A Comparative Life Cycle Analysis of an Active and a Passive Battery Thermal Management System for an Electric Vehicle: A Cold Plate and a Loop Heat Pipe

Abstract

1. Introduction

2. Methodology

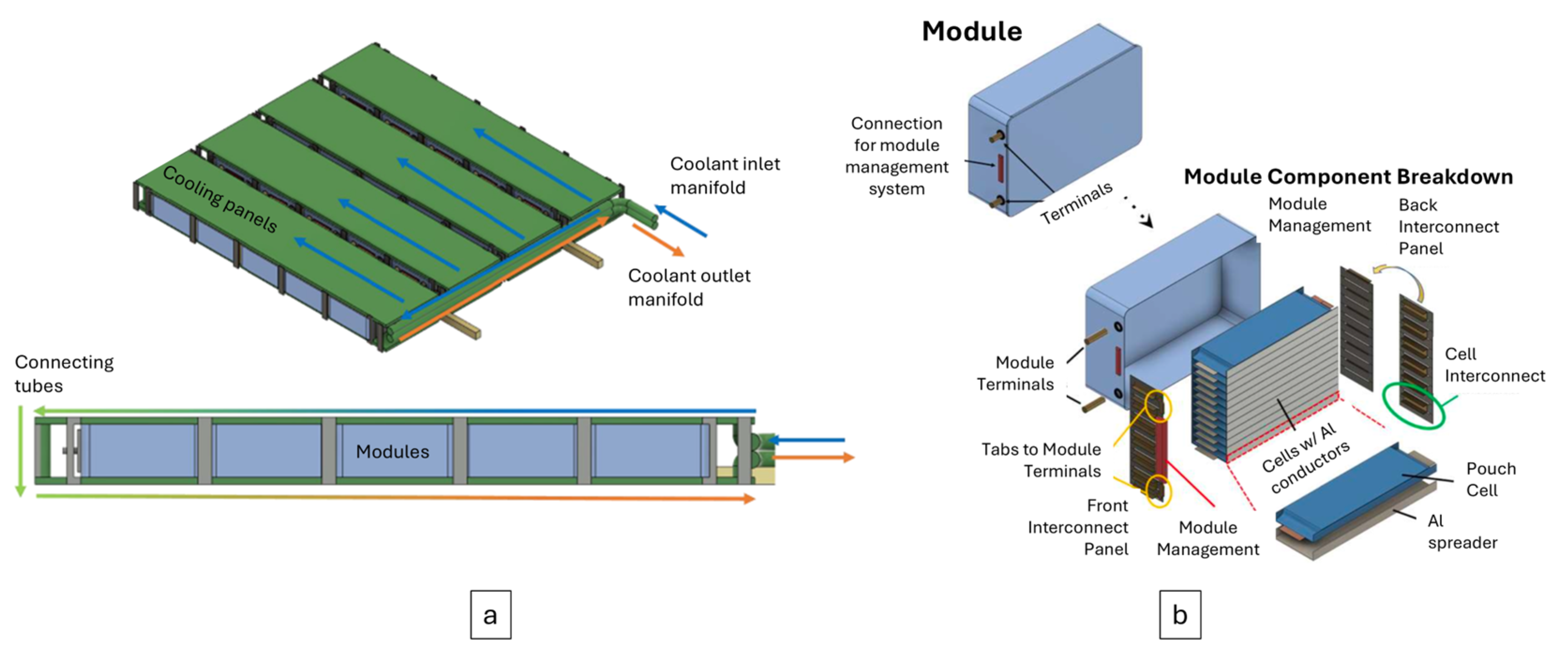

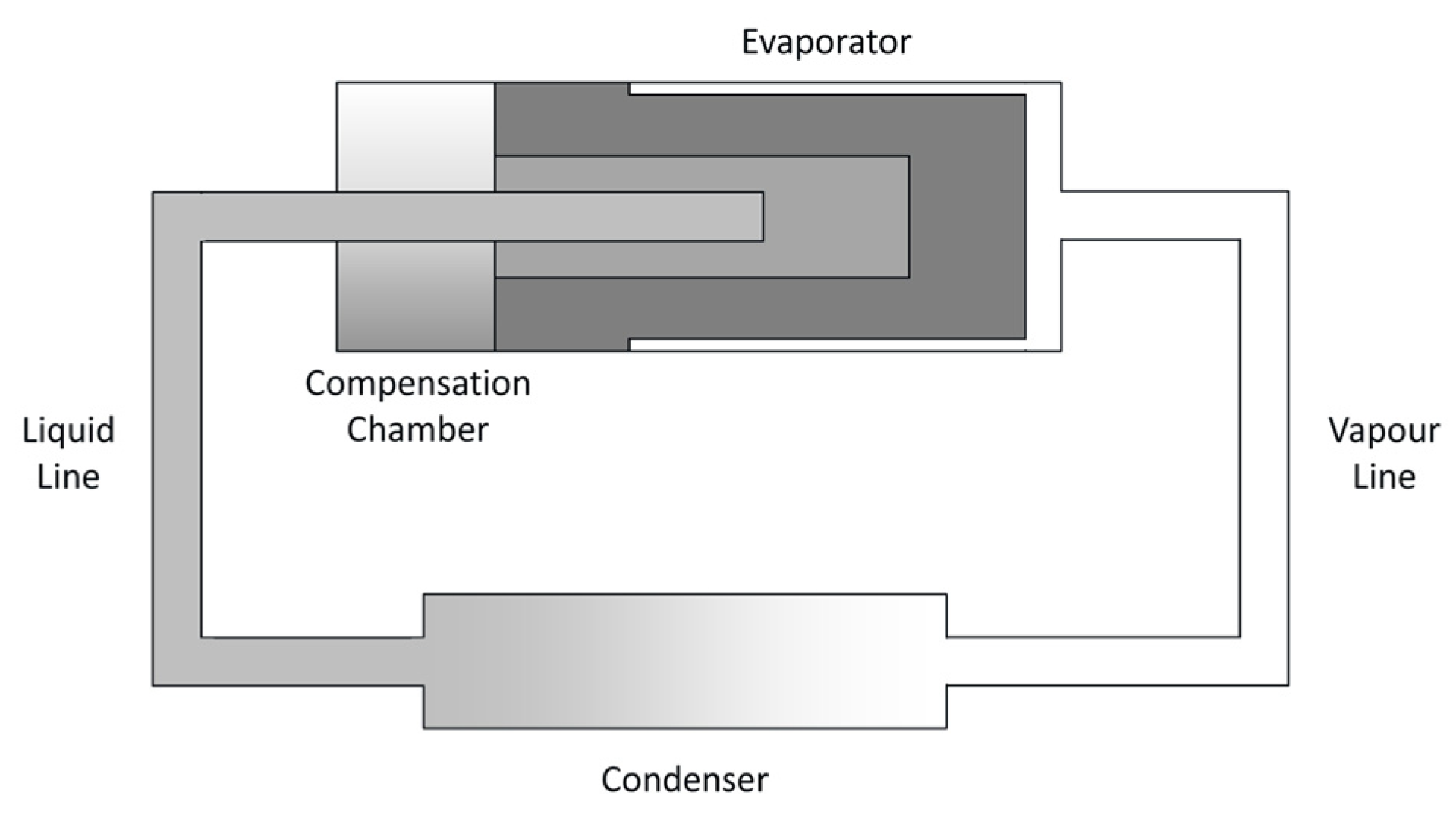

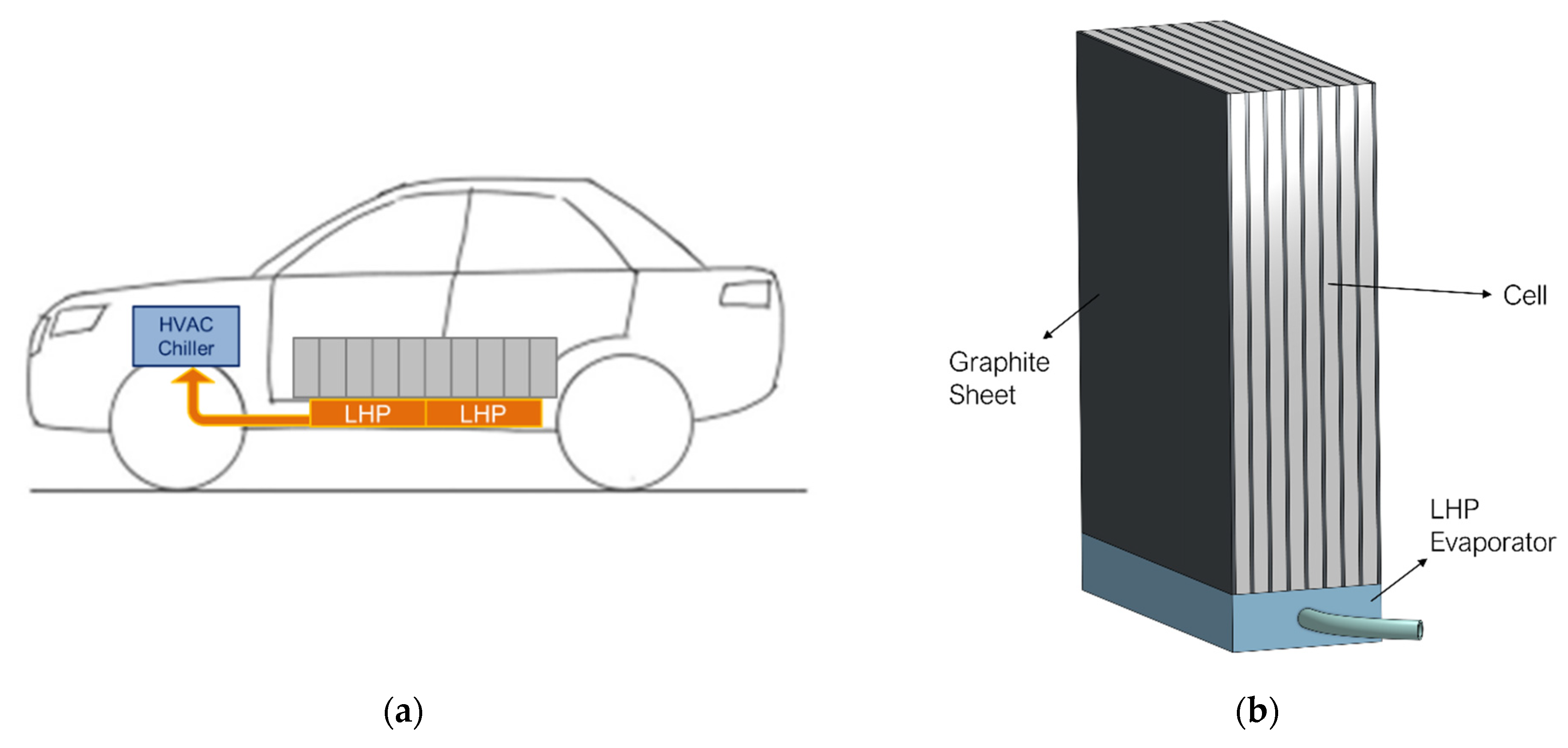

2.1. Battery Thermal Management Systems Under Analysis

2.2. Life Cycle Assessment

2.3. Data Collection

2.3.1. Raw Material Acquisition

2.3.2. Manufacturing

2.3.3. Use

2.3.4. Disposal and Recycling

3. Set-Up of a Sensitivity Scenario

4. Results

5. Sensitivity Analysis—Results for SS LHP and Comparison

6. Conclusions

- The LHP BTMS using stainless-steel components has over 50% lower impact across most environmental impact categories compared to the cold plate BTMS. This includes a 52% reduction in greenhouse gas emissions (kg CO2eq) and an over 60% improvement in freshwater ecotoxicity.

- The use of stainless steel instead of copper in the LHP system greatly reduces the impact on resource use, particularly for minerals and metals. This addresses a major weakness of the initial copper-based LHP design.

- The passive operation of the LHP system, without the need for a power-consuming coolant pump, leads to substantially lower energy usage and emissions during the use phase compared to the active cold plate.

- The LHP BTMS using stainless-steel components achieves a 40% reduction in overall system weight compared to the cold plate, which can provide additional benefits in vehicle applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BTMS | Battery Thermal Management System |

| DOD | Depth of Discharge |

| EF | Environmental Footprint |

| EV | Electric Vehicle |

| LCA | Life Cycle Assessment |

| LCIA | Life Cycle Impact Assessment |

| LCI | Life Cycle Inventory |

| LHP | Loop Heat Pipe |

| GHG | Greenhouse Gases |

| HVAC | Heating Ventilation and Air Conditioning |

| PCM | Phase Change Material |

| SEI | Solid Electrolyte Interphase |

| SOC | State of Charge |

| SS | Stainless Steel |

References

- European Parliament. Green Deal: Key to a Climate-Neutral and Sustainable EU; European Parliament: Strasbourg, France, 2024. [Google Scholar]

- UK Department for Transport. Transport and Environment Statistics: 2023; UK Department for Transport: London, UK, 2023. [Google Scholar]

- Olabi, A.G.; Maghrabie, H.M.; Adhari, O.H.K.; Sayed, E.T.; Yousef, B.A.A.; Salameh, T.; Kamil, M.; Abdelkareem, M.A. Battery Thermal Management Systems: Recent Progress and Challenges. Int. J. Thermofluids 2022, 15, 100171. [Google Scholar] [CrossRef]

- Iora, P.; Tribioli, L. Effect of Ambient Temperature on Electric Vehicles’ Energy Consumption and Range: Model Definition and Sensitivity Analysis Based on Nissan Leaf Data. World Electr. Veh. J. 2019, 10, 2. [Google Scholar] [CrossRef]

- Ramadass, P.; Haran, B.; White, R.; Popov, B.N. Capacity Fade of Sony 18650 Cells Cycled at Elevated Temperatures. J. Power Sources 2002, 112, 614–620. [Google Scholar] [CrossRef]

- Niculuţǎ, M.C.; Veje, C. Analysis of the Thermal Behavior of a LiFePO4 Battery Cell. J. Phys. Conf. Ser. 2012, 395, 012013. [Google Scholar] [CrossRef]

- Lin, J.; Liu, X.; Li, S.; Zhang, C.; Yang, S. A Review on Recent Progress, Challenges and Perspective of Battery Thermal Management System. Int. J. Heat Mass Transf. 2021, 167, 120834. [Google Scholar] [CrossRef]

- Tete, P.R.; Gupta, M.M.; Joshi, S.S. Developments in Battery Thermal Management Systems for Electric Vehicles: A Technical Review. J. Energy Storage 2021, 35, 102255. [Google Scholar] [CrossRef]

- Qin, P.; Liao, M.; Zhang, D.; Liu, Y.; Sun, J.; Wang, Q. Experimental and Numerical Study on a Novel Hybrid Battery Thermal Management System Integrated Forced-Air Convection and Phase Change Material. Energy Convers. Manag. 2019, 195, 1371–1381. [Google Scholar] [CrossRef]

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. A Critical Review of Thermal Issues in Lithium-Ion Batteries. J. Electrochem. Soc. 2011, 158, R1. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Zhang, H. A Review of Air-Cooling Battery Thermal Management Systems for Electric and Hybrid Electric Vehicles. J. Power Sources 2021, 501, 230001. [Google Scholar] [CrossRef]

- Wu, W.; Wang, S.; Wu, W.; Chen, K.; Hong, S.; Lai, Y. A Critical Review of Battery Thermal Performance and Liquid Based Battery Thermal Management. Energy Convers. Manag. 2019, 182, 262–281. [Google Scholar] [CrossRef]

- Roe, C.; Feng, X.; White, G.; Li, R.; Wang, H.; Rui, X.; Li, C.; Zhang, F.; Null, V.; Parkes, M.; et al. Immersion Cooling for Lithium-Ion Batteries—A Review. J. Power Sources 2022, 525, 231094. [Google Scholar] [CrossRef]

- Akbarzadeh, M.; Kalogiannis, T.; Jaguemont, J.; Jin, L.; Behi, H.; Karimi, D.; Beheshti, H.; Van Mierlo, J.; Berecibar, M. A Comparative Study between Air Cooling and Liquid Cooling Thermal Management Systems for a High-Energy Lithium-Ion Battery Module. Appl. Therm. Eng. 2021, 198, 117503. [Google Scholar] [CrossRef]

- Chen, K.; Wang, S.; Song, M.; Chen, L. Structure Optimization of Parallel Air-Cooled Battery Thermal Management System. Int. J. Heat Mass Transf. 2017, 111, 943–952. [Google Scholar] [CrossRef]

- Rabiei, M.; Gharehghani, A.; Andwari, A.M. Enhancement of Battery Thermal Management System Using a Novel Structure of Hybrid Liquid Cold Plate. Appl. Therm. Eng. 2023, 232, 121051. [Google Scholar] [CrossRef]

- Bernagozzi, M.; Georgoulas, A.; Miché, N.; Marengo, M. Heat Pipes in Battery Thermal Management Systems for Electric Vehicles: A Critical Review. Appl. Therm. Eng. 2023, 219, 119495. [Google Scholar] [CrossRef]

- Jaguemont, J.; Omar, N.; Van den Bossche, P.; Mierlo, J. Phase-Change Materials (PCM) for Automotive Applications: A Review. Appl. Therm. Eng. 2018, 132, 308–320. [Google Scholar] [CrossRef]

- Pambudi, N.A.; Sarifudin, A.; Firdaus, R.A.; Ulfa, D.K.; Gandidi, I.M.; Romadhon, R. The immersion cooling technology: Current and future development in energy saving. Alex. Eng. J. 2022, 61, 12. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2021.

- LU: Publications Office. International Reference Life Cycle Data System (ILCD) Handbook: General Guide for Life Cycle Assessment: Detailed Guidance; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- Chen, F.; Huang, R.; Wang, C.; Yu, X.; Liu, H.; Wu, Q.; Qian, K.; Bhagat, R. Air and PCM Cooling for Battery Thermal Management Considering Battery Cycle Life. Appl. Therm. Eng. 2020, 173, 115154. [Google Scholar] [CrossRef]

- Lander, L.; Kallitsis, E.; Hales, A.; Edge, J.S.; Korre, A.; Offer, G. Cost and Carbon Footprint Reduction of Electric Vehicle Lithium-Ion Batteries through Efficient Thermal Management. Appl. Energy 2021, 289, 116737. [Google Scholar] [CrossRef]

- Llera, R.; Vigil, M.; Díaz-Díaz, S.; Martínez Huerta, G.M. Prospective Environmental and Techno-Economic Assessment of Steam Production by Means of Heat Pipes in the Steel Industry. Energy 2022, 239, 122334. [Google Scholar] [CrossRef]

- Illner, M.; Thüsing, K.; Salles, A.; Trettenhann, A.; Albrecht, S.; Winkler, M. Switchable Heat Pipes for Eco-Friendly Battery Cooling in Electric Vehicles: A Life Cycle Assessment. Energies 2024, 17, 938. [Google Scholar] [CrossRef]

- Knehr, K.W.; Kubal, J.J.; Nelson, P.A.; Ahmed, S. A Manual for BatPaC v5.0 Battery Performance and Cost Modeling for Electric-Drive Vehicles; Argonne National Lab. (ANL): Argonne, IL, USA, 2022. [Google Scholar]

- Mahmoudinezhad, S.; Sadi, M.; Ghiasirad, H.; Arabkoohsar, A. A Comprehensive Review on the Current Technologies and Recent Developments in High-Temperature Heat Exchangers. Renew. Sustain. Energy Rev. 2023, 183, 113467. [Google Scholar] [CrossRef]

- Maydanik, Y.F. Loop Heat Pipes. Appl. Therm. Eng. 2005, 25, 635–657. [Google Scholar] [CrossRef]

- Nakamura, K.; Odagiri, K.; Nagano, H. Operational Characteristics of 10m-Class Long-Distance Loop Heat Pipe under Anti- Gravity Condition. In Proceedings of the Joint 18th IHPC and 12th IHPS, Jeju, Republic of Korea, 12–16 June 2016; pp. 384–391. [Google Scholar]

- Su, Q.; Chang, S.; Zhao, Y.; Zheng, H.; Dang, C. A Review of Loop Heat Pipes for Aircraft Anti-Icing Applications. Appl. Therm. Eng. 2018, 130, 528–540. [Google Scholar] [CrossRef]

- Domiciano, K.G.; Krambeck, L.; Flórez, J.P.M.; Mantelli, M.B.H. Thin Diffusion Bonded Flat Loop Heat Pipes for Electronics: Fabrication, Modelling and Testing. Energy Convers. Manag. 2022, 255, 115329. [Google Scholar] [CrossRef]

- Watanabe, N.; Mizutani, T.; Nagano, H. High-Performance Energy-Saving Miniature Loop Heat Pipe for Cooling Compact Power Semiconductors. Energy Convers. Manag. 2021, 236, 114081. [Google Scholar] [CrossRef]

- Somers-Neal, S.; Tomita, T.; Watanabe, N.; Ueno, A.; Nagano, H. Experimental Investigation of a 10 KW-Class Flat-Type Loop Heat Pipe for Waste Heat Recovery. Int. J. Heat Mass Transf. 2024, 231, 125865. [Google Scholar] [CrossRef]

- Nashine, C.; Pandey, M.; Baraya, K.K. Experimental Studies on the Transient Characteristics and Start-up Behaviour of a Miniature Loop Heat Pipe. Appl. Therm. Eng. 2025, 259, 124814. [Google Scholar] [CrossRef]

- Huang, B.-J.; Chuang, Y.-H.; Yang, P.-E. Low-Cost Manufacturing of Loop Heat Pipe for Commercial Applications. Appl. Therm. Eng. 2017, 126, 1091–1097. [Google Scholar] [CrossRef]

- Bernagozzi, M.; Georgoulas, A.; Miché, N.; Rouaud, C.; Marengo, M. A Novel Loop Heat Pipe Based Cooling System for Battery Packs in Electric Vehicles. In Proceedings of the 2020 IEEE Transportation Electrification Conference & Expo (ITEC), Chicago, IL, USA, 23–26 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 251–256. [Google Scholar]

- Bernagozzi, M.; Georgoulas, A.; Miché, N.; Rouaud, C.; Marengo, M. Novel Battery Thermal Management System for Electric Vehicles with a Loop Heat Pipe and Graphite Sheet Inserts. Appl. Therm. Eng. 2021, 194, 117061. [Google Scholar] [CrossRef]

- Bernagozzi, M. Development and Characterisation of an Innovative Battery Thermal Management System for Electric Vehicles with Loop Heat Pipes and Graphite Sheets. Doctoral Thesis, University of Brighton, Brighton, UK, 2022. [Google Scholar]

- Pelletier, N.; Allacker, K.; Pant, R.; Manfredi, S. The European Commission Organisation Environmental Footprint Method: Comparison with Other Methods, and Rationales for Key Requirements. Int. J. Life Cycle Assess. 2014, 19, 387–404. [Google Scholar] [CrossRef]

- Fazio, S.; Biganzioli, F.; De Laurentiis, V.; Zampori, L.; Sala, S.; Diaconu, E. Supporting Information to the Characterisation Factors of Recommended EF Life Cycle Impact Assessment Methods; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- Stocker, T.F.; Qin, D.; Plattner, G.-K.; Tignor, M.; Allen, S.K.; Boschung, J.; Nauels, A.; Xia, Y.; Bex, V.; Midgley, P.M. Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- World Meteorological Organization. Scientific Assessment of Ozone Depletion: 2014, Global Ozone Research and Monitoring Project Report No. 55; World Meteorological Organization: Geneva, Switzerland, 2014. [Google Scholar]

- Rosenbaum, R.K.; Bachmann, T.M.; Gold, L.S.; Huijbregts, M.A.J.; Jolliet, O.; Juraske, R.; Koehler, A.; Larsen, H.F.; MacLeod, M.; Margni, M.; et al. USEtox—The UNEP-SETAC Toxicity Model: Recommended Characterisation Factors for Human Toxicity and Freshwater Ecotoxicity in Life Cycle Impact Assessment. Int. J. Life Cycle Assess. 2008, 13, 532–546. [Google Scholar] [CrossRef]

- Fantke, P.; Evans, J.; Hodas, N.; Apte, J.; Jantunen, M.; Jolliet, O.; McKone, T.E. Health Impacts of Fine Particulate Matter. In Global Guidance for Life Cycle Impact Assessment Indicators: Volume 1; UNEP/SETAC Life Cycle Initiative: Paris, France, 2016; pp. 76–99. [Google Scholar]

- Frischknecht, R.; Braunschweig, A.; Hofstetter, P.; Suter, P. Human health damages due to ionising radiation in life cycle impact assessment. Environ. Impact Assess. Rev. 2000, 20, 2. [Google Scholar]

- van Zelm, R.; Huijbregts, M.A.J.; den Hollander, H.A.; van Jaarsveld, H.A.; Sauter, F.J.; Struijs, J.; van Wijnen, H.J.; van de Meent, D. European Characterization Factors for Human Health Damage of PM10 and Ozone in Life Cycle Impact Assessment. Atmos. Environ. 2008, 42, 441–453. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Seppälä, J.; Posch, M.; Johansson, M.; Hettelingh, J.-P. Country-Dependent Characterisation Factors for Acidification and Terrestrial Eutrophication Based on Accumulated Exceedance as an Impact Category Indicator (14 Pp). Int. J. Life Cycle Assess. 2006, 11, 403–416. [Google Scholar] [CrossRef]

- Posch, M.; Seppälä, J.; Hettelingh, J.-P.; Johansson, M.; Margni, M.; Jolliet, O. The Role of Atmospheric Dispersion Models and Ecosystem Sensitivity in the Determination of Characterisation Factors for Acidifying and Eutrophying Emissions in LCIA. Int. J. Life Cycle Assess. 2008, 13, 477–486. [Google Scholar] [CrossRef]

- Struijs, J.; Beusen, A.; van Jaarsveld, H.; Huijbregts, M.A.J. Aquatic Eutrophication. Chapter 6. In ReCiPe 2008 A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level. Report I: Characterisation Factors; Ministerie van VROM: The Hague, Netherlands, 2008. [Google Scholar]

- Bos, U.; Horn, R.; Beck, T.; Lindner, J.P.; Fischer, M. LANCA®—Characterization Factors for Life Cycle Impact Assessment. Version 2.0.; Fraunhofer Verlag: Stuggart, Germany, 2016. [Google Scholar]

- Boulay, A.-M.; Bare, J.; Benini, L.; Berger, M.; Lathuillière, M.J.; Manzardo, A.; Margni, M.; Motoshita, M.; Núñez, M.; Pastor, A.V.; et al. The WULCA Consensus Characterization Model for Water Scarcity Footprints: Assessing Impacts of Water Consumption Based on Available Water Remaining (AWARE). Int. J. Life Cycle Assess. 2018, 23, 368–378. [Google Scholar] [CrossRef]

- Van Oers, L.; Guinée, J. The Abiotic Depletion Potential: Background, Updates, and Future. Resources 2016, 5, 16. [Google Scholar] [CrossRef]

- CML—Department of Industrial Ecology CML-IA Characterisation Factors. Available online: https://www.universiteitleiden.nl/en/research/research-output/science/cml-ia-characterisation-factors (accessed on 18 December 2024).

- Pasaoglu, G.; Fiorello, D.; Martino, A.; Scarcella, G.; Alemanno, A.; Zubaryeva, A.; Thiel, C. Driving and Parking Patterns of European Car Drivers—A Mobility Survey; European Commission: Luxembourg, 2012. [Google Scholar]

- Kim, R.H.; Lee, N.H.; Yoon, S.P.; Song, S.H.; Park, J.K. Considerations on the Methane Correction Factor and Fraction of Methane Parameters in the IPCC First-Order Decay Model for Active Aeration Landfills. Waste Manag. 2023, 169, 232–242. [Google Scholar] [CrossRef] [PubMed]

- Celata, G.P.; Cumo, M.; Furrer, M. Experimental Tests of a Stainless Steel Loop Heat Pipe with Flat Evaporator. Exp. Therm. Fluid Sci. 2010, 34, 866–878. [Google Scholar] [CrossRef]

- Tian, T.; Li, H.; Zhang, W.; Lai, Q.; Xie, Y.; Tan, J. The Start-up Characteristics of a Novel Loop Heat Pipe with Stainless Steel Capillary Wick. Appl. Therm. Eng. 2025, 258, 124553. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, D.; Xu, J.; Zhang, L. Development of a Loop Heat Pipe with the 3D Printed Stainless Steel Wick in the Application of Thermal Management. Int. J. Heat Mass Transf. 2020, 161, 120258. [Google Scholar] [CrossRef]

- Maydanik, Y.F.; Chernysheva, M.A.; Pastukhov, V.G. Review: Loop Heat Pipes with Flat Evaporators. Appl. Therm. Eng. 2014, 67, 294–307. [Google Scholar] [CrossRef]

- Wirsch, P.J.; Thomas, S.K. Performance Characteristics of a Stainless Steel/Ammonia Loop Heat Pipe. J. Thermophys. Heat Trans. 1996, 10, 326–333. [Google Scholar] [CrossRef]

- Johnson, J.; Reck, B.K.; Wang, T.; Graedel, T.E. The Energy Benefit of Stainless Steel Recycling. Energy Policy 2008, 36, 181–192. [Google Scholar] [CrossRef]

- Capellán-Pérez, I.; Mediavilla, M.; de Castro, C.; Carpintero, Ó.; Miguel, L.J. Fossil Fuel Depletion and Socio-Economic Scenarios: An Integrated Approach. Energy 2014, 77, 641–666. [Google Scholar] [CrossRef]

- Li, Y.; Linke, B.S.; Voet, H.; Falk, B.; Schmitt, R.; Lam, M. Cost, Sustainability and Surface Roughness Quality—A Comprehensive Analysis of Products Made with Personal 3D Printers. CIRP J. Manuf. Sci. Technol. 2017, 16, 1–11. [Google Scholar] [CrossRef]

- Alvarado, S.; Maldonado, P.; Jaques, I. Energy and Environmental Implications of Copper Production. Energy 1999, 24, 307–316. [Google Scholar] [CrossRef]

- Silva, D.d.O.; Riehl, R.R. Thermal Behavior of Water-Copper and Water-Stainless Steel Heat Pipes Operating in Cycles. In Proceedings of the 2016 15th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Las Vegas, NV, USA, 31 May–3 June 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 6–11. [Google Scholar]

| Impact Category | Description |

|---|---|

| Climate change | Quantifies GHG emissions using the Intergovernmental Panel on Climate Change (IPCC) 2013 model as a baseline, for a 100 year-time horizon (GWP-100). The impact is measured in kilograms of carbon dioxide equivalents (CO2eq) [42]. |

| Ozone depletion | Calculates the destructive effects on the stratospheric ozone layer over a time horizon of 100 years. The impact is measured in trichlorofluoromethane equivalents (CFC-11eq). It uses the World Meteorological Organisation 2014 model as a baseline [43]. |

| Human toxicity | Assesses impacts on human health caused by the absorption of cancerous and non-cancerous (measured distinctly) substances. The impact is measured in Comparative Toxic Units for Humans (CTUh), using the USEtox (2008) model [44]. |

| Particulate matter (PM) | Assesses disease incidence due to kg of PM2.5 emitted, based on Fantke's (2016) model. The impact is measured in disease incidences [45]. |

| Ionising radiation | Quantifies the impact of ionising radiation on the population, based on Frischknecht's (2000) model. The impact is measured in Uranium 235 equivalents (U235eq) [46]. |

| Photochemical ozone formation | Calculates the impact of tropospheric ozone formation, based on Van Zelm's (2008) model [47], as applied in ReCiPe2008 [48]. The impact is measured in kilograms of Non-Methane Volatile Organic Compound equivalents (kg NMVOCeq). |

| Acidification | Evaluates the change in critical load exceedance of the sensitive area in terrestrial and main freshwater ecosystems, to which acidifying substances deposit, based on Seppälä’s (2006) [49] and Posch’s (2008) [50] models. The impact is measured in moles of hydrogen ion equivalents (mol H+ eq). |

| Eutrophication, terrestrial | Evaluates the change in critical load exceedance of the sensitive area, to which eutrophying substances deposit, based on Seppälä’s (2006) [49] and Posch's (2008) [50] models. The impact is measured in moles of nitrogen equivalents (mol N eq). |

| Eutrophication, aquatic freshwater/marine | Measures the degree to which the emitted nutrients reach the end compartment, based on Struijs's (2009) [51] model. The impact is measured in kilograms of phosphorous equivalents for the aquatic freshwater compartment (kg P eq) and kilograms of nitrogen equivalents for the marine compartment (kg N eq). |

| Ecotoxicity, freshwater | Measures the toxic effect on aquatic freshwater species, based on the USEtox (2008) model [44]. The impact is measured in Comparative Toxic Units for ecosystems (CTUe). |

| Land use | Measures four soil properties: biotic production, erosion resistance, groundwater regeneration, and mechanical filtration, based on LANCA® v 2.2 [52] as the baseline model. The impact is measured through a single soil quality score (Pts). |

| Water use | Evaluates the impact on the quantity of water deprived, based on the AWARE model [53]. The impact is measured in terms of volume (m3). |

| Resource use | The impact of the depletion of natural resources, based on Van Oers and Guinée [54], as implemented in the CML method, v. 4.8 (2016), available at [55]. Energy carriers are considered separately and measured in MJ equivalents, while mineral and metal resources are measured in Sb-equivalents. |

| Parameter | Value |

|---|---|

| Designated duration of power pulse | 10 |

| Target pack power, [kW] | 300 |

| Estimated pack power at target % OCV, [kW] | 440 |

| Target pack energy, [kWh] | 100 |

| Number of cells per module | 12 |

| Number of cells in parallel | 2 |

| Number of modules in row | 8 |

| Number of rows of modules per pack | 4 |

| Number of modules per pack | 32 |

| Number of modules in parallel | 2 |

| Cells per pack | 384 |

| Total cells per battery system | 384 |

| Battery system capacity, [Ah] | 284.1 |

| Components | Materials | Amount |

|---|---|---|

| 50% Coolant | Ethylene-Glycol | 5.52 |

| 50% Coolant | Water | 5.52 |

| Manifold | Steel, Chromium Steel 18/8 | 1 |

| Panels | Steel, Chromium Steel 18/8 | 16.5 |

| Pump | Aluminium, cast alloy | 2 |

| Total (kg) | 30.54 | |

| Number of modules | 32 |

| Number of LHP required per module | 2 |

| Number of LHP fluidic lines | 2 |

| Total number of pipes | 128 |

| Battery pack length [mm] | 1161.6 |

| Average pipe length [mm] | 580.8 |

| Total pipe length [m] | 74.35 |

| Components | Materials | Amount |

|---|---|---|

| Pipeline | Copper | 8.704 |

| Evaporators | Copper | 10.88 |

| Coolant (pipes) | Ethanol | 0.446 |

| Coolant (evaporator) | Ethanol | 0.614 |

| Total (kg) | 20.644 | |

| Cooling Plate Thermal Management System | |||

|---|---|---|---|

| Components | Processes | Amount | Unit |

| Pump | Casting, aluminium, lost-wax | 2 | kg |

| Cooling Panels | Metalworking, average for chromium steel product manufacturing | 16.5 | kg |

| Manifold | Casting, steel, lost-wax | 1 | kg |

| Manifold | Welding, arc, steel | 0.628 | m |

| Loop Heat Pipe Thermal Management System | |||

|---|---|---|---|

| Components | Processes | Amount | Unit |

| Pipeline | Metalworking, average for copper product manufacturing | 8.7 | kg |

| Pipeline (vacuum) | (Vacuum pumps energy consumption) Electricity, medium voltage | 147.84 | kWh |

| Evaporators | Metalworking, average for copper product manufacturing | 10.88 | kg |

| Evaporators (wick) | (sintering energy consumption) Electricity, medium voltage | 362.88 | kWh |

| Pump Power [W] | 573.07 |

| Average Daily Driving Time [h] | 1 |

| Battery Lifetime [years] | 8 |

| Total Driving Time [h] | 2920 |

| Charge Rate | 1C |

| Discharge Rate | C/3 |

| Total charging time [h] (discharging time/3) | 974 |

| Pump Working Time [h] | 3894 |

| Pump Energy Consumption [kWh] | 2231.15 |

| Components | Materials | Amount (kg) |

|---|---|---|

| Pipeline | Steel, Chromium Steel 18/8 | 7.70 |

| Evaporators | Steel, Chromium Steel 18/8 | 9.63 |

| Coolant (pipes) | Ethanol | 0.446 |

| Coolant (evaporator) | Ethanol | 0.614 |

| Total (kg) | 18.39 | |

| Loop Heat Pipe Thermal Management System | |||

|---|---|---|---|

| Components | Processes | Amount | Unit |

| Pipeline | Impact extrusion of steel, hot, initial warming | 7.70 | kg |

| Pipeline | Impact extrusion of steel, hot, deformation stroke | 7.70 | kg |

| Pipeline | Impact extrusion of steel, hot, tempering | 7.70 | kg |

| Pipeline (vacuum) | (Vacuum pumps energy consumption) Electricity, medium voltage | 148 | kWh |

| Evaporators | Metalworking, average for steel product manufacturing | 9.63 | kg |

| Evaporators (wick) | (sintering energy consumption) Electricity, medium voltage | 578 | kWh |

| Cold Plate System | |||||

|---|---|---|---|---|---|

| Impact Category | Unit | Total | Materials and Production | Use Phase | Disposal |

| Climate change | kg CO2eq | 2.05 × 103 | 3.79 × 102 | 1.64 × 103 | 3.01 × 101 |

| Ionising radiation | kBq U-235 eq | 8.12 × 10−5 | 2.34 × 10−5 | 5.78 × 10−5 | - |

| Photochemical ozone formation | kg NMVOC eq | 2.77 × 102 | 3.75 × 101 | 2.39 × 102 | - |

| Acidification | mol H+ eq | 5.70 | 1.49 | 4.21 | 8.95 × 10−3 |

| Eutrophication, freshwater | kg P eq | 8.37 × 10−5 | 2.10 × 10−5 | 6.27 × 10−5 | 8.34 × 10−10 |

| Eutrophication, marine | kg N eq | 2.38 × 10−5 | 6.48 × 10−6 | 1.73 × 10−5 | 5.11 × 10−8 |

| Eutrophication, terrestrial | mol N eq | 3.23 × 10−6 | 2.76 × 10−6 | 4.76 × 10−7 | 6.79 × 10−10 |

| Ecotoxicity, freshwater | CTUe | 1.02 × 101 | 1.87 | 8.32 | 1.12 × 10−3 |

| Land use | Pt | 9.18 × 10−1 | 1.38 × 10−1 | 7.77 × 10−1 | 2.25 × 10−3 |

| Water use | m3 depriv. | 2.01 | 4.15 × 10−1 | 1.57 | 3.08 × 10−2 |

| Resource use, fossils | MJ | 1.92 × 101 | 3.54 | 1.57 × 101 | 1.12 × 10−4 |

| Resource use, minerals and metals | kg Sb eq | 4.35 × 104 | 1.13 × 104 | 3.15 × 104 | 6.38 × 102 |

| Loop Heat Pipe system | ||||

|---|---|---|---|---|

| Impact Category | Unit | Total | Materials and Production | Disposal |

| Climate change | kg CO2eq | 6.14 × 102 | 5.94 × 102 | 2.03 × 101 |

| Ionising radiation | kBq U-235 eq | 4.58 × 10−5 | 4.58 × 10−5 | - |

| Photochemical ozone formation | kg NMVOC eq | 1.04 × 102 | 1.04 × 102 | - |

| Acidification | mol H+ eq | 3.54 | 3.53 | 6.05 × 10−3 |

| Eutrophication, freshwater | kg P eq | 4.78 × 10−5 | 4.78 × 10−5 | 5.64 × 10−10 |

| Eutrophication, marine | kg N eq | 1.71 × 10−4 | 1.71 × 10−4 | 3.45 × 10−8 |

| Eutrophication, terrestrial | mol N eq | 2.47 × 10−6 | 2.47 × 10−6 | 4.59 × 10−10 |

| Ecotoxicity, freshwater | CTUe | 1.49 × 101 | 1.49 × 101 | 7.54 × 10−4 |

| Land use | Pt | 1.20 | 1.20 | 1.52 × 10−3 |

| Water use | m3 depriv. | 1.11 | 1.09 | 2.08 × 10−2 |

| Resource use, fossils | MJ | 1.31 × 101 | 1.31 × 101 | 7.60 × 10−5 |

| Resource use, minerals and metals | kg Sb eq | 1.12 × 105 | 1.12 × 105 | 4.31 × 102 |

| Loop Heat Pipe System in Stainless Steel | ||||

|---|---|---|---|---|

| Impact Category | Unit | Total | Materials and Production | Disposal |

| Climate change | kg CO2eq | 6.46 × 102 | 6.28 × 102 | 1.81 × 101 |

| Ionising radiation | kBq U-235 eq | 8.51 × 101 | 8.51 × 101 | - |

| Photochemical ozone formation | kg NMVOC eq | 1.67 | 1.66 | 5.39 × 10−3 |

| Acidification | mol H+ eq | 3.16 | 3.16 | 6.72 × 10−4 |

| Eutrophication, freshwater | kg P eq | 2.83 × 10−1 | 2.82 × 10−1 | 1.35 × 10−3 |

| Eutrophication, marine | kg N eq | 6.20 × 10−1 | 6.02 × 10−1 | 1.86 × 10−2 |

| Eutrophication, terrestrial | mol N eq | 6.04 | 6.04 | 6.77 × 10−5 |

| Ecotoxicity, freshwater | CTUe | 1.35 × 104 | 1.32 × 104 | 3.84 × 102 |

| Land use | Pt | 1.60 × 103 | 1.60 × 103 | 6.91 |

| Water use | m3 depriv. | 1.23 × 102 | 1.23 × 102 | - |

| Resource use, fossils | MJ | 7.99 × 103 | 7.99 × 103 | - |

| Resource use, minerals and metals | kg Sb eq | 3.28 × 10−3 | 3.28 × 10−3 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monticelli, M.; Accardo, A.; Bernagozzi, M.; Spessa, E. A Comparative Life Cycle Analysis of an Active and a Passive Battery Thermal Management System for an Electric Vehicle: A Cold Plate and a Loop Heat Pipe. World Electr. Veh. J. 2025, 16, 100. https://doi.org/10.3390/wevj16020100

Monticelli M, Accardo A, Bernagozzi M, Spessa E. A Comparative Life Cycle Analysis of an Active and a Passive Battery Thermal Management System for an Electric Vehicle: A Cold Plate and a Loop Heat Pipe. World Electric Vehicle Journal. 2025; 16(2):100. https://doi.org/10.3390/wevj16020100

Chicago/Turabian StyleMonticelli, Michele, Antonella Accardo, Marco Bernagozzi, and Ezio Spessa. 2025. "A Comparative Life Cycle Analysis of an Active and a Passive Battery Thermal Management System for an Electric Vehicle: A Cold Plate and a Loop Heat Pipe" World Electric Vehicle Journal 16, no. 2: 100. https://doi.org/10.3390/wevj16020100

APA StyleMonticelli, M., Accardo, A., Bernagozzi, M., & Spessa, E. (2025). A Comparative Life Cycle Analysis of an Active and a Passive Battery Thermal Management System for an Electric Vehicle: A Cold Plate and a Loop Heat Pipe. World Electric Vehicle Journal, 16(2), 100. https://doi.org/10.3390/wevj16020100