1. Introduction

In many industrial and daily application scenarios today, permanent magnet DC brushless motors are widely used due to their high efficiency, high reliability, and many other advantages. However, in its actual operation, various complex environmental factors inevitably have an impact on the motor system [

1,

2]. For example, the vibration generated by a motor during operation is a common physical phenomenon. Vibration may originate from various factors such as the mechanical structural imbalance of the motor itself, unstable installation, or the inaccurate meshing of the transmission device [

3]. When a motor operates in a vibrating environment, the relative positions and interaction forces between its internal components undergo small but continuous changes, which can introduce system process noise and interfere with the normal operating state of the motor and the accuracy of control signals [

4,

5,

6]. For example, in the case of heating, the motor accumulates heat during its operation due to factors, such as winding current and eddy current losses in the iron core. The increase in temperature can cause changes in the physical properties of motor materials, such as an increase in resistivity, which can affect the electrical performance of the motor and generate noise signals that can be mixed into the system’s process [

7,

8]. In addition, various factors such as electromagnetic interference, humidity changes, and dust particle intrusion that may exist in the environment can generate system process noise to varying degrees, which has a negative impact on the performance and control accuracy of the motor [

9,

10].

Given these practical situations, when modeling permanent magnet brushless DC motors, the noise factors that exist in reality must not be ignored [

11,

12,

13]. The key situation of including noise in the model must be fully considered so that the established model can more realistically and accurately reflect the operating characteristics of the motor under actual working conditions [

14,

15], providing a reliable theoretical basis and data support for subsequent motor performance evaluation and control strategy design, etc., ensuring that the motor can stably, efficiently, and accurately play its role in the application field, meet the high-precision requirements [

16,

17,

18] of industrial production and the needs of people’s daily life for convenience. In addition, in model identification, when the driving data are affected by noise interference, it will have a significant impact on the accuracy of model identification. Measurement noise can mask or distort the true features of measurement data, leading to the inaccurate extraction of useful information from the data and subsequently affecting the accuracy of model parameters. Due to the influence of noise, the model may perform well on training data but cannot make good predictions on new data, resulting in a decrease in the model’s generalization ability. Meanwhile, measuring noise may lead to unstable model identification results, making the model susceptible to external interference in practical applications. Therefore, considering the influence of noise is one of the important aspects to improve the model identification performance [

19,

20,

21].

The current data-driven modeling methods show a diversified trend in motor modeling. Multiple algorithms have been applied [

22,

23], such as the BP neural network for motor inverse model construction to achieve high-precision position control and deep learning algorithms for the modeling and control of brushless DC motor drive systems. There are also methods such as support vector machine, kernel principal component analysis, extreme learning machine, and the physical information neural network, each with their own characteristics and advantages, used for modeling scenarios of different motors [

24,

25]. These methods have many advantages, such as improving model accuracy, accurately capturing the complex characteristics and nonlinear relationships of motors, learning, and training effective models based on actual data, adapting these to different types of motors and complex working conditions [

26,

27], and integrating multi-source data to promote the intelligent development of motor systems, assisting in performance evaluation, fault prediction, and optimized control. However, there are also challenges in current research, such as the poor interpretability of models, high requirements for data quality and quantity, the need to improve generalization ability, and some models are complex and have low computational efficiency.

In the research process of the parameter identification of data-driven motor models, the measurement data used will inevitably be affected by measurement noise [

28,

29,

30]. The main reasons for this are as follows: Firstly, the sensor itself has certain accuracy limitations and cannot measure physical quantities completely accurately, resulting in measurement results containing errors that manifest in the form of noise. Secondly, electromagnetic interference, temperature changes, vibrations, and other factors in the operating environment of the motor can affect the measurement of the sensor, resulting in measurement data deviating from the true value. In addition, the measurement signal may be subject to interference during transmission, resulting in damage to the integrity of the signal and the inclusion of noise in the measurement data [

31,

32,

33]. Finally, when preprocessing and filtering measurement data, improper processing methods may introduce additional errors and exacerbate the impact of measurement noise.

The presence of these measurement noises will have a significant impact on the accuracy of model identification [

34]. Measurement noise can mask or distort the true features of measurement data, leading to the inaccurate extraction of useful information from the data and subsequently affecting the accuracy of model parameters. Due to the presence of noise, the estimation of model parameters may deviate, making it difficult for the model to accurately reflect the actual characteristics of the motor [

35,

36,

37]. Meanwhile, due to the influence of noise, the model may perform well on training data but cannot make good predictions on new data, resulting in a decrease in the model’s generalization ability. In addition, measuring noise may lead to unstable estimation results of model parameters, making the model susceptible to external interference in practical applications and reducing its stability. Therefore, in the research of data-driven motor model parameter identification [

38,

39], effective noise processing methods such as data preprocessing, filtering, denoising, etc., need to be adopted to reduce the impact of measurement noise on the accuracy of model identification and improve the accuracy and reliability of the model.

In the application process of traditional subspace identification algorithms, the correlation between input signals and noise often interferes with the effectiveness of the algorithm. To address this issue, considering the situation where the driving data are contaminated by noise, a permanent magnet DC brushless motor model identification method based on an auxiliary variable closed-loop subspace identification algorithm was studied. This study draws on the model theory based on variable errors and introduces the key element of auxiliary variables [

40,

41], thus avoiding the complex projection process in classical subspace identification algorithms. At the same time, in the process of conducting principal component analysis on data, it effectively avoids the complex calculations faced when solving the analysis object in the previous principal component analysis process [

42,

43], greatly improving the practical application value and performance of the algorithm, and providing a more reliable theoretical basis and technical guarantee for related research and practical applications. The research contributions of this paper can be summarized into the following three points:

(1) A model identification method for automotive direct drive motors has been proposed, which can effectively handle the situation of noise pollution in driving data and improve the accuracy and stability of model identification.

(2) Drawing on the model theory based on variable error, auxiliary variables are introduced to avoid the complex projection process in traditional subspace identification algorithms, simplify algorithm implementation, and reduce computational complexity.

(3) The effectiveness and superiority of the proposed algorithm in actual working conditions were verified through the chassis dynamometer simulation testing of the vehicle-mounted permanent magnet DC brushless motor, providing a more reliable model basis for motor performance evaluation and control strategy design.

The rest of this paper is organized as follows. The construction of a data-driven identification model is presented in

Section 2. The improved closed-loop subspace identification algorithm for the motor model considering noise pollution is designed in

Section 3. The verification and analysis of results are provided in

Section 4, followed by the Conclusion in

Section 5.

4. Verification Results and Analysis

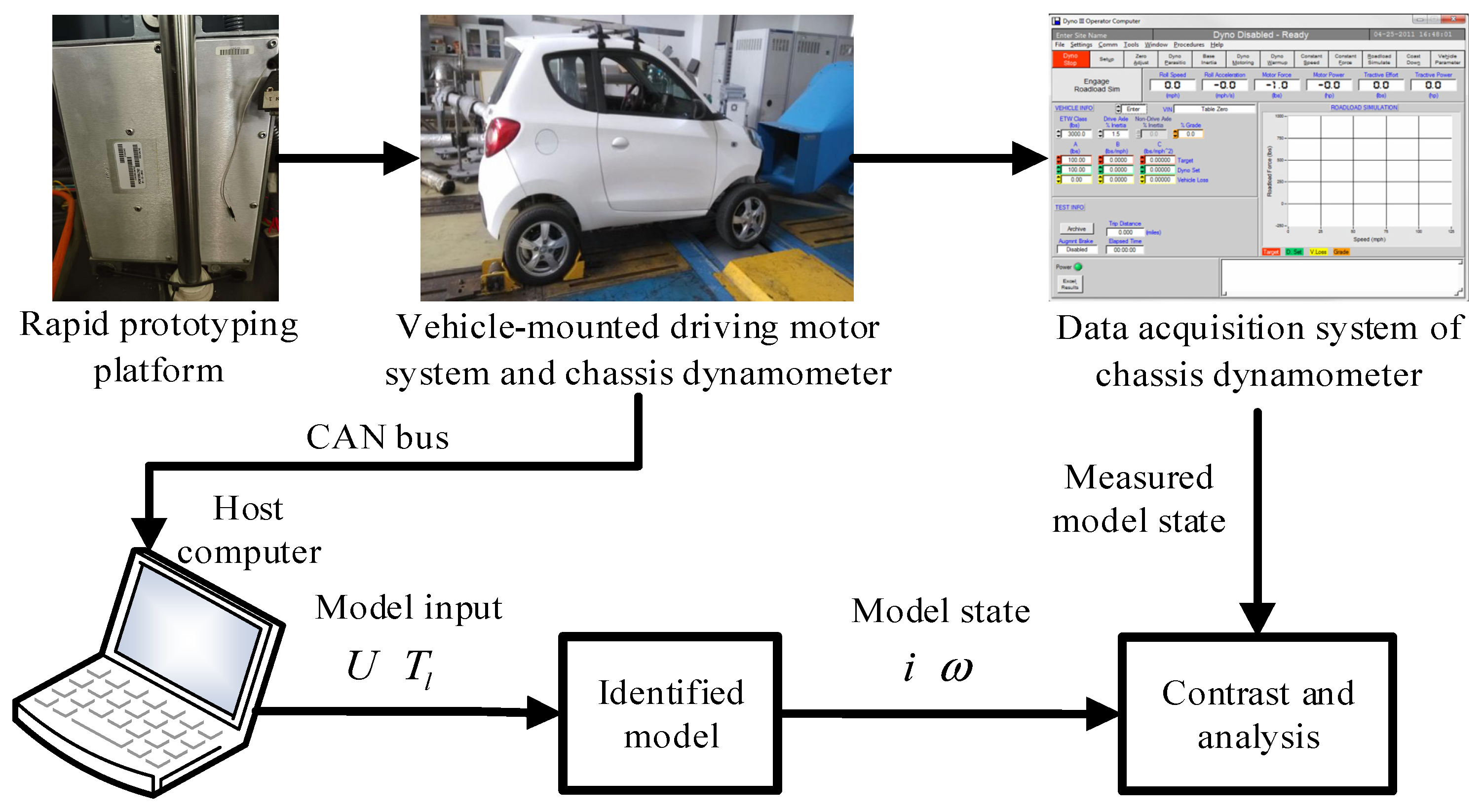

In order to more intuitively and effectively reflect the effectiveness of the proposed closed-loop subspace identification algorithm based on auxiliary variable principal component analysis in the parameter identification process of the permanent magnet DC brushless motor model, a chassis dynamometer simulation test of the vehicle-mounted permanent magnet DC brushless motor was conducted. Through independent experimental settings, different driving datasets from those used in the model identification process were collected to ensure independence between the model identification data and the model validation data, thereby more clearly reflecting the actual effectiveness of the proposed identification algorithm.

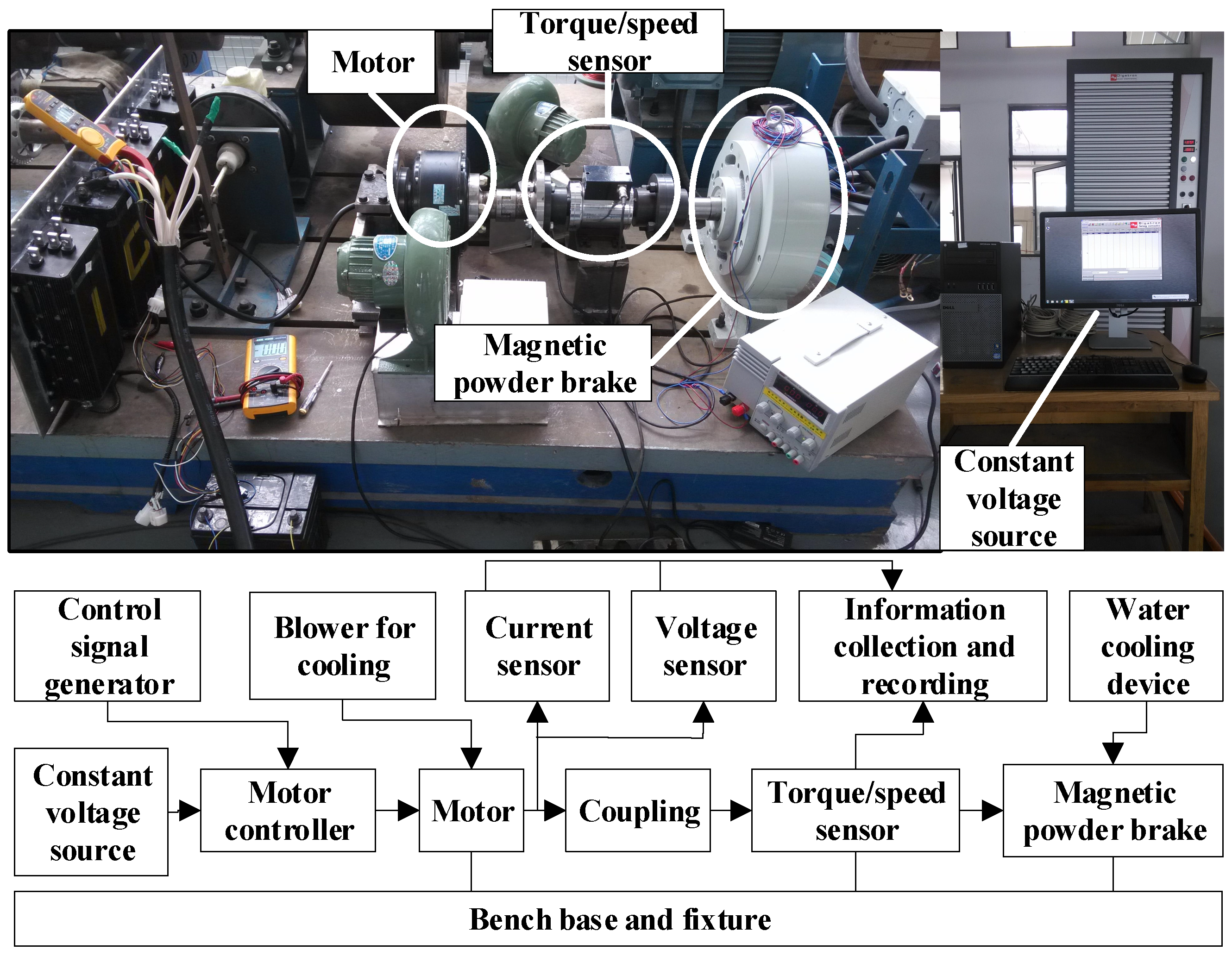

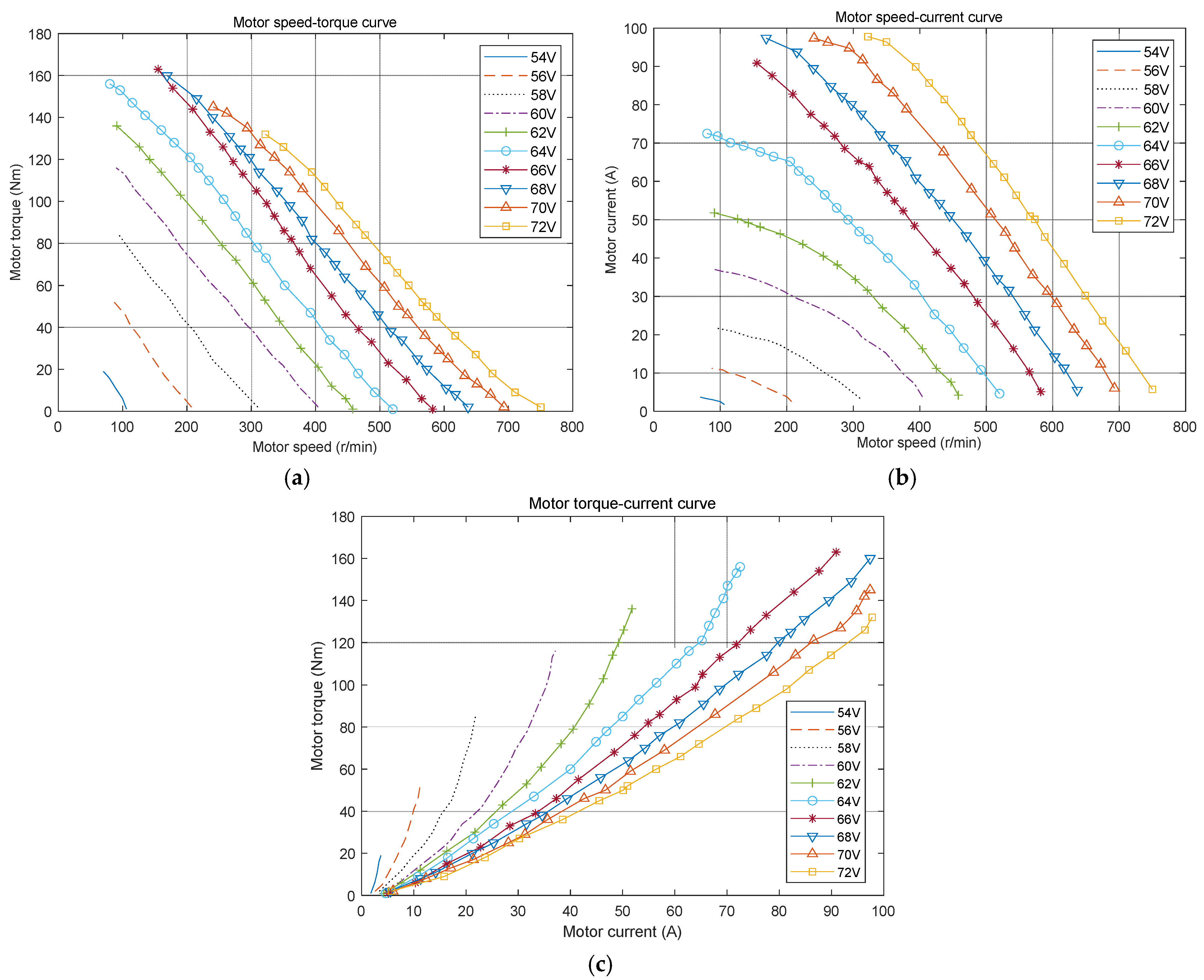

The chassis dynamometer simulation test of the vehicle-mounted permanent magnet DC brushless motor is shown in

Figure 3. The test vehicle was a distributed drive electric vehicle modified from a micro pure electric vehicle, which uses four-wheel hub motors to directly drive the vehicle. D2P MotoHawk (Fort Collins, CO, USA) rapid prototype of version V2.4 is a software and hardware platform developed based on the product ECU and Matlab/Simulink control system. MotoHawk utilizes a product-level ECU hardware platform to enable the development of motor drive control systems without the need for user redevelopment. During the experiment, MotoHawk was used to establish a motor control model, and a certain control signal voltage was given to simulate the process from motor start-up to steady-state driving at a constant speed under the fixed power demand state of the motor. The front wheels of the vehicle were placed on the drum of the chassis dynamometer test bench, and the entire body of the vehicle was fixed. Then, by setting different pedal openings of the vehicle (corresponding to the motor controller signal voltage), the process of accelerating from a standstill when the motor had a load was simulated. The signal voltage of the motor controller was pre-set based on the rapid prototyping controller, which can avoid control signal fluctuations and unnecessary motor state fluctuations caused by the driver stepping on the pedal. We simulated the process of accelerating the vehicle from start to constant speed under different pedal openings by setting different motor control signal voltages. In addition, the chassis dynamometer system also has a dedicated blower to simulate the wind resistance of the vehicle at different wind speeds.

The current sensor and voltage sensor installed on the drive motor were used to monitor the bus current and bus voltage of the motor controller. The speed sensor at the wheel was a photoelectric speed sensor. When the wheel or motor rotated, it could convert the light pulses within the cycle into electrical pulses, thereby equivalently converting the motor speed based on the time required for the motor to rotate once. The motor torque was collected and converted through the chassis dynamometer system. At the same time, the CAN bus channel was used to record and save all sensor signals and controller signals. The vehicle SPY records and stores control signals and sensor signals on the vehicle bus.

The proposed algorithm was used for model identification and construction, and model validation was conducted after model identification with the aim of examining the fit between identification results and actual outputs. An input is applied to the data for the constructed identification model; a series of identification data is generated; and then these data are compared with the actual output data. Comparing the degree of fit between the state data curves of two sets of models provides an important basis for evaluating the accuracy of model identification.

The convergence stability of the identification model characterizes the accuracy of the model, as well as the reliability based on the model observer and controller. By observing the zero-pole distribution of the identification model system matrix, the stability of the model can be determined. If the zeros and poles of the model matrix are distributed within the unit circle of the complex plane, this system is considered stable. The zero pole distributions of the N4SID and PCA-N4SID model identification algorithms are (0.6503, 0.5672), (0.6368, −0.5613), and (0.6122, 0.5072), (0.5694, −0.5106), respectively, as shown in

Figure 4. From this figure, it can be seen that the poles of both algorithms are within the unit circle, indicating that the identification models obtained are stable.

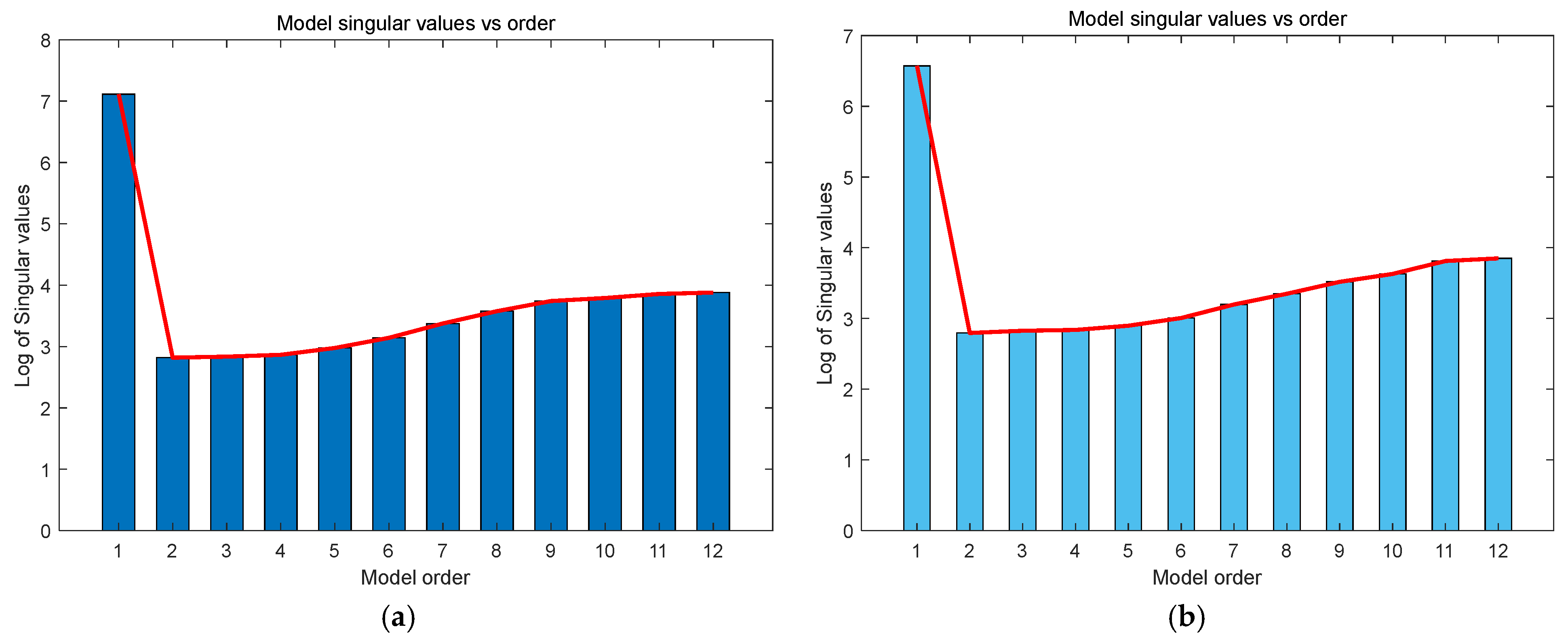

Singular value decomposition was performed on the constructed Hankel matrix by taking the first 12 singular values and calculating the logarithm. The relationship between the model order and the logarithm of the singular values is shown in

Figure 5. According to this figure, the trend of singular value logarithms for both the N4SID and PCA-N4SID algorithms changes when the order is two. When the model order is one, the logarithm of singular values under both algorithms is relatively large. When the model order is two, the logarithm of singular values under both algorithms reaches the minimum value. As the order of the model gradually increases from two, the logarithm of singular values under both algorithms also gradually increases. The results indicate that when the model order is two, the logarithm of singular values under both algorithms reaches the minimum extremum point. Therefore, the model order of both the N4SID and PCA-N4SID algorithms can be determined as two.

The parameter set of {

R,

Ka,

Kt,

b,

J,

L} obtained based on the N4SID algorithm is {0.6632, 0.0637, 11.1952, 0.6206, 7.6581, 0.1293}. The parameter set of {

R,

Ka,

Kt,

b,

J,

L} obtained based on the PCA-N4SID algorithm is {0.6877, 0.0603, 11.4288, 0.6429, 7.1433, 0.1249}. Then, the identified model is used to validate its accuracy. Firstly, the model state identification results are validated without noise pollution, and the comparative results obtained are shown in

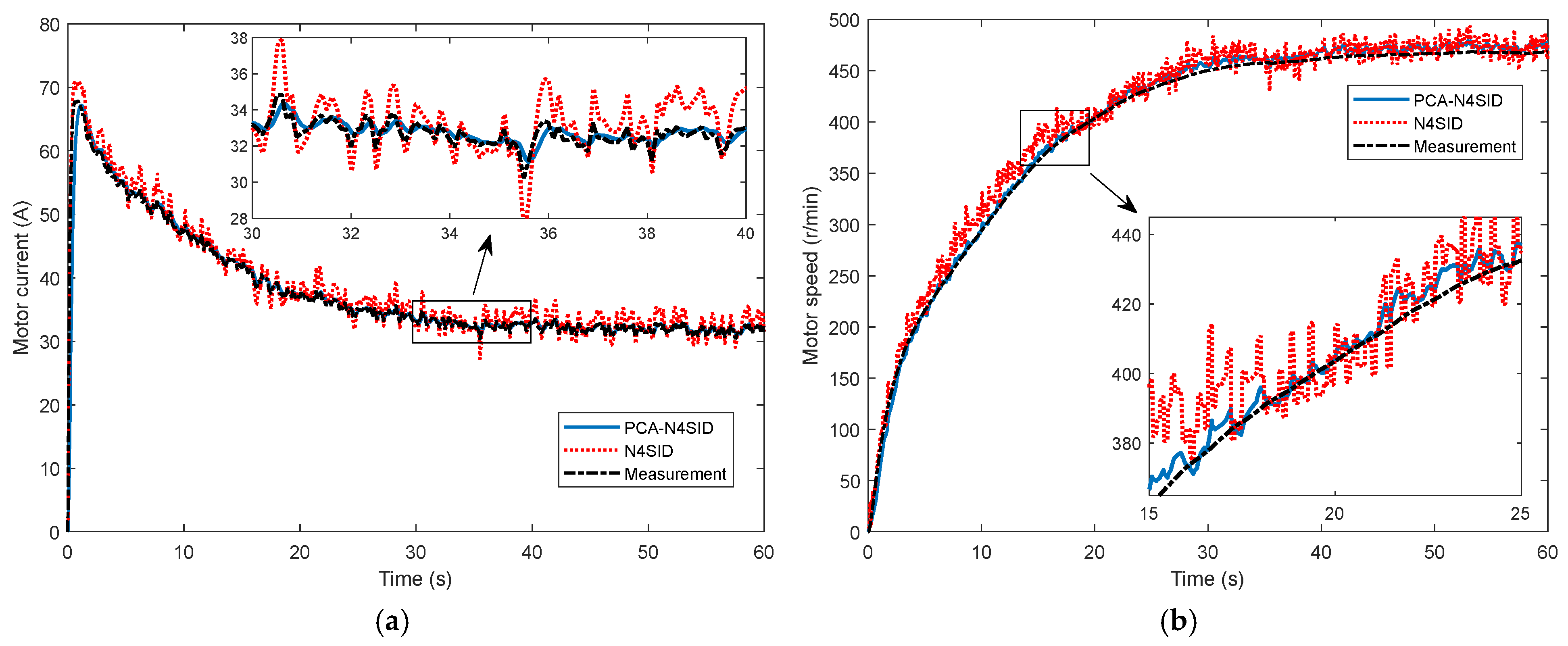

Figure 6. As shown in the figure, the identification models obtained by both algorithms can track the actual system state as a whole, and both the current and speed values are in good agreement with the overall trend of the actual measurement result curve. At the same time, the model state curve under the PCA-N4SID algorithm is generally smoother, while the model state curve under the N4SID algorithm has some fluctuations. By zooming in on the local image, it can be seen more clearly that the PCA-N4SID algorithm has a higher performance following accuracy and real-time performance.

Before comparing different algorithms, it is important to emphasize the importance of mean squared error and average error in model evaluation. The average error reflects the degree of deviation between the predicted value and the true value of the model, which can intuitively reflect the accuracy of the model. The mean square error amplifies the impact of the error through the square operation, taking into account not only the size of the error but also its stability, which can more comprehensively reflect the performance of the model. By simultaneously analyzing the average error and mean square error, it is possible to more accurately evaluate the performance of the model under different operating conditions and provide a basis for algorithm improvement.

In order to further demonstrate the superiority of PCA-N4SID in model identification accuracy, a quantitative representation method was used to statistically analyze the average error and mean square error of identifying model state variables under N4SID and PCA-N4SID algorithms. The results are shown in

Table 1. According to the quantitative comparison results, the mean model errors of current and speed under the N4SID algorithm reached 2.4685 and 3.6861, respectively, while the mean model errors of current and speed under the PCA-N4SID algorithm were 0.8627 and 1.0671, respectively. The mean squared errors of the current and speed models under the N4SID algorithm reached 2.9734 and 3.4964, respectively, while the mean squared errors of the current and speed models under the PCA-N4SID algorithm were 0.6119 and 0.8223, respectively. It can be inferred that the mean and mean square error of the current and speed models under the PCA-N4SID algorithm were significantly smaller compared to those under the N4SID algorithm, and the effectiveness of the proposed model identification method was verified.

In practical applications, noise pollution has a significant impact on motor performance. Noise mainly comes from sensor accuracy limitations, electromagnetic interference, temperature changes, vibrations, and other factors. These noises can mask or distort the true characteristics of measurement data, resulting in the inaccurate extraction of effective information from the data. Specifically, noise pollution can cause deviations in the estimation of motor model parameters, making it difficult for the model to perform a number of functions, including accurately reflecting the actual characteristics of the motor, reducing the generalization ability of the model, which makes it difficult to make good predictions on new data; and it also leads to unstable estimation results of model parameters, making the model susceptible to external interference in practical applications and reducing its stability. Therefore, analyzing the noise pollution levels under different simulation conditions can provide important references for comparing identification algorithms and evaluating models.

The model state identification results for when the input information contains 2% noise pollution are shown in

Figure 7. The model state identified based on the N4SID algorithm shows that during the process of starting and accelerating the motor to a steady and uniform speed, the deviation of the motor current model is relatively large in the initial stage. This is because at the moment of motor start-up, the motor current increases sharply, the numerical fluctuation is relatively large, and then the motor speed also changes rapidly. In this state, the input of the model is relatively unstable, leading to deviations in the identification results of the model state. When the motor speed is stable, the accuracy of the identification model is relatively higher. Relatively speaking, the identification algorithm based on PCA-N4SID has higher accuracy throughout the entire process of motor start-up and has a stable trend, reflecting that the PCA-N4SID algorithm can suppress the negative impact of input signal fluctuations on model accuracy.

The comparison results of error quantification between two identification algorithms when the input information contains 2% noise pollution are shown in

Table 2. In the quantitative comparison results, the mean model errors of current and speed under the N4SID algorithm reached 3.1689 and 5.1983, respectively, while the mean model errors of current and speed under the PCA-N4SID algorithm were 0.9167 and 1.1265, respectively. The mean squared errors of the current and speed models under the N4SID algorithm reached 3.7109 and 4.1284, respectively, while the mean squared errors of the current and speed models under the PCA-N4SID algorithm were 0.6613 and 0.8598, respectively. By comparison, it can be seen that under the condition of 2% noise pollution in the input information, the mean and mean square error of both identification algorithms increased. The current and speed errors increased more significantly under the N4SID algorithm, while the error values under the PCA-N4SID algorithm increased but still remained at the original level. In the case of signal noise pollution, the performance difference between N4SID and PCA-N4SID algorithms was more significant. The model state value error under the N4SID algorithm was relatively larger, while the error value under the PCA-N4SID algorithm was effectively controlled and did not significantly affect negative noise interference, thus verifying the fact that the PCA-N4SID algorithm can still maintain a good level of model identification accuracy under signal noise pollution.

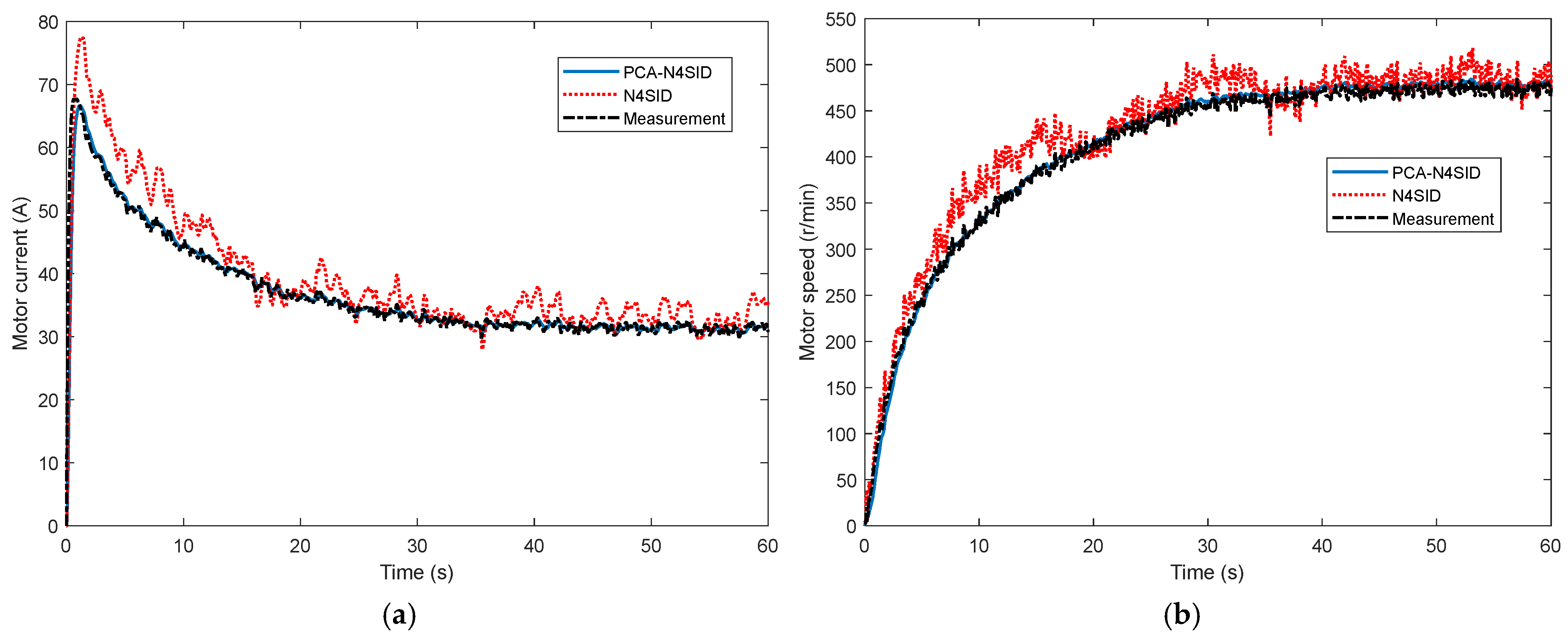

The model state identification results when the input information contains 5% noise pollution are shown in

Figure 8. As shown in the figure, as the level of noise pollution in the input information increases, the error in the model state identification results based on the N4SID algorithm further increases, especially during the acceleration process of motor start-up. In contrast, the PCA-N4SID algorithm can still maintain its original identification accuracy, thus verifying its anti-interference ability and good real-time tracking characteristics.

The comparison results of error quantification between two identification algorithms for when the input information contains 5% noise pollution are shown in

Table 3. In the quantitative comparison results, the mean model errors of current and speed under the N4SID algorithm reached 5.2937 and 6.8802, respectively, while the mean model errors of current and speed under the PCA-N4SID algorithm were 0.9504 and 1.3513, respectively. The mean squared errors of the current and speed models under the N4SID algorithm reached 4.3304 and 5.3111, respectively, while the mean squared errors of the current and speed models under the PCA-N4SID algorithm were 0.6965 and 0.9072, respectively. Comparing the data in

Table 3, it can be seen that the mean and mean square deviation of the error under the N4SID algorithm doubled compared to the noise-free situation, while the mean and mean square deviation of the error under the PCA-N4SID algorithm remained at their original levels, further demonstrating the model identification performance of the PCA-N4SID algorithm compared to the N4SID algorithm under noise pollution.

5. Conclusions

In response to the problem of the model identification of permanent magnet DC brushless motors and considering the potential negative impact of noise pollution on data collection, this study proposes a data-driven method for the model identification of permanent magnet DC brushless motors based on the auxiliary variable closed-loop subspace identification algorithm. To effectively weaken the correlation between input signals and noise, based on an error variable model, auxiliary variables are introduced to avoid the projection step of traditional subspace identification algorithms, and the algorithm’s implementation is optimized in the principal component analysis stage to simplify the solution process. The results indicate that the proposed PCA-N4SID algorithm can effectively handle the situation where driving data are contaminated by noise, and compared to the N4SID algorithm, the model identification accuracy was significantly improved.

In future research, the identification of motor models will present a multidimensional development trend. Intelligent and adaptive modeling will deeply integrate deep learning algorithms, utilizing their powerful feature extraction capabilities to automatically mine complex patterns in motor operation data. At the same time, adaptive modeling technology will be further developed, enabling models to be updated in real time to adapt to the dynamic characteristics of motors under different working conditions and load conditions. Multi-physics coupling modeling will pay more attention to the interaction of multiple fields in physics, such as electromagnetic, thermal, and mechanical fields. By establishing a unified multi-physics field model, the actual operating state of the motor can be more comprehensively reflected and the accuracy and reliability of the model can be improved. The application of digital twin technology will bring new development opportunities for motor model identification. By constructing the digital twin models of motors, real-time interaction and data sharing between physical motors and virtual models can be achieved, enabling a more accurate performance evaluation, fault prediction, and optimized control of motors.

The research on motor model identification will continue to expand in three directions: model-driven identification, data-driven identification, and model-data-fusion-driven identification. Model-driven identification will focus on fine-grained and multi-physics field-coupling modeling, combined with advanced numerical calculation methods, to more accurately describe the complex physical phenomena and interactions inside the motor, such as the coupling effects of electromagnetic fields, temperature fields, and stress fields. Data-driven identification will become more precise with the development of big data and artificial intelligence technologies, and deep learning algorithms will be widely used to mine complex patterns and nonlinear relationships in the data. The fusion of models and data-driven identification will become an important development direction. By combining prior knowledge, and the physical constraints driven by models with actual measurement data and using methods such as physical information neural networks to achieve deep fusion, more accurate and reliable motor models can be established, thus promoting the progress of motor model identification technology.