The Brazilian Program for Functional Safety Labeling of Critical Subsystems in Electric Vehicles: A Framework Based on Risk and Evidence

Abstract

1. Introduction

2. Materials and Methods

2.1. Analysis of International Vehicle Labeling Programs

2.2. Analysis of Operational Risks in Critical Subsystems

2.2.1. Subsystem Scope and Generic HARA

2.2.2. Derivation of the Generic Relative Risk Index (RRI_gen)

2.2.3. DRI Calculation Based on Submitted Technical Evidence

2.2.4. Calculation of the Vehicle’s Global Index (DRI_total) and Mapping to the Label

2.2.5. Sensitivity Analysis of the DRI Algorithm

2.2.6. Flow of the Classification Protocol

2.2.7. Justification of the Approach

2.3. Proposal for the Safety Label Structure

2.4. Classification Protocol and Voluntary Participation Model

2.4.1. Participation Process and Evidence Submission

2.4.2. Validation and Pilot Phase

2.4.3. International Recognition and Foreign Evidence

2.4.4. Traceability and Reliability Control

3. Results

3.1. Synthesis of the Analyzed International Programs

3.2. Qualitative Risk Classification by Subsystem

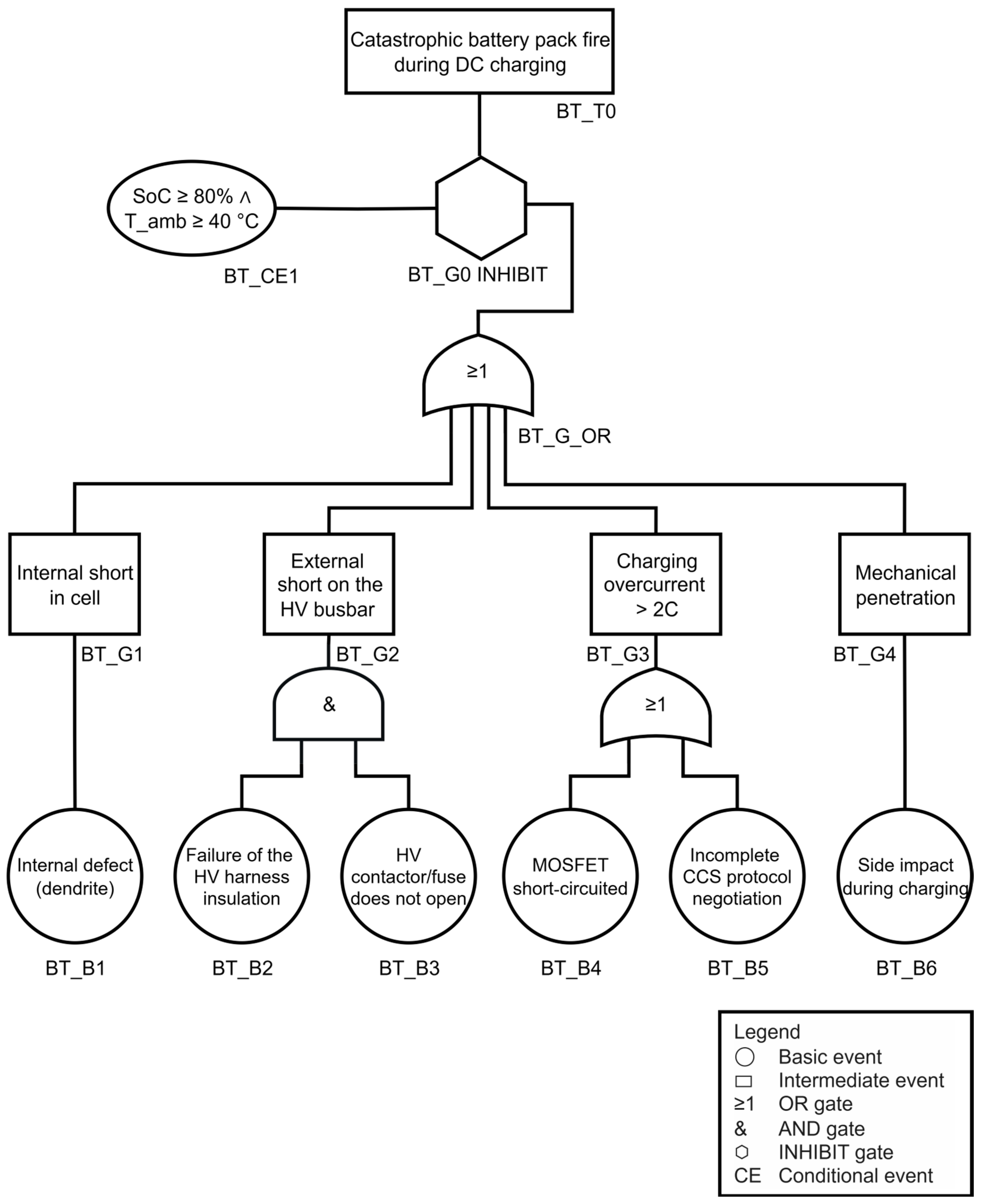

3.2.1. Battery Subsystem

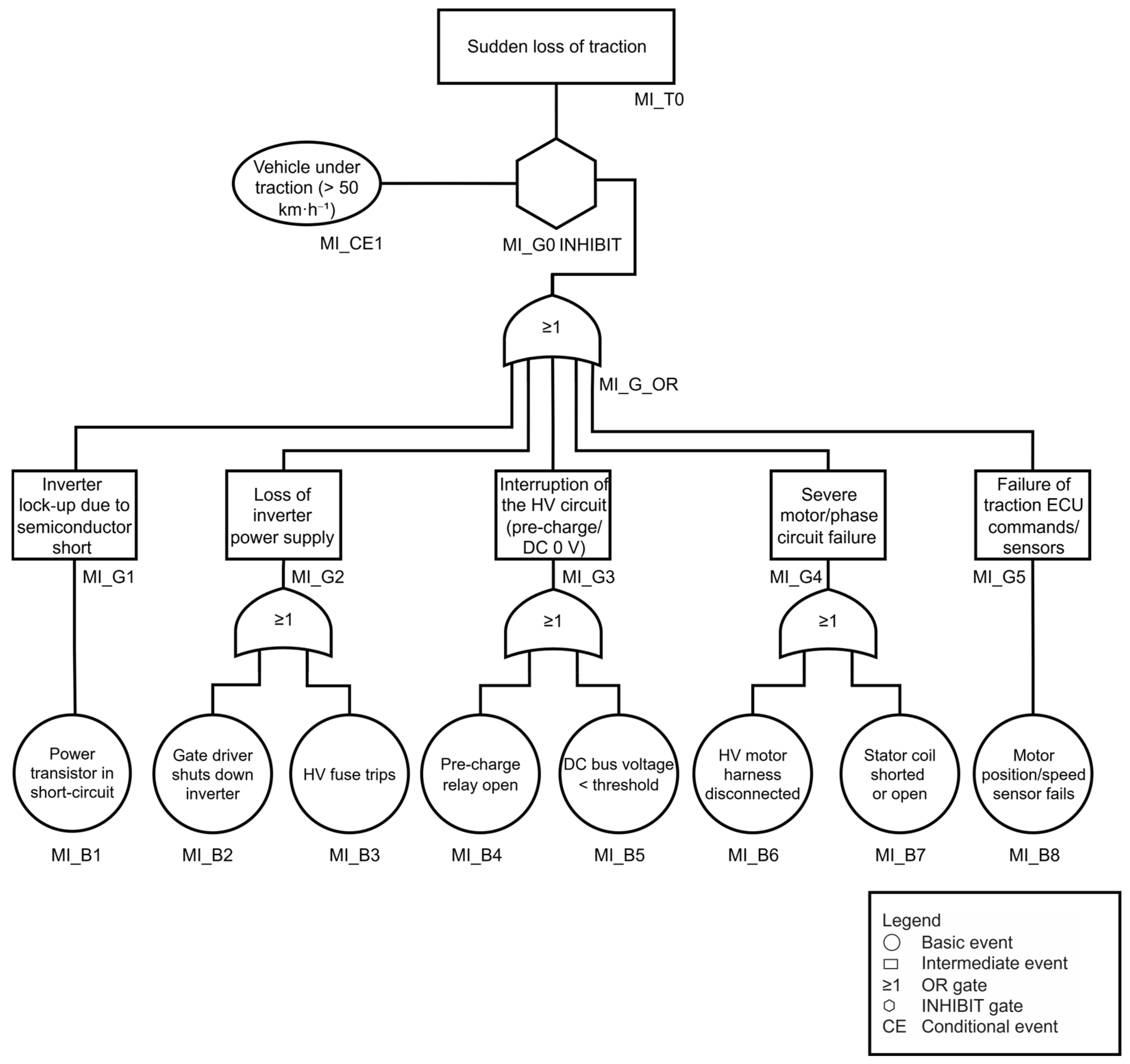

3.2.2. Electric Powertrain Subsystem

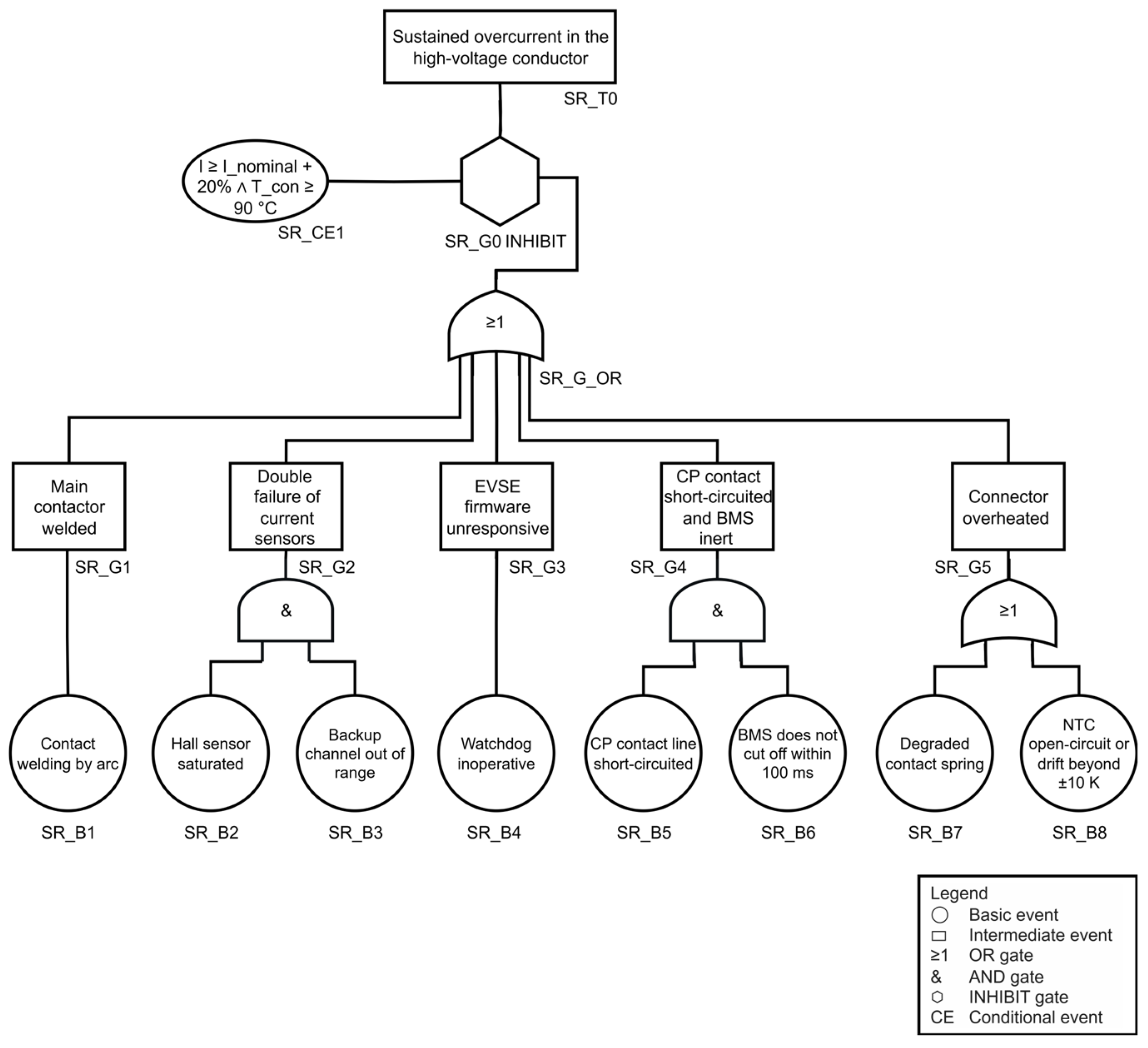

3.2.3. Charging System Subsystem

3.2.4. Cables and Connectors Subsystem

3.2.5. Calculations and Examples of the DRI

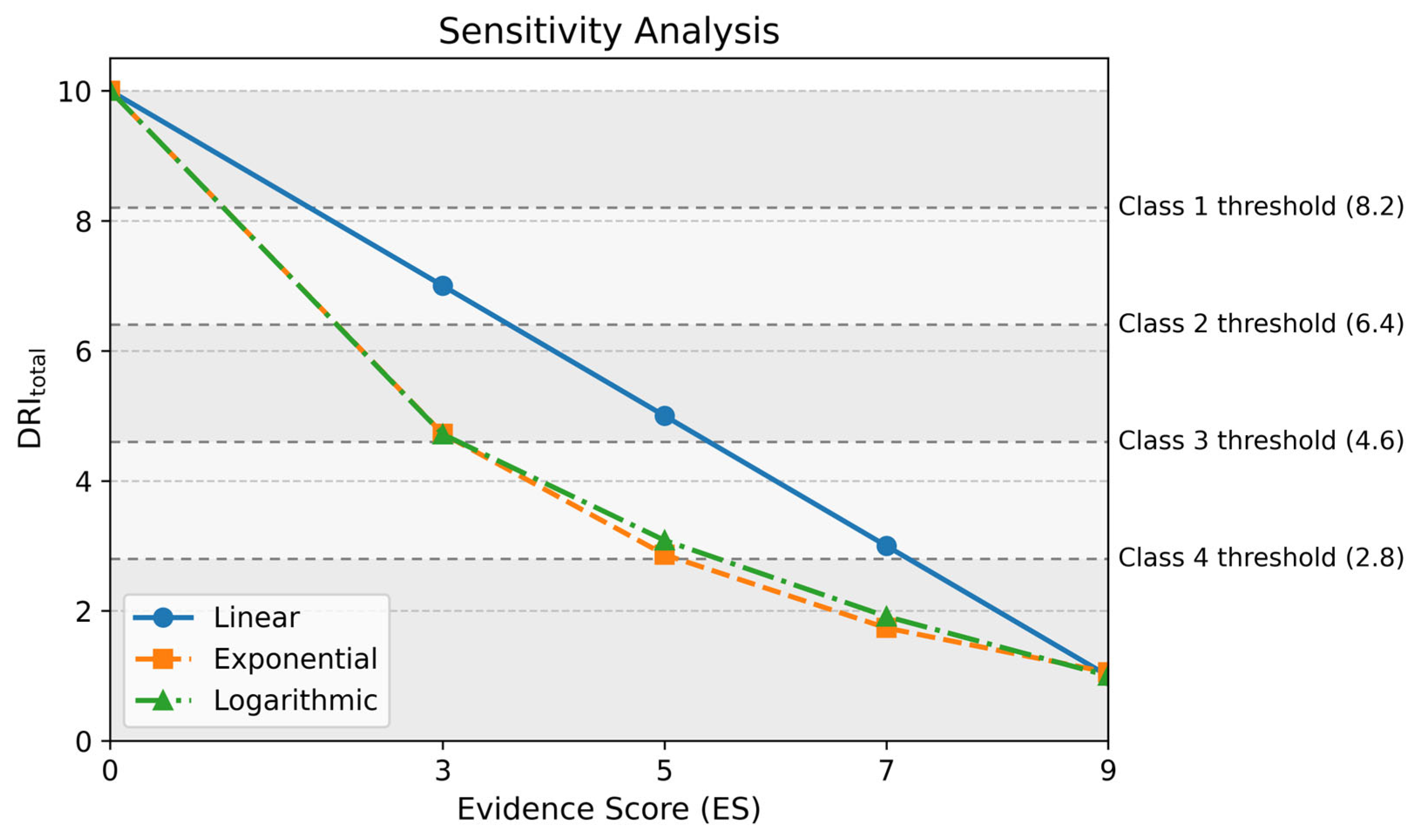

3.2.6. Sensitivity Analysis of the DRI Algorithm

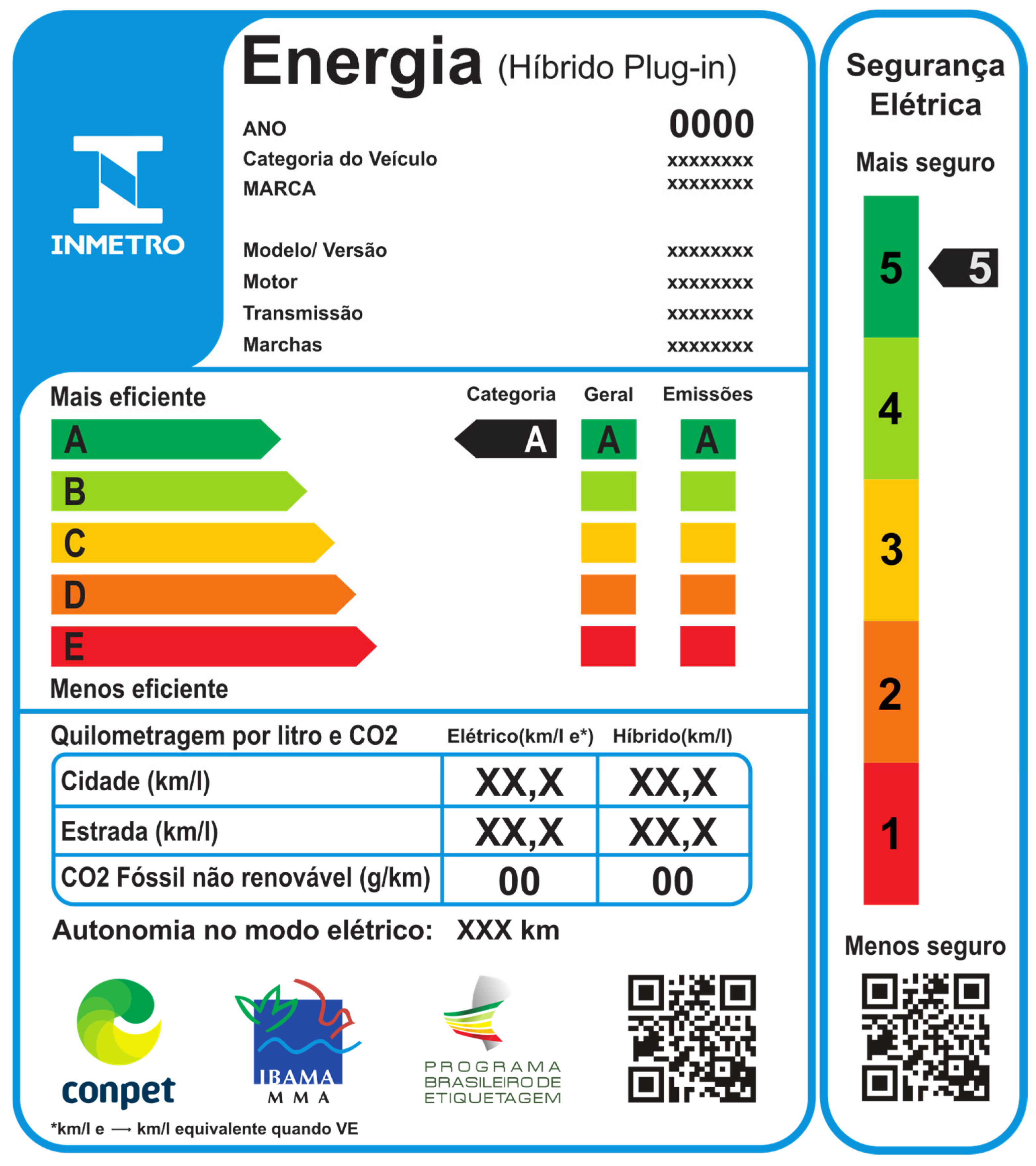

3.3. Proposed Structure of the Safety Label

3.4. Application Simulation

4. Discussion

4.1. Lessons Learned from International Models

4.2. Potential Benefits and Contributions

4.3. Governance, Updates, and Next Steps

4.3.1. Protocol Update

4.3.2. Cybersecurity Integration

4.3.3. Governance and Program Management

4.4. Challenges and Limitations

- Initial parametric robustness: The values assigned to Severity, Exposure, and Controllability are derived from international literature and engineering judgment. Although the generic HARA follows ISO 26262-3:2018 [17], the absence of national statistics could bias the RRI_gen. The pilot phase and the Delphi panel (Section 2.4) will enable the collection of field data to recalibrate these distributions. These records will subsequently be used to quantify the fault trees, gradually replacing the qualitative modeling with real occurrence rates and refining the S–E–C parameters.

- The assumption of independence among subsystems: The direct calculation of the DRI presupposes an absence of correlation between subsystem failures. In the pilot phase, empirical correlations must be estimated (as detailed in Section 2.2.4); if relevant, the model may be adjusted to incorporate coupling factors or common cause events in the FTAs.

- Linearization of the ASIL and model sensitivity: The conversion QM = 0.5, …, D = 4 is used solely for operational purposes and does not assume a real proportionality between the levels. Sensitivity tests (Section 2.2.5) indicated acceptable monotonicity, and the analysis in Section 3.2.6 showed that the model covers the entire scale (1–5) even in realistic and extreme ES scenarios, preserving the ordinal hierarchy and discriminatory power. However, the final adjustments of the linearization and class limits will depend on real data collected in the pilot phase, including complementary simulations based on realistic ES distributions, to ensure a better statistical fit to market data. These results show that the algorithm exhibits stable behavior, but its definitive calibration will be conditioned on empirical validation and the evolution of the protocol.

- Sample representativeness and subsystem coverage: The current protocol considers four high-voltage items, and the inclusion of new components will depend on Pareto analyses of the incidents recorded. Similarly, the simulated sample of 100 models (Section 3.4) must be compared with the actual fleet to validate the discriminatory power of the 1–5 scale.

- The cybersecurity dimension: Failures resulting from remote attacks can cause a loss of controllability without prior physical damage. The schedule for integrating the UN Regulation No. 155:2021 [122] and ISO/SAE 21434:2021 [123] module (Section 4.3.2) seeks to mitigate this gap, but it will require specific metrics and consistent integration with the Evidence Score (ES).

- Voluntary participation and governance: The program’s success is associated with a link to economic incentives and the transparency of audits. It will be necessary to define sustainable financing models to maintain the database and enable biennial revisions before implementation nationwide.

- Validation of the label layout: The graphic prototype (Figure 2, Section 3.3)—especially the ‘Electrical Safety’ column integrated into the ENCE—will be evaluated during the pilot phase for legibility, color contrast, and QR code ergonomics. Usability results may require dimensional or color adjustments before the final version, which would impact the industrial acceptance and communication effectiveness of the label.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADAS | Advanced driver assistance systems |

| AHP | Analytic Hierarchy Process |

| ARCAP | Auto Review Car Assessment Program |

| ASIL | Automotive safety integrity level |

| BEV | Battery electric vehicle |

| BMS | Battery management system |

| CATARC | China Automotive Technology and Research Center |

| CCS | Combined Charging System |

| CO2 | Carbon dioxide |

| CP | Control pilot |

| DOE | U.S. Department of Energy |

| DRI | Document Reliability Index |

| ECU | Electronic control unit |

| E/E | Electrical and electronic |

| ENCE | National Energy Conservation Label |

| EPA | U.S. Environmental Protection Agency |

| ES | Evidence Score |

| EV | Electric vehicle |

| EVSE | Electric vehicle supply equipment |

| FCV | Fuel cell vehicle |

| FS | Functional safety |

| FTA | Fault tree analysis |

| HARA | Hazard analysis and risk assessment |

| HV | High-voltage |

| HVAC | Heating, ventilation, and air conditioning |

| IAF-MLA | International Accreditation Forum Multilateral Recognition Arrangement |

| IIHS | Insurance Institute for Highway Safety |

| ILAC-MRA | International Laboratory Accreditation Cooperation Mutual Recognition Arrangement |

| Inmetro | Brazilian National Institute of Metrology, Quality and Technology |

| IRM | Insulation resistance monitoring |

| ISO | International Organization for Standardization |

| JNCAP | Japan New Car Assessment Program |

| KATRI | Korea Automobile Testing & Research Institute |

| KNCAP | Korean New Car Assessment Program |

| KOTSA | Korea Transportation Safety Authority |

| MCS | Minimal cut set |

| MOLIT | Ministry of Land, Infrastructure and Transport |

| MOSFET | Metal–oxide–semiconductor field-effect transistor |

| NCAP | New Car Assessment Program |

| NHTSA | U.S. National Highway Traffic Safety Administration |

| NMC | Lithium nickel manganese cobalt oxide |

| NTC | Negative temperature coefficient |

| PBE-V | Brazilian Vehicle Labeling Program |

| PHEV | Plug-in hybrid electric vehicle |

| Q10 | 10-year-old child dummy |

| QM | Quality management |

| QR code | Quick Response code |

| RDC-DD | Residual Direct Current Detection Device |

| RMS | Root mean square |

| RPN | Risk priority number |

| RRI_gen | Generic Relative Risk Index |

| RuNCAP | Russian New Car Assessment Program |

| SoC | State of Charge |

| UNECE | United Nations Economic Commission for Europe |

| VRU | Vulnerable road users |

| XLPE | Cross-linked polyethylene |

Appendix A

| ID | Event/Condition | Gate | S 1 |

|---|---|---|---|

| BT_T0 | Catastrophic battery pack fire during DC charging | EVENT | 3 |

| BT_G0 | BT_CE1 ∧ BT_G_OR | INHIBIT | – |

| BT_CE1 | SoC 2 ≥ 80% ∧ T_amb 3 ≥ 40 °C | COND | – |

| BT_G_OR | OR (BT_G1, …, BT_G4) | OR | – |

| BT_G1 | Internal short in cell | IE | 3 |

| BT_B1 | Internal defect (dendrite) | BASIC | 3 |

| BT_G2 | External short on the HV 4 busbar (BT_B2 ∧ BT_B3) | AND | – |

| BT_B2 | Failure of the HV 4 harness insulation | BASIC | 3 |

| BT_B3 | HV 4 contactor/fuse does not open | BASIC | 3 |

| BT_G3 | Charging overcurrent > 2C (BT_B4 ∨ BT_B5) | OR | – |

| BT_B4 | MOSFET 5 short-circuited | BASIC | 3 |

| BT_B5 | Incomplete CCS 6 protocol negotiation | BASIC | 2 |

| BT_G4 | Mechanical penetration | IE | 3 |

| BT_B6 | Side impact during charging | BASIC | 3 |

| MCS | Basic/Conditional Events | No. of Events |

|---|---|---|

| BT_MCS-1 | BT_CE1 + BT_B1 | 2 |

| BT_MCS-2 | BT_CE1 + BT_B2 + BT_B3 | 3 |

| BT_MCS-3 | BT_CE1 + BT_B4 | 2 |

| BT_MCS-4 | BT_CE1 + BT_B5 | 2 |

| BT_MCS-5 | BT_CE1 + BT_B6 | 2 |

Appendix B

| ID | Event/Condition | Gate | S 1 |

|---|---|---|---|

| MI_T0 | Sudden loss of traction | EVENT | 3 |

| MI_G0 | MI_CE1 ∧ MI_G_OR | INHIBIT | — |

| MI_CE1 | Vehicle under traction (>50 km·h−1) | COND | — |

| MI_G_OR | OR (MI_G1, …, MI_G5) | OR | — |

| MI_G1 | Inverter lock-up due to semiconductor short (MI_B1) | IE | — |

| MI_B1 | Power transistor in short-circuit | BASIC | 3 |

| MI_G2 | Loss of inverter power supply (MI_B2 ∨ MI_B3) | OR | — |

| MI_B2 | Gate driver shuts down inverter | BASIC | 3 |

| MI_B3 | HV 2 fuse trips | BASIC | 3 |

| MI_G3 | Interruption of the HV 2 circuit (pre-charge/DC 0 V) (MI_B4 ∨ MI_B5) | OR | — |

| MI_B4 | Pre-charge relay open | BASIC | 3 |

| MI_B5 | DC bus voltage < threshold | BASIC | 3 |

| MI_G4 | Severe motor/phase circuit failure (MI_B6 ∨ MI_B7) | OR | — |

| MI_B6 | HV 2 motor harness disconnected | BASIC | 3 |

| MI_B7 | Stator coil shorted or open | BASIC | 3 |

| MI_G5 | Failure of traction ECU 3 commands/sensors | IE | — |

| MI_B8 | Motor position/speed sensor fails | BASIC | 3 |

| MCS | Basic/Conditional Events | No. of Events |

|---|---|---|

| MI_MCS-1 | MI_CE1 + MI_B1 | 2 |

| MI_MCS-2 | MI_CE1 + MI_B2 | 2 |

| MI_MCS-3 | MI_CE1 + MI_B3 | 2 |

| MI_MCS-4 | MI_CE1 + MI_B4 | 2 |

| MI_MCS-5 | MI_CE1 + MI_B5 | 2 |

| MI_MCS-6 | MI_CE1 + MI_B6 | 2 |

| MI_MCS-7 | MI_CE1 + MI_B7 | 2 |

| MI_MCS-8 | MI_CE1 + MI_B8 | 2 |

Appendix C

| ID | Event/Condition | Gate | S 1 |

|---|---|---|---|

| SR_T0 | Sustained overcurrent in the high-voltage conductor | EVENT | 3 |

| SR_G0 | SR_CE1 ∧ SR_G_OR | INHIBIT | — |

| SR_CE1 | I ≥ I_nominal + 20% ∧ T_con 2 ≥ 90 °C | COND | — |

| SR_G_OR | OR (SR_G1, …, SR_G5) | OR | — |

| SR_G1 | Main contactor welded | IE | — |

| SR_B1 | Contact welding by arc | BASIC | 3 |

| SR_G2 | Double failure of current sensors (SR_B2 ∧ SR_B3) | AND | — |

| SR_B2 | Hall sensor saturated | BASIC | 3 |

| SR_B3 | Backup channel out of range | BASIC | 3 |

| SR_G3 | EVSE 3 firmware unresponsive | IE | — |

| SR_B4 | Watchdog inoperative | BASIC | 3 |

| SR_G4 | CP 4 contact short-circuited and BMS 5 inert (SR_B5 ∧ SR_B6) | AND | — |

| SR_B5 | CP 4 contact line short-circuited | BASIC | 3 |

| SR_B6 | BMS 5 does not cut off within 100 ms | BASIC | 3 |

| SR_G5 | Connector overheated (SR_B7 ∨ SR_B8) | OR | — |

| SR_B7 | Degraded contact spring | BASIC | 3 |

| SR_B8 | NTC 6 open-circuit or drift beyond ±10 K | BASIC | 3 |

| MCS | Basic/Conditional Events | No. of Events |

|---|---|---|

| SR_MCS-1 | SR_CE1 + SR_B1 | 2 |

| SR_MCS-2 | SR_CE1 + SR_B2 + SR_B3 | 3 |

| SR_MCS-3 | SR_CE1 + SR_B4 | 2 |

| SR_MCS-4 | SR_CE1 + SR_B5 + SR_B6 | 3 |

| SR_MCS-5 | SR_CE1 + SR_B7 | 2 |

| SR_MCS-6 | SR_CE1 + SR_B8 | 2 |

Appendix D

| ID | Event/Condition | Gate | S 1 |

|---|---|---|---|

| CC_T0 | Sustained electrical arc in the HV 2 harness | EVENT | 2 |

| CC_G0 | CC_CE1 ∧ CC_G_OR | INHIBIT | — |

| CC_CE1 | Continuous vibration ≥ 500 h·year−1 | COND | — |

| CC_G_OR | OR (CC_G1, …, CC_G7) | OR | — |

| CC_G1 | Abrasion of the insulating coating (CC_B1 ∨ CC_B2) | OR | — |

| CC_B1 | Repetitive cable–chassis friction | BASIC | 2 |

| CC_B2 | Loose or absent fastener | BASIC | 2 |

| CC_G2 | Thermal degradation and oxidation (CC_B3 ∧ CC_B4) | AND | — |

| CC_B3 | Exposure > 135 °C for 200 h | BASIC | 2 |

| CC_B4 | XLPE 3 oxidation | BASIC | 2 |

| CC_G3 | Slack in connector and high vibration (CC_B5 ∧ CC_B6) | AND | — |

| CC_B5 | Unengaged connector lock | BASIC | 2 |

| CC_B6 | Vibration > 10 g RMS 4 | BASIC | 2 |

| CC_G4 | Humidity in the harness (CC_B7 ∧ CC_B8) | AND | — |

| CC_B7 | Water infiltration | BASIC | 2 |

| CC_B8 | Inoperative humidity sensor | BASIC | 2 |

| CC_G5 | Failure of IRM 5 detection (CC_B9) | IE | — |

| CC_B9 | IRM 5 circuit with latent failure | BASIC | 2 |

| CC_G6 | Inoperative overcurrent protection (CC_B10) | IE | — |

| CC_B10 | HV 2 fuse does not open | BASIC | 2 |

| CC_G7 | Inoperative RDC-DD 6 protection (CC_B11 ∨ CC_B12) | OR | — |

| CC_B11 | Residual current sensor open/short-circuited | BASIC | 2 |

| CC_B12 | Detection algorithm locked (firmware) | BASIC | 2 |

| MCS | Basic/Conditional Events | No. of Events |

|---|---|---|

| CC_MCS-1 | CC_CE1 + CC_B1 | 2 |

| CC_MCS-2 | CC_CE1 + CC_B2 | 2 |

| CC_MCS-3 | CC_CE1 + CC_B3 + CC_B4 | 3 |

| CC_MCS-4 | CC_CE1 + CC_B5 + CC_B6 | 3 |

| CC_MCS-5 | CC_CE1 + CC_B7 + CC_B8 | 3 |

| CC_MCS-6 | CC_CE1 + CC_B9 | 2 |

| CC_MCS-7 | CC_CE1 + CC_B10 | 2 |

| CC_MCS-8 | CC_CE1 + CC_B11 | 2 |

| CC_MCS-9 | CC_CE1 + CC_B12 | 2 |

References

- International Energy Agency. Global EV Outlook 2022: Securing Supplies for an Electric Future; IEA: Paris, France, 2022. [Google Scholar]

- IEA. Global EV Outlook 2025: Expanding Sales in Diverse Markets; IEA: Paris, France, 2025. [Google Scholar]

- Bryła, P.; Chatterjee, S.; Ciabiada-Bryła, B. Consumer Adoption of Electric Vehicles: A Systematic Literature Review. Energies 2022, 16, 205. [Google Scholar] [CrossRef]

- Barassa, E. A Construção de Uma Agenda Para a Eletromobilidade No Brasil: Competências Tecnológicas e Governança. Ph.D. Thesis, Universidade Estadual de Campinas, Campinas, Brazil, 2019. [Google Scholar]

- Koniak, M.; Jaskowski, P.; Tomczuk, K. Review of Economic, Technical and Environmental Aspects of Electric Vehicles. Sustainability 2024, 16, 9849. [Google Scholar] [CrossRef]

- ISO 26262:2018; Road Vehicles—Functional Safety (All Parts). International Organization for Standardization: Geneva, Switzerland, 2018.

- Sanguesa, J.A.; Torres-Sanz, V.; Garrido, P.; Martinez, F.J.; Marquez-Barja, J.M. A Review on Electric Vehicles: Technologies and Challenges. Smart Cities 2021, 4, 372–404. [Google Scholar] [CrossRef]

- Huang, X.; Lin, Y.; Lim, M.K.; Tseng, M.-L.; Zhou, F. The Influence of Knowledge Management on Adoption Intention of Electric Vehicles: Perspective on Technological Knowledge. Ind. Manag. Data Syst. 2021, 121, 1481–1495. [Google Scholar] [CrossRef]

- Tanţău, A.; Gavrilescu, I. Key Anxiety Factors for Buying an Electric Vehicle. Manag. Mark. Chall. Knowl. Soc. 2019, 14, 240–248. [Google Scholar] [CrossRef]

- Velandia Vargas, J.E.; Seabra, J.E.A.; Cavaliero, C.K.N.; Walter, A.C.S.; Souza, S.P.; Falco, D.G. The New Neighbor across the Street: An Outlook for Battery Electric Vehicles Adoption in Brazil. World Electr. Veh. J. 2020, 11, 60. [Google Scholar] [CrossRef]

- ISO 26262-1:2018; Road Vehicles—Functional Safety—Part 1: Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2018.

- IEC 62660-1:2018; Secondary Lithium-Ion Cells for the Propulsion of Electric Road Vehicles—Part 1: Performance Testing. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- ISO 6469-3:2021; Electrically Propelled Road Vehicles—Safety Specifications—Part 3: Electrical Safety. International Organization for Standardization: Geneva, Switzerland, 2021.

- Ruiz, V.; Pfrang, A.; Kriston, A.; Omar, N.; Van den Bossche, P.; Boon-Brett, L. A Review of International Abuse Testing Standards and Regulations for Lithium Ion Batteries in Electric and Hybrid Electric Vehicles. Renew. Sustain. Energy Rev. 2018, 81, 1427–1452. [Google Scholar] [CrossRef]

- ISO 21448:2022; Road Vehicles—Safety of the Intended. International Organization for Standardization: Geneva, Switzerland, 2022.

- Portaria No. 169, de 3 de Maio de 2023; Instituto Nacional de Metrologia, Qualidade e Tecnologia: Rio de Janeiro, Brazil, 2023.

- ISO 26262-3:2018; Road Vehicles—Functional Safety—Part 3: Concept Phase. International Organization for Standardization: Geneva, Switzerland, 2018.

- Kellermann, M. Ensuring Quality to Gain Access to Global Markets: A Reform Toolkit; World Bank: Washington, DC, USA; Physikalisch-Technische Bundesanstalt: Braunschweig, Germany, 2019. [Google Scholar]

- Global NCAP. Vehicle Safety Rating Labelling Schemes for Consumers; Global New Car Assessment Programme: London, UK, 2023. [Google Scholar]

- National Highway Traffic Safety Administration. New Car Assessment Program Final Decision Notice—Advanced Driver Assistance Systems and Roadmap; NHTSA: Washington, DC, USA, 2024.

- National Highway Traffic Safety Administration. 49 CFR § 575.302—Vehicle Labeling of Safety Rating Information; NHTSA: Washington, DC, USA, 2023.

- National Highway Traffic Safety Administration. New Car Assessment Program; Request for Comments. Fed. Regist. 2023, 88, 34366–34410. [Google Scholar]

- U.S. Environmental Protection Agency; National Highway Traffic Safety Administration. Revisions and Additions to Motor Vehicle Fuel Economy Label. Fed. Regist. 2011, 76, 39478–39577. [Google Scholar]

- U.S. Government Publishing Office. Code of Federal Regulations. Title 40, Part 600, Subpart D—Fuel Economy Labeling; U.S. Government Publishing Office: Washington, DC, USA, 2024.

- U.S. Environmental Protection Agency. Learn About the Fuel Economy and Environment Label. Available online: https://www.epa.gov/greenvehicles/learn-about-fuel-economy-label (accessed on 23 May 2025).

- U.S. Department of Energy; U.S. Environmental Protection Agency. Learn More about the Fuel Economy Label for Electric Vehicles. Available online: https://www.fueleconomy.gov/feg/label/learn-more-electric-label.shtml (accessed on 23 May 2025).

- United States Congress. 49 U.S.C. § 32908—Fuel Economy Information; U.S. Government Publishing Office: Washington, DC, USA, 2023.

- U.S. Government Publishing Office. Code of Federal Regulations. Title 49, § 575.401—Vehicle Labeling of Fuel Economy, Greenhouse Gas and Other Pollutant Emissions Information; U.S. Government Publishing Office: Washington, DC, USA, 2023.

- CATARC. C-NCAP Management Regulation, 2021 ed.; China Automotive Technology and Research Center: Tianjin, China, 2020. [Google Scholar]

- CATARC. C-NCAP Official Website—About Us. Available online: https://www.c-ncap.org.cn/aboutus?columnId=7b969748ec9f442da3e708a0fa56c0f9 (accessed on 20 May 2025).

- CATARC. C-NCAP Management Regulation, 2024 ed.; China Automotive Technology and Research Center: Tianjin, China, 2024. [Google Scholar]

- CATARC. C-NCAP Technical Questions & Answers—FAQ. Available online: https://www.c-ncap.org.cn/questions-and-answers/cncap?columnId=00455c387ea911e8865ddbe7f209548c (accessed on 20 May 2025).

- CATARC. Industry Think Tank—Government Technical Support Section. Available online: https://www.catarc.ac.cn/zyyw/hyzk.html (accessed on 20 May 2025).

- Ministry of Land Infrastructure and Transport. KNCAP 20th Anniversary Ceremony—Press Release. Available online: https://www.molit.go.kr/english/USR/BORD0201/m_28286/DTL.jsp?id=eng_mltm_new&mode=view&idx=2894 (accessed on 22 May 2025).

- Ministry of Land Infrastructure and Transport. Regulation on Motor-Vehicle Safety Evaluation (MOLIT Notice 2022-305, effective 3 Jun 2022); MOLIT: Sejong, Republic of Korea, 2022. [Google Scholar]

- Ministry of Land Infrastructure and Transport. KNCAP Test and Assessment Protocol—GR-OP-1: General Provisions (Report No. GR-OP-1); MOLIT: Sejong, Republic of Korea, 2025. [Google Scholar]

- Ministry of Land Infrastructure and Transport. KNCAP Test and Assessment Protocol—GR-AP-1: Method for Calculating the Comprehensive Safety Grade (Report No. GR-AP-1); MOLIT: Sejong, Republic of Korea, 2025. [Google Scholar]

- Korea Transportation Safety Authority. KNCAP Test Results Portal— Automobile Safety Evaluation Results. Available online: https://www.kncap.org/indexNew.jsp (accessed on 22 May 2025).

- Korea Transportation Safety Authority. Vehicle Safety Research—KATRI (Brochure). Available online: https://main.kotsa.or.kr/resources/upload/2024/08/brochure_eng_202408.pdf (accessed on 22 May 2025).

- Ministry of Land Infrastructure and Transport. Regulation for Enforcement of the Motor-Vehicle Management Act (Ordinance No. 1484); MOLIT: Sejong, Republic of Korea, 2025. [Google Scholar]

- Ministry of Land Infrastructure and Transport. KNCAP Test and Assessment Protocol—GR-OP-2: Requirements and Procedures for Re-Tests (Report No. GR-OP-2); MOLIT: Sejong, Republic of Korea, 2025. [Google Scholar]

- Euro NCAP. Euro NCAP Vision 2030: A Safer Future for Mobility; Euro NCAP: Leuven, Belgium, 2022. [Google Scholar]

- Euro NCAP. Assessment Protocol—Adult Occupant Protection, Version 9.3; Euro NCAP: Leuven, Belgium, 2023. [Google Scholar]

- Euro NCAP. Visual Identity Guidelines 2025, Version 2; Euro NCAP: Leuven, Belgium, 2025. [Google Scholar]

- Euro NCAP. Application of Star Ratings Protocol, Version 1.8.1; Euro NCAP: Leuven, Belgium, 2021. [Google Scholar]

- Euro NCAP. Test Protocol—AEB/LSS VRU Systems, Version 4.5.1; Euro NCAP: Leuven, Belgium, 2024. [Google Scholar]

- Euro NCAP. Test Protocol—AEB Car-to-Car Systems, Version 4.3.1; Euro NCAP: Leuven, Belgium, 2024. [Google Scholar]

- Euro NCAP. Vehicle Selection, Specification, Testing and Retesting (VSSTR) Protocol, Version 7.4.3; Euro NCAP: Leuven, Belgium, 2021. [Google Scholar]

- Euro NCAP. Assessment Protocol—Safety Assist: Safe Driving, Version 10.4; Euro NCAP: Leuven, Belgium, 2024. [Google Scholar]

- Euro NCAP. Assessment Protocol—Safety Assist: Collision Avoidance, Version 10.4.1; Euro NCAP: Leuven, Belgium, 2024. [Google Scholar]

- Euro NCAP. Assessment Protocol—Child Occupant Protection, Version 8.1; Euro NCAP: Leuven, Belgium, 2023. [Google Scholar]

- Green NCAP. Green NCAP Announces Final LCA Awardees: The Greenest Cars of 2024. Available online: https://www.greenncap.com/press-releases/greenest-cars-2024/ (accessed on 23 May 2025).

- Green NCAP. Consortium—Green NCAP. Available online: https://www.greenncap.com/members/ (accessed on 25 May 2025).

- Green NCAP. Rating Procedure 2022 Version 3.0.0; Green NCAP: Leuven, Belgium, 2022. [Google Scholar]

- Green NCAP. Greener Choice: LCA Award—Calculation Rules and Criteria; Green NCAP: Leuven, Belgium, 2024. [Google Scholar]

- Green NCAP. Overall Test Procedure Version 3.0.0; Green NCAP: Leuven, Belgium, 2022. [Google Scholar]

- Jungmeier, G.; Meltzer, A.; Beermann, M. Estimated Greenhouse Gas Emissions and Primary Energy Demand of Passenger Vehicles—Life Cycle Assessment Methodology and Data; Green NCAP: Leuven, Belgium, 2024. [Google Scholar]

- Green NCAP. WLTC+ CAT (Cold Ambient Temperature) Test Procedure Version 2.0.0; Green NCAP: Leuven, Belgium, 2022. [Google Scholar]

- Green NCAP. WLTC+ Test Procedure (World-Harmonised Light-Duty Vehicle Test Cycle Custom Tailored for Green NCAP) Version 3.0.0; Green NCAP: Leuven, Belgium, 2022. [Google Scholar]

- Green NCAP. PEMS+ Test Procedure (Real-World Environmental Performance Custom Tailored for Green NCAP) Version 3.0.0; Green NCAP: Leuven, Belgium, 2022. [Google Scholar]

- Green NCAP. Special Requirements for Hybrid Electric Vehicles Version 2.0.0; Green NCAP: Leuven, Belgium, 2022. [Google Scholar]

- Latin NCAP. Latin NCAP—About Us. Available online: https://www.latinncap.com/en/about-us (accessed on 25 May 2025).

- Furas, A.; Ramos, J.; Bhalla, K.; Garrido, N.; Zamora, E. Mejora de Los Estándares de Seguridad de Los Vehículos En América Latina y El Caribe a Través de La Adopción de Reglamentos ONU y Sistemas de Información al Consumidor: Informe Final Del Proyecto Bien Público Regional (BPR); Banco Interamericano de Desarrollo: Washington, DC, USA, 2019. [Google Scholar]

- Latin NCAP. Car Specification, Sponsorship, Testing and Retesting Protocol 2020–2024, Version 1.1.2; Latin NCAP: Montevideo, Uruguay, 2020. [Google Scholar]

- Latin NCAP. Assessment Protocol—Safety Assist (2026–2029); Latin NCAP: Montevideo, Uruguay, 2024. [Google Scholar]

- Latin NCAP. Testing Protocols (2026–2029); Latin NCAP: Montevideo, Uruguay, 2024. [Google Scholar]

- Latin NCAP. Assessment Protocol—Adult Occupant Protection (2026–2029); Latin NCAP: Montevideo, Uruguay, 2024. [Google Scholar]

- Euro NCAP. TB 011—Technical Bulletin—Testing of Electric Vehicles, Version 1.0; Euro NCAP: Leuven, Belgium, 2010. [Google Scholar]

- Latin NCAP. Testing Protocol—Moose Test, Version 1.0.1; Latin NCAP: Montevideo, Uruguay, 2020. [Google Scholar]

- Latin NCAP. Assessment Protocol—Adult Occupant Protection (2020–2024); Latin NCAP: Montevideo, Uruguay, 2020. [Google Scholar]

- Latin NCAP. Assessment Protocol—Child Occupant Protection (2020–2024); Latin NCAP: Montevideo, Uruguay, 2020. [Google Scholar]

- Latin NCAP. Assessment Protocol—Child Occupant Protection (2026–2029); Latin NCAP: Montevideo, Uruguay, 2024. [Google Scholar]

- Latin NCAP. Assessment Protocol—Safety Assist (2020–2024); Latin NCAP: Montevideo, Uruguay, 2020. [Google Scholar]

- Latin NCAP. Assessment Protocol—Pedestrian Protection (2020–2024); Latin NCAP: Montevideo, Uruguay, 2020. [Google Scholar]

- Latin NCAP. Assessment Protocol—Pedestrian Protection (2026–2029); Latin NCAP: Montevideo, Uruguay, 2024. [Google Scholar]

- Latin NCAP. Assessment Protocol—Overall Rating (2020–2024); Latin NCAP: Montevideo, Uruguay, 2020. [Google Scholar]

- Latin NCAP. Assessment Protocol—Overall Rating (2026–2029); Latin NCAP: Montevideo, Uruguay, 2024. [Google Scholar]

- Ibama; Inmetro. Portaria Conjunta No 2, de 16 de Dezembro de 2010; Instituto Brasileiro do Meio Ambiente e dos Recursos Naturais Renováveis: Brasília, Brazil; Instituto Nacional de Metrologia, Qualidade e Tecnologia: Rio de Janeiro, Brazil, 2010.

- Inmetro. Programa Completa 15 Anos Em 2023 e Abrange 100% Da Frota. Available online: https://www.gov.br/inmetro/pt-br/centrais-de-conteudo/noticias/inmetro-publica-portaria-com-aperfeicoamentos-do-pbe-veicular (accessed on 23 May 2025).

- Brasil. Lei No 14.902, de 27 de Junho de 2024; Diário Oficial da União: Brasília, Brazil, 2024.

- ABNT NBR 7024:2017; Veículos Rodoviários Automotores—Determinação Do Consumo de Combustível Em Veículos Leves. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2017.

- Ministério da Indústria Comércio Exterior e Serviços. Portaria No 2.202, de 28 de Dezembro de 2018; Diário Oficial da União: Brasília, Brazil, 2018.

- SAE J1634:2020; Electric Vehicle Energy Consumption and Range Test Procedure. SAE International: Warrendale, PA, USA, 2020.

- ABNT NBR 16567:2020; Veículos Rodoviários Automotores—Veículos Elétricos e Híbridos—Procedimento de Ensaio Para Determinação Do Consumo de Energia Elétrica, Autonomia e Eficiência Energética. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2020.

- Inmetro. Veículos Leves 2025—17.o Ciclo: Tabela Técnica Do PBE-V; Instituto Nacional de Metrologia, Qualidade e Tecnologia: Rio de Janeiro, Brazil, 2025.

- IEC 62660-2:2018; Secondary Lithium-Ion Cells for the Propulsion of Electric Road Vehicles—Part 2: Reliability and Abuse Testing. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- IEC 61851-1:2017; Electric Vehicle Conductive Charging System—Part 1: General Requirements. International Electrotechnical Commission: Geneva, Switzerland, 2017.

- IEC 61851-23:2023; Electric Vehicle Conductive Charging System—Part 23: DC Electric Vehicle Supply Equipment. International Electrotechnical Commission: Geneva, Switzerland, 2023.

- IEC 62196-3:2022; Plugs, Socket-Outlets, Vehicle Connectors and Vehicle Inlets—Conductive of Electric Vehicles—Part 3: Dimensional Compatibility Requirements for DC and AC/DC Pin and Contact-Tube Vehicle Couplers. International Electrotechnical Commission: Geneva, Switzerland, 2022.

- ISO 26262-2:2018; Road Vehicles—Functional Safety—Part 2: Management of Functional Safety. International Organization for Standardization: Geneva, Switzerland, 2018.

- Arvidsson, R. On the Use of Ordinal Scoring Scales in Social Life Cycle Assessment. Int. J. Life Cycle Assess. 2019, 24, 604–606. [Google Scholar] [CrossRef]

- IEC 60812:2018; Failure Modes and Effects Analysis (FMEA and FMECA). International Electrotechnical Commission: Geneva, Switzerland, 2018.

- ISO/IEC 17011:2017; Conformity Assessment—Requirements for Accreditation Bodies Accrediting Conformity Assessment Bodies. International Organization for Standardization/International Electrotechnical Commission: Geneva, Switzerland, 2017.

- International Laboratory Accreditation Cooperation; International Accreditation Forum. Recommended Guide for Engaging with Government & Regulators; ILAC: Silverwater, Australia; IAF: Chelsea, QC, Canada, 2018. [Google Scholar]

- International Laboratory Accreditation Cooperation; International Accreditation Forum. Accreditation: A Global Tool to Support Public Policy; ILAC: Silverwater, Australia; IAF: Chelsea, QC, Canada, 2023. [Google Scholar]

- ISO/IEC 17065:2012; Conformity Assessment—Requirements for Bodies Certifying Products, Processes and Services. International Organization for Standardization/International Electrotechnical Commission: Geneva, Switzerland, 2012.

- ISO/IEC 17025:2017; General Requirements for the Competence of Testing and Calibration Laboratories. International Organization for Standardization/International Electrotechnical Commission: Geneva, Switzerland, 2017.

- IEC 61025:2006; Fault Tree Analysis (FTA). International Electrotechnical Commission: Geneva, Switzerland, 2006.

- ISO 26262-8:2018; Road Vehicles—Functional Safety—Part 8: Supporting Processes. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 26262-5:2018; Road Vehicles—Functional Safety—Part 5: Product Development at the Hardware Level. International Organization for Standardization: Geneva, Switzerland, 2018.

- IEC 61709:2017; Electric Components—Reliability—Reference Conditions for Failure Rates and Stress Models for Conversion. International Electrotechnical Commission: Geneva, Switzerland, 2017.

- Dorsz, A.; Lewandowski, M. Analysis of Fire Hazards Associated with the Operation of Electric Vehicles in Enclosed Structures. Energies 2021, 15, 11. [Google Scholar] [CrossRef]

- Bąkowski, H.; Przytuła, I.; Cebulska, W.; Hadryś, D.; Ćwiek, J. The Impact of Mechanical Failure of 18650 Batteries on the Safety of Electric Transport Operations. Energies 2024, 17, 5980. [Google Scholar] [CrossRef]

- Vega-Muratalla, V.O.; Ramírez-Márquez, C.; Lira-Barragán, L.F.; Ponce-Ortega, J.M. Review of Lithium as a Strategic Resource for Electric Vehicle Battery Production: Availability, Extraction, and Future Prospects. Resources 2024, 13, 148. [Google Scholar] [CrossRef]

- Jiang, L.; Diao, X.; Zhang, Y.; Zhang, J.; Li, T. Review of the Charging Safety and Charging Safety Protection of Electric Vehicles. World Electr. Veh. J. 2021, 12, 184. [Google Scholar] [CrossRef]

- Spotnitz, R.; Franklin, J. Abuse Behavior of High-Power, Lithium-Ion Cells. J. Power Sources 2003, 113, 81–100. [Google Scholar] [CrossRef]

- Wang, C.-Y.; Liu, T.; Yang, X.-G.; Ge, S.; Stanley, N.V.; Rountree, E.S.; Leng, Y.; McCarthy, B.D. Fast Charging of Energy-Dense Lithium-Ion Batteries. Nature 2022, 611, 485–490. [Google Scholar] [CrossRef]

- Sun, P.; Bisschop, R.; Niu, H.; Huang, X. A Review of Battery Fires in Electric Vehicles. Fire Technol. 2020, 56, 1361–1410. [Google Scholar] [CrossRef]

- Zhang, Z.; Dong, H.; Wang, L.; Wang, Y.; He, X. Tracing Root Causes of Electric Vehicle Fires. Energy Technol. 2024, 12, 2400931. [Google Scholar] [CrossRef]

- Choudhary, A.; Fatima, S.; Panigrahi, B.K. State-of-the-Art Technologies in Fault Diagnosis of Electric Vehicles: A Component-Based Review. IEEE Trans. Transp. Electrif. 2023, 9, 2324–2347. [Google Scholar] [CrossRef]

- Rajashekara, K. Present Status and Future Trends in Electric Vehicle Propulsion Technologies. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 3–10. [Google Scholar] [CrossRef]

- Khaneghah, M.Z.; Alzayed, M.; Chaoui, H. Fault Detection and Diagnosis of the Electric Motor Drive and Battery System of Electric Vehicles. Machines 2023, 11, 713. [Google Scholar] [CrossRef]

- Pereirinha, P.G. Electric Vehicles. In Encyclopedia of Electrical and Electronic Power Engineering; García, J., Ed.; Elsevier: Oxford, UK, 2023; Volume 1, pp. 350–387. [Google Scholar]

- Linja-Aho, V. Electric Vehicle Charging Safety—The State of Art, Best Practices, and Regulatory Aspects. In Proceedings of the 2024 IEEE IAS Electrical Safety Workshop (ESW), Tucson, AZ, USA, 4–8 March 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–10. [Google Scholar]

- Wang, B.; Dehghanian, P.; Wang, S.; Mitolo, M. Electrical Safety Considerations in Large-Scale Electric Vehicle Charging Stations. IEEE Trans. Ind. Appl. 2019, 55, 6603–6612. [Google Scholar] [CrossRef]

- Larsson, F.; Andersson, P.; Mellander, B.E. Are Electric Vehicles Safer than Combustion Engine Vehicles? In Systems Perspectives on Electromobility; Sandén, B., Ed.; Chalmers University of Technology: Gothenburg, Sweden, 2013; pp. 33–44. [Google Scholar]

- De Hoog, J.; Jaguemont, J.; Abdel-Monem, M.; Van Den Bossche, P.; Van Mierlo, J.; Omar, N. Combining an Electrothermal and Impedance Aging Model to Investigate Thermal Degradation Caused by Fast Charging. Energies 2018, 11, 804. [Google Scholar] [CrossRef]

- Liu, Y.; Swingler, J.; Flynn, D. Failure Mode Mechanism and Effect Analysis of High Voltage DC Arcs in Electric Vehicle Cable. In Proceedings of the 2021 6th Asia Conference on Power and Electrical Engineering (ACPEE), Chongqing, China, 8–11 April 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 6–13. [Google Scholar]

- Han, T.; Li, W.; Zheng, Z.; Li, Y.; Chu, J.; Hao, C. Insulation Aging Evaluation Method of High Voltage Cable Based on Dielectric Loss Characteristics. Energies 2025, 18, 1267. [Google Scholar] [CrossRef]

- Zhang, Y.; Hou, Z.; Wu, K.; Wang, S.; Li, J.; Li, S. Influence of Oxygen Diffusion on Thermal Ageing of Cross-Linked Polyethylene Cable Insulation. Materials 2020, 13, 2056. [Google Scholar] [CrossRef] [PubMed]

- Inmetro. Máscara PBEV 2025—Programa Brasileiro de Etiquetagem Veicular. Available online: https://www.gov.br/inmetro/pt-br/assuntos/avaliacao-da-conformidade/programa-brasileiro-de-etiquetagem/tabelas-de-eficiencia-energetica/veiculos-automotivos-pbe-veicular/mascara-pbev-2025-mar-11.pdf/view (accessed on 12 August 2025).

- UNECE. UN Regulation No. 155—Uniform Provisions Concerning the Approval of Vehicles with Regards to Cyber Security and Cyber Security Management System; United Nations Economic Commission for Europe: Geneva, Switzerland, 2021. [Google Scholar]

- ISO/SAE 21434:2021; Road Vehicles—Cybersecurity Engineering. International Organization for Standardization: Geneva, Switzerland; SAE International: Warrendale, PA, USA, 2021.

- ISO/IEC 17067:2013; Conformity Assessment—Fundamentals of Product Certification and Guidelines for Product Certification Schemes. International Organization for Standardization/International Electrotechnical Commission: Geneva, Switzerland, 2013.

| Program | Region | Program Type | Technical Focus | Classification System | Physical Label |

|---|---|---|---|---|---|

| NHTSA NCAP | USA | Governmental informative | Vehicle safety | Stars (1–5) | Mandatory only for tested vehicles |

| C-NCAP | China | Governmental voluntary | Vehicle safety | Stars (0–5) + Super Five-Star seal | Not mandatory |

| KNCAP | Republic of Korea | Governmental informative | Vehicle safety | Classes (1–5) | Not mandatory |

| Euro NCAP | Europe | Independent voluntary | Vehicle safety | Stars (0–5) | Not mandatory |

| Latin NCAP | Latin America and the Caribbean | Independent voluntary | Vehicle safety | Stars (0–5) | Not mandatory |

| EPA/DOE Label | USA | Governmental regulatory | Energy efficiency, emissions, and cost of use | Emissions indices (1–10) + energy consumption (absolute) | Mandatory |

| Green NCAP | Europe | Independent voluntary | Energy efficiency, emissions, and life-cycle | Green stars (0–5) | Not mandatory |

| PBE-V (Inmetro) | Brazil | Governmental informative | Energy efficiency and emissions | Classes (A–E) | Mandatory for participating vehicles |

| Parameter | Class | Justification |

|---|---|---|

| Severity | S3 | Catastrophic fire with the potential for multiple casualties |

| Exposure | E3 | Frequent use of fast DC charging |

| Controllability | C3 | Cell-to-module propagation in minutes; driver has no means of containment |

| Parameter | Class | Justification |

|---|---|---|

| Severity | S3 | Sudden loss of directional control, with the potential for high-energy collision and fatal injuries |

| Exposure | E3 | Failure is possible during active driving (medium frequency) |

| Controllability | C3 | Instantaneous overcurrent; the driver has no means of mitigation |

| Parameter | Class | Justification |

|---|---|---|

| Severity | S3 | Localized overheating with fire risk in the connector, with the potential for a vehicle fire |

| Exposure | E3 | Fast DC charging is used frequently in intensive urban cycles |

| Controllability | C3 | Progressive and unperceivable heating; user has no means of direct intervention |

| Parameter | Class | Justification |

|---|---|---|

| Severity | S2 | Localized electrical arc can cause severe burns or a localized fire (serious injuries) |

| Exposure | E3 | Vibration/abrasion in urban use; monthly or more frequent occurrence |

| Controllability | C2 | Protective devices interrupt the circuit with a delay; situations remain “normally controllable” (>90%) |

| Subsystem | S–E–C | ASIL_gen | RRI_gen |

|---|---|---|---|

| Battery | S3–E3–C3 | C | 3 |

| Electric Powertrain | S3–E3–C3 | C | 3 |

| Charging System | S3–E3–C3 | C | 3 |

| Cables and Connectors | S2–E3–C2 | A | 1 |

| ES | DRI_lin | Class_lin | DRI_exp | Class_exp | DRI_log | Class_log |

|---|---|---|---|---|---|---|

| 0 | 10.00 | 1 | 10.00 | 1 | 10.00 | 1 |

| 3 | 7.00 | 2 | 4.72 | 3 | 4.72 | 3 |

| 5 | 5.00 | 3 | 2.87 | 4 | 3.08 | 4 |

| 7 | 3.00 | 4 | 1.74 | 5 | 1.90 | 5 |

| 9 | 1.00 | 5 | 1.05 | 5 | 1.00 | 5 |

| Scenario | ES Configuration 1 | DRI_lin | Class_lin | DRI_exp | Class_exp | DRI_log | Class_log |

|---|---|---|---|---|---|---|---|

| S-2 (min) | 9 9 9 7 | 1.20 | 5 | 1.12 | 5 | 1.09 | 5 |

| S-2 (max) | 5 5 5 3 | 5.20 | 3 | 3.05 | 4 | 3.25 | 4 |

| S-3 (min) | QM, ES = 9 | 0.20 | 5 | 0.21 | 5 | 0.20 | 5 |

| S-3 (max) | ASIL D, ES = 0 | 16.00 | 1 | 16.00 | 1 | 16.00 | 1 |

| Class | DRI_total Range | n | Average DRI_total |

|---|---|---|---|

| 5 (safest) | <2.8 | 12 | 2.24 |

| 4 | ≥2.8 and <4.6 | 30 | 3.65 |

| 3 | ≥4.6 and <6.4 | 34 | 5.33 |

| 2 | ≥6.4 and <8.2 | 19 | 7.20 |

| 1 (least safe) | ≥8.2 | 5 | 8.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mianes, R.L.; Reguly, A.; ten Caten, C.S. The Brazilian Program for Functional Safety Labeling of Critical Subsystems in Electric Vehicles: A Framework Based on Risk and Evidence. World Electr. Veh. J. 2025, 16, 644. https://doi.org/10.3390/wevj16120644

Mianes RL, Reguly A, ten Caten CS. The Brazilian Program for Functional Safety Labeling of Critical Subsystems in Electric Vehicles: A Framework Based on Risk and Evidence. World Electric Vehicle Journal. 2025; 16(12):644. https://doi.org/10.3390/wevj16120644

Chicago/Turabian StyleMianes, Rodrigo Leão, Afonso Reguly, and Carla Schwengber ten Caten. 2025. "The Brazilian Program for Functional Safety Labeling of Critical Subsystems in Electric Vehicles: A Framework Based on Risk and Evidence" World Electric Vehicle Journal 16, no. 12: 644. https://doi.org/10.3390/wevj16120644

APA StyleMianes, R. L., Reguly, A., & ten Caten, C. S. (2025). The Brazilian Program for Functional Safety Labeling of Critical Subsystems in Electric Vehicles: A Framework Based on Risk and Evidence. World Electric Vehicle Journal, 16(12), 644. https://doi.org/10.3390/wevj16120644