The modeling results presented in this section consist of energy consumption, greenhouse gas emissions, and total costs for each of the considered bus technologies. A cost–benefit analysis is then presented to prioritize the different bus technologies by their environmental contributions in terms of savings in GHG emissions relative to the reference diesel bus.

3.2. GHG and Pollutant Emissions

The modeling results for GHG emissions (CO

2, CH

4, and N

2O) are shown in

Figure 3 for all bus technologies under the four driving scenarios considered. The emissions are estimated for the worst-case scenario (full bus capacity and operating with the use of climate control auxiliaries). Emission calculations for electric bus technology are conservatively done on a WTW basis instead of a TTW (or tailpipe) basis in order to level the comparison with the other technologies, since electric buses have no tailpipe emissions as the use of the battery for on-road operation does not consume hydrocarbon fuels. Two scenarios for electric buses are modeled to reflect the current (year 2025) “dirty” electricity production mix (labeled Mix 2015 as it hasn’t changed since the reference year 2015) in Lebanon, which currently still relies on the use of heavy fuel oil (HFO) and diesel to generate electricity in power plants; and, a cleaner future scenario (year 2030) relying on natural gas and a share of renewable energy sources (Mix 2030), as per existing government plans [

30].

Following the estimated energy consumption trends, the lowest GHG emissions for all bus technologies occur under BRT operation and are significantly lower than those estimated under severe congestion conditions. Electric buses, which have zero tailpipe emissions under all driving conditions, consume electric energy from power plants when recharging batteries on board and, therefore, have the highest contribution to GHG emissions under the current polluting Mix 2015. However, under the cleaner Mix 2030, electric buses become the greenest technology in all operating conditions. CNG and hybrid bus technologies have comparable performances in more flowing traffic (less than 5% difference in their GHG emissions in off-peak and BRT operation), but the differences become significantly pronounced in congested traffic (reaching 62.7% higher GHG emissions for CNG in severe congestion). This is due to the additional fuel consumption for CNG technology, while hybrid buses can rely more on zero-emission battery power in those conditions.

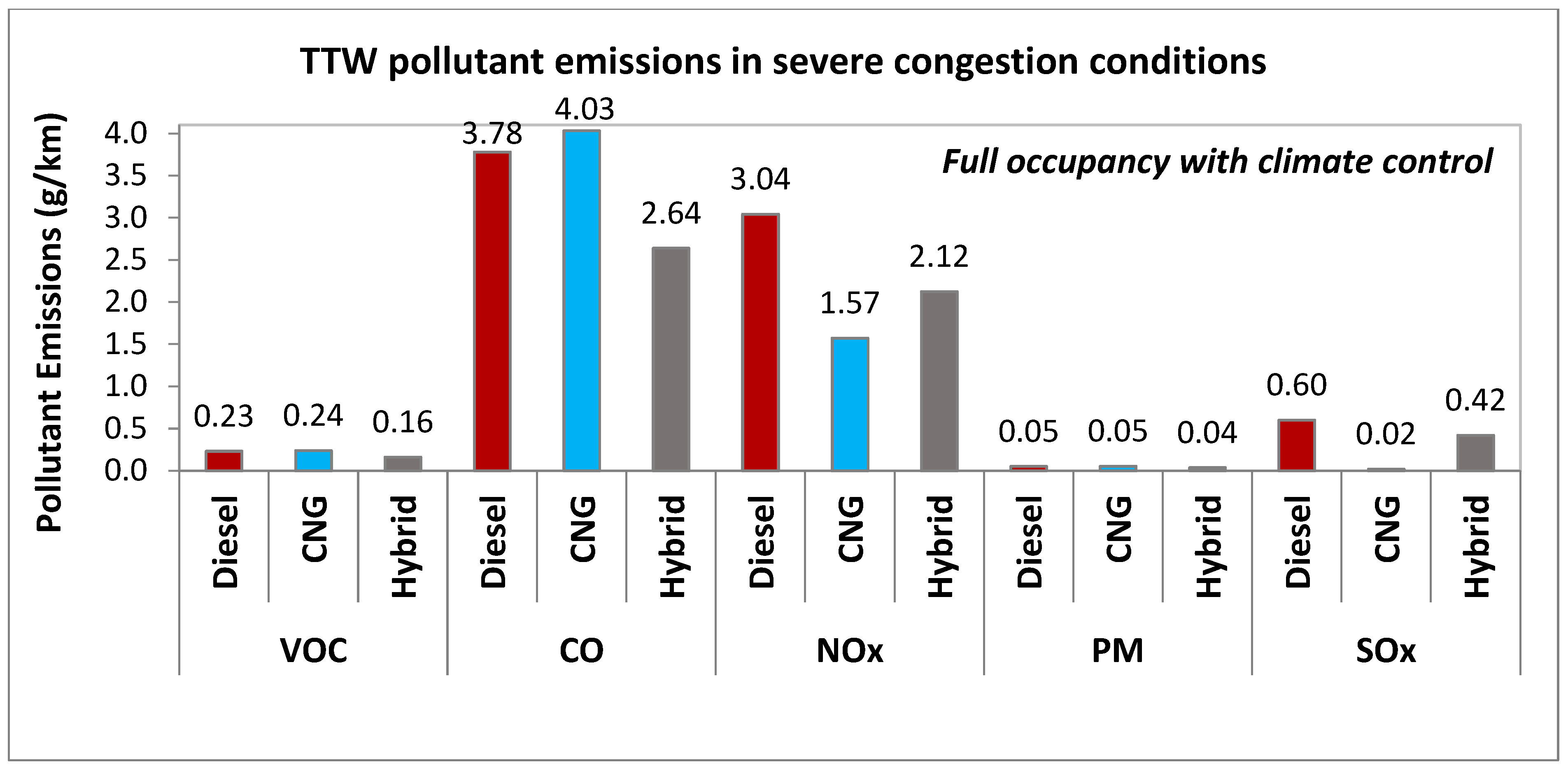

Pollutant emission results are summarized in

Figure 4 for atmospheric pollutants relevant to air quality, namely, volatile organic compounds (VOC), carbon monoxide (CO), nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter (PM), estimated on a TTW basis to reflect their impact on human health inside the city. The results shown are for severe congestion conditions with use of climate-control auxiliaries as a conservative estimate of the worst-case scenario, noting that electric bus technology has zero tailpipe emissions and therefore does not appear in the figure below. Hybrid technology comes out as the better performer for VOC, CO, and PM; however, this only holds true for the severe congestion conditions shown below. Under all other driving conditions, CNG technology is comparable or better than hybrid buses for all pollutant emissions [

12]. This makes CNG buses relatively attractive for cleaning up polluted cities in developing countries, as is the case of Lebanon’s GBA, especially since road transport in Lebanon is the largest contributor to CO emissions [

31].

And as with GHG emissions, dedicated lane service with a BRT type of operation can make all bus technologies even more effective contributors to cleaning the air quality inside the city (see [

12] for a detailed comparison of all pollutant emissions).

It is also noteworthy that under the 2030 electricity production mix, the WTW modeling results show a significantly reduced impact at power plants due to the reliance on natural gas and renewables as less-polluting energy sources for power generation [

12]. This means that the introduction of electric bus technology can clean up the environment inside the city without negatively impacting urban areas where power plants are located, especially when also considering the reduction in car use for commuting as urban and suburban residents are given the option to switch to modern public buses [

32].

3.3. Total Costs

Table 5 provides the estimated total costs for each bus technology, including bus purchase, operating and maintenance (O&M), and applicable infrastructure costs computed over the service life of the bus for each of the four considered driving conditions. These costs do not include any government subsidy as per the baseline scenario defined in

Section 2.

Table 6 breaks down the total costs above to present the estimated acquisition costs per bus kilometer for each technology computed over the service life of the bus.

All alternative-fuel bus technologies have a higher acquisition cost than diesel buses as the most mature technology, with electric buses being significantly higher due to the cost of the large battery pack. This is a discouraging factor for operators when it comes to transitioning away from diesel bus technology, but which can be compensated for with government subsidies, battery-swapping stations, and/or optimal battery sizing adapted for local driving and route service conditions [

33].

A second breakdown of the total costs is given in

Table 7, which summarizes the estimated O&M costs per bus-kilometer traveled over the estimated average mileage of 100,000 km per year under each operating condition for each of the considered technologies.

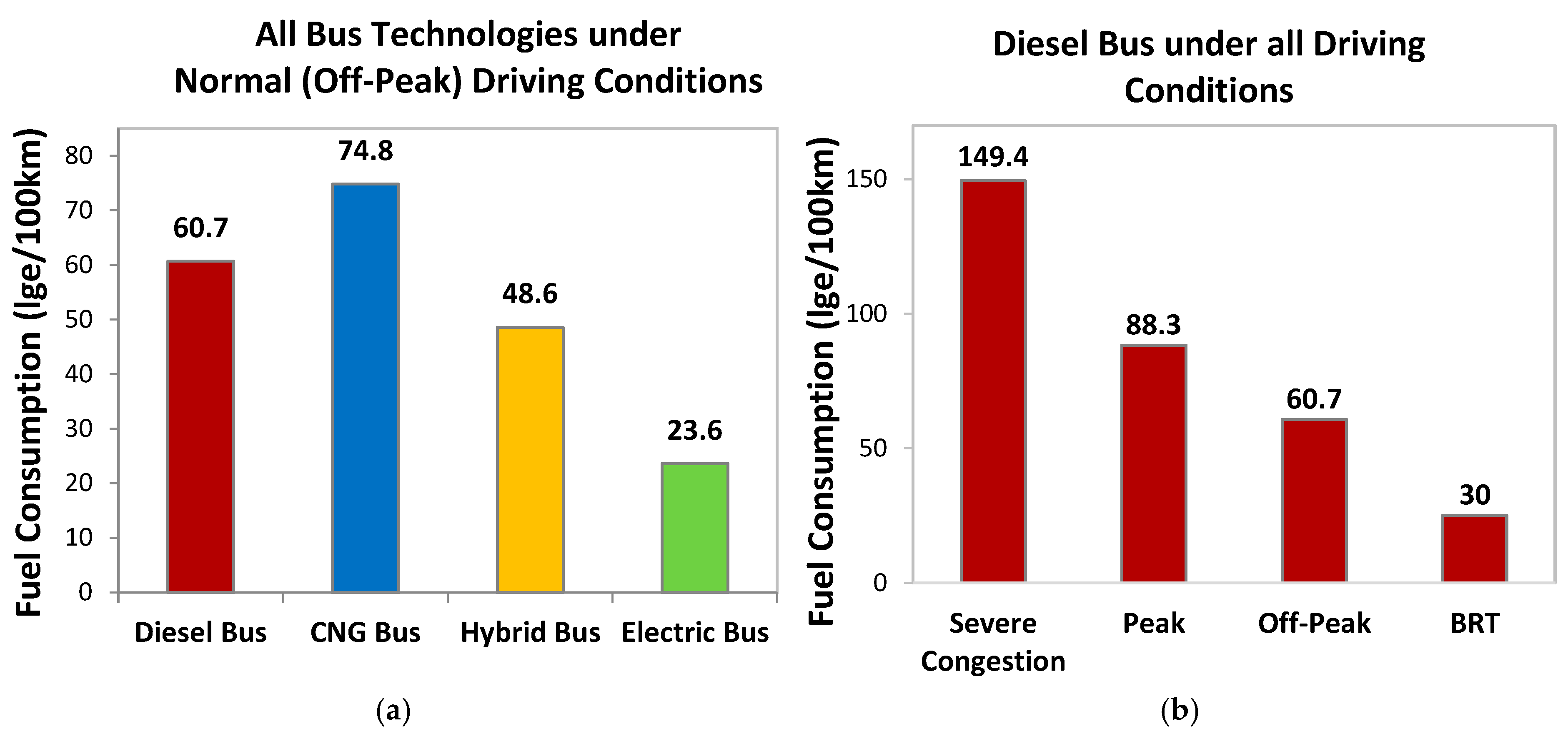

The results show two main trends: first, that electric buses have the lowest operating cost out of all the evaluated technologies, less than diesel by about 29.3% in normal (off-peak) driving conditions. This is expected since there are fewer components in the electric bus powertrain than in other bus technologies with conventional engines, where a number of moving parts also require frequent replacement [

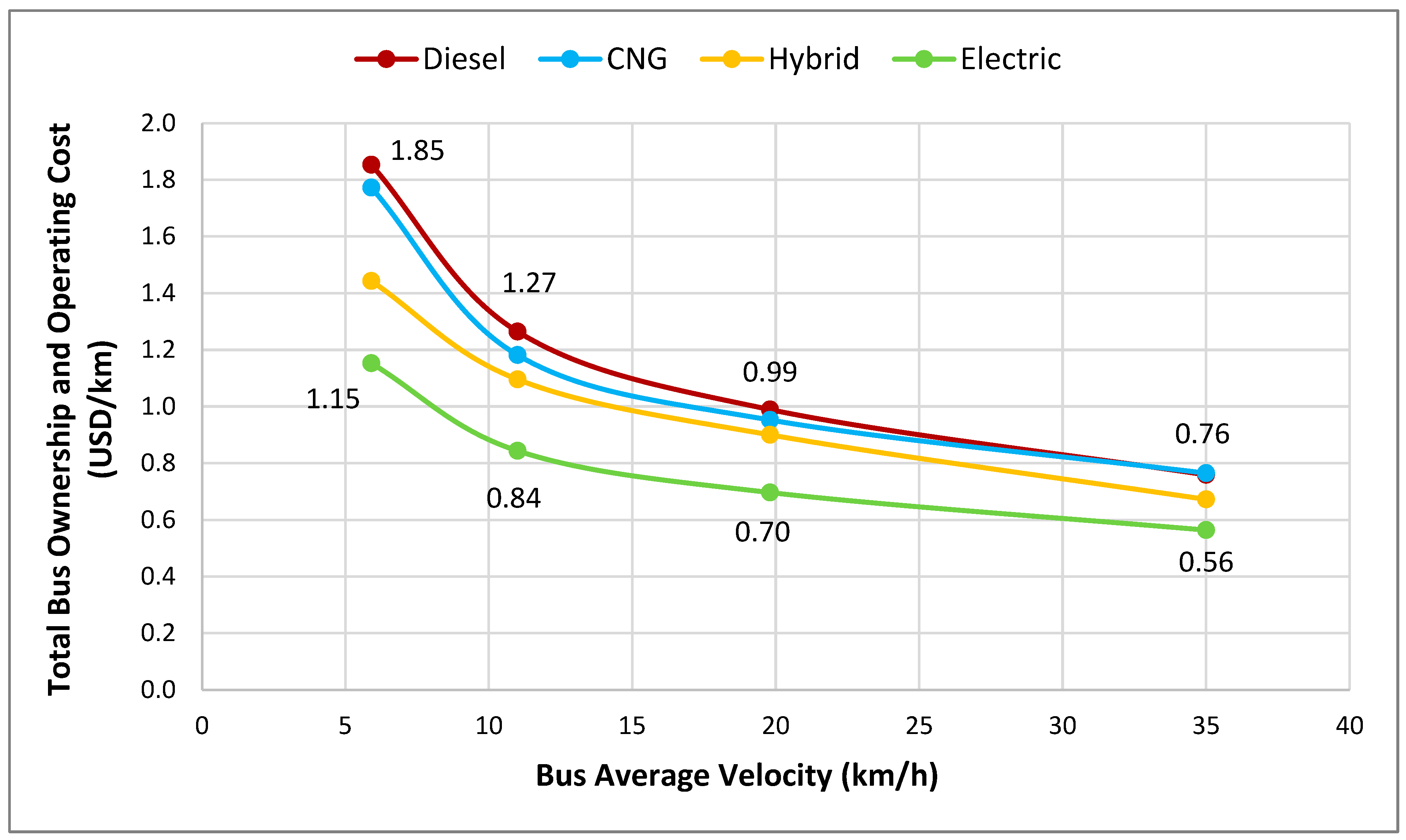

34]. The second observed trend is that driving conditions greatly impact bus operating costs for all technologies, as illustrated in

Figure 5. Specifically, bus O&M costs for every bus technology are greatly reduced when operating at higher average speeds as can be achieved in BRT operation on dedicated lanes, ranging between a 51.3% reduction for electric buses and 58.9% for diesel. This is because there is less fuel consumption and less wear and tear in free-flow conditions, with all engine technologies operating at higher efficiency [

35].

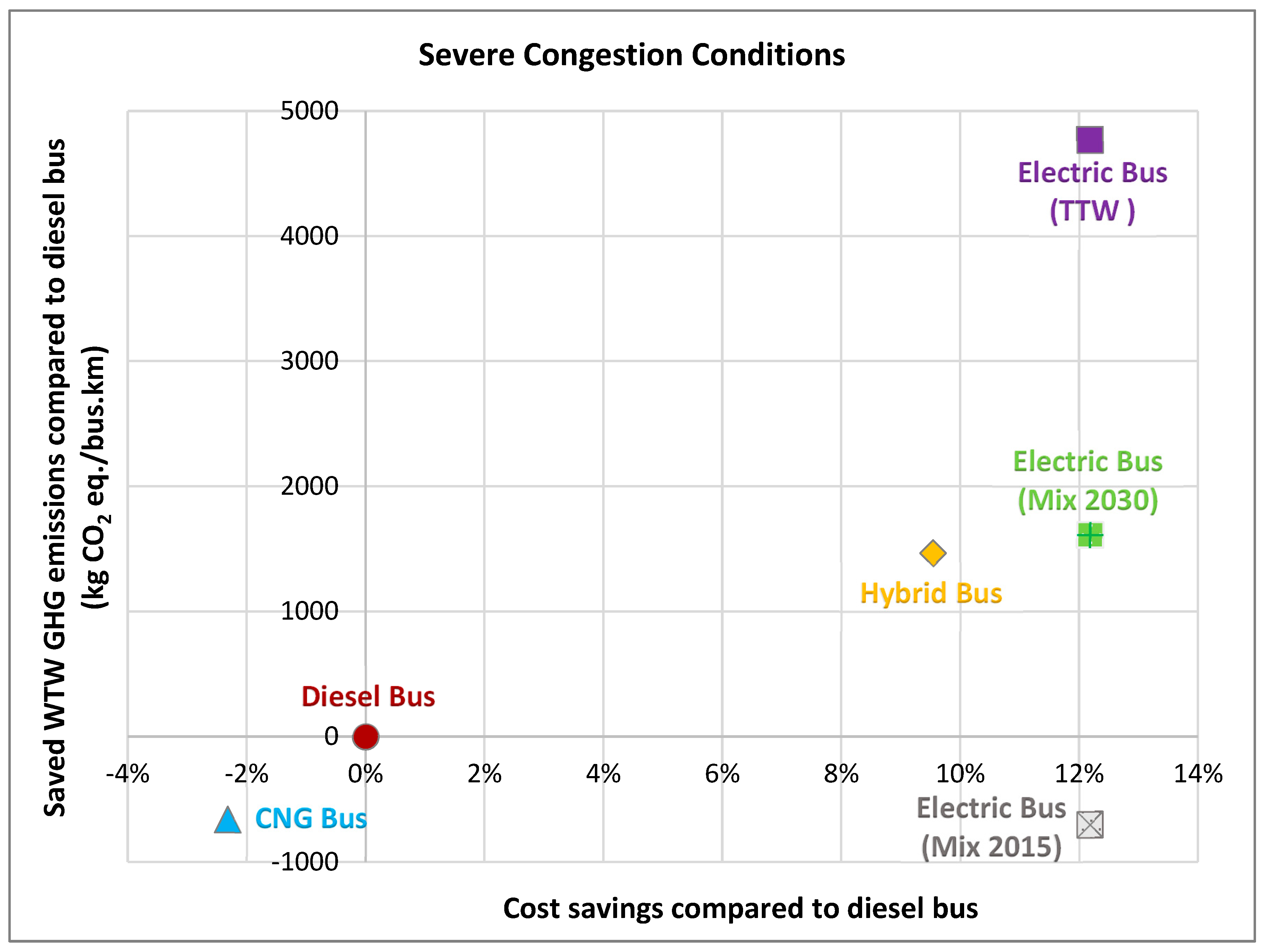

The WTW GHG emission savings for each technology over the reference diesel bus were attributed to the corresponding total bus cost in order to prioritize the different technologies by their environmental-to-cost performance. The results are illustrated in

Figure 6 for severe congestion conditions as the more common operating condition during work commutes in GBA.

Results show that hybrid buses provide positive environmental-to-cost performance over diesel buses, while CNG buses are not competitive in severe congestion due to their lower engine efficiency in these conditions. Electric buses are only effective using the 2030 electricity production mix, but their performance is only comparable to hybrid technology in the considered scenario of zero government subsidies for bus technologies (about 10% more reduction in GHG emissions for 3% less total cost than hybrid buses). This is due to the lower maintenance cost of electric buses compared to the other conventional engine technologies. This means a clean electricity mix is essential to be able to operate electric buses in an environmentally beneficial way, but also that this technology is not very competitive without government subsidies. However, battery technologies are advancing at an accelerated pace, which is expected to extend battery service life. In this case, zero battery replacement cost could be assumed over the vehicle service life, which would make electric and hybrid technologies even more cost-effective.

Note that even under the current dirty electricity mix 2015, electric buses are more cost-effective than diesel buses, though not more environmentally beneficial. The TTW results are only shown to illustrate the importance of considering power-plant emissions since TTW figures overestimate the environmental benefits of battery-electric technology, in this case by about 67% additional GHG reduction than on a WTW basis. But it is also important to note that since the above figure only illustrates performance in worst-case (severe congestion) conditions, then the overall performance of each bus technology will be more beneficial when averaging it out over all modes of operation.

Furthermore, the transition to alternative-fuel bus technologies typically benefits from a number of incentive schemes, many of which are already commonplace worldwide to encourage new technology adoption [

36], such as tax exemptions and reduced customs and registration fees [

5]. The incentives mainly intend to reduce the bus purchase and ownership costs, which can be substantially higher for newer bus technologies compared to conventional diesel buses. For example, in neighboring Jordan, a country facing similar economic challenges, the government recently reduced the sales tax and customs duties by more than 50% for operators replacing their buses with newer models, making electric buses more competitive and increasing their adoption rates [

37].

Along those lines,

Table 8 presents the estimated economic incentives for each technology based on the proposed bus purchase cost subsidy scheme under a potential external funding scenario for Lebanon (as introduced in

Section 2). Note that this assumes the same level of purchase subsidy across all technologies, which gives battery-electric technology a competitive advantage over other bus technologies since the electric-vehicle purchase cost is highest due to the high cost of the battery.

Table 9 presents the subsidized total costs (including purchase, O&M, and infrastructure costs with government subsidies) for each bus technology, computed over the service life of the bus based on the defined government subsidy scheme for all driving conditions.

The subsidized total cost figures show a marked improvement in the competitiveness of diesel bus technology, becoming much more efficient when operated in a BRT system and bridging the gap with electric buses since diesel engines have their highest efficiency in free-flow conditions. This also means CNG technology becomes even less competitive compared to diesel in BRT operation. This is due to the relatively higher ownership costs of the bus technology, in addition to the higher fuel consumption due to the higher weight of the storage tanks (heavy high-pressure vessels) as a consequence of the lower fuel-energy density of natural gas. However, it should be kept in mind that the environmental performance of CNG is much better than diesel when it comes to cleaning up highly polluted cities, as is common in developing countries, specifically for NOx and SOx pollutants.

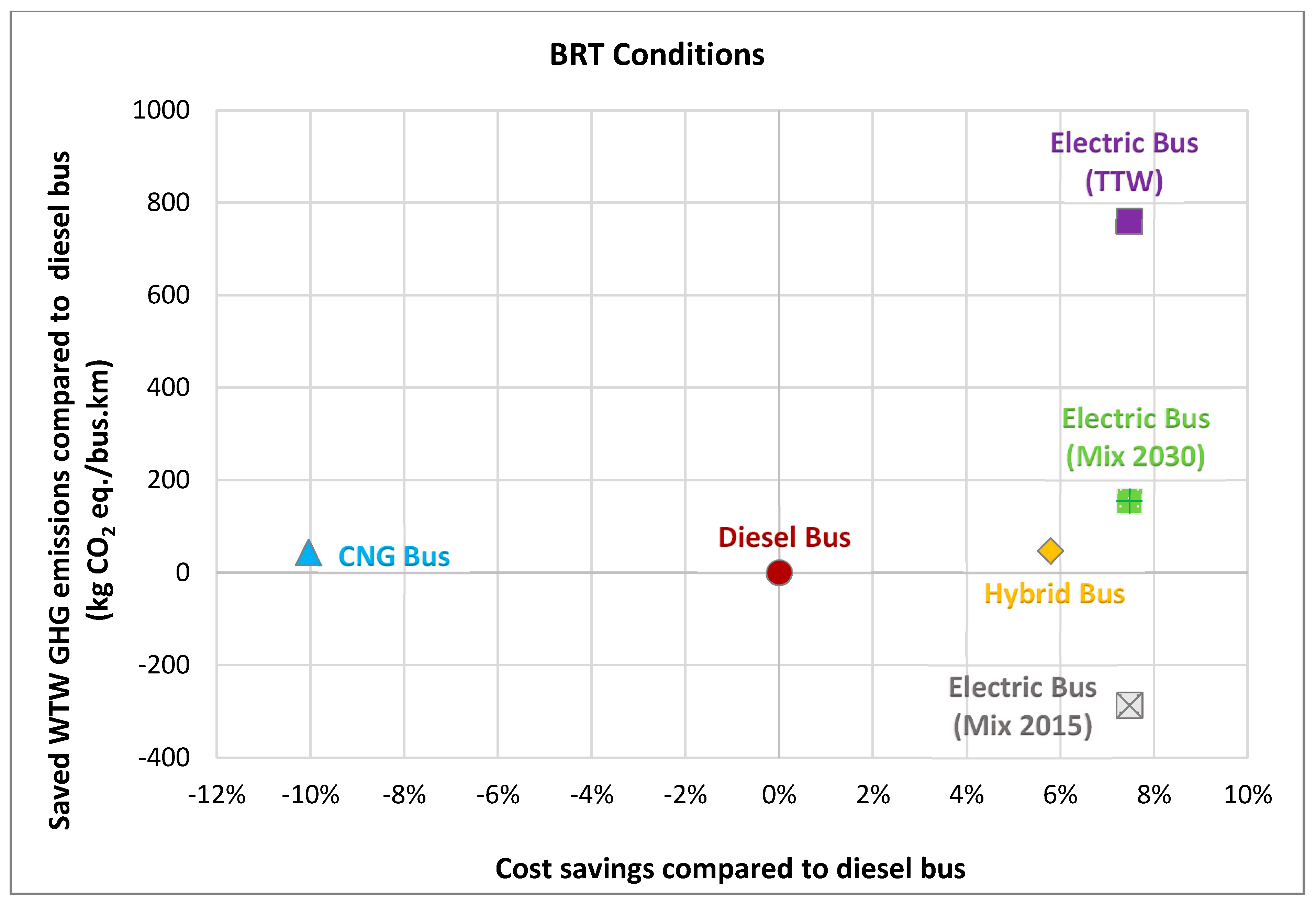

The performance of the considered technologies under free-flow conditions typical of BRT operation on a dedicated lane are illustrated in

Figure 7. Only subsidized costs will be considered further in this study based on previous experience in developed countries where government support has been typically needed to ensure adoption of new vehicle technologies.

As discussed above, diesel buses under BRT conditions are able to bridge the gap with hybrid and electric technologies for both environmental and cost savings due to their improved engine efficiency in free-flow conditions, and put further distance with CNG technology, but only in terms of cost savings. And while battery-electric buses remain the top-performing technology with approximately 8% cost savings over diesel, this is only due to the high (80%) and equal subsidy level across all technologies, which is not reasonable in developing countries. This is in agreement with other studies in similar contexts [

38,

39,

40]. For subsidy levels below approximately 60% of the bus purchase cost, electric bus technology becomes more costly to own and operate than diesel in BRT operation, while hybrid technology requires at least a 50% subsidy to remain cost competitive compared to diesel buses.

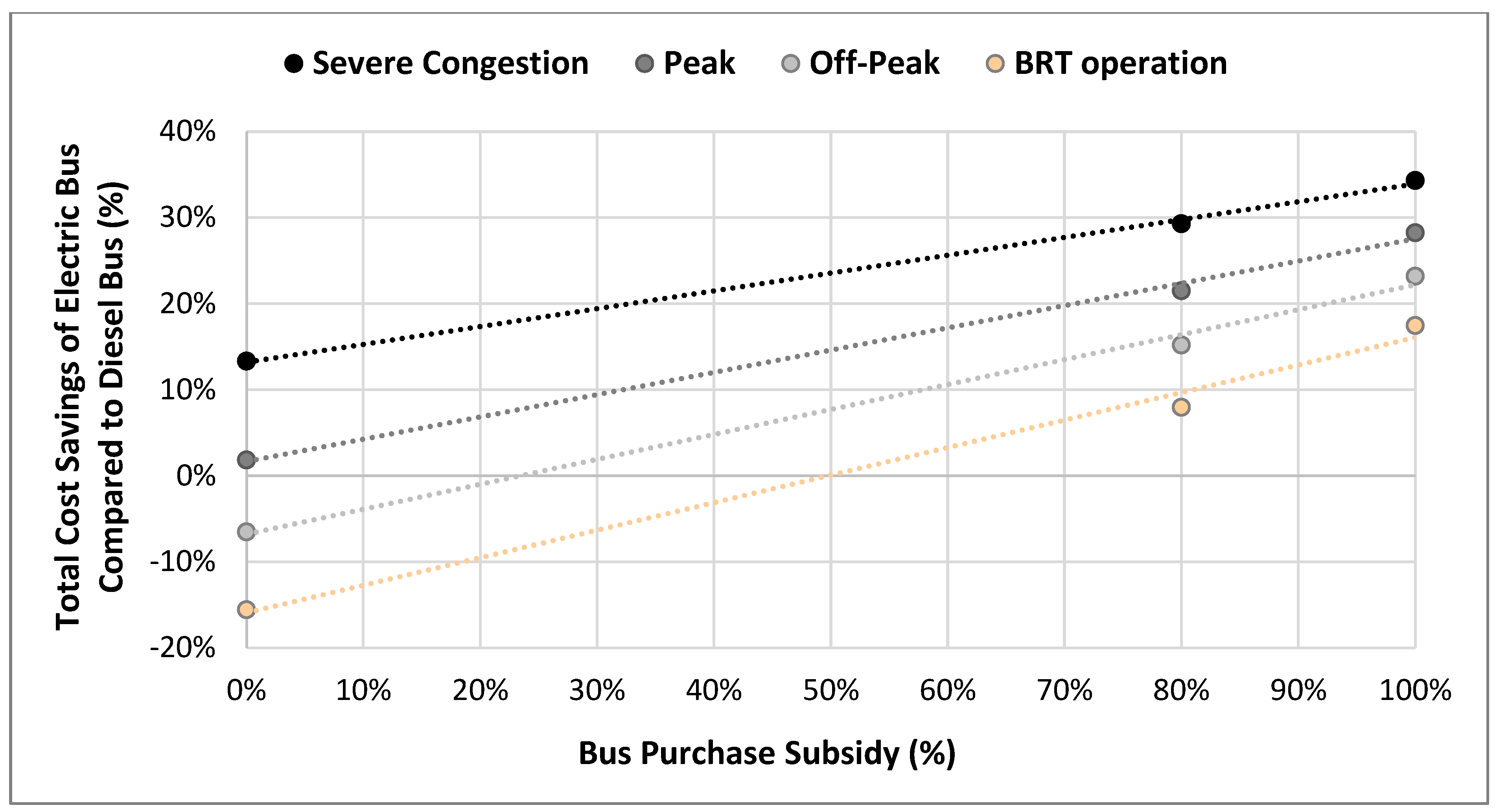

Figure 8 further illustrates a sensitivity analysis on the required subsidy levels for electric bus technology relative to the reference diesel bus over the service life of the bus under all driving conditions. The results show that electric buses are always cost-effective in congested driving conditions, even when no subsidy is considered. However, diesel buses are more cost-competitive in less congested conditions, unless significant subsidies of approximately 30% and above are provided on the bus purchase cost for electric technology in this case. Note that purchase and O&M costs of electric bus technology are on a decreasing trend as the technology is improved and adoption reaches economies of scale, which can make it competitive under all driving conditions for lower subsidy figures [

41].

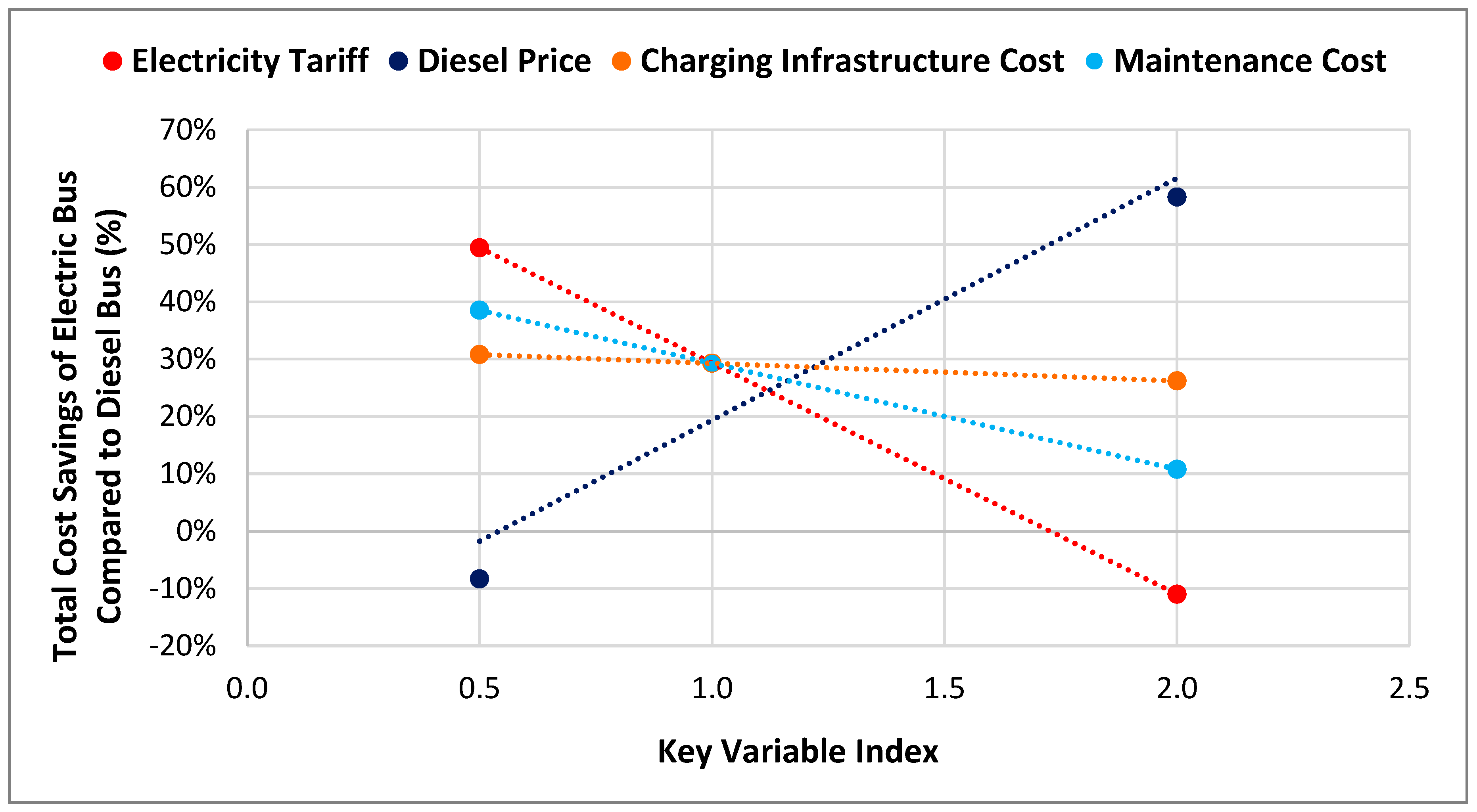

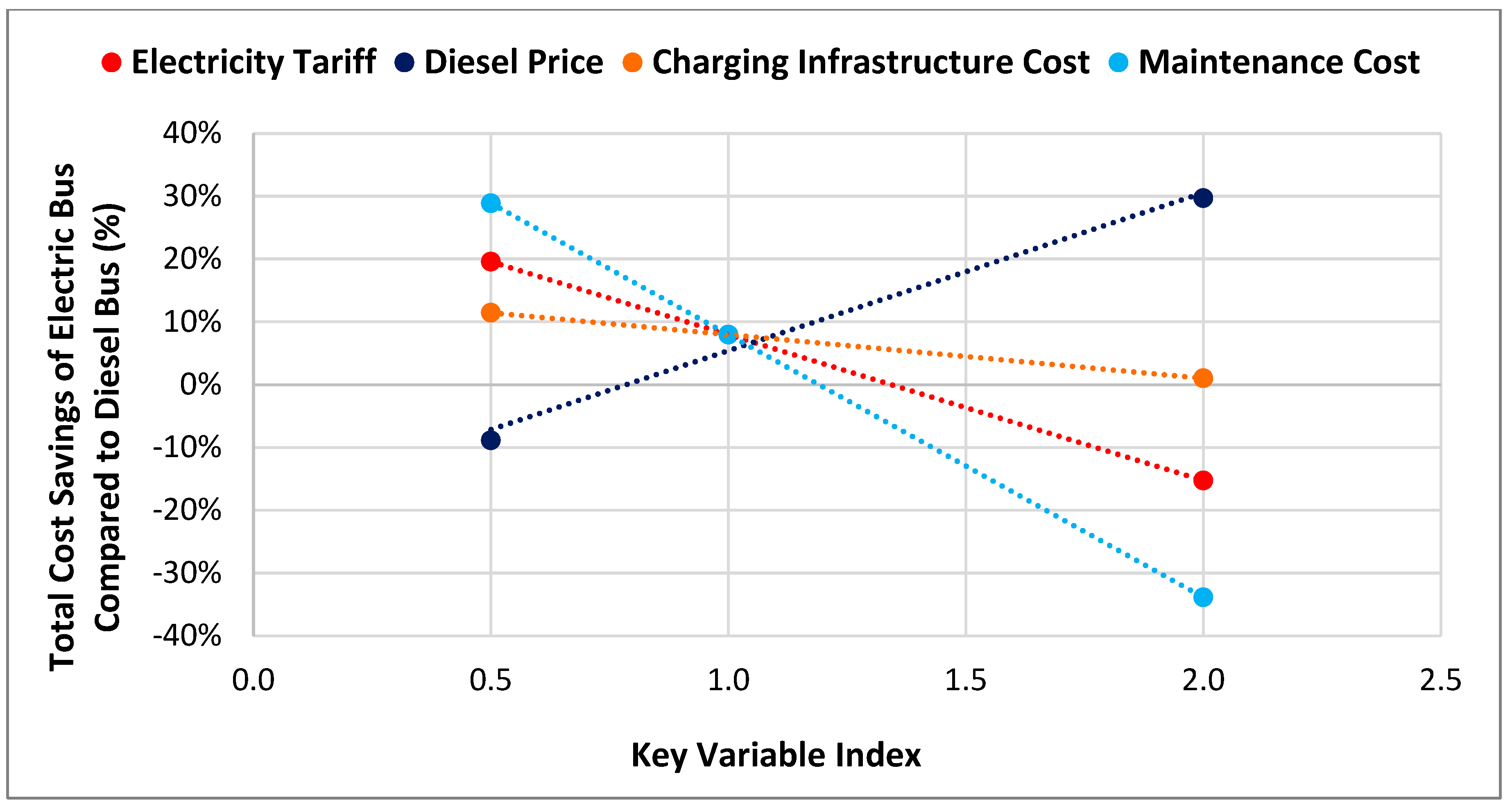

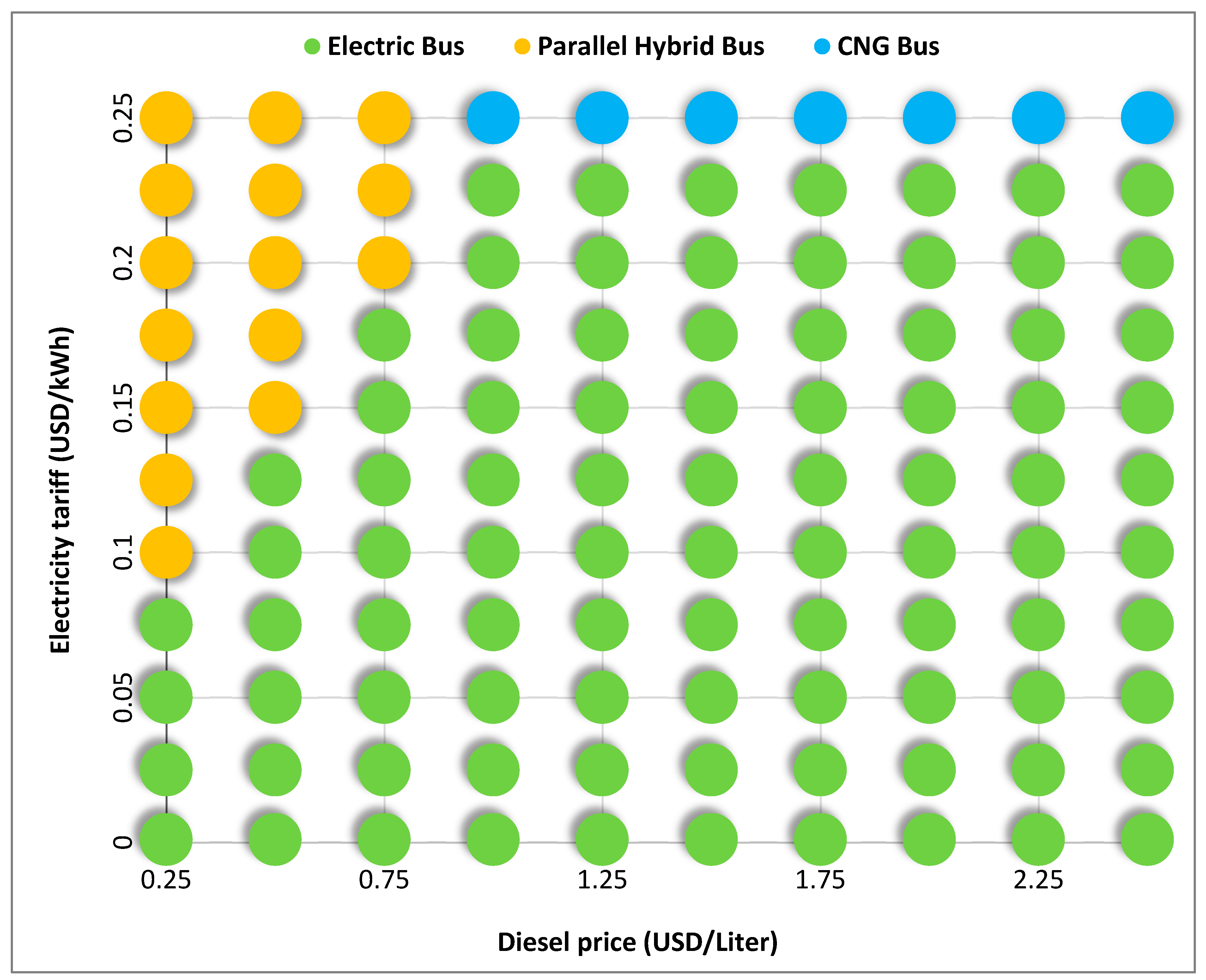

Similarly, for the dominant electric bus technology, additional sensitivity analyses on key variables (the price of diesel fuel, electricity tariff, charging infrastructure cost, and maintenance cost) were done to assess their impact on the total cost of electric bus relative to diesel under the two extremes of operating conditions (severe congestion and BRT operation on dedicated lane), as shown in

Figure 9 and

Figure 10, respectively. The key parameters were varied between half and double their initial values of 0.73 USD/L for diesel fuel, 0.13 USD/kWh for electricity tariff, 50,000 USD/bus for infrastructure cost, and 0.36 USD/km for maintenance costs.

Some important conclusions can be drawn for the case of Lebanon from the sensitivity analysis shown—most notably that bus maintenance costs and diesel prices have the highest impacts on the total potential cost savings of electric bus technology. For example, if the diesel price increases to double its current value of 0.73 USD/L, the cost savings of electric buses relative to diesel buses ranges between +30% in BRT operation and +60% in severe congestion conditions.

Similarly, cost savings between +30% and +40% can be achieved if maintenance costs are reduced by half of the assumed value for electric buses, which in this study are considered identical to those of diesel buses because of the lack of available maintenance cost data for electric buses. Note, however, that maintenance costs of electric bus technology are expected to be lower than those of diesel buses, due to having fewer components in the electric bus powertrain [

25]. Therefore, the results presented in this study underestimate the cost savings of electric bus technology and are used as a conservative estimate.

Similar trends and substantial savings in the cost for electric bus technology are observed if the electricity tariff is incentivized for mass transit, ranging between +20% and +50% in cost savings under BRT and severe congestion conditions, respectively, if the electricity tariff is reduced to half of its current value of 0.13 USD/kWh.

However, electric bus costs are not remarkably sensitive to the variation in the charging infrastructure cost as considered in this study, since this cost component (estimated at USD 50,000 per CNG or electric bus technology from previous studies) has a relatively small contribution to the capital cost. It is worth noting, however, that this assumption underestimates the complexity and associated potential costs of deploying infrastructure for operating these new technologies, which goes beyond the costs of the charging equipment to include ancillary costs related to facility upgrades and the training of personnel on bus maintenance and operational procedures, but which are outside the scope of this study.