Thermal Management Systems for Lithium-Ion Batteries for Electric Vehicles: A Review

Abstract

1. Introduction

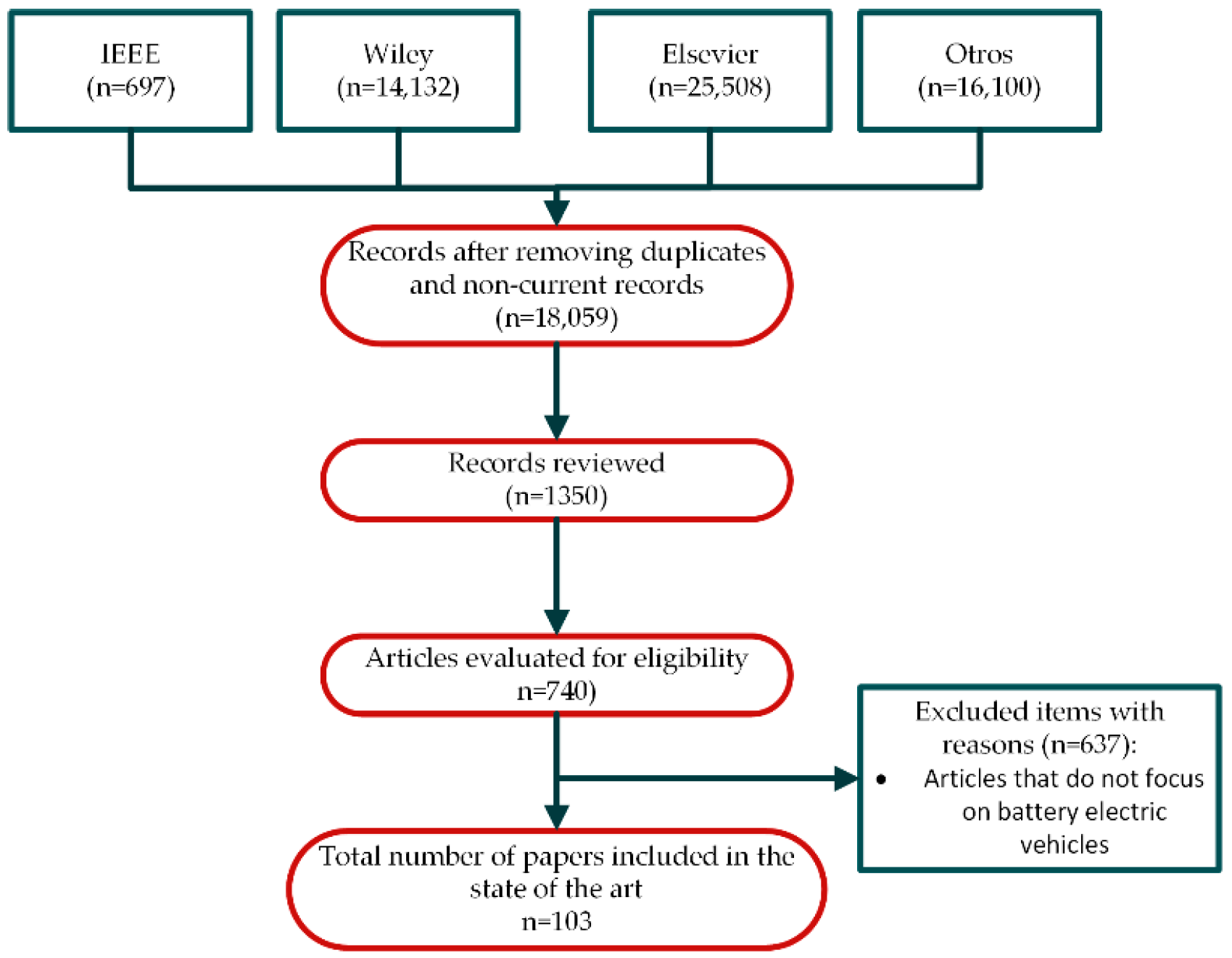

2. Methodology

3. Results

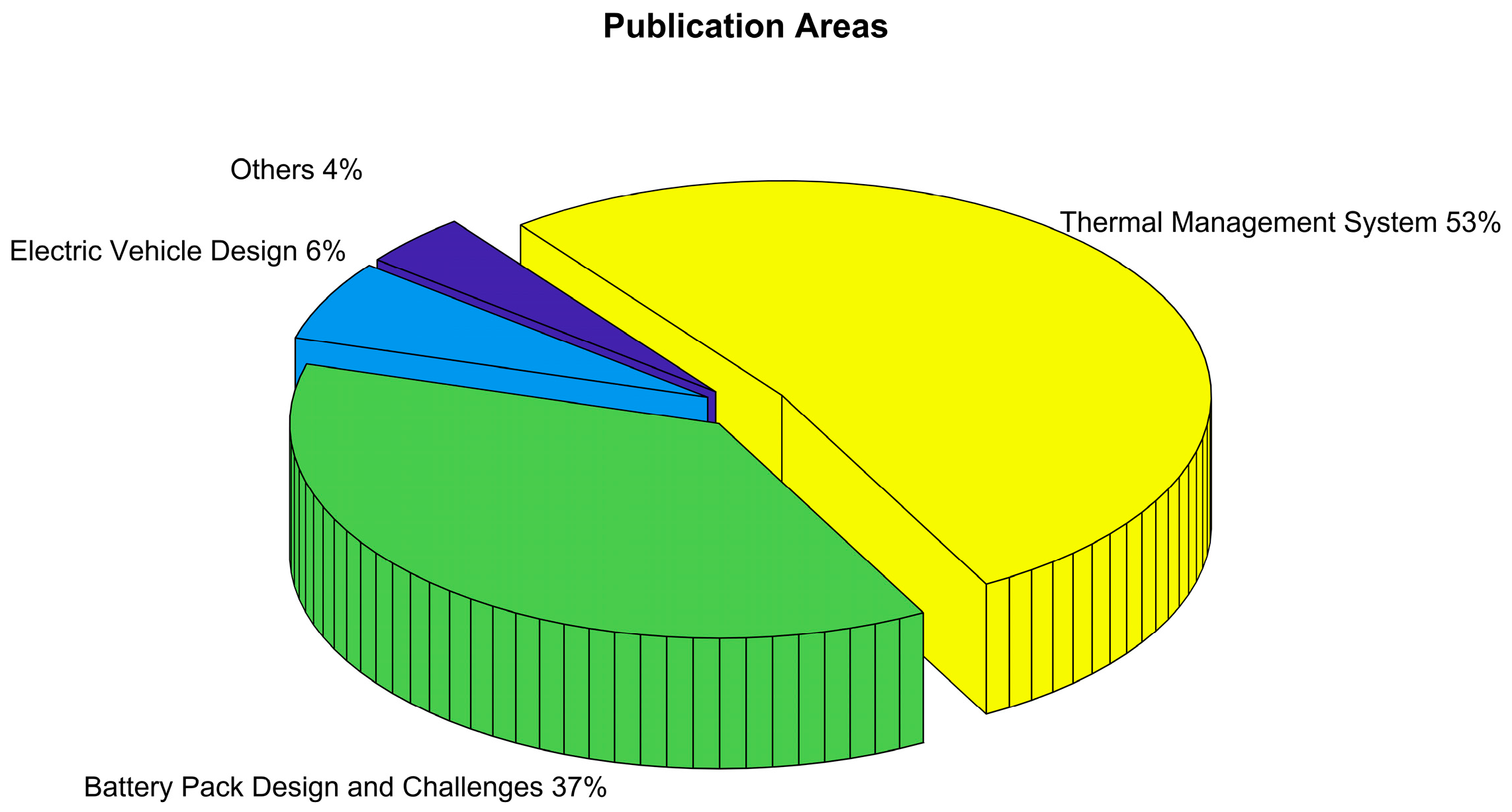

3.1. Areas of Publication

3.2. Battery Thermal Management System (BTMS)

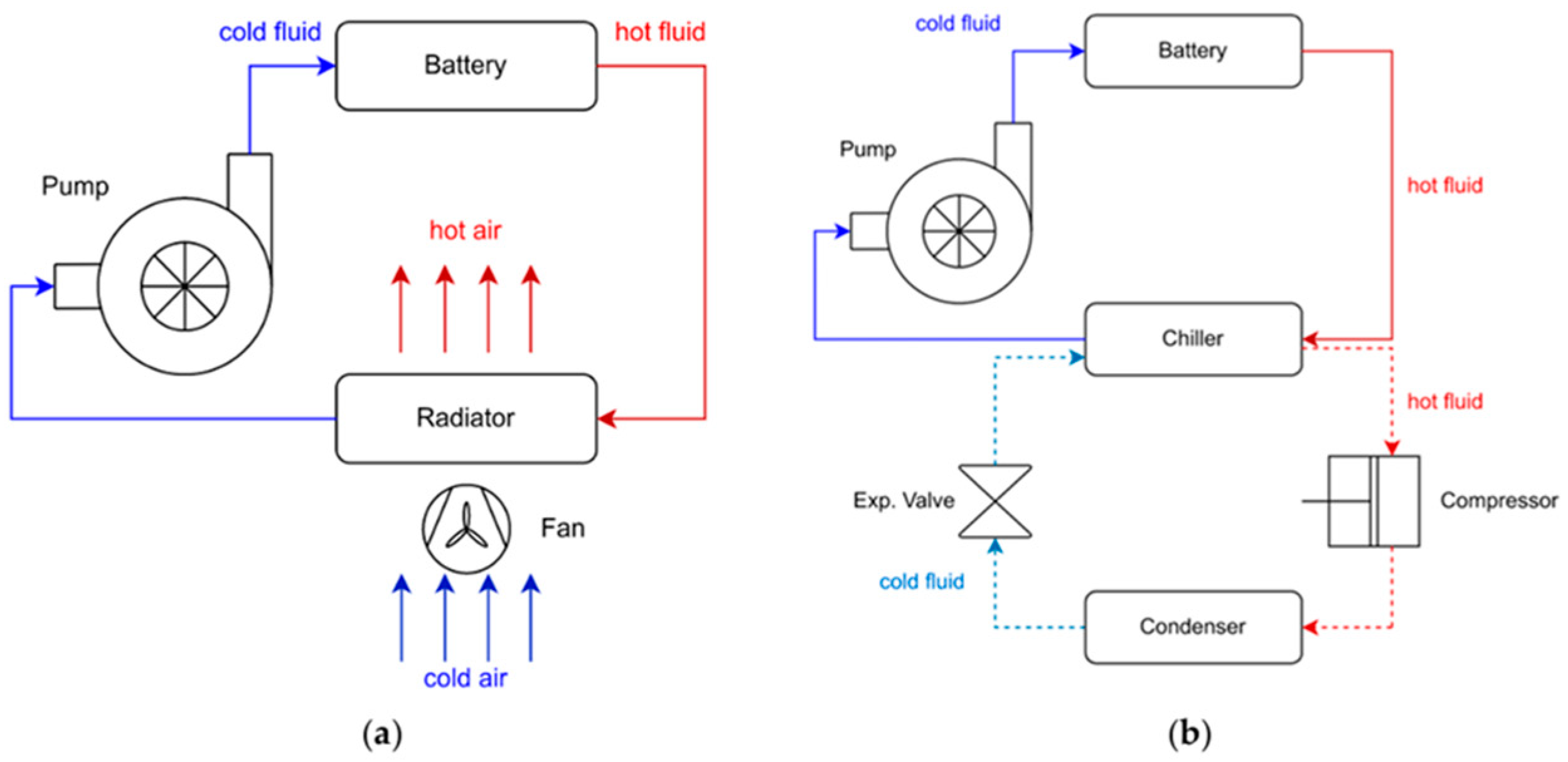

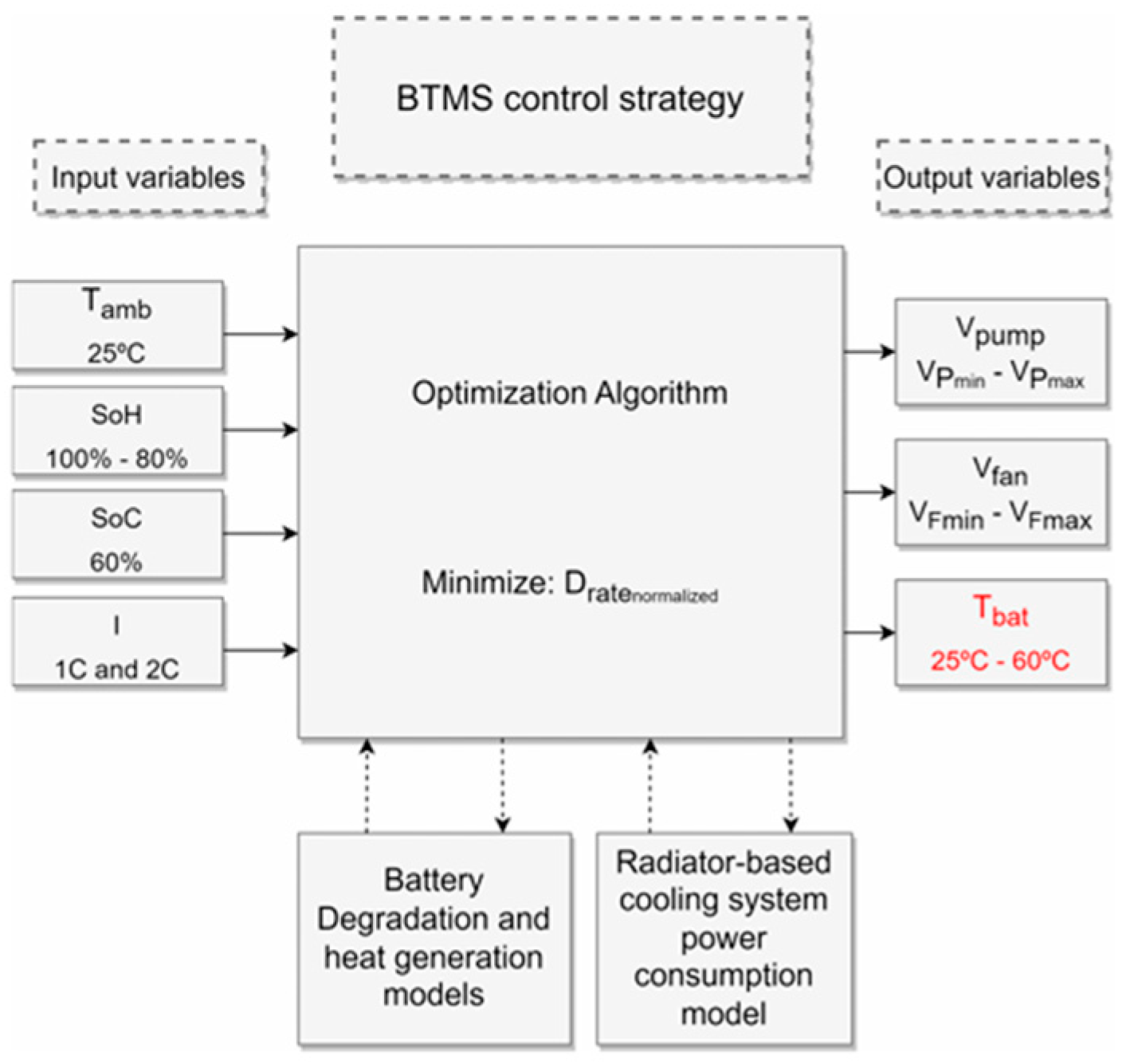

3.2.1. Liquid Cooling for BTMSs

3.2.2. Air Cooling for BTMS

- Natural Convection

- Simple and cost-effective design, as no additional components are needed.

- Lower efficiency in high-power systems due to limited heat dissipation capacity.

- Dependence on system orientation and design since air movement follows natural gravitational patterns.

- Forced Convection

- Greater effectiveness in thermal regulation by actively controlling air movement.

- Increased energy consumption due to mechanical components.

- Suitable for high-energy-density systems, where substantial heat removal is crucial.

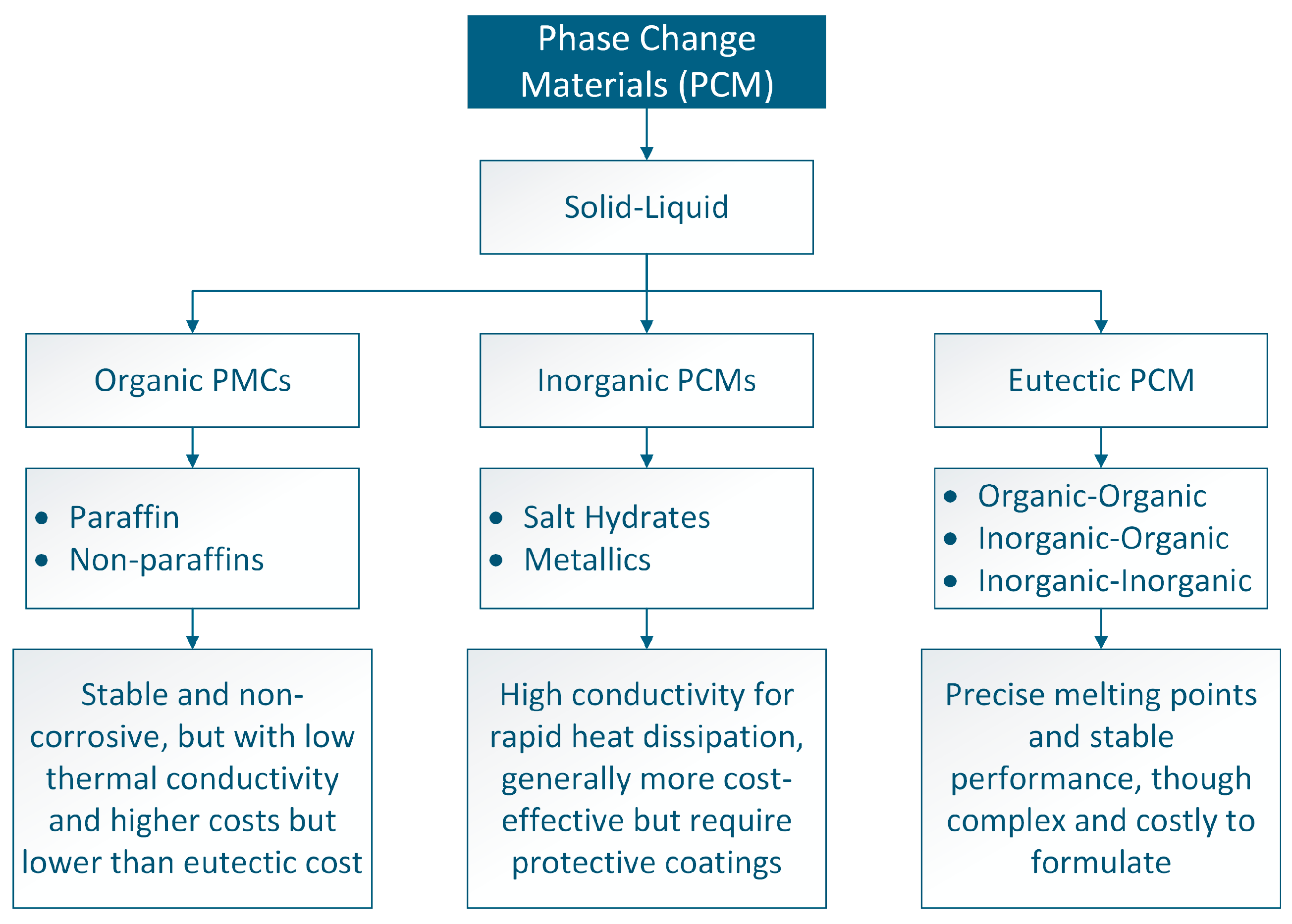

3.2.3. Phase Change Materials (PCMs) for BTMSs

3.2.4. Hybrid Cooling for BTMSs

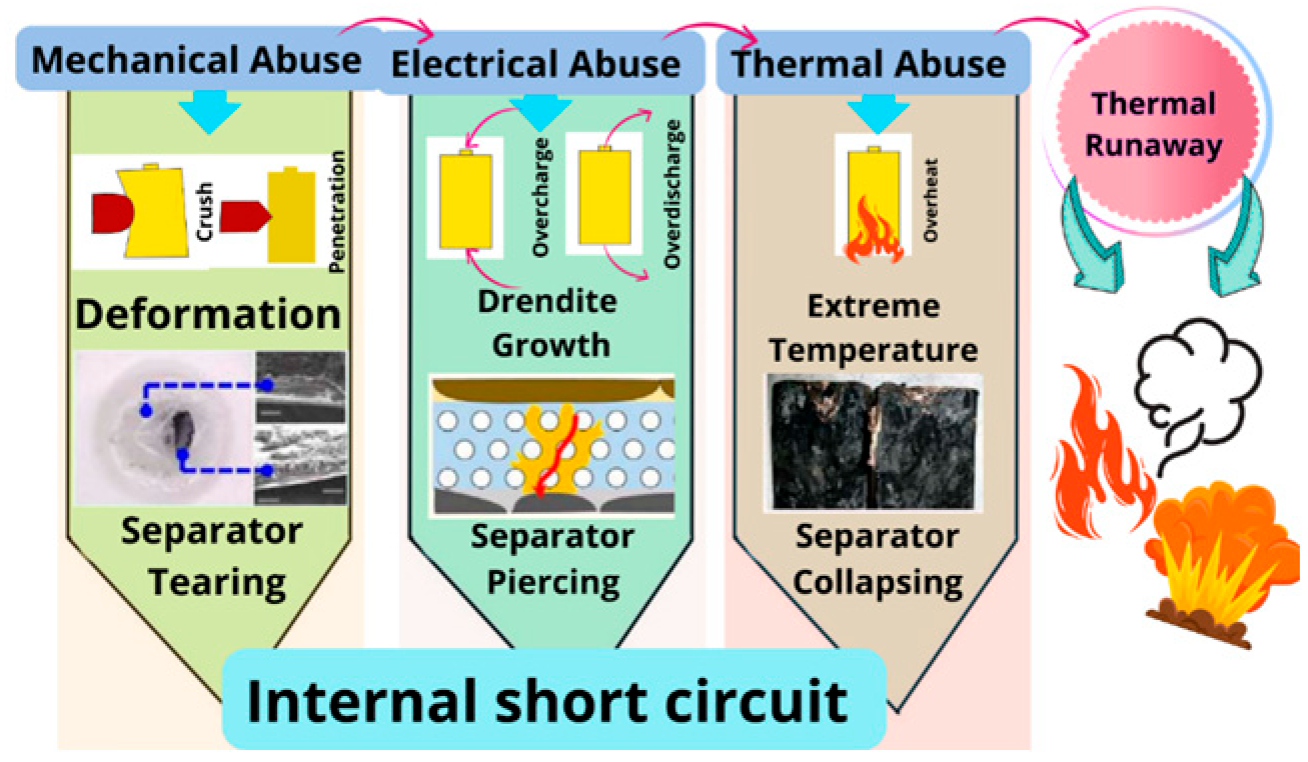

3.3. Battery Pack Design and Challenges

3.4. Electric Vehicle Design

3.5. Other

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tang, A.; Li, J.; Lou, L.; Shan, C.; Yuan, X. Optimization design and numerical study on water cooling structure for power lithium battery pack. Appl. Therm. Eng. 2019, 159, 113760. [Google Scholar] [CrossRef]

- Zhuang, W.; Liu, Z.; Su, H.; Chen, G. An intelligent thermal management system for the optimized lithium-ion battery pack. Appl. Therm. Eng. 2021, 189, 116767. [Google Scholar] [CrossRef]

- Park, S.; Jang, D.S.; Lee, D.; Hong, S.H.; Kim, Y. Simulation on cooling performance characteristics of a refrigerant-cooled active thermal management system for lithium ion batteries. Int. J. Heat Mass Transf. 2019, 135, 131–141. [Google Scholar] [CrossRef]

- Park, S.; Lee, H.; Park, C.; An, J.; Kim, C.-W. Optimization using kriging metamodel and CMA-ES to improve temperature uniformity of Electric Vehicle liquid-cooled cylindrical Li-ion battery BTMS. J. Comput. Des. Eng. 2025, 12, 167–178. [Google Scholar] [CrossRef]

- Pires, R.A., Jr.; Carvalho, S.A.; Cardoso Filho, B.J.; Pires, I.A.; Huebner, R.; Maia, T.A. The Assessment of Electric Vehicle Storage Lifetime Using Battery Thermal Management System. Batteries 2022, 9, 10. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, C.; Hu, X.; Lin, X.; Zhang, Y.; Li, W. An MPC-based control strategy for electric vehicle battery cooling considering energy saving and battery lifespan. IEEE Trans. Veh. Technol. 2020, 69, 14657–14673. [Google Scholar] [CrossRef]

- Li, M.; Wang, J.; Guo, Q.; Li, Y.; Xue, Q.; Qin, G. Numerical analysis of cooling plates with different structures for electric vehicle battery thermal management systems. J. Energy Eng. 2020, 146, 04020037. [Google Scholar] [CrossRef]

- Liu, F.-F.; Lan, F.-C.; Chen, J.-Q.; Li, Y.-G. Experimental investigation on cooling/heating characteristics of ultra-thin micro heat pipe for electric vehicle battery thermal management. Chin. J. Mech. Eng. 2018, 31, 1–10. [Google Scholar] [CrossRef]

- Akinlabi, A.H.; Solyali, D. Configuration, design, and optimization of air-cooled battery thermal management system for electric vehicles: A review. Renew. Sustain. Energy Rev. 2020, 125, 109815. [Google Scholar] [CrossRef]

- Xie, J.; Ge, Z.; Zang, M.; Wang, S. Structural optimization of lithium-ion battery pack with forced air cooling system. Appl. Therm. Eng. 2017, 126, 583–593. [Google Scholar] [CrossRef]

- Fan, Y.; Lyu, P.; Zhan, D.; Ouyang, K.; Tan, X.; Li, J. Surrogate model-based multiobjective design optimization for air-cooled battery thermal management systems. Eng. Appl. Comput. Fluid Mech. 2022, 16, 1031–1047. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Y.; Sun, W.; Song, X.; Zhang, J. Multidisciplinary and multifidelity design optimization of electric vehicle battery thermal management system. J. Mech. Des. 2018, 140, 094501. [Google Scholar] [CrossRef]

- Qian, X.; Xuan, D.; Zhao, X.; Shi, Z. Heat dissipation optimization of lithium-ion battery pack based on neural networks. Appl. Therm. Eng. 2019, 162, 114289. [Google Scholar] [CrossRef]

- Wang, M.; Teng, S.; Xi, H.; Li, Y. Cooling performance optimization of air-cooled battery thermal management system. Appl. Therm. Eng. 2021, 195, 117242. [Google Scholar] [CrossRef]

- Chen, K.; Song, M.; Wei, W.; Wang, S. Design of the structure of battery pack in parallel air-cooled battery thermal management system for cooling efficiency improvement. Int. J. Heat Mass Transf. 2019, 132, 309–321. [Google Scholar] [CrossRef]

- Suryavanshi, S.S.; Ghanegaonkar, P.M. Improving Electric Vehicle Air-Cooled Cylindrical Battery Temperature Control Systems: A Computational Fluid Dynamics (CFD) Study of an Innovative Uniform Flow Distribution Plate. Energy Storage 2025, 7, e70108. [Google Scholar] [CrossRef]

- Li, W.; Peng, X.; Xiao, M.; Garg, A.; Gao, L. Multi-objective design optimization for mini-channel cooling battery thermal management system in an electric vehicle. Int. J. Energy Res. 2019, 43, 3668–3680. [Google Scholar] [CrossRef]

- Sun, Z.; Fan, R.; Yan, F.; Zhou, T.; Zheng, N. Thermal management of the lithium-ion battery by the composite PCM-Fin structures. Int. J. Heat Mass Transf. 2019, 145, 118739. [Google Scholar] [CrossRef]

- Budiman, A.C.; Kaleg, S.; Hapid, A. Experimental Investigation of Phase Change Materials Thermal Barriers in Electric Vehicle Battery Module. In Proceedings of the 2020 International Conference on Sustainable Energy Engineering and Application (ICSEEA), Tangerang, Indonesia, 18–20 November 2020; pp. 30–34. [Google Scholar]

- Dolla, D.A.; Fetene, M.G. Investigations of phase change materials in battery thermal management systems for electric vehicles: A review. Mater. Res. Express 2024, 11, 012002. [Google Scholar] [CrossRef]

- Talluri, T.; Kim, T.H.; Shin, K.J. Analysis of a battery pack with a phase change material for the extreme temperature conditions of an electrical vehicle. Energies 2020, 13, 507. [Google Scholar] [CrossRef]

- Khan, F.N.U.; Rasul, M.G.; Sayem, A.; Mandal, N.K. Design and optimization of lithium-ion battery as an efficient energy storage device for electric vehicles: A comprehensive review. J. Energy Storage 2023, 71, 108033. [Google Scholar] [CrossRef]

- Zuber, M.; Chethan, K.; Keni, L.G.; Magami, I.A.B.; Kini, C.R. Enhancing Electric Vehicle Battery Thermal Management using Phase Change Materials: A CFD Analysis for Improved Heat Dissipation. CFD Lett. 2024, 16, 138–149. [Google Scholar]

- Ali, S.; Khan, M.M.; Irfan, M. Thermal Performance Enhancement of Lithium-Ion Batteries Using Phase Change Material and Fin Geometry Modification. World Electr. Veh. J. 2024, 15, 42. [Google Scholar] [CrossRef]

- Cicconi, Kumar, Design approaches for Li-ion battery packs: A review. J. Energy Storage 2023, 73, 109197. [CrossRef]

- Dewangan, A.; Shukla, A.K. Enhancing Li-Ion Electric Vehicle Battery Performance: Analysis of Advanced Thermal Management Cooling Strategies with Phase Change Material. Energy Technol. 2024, 2301665. [Google Scholar] [CrossRef]

- Smith, J.; Singh, R.; Hinterberger, M.; Mochizuki, M. Battery thermal management system for electric vehicle using heat pipes. Int. J. Therm. Sci. 2018, 134, 517–529. [Google Scholar] [CrossRef]

- Wei, Y.; Agelin-Chaab, M. Development and experimental analysis of a hybrid cooling concept for electric vehicle battery packs. J. Energy Storage 2019, 25, 100906. [Google Scholar] [CrossRef]

- Saeedipour, S.; Gharehghani, A.; Ahbabi Saray, J.; Andwari, A.M.; Mikulski, M. Proposing a hybrid thermal management system based on phase change material/metal foam for lithium-ion batteries. World Electr. Veh. J. 2023, 14, 240. [Google Scholar] [CrossRef]

- Ma, Y.; Ma, Q.; Ding, H.; Hu, Y.; Chen, H. Multi-layer NMPC for battery thermal management optimization strategy of connected electric vehicle integrated with waste heat recovery. IEEE Trans. Intell. Transp. Syst. 2023, 25, 6133–6146. [Google Scholar] [CrossRef]

- Kim, J.; Oh, J.; Lee, H. Review on battery thermal management system for electric vehicles. Appl. Therm. Eng. 2019, 149, 192–212. [Google Scholar] [CrossRef]

- Yang, X.-G.; Liu, T.; Wang, C.-Y. Thermally modulated lithium iron phosphate batteries for mass-market electric vehicles. Nat. Energy 2021, 6, 176–185. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L.; Sun, F.; Wang, Z. An overview on thermal safety issues of lithium-ion batteries for electric vehicle application. IEEE Access 2018, 6, 23848–23863. [Google Scholar] [CrossRef]

- Bukya, M.; Reddy, R.M.; Doddipatla, A.R.; Kumar, R.; Mathur, A.; Gupta, M.; Garimella, A. Electro-thermal performance evaluation of a prismatic battery pack for an electric vehicle. High Temp. Mater. Process. 2024, 43, 20220311. [Google Scholar] [CrossRef]

- Lin, J.; Liu, X.; Li, S.; Zhang, C.; Yang, S. A review on recent progress, challenges and perspective of battery thermal management system. Int. J. Heat Mass Transf. 2021, 167, 120834. [Google Scholar] [CrossRef]

- Rohini, A.; Abishek, A.; Jeeva, S. Analysis on a Battery Thermal Management System of an Lithium-Ion Powered Battery with Heat Sink for an Electric Vehicle. J. Phys. Conf. Ser. 2024, 2748, 012017. [Google Scholar] [CrossRef]

- Benabdelaziz, K.; Lebrouhi, B.; Maftah, A.; Maaroufi, M. Novel external cooling solution for electric vehicle battery pack. Energy Rep. 2020, 6, 262–272. [Google Scholar] [CrossRef]

- Escobar, C.; Gong, Z.; Da Silva, C.; Trescases, O.; Amon, C.H. Effect of Cell-to-Cell Thermal Imbalance and Cooling Strategy on Electric Vehicle Battery Performance and Longevity. In Proceedings of the 2022 21st IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (iTherm), San Diego, CA, USA, 31 May–3 June 2022; pp. 1–9. [Google Scholar]

- Fang, G.; Huang, Y.; Yuan, W.; Yang, Y.; Tang, Y.; Ju, W.; Chua, F.; Zhao, Z. Thermal management for a tube–shell Li-ion battery pack using water evaporation coupled with forced air cooling. RSC Adv. 2019, 9, 9951–9961. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J. Electric vehicle battery thermal and cabin climate management based on model predictive control. J. Mech. Des. 2021, 143, 031705. [Google Scholar] [CrossRef]

- Saw, L.H.; Poon, H.M.; Thiam, H.S.; Cai, Z.; Chong, W.T.; Pambudi, N.A.; King, Y.J. Novel thermal management system using mist cooling for lithium-ion battery packs. Appl. Energy 2018, 223, 146–158. [Google Scholar] [CrossRef]

- Kannan, C.; Vignesh, R.; Karthick, C.; Ashok, B. Critical review towards thermal management systems of lithium-ion batteries in electric vehicle with its electronic control unit and assessment tools. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 1783–1807. [Google Scholar] [CrossRef]

- Schimpe, M.; von Kuepach, M.E.; Naumann, M.; Hesse, H.C.; Smith, K.; Jossen, A. Comprehensive modeling of temperature-dependent degradation mechanisms in lithium iron phosphate batteries. ECS Trans. 2018, 80, 147. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J. A model predictive control-based energy management strategy considering electric vehicle battery thermal and cabin climate control. In Proceedings of the ASME 2020 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Louis, MO, USA, 17–19 August 2020; American Society of Mechanical Engineers: New York, NY, USA, 2020; Volume 84003, p. V11AT11A022. [Google Scholar]

- Spitthoff, L.; Shearing, P.R.; Burheim, O.S. Temperature, ageing and thermal management of lithium-ion batteries. Energies 2021, 14, 1248. [Google Scholar] [CrossRef]

- Hameed, M.M.; Mansor, M.; Azrin Mohd Azau, M.; Muhsin, S. Thermoelectric cooler performance enhancement using thermoelectric generators and their use as a single model to improve the performance of thermal battery management systems for electric vehicles. Energy Storage 2023, 5, e406. [Google Scholar] [CrossRef]

- Kong, J.-z.; Yang, F.; Zhang, X.; Pan, E.; Peng, Z.; Wang, D. Voltage-temperature health feature extraction to improve prognostics and health management of lithium-ion batteries. Energy 2021, 223, 120114. [Google Scholar] [CrossRef]

- Katoch, S.S.; Eswaramoorthy, M. A detailed review on electric vehicles battery thermal management system. IOP Conf. Ser. Mater. Sci. Eng. 2020, 912, 042005. [Google Scholar] [CrossRef]

- Feng, H.; Song, D. A health indicator extraction based on surface temperature for lithium-ion batteries remaining useful life prediction. J. Energy Storage 2021, 34, 102118. [Google Scholar] [CrossRef]

- Mohandass, M.; Regan, R.; Vignesh, A.; Sabari, V. Battery Thermal Management System for Electric Vehicle Using LABVIEW. In Proceedings of the 2024 International Conference on IoT Based Control Networks and Intelligent Systems (ICICNIS), Bengaluru, India, 17–18 December 2024; pp. 586–592. [Google Scholar]

- Magendran, S.S.; Khan, F.S.A.; Mubarak, N.; Vaka, M.; Walvekar, R.; Khalid, M.; Abdullah, E.; Nizamuddin, S.; Karri, R.R. Synthesis of organic phase change materials (PCM) for energy storage applications: A review. Nano-Struct. Nano-Objects 2019, 20, 100399. [Google Scholar] [CrossRef]

- Deng, J.; Bae, C.; Denlinger, A.; Miller, T. Electric vehicles batteries: Requirements and challenges. Joule 2020, 4, 511–515. [Google Scholar] [CrossRef]

- Ahmad, F.; Saad Alam, M.; Saad Alsaidan, I.; Shariff, S.M. Battery swapping station for electric vehicles: Opportunities and challenges. IET Smart Grid 2020, 3, 280–286. [Google Scholar] [CrossRef]

- Omariba, Z.B.; Zhang, L.; Sun, D. Review of battery cell balancing methodologies for optimizing battery pack performance in electric vehicles. IEEE Access 2019, 7, 129335–129352. [Google Scholar] [CrossRef]

- Itani, K.; De Bernardinis, A. Review on New-Generation Batteries Technologies: Trends and Future Directions. Energies 2023, 16, 7530. [Google Scholar] [CrossRef]

- Chen, W.; Liang, J.; Yang, Z.; Li, G. A review of lithium-ion battery for electric vehicle applications and beyond. Energy Procedia 2019, 158, 4363–4368. [Google Scholar] [CrossRef]

- Hasib, S.A.; Islam, S.; Chakrabortty, R.K.; Ryan, M.J.; Saha, D.K.; Ahamed, M.H. A comprehensive review of available battery datasets, RUL prediction approaches, and advanced battery management. IEEE Access 2021, 9, 86166–86193. [Google Scholar] [CrossRef]

- Tantia, S. Evaluating the Reliability and Safety of Lithium-Ion Batteries in Electric Vehicles: Advancements, Challenges, and Environmental Considerations. Glob. J. Sci. Front. Res. 2024, 23, 1–9. [Google Scholar] [CrossRef]

- Omariba, Z.B.; Gichana, S.M. Applications of Rechargeable Lithium-Ion Battery in Electric Vehicles: A Review. Int. J. Sci. Res. 2021, 10, 782–790. [Google Scholar] [CrossRef]

- Rafik, O.; Capitaine, A.; Briat, O.; Vinassa, J.-M. Performance characterization of lithium-ion battery and ageing under constant stress conditions at low temperature. In Proceedings of the 35 European Symposium on Reliability of Electron Devices, Failure Physics and Analysis, Parma, Italy, 23–26 September 2024. [Google Scholar]

- Shen, W.; Wang, N.; Zhang, J.; Wang, F.; Zhang, G. Heat generation and degradation mechanism of lithium-ion batteries during high-temperature aging. ACS Omega 2022, 7, 44733–44742. [Google Scholar] [CrossRef]

- Ouyang, D.; Weng, J.; Chen, M.; Liu, J.; Wang, J. Experimental analysis on the degradation behavior of overdischarged lithium-ion battery combined with the effect of high-temperature environment. Int. J. Energy Res. 2020, 44, 229–241. [Google Scholar] [CrossRef]

- Shchurov, N.I.; Dedov, S.I.; Malozyomov, B.V.; Shtang, A.A.; Martyushev, N.V.; Klyuev, R.V.; Andriashin, S.N. Degradation of lithium-ion batteries in an electric transport complex. Energies 2021, 14, 8072. [Google Scholar] [CrossRef]

- Hu, X.; Moura, S.J.; Murgovski, N.; Egardt, B.; Cao, D. Integrated optimization of battery sizing, charging, and power management in plug-in hybrid electric vehicles. IEEE Trans. Control. Syst. Technol. 2015, 24, 1036–1043. [Google Scholar] [CrossRef]

- Thiruvonasundari, D.; Deepa, K. Optimized passive cell balancing for fast charging in electric vehicle. IETE J. Res. 2023, 69, 2089–2097. [Google Scholar] [CrossRef]

- Ding, N.; Prasad, K.; Lie, T. Design of a hybrid energy management system using designed rule-based control strategy and genetic algorithm for the series-parallel plug-in hybrid electric vehicle. Int. J. Energy Res. 2021, 45, 1627–1644. [Google Scholar] [CrossRef]

- Li, W.; Garg, A.; Xiao, M.; Peng, X.; Le Phung, M.L.; Tran, V.M.; Gao, L. Intelligent optimization methodology of battery pack for electric vehicles: A multidisciplinary perspective. Int. J. Energy Res. 2020, 44, 9686–9706. [Google Scholar] [CrossRef]

- Li, Y.; Li, K.; Xie, Y.; Liu, B.; Liu, J.; Zheng, J.; Li, W. Optimization of charging strategy for lithium-ion battery packs based on complete battery pack model. J. Energy Storage 2021, 37, 102466. [Google Scholar] [CrossRef]

- Lin, C.; Gao, F.; Wang, W.; Chen, X. Multi-objective optimization design for a battery pack of electric vehicle with surrogate models. J. Vibroeng. 2016, 18, 2343–2358. [Google Scholar] [CrossRef]

- Shui, L.; Chen, F.; Garg, A.; Peng, X.; Bao, N.; Zhang, J. Design optimization of battery pack enclosure for electric vehicle. Struct. Multidiscip. Optim. 2018, 58, 331–347. [Google Scholar] [CrossRef]

- Zulueta, A.; Ispas-Gil, D.A.; Zulueta, E.; Garcia-Ortega, J.; Fernandez-Gamiz, U. Battery sizing optimization in power smoothing applications. Energies 2022, 15, 729. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, S.; Shahin, M.E.; Niu, X.; Gao, L.; Chin, C.M.M.; Bao, N.; Wang, C.-T.; Garg, A.; Goyal, A. Multi-objective optimization of lithium-ion battery pack casing for electric vehicles: Key role of materials design and their influence. Int. J. Energy Res. 2020, 44, 9414–9437. [Google Scholar] [CrossRef]

- Hasan, M.M.; Berseneff, B.; Meulenbroeks, T.; Cantero, I.; Chakraborty, S.; Geury, T.; Hegazy, O. A Multi-Objective Co-Design Optimization Framework for Grid-Connected Hybrid Battery Energy Storage Systems: Optimal Sizing and Selection of Technology. Energies 2022, 15, 5355. [Google Scholar] [CrossRef]

- Pelletier, L.; LeBel, F.-A.; Antunes, C.H.; Trovão, J.P.F. Sizing of a battery pack based on series/parallel configurations for a high-power electric vehicle as a constrained optimization problem. IEEE Trans. Veh. Technol. 2020, 69, 14150–14159. [Google Scholar] [CrossRef]

- Sulaiman, N.; Hannan, M.; Mohamed, A.; Ker, P.J.; Majlan, E.; Daud, W.W. Optimization of energy management system for fuel-cell hybrid electric vehicles: Issues and recommendations. Appl. Energy 2018, 228, 2061–2079. [Google Scholar] [CrossRef]

- Pozzi, A.; Torchio, M.; Braatz, R.D.; Raimondo, D.M. Optimal charging of an electric vehicle battery pack: A real-time sensitivity-based model predictive control approach. J. Power Sources 2020, 461, 228133. [Google Scholar] [CrossRef]

- Verbrugge, M.W.; Wampler, C.W. On the optimal sizing of batteries for electric vehicles and the influence of fast charge. J. Power Sources 2018, 384, 312–317. [Google Scholar] [CrossRef]

- Baazouzi, S.; Rist, F.; Weeber, M.; Birke, K. Optimization of Disassembly Strategies for Electric Vehicle Batteries. Batteries 2021, 7, 74. [Google Scholar] [CrossRef]

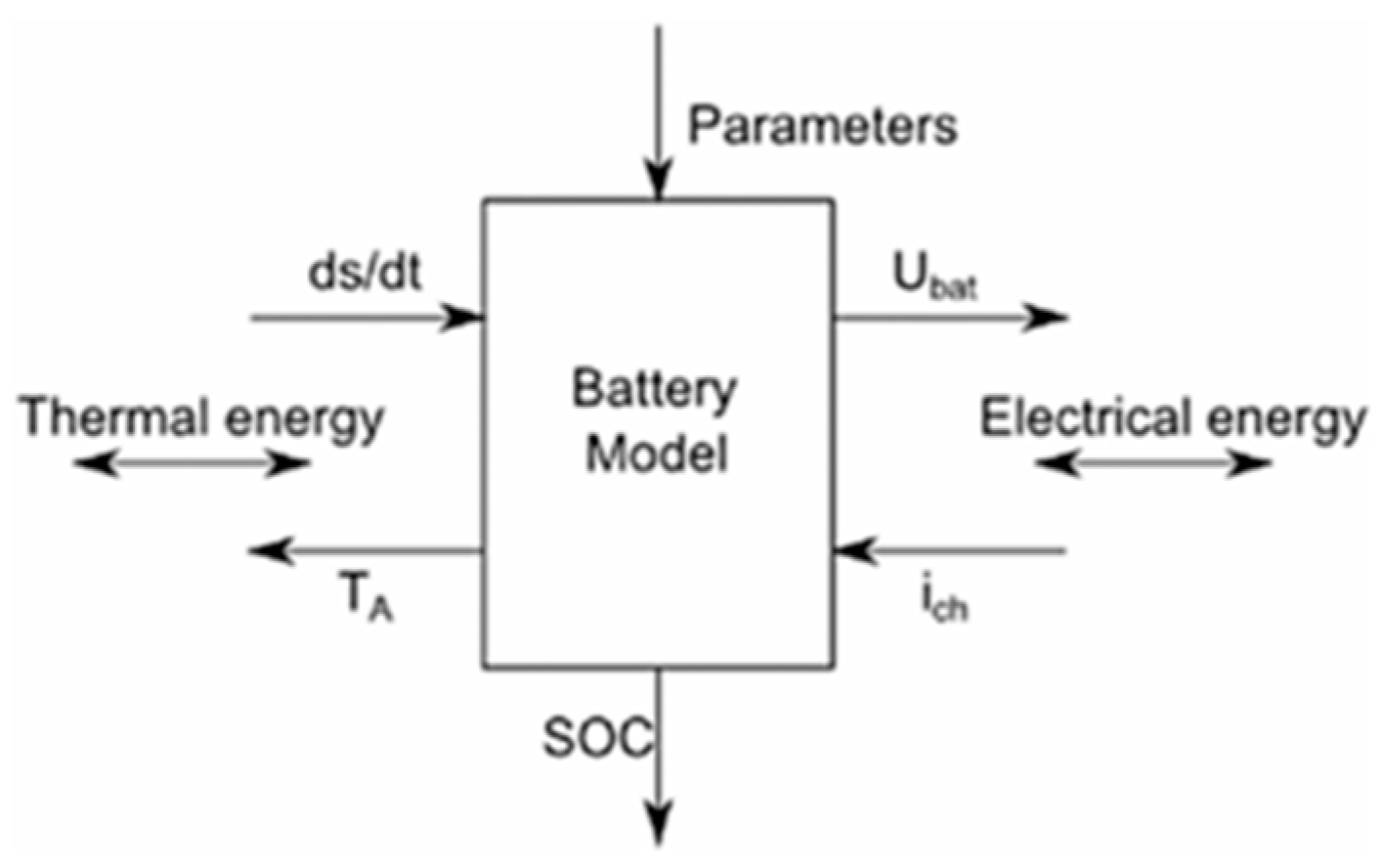

- Benabdelaziz, K.; Maaroufi, M. Battery dynamic energy model for use in electric vehicle simulation. Int. J. Hydrogen Energy 2017, 42, 19496–19503. [Google Scholar] [CrossRef]

- Sandeep, V.; Shastri, S.; Sardar, A.; Salkuti, S.R. Modeling of battery pack sizing for electric vehicles. Int. J. Power Electron. Drive Syst. 2020, 11, 1987. [Google Scholar] [CrossRef]

- Omariba, Z.B.; Jared, O.K. Modelling and simulation of lithium-ion battery with temperature effects using MATLAB/Simulink. Int. J. Res. Adv. Eng. Technol. 2019, 5, 67–76. [Google Scholar]

- Ricco, M.; Meng, J.; Gherman, T.; Grandi, G.; Teodorescu, R. Smart battery pack for electric vehicles based on active balancing with wireless communication feedback. Energies 2019, 12, 3862. [Google Scholar] [CrossRef]

- Vaghela, R.; Ramani, P.; Sarda, J.; Hui, K.L.; Sain, M. Analysis of State-of-Health Estimation Approaches and Constraints for Lithium-Ion Batteries in Electric Vehicles. Int. J. Energy Res. 2024, 2024, 6488186. [Google Scholar] [CrossRef]

- Miri, I.; Fotouhi, A.; Ewin, N. Electric vehicle energy consumption modelling and estimation—A case study. Int. J. Energy Res. 2021, 45, 501–520. [Google Scholar] [CrossRef]

- Zeng, X.; Li, M.; El-Hady, D.A.; Alshitari, W.; Al-Bogami, A.S.; Lu, J.; Amine, K. Commercialization of lithium battery technologies for electric vehicles. Adv. Energy Mater. 2019, 9, 1900161. [Google Scholar] [CrossRef]

- Li, W.; Chen, S.; Peng, X.; Xiao, M.; Gao, L.; Garg, A.; Bao, N. A comprehensive approach for the clustering of similar-performance cells for the design of a lithium-ion battery module for electric vehicles. Engineering 2019, 5, 795–802. [Google Scholar] [CrossRef]

- Pelletier, L.; LeBel, F.-A.; Rubio, R.G.; Roux, M.-A.; Trovao, J.P. Design of a high performance battery pack as a constraint satisfaction problem. In Proceedings of the 2018 IEEE Vehicle Power and Propulsion Conference (VPPC), Chicago, IL, USA, 27–30 August 2018; pp. 1–6. [Google Scholar]

- Hussain, M.A.; Soldati, A.; Sozzi, G. Impact of Constant and Pulsed Active Balancing Current Patterns on the Aging of Lithium-ion Batteries. In Proceedings of the 35th European Symposium on Reliability of Electron Devices, Failure Physics and Analysis, Parma, Italy, 23–26 September 2024. [Google Scholar]

- Kumar, P.; Gill, A.; Johar, A.K. Battery Management System for Cell Balancing in an Electric Vehicle. In Advances in Machinery, Materials Science and Engineering Application IX; IOS Press: Amsterdam, The Netherlands, 2023; pp. 761–766. [Google Scholar]

- Omariba, Z.B.; Zhang, L.; Sun, D. Review on health management system for lithium-ion batteries of electric vehicles. Electronics 2018, 7, 72. [Google Scholar] [CrossRef]

- Sanguesa, J.A.; Torres-Sanz, V.; Garrido, P.; Martinez, F.J.; Marquez-Barja, J.M. A review on electric vehicles: Technologies and challenges. Smart Cities 2021, 4, 372–404. [Google Scholar] [CrossRef]

- Jung, C. Power Up with 800-V Systems: The benefits of upgrading voltage power for battery-electric passenger vehicles. IEEE Electrif. Mag. 2017, 5, 53–58. [Google Scholar] [CrossRef]

- Tran, M.-K.; Akinsanya, M.; Panchal, S.; Fraser, R.; Fowler, M. Design of a hybrid electric vehicle powertrain for performance optimization considering various powertrain components and configurations. Vehicles 2020, 3, 20–32. [Google Scholar] [CrossRef]

- Alegre, S.; Míguez, J.V.; Carpio, J. Modelling of electric and parallel-hybrid electric vehicle using Matlab/Simulink environment and planning of charging stations through a geographic information system and genetic algorithms. Renew. Sustain. Energy Rev. 2017, 74, 1020–1027. [Google Scholar] [CrossRef]

- Sharmila, B.; Srinivasan, K.; Devasena, D.; Suresh, M.; Panchal, H.; Ashokkumar, R.; Meenakumari, R.; Kumar sadasivuni, K.; Shah, R.R. Modelling and performance analysis of electric vehicle. Int. J. Ambient. Energy 2022, 43, 5034–5040. [Google Scholar] [CrossRef]

- Shen, Z.-J.M.; Feng, B.; Mao, C.; Ran, L. Optimization models for electric vehicle service operations: A literature review. Transp. Res. Part B Methodol. 2019, 128, 462–477. [Google Scholar] [CrossRef]

- Delmas, C. Sodium and sodium-ion batteries: 50 years of research. Adv. Energy Mater. 2018, 8, 1703137. [Google Scholar] [CrossRef]

- Pózna, A.I.; Hangos, K.M.; Magyar, A. Design of experiments for battery aging estimation. IFAC-PapersOnLine 2018, 51, 386–391. [Google Scholar] [CrossRef]

- Momen, F.; Rahman, K.; Son, Y. Electrical propulsion system design of Chevrolet Bolt battery electric vehicle. IEEE Trans. Ind. Appl. 2018, 55, 376–384. [Google Scholar] [CrossRef]

| Approach | References | Summary |

|---|---|---|

| Liquid Cooling | [1,2,3,4,5,6,7,8] | In some articles, it can be seen that they perform optimizations of the water-cooling structure, as well as simulations of the cooling characteristics of an active thermal management system or numerical analyses of cooling plates with different structures, among other aspects. |

| Air Cooling | [9,10,11,12,13,14,15,16] | In some articles, it can be seen that they perform optimizations of air thermal management systems, structural optimizations, or spacing of a battery pack, as well as improvements in cooling performance and design of the structure in parallel thermal management systems, among other aspects. |

| Phase Change Materials | [17,18,19,20,21,22,23,24,25,26] | In some articles, it can be seen that they introduce atomization cooling, analyze the use of PCM as expanded graphite to enhance heat transfer, investigate the thermal properties of PCM, improve thermal performance by utilizing PCM, and modify the geometry of the fins, among other aspects. |

| Hybrids | [27,28,29,30] | In some articles, it is evident that a hybrid thermal management system is being developed, incorporating PCM and metal foam, as well as thermoelectric cooling, among other aspects. |

| Multiple Types of Cooling | [31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50] | In most articles in this section, summaries of the four primary cooling methods are presented. |

| Ref. | Strategies of Cold Plate | Battery Used | Inlet Temperature | Flow Rate | Heat or Temperature Equation | Objectives |

|---|---|---|---|---|---|---|

| [1] | At the bottom, on two side walls, and at the bottom and on two side walls | Lithium iron phosphate (LiFePO4) of 50 Ah | (15, 20, 25) °C | (1, 2, 3) L/min | ||

| [2] | Two side walls | Lithium-ion | 20 °C | 0.06266 kg/s | ||

| [3] | Top and bottom | LiFePO4 | 20 °C | 50 kg h−1 | ||

| [4] | Top and bottom | NMC Li-ion | 298.15 K | Velocity = 0.1 m/s with a viscosity = 1.003 × 10−3 | ||

| [5] | Radiator-based and refrigeration-based strategy | NMC and NCA Lithium-ion | 25 °C | m3/s |

Min | |

| [6] | Bottom with a radiator | Lithium-ion | 20 °C | (10, 20, 30 & 40) L/min | ||

| [7] | Bottom | Lithium-ion | 308.15 K | No less than 0.0223 kg/s | ||

| [8] | Top and bottom | Lithium-ion | 30 °C | Flow speed = 6 ± 0.8 m/s | __ |

| Ref. | Design Variables | Number of Cells | Flow Rate | Heat or Temperature Equation | Objectives |

|---|---|---|---|---|---|

| [9] | Cell Spacing, cooling channel size, air supply strategy, others | (8, 88) prismatic, (7, 14, 25, 30, 60, and 66) cylindrical | (0.012) kg/s (0.01, 0.05, 0.1, 0.5) m/s (10.2, 20.4, 30.6, 40.6) m3/h | ||

| [10] | Air inlet angle, the air outlet angle, and the air flow channel | 10 orthogonal | Air flow = 3 m s−1 Outside air = 5 W m−2 k−1 | ||

| [11] | Cell space combination and channel height | 4P128S cylindrical | Flow inlet velocity = 5 m/s | ||

| [12] | Multidisciplinary design optimization (MDO) based on fidelity | 10 prismatic | The mass flow rate of the cooling air = (0.001–0.020) kg/s | __ | |

| [13] | Cell space combination and cooling channel configuration | Cylindrical | Air flow rate = 40.3 m3/h Air inlet = 3 m/s | ||

| [14] | Airflow velocity and cooling channel configuration | 8 prismatic | Airflow velocity = 3, 3.5, and 4 m/s | __ | |

| [15] | Heat transfer model for cell spacing optimization | 45 prismatic | Inlet air flow rates = 0.008, 0.010, 0.012, 0.015 m3/s | ||

| [16] | Different positions of the inlet vent with and without the flow diverter disc | 26,650 cylindrical in a 5P5S configuration | Air speeds = 0.8, 5, and 30 m/s | Optimum thermal performance |

| Cooling Type | Advantages | Disadvantages | Recommended Application |

|---|---|---|---|

| Air | Low cost, easy implementation, and maintenance. It does not require additional components. | Low heat dissipation capacity due to low air conductivity. It can generate temperature gradients inside the battery pack. | Low-power applications in small electric vehicles or hybrids, where simplicity and cost are a priority. |

| Liquid | Efficient heat dissipation, uniform distribution, and precise temperature control. | Increased complexity and cost due to the need for pumps, piping, and radiators. Risk of leakage. | Essential for high-performance EVs and large-capacity batteries needing thermal stability. |

| PCM | Ensures stable temperature and safety without extra energy. | Low long-term heat dissipation and material degradation risk. | Ensures stable thermal control in moderate cycling systems without extra power. |

| Hybrid | Enhances efficiency and stability by merging previous methods. | Increased design and implementation complexity, high costs, and need for precise integration. | Essential for precise thermal control in high-performance EVs and dense batteries. |

| Area | Ref. | Highlights of the Papers | |

|---|---|---|---|

| Requirements and Challenges | [52,53,54,55,56,57,58,59,60,61,62,63] | Reduce costs, improve performance (drive range), fast charging, and safety. | |

| Integrated Optimization | [64,65,66,67,68,69,70,71,72,73,74,75,76,77,78] | Optimization framework for battery sizing. Passive cell balancing and sensitivity-based model predictive control (sMPC) approach for optimal and fast charging. | |

| Modeling and Simulation | [79,80,81,82,83,84] | A dynamic battery energy model optimizes battery pack sizing based on vehicle energy consumption, considering mass, specific energy, and range. | |

| Others | Marketing | [85] | Commercialization of lithium battery technologies, obstacles in battery development, including cost reduction, scalability, and longevity, required for widespread EV adoption. |

| Design | [86,87] | Design a battery pack for a racing application. Clustering-based approach using k-means and support vector clustering (SVC) algorithms. | |

| Balancing | [88,89,90] | Constant and pulsed active balancing current patterns on the aging of LIBs. | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gómez Díaz, K.Y.; De León Aldaco, S.E.; Aguayo Alquicira, J.; Ponce Silva, M.; Portillo Contreras, S.; Sánchez Vargas, O. Thermal Management Systems for Lithium-Ion Batteries for Electric Vehicles: A Review. World Electr. Veh. J. 2025, 16, 346. https://doi.org/10.3390/wevj16070346

Gómez Díaz KY, De León Aldaco SE, Aguayo Alquicira J, Ponce Silva M, Portillo Contreras S, Sánchez Vargas O. Thermal Management Systems for Lithium-Ion Batteries for Electric Vehicles: A Review. World Electric Vehicle Journal. 2025; 16(7):346. https://doi.org/10.3390/wevj16070346

Chicago/Turabian StyleGómez Díaz, Kenia Yadira, Susana Estefany De León Aldaco, Jesus Aguayo Alquicira, Mario Ponce Silva, Samuel Portillo Contreras, and Oscar Sánchez Vargas. 2025. "Thermal Management Systems for Lithium-Ion Batteries for Electric Vehicles: A Review" World Electric Vehicle Journal 16, no. 7: 346. https://doi.org/10.3390/wevj16070346

APA StyleGómez Díaz, K. Y., De León Aldaco, S. E., Aguayo Alquicira, J., Ponce Silva, M., Portillo Contreras, S., & Sánchez Vargas, O. (2025). Thermal Management Systems for Lithium-Ion Batteries for Electric Vehicles: A Review. World Electric Vehicle Journal, 16(7), 346. https://doi.org/10.3390/wevj16070346