Investigation into the Prediction of the Service Life of the Electrical Contacting of a Wheel Hub Drive

Abstract

1. Introduction

2. Materials and Methods

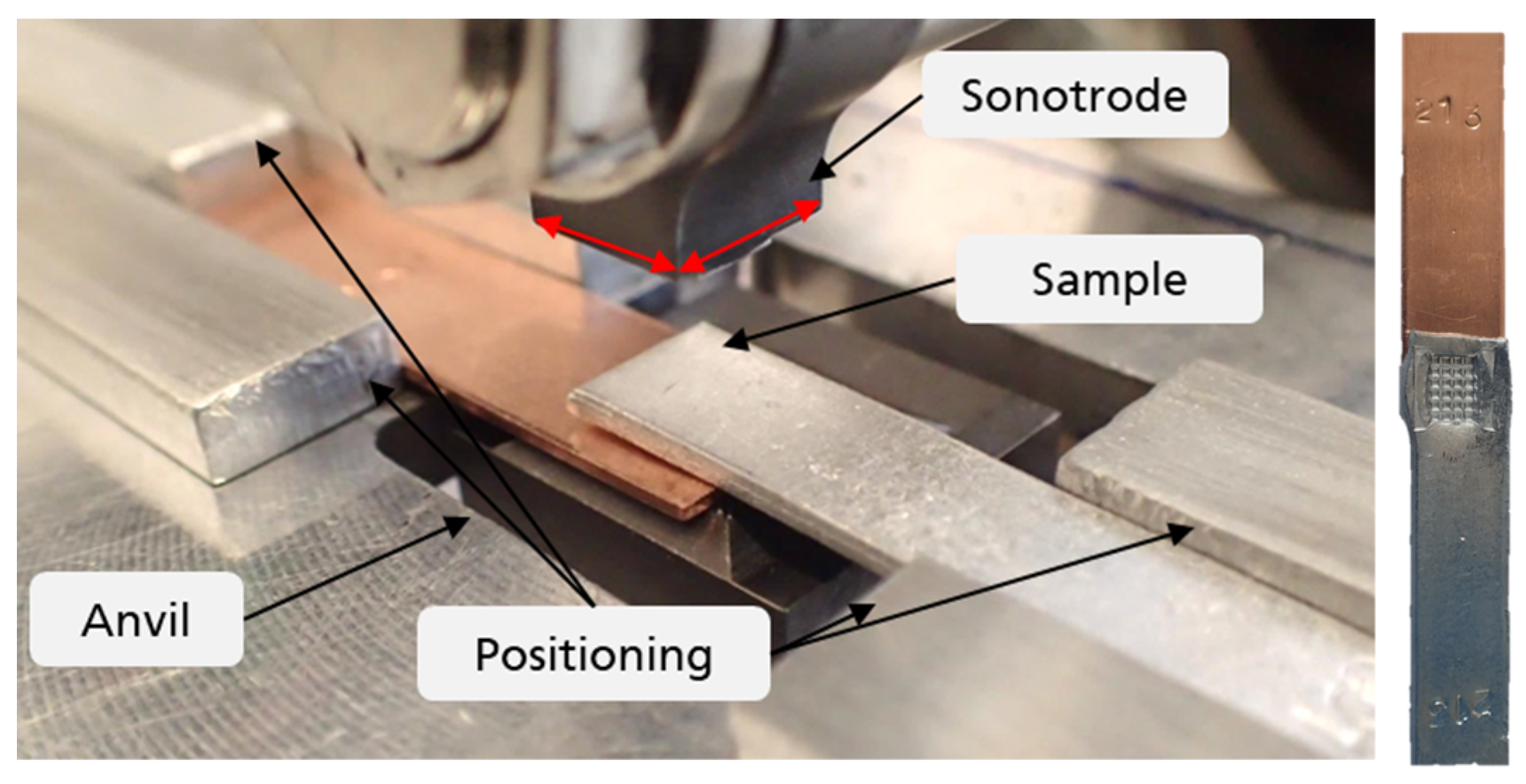

2.1. Sample Preparation

2.2. Materials

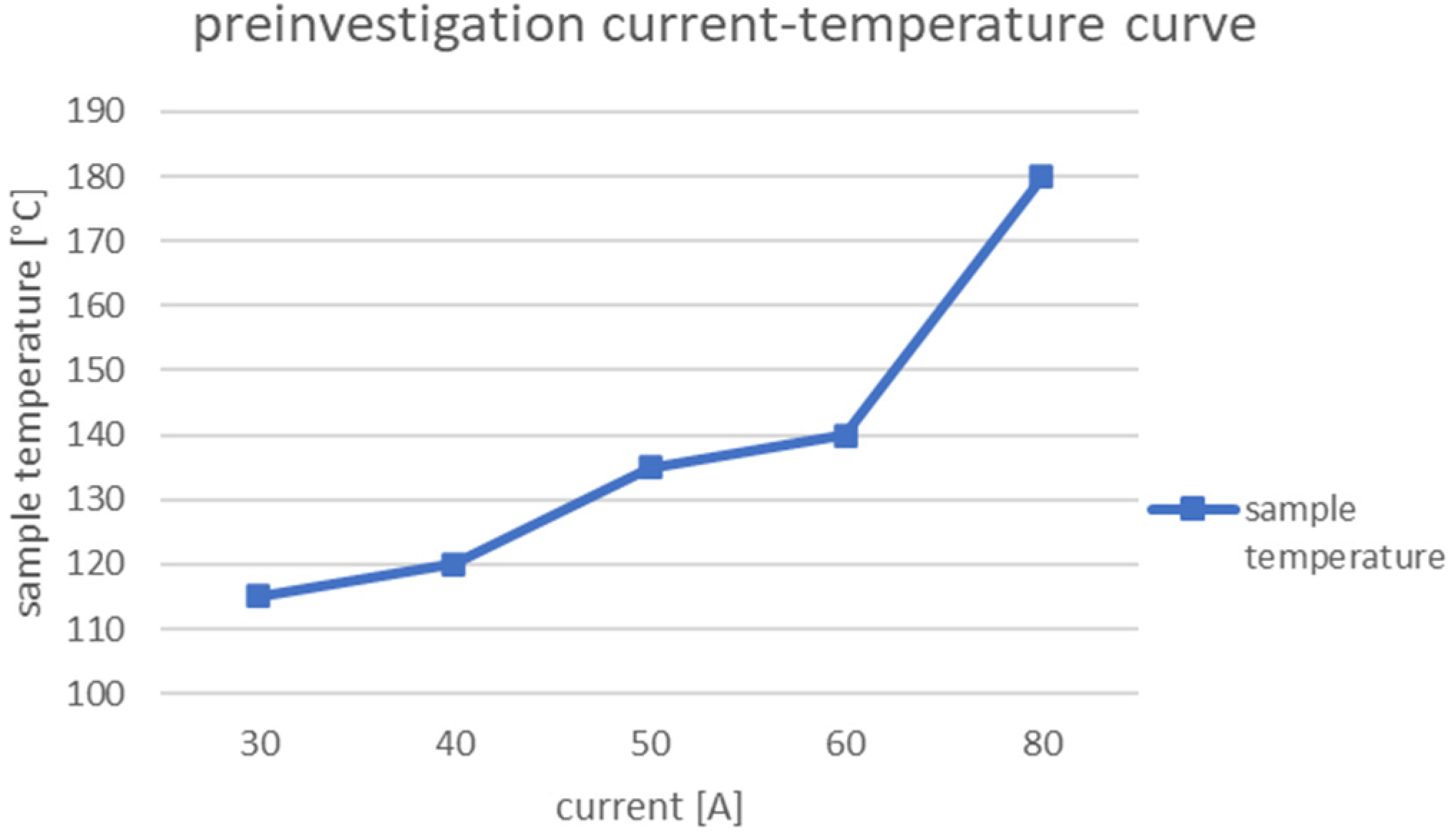

2.3. Experimental and Measurement Setup

- Measurement of electrical resistance using the four-wire method based on DIN IEC 60468.

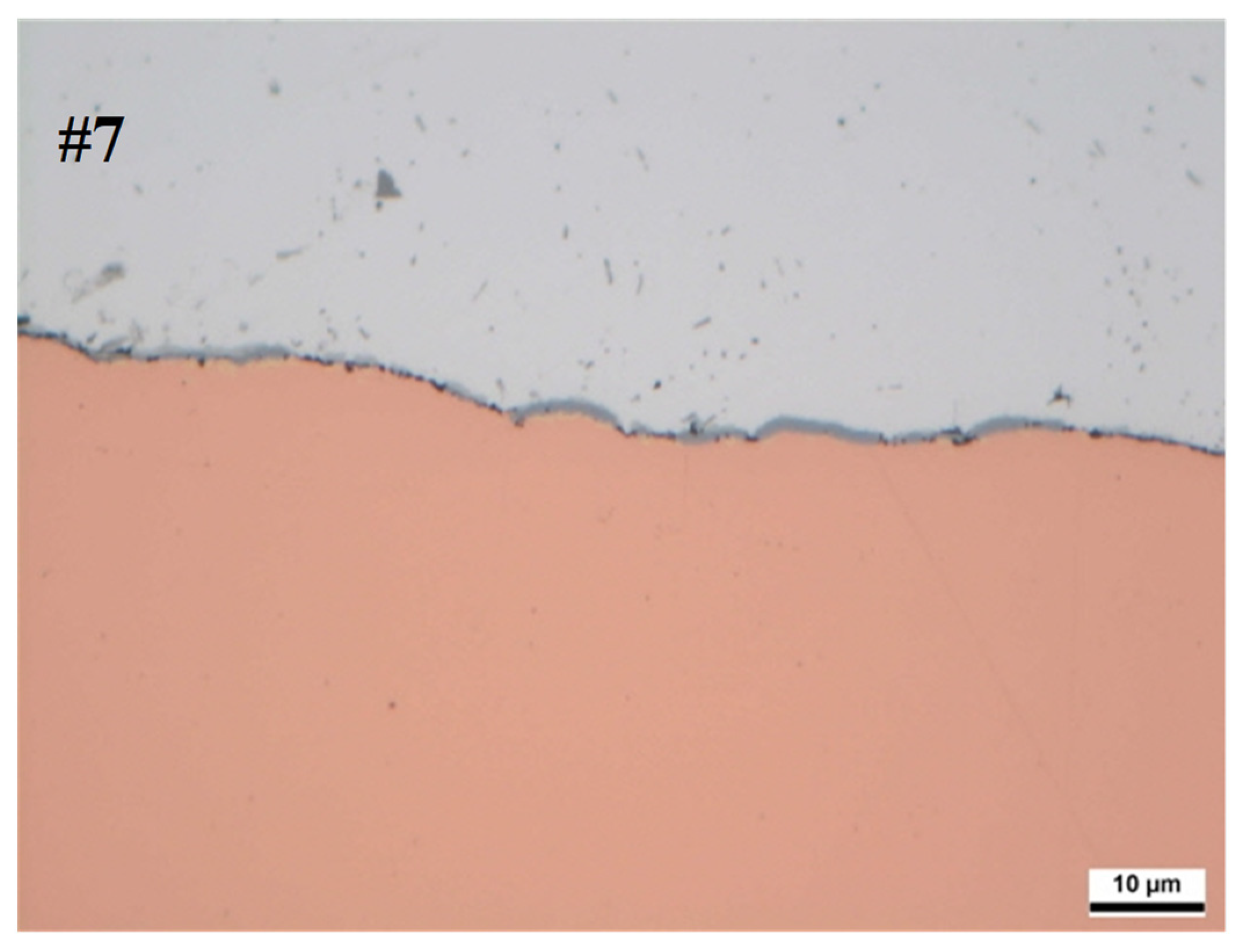

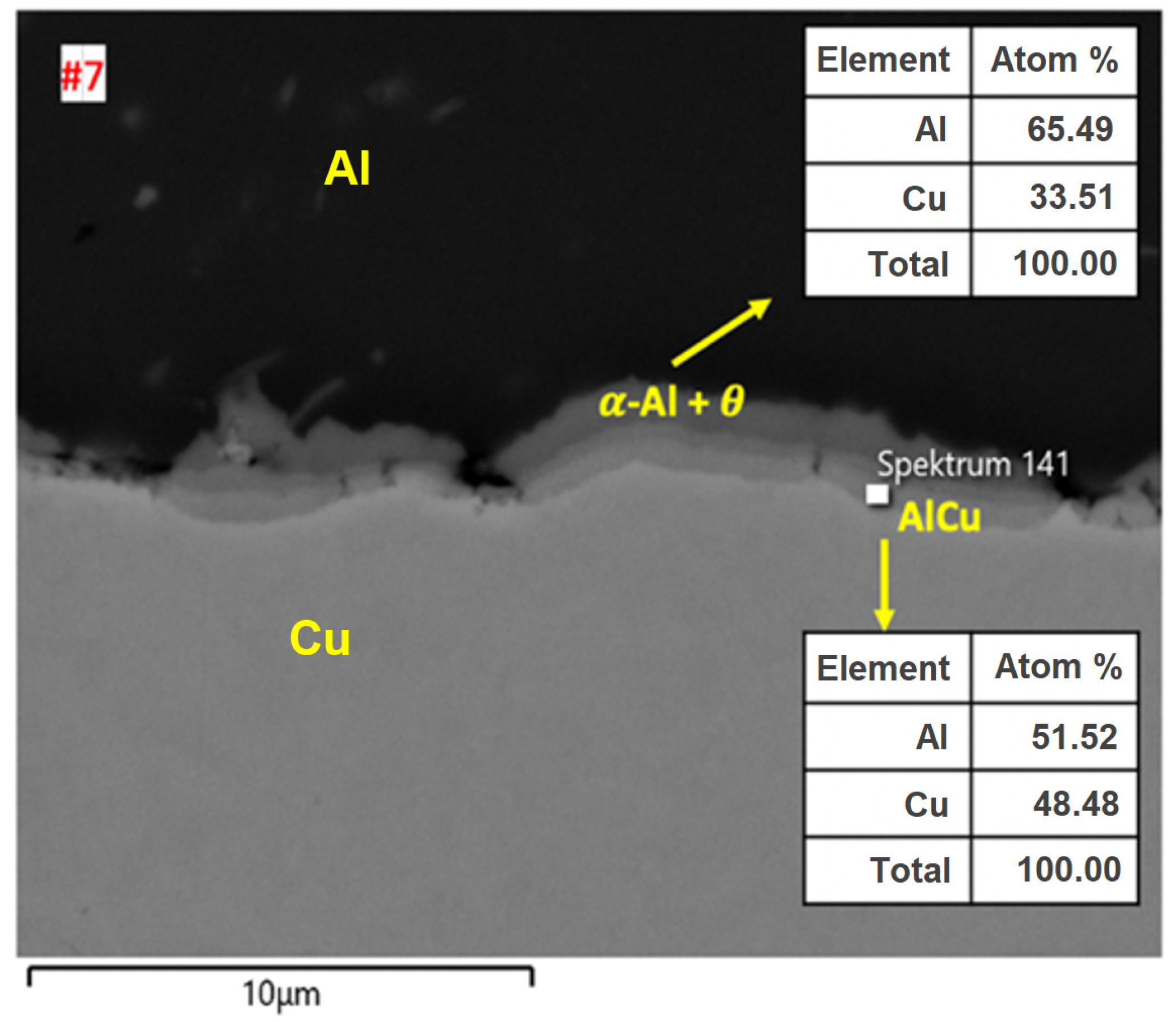

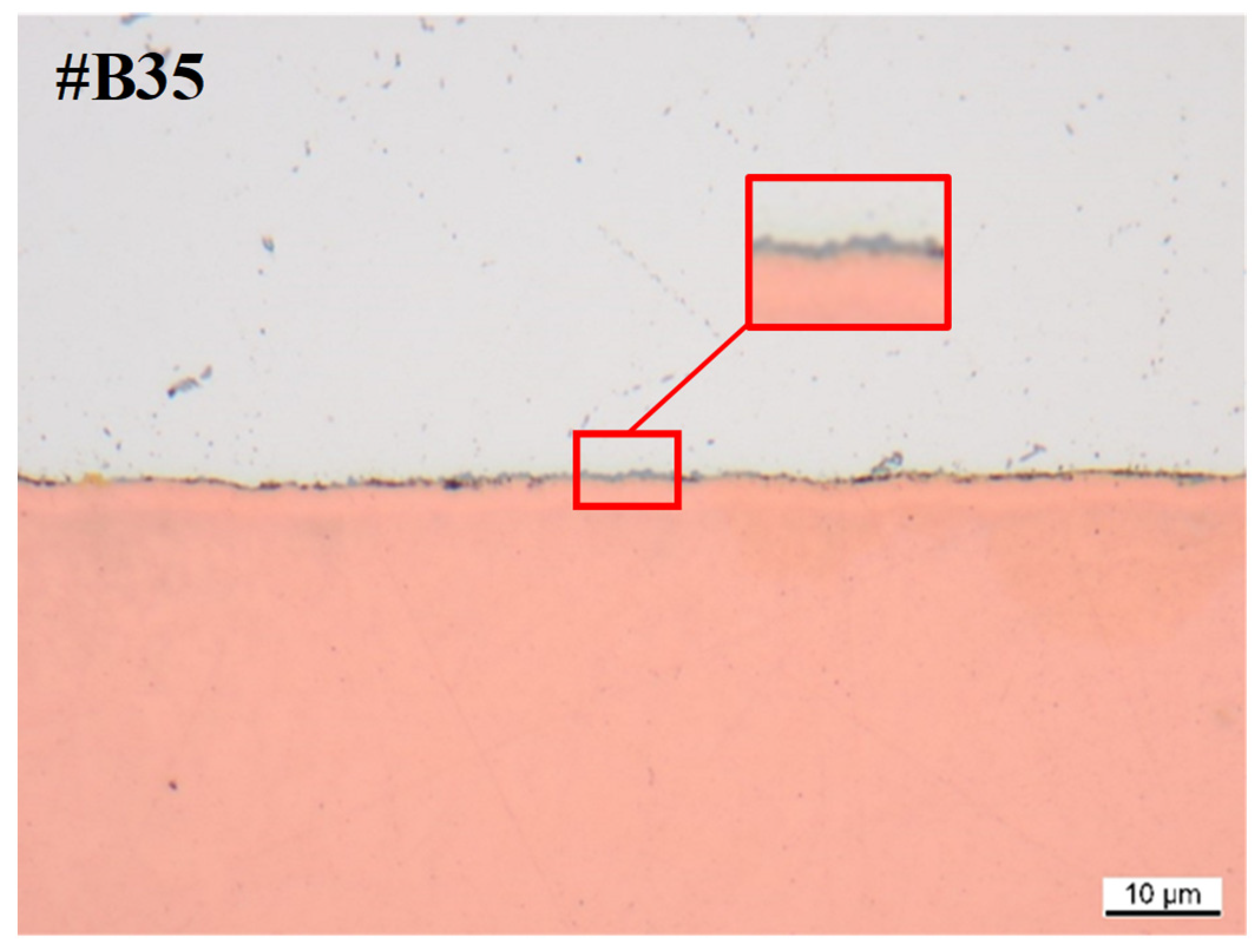

- Micrographs and microscope images are used to identify the intermetallic phases and their width.

- Images of selected samples are used with scanning electron microscope (SEM) with energy dispersive X-ray spectroscopy (EDS) to identify the phase composition.

3. Results

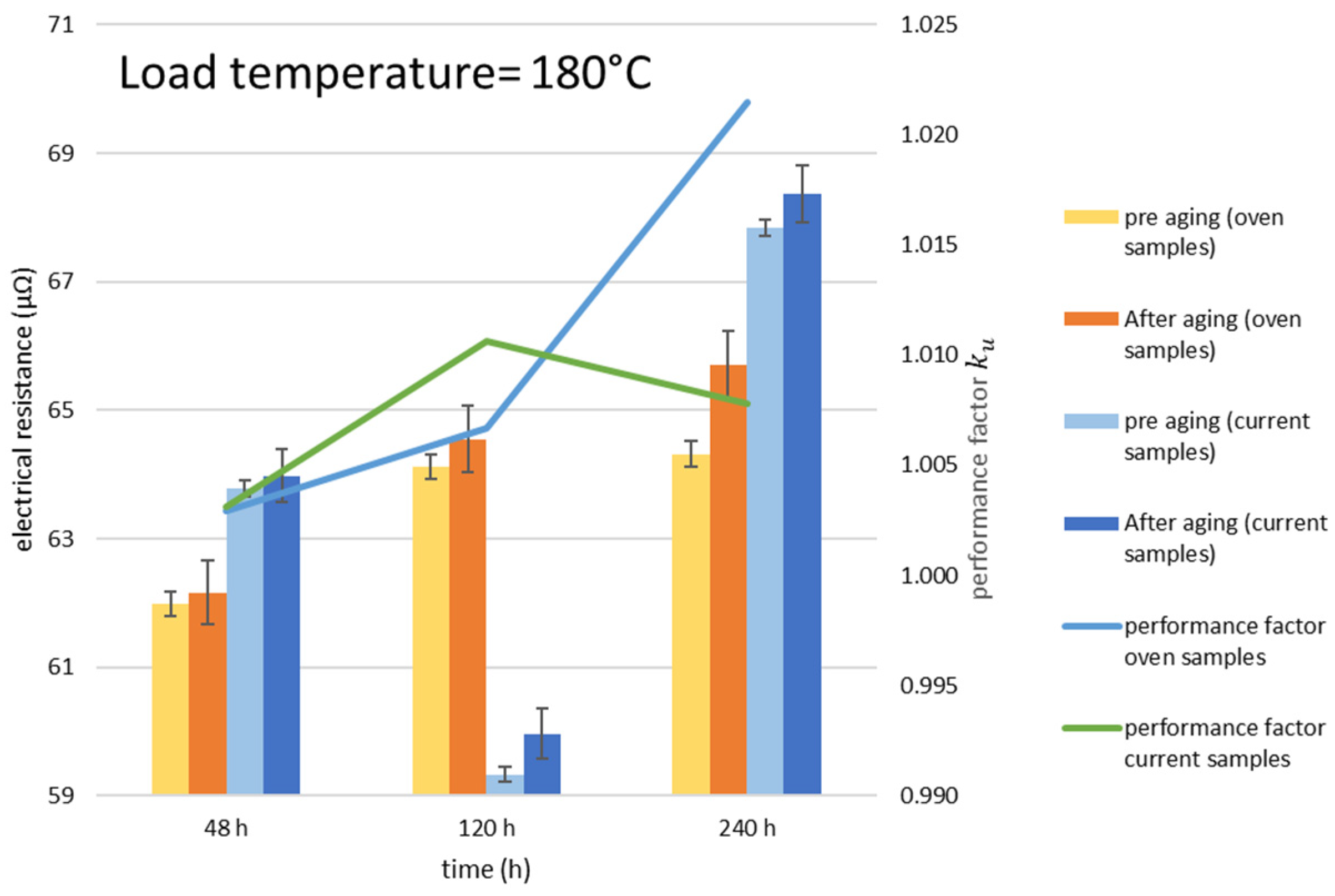

3.1. Comparison of Thermal Aging at Maximum Temperature 180 °C

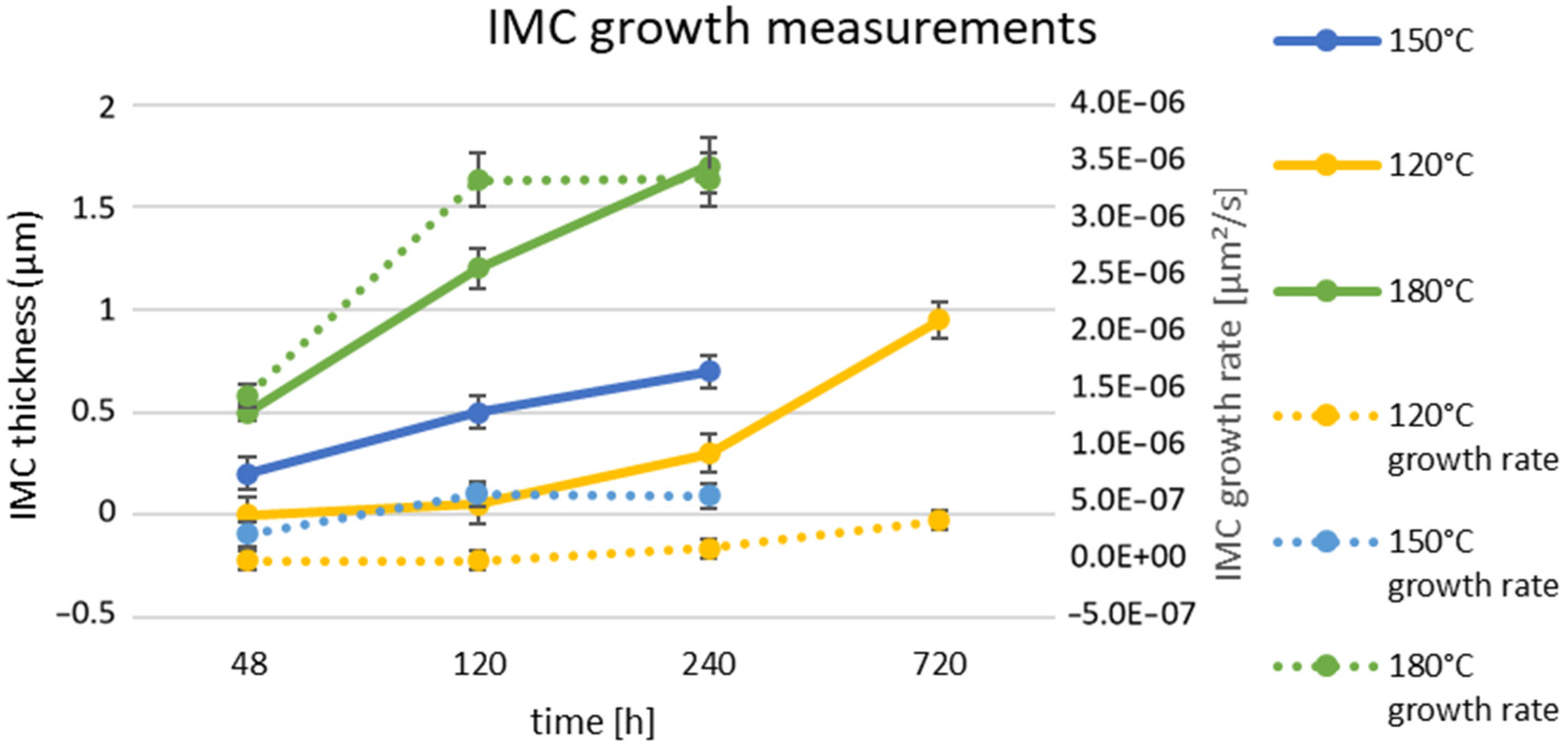

3.2. Test Results at Typical Operating Temperatures

3.3. Formation and Growth of the Intermetallic Phases Under Typical Operating Conditions

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Reske, K. Langzeitverhalten von Schweißverbindungen mit Aluminiumleitungen für Hybrid- und Elektrofahrzeuge. Ph.D. Thesis, Technische Universität München, München, Germany, 2015. [Google Scholar]

- Pfeifer, S. Einfluss Intermetallischer Phasen der Systeme Al-Cu und Al-Ag auf den Widerstand Stromtragender Verbindungen im Temperaturbereich von 90 °C bis 200 °C. Ph.D. Thesis, TU Dresden, Dresden, Germany, 2015. [Google Scholar]

- Oberst, M.; Schlegel, S.; Grossmann, S.; Willing, H.; Freudenberger, R. Impact of the Formation of Intermetallic Compounds in Current-Carrying Connections. IEEE Trans. Device Mater. Relib. 2020, 20, 157–166. [Google Scholar] [CrossRef]

- Elkjaer, A.; Sørhaug, J.A.; Ringen, G.; Bjørge, R.; Grong, Ø. Electrical and thermal stability of Al-Cu welds: Performance benchmarking of the hybrid metal extrusion and bonding process. J. Manuf. Process. 2022, 79, 626–638. [Google Scholar] [CrossRef]

- Liu, C.-P.; Chang, S.-J.; Liu, Y.-F.; Chen, W.-S. Cu-Al interfacial formation and kinetic growth behavior during HTS reliability test. J. Mater. Process. Technol. 2019, 267, 90–102. [Google Scholar] [CrossRef]

- Hiu, X. Growth of Intermetallic Compounds in Thermosonic Copper Wire Bonding on Aluminum Metallization. J. Electron. Mater. 2009, 2010, 124–131. [Google Scholar]

- Kim, H.-J.; Lee, J.Y.; Paik, K.-W.; Koh, K.-W.; Won, J.; Choe, S.; Lee, J.; Moon, J.-T.; Park, Y.-J. Effects of Cu/Al intermetallic compound (IMC) on copper wire and aluminum pad bondability. IEEE Trans. Comp. Packag. Technol. 2003, 26, 367–374. [Google Scholar] [CrossRef]

- Funamizu, Y.; Watanabe, K. Interdiffusion in the Al-Cu System. Sendai, September 22, 1968. In Proceedings of the Autumn Meeting of the Japan Institute of Metals, Sendai, Japan, 22 September 1968; Available online: https://www.jstage.jst.go.jp/article/matertrans1960/12/3/12_3_147/_pdf/-char/en (accessed on 19 January 2025). [CrossRef]

- Branson Ultrasonics Corporation. Branson-Ultraweld-L20-Technsiches Datenblatt; Branson Ultrasonics Corporation: Brookfield, CO, USA, 2012. [Google Scholar]

- RHEINFELDEN ALLOYS GmbH & Co. KG. RHEINFELDEN-ALLOYS_2016_Handbuch-Hüttenaluminium-Gusslegierungen_DE; RHEINFELDEN ALLOYS GmbH & Co.: Rheinfelden, Switzerland, 2016. [Google Scholar]

- Aurubis AG. Werkstoff Datenblatt Cu-PHC; Aurubis AG: Hamburg, Germany, 2009. [Google Scholar]

- Nabertherm. Advanced Materials: Öfen und Wärmebehandlungsanlagen; Bedienungsanleitung Ofen TR1050. 2021. Available online: https://nabertherm.com/de/produkte/labor/trockenschraenke/trockenschraenke-elektrisch-beheizt (accessed on 19 January 2025).

- Oberst, M.; Schlegel, S.; Großmann, S. On the Aging of Electrical Joints with a Copper and an Aluminum Contact Member. In Proceedings of the Sixty-Fifth IEEE Holm Conference on Electrical Contacts, Milwaukee, WI, USA, 15–18 September 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Bergmann, R. Zum Langzeitverhalten des Widerstandes Elektrischer Stromschienenverbindungen; TU Dresden: Dresden, Germany, 1995. [Google Scholar]

- Bargel, H.-J.; Schulze, G. Werkstoffkunde, 10th ed.; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-79296-3. [Google Scholar]

- Braunović, M.; Aleksandrov, N. Intermetallic compounds at aluminum-to-copper and copper-to-tin electrical interfaces—Electrical Contact. IEEE Trans. Comp. Hybrids Manufact. Technol. 1992, 1992, 25–34. [Google Scholar]

- Guo, Y.; Liu, G.; Jin, H.; Shi, Z.; Qiao, G. Intermetallic phase formation in diffusion-bonded Cu-Al laminates. J. Mater. Sci. 2011, 46, 2467–2473. [Google Scholar] [CrossRef]

- Ponweiser, N.; Lengauer, C.L.; Richter, K.W. Re-investigation of phase equilibria in the system Al-Cu and structural analysis of the high-temperature phase η1-Al1-δCu. Intermetallics 2011, 19, 1737–1746. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.Y.; Li, D.; Zhang, Y.S. Effect of welding energy on interface zone of Al–Cu ultrasonic welded joint. Sci. Technol. Weld. Join. 2013, 18, 354–360. [Google Scholar] [CrossRef]

- Zhang, G.; Takahashi, Y.; Heng, Z.; Takashima, K.; Misawa, K. Ultrasonic Weldability of Al Ribbon to Cu Sheet and the Dissimilar Joint Formation Mode. Mater. Trans. 2015, 56, 1842–1851. [Google Scholar] [CrossRef]

- Fujii, H.T.; Endo, H.; Sato, Y.S.; Kokawa, H. Interfacial microstructure evolution and weld formation during ultrasonic welding of Al alloy to Cu. Mater. Charact. 2018, 139, 233–240. [Google Scholar] [CrossRef]

- Erk, A.; Schmelzle, M. Grundlagen der Schaltgerätetechnik: Kontaktglieder und Löscheinrichtungen elektrischer Schaltgeräte der Energietechnik, 1., 974; Springer: Berlin/Heidelberg, Germany, 1974; ISBN 9783642503405. [Google Scholar]

- Vinaricky, E. Elektrische Kontakte, Werkstoffe und Anwendungen: Grundlagen, Technologien, Prüfverfahren, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 978-3-642-45426-4. [Google Scholar]

- Solchenbach, T.; Plapper, P.; Cai, W. Electrical performance of laser braze-welded_kommentiert. J. Manuf. Process. 2014, 16, 183–189. [Google Scholar] [CrossRef]

- Abbasi, M.; Karimi Taheri, A.; Salehi, M.T. Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process. J. Alloys Compd. 2001, 319, 233–241. [Google Scholar] [CrossRef]

| Properties | Unit | Manufacturer Value | Own Measurements |

|---|---|---|---|

| Melting point | °C | 655–660 | |

| Specific electrical resistivity | µΩcm | 2.74–2.90 | 3.06 |

| Density | g/cm3 | 2.67 | |

| Tensile strength | N/mm2 | 80–120 | 62 |

| Yield strength | N/mm2 | 20–40 | 22 |

| Properties | Unit | Manufacturer Value | Own Measurements |

|---|---|---|---|

| Melting point | °C | 1083 | |

| Specific electrical resistivity | µΩcm | ≥1.72 | 1.72 |

| Density | g/cm3 | 8.94 | |

| Tensile strength | N/mm2 | 220–260 | 240 |

| Yield strength | N/mm2 | ≤140 | 87 |

| Temperature of the Thermal Load IMC Growth Rate | Limit Value of the IMC Thickness | ||||

|---|---|---|---|---|---|

| 10 µm | 8 µm | 6 µm | 4 µm | 2 µm | |

| 120 °C | 242,526 h | 155,216 h | 87,309 h | 38,804 h | 9701 h |

| 150 °C | 60,504 h | 38,722 h | 21,781 h | 9680 h | 2420 h |

| 180 °C | 10,256 h | 6564 h | 3692 h | 1641 h | 410 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hempel, M.; Umland, N.; Busse, M. Investigation into the Prediction of the Service Life of the Electrical Contacting of a Wheel Hub Drive. World Electr. Veh. J. 2025, 16, 68. https://doi.org/10.3390/wevj16020068

Hempel M, Umland N, Busse M. Investigation into the Prediction of the Service Life of the Electrical Contacting of a Wheel Hub Drive. World Electric Vehicle Journal. 2025; 16(2):68. https://doi.org/10.3390/wevj16020068

Chicago/Turabian StyleHempel, Markus, Niklas Umland, and Matthias Busse. 2025. "Investigation into the Prediction of the Service Life of the Electrical Contacting of a Wheel Hub Drive" World Electric Vehicle Journal 16, no. 2: 68. https://doi.org/10.3390/wevj16020068

APA StyleHempel, M., Umland, N., & Busse, M. (2025). Investigation into the Prediction of the Service Life of the Electrical Contacting of a Wheel Hub Drive. World Electric Vehicle Journal, 16(2), 68. https://doi.org/10.3390/wevj16020068