A Four-Party Evolutionary Game Analysis of Retired Power Battery Recycling Strategies Under the Low Carbon Goals

Abstract

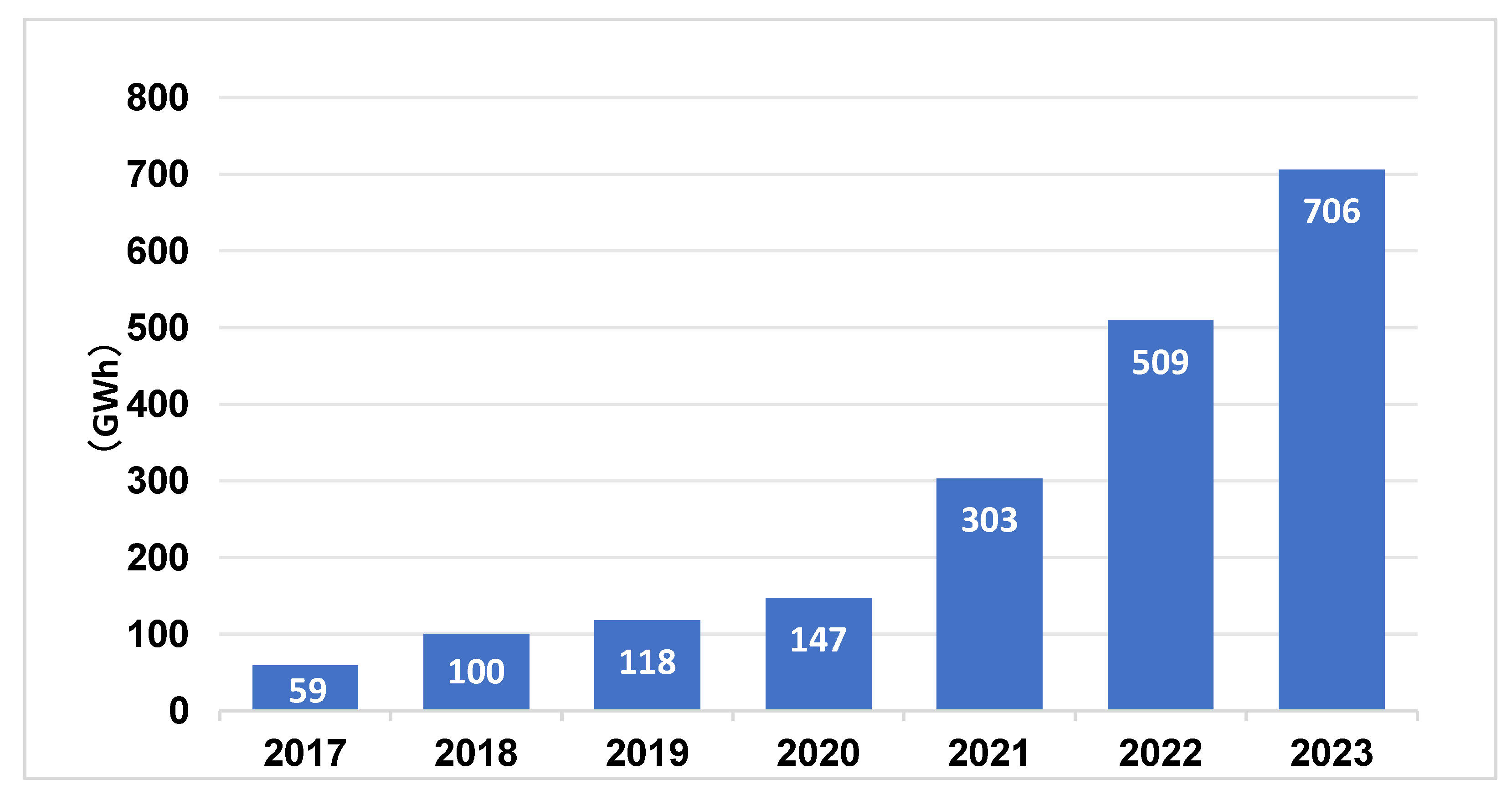

1. Introduction

2. Literature Review

2.1. Research on Recycling Models of Power Batteries

2.2. Research on Policies for Power Battery Recycling

2.3. Current Status of Recycling Research Using Evolutionary Game Theory

3. Methods

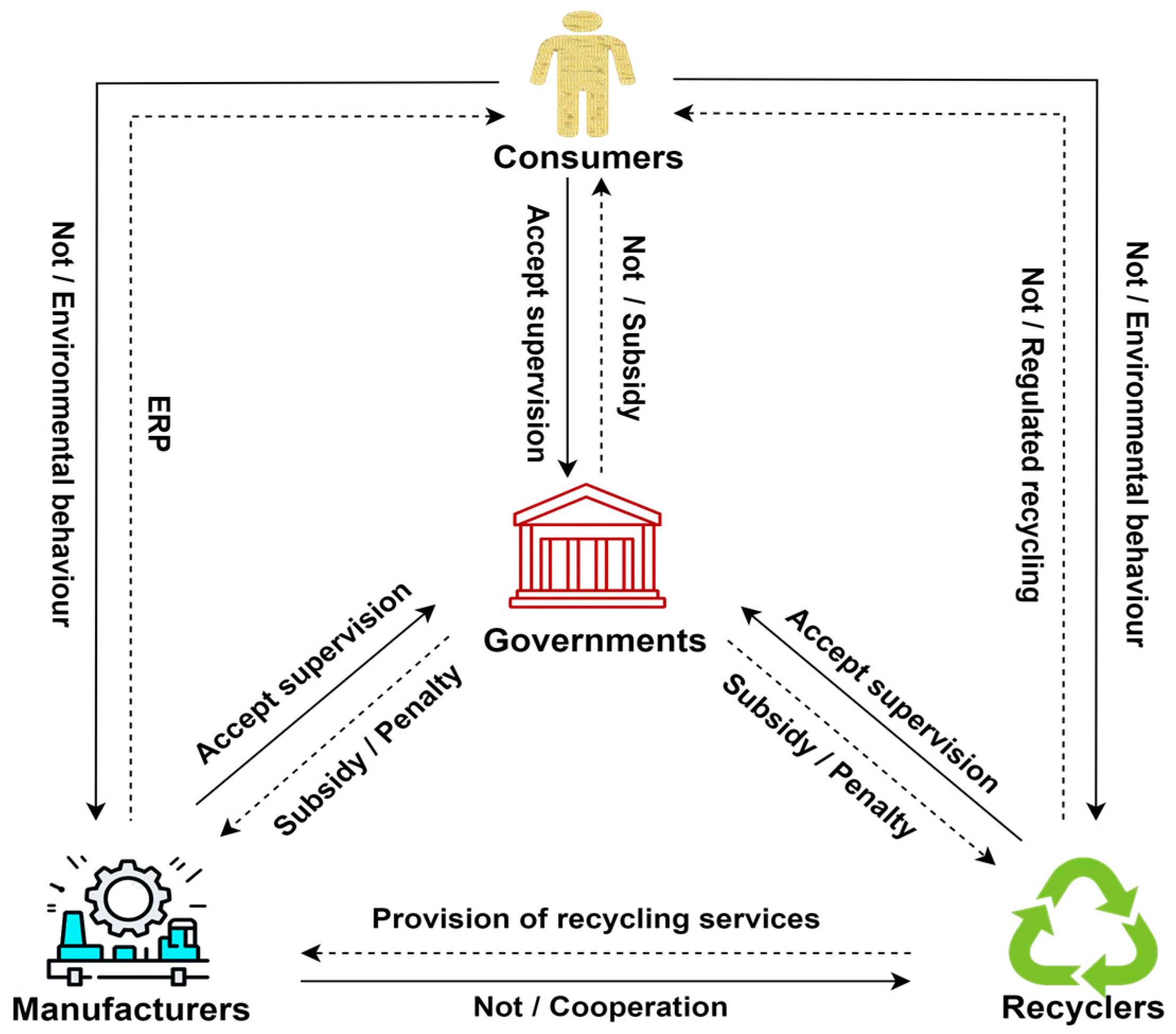

3.1. Model Description

3.2. Model Assumptions

3.3. Payoff Matrix

4. Results

4.1. Evolutionary Game Stability Analysis

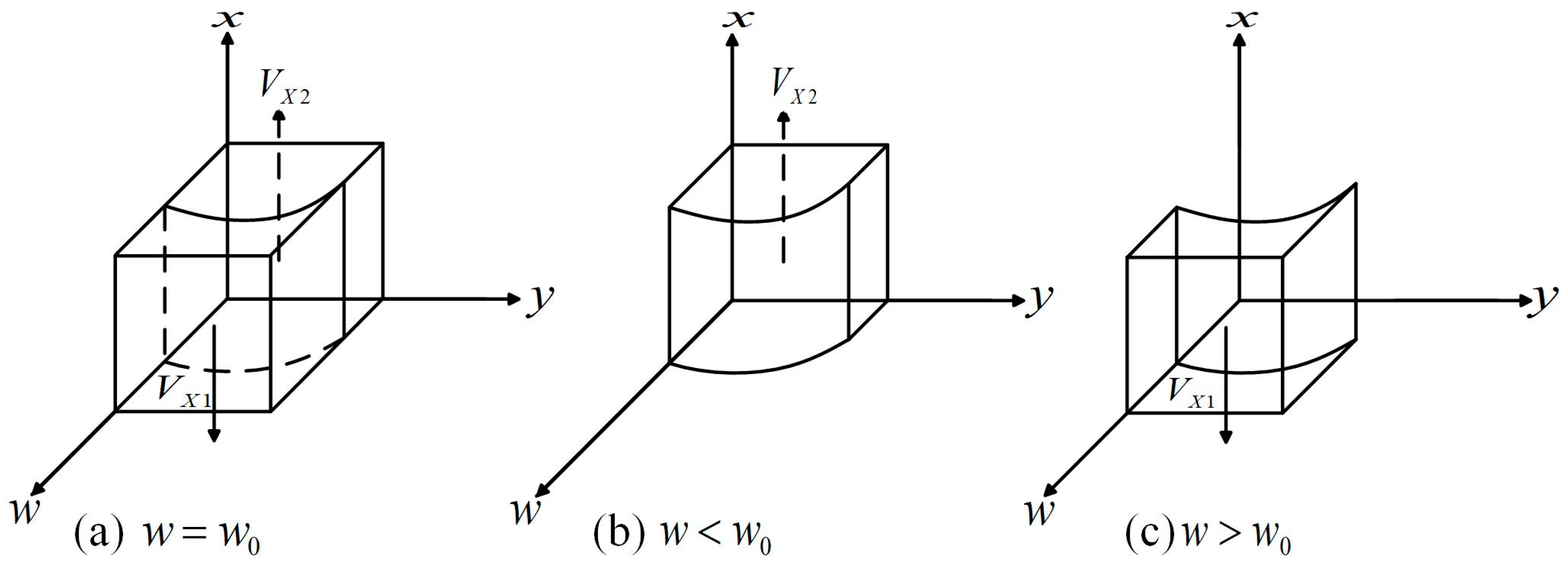

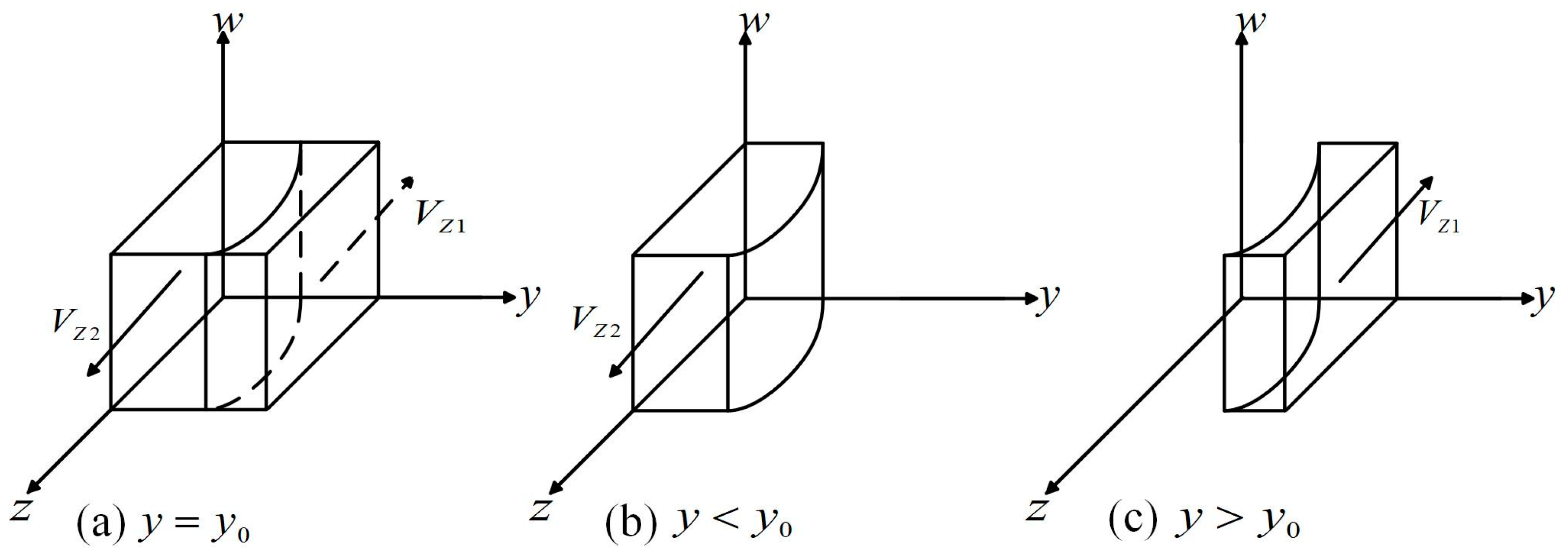

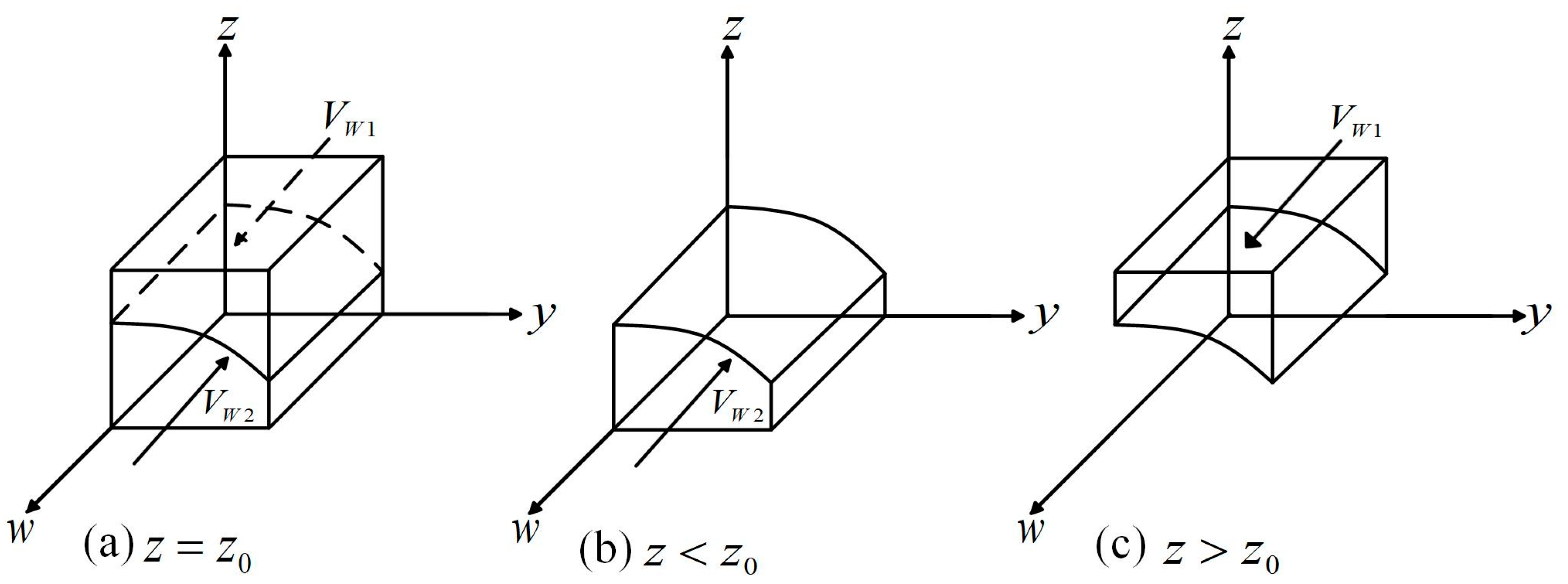

4.1.1. Stability Analysis of the Government’s Strategy

4.1.2. Stability Analysis of the Manufacturer’s Strategy

4.1.3. Stability Analysis of the Recycler’s Strategy

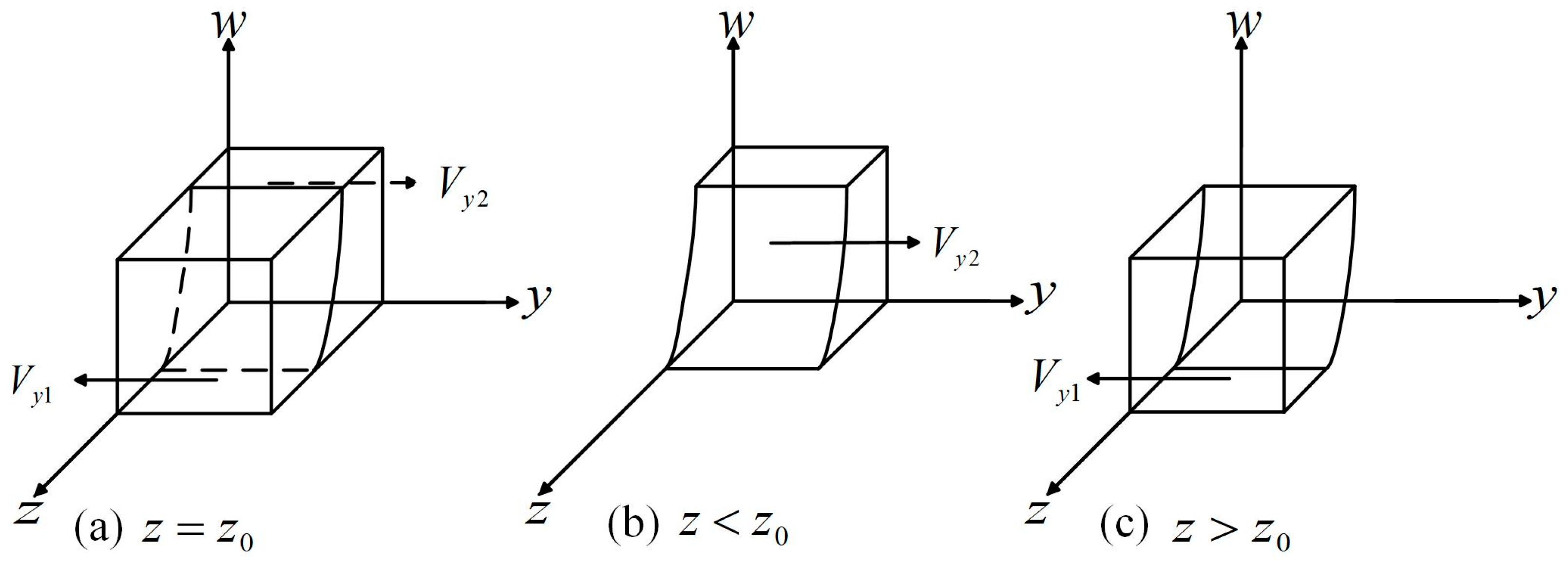

4.1.4. Stability Analysis of the Consumer’s Strategy

4.1.5. Local Stability Analysis of the System

4.2. Numerical Simulation Analysis

4.3. Sensitivity Analysis

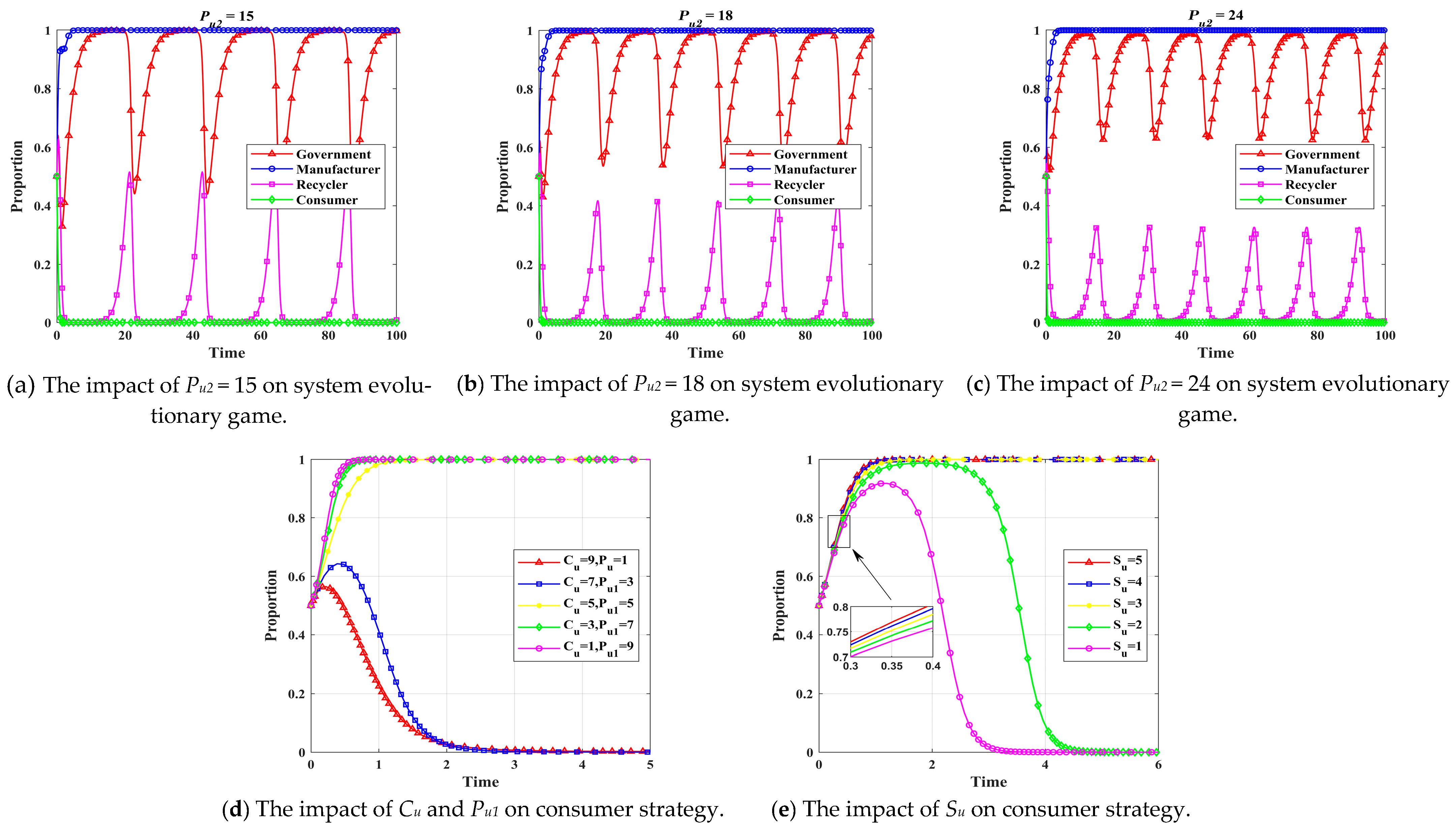

4.3.1. Analysis of Factors Influencing Government Decision-Making

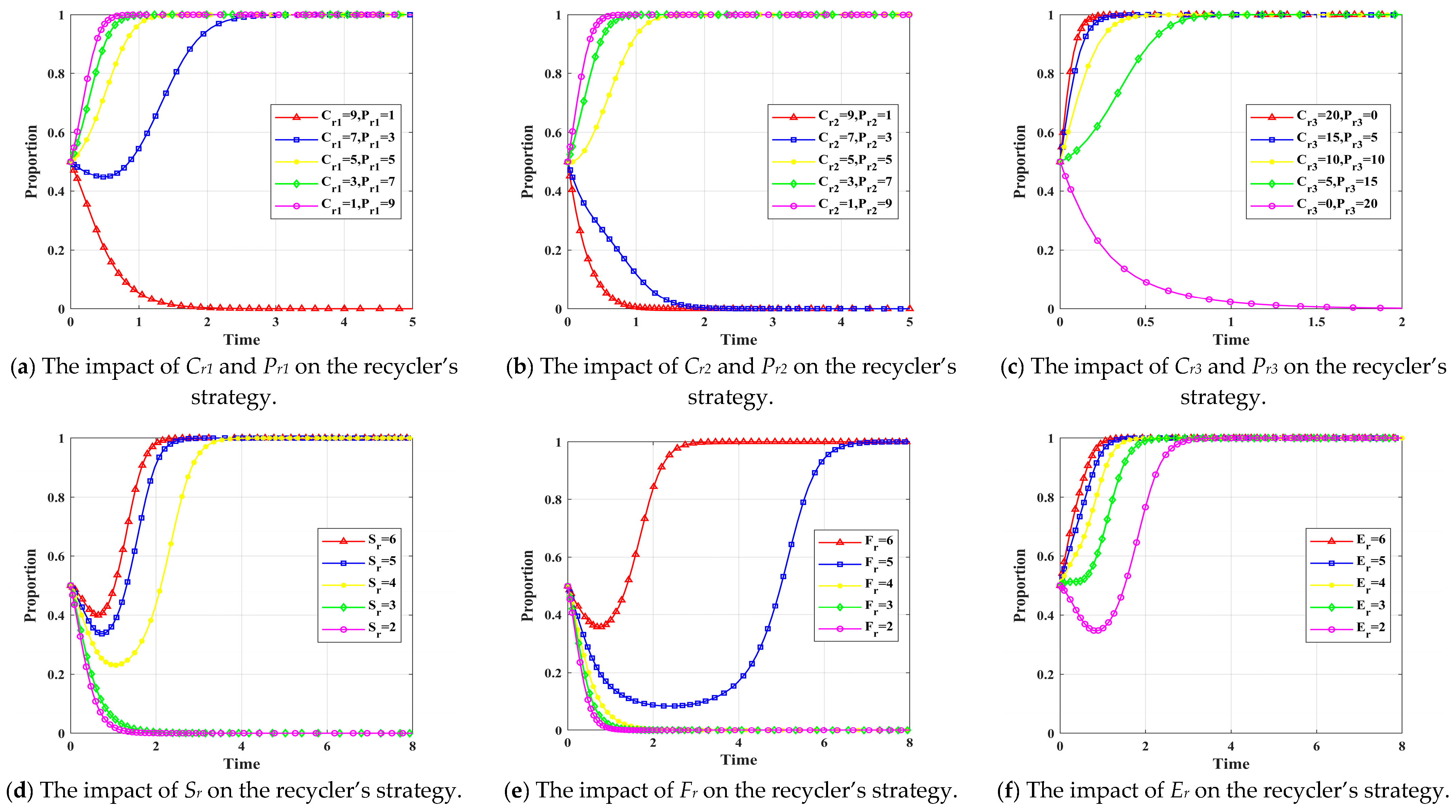

4.3.2. Analysis of Factors Influencing the Recyclers’ Decision-Making

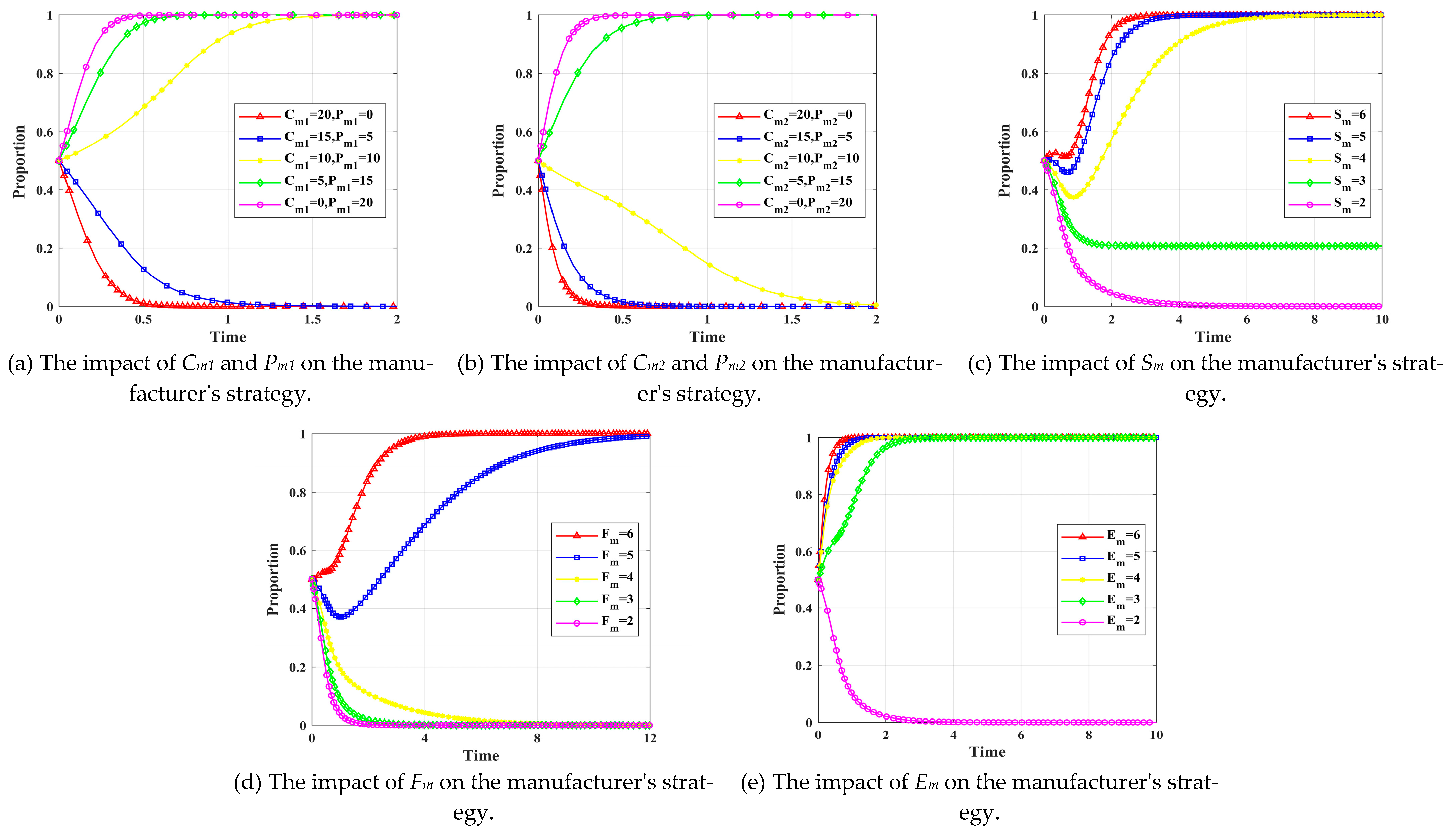

4.3.3. Analysis of Factors Influencing Manufacturer Decision-Making

4.3.4. Analysis of Factors Influencing the Consumers’ Decision-Making

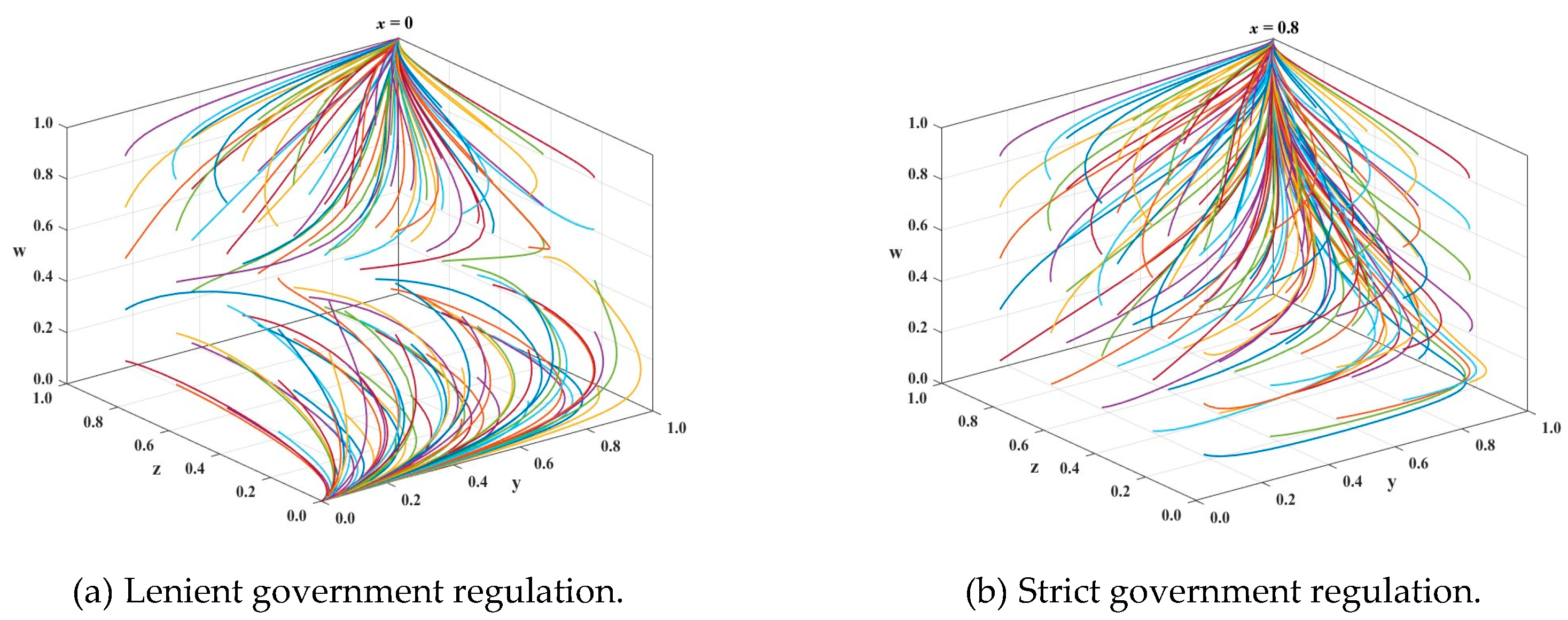

4.3.5. Influence of Government Regulatory Probability

5. Conclusions and Recommendations

5.1. Conclusions

- Long-term evolution may yield three stable strategy combinations. Firstly, when the government, manufacturers, recyclers, and consumers all adopt proactive recycling strategies, the system evolves toward a Pareto optimal state. Secondly, if the government pursues a lenient regulatory strategy, the system may transition to a transitional state (0,1,1,1), but this state is challenging to maintain. Thirdly, in the absence of stringent long-term regulation, the system is likely to evolve toward a Pareto worst state (0,0,0,0), which would be highly detrimental to the development of the used PB recycling market.

- Increasing the level of government subsidies can temporarily extend the period of strict regulation. However, long-term subsidies beyond a certain threshold may lead to diminishing marginal returns and the inefficient allocation of fiscal resources. Manufacturers and recyclers are particularly sensitive to subsidy policies, so policy formulation should prioritize these groups. Enhancing the government’s overall benefits and increasing the penalties for non-compliance could help strengthen the government’s resolve and capability to enforce strict regulations.

- The manufacturers’ engagement in spent PB recycling is primarily driven by profit considerations. Within a collaborative environment supported by multi-stakeholder cooperation and favorable policies, their recycling practices exhibit long-term stability and sustainability. Policy incentives and enhanced reputational value could further motivate manufacturers to participate. Additionally, manufacturers are highly sensitive to fluctuations in subsidy policies, which directly influence their decision to engage in recycling activities.

- Collaboration with manufacturers enables recyclers to share the costs and risks, thereby promoting the adoption of compliant recycling strategies. However, under economic pressures or insufficient external support, recyclers may resort to non-compliant practices that offer higher profits but pose environmental, legal, and reputational risks. While subsidy policies provide an immediate incentive for compliant behavior, penalty mechanisms have a relatively delayed impact, and reputational benefits offer a positive incentive for decision-making.

- The consumers’ environmentally friendly behaviors directly influence the strategic choices of recyclers and manufacturers as well as market stability. Economic incentives positively promote consumer engagement in environmental protection, whereas financial losses significantly dampen their participation. Subsidy policies could enhance consumer awareness of environmental protection in the short-term, but excessive long-term subsidies may undermine the stability of compliant recycling channels by providing insufficient support for other recycling entities, potentially causing market imbalances.

5.2. Recommendations

- The government should strengthen its regulatory role, delineate clear accountability boundaries, and refine subsidy policies to give priority to supporting manufacturers and recyclers, mitigating the inevitable economic costs they encounter, and enhancing consumer participation. Additionally, it should advance the standardization of emerging technologies and establish a digital traceability system for the supply chain. Moreover, it is crucial to refine market entry and exit mechanisms and enhance collaborative governance among multiple stakeholders. The government should also streamline regulatory procedures to reduce administrative and enforcement costs, and bolster environmental oversight to diminish the risks of environmental pollution and decrease the costs associated with environmental remediation.

- Manufacturers are encouraged to reduce recycling costs through technological innovation and process optimization as well as alleviate cost pressures by leveraging government subsidies and preferential tax policies. Additionally, manufacturers should strengthen partnerships with recyclers to share costs and enhance efficiency. Prioritizing reputation management, promoting recycling initiatives, and establishing digital recycling platforms through government-backed programs are crucial for boosting environmental standing and reinforcing the positive impact of reputational incentives.

- Recyclers should enhance cooperation with manufacturers to share the costs and profits, thereby reducing the risks. They should also optimize the cost structures and improve recycling efficiency and quality through technological innovation. On this basis, actively pursuing government subsidies and other policy incentives could strengthen the economic motivation for compliant recycling practices. Additionally, focusing on reputation management and enhancing brand value and social recognition through compliant operations will bolster market competitiveness.

- Consumers are encouraged to proactively select compliant and convenient recycling channels to reduce the recycling and waste management costs. They should also rationally weigh the costs and benefits of eco-friendly behaviors and actively utilize government subsidies to transition from non-environmentally friendly to environmentally friendly practices. Enhancing environmental awareness and resisting the allure of short-term economic gains are crucial for sustaining individual eco-friendly behaviors.

5.3. Limitations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| NEV | New energy vehicle |

| EPR | Extended producer responsibility |

| PB | Power battery |

| ESS | Evolutionarily stable strategy |

| CLSC | Closed-loop supply chain |

References

- Achakulwisut, P.; Erickson, P.; Guivarch, C.; Schaeffer, R.; Brutschin, E.; Pye, S. Global fossil fuel reduction pathways under different climate mitigation strategies and ambitions. Nat. Commun. 2023, 14, 5425. [Google Scholar] [CrossRef]

- Liu, Z.; Deng, Z.; Davis, S.; Ciais, P. Monitoring global carbon emissions in 2022. Nat. Rev. Earth Environ. 2023, 4, 205–206. [Google Scholar] [CrossRef] [PubMed]

- Evro, S.; Oni, B.A.; Tomomewo, O.S. Global Strategies for a Low-Carbon Future: Lessons from the US, China, and EU’s Pursuit of Carbon Neutrality. J. Clean. Prod. 2024, 461, 142635. [Google Scholar] [CrossRef]

- Way, R.; Ives, M.C.; Mealy, P.; Farmer, J.D. Empirically grounded technology forecasts and the energy transition. Joule 2022, 6, 2057–2082. [Google Scholar] [CrossRef]

- Speizer, S.; Fuhrman, J.; Lopez, L.A.; George, M.; Kyle, P.; Monteith, S.; McJeon, H. Integrated assessment modeling of a zero-emissions global transportation sector. Nat. Commun. 2024, 15, 4439. [Google Scholar] [CrossRef] [PubMed]

- Tuffour, J.P.; Ewing, R. Can battery electric vehicles meet sustainable energy demands? Systematically reviewing emissions, grid impacts, and coupling to renewable energy. Energy Res. Soc. Sci. 2024, 114, 103625. [Google Scholar] [CrossRef]

- Mauler, L.; Duffner, F.; Zeier, W.G.; Leker, J. Battery cost forecasting: A review of methods and results with an outlook to 2050. Energy Res. Soc. Sci. 2021, 14, 4712–4739. [Google Scholar] [CrossRef]

- Neumann, J.; Petranikova, M.; Meeus, M.; Gamarra, J.D.; Younesi, R.; Winter, M.; Nowak, S. Recycling of lithium-ion batteries—Current state of the art, circular economy, and next generation recycling. Adv. Energy Mater. 2022, 12, 2102917. [Google Scholar] [CrossRef]

- Nuroldayeva, G.; Serik, Y.; Adair, D.; Uzakbaiuly, B.; Bakenov, Z. State of Health Estimation Methods for Lithium-Ion Batteries. Int. J. Energy Res. 2023, 2023, 4297545. [Google Scholar] [CrossRef]

- Wang, S.; Lai, Y.; Yang, J.; Zhao, J.; Zhang, Y.; Chen, M.; Tang, J.; Xu, J.; Su, M. Advances in Recycling Technologies of Critical Metals and Resources from Cathodes and Anodes in Spent Lithium-Ion Batteries. Separations 2024, 12, 4. [Google Scholar] [CrossRef]

- Ma, X.; Meng, Z.; Bellonia, M.V.; Spangenberger, J.; Harper, G.; Gratz, E.; Olivetti, E.; Arsenault, R.; Wang, Y. The evolution of lithium-ion battery recycling. Nat. Rev. Clean Technol. 2025, 1, 75–94. [Google Scholar]

- Lee, J.; Choe, H.; Yoon, H.Y. Past trends and future directions for circular economy in electric vehicle waste battery reuse and recycling: A bibliometric analysis. Sustain. Energy Technol. Assess. 2025, 75, 104198. [Google Scholar]

- Istrate, R.; Mas-Fons, A.; Beylot, A.; Northey, S.; Vaidya, K.; Sonnemann, G.; Kleijn, R.; Steubing, B. Decarbonizing lithium-ion battery primary raw materials supply chain. Joule 2024, 8, 2992–3016. [Google Scholar]

- Dobó, Z.; Dinh, T.; Kulcsár, T. A review on recycling of spent lithium-ion batteries. Energy Rep. 2023, 9, 6362–6395. [Google Scholar]

- Preet, S.; Smith, S.T. A comprehensive review on the recycling technology of silicon-based photovoltaic solar panels: Challenges and future outlook. J. Cleaner Prod. 2024, 448, 141661. [Google Scholar]

- Rezaei, M.; Nekahi, A.; MR, A.K.; Nizami, A.; Li, X.; Deng, S.; Nanda, J.; Zaghib, K. A review of lithium-ion battery recycling for enabling a circular economy. J. Power Sources 2025, 630, 236157. [Google Scholar]

- Zhou, Y.; Cui, X.D.; Lin, A.J.; Dong, Y.; Duan, L.G. Environmental life cycle assessment on the recycling processes of power batteries for new energy vehicles. J. Clean. Prod. 2025, 488, 144641. [Google Scholar]

- Man, G.T.; Iordache, A.M.; Zgavarogea, R.; Nechita, C. Recycling Lithium-Ion Batteries—Technologies, Environmental, Human Health, and Economic Issues—Mini-Systematic Literature Review. Membranes 2024, 14, 277. [Google Scholar] [CrossRef]

- Bae, H.; Kim, Y. Technologies of lithium recycling from waste lithium ion batteries: A review. Mater. Adv. 2021, 2, 3234–3250. [Google Scholar]

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar]

- Blömeke, S.; Scheller, C.; Cerdas, F.; Thies, C.; Hachenberger, R.; Gonter, M.; Herrmann, C.; Spengler, T.S. Material and energy flow analysis for environmental and economic impact assessment of industrial recycling routes for lithium-ion traction batteries. J. Clean. Prod. 2022, 377, 134344. [Google Scholar]

- Zhao, T.; Mahandra, H.; Marthi, R.; Ji, X.; Zhao, W.; Chae, S.; Traversy, M.; Li, W.; Yu, F.; Li, L.; et al. An overview on the life cycle of lithium iron phosphate: Synthesis, modification, application, and recycling. Chem. Eng. J. 2024, 485, 149923. [Google Scholar]

- Wang, M.; Liu, K.; Dutta, S.; Alessi, D.S.; Rinklebe, J.; Ok, Y.S.; Tsang, D.C. Recycling of lithium iron phosphate batteries: Status, technologies, challenges, and prospects. Renew. Sustain. Energy Rev. 2022, 163, 112515. [Google Scholar]

- Tripathy, A.; Bhuyan, A.; Padhy, R.; Mangla, S.K.; Roopak, R. Drivers of lithium-ion batteries recycling industry toward circular economy in industry 4.0. Comput. Ind. Eng. 2023, 179, 109157. [Google Scholar]

- Dos Santos, M.P.; Garde, I.A.A.; Ronchini, C.M.B.; Cardozo Filho, L.; De Souza, G.B.M.; Abbade, M.L.F.; Regone, N.N.; Jegatheesan, V.J.; De Oliveira, J.A. A technology for recycling lithium-ion batteries promoting the circular economy: The RecycLib. Resour. Conserv. Recycl. 2021, 175, 105863. [Google Scholar]

- Roy, J.J.; Phuong, D.M.; Verma, V.; Chaudhary, R.; Carboni, M.; Meyer, D.; Cao, B.; Srinivasan, M. Direct recycling of Li-ion batteries from cell to pack level, Challenges and prospects on technology, scalability, sustainability, and economics. Carbon Energy 2024, 6, e492. [Google Scholar]

- Chen, G.; Shi, H.; Ding, H.; Zhang, X.; Gu, T.; Zhu, M.; Tan, W. Multi-scale analysis of nickel ion tolerance mechanism for thermophilic Sulfobacillus thermosulfidooxidans in bioleaching. J. Hazard. Mater. 2023, 443, 130245. [Google Scholar]

- Roy, J.J.; Rarotra, S.; Krikstolaityte, V.; Zhuoran, K.W.; Cindy, Y.D.I.; Tan, X.Y.; Carboni, M.; Meyer, D.; Yan, Q.; Srinivasan, M. Green recycling methods to treat lithium-ion batteries E-waste, a circular approach to sustainability. Adv. Mater. 2022, 34, 2103346. [Google Scholar]

- Cheng, A.L.; Fuchs, E.R.H.; Karplus, V.J.; Michalek, J.J. Electric vehicle battery chemistry affects supply chain disruption vulnerabilities. Nat. Commun. 2024, 15, 2143. [Google Scholar]

- Bulut, M.S.; Ordu, M.; Der, O.; Basar, G. Sustainable thermoplastic material selection for hybrid vehicle battery packs in the automotive industry: A comparative multi-criteria decision-making approach. Polymers 2024, 16, 2768. [Google Scholar] [CrossRef]

- Wazeer, A.; Das, A.; Abeykoon, C.; Sinha, A.; Karmakar, A. Phase change materials for battery thermal management of electric and hybrid vehicles: A review. Energy Nexus 2022, 7, 100131. [Google Scholar]

- Mirzaei Omrani, M.; Jannesari, H. Economic and environmental assessment of reusing electric vehicle lithium-ion batteries for load leveling in the residential, industrial and photovoltaic power plants sectors. Renew. Sustain. Energy Rev. 2019, 116, 109413. [Google Scholar] [CrossRef]

- Skeete, J.-P.; Wells, P.; Dong, X.; Heidrich, O.; Harper, G. Beyond the EVent horizon: Battery waste, recycling, and sustainability in the United Kingdom electric vehicle transition. Energy Res. Soc. Sci. 2020, 69, 101581. [Google Scholar]

- Biswal, B.K.; Zhang, B.; Tran, P.T.M.; Zhang, J.; Balasubramanian, R. Recycling of spent lithium-ion batteries for a sustainable future: Recent advancements. Chem. Soc. Rev. 2024, 53, 5552–5592. [Google Scholar] [PubMed]

- Karimzadeh, S.; Safaei, B.; Yuan, C.; Jen, T.-C. Emerging atomic layer deposition for the development of high-performance lithium-ion batteries. Electrochem. Energy Rev. 2023, 6, 24. [Google Scholar]

- Nasajpour-Esfahani, N.; Garmestani, H.; Bagheritabar, M.; Jasim, D.J.; Toghraie, D.; Dadkhah, S.; Firoozeh, H. Comprehensive review of lithium-ion battery materials and development challenges. Renew. Sustain. Energy Rev. 2024, 203, 114783. [Google Scholar]

- Miranda, D.; Gonçalves, R.; Wuttke, S.; Costa, C.M.; Lanceros-Méndez, S. Overview on theoretical simulations of lithium-ion batteries and their application to battery separators. Adv. Energy Mater. 2023, 13, 2203874. [Google Scholar]

- Rajaeifar, M.A.; Ghadimi, P.; Raugei, M.; Wu, Y.; Heidrich, O. Challenges and recent developments in supply and value chains of electric vehicle batteries: A sustainability perspective. Resour. Conserv. Recycl. 2022, 180, 106144. [Google Scholar]

- Hosseini-Motlagh, S.-M.; Nouri-Harzvili, M.; Johari, M.; Sarker, B.R. Coordinating economic incentives, customer service and pricing decisions in a competitive closed-loop supply chain. J. Clean. Prod. 2020, 255, 120241. [Google Scholar]

- Lander, L.; Cleaver, T.; Rajaeifar, M.A.; Nguyen-Tien, V.; Elliott, R.J.; Heidrich, O.; Kendrick, E.; Edge, J.S.; Offer, G. Financial viability of electric vehicle lithium-ion battery recycling. Iscience 2021, 24, 102787. [Google Scholar]

- Chinen, K.; Matsumoto, M.; Tong, P.; Han, Y.S.; Niu, K.-H.J. Electric vehicle owners’ perception of remanufactured batteries: An empirical study in China. Sustainability 2022, 14, 10846. [Google Scholar] [CrossRef]

- Kushwaha, S.; Chan, F.T.; Chakraborty, K.; Pratap, S. Collection and remanufacturing channels selection under a product take-back regulation with remanufacturing target. Int. J. Prod. Res. 2022, 60, 7384–7410. [Google Scholar] [CrossRef]

- Bhuyan, A.; Tripathy, A.; Padhy, R.; Gautam, A. Evaluating the lithium-ion battery recycling industry in an emerging economy: A multi-stakeholder and multi-criteria decision-making approach. J. Clean. Prod. 2022, 331, 130007. [Google Scholar] [CrossRef]

- Melin, H.E.; Rajaeifar, M.A.; Ku, A.Y.; Kendall, A.; Harper, G.; Heidrich, O. Global implications of the EU battery regulation. Science 2021, 373, 384–387. [Google Scholar] [CrossRef]

- Giosuè, C.; Marchese, D.; Cavalletti, M.; Isidori, R.; Conti, M.; Orcioni, S.; Ruello, M.L.; Stipa, P. An exploratory study of the policies and legislative perspectives on the end-of-life of lithium-ion batteries from the perspective of producer obligation. Sustainability 2021, 13, 11154. [Google Scholar] [CrossRef]

- Tembo, P.M.; Dyer, C.; Subramanian, V. Lithium-ion battery recycling—A review of the material supply and policy infrastructure. NPG Asia Mater. 2024, 16, 43. [Google Scholar] [CrossRef]

- Ahlers, J.; Hemkhaus, M.; Hibler, S.; Hannak, J. Analysis of Extended Producer Responsibility Schemes; Adelphi Consult GmbH: Berlin, Germany, 2021. [Google Scholar]

- Zan, X.; Zhang, D. Analysis on the optimal recycling path of Chinese lead-acid battery under the extended producer responsibility system. Sustainability 2022, 14, 4950. [Google Scholar] [CrossRef]

- Compagnoni, M.; Grazzi, M.; Pieri, F.; Tomasi, C. Extended producer responsibility and trade flows in waste: The case of batteries. Environ. Resour. Econ. 2025, 88, 43–76. [Google Scholar] [CrossRef]

- Van Hoof, G.; Robertz, B.; Verrecht, B. Towards sustainable battery recycling: A carbon footprint comparison between pyrometallurgical and hydrometallurgical battery recycling flowsheets. Metals 2023, 13, 1915. [Google Scholar] [CrossRef]

- Feng, Z.; Luo, N.; Shalpegin, T.; Cui, H. The influence of carbon emission reduction instruments on blockchain technology adoption in recycling batteries of the new energy vehicles. Int. J. Prod. Res. 2024, 62, 891–908. [Google Scholar] [CrossRef]

- Júnior, C.A.R.; Sanseverino, E.R.; Gallo, P.; Koch, D.; Schweiger, H.-G.; Zanin, H. Blockchain review for battery supply chain monitoring and battery trading. Renew. Sustain. Energy Rev. 2022, 157, 112078. [Google Scholar]

- Narang, P.; De, P.K.; Lim, C.P.; Kumari, M. Optimal recycling model selection in a closed-loop supply chain for electric vehicle batteries under carbon cap-trade and reward-penalty policies using the Stackelberg game. Comput. Ind. Eng. 2024, 196, 110512. [Google Scholar]

- Kim, T.; Yoon, C.; Jung, S. A Study on the Battery Recycling Process and Risk Estimation. Int. J. Environ. Res. Public Health 2024, 21, 1649. [Google Scholar] [CrossRef]

- Li, G.; Lu, M.; Lai, S.; Li, Y. Research on power battery recycling in the green closed-loop supply chain: An evolutionary game-theoretic analysis. Sustainability 2023, 15, 10425. [Google Scholar] [CrossRef]

- Ren, G.; Eveleigh, T. A quantitative assessment of policy-driven impacts on circular economy of electric vehicle batteries in the United States. Environ. Syst. Decis. 2025, 45, 4. [Google Scholar] [CrossRef]

- Thompson, D.L.; Hartley, J.M.; Lambert, S.M.; Shiref, M.; Harper, G.D.J.; Kendrick, E.; Anderson, P.; Ryder, K.S.; Gaines, L.; Abbottet, A.P. The importance of design in lithium ion battery recycling–a critical review. Green Chem 2020, 22, 7585–7603. [Google Scholar]

- Wang, J.; He, Y.-Q.; Wang, H.-G.; Wu, R.-F. Low-carbon promotion of new energy vehicles: A quadrilateral evolutionary game. Renew. Sustain. Energy Rev. 2023, 188, 113795. [Google Scholar]

- Xiao, M.; Xu, C.; Xie, F. Research on the impact of information sharing and government subsidy on competitive power battery recycling. J. Clean. Prod. 2024, 467, 1429. [Google Scholar]

- He, L.; Sun, B. Exploring the EPR system for power battery recycling from a supply-side perspective: An evolutionary game analysis. Waste Manag. 2022, 140, 204–212. [Google Scholar]

- Traulsen, A.; Glynatsi, N.E. The future of theoretical evolutionary game theory. Philos. Trans. R. Soc. B 2023, 378, 20210508. [Google Scholar]

- Márquez, A.J.C.; Rutkowski, E.W. Waste management drivers towards a circular economy in the global south—The Colombian case. Waste Manag. 2020, 110, 53–65. [Google Scholar]

- Campitelli, A.; Kannengießer, J.; Schebek, L. Approach to assess the performance of waste management systems towards a circular economy: Waste management system development stage concept (WMS-DSC). MethodsX 2022, 9, 101634. [Google Scholar]

- D’Adamo, I.; Mazzanti, M.; Morone, P.; Rosa, P. Assessing the relation between waste management policies and circular economy goals. Waste Manag. 2022, 154, 27–35. [Google Scholar] [CrossRef] [PubMed]

- Smol, M.; Duda, J.; Czaplicka-Kotas, A.; Szołdrowska, D. Transformation towards circular economy (CE) in municipal waste management system: Model solutions for Poland. Sustainability 2020, 12, 4561. [Google Scholar] [CrossRef]

- Wysokińska, Z. A review of transnational regulations in environmental protection and the circular economy. Compar. Econ. Res. Cent. East Eur. 2020, 23, 149–168. [Google Scholar]

- Zhang, H.; Zhu, K.; Hang, Z.; Zhou, D.; Zhou, Y.; Xu, Z. Waste battery-to-reutilization decisions under government subsidies: An evolutionary game approach. Energy 2022, 259, 124835. [Google Scholar]

- Guo, S.; Liu, G.; Guo, X.; Wang, Y. Game evolution and simulation analysis of power battery recycling in China under conflicting supply and demand of critical metals. Front. Energy Res. 2022, 10, 984437. [Google Scholar]

- Li, Y.; Zhang, J. Evolutionary Game Analysis of Low-Carbon Incentive Behaviour of Power Battery Recycling Based on Prospect Theory. Sustainability 2024, 16, 2793. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, F.; Zhang, W.; Ke, S.; Wang, X. Multi-agent behavioral strategy game and synergy evolution path of the retired power battery recycling system. Manag. Decis. Econ. 2024, 45, 3993–4011. [Google Scholar]

- Xia, X.; Li, P.; Cheng, Y. Tripartite evolutionary game analysis of power battery carbon footprint disclosure under the EU battery regulation. Energy 2023, 284, 129315. [Google Scholar]

- Shekarian, E.; Flapper, S.D. Analyzing the structure of closed-loop supply chains: A game theory perspective. Sustainability 2021, 13, 1397. [Google Scholar] [CrossRef]

- Basteck, C.; Ehlers, L. Strategy-proof and envy-free random assignment. J. Econ. Theory 2023, 209, 105618. [Google Scholar]

- Sayem, F.R.; Bin Islam, S.; Naznine, M.; Nashbat, M.; Hasan-Zia, M.; Kunju, A.K.A.; Khandakar, A.; Ashraf, A.; Majid, M.E.; Kashem, S.B.A.; et al. Enhancing waste sorting and recycling efficiency: Robust deep learning-based approach for classification and detection. Neural Comput. Appl. 2024, 37, 4567–4583. [Google Scholar]

- Nie, S.; Cai, G.; Huang, Y.; He, J. Deciphering stakeholder strategies in electric vehicle battery recycling: Insights from a tripartite evolutionary game and system dynamics. J. Clean. Prod. 2024, 452, 142174. [Google Scholar] [CrossRef]

- Zheng, Y.; Xu, Y. Optimizing Green Strategy for Retired Electric Vehicle Battery Recycling: An Evolutionary Game Theory Approach. Sustainability 2023, 15, 15464. [Google Scholar] [CrossRef]

- Huang, X.; Lin, Y.; Lim, M.K.; Zhou, F.; Liu, F. Electric vehicle charging station diffusion: An agent-based evolutionary game model in complex networks. Energ 2022, 257, 124700. [Google Scholar]

- Wei, L.; Wang, C.; Li, Y. Governance strategies for end-of-life electric vehicle battery recycling in China: A tripartite evolutionary game analysis. Front. Environ. Sci. 2022, 10, 1071688. [Google Scholar]

- Du, B.; Hou, H.; Xu, H.; Zhang, M. How to solve the problem of irregular recycling of spent lead-acid batteries in China?—An analysis based on evolutionary game theory. J. Clean. Prod. 2023, 421, 138514. [Google Scholar]

- Bastos, J.; Buzzi, C.; Santana, P. On structural stability of evolutionary stable strategies. J. Differ. Equ. 2024, 389, 190–227. [Google Scholar]

- Liao, D.; Tan, B. An evolutionary game analysis of new energy vehicles promotion considering carbon tax in post-subsidy era. Energy. 2023, 264, 126156. [Google Scholar]

- Wang, E.; Nie, J.; Wang, Y. Government subsidy strategies for the new energy vehicle power battery recycling industry. Sustainability 2023, 15, 2090. [Google Scholar] [CrossRef]

- Li, D.; Jiang, P.; Hu, C.; Yan, T. Comparison of local and global sensitivity analysis methods and application to thermal hydraulic phenomena. Prog. Nucl. Energy 2023, 158, 104612. [Google Scholar]

- Demir, G.; Chatterjee, P.; Pamucar, D. Sensitivity analysis in multi-criteria decision making: A state-of-the-art research perspective using bibliometric analysis. Expert Syst. Appl. 2024, 237, 121660. [Google Scholar]

| Consumers | Governments | |||||

| Strict Supervision | Lax Regulation | |||||

| Manufacturers | Manufacturers | |||||

| Participation in Recycling | No Participation in Recycling | Participation in Recycling | No Participation in Recycling | |||

| Recyclers | Compliance recycling | Environmental behavior | ||||

| Not environmental behavior | ||||||

| Non-compliant recycling | Environmental behavior | |||||

| 0 | ||||||

| Not environmental behavior | ||||||

| 0 | ||||||

| Equilibrium Point | Eigenvalue ) | Sign | Stability | Equilibrium Point | Eigenvalue ) | Sign | Stability |

|---|---|---|---|---|---|---|---|

| x | ESS | x | ESS | ||||

| - | - | ||||||

| - | - | ||||||

| - | - | ||||||

| ) | x | Unstable | x | Unstable | |||

| + | + | ||||||

| - | - | ||||||

| - | + | ||||||

| x | Unstable | x | Unstable | ||||

| - | - | ||||||

| + | + | ||||||

| x | + | ||||||

| + | Unstable | - | Unstable | ||||

| x | + | ||||||

| x | x | ||||||

| + | + | ||||||

| x | Unstable | x | Unstable | ||||

| x | + | ||||||

| + | x | ||||||

| x | x | ||||||

| x | Unstable | x | Unstable | ||||

| x | - | ||||||

| x | x | ||||||

| + | + | ||||||

| x | Unstable | x | Unstable | ||||

| + | + | ||||||

| + | + | ||||||

| + | + | ||||||

| x | Unstable | x | ESS | ||||

| x | - | ||||||

| + | x | ||||||

| - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Zhong, S.; Ding, Z. A Four-Party Evolutionary Game Analysis of Retired Power Battery Recycling Strategies Under the Low Carbon Goals. World Electr. Veh. J. 2025, 16, 187. https://doi.org/10.3390/wevj16030187

Yang L, Zhong S, Ding Z. A Four-Party Evolutionary Game Analysis of Retired Power Battery Recycling Strategies Under the Low Carbon Goals. World Electric Vehicle Journal. 2025; 16(3):187. https://doi.org/10.3390/wevj16030187

Chicago/Turabian StyleYang, Lijun, Shuangxi Zhong, and Zhenggang Ding. 2025. "A Four-Party Evolutionary Game Analysis of Retired Power Battery Recycling Strategies Under the Low Carbon Goals" World Electric Vehicle Journal 16, no. 3: 187. https://doi.org/10.3390/wevj16030187

APA StyleYang, L., Zhong, S., & Ding, Z. (2025). A Four-Party Evolutionary Game Analysis of Retired Power Battery Recycling Strategies Under the Low Carbon Goals. World Electric Vehicle Journal, 16(3), 187. https://doi.org/10.3390/wevj16030187