Abstract

Recent fire incidents following electric vehicle (EV) collisions have been increasing rapidly in Korea, corresponding to the growing distribution of EVs. While the overall number of EV fires is lower compared to those involving internal combustion engine (ICE) vehicles, EV fires can lead to more severe outcomes. Current regulations for post-crash fuel system integrity evaluation do not differentiate between EVs and ICE vehicles. However, the causes of fires in these vehicles differ due to variations in the design and construction of their fuel systems. This study analyzed seventeen cases of EV post-crash fires in Korea to derive two representative risk scenarios for EV post-crash fires. The first scenario involves significant intrusion into the EV front-end structure resulting from high-speed frontal collisions, while the second scenario involves direct impacts to the battery pack mounted under the vehicle from road curbs at low speeds (30–40 km/h). Based on these scenarios, we conducted tests to assess battery damage severity under two crash test modes, simulating both high-speed frontal collisions and low-speed curb impacts. The test results led to the development of a draft crash test concept to evaluate EV post-crash fire risks. Furthermore, we assessed the reproducibility of these test modes in relation to actual EV post-crash fires. Our findings indicate that square-shaped impactors provide higher reproducibility in simulating real EV post-crash fire incidents compared to hemisphere-shaped impactors. Additionally, a fire occurred 31 days after the storage of a crash-evaluated battery test specimen, which was determined to be caused by moisture invasion during post-crash storage, accelerating a micro-short circuit. This study aims to contribute to the development of new evaluation methods for the Korean New Car Assessment Program (KNCAP) to enhance EV post-crash fire safety by utilizing these test results to refine collision severity evaluation methods.

1. Introduction

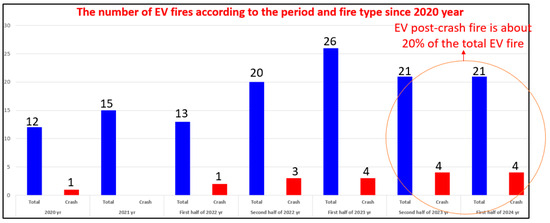

The global supply of electric vehicles (EVs) is rapidly increasing due to government policies aimed at expanding the adoption of eco-friendly vehicles [1]. As the volume of EVs grows, the number of EV-related fires has also risen. These fires can occur for a variety of reasons, including collision accidents, defects in the battery control system, or issues with individual cells [2,3,4]. Although fires following EV collisions account for less than approximately 10% of all EV fires in Korea, their frequency is steadily increasing. In Korea, a total of 17 EV fires have occurred from the first incident in December 2020 to July 2024. Since 2023, the share of post-collision fires in total EV fires has consistently risen (′23 to ′24.7). The number of casualties resulting from these post-collision fires is increasing, likely due to the difficulty in extinguishing fires once they occur (see Figure 1).

Figure 1.

Number of EV fires by period and fire type from ′23 to ′24.7 in Korea.

Current crash safety regulations for EVs are the same as those for vehicles using other fuels [5,6,7]. Additionally, EVs do not appear to be more vulnerable than vehicles using conventional fuels, according to the results of the Self-Certification Compliance Investigation and the New Car Assessment Program (KNCAP) conducted in Korea. However, the vulnerability of the battery has been highlighted in the undercarriage test, which simulates bottom collisions, as evidenced by data from the EVERSAFE European project [8]. Furthermore, there is a need for further research on post-collision fires in EVs, particularly concerning the direction of impact. Current crash test methods are limited in evaluating collision severity, as the impact location of the EV battery pack significantly influences the potential for fire and explosion [9,10,11,12,13].

Therefore, the objective of this study is to derive crash test modes that reflect vulnerable situations, such as fire or explosion, based on real-world post-collision fire scenarios involving EVs. This study aims to develop test protocols and standards to evaluate the likelihood and mechanisms of fire occurrence following an EV collision, utilizing the derived crash test modes in Korea.

2. Representative Crash Scenario of Post-Collision Fires in Electric Vehicles in Korea

Since the first EV fire accident following a collision occurred in December 2020 in Korea, a total of 17 post-collision EV fire accidents have been recorded. Among these, 13 fires were initiated by the EV battery, while the other 4 cases had initial fires originating from the electrical room or high-voltage connectors. Notably, the majority of these fires occurred due to collisions with road infrastructure or building walls, with only one instance involving a vehicle-to-vehicle collision (see Table 1).

Table 1.

Impact types and number of fires/explosions from batteries after EV crashes.

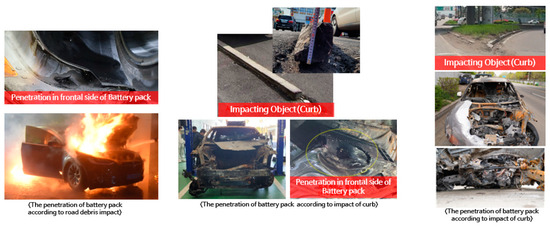

This study confirmed that physical damage, such as excessive deformation or penetration of the battery pack, was present in all post-crash EV fires. These damages were primarily caused by direct impacts to the battery pack from road infrastructure, such as curbs, or by deformed vehicle structures. Of the 13 cases, 9 involved frontal collisions. This study analyzed these incidents and found that high-speed frontal collisions caused significant deformation of the front body structure, which led to the destruction of the battery pack. This damage subsequently resulted in direct impacts to the internal modules and/or cells of the battery.

Three of the thirteen cases confirmed that the battery pack, mounted on the bottom of the EV, was directly impacted by road debris or curbs, leading to penetration and deformation of the battery pack. These cases demonstrated that EV fires can occur even in low-speed collisions (approximately 20 km/h or less) when the battery pack is directly impacted by road curbs or other road infrastructure.

In all post-crash fire cases, fires or explosions occurred immediately following the collision.

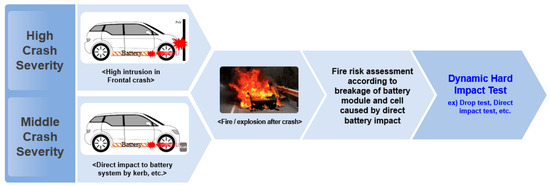

In conclusion, post-crash fires in EVs in Korea can be categorized into two primary scenarios: high-speed frontal collisions and low-speed bottom impacts. Interestingly, in both types of collisions, the battery pack was primarily impacted at the front end of the vehicle, as illustrated in Figure 2 and Figure 3. Representative post-crash fire scenarios for EVs were derived from data on EV fire accidents in Korea, as shown in Figure 4.

Figure 2.

Damage shapes of vehicle structures and battery packs in post-collision fires following high-speed frontal collisions in EVs. (Red and yellow cycles are battery impact points).

Figure 3.

Damage shapes of vehicle structures and battery packs in post-collision fires from direct impacts to the battery pack located at the bottom of EVs. (Yellow cycle is battery impact point).

Figure 4.

Two representative fire scenarios after EV collisions in Korea.

3. Evaluation of Battery Damage Severity According to Crash Modes Reflecting Two Post-Crash Fire Scenarios in Electric Vehicles

3.1. Crash Mode 1: Battery Damage Severity in High-Speed Frontal Collisions with Road Infrastructure (e.g., Impact Attenuators and Street Trees)

High-speed frontal collisions result in significant deformation of the vehicle’s front structure. To simulate such collisions, this test mode was designed as the frontal center-pole impact mode, reflecting one of the most severe crash types encountered in real road conditions, which can cause extensive deformation of the front structure. The impact speed was set at 56 km/h, a velocity derived from GIDAS data that encompass the severity of most real-world road collisions, as shown in Figure 5.

Figure 5.

Impact velocity reflecting field accident coverage for frontal pole collisions based on German accident research (GIDAS).

This study analyzed the impact of crash severity on batteries by comparing the front structure of electric vehicles (EVs) and internal combustion engine (ICE) vehicles in the above-mentioned crash test modes. The EVs in this study were equipped with pouch-type lithium-ion polymer batteries. To minimize the risk of fire or explosion, the batteries were set to a low state of charge (SOC) of approximately 30% or lower during the indoor crash test evaluations.

The evaluation of the 56 km/h frontal center-pole impact mode revealed the following key findings:

First, despite most real-world EV post-crash fires in Korea occurring in high-speed frontal collisions, the 56 km/h frontal center-pole test did not trigger any fire or explosion risks from the battery pack. This indicates that fire or explosion in high-speed frontal collisions involving EVs is likely to be a rare edge case.

Second, it was observed that the amount of front intrusion in EVs was greater than that in ICE vehicles. In this test, although the rigid pole (used as an external barrier) did not directly impact the EV battery, the greater depth of intrusion of the EV’s front structure increased the risk of direct battery collisions compared to ICE vehicles (see Figure 6).

Figure 6.

Comparison of front-end intrusion between EVs and ICEVs following a 56 km/h frontal center-pole impact test. (The red line is the foremost position of the battery and the blue line is the intrusion depth of the vehicle front structure).

However, although the EV showed substantial intrusion into the front section, the damage to the battery pack was minimal, consisting only of minor scratches and dents (see Figure 7). In contrast, the relatively smaller deformation in the ICE vehicle’s front section was predicted to result in more significant impacts to the battery pack due to the presence of engine and transmission components in the front section.

Figure 7.

Comparison of battery pack damage between EVs and ICEVs following a 56 km/h frontal center-pole impact test.

Third, no deformation or penetration of the battery pack was observed, and there was no direct damage to the battery modules or cells. CT scans confirmed that there was no damage to the cells within the modules adjacent to the impact zone (see Figure 8).

Figure 8.

CT scan of battery modules after a 56 km/h frontal center-pole test.

As a result, the fire risk due to battery damage is considered low for electric vehicles, such as the tested vehicle, in most frontal collisions that may occur under real-world road conditions. Additionally, it is believed that minimizing battery damage during crash tests at speeds that reflect the severity of real-world roadway conditions would reduce the risk of fire from the battery in the event of an actual road crash.

3.2. Crash Mode 2: Battery Damage Severity Due to Impact on Batteries Mounted on the Bottom of EVs by Road Curbs, etc., at Low Speed

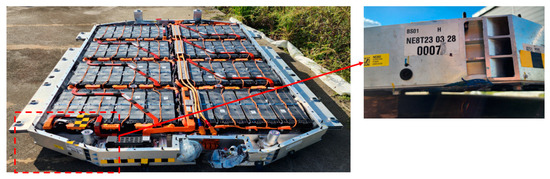

Crash Mode 2 was designed to evaluate the risk of fire or explosion when the battery pack mounted on the bottom of an EV is directly impacted by a road curb. Initially, both full-scale vehicle tests and trolley-mounted battery tests were considered; however, further evaluation of reproducibility and repeatability was necessary. Consequently, the crash evaluation was performed by simulating impact energy equivalent to that of a 2000 kg EV impacting a road curb at approximately 17–18 km/h. The representative impact object, derived from Korea’s road curb specifications, was used to simulate this impact. The battery used in the evaluation test is a lithium-ion polymer pouch-type battery. The SOC of the battery was 90%.

This test was conducted outdoors to account for the risk of fire or explosion resulting from the direct impact of the battery pack on an impactor simulating the road curb structure. The battery drop test was carried out in the test mode shown in Figure 9, during which kinetic energy was converted into potential energy, replicating the impact during an EV crash. Considering both the lowest ground clearance of the vehicle and the curb height on the road, the impact height between the battery and the impactor was determined, with a maximum overlap of 5 cm expected between the front end of the battery and the road curb.

Figure 9.

Battery drop test to reflect crash energy equivalent to the bottom impact (17–18 km/h) of EVs at the curb.

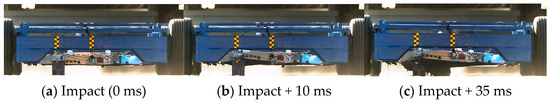

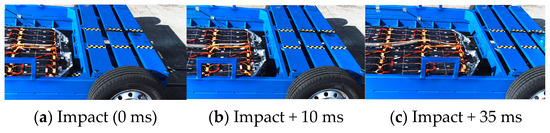

First, deformation and penetration of the battery pack occurred at all three impact points, as shown in Figure 10. It was observed that direct impact to the EV battery by the curb at low impact speeds (approximately 20 km/h or less) caused more damage to the battery located at the bottom of the vehicle than a high-speed frontal crash (approximately 56 km/h or more).

Figure 10.

Damage and penetration of battery packs in the 4.9 m battery drop test.

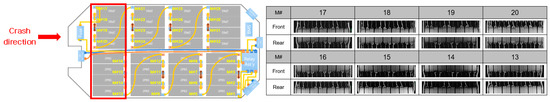

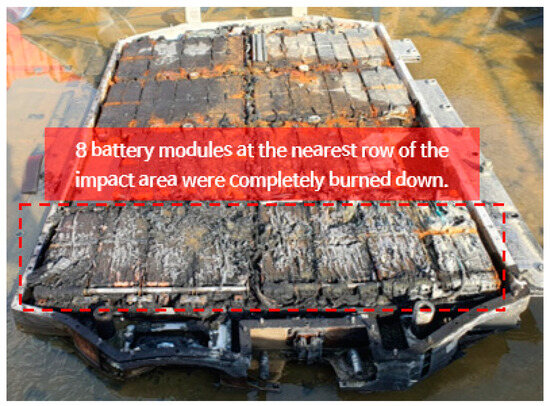

Second, a fire ignited in the tested battery approximately 2 h after the drop test, with only the eight battery modules adjacent to the impact area burning, as shown in Figure 11. This confirmed that the most vulnerable area of the battery in a direct impact is the location closest to the impact zone.

Figure 11.

Burned battery after 4.9 m battery drop test.

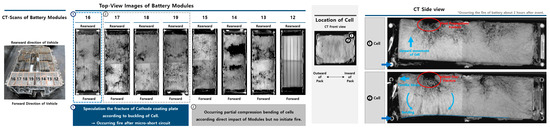

Third, a CT scan was performed on the fully burned modules adjacent to the impact surface of the battery pack, as shown in Figure 12. The CT scan revealed that the cells within the battery pack were damaged due to the fracture of the pack. It was confirmed that the cell in contact with the lateral support bar inside the battery pack also experienced movement or local compression deformation due to the impactor penetrating the pack. Based on the battery fire analysis, it was confirmed that the first fire occurred in battery module No. 16 in the front row, where the impactor collided. The impact was transmitted directly to the battery module through the penetration of the battery pack. The fire was likely caused by the anode material tearing first, followed by damage to the separator due to the tensile deformation of the cell during compressive deformation.

Figure 12.

CT scan analysis of the burned battery following the 4.9 m battery drop test.

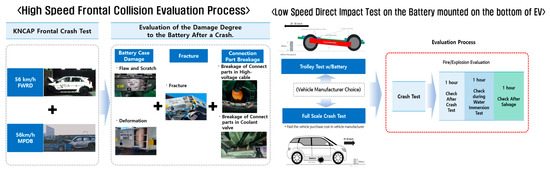

4. Development of New Draft EV Post-Crash Fire Safety Protocol Concepts for KNCAP

This study analyzed both the battery fire occurrence mechanisms and the associated risks by examining fire scenarios from representative EV crash accidents in Korea. Based on this analysis, it was determined that the new EV post-crash fire safety protocol should prioritize protecting the battery from deformation in high-speed frontal collisions and mitigating fire risks arising from low-speed, direct bottom impacts. As discussed in Section 2 and Section 3, it was confirmed that direct impacts to the EV battery pack are the primary cause of post-crash fires, according to both the fire incident data in Korea and the evaluation tests reflecting representative EV crash scenarios. However, it was concluded that evaluating both fire risk mechanisms simultaneously would be challenging.

The fire mechanism in high-speed frontal collisions is attributed to direct damage to the battery. As outlined in the conclusion of Section 3.1, it is believed that EV fires can be prevented by minimizing damage to the battery during collision conditions typical of domestic roads. The frontal crash test: Given that domestic safety regulations (KMVSS) and the Korean New Car Assessment Program (KNCAP) already address most real-world crash scenarios, it is assumed that most fires in high-speed frontal collisions can be prevented by minimizing damage to battery cases in such crash conditions.

However, it is challenging to address low-speed direct collisions with existing collision evaluation methods, necessitating the development of a new evaluation approach. Since the battery, which is mounted at the center of the vehicle, will first impact the front-end structure of the vehicle, rather than directly impacting the battery when hitting objects like curbs, ensuring reproducibility and repeatability under full vehicle crash conditions becomes difficult. Therefore, trolley tests that reflect full-scale vehicle conditions are considered more appropriate for evaluating battery damage severity in the event of an electric vehicle collision.

In this context, we developed new draft EV post-crash fire safety protocol concepts, as shown in Figure 13, based on the following considerations:

Figure 13.

Initial draft of new EV post-crash fire safety protocol concepts for direct impact on the batteries mounted at the bottom of EVs by road curbs or similar road debris at low speeds, derived from this research.

- -

- Impact Speed: Reflecting the representative crash speed of low-speed direct bottom impacts, impact speed is derived from domestic and international literature research.

- -

- Impactor: The hemispherical type applies the existing impactor for undercarriage vehicle tests, and the square type applies the domestic standard curb size in Korea.

The draft concepts will undergo further investigation to develop detailed protocols, including collision speed and impact location, among others.

5. Evaluation of Battery Damage Severity Based on Initial Draft of New EV Post-Crash Fire Safety Protocol Concepts (Low-Speed, Direct-Impact Test on the Battery)

In order to evaluate the reproducibility of the new draft EV post-crash fire safety protocol in real EV fire accidents, tests were first conducted to analyze the effect of two impactor types, as shown in Figure 13, since the shape of the impactor can significantly influence the EV post-crash fire mechanism [14]. A trolley mounted with the battery was used to replicate the same curb weight conditions as a full-scale vehicle, ensuring similar reproducibility to real electric vehicle crash scenarios. The overlap height between the front face of the battery and the impactor was set to 50 mm, and the state of charge (SOC) of the battery was maintained above 95% (see Table 2).

Table 2.

Comparison between full-scale vehicle and trolley with test battery.

5.1. Crash Mode 3: 30 km/h Trolley Test Using a Hemispherical Impactor

The hemispherical impactor used in this test is of the same specification type employed in the bottom-scraping test in the 2024 C-NCAP [15]. As a result of the 30 km/h trolley impact test with the hemispherical impactor, the following main characteristics were observed:

A crash mechanism similar to the bottom-scraping test condition occurred, despite the impact being directed at the frontal face of the battery pack, as shown in Figure 14 and Figure 15 The front face of the battery pack showed minimal deformation following the crash impact.

Figure 14.

Frontal view of 30 km/h trolley test using a hemispherical impactor.

Figure 15.

Minor damage to the bottom of the battery packs following 30 km/h trolley test using a hemispherical impactor.

As shown in Figure 16, no damage was observed to the battery cells or modules as a result of tensile or compressive forces, due to the minimal movement of the battery modules during the crash.

Figure 16.

Frontal view of 30 km/h trolley test using a hemispherical impactor.

Post-crash monitoring over 12 h revealed no drop in battery voltage, nor were there any instances of fire or explosion.

5.2. Crash Mode 4: 30 km/h Trolley Test Using a Square Impactor

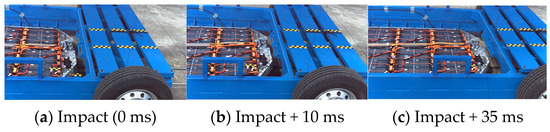

The square impactor reflects the standard road curb shape in Korea. As a result of the 30 km/h trolley impact test using the square impactor, the following key characteristics were identified:

The crash mechanism of Crash Mode 4 was observed to resemble aspects of both Crash Modes 2 and 3. The first characteristic noted was the fracture and deformation of the front face of the battery pack, which caused the lateral support bar to impact the battery modules adjacent to the impact location, similar to Crash Mode 2. As a result, the deformation geometry of the frame inside the battery pack was found to be similar to or more severe than that observed in Crash Mode 2. The second characteristic was a bottom-scraping mechanism similar to Crash Mode 3, although it was more severe (see Figure 17 and Figure 18).

Figure 17.

Frontal view of 30 km/h trolley test using a square impactor.

Figure 18.

Excessive damage to the front face and internal frame of the battery packs following 30 km/h trolley test using a square impactor.

As shown in Figure 19, the battery cells and modules were impacted by the internal frame of the battery pack due to the large deformation and fracture of the pack. Despite the severe damage, no fire or explosion occurred during the 12 h of post-crash monitoring, in contrast to Crash Mode 2.

Figure 19.

Frontal view of 30 km/h trolley test using a square impactor.

However, after storing the two tested batteries, one battery (used in the hemispherical impactor crash test) caught fire after 31 days, while the other battery, which did not catch fire (used in the square impactor for crash testing), was disassembled and found to have moisture in the internal modules.

6. Conclusions

This study confirmed the fire occurrence mechanisms following electric vehicle (EV) crashes through both crash evaluation tests and an analysis of 13 accident datasets from Korea between 2021 and 2024. 7. Based on the analysis of EV post-crash fire accident data, crash test results reflecting the severity of EV fire accidents, and draft concepts for EV post-crash fire safety protocols, the following conclusions can be drawn:

- Post-crash fires in EVs in Korea primarily occurred in high-speed frontal collisions and low-speed direct impacts to the battery mounted at the bottom of the vehicle. Additionally, these fires were caused by direct damage to the battery pack (e.g., excessive deformation and penetration) resulting from direct impacts to the cells and modules within the battery pack.

- This study confirmed that the mechanisms causing direct impact to the battery differ in high-speed frontal collisions between EVs and internal combustion engine (ICE) vehicles. In the case of EVs, the battery pack can be damaged due to intrusion from external structures resulting from excessive deformation of the front structure. Conversely, for ICE vehicles, the front structure can cause damage to the battery pack by moving the front drive components or rigid parts into the battery zone, thereby impacting the battery pack.

- The fire mechanisms caused by the breakage of modules and/or cells within the battery pack were identified. It was confirmed that battery fires can occur not only from direct cell breakage due to impact but also from cell fractures induced by tensile deformation during the impact event.

- Regarding the impactor geometry, it was found that the square impactor type exhibited better reproducibility of the battery damage observed in real-world EV post-crash fire accidents in Korea compared to the hemispherical type.

- In real-world road crashes in Korea, EV fires typically occurred immediately after the crash. However, in the evaluation tests, fires were observed to occur as long as 2 h or even 31 days after the crash. This discrepancy is attributed to the lower severity of battery damage in the evaluation tests compared to real-world accidents, which resulted in micro-short circuits during the evaluation tests, as opposed to the large short circuits typically seen in real-world collisions. As mentioned in Chapter 4, the battery that caught fire 31 days after the crash test indicated the potential for moisture invasion into the micro-shorted battery. Therefore, it is recommended to include an additional evaluation, such as an immersion test (according to KMVSS), to assess the waterproof performance of the battery.

- This study has derived EV post-crash fire safety assessment concepts that can be applied to future KNCAP regulations, with the following considerations:

- -

- The new EV post-crash fire safety test concept should accurately represent the fire mechanisms observed in real EV crash accidents.

- -

- It is reasonable to develop separate evaluation methods for high-speed frontal collisions and low-speed bottom impacts, as the mechanisms causing damage to the battery differ between these two crash types.

- Although further modifications and improvements will be made before KNCAP is implemented in 2026, this research has established new test protocols aimed at minimizing post-crash fires in electric vehicles, as shown in Figure 20.

Figure 20. New draft EV post-crash fire safety protocol concepts for future KNCAP (′26) derived from this research.

Figure 20. New draft EV post-crash fire safety protocol concepts for future KNCAP (′26) derived from this research.

Author Contributions

Conceptualization, J.M.; Methodology, J.I.; Data curation, J.I. and H.K.; Writing—original draft, J.I.; Writing—review & editing, J.M.; Supervision, H.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [Korea Agency for Infrastructure Technology Advancement] grant number [Project No. RS-2023-00243574].

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

This study was financially supported by the following research project: ‘Development of Electric Vehicles Safety Evaluation and Integrated Safety Management Technology’.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- BP. Statistical Review of World Energy 2018; BP: London, UK, 2018; pp. 1–53. [Google Scholar]

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards. J. Energy Chem. 2021, 59, 83–99. [Google Scholar]

- Sun, P.; Bisschop, R.; Niu, H.; Huang, X. A Review of Battery Fires in Electric Vehicles. Fire Technol. 2020, 56, 1361–1410. [Google Scholar] [CrossRef]

- Lecocq, A.; Bertana, M.; Truchot, B.; Marlair, G. Comparison of the fire consequences of an electric vehicle and an internal combustion engine vehicle. In Proceedings of the International Conference on Fires in Vehicles—FIVE 2012, Chicago, IL, USA, 27–28 September 2012; Volume 2, pp. 183–194. [Google Scholar]

- Zhao, C.; Hu, W.; Meng, D.; Mi, W.; Wang, X.; Wang, J. Full-scale experimental study of the characteristics of electric vehicle fires process and response measures. Case Stud. Therm. Eng. 2024, 53, 103889. [Google Scholar] [CrossRef]

- Bisschop, R.; Willstrand, O.; Amon, F.; Rosenggren, M. Fire Safety of Lithium-Ion Batteries in Road Vehicles; RISE Research Institutes of Swede: Gothenburg, Sweden, 2019. [Google Scholar] [CrossRef]

- Linja-Aho, V. Perceived and Actual Fire Safety—Case of Hybrid and Electric Vehicle Fires in Finland 2015–2023. WSEAS Trans. Environ. Dev. 2023, 19, 1313–1328. [Google Scholar]

- Leost, Y.; Boljen, M. Crash simulations of electric cars in the EVERSAFE Project. In COMPLAS XIII: Proceedings of the XIII International Conference on Computational Plasticity: Fundamentals and Applications, Barcelona, Spain, 1–3 September 2015; LS-DYNA Form (2014); CIMNE: Barcelona, Spain, 2015; pp. 149–160. [Google Scholar]

- Chen, J.; Xiong, P.; Li, K.; Yang, S. Optimization Study of Fire Prevention Structure of Electric Vehicle Based on Bottom Crash Protection. Fire 2024, 7, 209. [Google Scholar] [CrossRef]

- Xia, Y.; Wierzbicki, T.; Sahraei, E.; Zhang, X.W. Damage of cells and battery packs due to ground impact. J. Power Sources 2014, 267, 78–97. [Google Scholar] [CrossRef]

- Yu, D.; Ren, D.S.; Dai, K.R.; Zhang, H.; Zhang, J.M.; Yang, B.Q.; Ma, S.J.; Wang, X.F.; You, Z. Failure mechanism and predictive model of lithium-ion batteries under extremely high transient impact. J. Energy Storage 2021, 43, 103191. [Google Scholar] [CrossRef]

- Lian, Y.F.; Wang, X.Y.; Tian, Y.T.; Liu, K.P. Lateral Collision Avoidance Robust Control of Electric Vehicles Combining a Lane-Changing Model Based on Vehicle Edge Turning Trajectory and a Vehicle Semi-Uncertainty Dynamic Model. Int. J. Automot. Technol. 2018, 19, 331–343. [Google Scholar] [CrossRef]

- Wierzbicki, T.; Sahraei, E. Homogenized mechanical properties for the jellyroll of cylindrical Lithium-ion cells. J. Power Sources 2013, 241, 467–476. [Google Scholar] [CrossRef]

- Xia, Y.; Chen, G.; Zhou, Q.; Shi, X.; Shi, F. Failure behaviours of 100% SOC lithium-ion battery modules under different impact loading conditions. Eng. Fail. Anal. 2017, 82, 149–160. [Google Scholar] [CrossRef]

- CATARC, C-NCAP Management Regulation—Appendix N Electric Vehicle Bottom-Scraping Test Protocol, 2024 Version. Available online: https://www.safetywissen.com/object/B04/B04.9mk7389036lcyd8feqn42287ocq0ia63841175087/safetywissen?prev=%2Flatest_updates%2F (accessed on 11 February 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).