The Study of Waste Heat Recovery of the Thermal Management System of Electric Vehicle Based on Simulation and Experimental Analyses

Abstract

1. Introduction

2. System Integration and Simulation Model Development

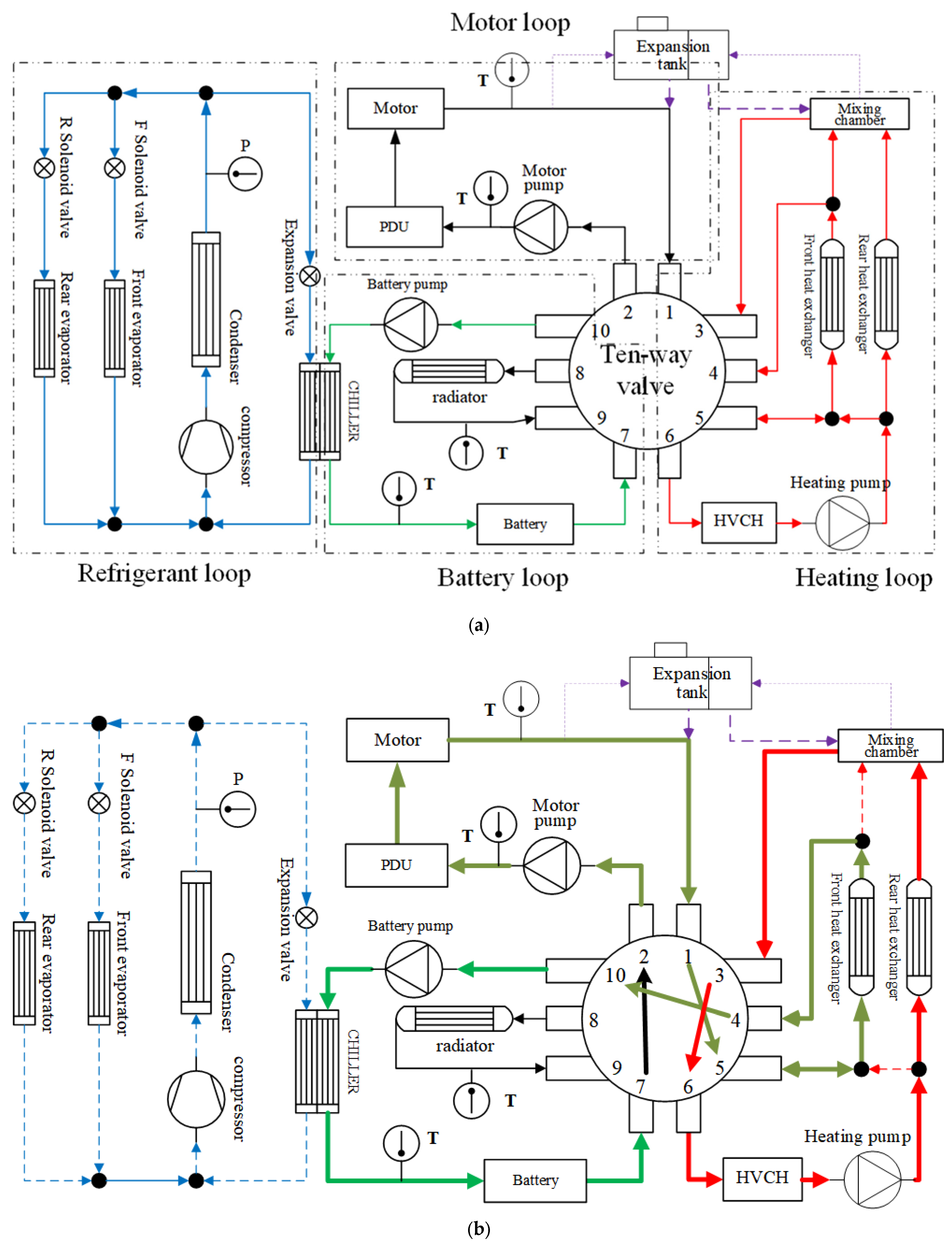

2.1. System Architecture Integration

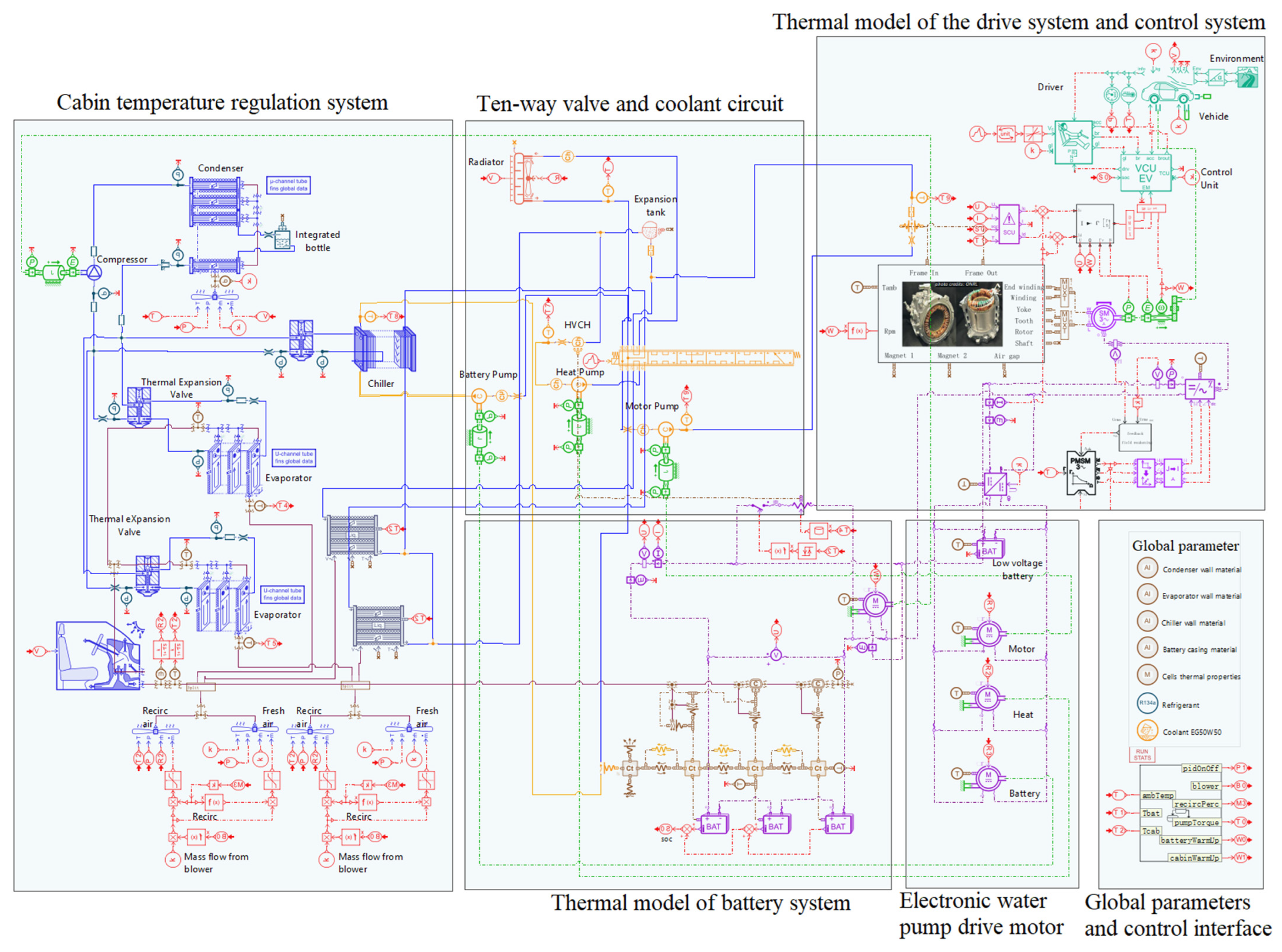

2.2. Development of Simulation Model

3. Parameter Matching and Model Validation

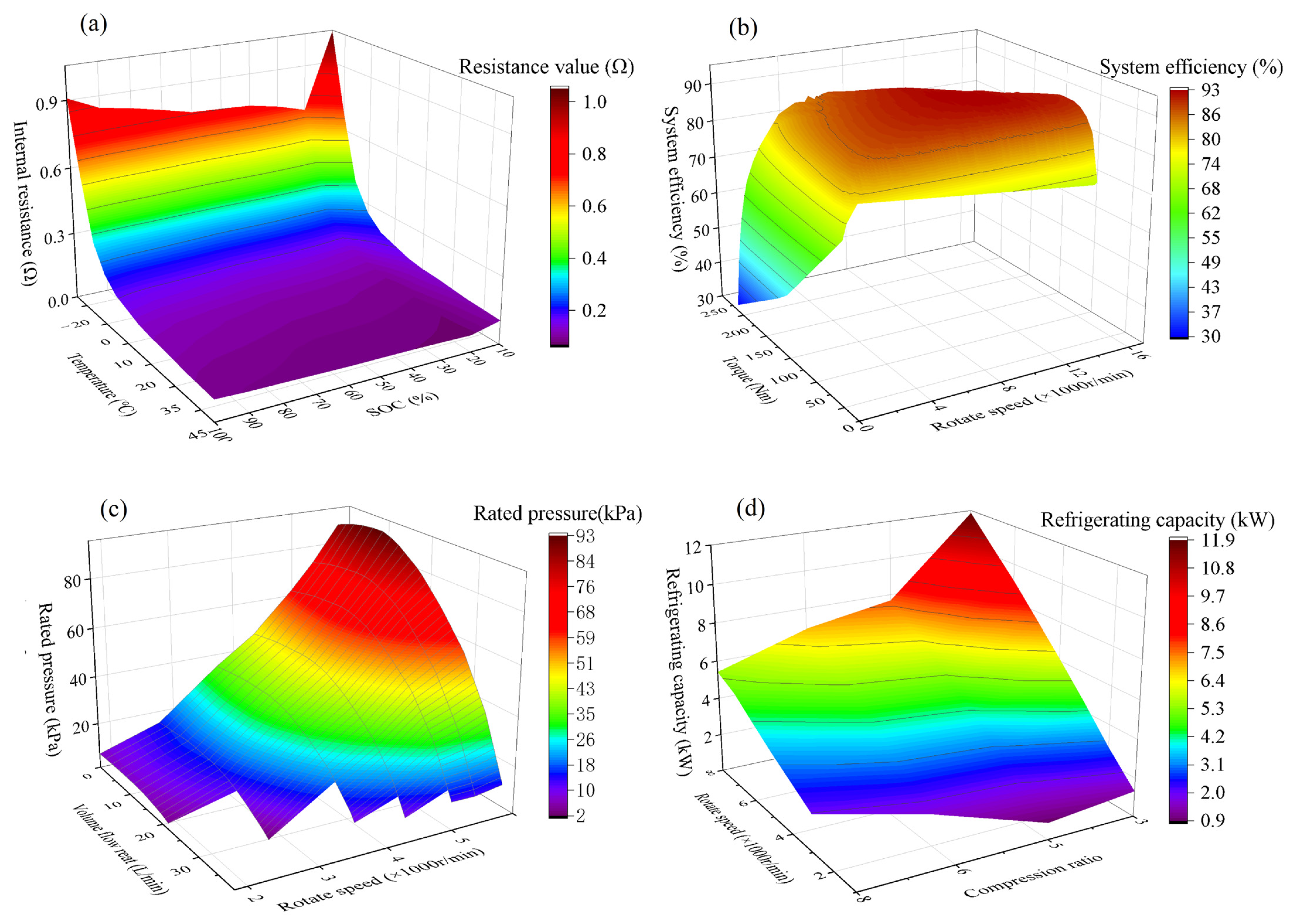

3.1. Parameter Matching

- Hysteresis loss term (): Retains the linear frequency dependence () as energy loss per cycle scales with hysteresis loop area.

- Eddy current loss term (): Reflects the quadratic frequency dependence () derived from Maxwell’s equations, where induced eddy currents dissipate power proportionally to (dB/dt)2.

- Excess loss term (): Introduces an intermediate frequency exponent () to model anomalous losses caused by domain wall motion and localized eddy currents.

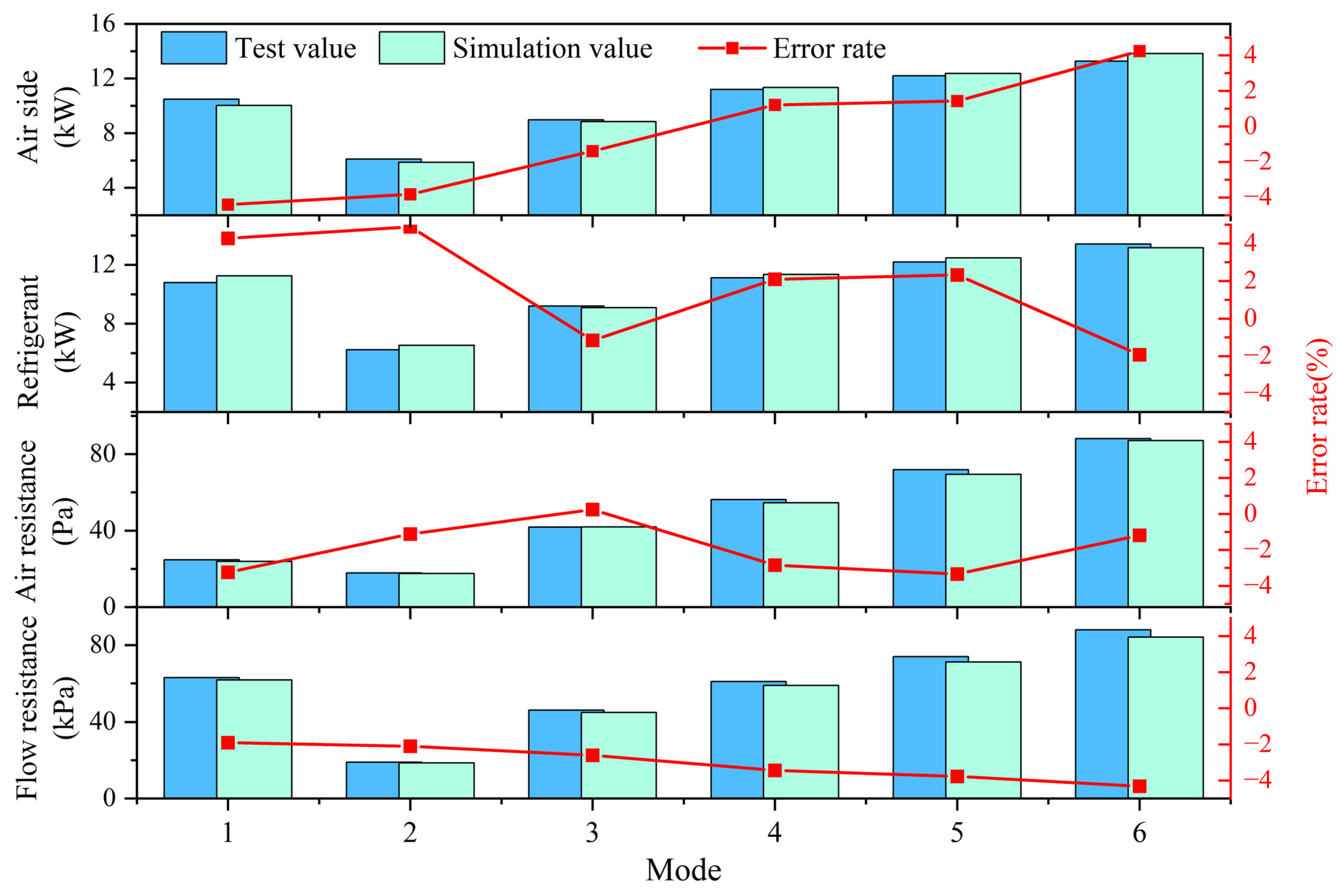

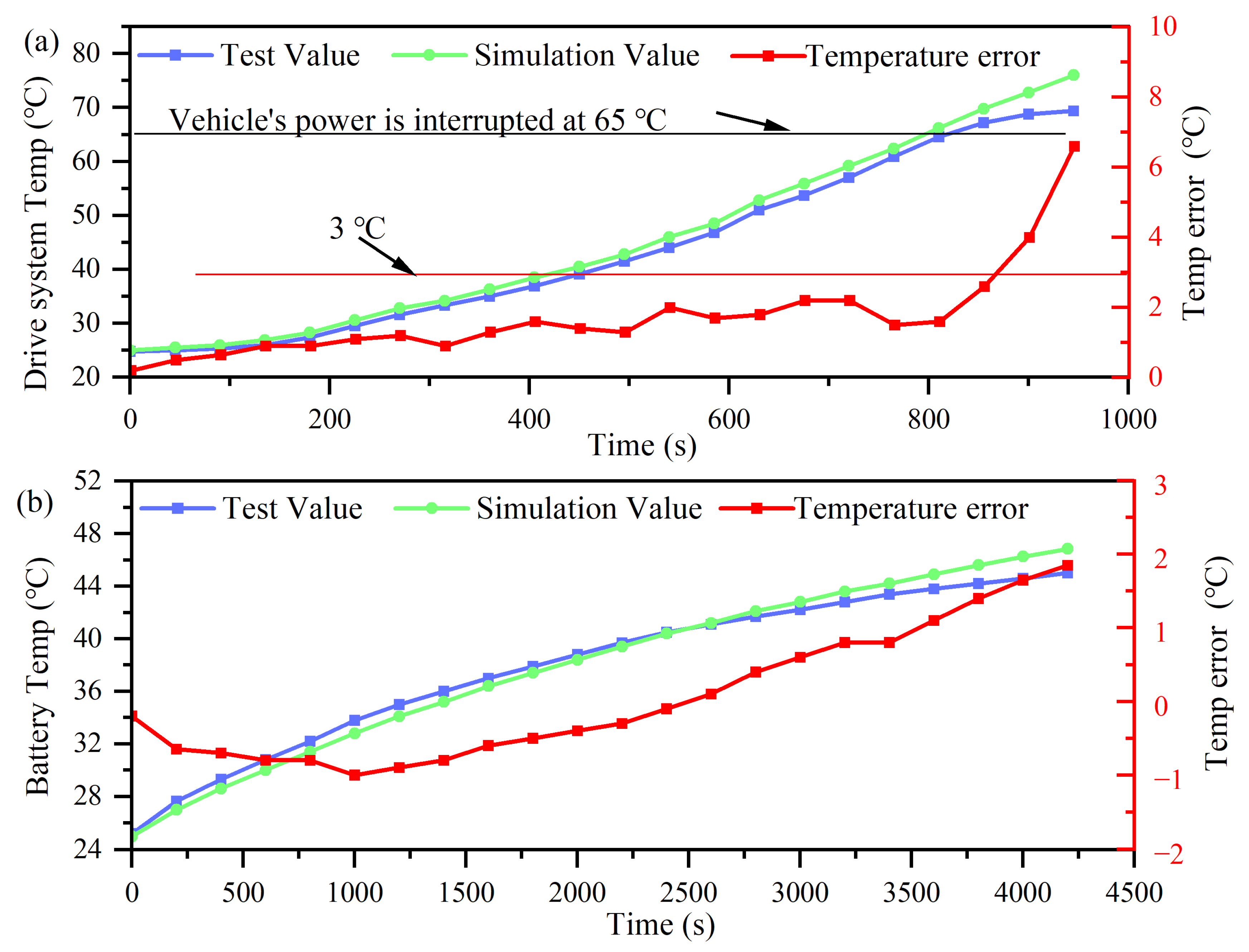

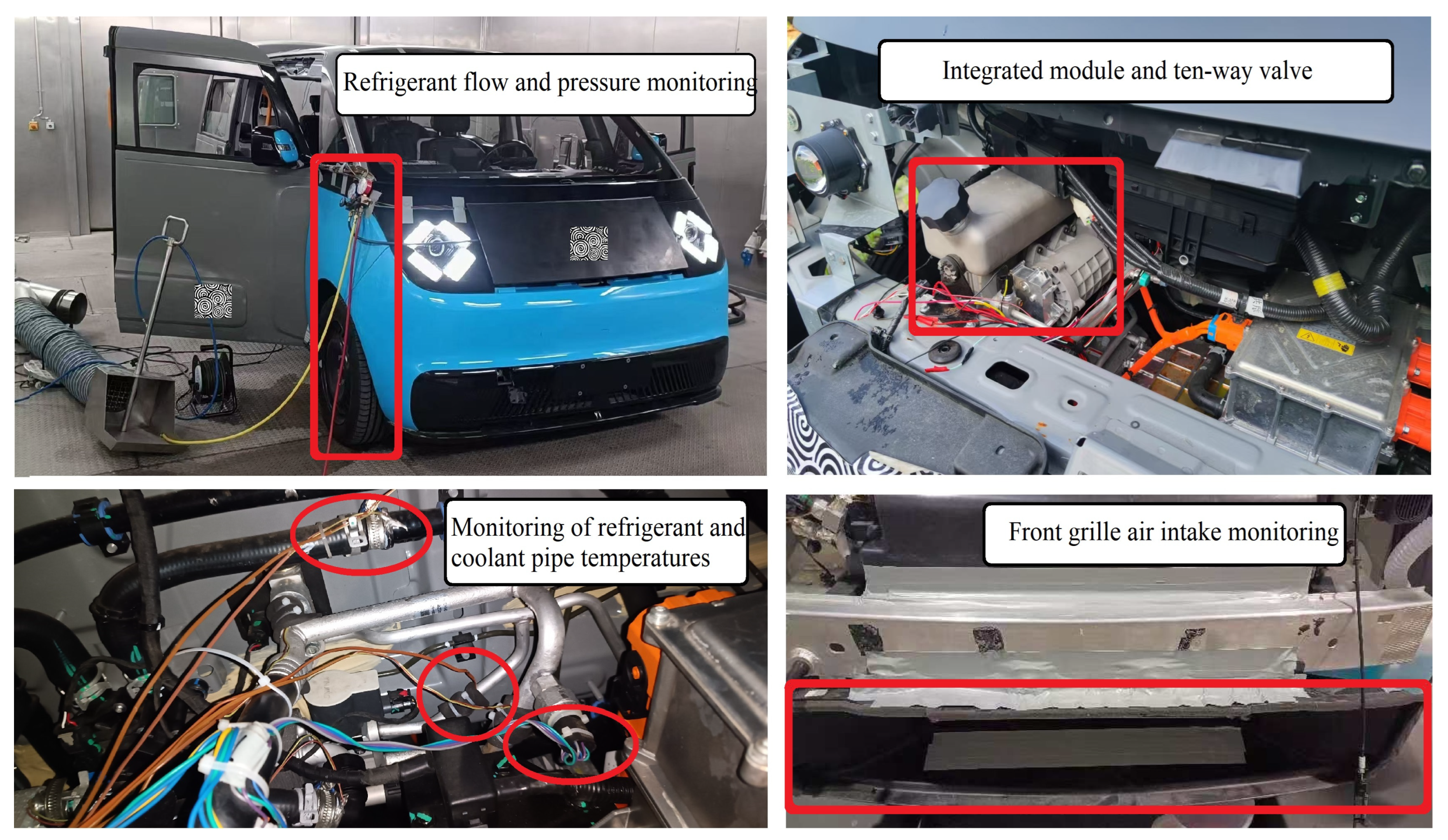

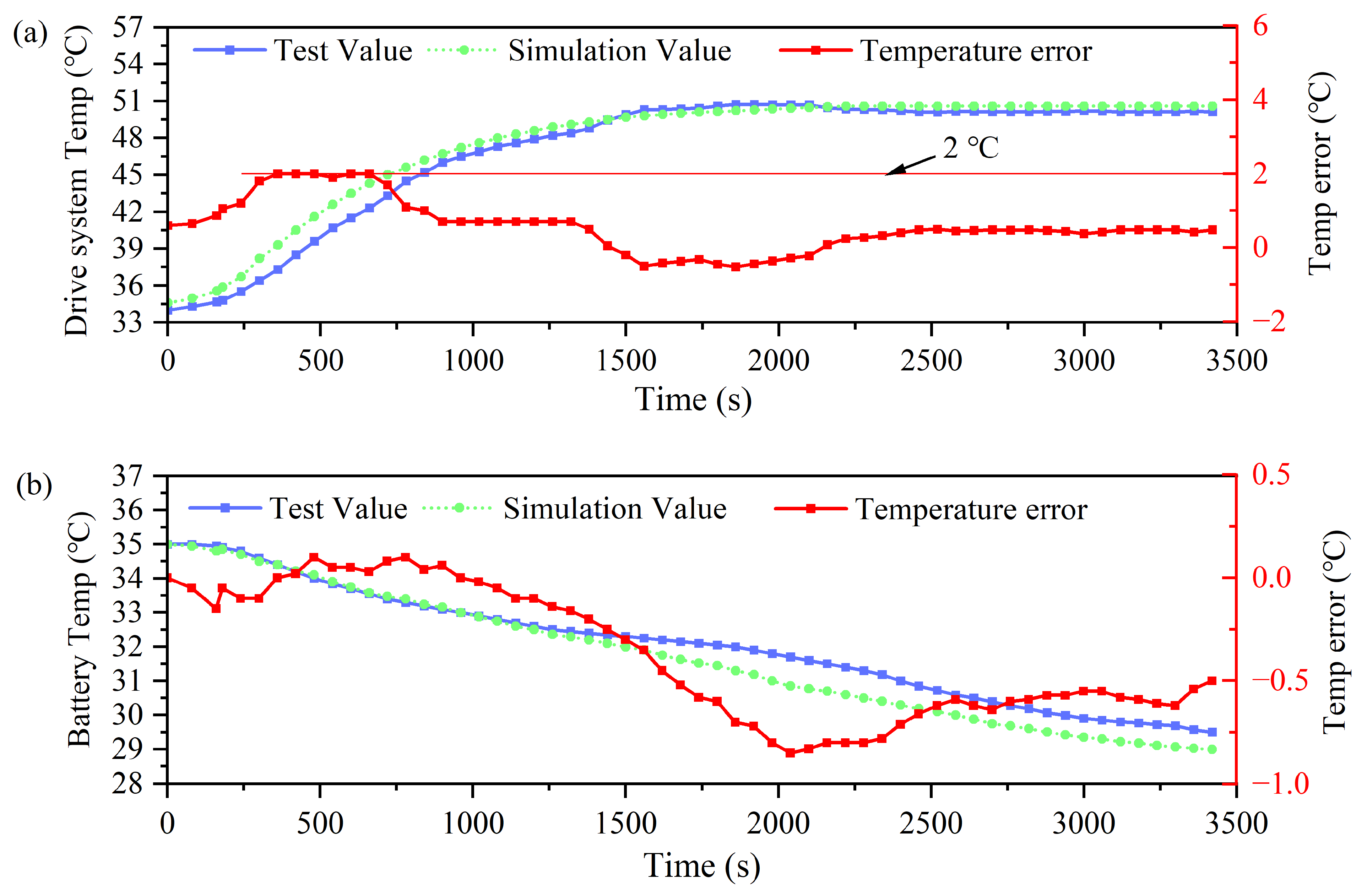

3.2. Model Validation

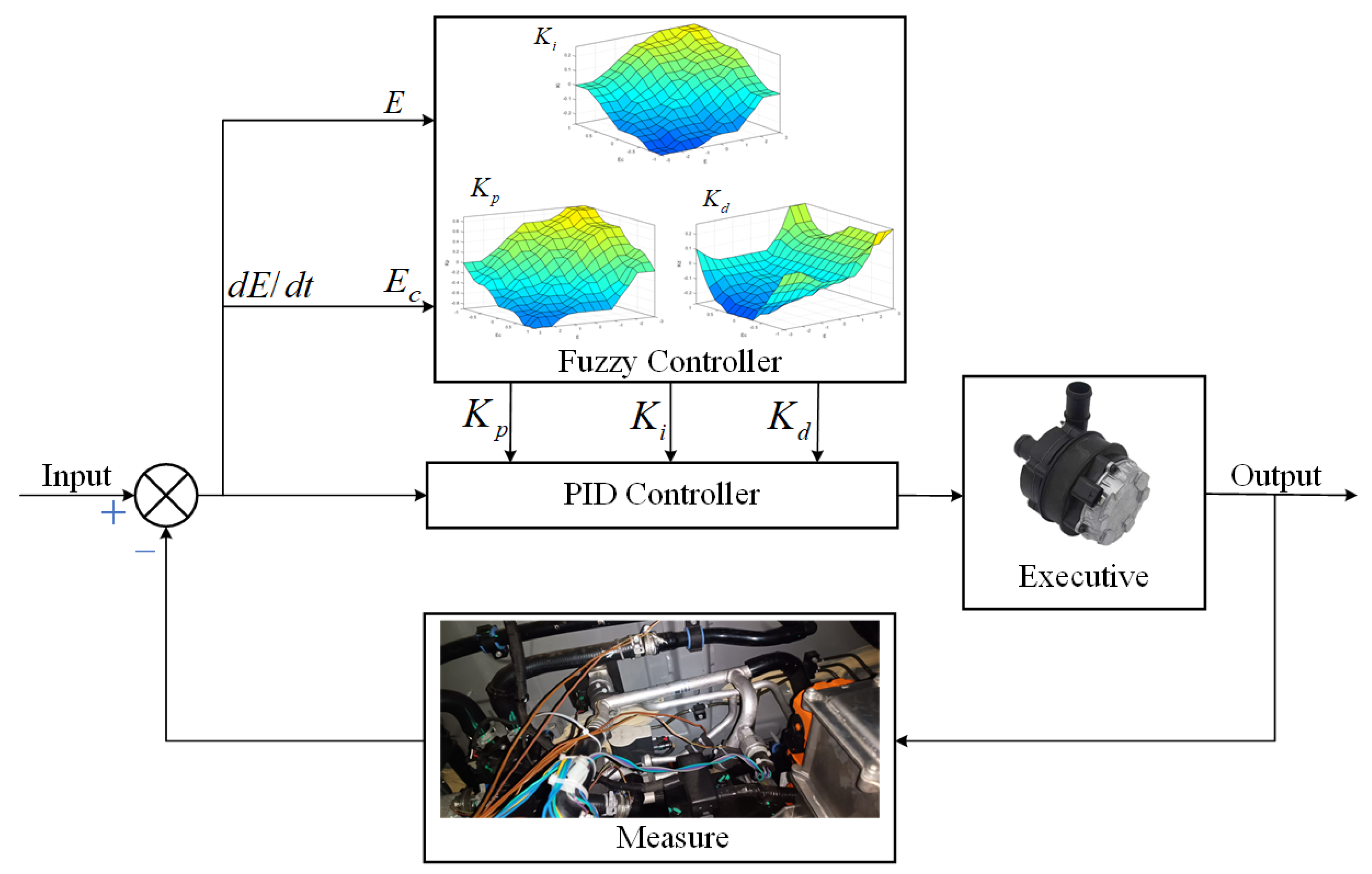

4. Design of Fuzzy PID Controller for Electric Water Pump

5. Performance Test Verification of the Vehicle TMS

5.1. Test Condition Settings

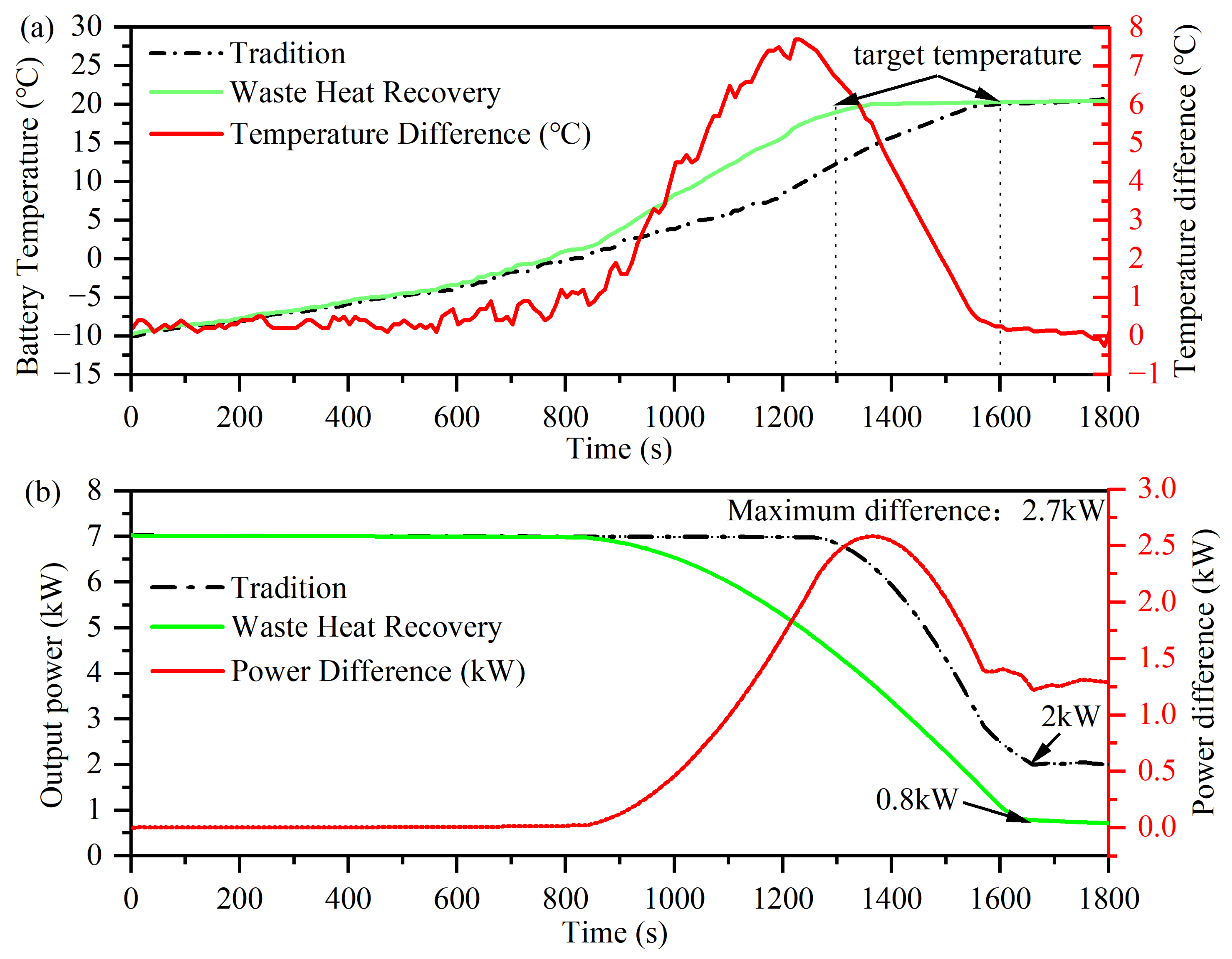

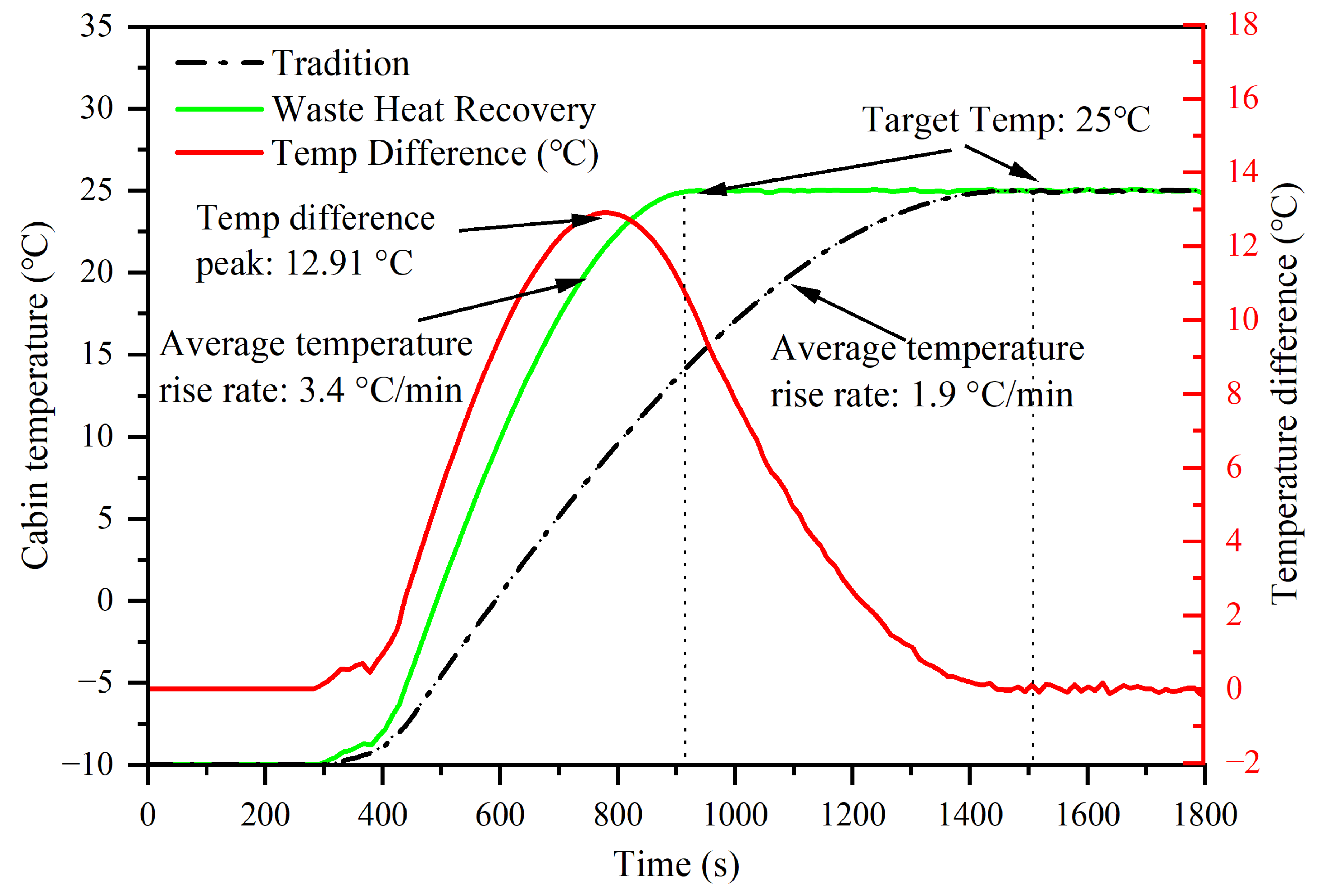

5.2. Test Result Analysis

6. Conclusions

- (1)

- A novel, highly integrated TMS based on a 10-way valve with 6 working modes is proposed, which can eliminate the need for multiple valves and plate heat exchangers, offering improved energy efficiency, optimized control logic, space savings, and precise temperature regulation.

- (2)

- An integrated TMS architecture simulation model was employed based on the AMEsim2304 platform, and the accuracy of the model was validated through comparative analysis with laboratory and environmental chamber test results. The condenser heat transfer system simulation errors can be controlled below 5%, the heating characteristics system (including battery system and drive system) deviations are within 3 °C, and thermal management characteristics system errors are less than 2 °C.

- (3)

- A classical control strategy based on fuzzy PID was introduced to regulate the electronic water pump, which could significantly improve system efficiency and reduce system energy consumption. Comparative tests under −10 °C conditions showed substantial improvements: a 300 s reduction in battery heating time to 20 °C, a 43.7% increase in the cabin temperature rise rate, and a 10% decrease in HVCH heating energy consumption compared to traditional systems.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cao, Y.; Liang, C.; Cheng, S.; Yin, X.; Chen, D.; Liu, Z.; Sun, C.; Chen, T. Predictive Energy Management Strategy for Heavy-Duty Series Hybrid Electric Vehicles Based on Drive Power Prediction. World Electr. Veh. J. 2025, 16, 186. [Google Scholar] [CrossRef]

- Xu, F.; Tan, K.Y. Optimal decisions of closed-loop electric vehicle batteries supply chains under extended producer responsibility policies. Int. J. Syst. Sci.-Oper. Logist. 2025, 12, 2437153. [Google Scholar] [CrossRef]

- Bai, Z.P.; Yu, Y.Y.; Zhang, J.Y.; Hu, H.M.; Xing, M.Y.; Yao, H.W. Study on Fire Characteristics of Lithium Battery of New Energy Vehicles in a Tunnel. Process Saf. Environ. Prot. 2024, 186, 728–737. [Google Scholar] [CrossRef]

- Guo, R.; Miao, Q.; Xu, Y. Review of Graphene Applications in Electric Vehicle Thermal Management Systems. World Electr. Veh. J. 2025, 16, 166. [Google Scholar] [CrossRef]

- Lin, Y.H.; Hung, Y.H. Integrated thermal and energy management systems using particle swarm optimization for energy optimization in electric vehicles. Case Stud. Therm. Eng. 2025, 71, 106136. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Li, B.; Yan, Y. A Critical Review of Thermal Management Models and Solutions of Lithium-Ion Batteries for the Development of Pure Electric Vehicles. Renew. Sustain. Energy Rev. 2016, 64, 106–128. [Google Scholar] [CrossRef]

- Bahiraei, F.; Ghalkhani, M.; Fartaj, A.; Nazri, G. Electrochemical–Thermal Evaluation of an Integrated Thermal Management System for Lithium-Ion Battery Modules. Adv. Theory Simul. 2018, 1, 201800021. [Google Scholar] [CrossRef]

- Hong, J.; Song, J.; Han, U.; Kim, H.; Choi, H.; Lee, H. Performance Investigation of Electric Vehicle Thermal Management System with Thermal Energy Storage and Waste Heat Recovery Systems. eTransportation 2024, 20, 100317. [Google Scholar] [CrossRef]

- Wei, C.; Hofman, T.; Caarls, E.I.; Van Iperen, R. Evolution and Classification of Energy and Thermal Management Systems in Electrified Powertrains. In Proceedings of the 2019 IEEE Vehicle Power and Propulsion Conference, VPPC 2019—Proceedings, Hanoi, Vietnam, 14–17 October 2019; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2019. [Google Scholar]

- Popescu, M.; Staton, D.; Boglietti, A.; Cavagnino, A.; Hawkins, D.; Goss, J. Modern Heat Extraction Systems for Electrical Machines—A Review. In Proceedings of the 2015 IEEE Workshop on Electrical Machines Design, Control and Diagnosis, WEMDCD 2015, Turin, Italy, 26–27 March 2015; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2015; pp. 289–296. [Google Scholar]

- Lajunen, A.; Yang, Y.; Emadi, A. Review of Cabin Thermal Management for Electrified Passenger Vehicles. IEEE Trans. Veh. Technol. 2020, 69, 6025–6040. [Google Scholar] [CrossRef]

- Marshall, G.J.; Mahony, C.P.; Rhodes, M.J.; Daniewicz, S.R.; Tsolas, N.; Thompson, S.M. Thermal Management of Vehicle Cabins, External Surfaces, and Onboard Electronics: An Overview. Engineering 2019, 5, 954–969. [Google Scholar] [CrossRef]

- Liang, K.F.; Zhang, Y.P.; Wang, W.B.; Gao, C.Y.; Chen, H.Y.; Li, K.; Zhou, X.; Chen, B.; Cao, Y.; Wang, W.M.; et al. Performance Analysis and Multi-Objective Optimization of Refrigerant-Based Integrated Thermal Management System for Electric Vehicles. Appl. Therm. Eng. 2024, 244, 122707. [Google Scholar] [CrossRef]

- Dan, D.; Zhao, Y.; Wei, M.; Wang, X. Review of Thermal Management Technology for Electric Vehicles. Energies 2023, 16, 4693. [Google Scholar] [CrossRef]

- Zhan, J.; Deng, Y.; Ren, J.; Gao, Y.; Liu, Y.; Rao, S.; Li, W.; Gao, Z. Cell Design for Improving Low-Temperature Performance of Lithium-Ion Batteries for Electric Vehicles. Batteries 2023, 9, 373. [Google Scholar] [CrossRef]

- Jaguemont, J.; Boulon, L.; Dubé, Y. A Comprehensive Review of Lithium-Ion Batteries Used in Hybrid and Electric Vehicles at Cold Temperatures. Appl. Energy 2016, 164, 99–114. [Google Scholar] [CrossRef]

- Ma, J.; Sun, Y.; Zhang, S.; Li, J.; Li, S. Experimental Study on the Performance of Vehicle Integrated Thermal Management System for Pure Electric Vehicles. Energy Convers. Manag. 2022, 253, 115183. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, Q.; Hu, S.; Xu, X. Research on Performance of Thermal Management System Integrated with Multiple Heat Exchange Methods. Ionics 2022, 28, 789–799. [Google Scholar] [CrossRef]

- Lian, Y.; Ling, H.; Zhu, J.; Lv, J.; Xie, Z. Thermal Management Optimization Strategy of Electric Vehicle Based on Dynamic Programming. Control Eng. Pract. 2023, 137, 105562. [Google Scholar] [CrossRef]

- Li, K.; Liu, Q.; Hu, Y.; Gao, J.; Chen, H. A Coupling Thermal Management Strategy Based on Fuzzy Control for a Range Extended Electric Vehicle Power System. IEEE Trans. Veh. Technol. 2022, 71, 2573–2586. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, Y.K.; Yu, H.Z.N.; An, X.P.; Li, J.Y. Comparative Analysis of China Light-duty Vehicle Test cycle for Passenger Car and Other Typical Driving Cycles. E3S Web Conf. 2021, 241, 02002. [Google Scholar] [CrossRef]

- Inoue, K.; Okada, N.; Kiyose, H.; Kato, T. Numerical Design Methodology of Optimal Trajectories for Efficient Induction Motor Drive based on a Loss Map. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 3154–3158. [Google Scholar]

- Aarniovuori, L.; Laurila, L.I.E.; Niemela, M.; Pyrhonen, J.J. Measurements and Simulations of DTC Voltage Source Converter and Induction Motor Losses. IEEE Trans. Ind. Electron. 2012, 59, 2277–2287. [Google Scholar] [CrossRef]

- Zhang, S. Application of Fuzzy PID Control in Motor Test; Atlantis Press: Dordrecht, The Netherlands, 2017. [Google Scholar]

- Lee, C.C. Fuzzy Logic in Control Systems: Fuzzy Logic Controller—Part I. IEEE Trans. Syst. Man Cybern. 1990, 20, 404–418. [Google Scholar] [CrossRef]

- ISO 16750-4:2010; International Organization for Standardization. Road Vehicles—Environmental Conditions and Testing for Electrical and Electronic Equipment—Part 4: Climatic Loads. ISO: Geneva, Switzerland, 2010.

| Working Condition | Air Speed (m/s) | Inlet Dry Bulb Temperature (°C) | Inlet Pressure (Mpa) | Degree of Supercooling (°C) | Degree of Superheat (°C) |

|---|---|---|---|---|---|

| 1 | 1.80 | 35.06 | 1.606 | 5.53 | 24.49 |

| 2 | 1.50 | 40.07 | 1.495 | 5.68 | 25.33 |

| 3 | 2.50 | 40.06 | 1.495 | 5.97 | 25.24 |

| 4 | 3.00 | 40.02 | 1.498 | 4.58 | 24.77 |

| 5 | 3.50 | 40.02 | 1.490 | 5.44 | 24.81 |

| 6 | 4.00 | 40.01 | 1.487 | 5.46 | 24.38 |

| Performance Parameter | Tradition | Waste Heat Recovery | Save Energy Consumption (%) |

|---|---|---|---|

| TMS heating energy consumption (kWh) | 3 | 2.7 | 10% (±1.7%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, W.; Yang, Q.; Xu, L.; Li, X. The Study of Waste Heat Recovery of the Thermal Management System of Electric Vehicle Based on Simulation and Experimental Analyses. World Electr. Veh. J. 2025, 16, 298. https://doi.org/10.3390/wevj16060298

Lu W, Yang Q, Xu L, Li X. The Study of Waste Heat Recovery of the Thermal Management System of Electric Vehicle Based on Simulation and Experimental Analyses. World Electric Vehicle Journal. 2025; 16(6):298. https://doi.org/10.3390/wevj16060298

Chicago/Turabian StyleLu, Weiwei, Qingxia Yang, Liyou Xu, and Xiuqing Li. 2025. "The Study of Waste Heat Recovery of the Thermal Management System of Electric Vehicle Based on Simulation and Experimental Analyses" World Electric Vehicle Journal 16, no. 6: 298. https://doi.org/10.3390/wevj16060298

APA StyleLu, W., Yang, Q., Xu, L., & Li, X. (2025). The Study of Waste Heat Recovery of the Thermal Management System of Electric Vehicle Based on Simulation and Experimental Analyses. World Electric Vehicle Journal, 16(6), 298. https://doi.org/10.3390/wevj16060298