Creating an Extensive Parameter Database for Automotive 12 V Power Net Simulations: Insights from Vehicle Measurements in State-of-the-Art Battery Electric Vehicles

Abstract

1. Introduction

- Wire lengths and their derivative parameters, such as resistance and inductance;

- Installed low-voltage loads, their power consumption, and input capacitances.

2. Power Net Simulation

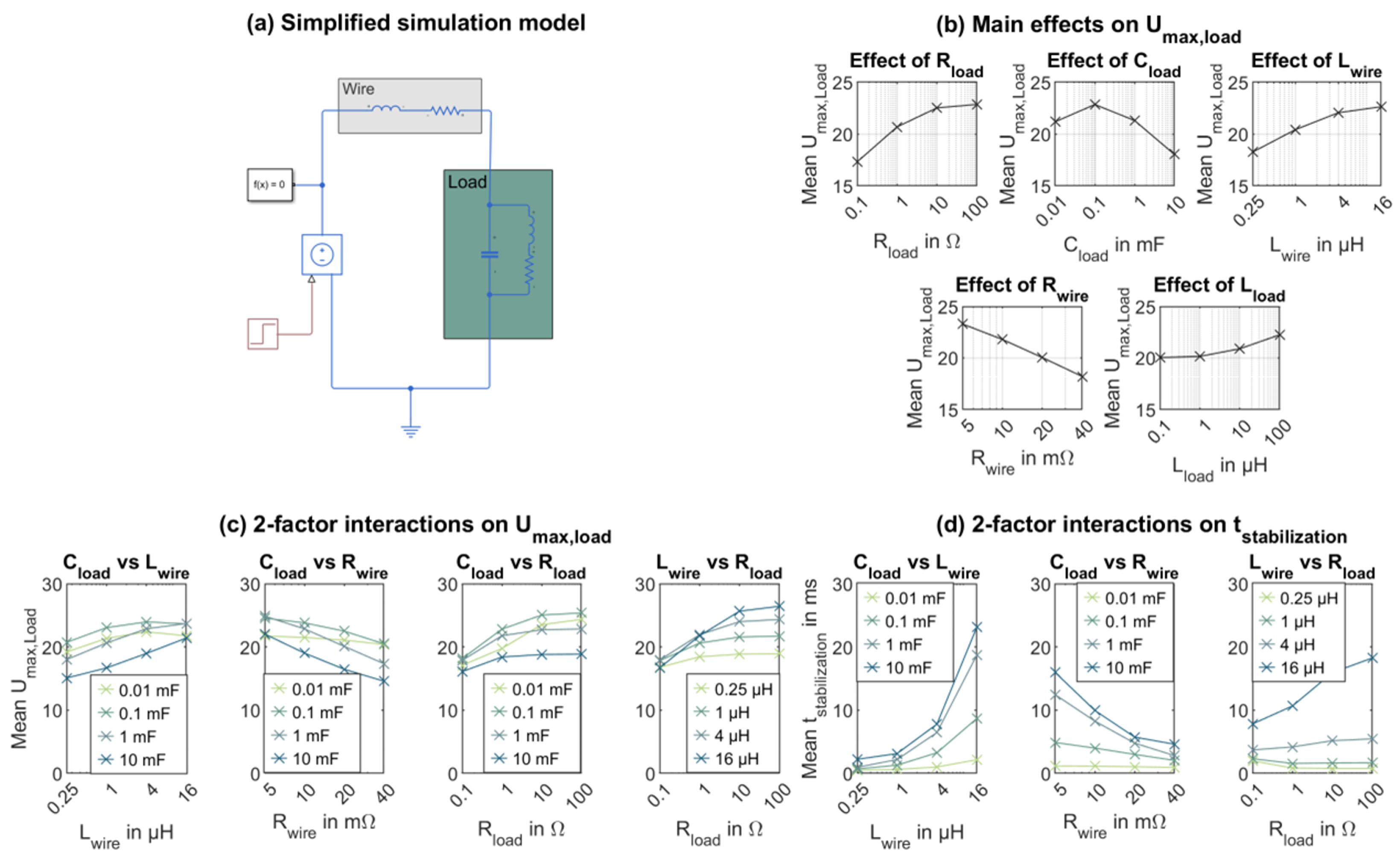

2.1. Key Parameters for Highly Dynamic Simulations

2.2. Preliminary Study on Parameter Effects

3. Methodology

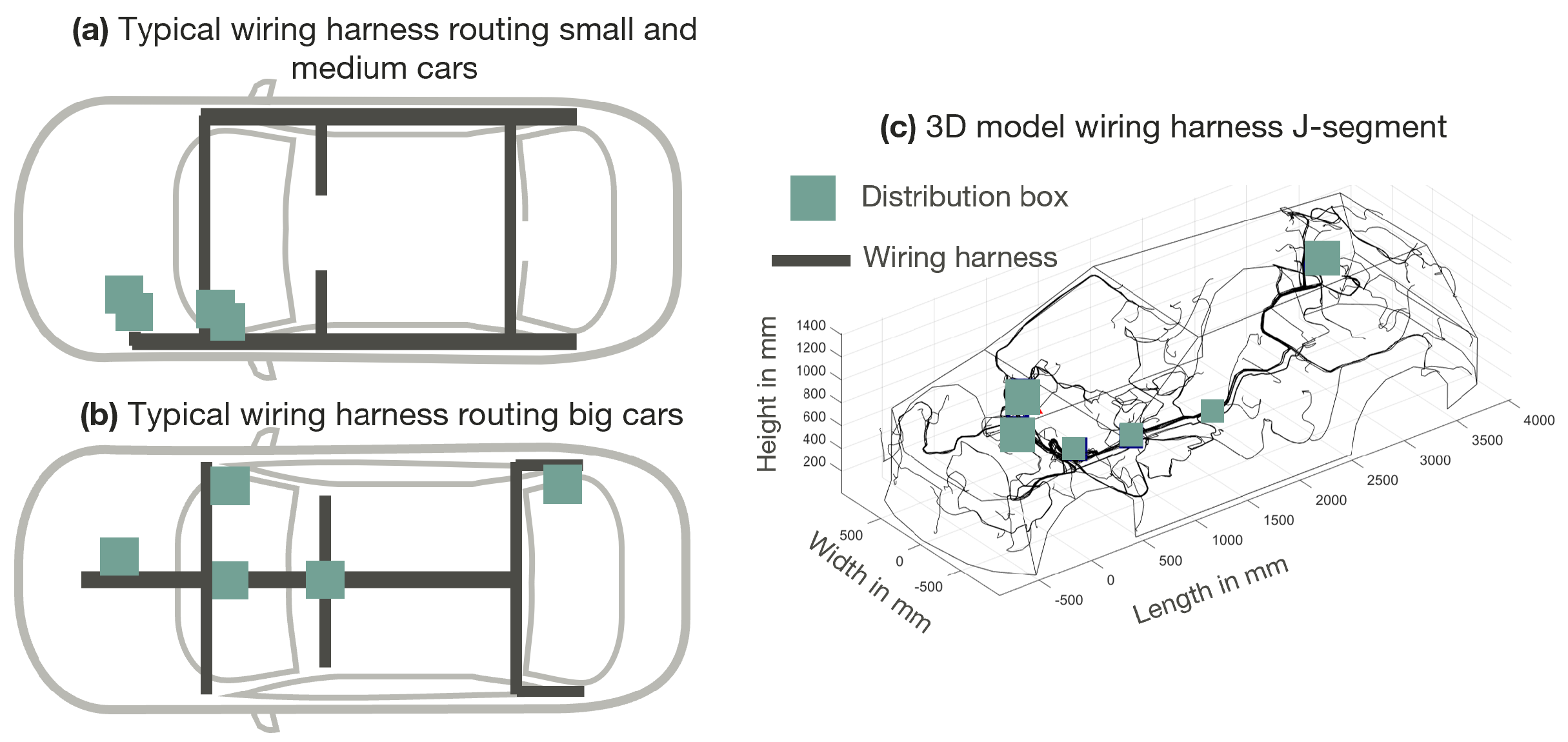

3.1. Three-Dimensional Data Analysis

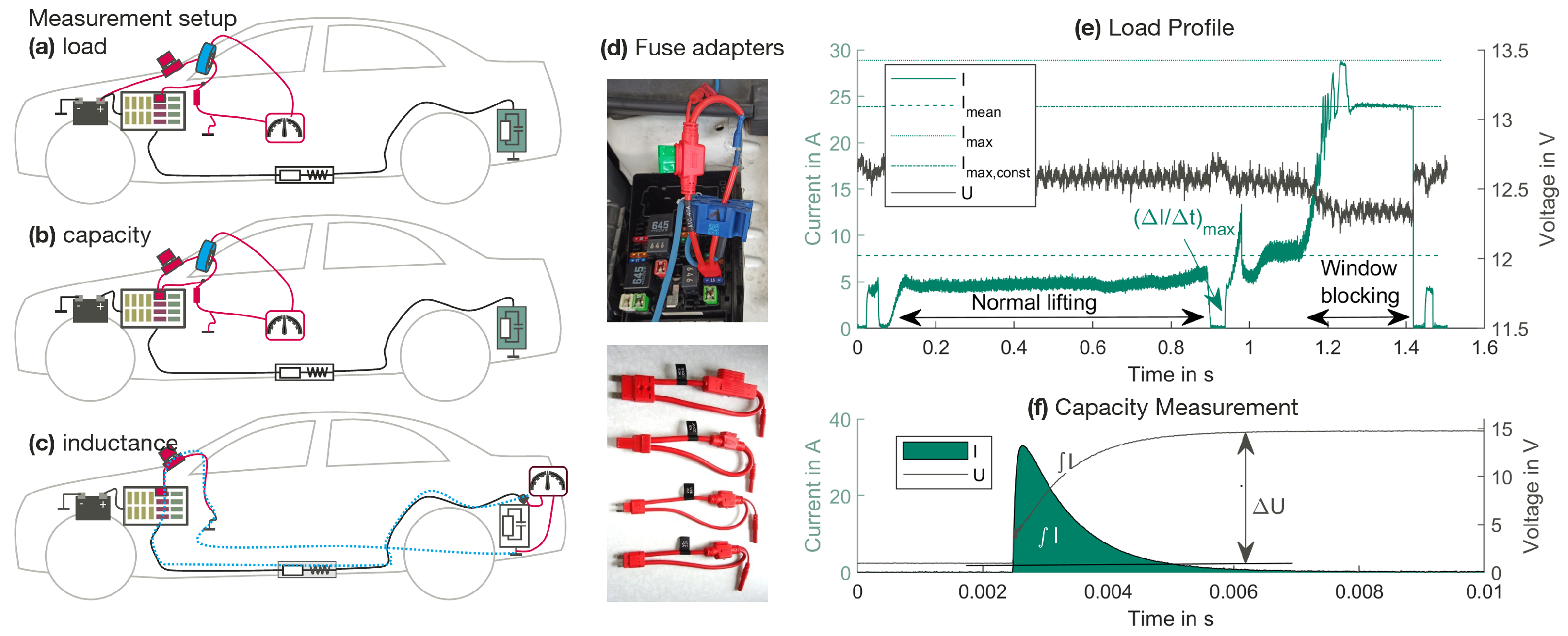

3.2. Vehicle Measurements

3.2.1. Load Measurements

3.2.2. Capacitance Measurements

3.2.3. Inductance Validation

3.3. Test Vehicles and Measurement Equipment

4. Results and Analysis

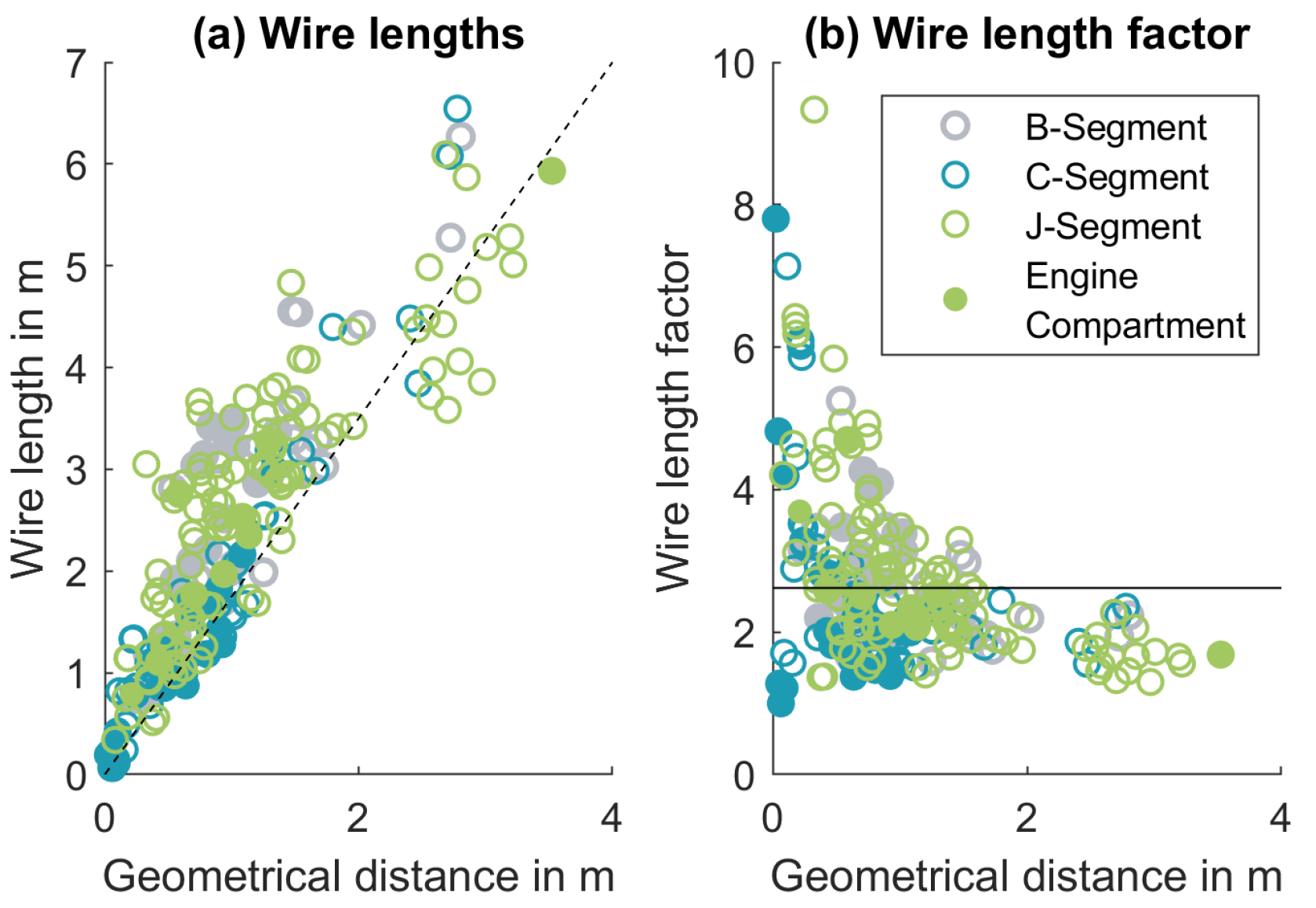

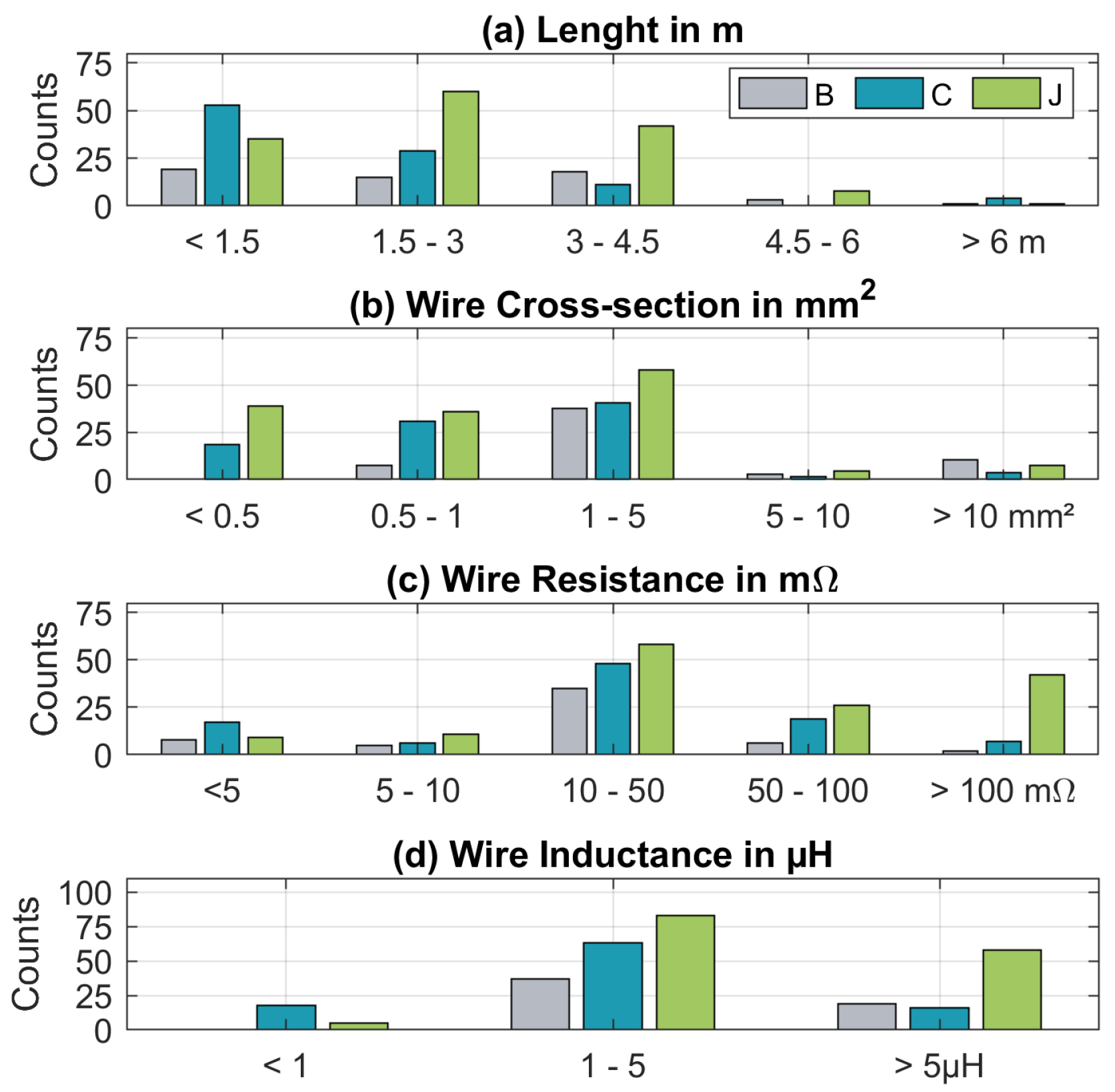

4.1. Wiring Harness Data Derived from 3D Data Analysis

4.1.1. General Analysis of the Wiring Harness

4.1.2. In-Depth Analysis of Three Exemplary Vehicles

4.2. Load Data Based on Vehicle Measurements

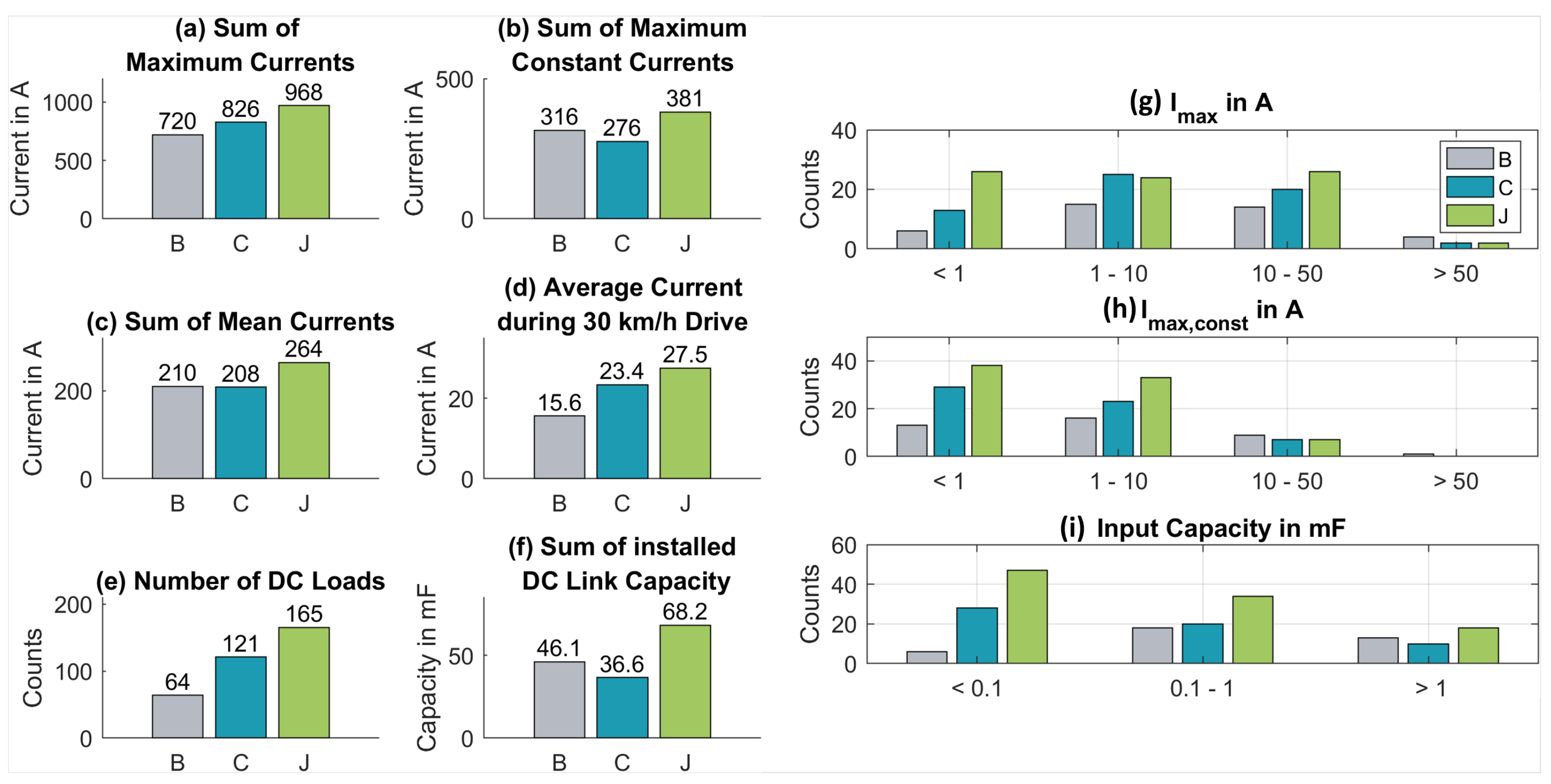

4.2.1. General Analysis

4.2.2. Findings Relevant to the 48 V Discussion

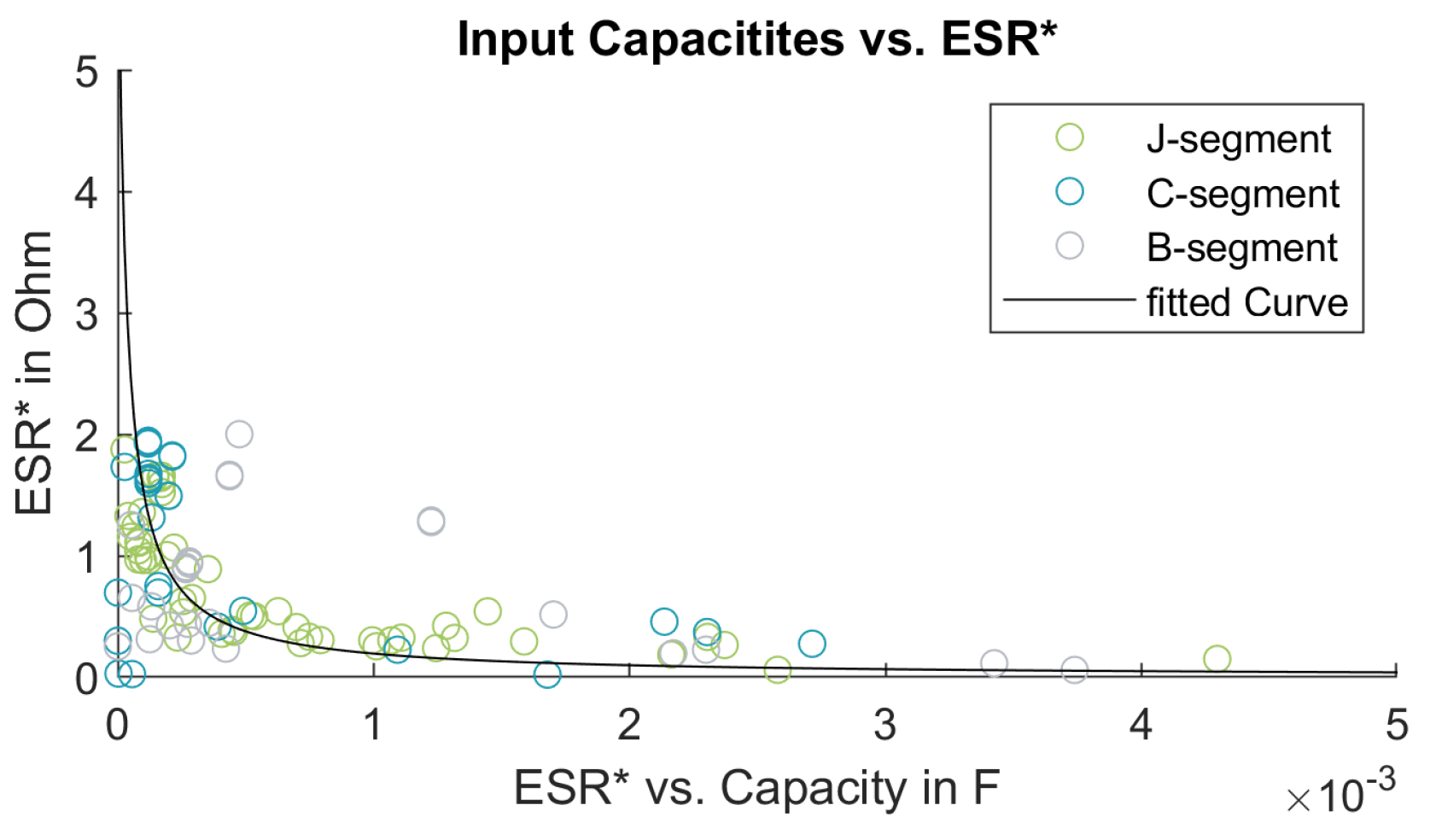

4.2.3. Input Capacitances

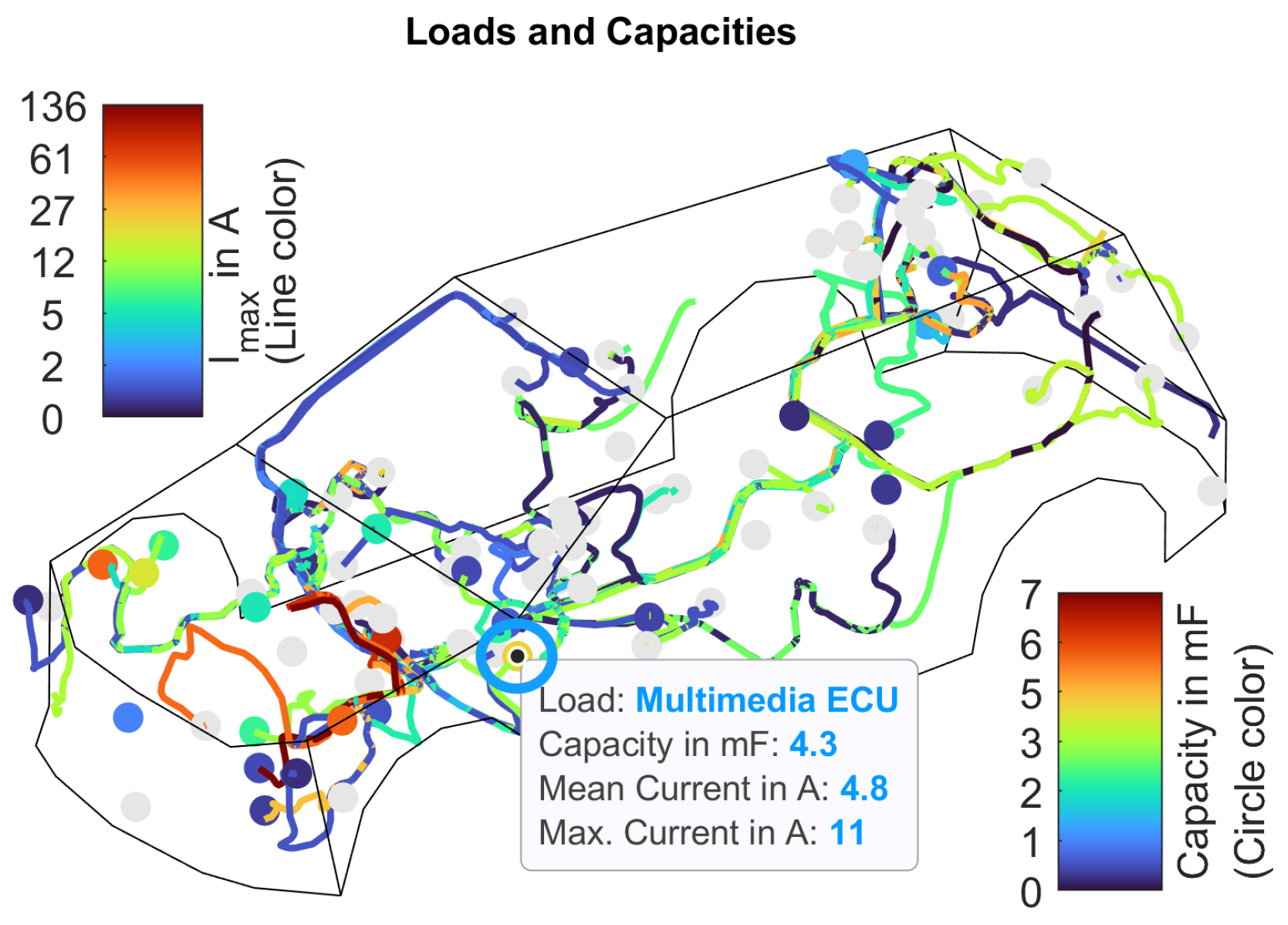

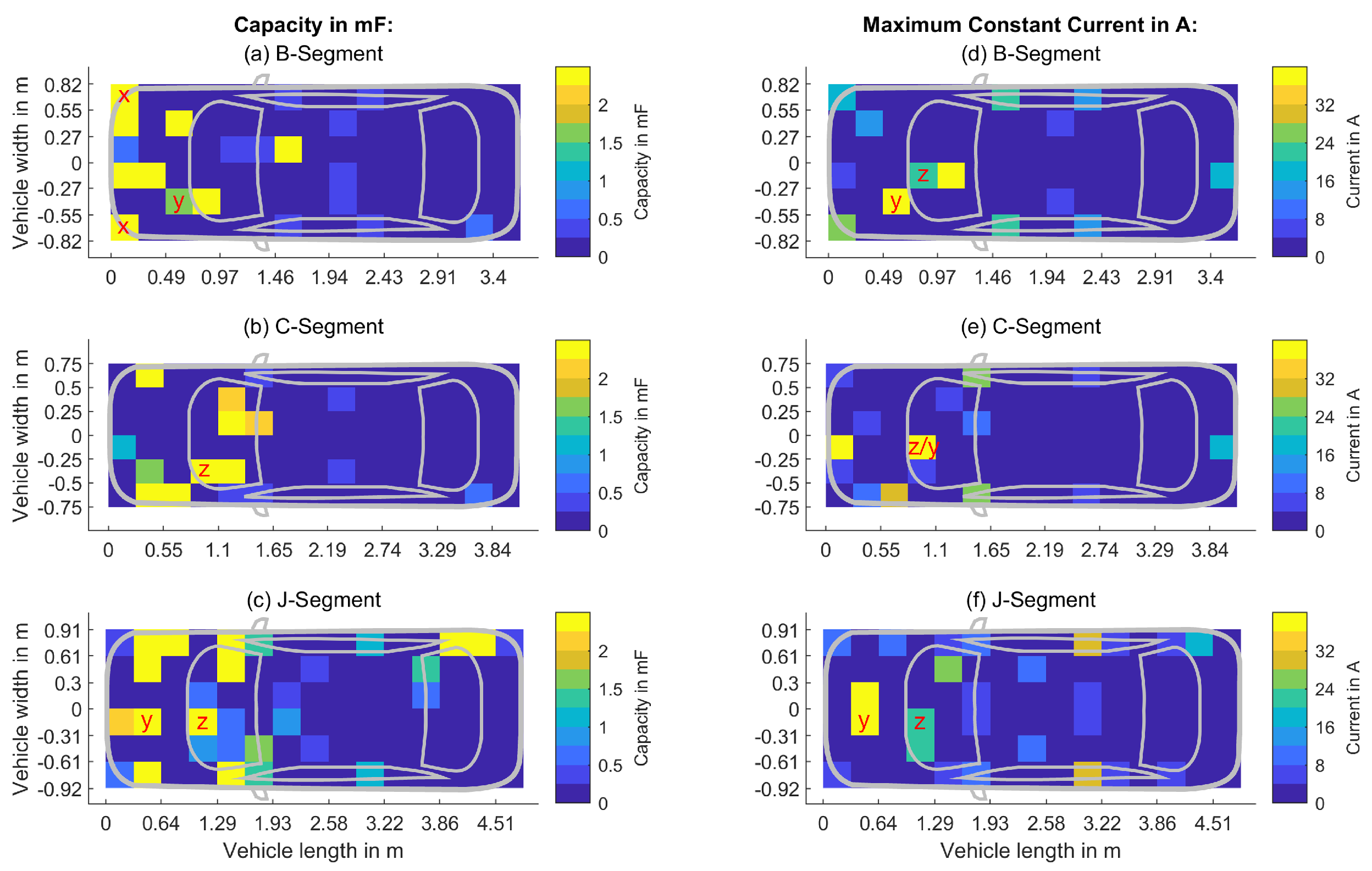

4.2.4. Two-/Three-Dimensional Analysis

4.2.5. Inductance Validation

4.3. Critiques

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brandt, L.S. Architekturgesteuerte Elektrik/Elektronik Baukastenentwicklung im Automobil. Doctoral Thesis, Technische Universität München, München, Germany, 2015. [Google Scholar]

- Daniel, F.; Eppler, A.; Schwarz, T.; Bauer, M.; Berger, R. The Wiring Harness Segment—Keeping up or Falling Behind? Whitepaper, Technical Report December 2022; Roland Berger: München, Germany, 2022. [Google Scholar]

- LEONI. Harness the Full Potential of Wiring Systems, Nürnberg Germany. 2025. Available online: https://www.leoni.com/markets-solutions/wiring-systems/innovations/zonal-architecture (accessed on 1 March 2025).

- Jang, H.; Park, C.; Goh, S.; Park, S. Design of a Hybrid In-Vehicle Network Architecture Combining Zonal and Domain Architectures for Future Vehicles. In Proceedings of the 2023 IEEE 6th International Conference on Knowledge Innovation and Invention, ICKII 2023, Sapporo, Japan, 11–13 August 2023; pp. 33–37. [Google Scholar] [CrossRef]

- Jagfeld, S.M.P.; Weldle, R.; Knorr, R.; Fill, A.; Birke, K.P. What is Going on within the Automotive PowerNet? SAE Tech. Pap. Ser. 2024, 1, 1–16. [Google Scholar] [CrossRef]

- Ruf, F. Auslegung und Topologieoptimierung von Spannungsstabilen Energiebordnetzen. Doctoral Thesis, Technische Universität München, München, Germany, 2015. [Google Scholar]

- Wang, J. Simulationsumgebung zur Bewertung von Bordnetz-Architekturen mit Hochleistungsverbrauchern. Doctoral Thesis, Universität Kassel, Kassel, Germany, 2016. [Google Scholar]

- Gerten, M.; Rübartsch, M.; Frei, S. Transient Analysis of Switching Events and Electrical Faults in Automotive Power Supply Systems. In Proceedings of the EEHE 2022, Bamberg, Germany, 12–13 June 2022. [Google Scholar]

- Schwimmbeck, S.; Buchner, Q.; Herzog, H.G. Evaluation of Short-Circuits in Automotive Power Nets with Different Wire Inductances. In Proceedings of the 2018 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles and International Transportation Electrification Conference, ESARS-ITEC, Nottingham, UK, 7–9 November 2018. [Google Scholar] [CrossRef]

- Gerten, M.; Frei, S.; Kiffmeier, M.; Bettgens, O. Influence of Electronic and Melting Fuses on the Transient Behavior of Automotive Power Supply Systems. IEEE Trans. Transp. Electrif. 2023, 10, 4065–4073. [Google Scholar] [CrossRef]

- Önal, S.; Kiffmeier, M.; Frei, S. Modellbasierte intelligente Sicherungen mit umgebungsadaptiver Anpassung der Auslöseparameter. In Elektrik/Elektronik in Hybrid- und Elektrofahrzeugen und Elektrisches Energiemanagement VIII; Expert-Verlag GmbH Fachverlag für Wirtschaft und Technik: Tübingen, Germany, 2018; pp. 139–156. [Google Scholar]

- Önal, S.; Frei, S. Elektrothermische Modellierung von Kfz-Schmelzsicherungen für dynamische Belastungen. In Proceedings of the Automotive Meets Electronics—7. GMM-Fachtagung, Dortmund, Germany, 1–2 March 2016; pp. 64–69. [Google Scholar]

- Kohler, T.P.; Gehring, R.; Froeschl, J.; Dornmair, R.; Schramm, C.; Ruf, F.; Thanheiser, A.; Buecherl, D.; Herzog, H.G. Sensitivity analysis of voltage behavior in vehicular power nets. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Kull, M.; Feser, K.; Reinhardt, U. Measurements and simulations of transient switching phenomena in modern passenger cars. SAE Tech. Pap. 2004, 113, 221–225. [Google Scholar] [CrossRef]

- Gehring, R.; Fröschl, J.; Kohler, T.P.; Herzog, H.G. Modeling of the automotive 14 V power net for voltage stability analysis. In Proceedings of the 5th IEEE Vehicle Power and Propulsion Conference, VPPC ’09, Dearborn, MI, USA, 7–10 September 2009; pp. 71–77. [Google Scholar] [CrossRef]

- Helms, H.; Bruch, B.; Räder, D.; Hausberger, S.; Lipp, S.; Mater, C. Abschlussbericht: Energieverbrauch von Elektroautos (BEV). TEXTE Umweltbundesamt 2022, 160, 42–44. [Google Scholar]

- Suchaneck, A. Energiemanagement-Strategien für Batterieelektrische Fahrzeuge. Doctoral Thesis, Karlsruher Instituts für Technologie, Karlsruhe, Germany, 2018. [Google Scholar]

- VARTA. Electrical Consumers in Cars—How Much Power do They Use? Ellwang, Germany, 2018. Available online: https://batteryworld.varta-automotive.com/en-be/electrical-consumers-in-cars-how-much-power-do-they-use (accessed on 1 March 2025).

- Kruppok, K.; Jaeger, B.; Kriesten, R. Auswirkung der Elektrifizierung von Nebenverbrauchern auf das Energiemanagement im Kraftfahrzeug. Forsch. Aktuell 2016, 47–49. [Google Scholar]

- Lawrence, C.P. Improving Fuel Economy via Management of Auxiliary Loads in Fuel-Cell Electric Vehicles. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2007. [Google Scholar]

- A2MAC1 Group. A2MAC1 Vehicle Database 3D Explorer. Available online: https://ibp.a2mac1.com/auth/sign-in (accessed on 1 March 2025).

- Grover, F.W. Inductance Calculations; Dover Books on Electrical Engineering; Dover Publications: Mineola, NY, USA, 2013. [Google Scholar]

- Frauenhofer, M. Bordnetz im PPE. In Proceedings of the Kooperationsforum Bordnetze, Ingolstadt, Germany, 26 November 2024. [Google Scholar]

- Huck, T.; Achtzehn, A.; Hoos, F.; Fuchs, A.; Stüble, J.; Traub, T.T.; Kourtidis, V.; Eder, M.; Wehefritz, K. Mit Neuen Energiebordnetzen in die Zukunft der Mobilität—Whitepaper; Robert Bosch GmbH: Gerlingen, Germany, 2024. [Google Scholar]

- Choi, Y. Reducing Range Anxiety by Reducing Harness Weight Using Power Modules—Company Presentation; Technical Report; VICOR: Andover, MA, USA, 2023. [Google Scholar]

- Seifert, K. How to Make the Leap to 48V Electrical Architectures—Whitepaper; Technical Report; Aptiv: Dublin, Ireland, 2023. [Google Scholar]

- Evtimov, I.; Ivanov, R.; Sapundjiev, M. Energy consumption of auxiliary systems of electric cars. MATEC Web Conf. 2017, 133, 2–6. [Google Scholar] [CrossRef]

- Ludwig, K.; Rifai, F. Power distribution in modern vehicle architectures. In Proceedings of the Elektrik, Elektronik in Hybrid- und Elektrofahrzeugen 2024, Essen, Germany, 15–16 May 2024. [Google Scholar]

- Gambino, G. Selecting the Right Power Switch for Automotive High-Current Electronic Fuses. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

| B-Segment | C-Segment | J-Segment | |

|---|---|---|---|

| in mV | 77 | 40 | 47.5 |

| in W | 202 | 167 | 173 |

| in J | 0.2 | 0.19 | 0.28 |

| in J | 9 | 7.5 | 14 |

| Load Name | Fuse Value (in A) | I_max (in A) | I_max,const (in A) | I_mean (in A) | DI/dt (in A/ms) | C | I_max (literature) | I_mean (literature) |

|---|---|---|---|---|---|---|---|---|

| ADAS ECU | -/-/10 | -/-/4 | -/-/4 | -/-/3 | -/-/4 | -/-/2.2 | ||

| Brake | 120/163/100 | 111/100/80 | 18/14/17 | 18/14/17 | 14/38/79 | 0.1/2.9/7.2 | ||

| Cabin fan | 40/30/- | 26/8/- | 23/5/- | 18/3/- | 3/3/- | -/2/- | 12–29 | 7–29 |

| Cabin heater | 100/-/- | 75/-/- | 50/-/- | 40/-/- | 44/-/- | 0/-/- | 107–286 | 71–214 |

| Climate system | 10/8/- | 1/2/- | 0/1/- | 0/1/- | 0/2/- | 1.2/1.5/- | ||

| Display | -/8/10 | -/2/2 | -/1/1 | -/0/1 | -/1/1 | -/2.1/1.2 | ||

| Door lock | -/-/20 | -/-/ 8 | -/-/7 | -/-/6 | -/-/6 | -/-/- | ||

| Electric tailgate | -/-/40 | -/-/32 | -/-/8 | -/-/4 | -/-/5 | -/-/- | 7 | 2 |

| Electric window | 30/30/30 | 22/26/29 | 20/25/24 | 8/6/8 | 13/13/5 | 0.3/-/- | 11 | 6–11 |

| Engine fan | 60/50/125 | 8/47/- | 5/40/- | 3/33/- | 3/7/- | 3.4/-/- | 57 | 14 |

| Front window heater | 0/40/- | 0/30/- | 0/29/- | 0/28/- | 0/29/- | 0/-/- | 9–143 | 18 |

| Light (per beam) | 10/0/0 | 11/12/4 | 1/3/3 | 0/3/2 | 0/0/2 | -/5.4/- | 4 | 0–4 |

| Panel Heating | -/-/ 30 | -/-/ 11 | -/-/ 6 | -/-/ 4 | -/-/ 6 | -/-/ 0.1 | ||

| Panorma roof | -/-/10 | -/-/1 | -/-/0 | -/-/0 | -/-/1 | -/-/1.4 | ||

| Radar | -/-/15 | -/-/- | -/-/- | -/-/- | -/-/- | -/-/1.1 | ||

| Rear window heater | 40/30/- | 22/17/- | 19/16/- | 17/14/- | 22/17/- | -/-/- | 9–14 | 9–14 |

| Seat heater (per seat) | 30/-/30 | 6/12/12 | 6/3.3/7 | 5/2.4/3 | 3/-/7 | 0.4/-/- | 14 | 2–14 |

| Steering | 80/80/250 | 67/98/136 | 56/31/32 | 16/31/32 | 31/12/9 | 1.7/0/0.5 | 107 | 29–57 |

| Trailer ECU | -/-/20 | -/-/- | -/-/- | -/-/- | -/-/- | -/-/5 | ||

| Trunk lock | -/-/40 | -/-/7 | -/-/6 | -/-/4 | -/-/2 | -/-/- | ||

| Washer pump | 20/0/30 | 15/-/25 | 5/-/6 | 6/-/6 | 14/-/24 | -/0.04/0.4 | 7 | 4 |

| Water pump | -/0/30 | -/0/10 | -/0/9 | -/0/5 | -/0/13 | -/0/2.6 | 36 | 0–7 |

| Wiper back | 0/-/0 | 0/-/0 | 0/-/0 | 0/-/0 | 0/-/0 | 0/-/0 | ||

| Wiper front | -/30/30 | -/18/29 | -/6/23 | -/6/6 | -/0/11 | -/0.8/0.7 | 6–11 | 2–11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jagfeld, S.M.P.; Schlautmann, T.; Weldle, R.; Fill, A.; Birke, K.P. Creating an Extensive Parameter Database for Automotive 12 V Power Net Simulations: Insights from Vehicle Measurements in State-of-the-Art Battery Electric Vehicles. World Electr. Veh. J. 2025, 16, 257. https://doi.org/10.3390/wevj16050257

Jagfeld SMP, Schlautmann T, Weldle R, Fill A, Birke KP. Creating an Extensive Parameter Database for Automotive 12 V Power Net Simulations: Insights from Vehicle Measurements in State-of-the-Art Battery Electric Vehicles. World Electric Vehicle Journal. 2025; 16(5):257. https://doi.org/10.3390/wevj16050257

Chicago/Turabian StyleJagfeld, Sebastian Michael Peter, Tobias Schlautmann, Richard Weldle, Alexander Fill, and Kai Peter Birke. 2025. "Creating an Extensive Parameter Database for Automotive 12 V Power Net Simulations: Insights from Vehicle Measurements in State-of-the-Art Battery Electric Vehicles" World Electric Vehicle Journal 16, no. 5: 257. https://doi.org/10.3390/wevj16050257

APA StyleJagfeld, S. M. P., Schlautmann, T., Weldle, R., Fill, A., & Birke, K. P. (2025). Creating an Extensive Parameter Database for Automotive 12 V Power Net Simulations: Insights from Vehicle Measurements in State-of-the-Art Battery Electric Vehicles. World Electric Vehicle Journal, 16(5), 257. https://doi.org/10.3390/wevj16050257