DC buses, but this increases the fault disturbance size to 7% of the total capacity. However, the EVFS model in this study is considered to group six EV chargers in each zone to limit the peak fault disturbance of a single zonal isolation to 5% of the total EVFS rating.

6. Evaluation of the Proposed Multi-Zone EVFS Architecture

6.1. Structural Comparison of the Proposed EVFS Architecture

Although several novel EVFS architectures have been proposed in the literature, in practice, each architecture presents unique implementation and adoption challenges. Therefore, the proposed EVFS architecture avoids complex and costly SST isolation, as in [11,15], as well as the uncommon bipolar DC-bus practices of [21]. The proposed EVFS architecture selectively uses an isolated reconfigurable LLC and a non-isolated buck–boost CLLC-PPC for the DC-DC stages at the EV side and BESS side, respectively. The strategic placement of isolated and non-isolated DC-DC stages simplifies the architecture, making it cost-effective for commercial EVFS deployment compared to other complex DC-bus architectures. However, galvanic isolation is ensured on the EV side for the proposed EVFS architecture, which is absent in the EVFS architectures of [11,21].

The proposed architecture incorporates multi-zonal divisions and the interconnection of zones in the EVFS network, which is absent in other EVFS architectures in the literature. The zonal grouping introduced in the proposed EVFS model is essential for ensuring reliable operation and charging service for a future MW-scale EVFS facility with multiple fast chargers. The operational effectiveness of zonal grouping is significant during DC-bus faults, which is presented with an example in Section 6.3. The above-discussed key differences related to the system structure and power stages of the proposed EVFS architecture with respect to other available EVFS architectures are listed in Table 1.

Table 1.

Comparison of power stages in the proposed EVFS with other architectures.

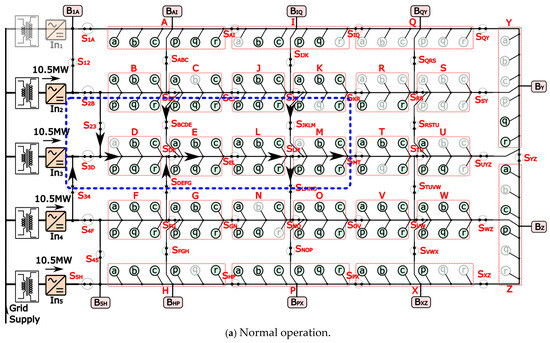

6.2. Comparison of the System Efficiency and Converter Ratings of the Proposed EVFS Architecture

To compare the system efficiency and power ratings of the proposed EVFS, three other EVFS architectures are considered: a regular common AC-bus EVFS, a common DC-bus EVFS, and an existing commercial EVFS. The complex and less common EVFS architectures discussed in [11,15,21] are excluded. The four EVFS architectures considered for the comparison are modeled to support the same 55 MW total-capacity EVFS with 156 EV fast chargers. Estimating the system efficiency requires both the full-day power traces and the approximate efficiencies of the main power converter stages involved in an EVFS.

Using Figure 8, the full-day EV demand curve (peaking near 45 MW) is reconsidered to carry out an efficiency analysis. Assuming 35% peak shaving via BESS support, the typical power traces derived for 24 h are shown in Figure 11. In this figure, EV demand, BESS discharging, and BESS charging are represented as A(t), B(t), and C(t), respectively. The net grid-supplied power, defined as A(t) − B(t) + C(t), results in a flattened curve due to BESS peak shaving, as in Figure 8. BESS recharging is scheduled during the off-peak period between 8 PM and 8 AM (lower grid pricing period). The discharging energy is calculated from the area under the B(t) curve. A flat, trapezoidal charging curve C(t) is then derived with an area equal to the discharged energy. Assuming 1-h rise and fall times for C(t), the height is adjusted to match the total charge–discharge energy. Note that the power traces in Figure 11 do not account for power conversion losses representing an ideal case.

Figure 11.

An example of power traces for EVFS with 35% peak load shaving from BESS support.

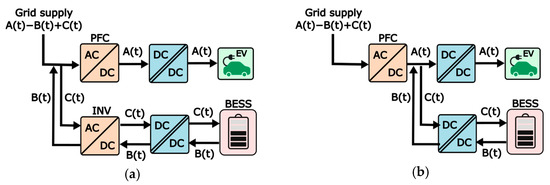

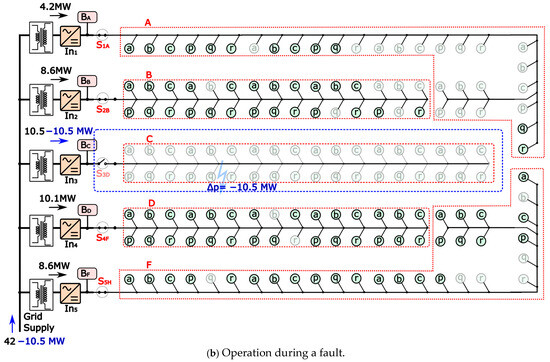

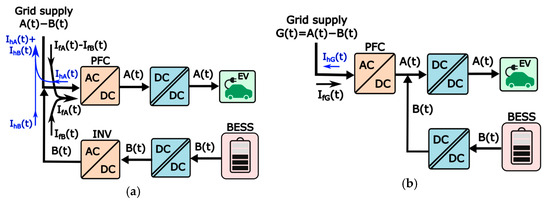

To evaluate the system efficiency for each architecture, it is necessary to identify the power conversion stages along the power flow paths, as illustrated in Figure 12. The power paths for common AC-bus and existing commercial EVFS architectures are shown in Figure 12a, while the common DC-bus and proposed EVFS architectures are shown in Figure 12b. Although the commercial EVFS has grouped DC-DC stages connected to their corresponding single AC-DC stage, the AC-bus-integrated BESS causes a basic power flow resembling a common AC-bus structure. Therefore, the power flow paths for both EVFS models are present in a common way, as shown in Figure 12a. Similarly, in Figure 12b, the power flow of the proposed model is similar to that of the common DC-bus system, except that it uses PPC DC-DC stages for BESS integration with the common DC bus.

Figure 12.

Basic power flow model with power converter stages for (a) the common AC-bus and existing commercial EVFS architectures and (b) the common DC-bus and proposed EVFS architectures.

In Figure 12a, the AC-bus-linked BESS requires PFC units rated to handle the peak value of A(t) and inverters rated for the peak value of B(t). For the example shown in Figure 11, this results in approximately 60 MW of peak power processed by all AC-DC units. In contrast, the DC-bus-integrated BESS system in Figure 12b requires only 30 MW of AC-DC conversion, as BESS peak shaving has already flattened the load on the common DC-bus side. This highlights the efficiency and size advantages of DC-bus BESS integration for an EVFS. Therefore, to reduce installation costs, existing commercial EVFS systems must adopt DC-bus BESS integration.

Using the power flow paths in Figure 12, the approximate operational efficiency of each power conversion stage is introduced for the estimation of the overall system efficiency of each EVFS architecture. Corresponding to the efficiency considerations for AC-DC stages, the reference designs of the inverter and the PFC designs from [39,40,41] demonstrated a peak efficiency of ~98.5%. On the other hand, for the full-power isolated DC-DC stages, the power converter designs from [41,44,48,49] achieved a peak efficiency of nearly 98%. In [33], the round-trip efficiency of an AC-bus-linked 2 MW BESS pack is shown to be in the range of 92% to 93.7%. Hence, an average value of 93% for the round-trip efficiency is considered for the AC-bus BESS-integrated EVFS models in Figure 12a. Moreover, the efficiency of the remaining AC-DC stages and the isolated DC-DC stages is commonly considered to be 98.5% and 98%, respectively. PPC DC-DC converters showed a efficiency range of 98.7% to 99.5% for 20% partiality by using the SUD-PPC topology in [58], but an average operational efficiency of 99% for the PPC DC-DC stage is considered for the BESS DC-DC stage in the proposed EVFS model.

Considering the example of 35% peak load shaving of the EV demand in Figure 11, the previously considered approximate power stage efficiencies are used in the power flow paths in Figure 12 for the estimation of the new power traces along with the system losses. From the obtained power traces, the 24 h energy input and output of the system are calculated, and the total system efficiency of the four selected EVFS architectures is estimated. Since the total BESS size is chosen considering 35% peak shaving for the rated 55 MW EVFS capacity, the required full-power rating for BESS-integrated power converters should be nearly 20 MW. Correspondingly, the total rating of the AC-DC and DC-DC power conversion stages required for each EVFS architecture is calculated. The full-demand power converter rating requirements of each EVFS model and the estimated system efficiencies are given in Table 2.

Table 2.

Comparison of power converter ratings and system efficiencies of the EVFS architectures.

As shown in Table 2, the proposed EVFS architecture has the highest estimated efficiency of 96.23% due to the presence of PPC stages for BESS integration in the common DC-bus structure. The existing commercial EVFS model shows a lower estimated efficiency than the regular common DC-bus architecture due to the AC-bus linking of BESS units. However, in practice, the common AC-bus architecture will have even lower system efficiency than the tabulated value when the averaged charge cycle efficiencies of two-stage EV chargers are considered, as in [56].

Corresponding to the total power converter ratings, both common AC-bus and existing EVFS models typically require the highest size of 150 MW of power conversion units for the 55 MW EVFS with an AC-bus-integrated BESS. On the other hand, the regular common DC-bus EVFS architecture requires 110 MW of power conversion units due to the reduced AC-DC sizing from the DC-bus-integrated BESS. However, by using 20% partially rated PPCs for BESS integration, the proposed EVFS model achieves the lowest total power converter rating requirement of just 94 MW to handle the same 55 MW full-capacity EVFS. This additional deduction compared to the common DC-bus EVFS is achieved by optimizing the total size of BESS DC-DC stages by using 20% PPC DC-DC in the proposed EVFS (Note: The 20% power-rated PPC converter can still handle the total 100% DC power due to the merits of its topological design [57]).

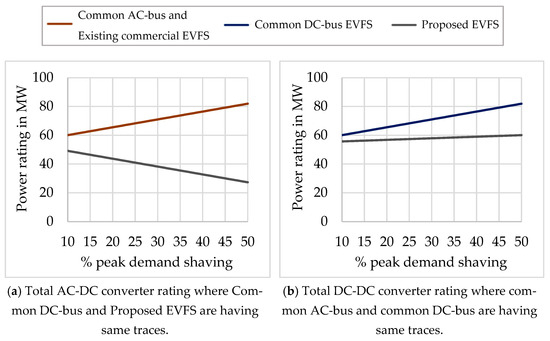

The calculations provided in Table 2 are derived from the consideration that the BESS is sized to support 35% total demand shaving. The corresponding changes in the total power converter requirements and the system efficiency by extending these estimations further by varying the peak demand shaving from 10% to 50% are shown in Figure 13. The power rating requirements of the total AC-DC and total DC-DC stages are shown in Figure 13a,b, respectively. The overall power converter requirements corresponding to each EVFS model shown in Figure 13c are the sums of the variations in Figure 13a,b.

Figure 13.

Variations in the EVFS parameters corresponding to the value of peak demand shaving.

In Figure 13c, it can be observed that the AC-DC and DC-DC power converter ratings required for both the common AC bus and the existing commercial EVFS increase along with the increase in BESS sizing corresponding to the peak load shaving requirement. However, due to the DC-bus-linked BESS power flow path, the total AC-DC power requirement for the common DC-bus EVFS decreases with an increase in the percentage of peak shaving, as shown in Figure 13a. However, this reduced AC-DC rating is compensated by the increasing DC-DC converter requirement at the BESS side, as shown in Figure 13b. As a result, the total power converter rating for the regular DC-bus EVFS remains constant at 110 MW, as shown in Figure 13c. The 110 MW rating of power converters is exactly equal to double the peak charging capacity of the considered 55 MW EVFS. In contrast to the regular DC-bus EVFS, the proposed EVFS architecture with PPC DC-DC units on the BESS side shows a small increase in the total DC-DC requirement in Figure 13b, whereas the net AC-DC rating decrease is the same as that of the common DC-bus EVFS in Figure 13a. Taking these results together, the proposed EVFS architecture retains the converter rating savings of AC-DC through the DC-bus-linked PPC-coupled BESS and collectively demonstrates a net decrease in the total power converter rating requirement with the increase in peak load shaving, as shown in Figure 13c. On the other hand, the proposed EVFS exhibits a decrease in system efficiency compared to other EVFS models with an increase in the peak demand shaving percentage, as shown in Figure 13d.

6.3. Evaluation of the Multi-Zonal Operation of the Proposed EVFS Architecture

In the proposed EVFS model, the multi-zonal division with the isolation of DC switches is incorporated to ensure fault-tolerant, reliable operation of a DC network with a large number of EV chargers, as previously mentioned in Section 5.4. Additional vertically interconnecting DC links are provided for better utilization of input-side AC-DC units and BESS units. Each aspect of the merits of multi-zonal operation is demonstrated with examples in this subsection (Note: For simplified analysis, the total EVFS load is considered to be supplied from the grid without peak shaving by the BESS for all of the cases described below).

Reconsider the vertically interconnected DC network of the 26-zone 156-stall EVFS layout modeled in Section 5.4. At an operational instant during the day, assume that the proposed EVFS model is actively powering 120 EV chargers, as shown in Figure 14, with nearly 42 MW of total charging demand on the DC network. During this instant, the system is considered to be powered by four AC-DC units, In2 to In5 on the grid side, as shown in Figure 14a. Now, assume that a fault has occurred at a common DC-bus point inside Zone E. Then, the fault-affected Zone E is isolated from the DC network using (SDE, SBCDE, SEL) switches, causing a small 2 MW (~5%) power change in the total demand on the DC network. Immediately, power flow redistribution occurs along the cross-connected DC network around Zone E, as shown in Figure 14b (power flow direction changes are marked with blue arrows) for a new charging demand at 40 MW. Since each zone is grouped with six EV chargers, the fault disturbance is limited to a 2 MW change in the total demand on the DC network. Subsequently, the corresponding voltage disturbance stays small, with minimal impact on the overall system control stability. If each zone is grouped with eight EV chargers, then the power change due to zone isolation under fault conditions will be 2.8 MW, i.e., a change of nearly 7%. Then, the EVFS system must be designed with a higher fault tolerance to withstand this impact. On the other hand, the vertically interconnecting DC links across the AC-DC stages help in dividing the total −2 MW load change between In2 to In5 as a small disturbance of −0.5 MW for each input-side unit. Additionally, the impact of the fault disturbance in Zone E shown in Figure 14b is limited to a minimal area of the DC network.

Figure 14.

Power flow redistribution around the Zone E fault area for the proposed 26-zone EVFS model with the vertically cross-connecting buses, considered for the same instant when 120 EV chargers are actively operating (Note: Black arrows indicate pre-fault power flow direction and blue arrows indicates only the power flow changes after post-fault isolation).

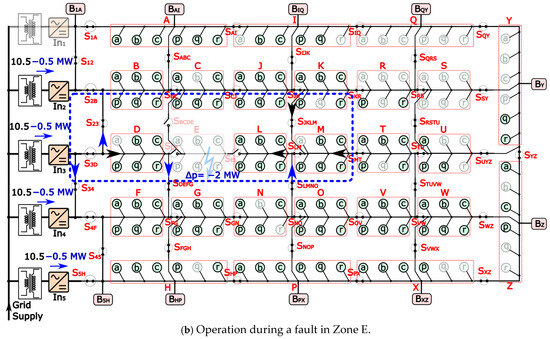

For a demonstration of the significance of vertically interconnecting DC links, the fault condition in Figure 14 is reconsidered for the 26-zone EVFS model without the vertical DC links, as shown in Figure 15. During the pre-fault condition shown in Figure 15a, the AC-DC unit In3 acts as a main source for powering Zones D to U along line 3. Now, assume that a DC-bus fault at the same location has isolated Zone E from the DC network using (SDE, SEL) switches. Although the change in the demand on the DC network is the same at 2 MW, it creates a large disturbance in the power distribution of the overall DC network, as shown in Figure 15b. The absence of interconnecting DC links near AC-DC stages limits the power supply from unit In3 to Zone D alone, resulting in a sudden power change of −8.5 MW (~80%) for In3 after the fault isolation, as shown in Figure 15b. Additionally, the isolation of In3 from the DC network imposes a +3 MW (30%) load change on the other three AC-DC units under operation, which can be seen in Figure 16b. Therefore, the interconnecting DC links across the AC-DC units are highly crucial for normalizing the fault impact on the power sharing of the AC-DC units.

Figure 15.

Power flow redistribution around the Zone E fault area for the 26-zone EVFS model without the vertically cross-connecting buses, considered for the same instant when 120 EV chargers are actively operating (Note: Black arrows indicate pre-fault power flow and blue arrows indicates only the power flow changes after post-fault isolation).

Figure 16.

Power flow redistribution with a DC-bus fault for the same 156-charger EVFS model without multi-zonal grouping and vertically interconnecting DC links, considered for the same case with 120 EV chargers as an active load (Note: Black arrows indicate pre-fault power flow and blue arrows indicates only the power flow changes after post-fault isolation).

On the other hand, the absence of vertically interconnecting DC links among the charging zones creates a long power flow path for reaching the subsequent Zones L to U along line 3, as shown in Figure 15b. Along these long paths, the redirected charging power flow for Zones L to U overloads the DC buses along lines 2 and 4, causing additional voltage disturbances on their path. Even with a minimum probability, if a subsequent DC-bus fault occurs on the other end at Zone U in the same lane, the charging service to the EVs in all of the intermediate Zones L, M, and T will be terminated. Therefore, the absence of vertical interconnections between the charging zones will not increase the fault impact area in the DC network, but it also terminates the active charging service for a greater number of zones in the event of two or more zonal faults.

To demonstrate the significance of zonal grouping, consider the same 156-charger EVFS model without multi-zonal divisions, as shown in Figure 16. Under the pre-fault conditions, each AC-DC stage is assigned to power its own charging lane, as shown in Figure 16a. Now, a single DC-bus fault on Lane C terminates the service for the entire lane of 36 charging stalls, as shown in Figure 16b. Lane C has an active pre-fault charging demand of 10.5 MW. The sudden isolation of the total 10.5 MW lane is directly reflected on the grid side, which undergoes a sudden load change of nearly ~25%, as shown in Figure 16b. Such a high MW demand change on the grid induces large voltage disturbances into the supply side unless the connected grid has a strong short-circuit ratio (i.e., a strong HV grid) at the point of coupling. Hence, the adoption of a multi-zonal DC network in the EVFS avoids the propagation of EVFS DC-bus faults into the grid side.

In summary, the merits of each aspect of the interconnected multi-zonal structure of the proposed EVFS architecture are listed in Table 3.

Table 3.

Merits of the multi-zonal structure of the proposed EVFS architecture.

According to the above-discussed examples, the proposed multi-zone structure not only sustains the DC-bus faults but also withstands voltage fluctuations in the DC network, where all of the AC-DC units collectively act to suppress sudden disturbances. Therefore, the interconnected DC-mesh network structure of the proposed EVFS architecture, with zonal divisions and an isolated DC-switch protection scheme, helps achieve a reliable charging service for a large commercial EVFS. However, the total number of charging zones and the sizing of each zone depend on the DC network’s stability and other cost factors mentioned in Section 5.4. The proposed zonal sizing can be adjusted based on the practical feasibility of the EVFS site conditions.

6.4. Grid Impacts of the Proposed Multi-Zone EVFS Architecture

Consider the power and current flows for the EVFS models shown in Figure 17 during the BESS discharging period within the peak load shaving interval. In the AC-bus-linked BESS EVFS path in Figure 17a, although the net fundamental current component on the grid side corresponds to the effective peak shaved power, the total harmonic current on the grid side is the sum of harmonics generated by both the AC-DC stages of the EV chargers and the BESS. In contrast, for the DC-bus-linked BESS EVFS shown in Figure 17b, the total harmonics induced into the grid correspond only to the peak shaved current magnitude. At the peak EV demand instant with 35% peak shaving, the total harmonics in the DC-link BESS model are approximately 50% of those in the AC-link BESS model. Therefore, the proposed EVFS model exhibits minimum grid harmonics due to its DC-linked BESS units. Furthermore, the multi-zonal structure prevents grid-side propagation of high load fluctuations caused by DC-bus faults in the EVFS, as demonstrated in Figure 16. This feature is not present in other EVFS architectures. Consequently, the proposed EVFS, which incorporates both a DC-linked BESS and a multi-zonal structure, will have minimal impact on the utility grid in terms of harmonic distortion, demand-side fault disturbances, and voltage fluctuations.

Figure 17.

Harmonic current path of AC-DC power stages during peak load shaving through BESS discharge for (a) common AC-bus and existing commercial EVFS architectures and (b) Common DC-bus and proposed EVFS architectures.

7. Conclusions

In this paper, the evolution of EVFS architectures is examined by reviewing various common bus architectures presented in the literature. Among them, the Phase-II common DC bus is found to be a prominent foundation for most modern EVFS architectures. However, in the actual practice of existing commercial EVFSs, it is observed that common DC-bus integration is limited to grouping a few EV charging stalls, and the BESS units are still integrated on the LV-AC side. Therefore, the implementation challenges and the requirements for modern EVFSs have been reassessed for the full adoption of the common DC-bus architecture in EVFSs. Subsequently, an effective multi-zone EVFS architecture is proposed to address the identified implementation challenges while meeting modern EVFS requirements. The proposed EVFS architecture features an isolated reconfigurable LLC with a three-winding HFT and non-isolated bidirectional PPC topologies as optimal choices for DC-DC stages on the EV charging side and BESS side, respectively. Moreover, the grid and EV-to-EV galvanic isolation requirements are not compromised in the proposed optimal EVFS architecture.

The proposed EVFS architecture is evaluated to compare its performance with other EVFS architectures. From calculations, it is observed that the AC-bus linking of the BESS imposes all the drawbacks of the common AC-bus architecture on the existing commercial EVFS architecture. Both the common AC bus and existing EVFS require the highest converter rating requirement, which increases with the peak shaving percentage requirement. However, the common DC bus requires a total power converter rating that is double the total charging capacity of the EVFS, irrespective of the percentage of peak shaving. In contrast to these architectures, the proposed EVFS with the optimal choice of the PPC DC-DC stage at the BESS shows a decrease in the overall power converter rating requirement for a corresponding increase in the percentage of peak shaving. Additionally, the estimated system efficiency calculations demonstrated the proposed EVFS as a superior model compared to other common EVFS architectures.

The proposed EVFS introduces zonal grouping of EV chargers, zonal fault isolations, and zonal interconnection provisions for improving the charging service reliability in accordance with MW-scale EVFS commercial models. These multi-zonal features are not present in any other EVFS architectures. In examples of the operation of a 26-zone, 156-stall, 55 MW capacity EVFS, the proposed EVFS model demonstrated reliable post-fault operation, better fault tolerance, normalized distribution of load fluctuations, and minimal demand change disturbances on the grid side. Hence, the proposed multi-zone EVFS architecture is an efficient, power-dense, and reliable structure, making it the most suitable solution for adoption in the large MW-scale commercial EVFSs of the future.

Author Contributions

Conceptualization, S.B.A.; Methodology, S.B.A. and K.R.; Validation, S.B.A. and K.R.; Formal analysis, S.B.A. and K.R.; Investigation, S.B.A.; Writing—original draft, S.B.A.; Writing—review & editing, K.R.; Supervision, K.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Available online: https://afdc.energy.gov/fuels/electricity-infrastructure-trends (accessed on 6 April 2025).

- Available online: https://insideevs.com/news/717202/tesla-supercharging-network-deployment-2024q1/ (accessed on 6 April 2025).

- Available online: https://media.electrifyamerica.com/releases/244 (accessed on 6 April 2025).

- Available online: https://economictimes.indiatimes.com/industry/renewables/500-km-range-after-15-minutes-charging-this-new-tech-may-revolutionise-ev-sector/articleshow/106014324.cms?from=mdr (accessed on 6 April 2025).

- Available online: https://www.byd.com/mea/news-list/byd-unveils-super-e-platform-with-megawatt-flash-charging (accessed on 6 April 2025).

- Available online: https://www.fox13seattle.com/news/largest-ev-charging-mount-vernon (accessed on 6 April 2025).

- Available online: https://evchargingstations.com/chargingnews/tesla-announces-a-massive-168-stall-supercharging-oasis/ (accessed on 6 April 2025).

- The EV Transition Explained: Charger Infrastructure—IEEE Spectrum. Available online: https://spectrum.ieee.org/the-ev-transition-explained-2658463735 (accessed on 6 April 2025).

- Bai, S.; Yu, D.; Lukic, S. Optimum design of an EV/PHEV charging station with DC bus and storage system. In Proceedings of the IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010; pp. 1178–1184. [Google Scholar]

- Srdic, S.; Lukic, S. Toward Extreme Fast Charging: Challenges and Opportunities in Directly Connecting to Medium-Voltage Line. IEEE Electrif. Mag. 2019, 7, 22–31. [Google Scholar] [CrossRef]

- Iyer, V.M.; Gulur, S.; Gohil, G.; Bhattacharya, S. An Approach Towards Extreme Fast Charging Station Power Delivery for Electric Vehicles with Partial Power Processing. IEEE Trans. Ind. Electron. 2020, 67, 8076–8087. [Google Scholar] [CrossRef]

- Hoffmann, F.; Person, J.; Andresen, M.; Liserre, M.; Freijedo, F.D.; Wijekoon, T. A Multiport Partial Power Processing Converter With Energy Storage Integration for EV Stationary Charging. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 7950–7962. [Google Scholar] [CrossRef]

- Chandra Mouli, G.R.; Schijffelen, J.; van den Heuvel, M.; Kardolus, M.; Bauer, P. A 10 kW Solar-Powered Bidirectional EV Charger Compatible With Chademo and COMBO. IEEE Trans. Power Electron. 2019, 34, 1082–1098. [Google Scholar] [CrossRef]

- Kolar, J.W.; Ortiz, G. Solid-state-transformers: Key components of future traction and smart grid systems. In Proceedings of the International Power Electronics Conference-ECCE Asia (IPEC 2014), Hiroshima, Japan, 18–21 May 2014; pp. 18–21. [Google Scholar]

- Nair, A.C.; Fernandes, B.G. Solid-State Transformer Based Fast Charging Station for Various Categories of Electric Vehicles with Batteries of Vastly Different Ratings. IEEE Trans. Ind. Electron. 2021, 68, 10400–10411. [Google Scholar] [CrossRef]

- Bahrami, A.; Narimani, M. A New Medium-Voltage Architecture for Ultra-Fast Electric Vehicle (EV) Charging Stations. In Proceedings of the 2023 IEEE Applied Power Electronics Conference and Exposition (APEC), Orlando, FL, USA; 2023; pp. 3111–3118. [Google Scholar] [CrossRef]

- Ferreira Costa, L.; De Carne, G.; Buticchi, G.; Liserre, M. The Smart Transformer: A solid-state transformer tailored to provide ancillary services to the distribution grid. IEEE Power Electron. Mag. 2017, 4, 56–67. [Google Scholar] [CrossRef]

- De Seram, R.; Golder, A.; Williamson, S.S. Recent Advancements in Solid State Transformer-based EV Fast Charging Stations. In Proceedings of the 2023 IEEE 14th International Conference on Power Electronics and Drive Systems (PEDS), Montreal, QC, Canada, 7–10 August 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Starke, M.; Moorthy, R.S.K.; Adib, A.; Dean, B.; Chinthavali, M.; Xiao, B.; Campbell, S. A MW scale charging architecture for supporting extreme fast charging of heavy-duty electric vehicles. In Proceedings of the 2022 IEEE Transportation Electrification Conference & Expo (ITEC), Anaheim, CA, USA, 15–17 June 2022; pp. 485–490. [Google Scholar] [CrossRef]

- Vasiladiotis, M.; Rufer, A. A Modular Multiport Power Electronic Transformer with Integrated Split Battery Energy Storage for Versatile Ultrafast EV Charging Stations. IEEE Trans. Ind. Electron. 2015, 62, 3213–3222. [Google Scholar] [CrossRef]

- Rivera, S.; Wu, B.; Kouro, S.; Yaramasu, V.; Wang, J. Electric Vehicle Charging Station Using a Neutral Point Clamped Converter with Bipolar DC Bus. IEEE Trans. Ind. Electron. 2015, 62, 1999–2009. [Google Scholar] [CrossRef]

- Tan, L.; Wu, B.; Yaramasu, V.; Rivera, S.; Guo, X. Effective Voltage Balance Control for Bipolar-DC-Bus-Fed EV Charging Station with Three-Level DC–DC Fast Charger. IEEE Trans. Ind. Electron. 2016, 63, 4031–4041. [Google Scholar] [CrossRef]

- Rivera, S.; Wu, B. Electric Vehicle Charging Station with an Energy Storage Stage for Split-DC Bus Voltage Balancing. IEEE Trans. Power Electron. 2017, 32, 2376–2386. [Google Scholar] [CrossRef]

- Pires, V.F.; Cordeiro, A.; Roncero-Clemente, C.; Rivera, S.; Dragičević, T. DC–DC Converters for Bipolar Microgrid Voltage Balancing: A Comprehensive Review of Architectures and Topologies. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 981–998. [Google Scholar] [CrossRef]

- Available online: https://teslamotorsclub.com/tmc/threads/supercharger-mountain-view-ca-1049-el-monte-ave-live-12-jul-2024-12-v4-stalls.323153/ (accessed on 6 April 2025).

- Available online: https://evchargingstations.com/chargingnews/tesla-v4-supercharger-cabinet-specs/ (accessed on 6 April 2025).

- Rivera, S.; Kouro, S.; Vazquez, S.; Goetz, S.M.; Lizana, R.; Romero-Cadaval, E. Electric Vehicle Charging Infrastructure: From Grid to Battery. IEEE Ind. Electron. Mag. 2021, 15, 37–51. [Google Scholar] [CrossRef]

- Available online: https://www.tesla.com/megapack/design (accessed on 6 April 2025).

- Available online: https://www.teslarati.com/how-many-evs-sold-us-2024-model/ (accessed on 6 April 2025).

- Available online: https://electrek.co/2025/01/14/top-10-best-selling-evs-us-2024/ (accessed on 6 April 2025).

- Available online: https://www.caranddriver.com/news/g29994375/future-electric-cars-trucks/ (accessed on 6 April 2025).

- Available online: https://cars.usnews.com/cars-trucks/advice/future-electric-cars?slide=2 (accessed on 6 April 2025).

- Available online: https://ev.com/news/tesla-rolls-out-megapackchargers-to-ease-holiday-ev-charging-surge (accessed on 6 April 2025).

- Negarestani, S.; Fotuhi-Firuzabad, M.; Rastegar, M.; Rajabi-Ghahnavieh, A. Optimal Sizing of Storage System in a Fast Charging Station for Plug-in Hybrid Electric Vehicles. IEEE Trans. Transp. Electrif. 2016, 2, 443–453. [Google Scholar] [CrossRef]

- Hussain, A.; Bui, V.-H.; Kim, H.-M. Optimal Sizing of Battery Energy Storage System in a Fast EV Charging Station Considering Power Outages. IEEE Trans. Transp. Electrif. 2020, 6, 453–463. [Google Scholar] [CrossRef]

- Li, J.; He, S.; Yang, Q.; Ma, T.; Wei, Z. Optimal Design of the EV Charging Station with Retired Battery Systems Against Charging Demand Uncertainty. IEEE Trans. Ind. Inform. 2023, 19, 3262–3273. [Google Scholar] [CrossRef]

- Theodore, A.M.; Şahin, M.E. Modeling and simulation of a series and parallel battery pack model in MATLAB/Simulink. Turk. J. Electr. Power Energy Syst. 2024, 4, 2–12. [Google Scholar]

- Available online: https://www.ti.com/lit/an/slla497/slla497.pdf?ts=1751325947763 (accessed on 6 April 2025).

- Available online: https://www.ti.com/content/dam/videos/external-videos/en-us/3/3816841626001/5785710439001.mp4/subassets/deep_dive_on_sic-based_10kw_grid_tie_inverter_design_challenges.pdf (accessed on 6 April 2025).

- Available online: https://www.ti.com/lit/ug/tidue53j/tidue53j.pdf?ts=1751264681031 (accessed on 6 April 2025).

- Available online: https://www.ti.com/lit/ug/tiduf18a/tiduf18a.pdf (accessed on 6 April 2025).

- Zientarski, J.R.R.; Martins, M.L.d.S.; Pinheiro, J.R.; Hey, H.L. Series-Connected Partial-Power Converters Applied to PV Systems: A Design Approach Based on Step-Up/Down Voltage Regulation Range. IEEE Trans. Power Electron. 2018, 33, 7622–7633. [Google Scholar] [CrossRef]

- Rehlaender, P.; Schafmeister, F.; Böcker, J. Interleaved Single-Stage LLC Converter Design Utilizing Half- and Full-Bridge Configurations for Wide Voltage Transfer Ratio Applications. IEEE Trans. Power Electron. 2021, 36, 10065–10080. [Google Scholar] [CrossRef]

- Xue, B.; Wang, H.; Liang, J.; Cao, Q.; Li, Z. Phase-Shift Modulated Interleaved LLC Converter With Ultrawide Output Voltage Range. IEEE Trans. Power Electron. 2021, 36, 493–503. [Google Scholar] [CrossRef]

- Elezab, A.; Zayed, O.; Abuelnaga, A.; Narimani, M. High Efficiency LLC Resonant Converter With Wide Output Range of 200–1000 V for DC-Connected EVs Ultra-Fast Charging Stations. IEEE Access 2023, 11, 33037–33048. [Google Scholar] [CrossRef]

- Li, Z.; Xue, B.; Wang, H. An Interleaved Secondary-Side Modulated LLC Resonant Converter for Wide Output Range Applications. IEEE Trans. Ind. Electron. 2020, 67, 1124–1135. [Google Scholar] [CrossRef]

- Althurthi, S.B.; Rajashekara, K.; Debnath, T. A Novel Ultrawide Output Range DC–DC Converter for EV Fast Charging. IEEE J. Emerg. Sel. Top. Ind. Electron. 2024, 5, 586–596. [Google Scholar] [CrossRef]

- Lyu, D.; Soeiro, T.B.; Bauer, P. Design and Implementation of a Reconfigurable Phase Shift Full-Bridge Converter for Wide Voltage Range EV Charging Application. IEEE Trans. Transp. Electrif. 2023, 9, 1200–1214. [Google Scholar] [CrossRef]

- Zayed, O.; Elezab, A.; Abuelnaga, A.; Narimani, M. A Dual-Active Bridge Converter With a Wide Output Voltage Range (200–1000 V) for Ultrafast DC-Connected EV Charging Stations. IEEE Trans. Transp. Electrif. 2023, 9, 3731–3741. [Google Scholar] [CrossRef]

- Texas Instruments Design Guide: TIDM-02002, Bidirectional CLLLC Resonant Dual Active Bridge (DAB) Reference Design for HEV/EV Onboard Charger, TIDM-02002 Reference Design. [Online]. March 2019. Available online: https://www.ti.com/lit/pdf/tidt094 (accessed on 6 April 2025).

- Infineon Technologies Design Guide: UG 2020-31, 11 kW Bi-Directional CLLC DC-DC Converter with 1200 V and 1700 V CoolSiC™ MOSFET. [Online]. Available online: https://www.infineon.com/dgdl/Infineon-UG-2020-31_REF_DAB11KIZSICSYS-UserManual-v01_01-EN.pdf?fileId=5546d46276fb756a0177060f64a829de (accessed on 6 April 2025).

- dos Santos, N.G.F.; Zientarski, J.R.R.; Martins, M.L.d.S. A Review of Series-Connected Partial Power Converters for DC–DC Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 7825–7838. [Google Scholar] [CrossRef]

- Anzola, J.; Aizpuru, I.; Romero, A.A.; Loiti, A.A.; Lopez-Erauskin, R.; Artal-Sevil, J.S.; Bernal, C. Review of Architectures Based on Partial Power Processing for DC-DC Applications. IEEE Access 2020, 8, 103405–103418. [Google Scholar] [CrossRef]

- Rivera, S.; Rojas, J.; Kouro, S.; Lehn, P.W.; Lizana, R.; Renaudineau, H.; Dragičević, T. Partial-Power Converter Topology of Type II for Efficient Electric Vehicle Fast Charging. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 7839–7848. [Google Scholar] [CrossRef]

- Iyer, V.M.; Gulur, S.; Bhattacharya, S.; Ramabhadran, R. A partial power converter interface for battery energy storage integration with a DC microgrid. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 5783–5790. [Google Scholar]

- Rivera, S.; Flores-Bahamonde, F.; Renaudineau, H.; Dragicevic, T.; Kouro, S. A Buck-Boost Series Partial Power Converter using a Three-Port Structure for Electric Vehicle Charging Stations. In Proceedings of the 2021 IEEE 12th Energy Conversion Congress & Exposition—Asia (ECCE-Asia), Singapore, 24–27 May 2021; pp. 1749–1754. [Google Scholar] [CrossRef]

- Althurthi, S.B.; Rajashekara, K.; Rathore, V. A Dual Power Path DC-DC Step Up/Down Partial Power Converter for Electric Vehicle Fast Charging. In Proceedings of the 2023 IEEE Energy Conversion Congress and Exposition (ECCE), Nashville, TN, USA, 29 October–2 November 2023; pp. 6365–6370. [Google Scholar] [CrossRef]

- Muñoz, R.V.; Renaudineau, H.; Rivera, S.; Kouro, S. Evaluation of DC-DC buck-boost partial power converters for EV fast charging application. In Proceedings of the IECON 2021—47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, ON, Canada, 13–16 October 2021; pp. 1–6. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).