1. Introduction

The rapid development of the automotive industry has brought about earth-shaking changes to the world, especially the flourishing development of electric vehicles (EVs) worldwide [

1]. As the energy source of EVs, the power battery plays a crucial role. Lithium batteries have become the core energy source of EVs due to their outstanding advantages, such as high energy density, good cycling characteristics, and no memory effect. The performance and safety of their systems are particularly critical [

2]. Users generally express the core concern of low-temperature endurance in the promotion and application of EVs. Range anxiety comes from the serious decline in the performance of the power battery in low temperatures. As the core energy source of vehicles, it directly affects the performance of vehicles [

3,

4]. Low temperature not only affects the performance of vehicles but also brings irreversible degradation of battery performance (decrease in capacity retention) and irreversible damage (internal structural changes, low-temperature lithium deposition), accelerating battery aging [

5,

6]. As the primary guarantee for battery performance and safety, the battery thermal management system should optimize the working environment of the battery, control the battery to operate within the allowable temperature range, and improve the performance. Therefore, attempting to develop an efficient thermal management system to solve the performance degradation dilemma faced by batteries in low temperatures has important academic value and practical significance and is also in line with the current trend of “high-end” development of battery technology.

The main technical solutions for low-temperature thermal management can be divided into two categories: internal heating and external heating. The internal heating method increases heat generation by creating a large internal resistance at low temperatures, thereby achieving heating of the battery [

7]. Its main features are no intermediate steps for heat transfer, no need for additional heat transfer systems or circuit components, ensuring uniform heating of the battery, and overall fast and efficient heating [

8]. In specific applications, internal heating can be divided into alternating current heating and self-heating. The alternating current heating is affected by factors such as application voltage, frequency, current form, and current amplitude [

9,

10,

11]. In related studies, alternating current can effectively heat a lithium battery during low-temperature charging, but under low-frequency application conditions, it is prone to lithium-ion deposition [

12] and battery aging [

13]. Although there have been many publicly reported studies on the internal heating of lithium batteries, the technology is still in the theoretical exploration stage, and there is still a long way to go before it can be practically applied.

External heating refers to heating outside the battery, mainly including forced air heating, flowing liquid heating, contact thermal resistance heating, heat pipe heating, and composite thermal management technologies of two or more of the above [

14]. Air heating is the use of a heating device to heat the air and then use hot air to preheat the battery and heat the lithium battery through thermal conduction. However, the air heating system has blind spots inside the battery compartment that cannot be reached, resulting in temperature uncertainty and low efficiency of the air heating system [

15]. The heating technology using liquid as a heat exchange medium refers to heating battery packs through thermal conduction. In current research, by arranging some sealed pipelines and using a heat transfer working fluid to flow through the pipelines to transfer heat to the battery pack, in addition to traditional liquid flow preheating devices, tube bundle liquid flow heating devices are also designed to make the battery pack lightweight. Compared with air heating, using liquid heat flow for heating can achieve higher heat transfer efficiency. However, the traditional method of passing liquid into the bottom of the battery box has higher requirements for the sealing of the battery box, and its reliability is more difficult to guarantee [

16]. Contact thermal resistance heating mainly refers to the use of heating elements to heat the battery. It mainly includes two heating methods: metal heating film and PTC material. Contact thermal resistance heating can achieve a good heating effect, but the heating system has insulation failure, electrical safety, and overheating risks [

17].

Heat pipe heating mainly refers to the transfer of heat generated by electric heating to the heat pipe. By utilizing the bidirectional thermal conductivity of the heat pipe, the condensation end is used as the battery heating end, and the heat is transferred to the heat absorption end through internal fluid motion. Its main principle lies in the advantages of high thermal conductivity, high heat flux density, flexible contact structure, and good temperature equalization effect of heat pipes [

18,

19], which have been widely used in the field of heat dissipation in microelectrical systems such as electronic chips for a long time. There are many current studies on the heat dissipation of lithium batteries around heat pipes [

20,

21,

22]. He [

23] proposed a thermal management system with a combination of heat pipes and liquid-cooled plates; the coverage angle of the aluminum plate on the battery had the greatest impact on the system cooling performance. When the height, thickness, coverage angle of the aluminum plate on the battery, and coverage angle of the heat pipe were greater than 50 mm, 2 mm, 75°, and 60°, respectively, it could ensure that the battery obtained a good working temperature range. And the highest temperature was 37.58 °C, with a temperature difference of 3.67 °C. Liang [

24] proposed a battery thermal management with flat plate heat pipes and conducted cooling tests on a cylindrical battery at a discharge rate of 5C. The results showed that using flat plate heat pipes to cool the battery pack could limit its temperature to within 50 °C, and the temperature difference in the battery pack did not exceed 5 °C.

However, research has found that there are not many studies on low-temperature thermal management around heat pipes, although there are also literature reports on related applications [

25,

26]. Chen [

27] designed a low-temperature heating module for a battery with heat pipes, inserting the heat transfer section of the heat pipe between the large side of the battery and the battery. Under low-temperature conditions of −20 °C, the heat pipe can ensure continuous operation, which proves the possibility of using the heat pipe for low-temperature heating management of electric vehicle power batteries. From the above analysis, it can be seen that heat pipe heating has a bright future. However, it still has significant limitations. Firstly, the use of heat pipes for battery thermal management is limited, and publicly reported literature indicates that heat pipes are mostly used for high-temperature thermal management. However, there are few literature reports on low-temperature thermal management related to it. Secondly, the integration research of heat pipes with other schemes is not sufficient. Pulsating heat pipes are only a heat transfer device. How to efficiently match them with other preheating technologies, fully utilize or maximize their role as an efficient heat transfer device, and achieve the goal of low-temperature thermal management of batteries is the key.

To address the above limitations, this study proposes a low-temperature thermal management system for lithium batteries with pulsating heat pipes. The effectiveness of the proposed system is examined in different low-temperature scenarios, aiming to fill the gap in research on pulsating heat pipes in low-temperature thermal management of lithium batteries and expand the application scenarios of pulsating heat pipes. Undoubtedly, this has significant academic significance. The innovation and contribution of the research are as follows: (1) a low-temperature thermal management scheme with pulsating heat pipes has been proposed, laying the foundation for efficient battery thermal management; (2) energy consumption and optimal performance thermal management strategies for low-temperature scenarios have been proposed, providing new insights for low-temperature heating of batteries; and (3) the efficiency and reliability of the pulsating heat pipe thermal management system and corresponding strategy have been verified, expanding the application scope of heat pipes.

2. Materials and Methods

Preliminary preparations were made from the aspects of pulsating heat pipe design and manufacturing, design of pulsating heat pipe thermal management system, design of thermal management strategy, performance testing bench construction, and performance testing projects. The specific contents are as follows:

2.1. Pulsating Heat Pipe Design and Manufacturing

Pulsating heat pipes mainly consist of two parts: the internal working fluid and the pipe body. Firstly, the choice of working fluid. Working fluids can be divided into traditional working fluids and non-traditional working fluids (nanofluids). Nanofluids prepared with metal nanoparticles can significantly enhance the heat transfer ability of the working fluid [

28], while also exhibiting higher stability. Titanium dioxide has good durability/heat resistance, chemical stability, dispersion stability, strong environmental friendliness, and is safe for humans [

29,

30]. Meanwhile, titanium dioxide has a wide range of sources and low production costs [

31,

32]. The basic solutions of nanofluids mainly include water, ethanol, propanol, paraffin oil, etc. Nanofluids with ethanol and propanol exhibit superior thermal conductivity [

33,

34], mainly due to the functional groups of double bonds in ethanol, which facilitate the formation of stable compounds with other substances. In addition, ethanol has lower dynamic viscosity and greater latent heat and specific heat compared to water, which is beneficial for the low-temperature start-up of heat pipes. Based on the aforementioned analysis, commercially available titanium dioxide nanofluid was adopted as the working fluid for the pulsating heat pipe in this study, with ethanol serving as the base solution. According to relevant literature, the heat transfer performance of the heat pipe is optimal when the filling ratio is 50% and the volume concentration of the nanofluid working fluid is 2% [

2].

Next, the design of pulsating heat pipes needs to adapt to the battery thermal load, respond to changes in battery thermal load, and meet heating requirements. The selection of pulsating heat pipes requires consideration of heat pipe parameters and battery characteristics. The thermal conductivity of pipes is one of the main factors affecting the heat transfer capacity of pulsating heat pipes. The selected material should have good thermal conductivity to withstand higher temperatures and be compatible with the working fluid. Choose copper material (copper has a high thermal conductivity of about 400 W/m·K [

35]) as the heat pipe material. A circular cross-section helps the liquid film to always adhere to the inner wall of the heat pipe, better absorbing and dispersing heat from the evaporation and condensation sections [

36]. Additionally, a circular cross-section has lower flow resistance, and the cross-section of the pulsating heat pipe is determined to be circular. The number of turns of pulsating heat pipes is directly related to the total heat flux and is also limited by practical conditions. According to the actual size of the battery and the constraints of the thermal management system, the pulsating heat pipe should be designed to cover the large side of the battery as much as possible, ensuring that heat is transferred to the surface of the battery as much as possible. The number of turns is determined to be 5. According to the actual design of the thermal management system with pulsating heat pipes, the length of the pulsating heat pipe evaporation section is selected as 45 mm, and the length of the condensation section is 183 mm.

The operation of pulsating heat pipes is based on the oscillatory motion of gas and liquid plugs, and the relative strength must comply with relevant standards [

37] to achieve good oscillatory motion and meet heat transfer requirements. Furthermore, considering the relationship between the inner diameter size and the frictional resistance of the working fluid, the minimum inner diameter is also subject to certain constraints [

38]. The specific description is as follows:

where

is the surface tension of the working fluid (N/m);

is the inner diameter of the heat pipe (m);

is the gravity acceleration (N/kg);

is the density of gas plugs (kg/m

3);

is the density of liquid plugs (kg/m

3);

is the bond number;

is the Euler number.

The inner diameter of pulsating heat pipes is usually within the range of 1 mm to 8 mm [

39]. With actual processing technology, the designed inner diameter is determined to be 5 mm. Finally, a vacuum pump is used to evacuate the heat pipe, and nanofluid is injected into the heat pipe (titanium dioxide nanofluid with a filling rate of 50% and a working fluid concentration of 2% has the best heat transfer ability). Then, the heat pipe is sealed, and finally, the pulsating heat pipe is obtained.

2.2. Design of Pulsating Heat Pipe Thermal Management System

The pulsating heat pipe thermal management system mainly includes core components such as a lithium battery, high thermal conductivity pulsating heat pipes, aluminum homogenization plates, heating plates, and thermal management control subsystems. As shown in

Figure 1, a commercially available lithium iron phosphate battery (Yiwei Lithium Energy Co., Ltd., Huizhou, China) with a capacity of 68 Ah is selected as the research object. Adopting a heating scheme that combines mica heating plates and pulsating heat pipe heat exchangers for thermal management of the battery in low-temperature environments. That is, adding a pulsating heat pipe heat exchanger (Laboratory self processing, Harbin, China) on the large side of the battery, wherein the pulsating heat pipe heat exchanger consists of the pulsating heat pipe mentioned earlier and an aluminum homogenization plate (Laboratory self processing, Harbin, China). The main function of the aluminum homogenization plate is to uniformly transfer the temperature to the large side of the battery, achieving uniform heating of the large side of the battery. The heat pipe is embedded in the homogenization plate to achieve sufficient contact between the two, and the heat pipe evaporation end is in contact with the heating plate. The heat is transferred from the evaporation end of the heat pipe to the condensation end, while the heat from the condensation end is transferred to the surface of the battery through the aluminum homogenization plate, thereby achieving heating of the battery. The detailed parameters are shown in

Table 1, and the specific control strategy will be elaborated on in

Section 2.3.

2.3. Design of Thermal Management Strategy

The original intention of low-temperature heating management for lithium batteries is to reduce potential safety risks such as performance degradation and lithium deposition caused by low temperature. The low-temperature heating management strategies usually require consideration of the target temperature of the lithium battery. Generally speaking, a battery can be freely charged and discharged above 0 °C. Sometimes, it is necessary to reduce the impact of environmental temperature on battery performance and ensure that the battery is within the ideal temperature range. However, this ignores the parasitic energy consumed by the system, as the heating element consumes a significant amount of energy for low-temperature heating. It is of great significance to ensure the low-temperature performance of the battery while reducing the energy consumption of the pulsating heat pipe thermal management system.

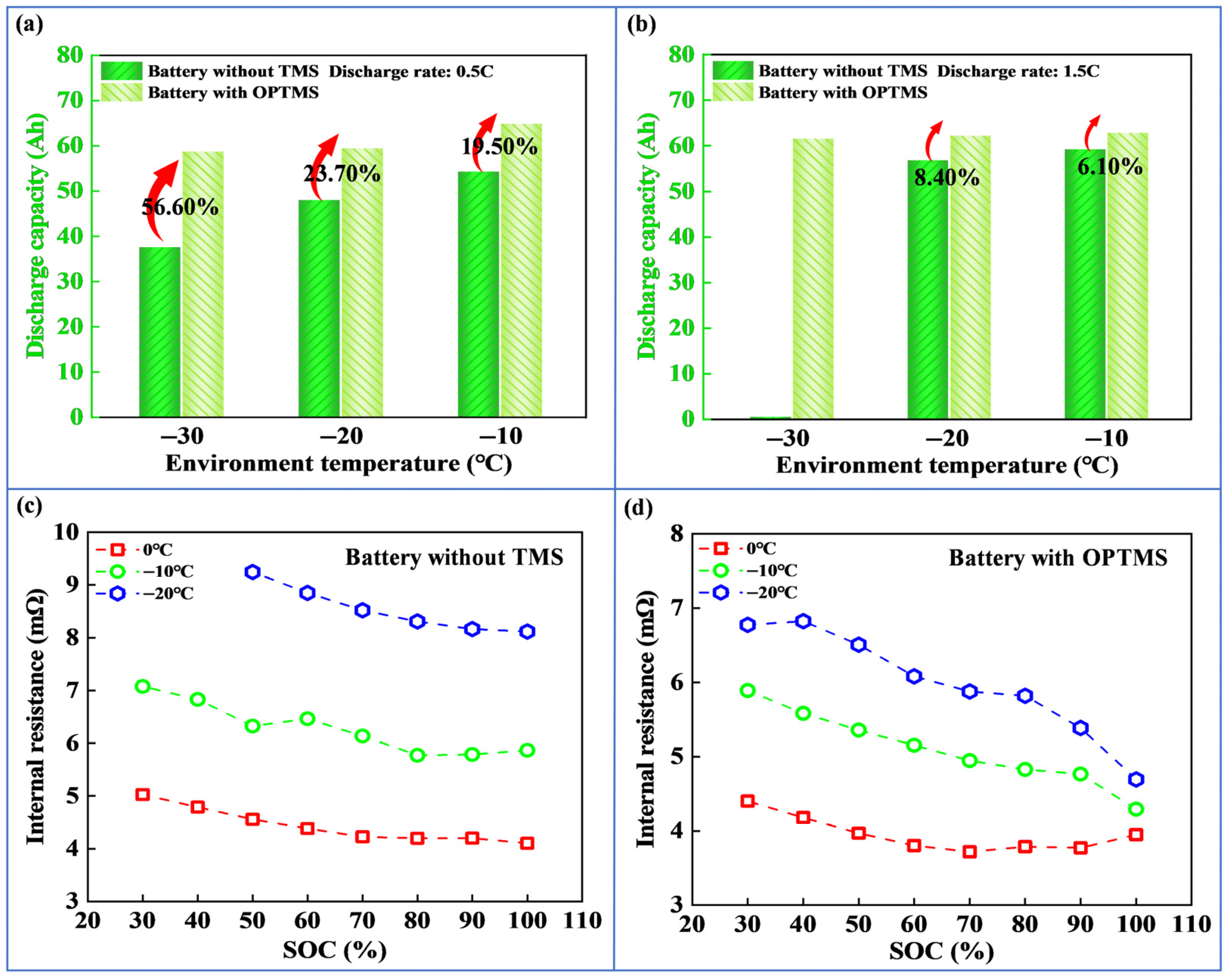

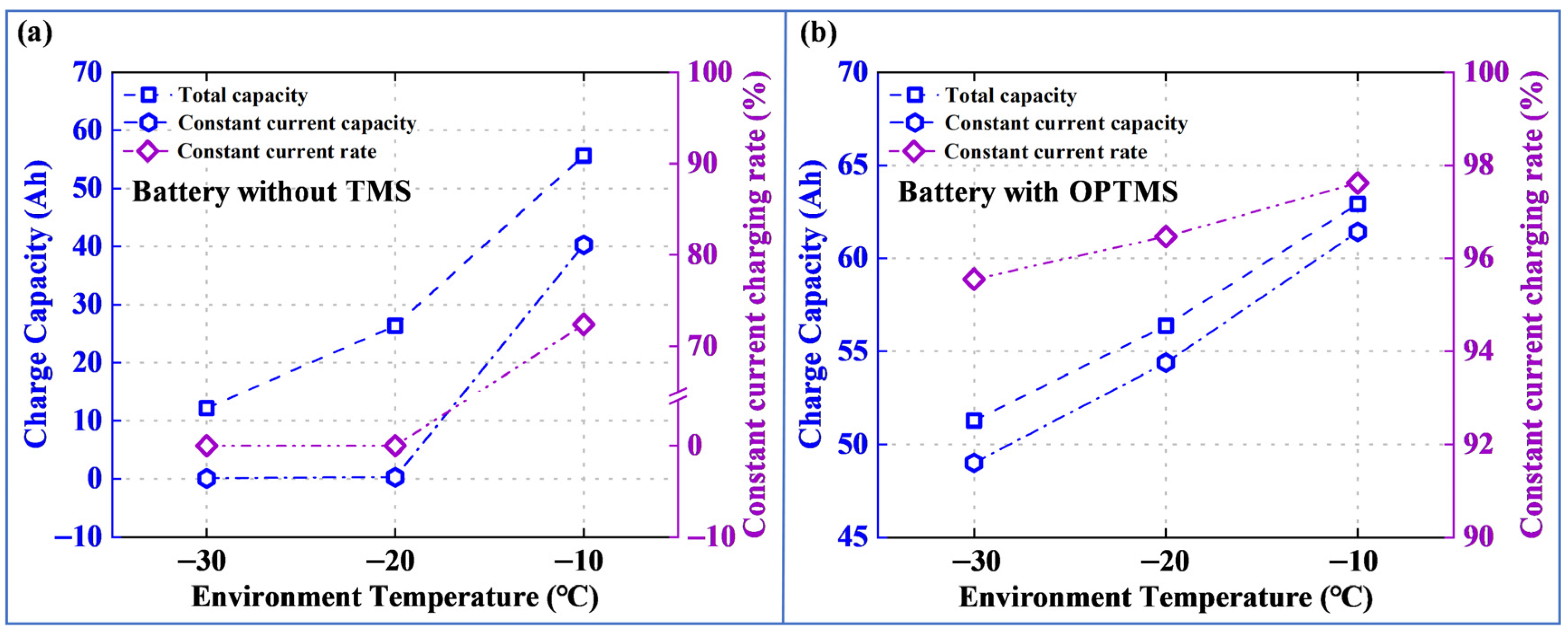

Therefore, it is very necessary to have a real-time temperature control strategy, which can ensure that the average temperature of the battery is within the allowable temperature range, effectively exert the electrical performance of the battery, and reduce the energy consumption of thermal management systems. Therefore, this paper proposes an optimal performance thermal management strategy (OPTMS) and an optimal energy consumption thermal management strategy (OECTMS). OPTMS aims to keep the battery operating within the optimal temperature range by controlling the continuous operation of the heating element and maximizing the performance of the battery; OECTMS aims to ensure that the battery operates within the allowable temperature range and reduce the system energy consumption caused by heating plates.

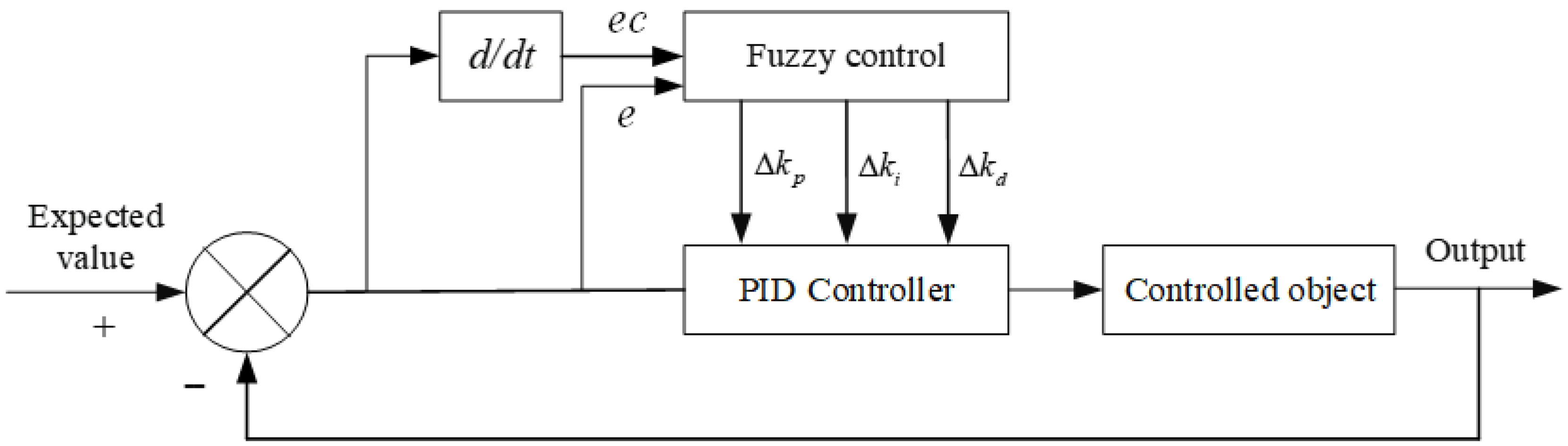

OPTMS ensures that the heating element operates throughout the entire process without the need for control. However, OECTMS requires the control of mica heating plates. Although PID control has significant advantages in industrial control, such as obvious control effects, simple system composition, and easy adjustment of control parameters [

40]. However, lithium battery systems exhibit highly nonlinear time-varying characteristics, and PID control technology shows significant lag for thermal management system control. Fuzzy control, as a representative of control theory that can be implemented industrially, is suitable for dealing with complex problems such as nonlinearity, multidimensionality, and multi-field coupling [

41]. Therefore, a PID controller with fuzzy control is developed for the OECTMS, as shown in

Figure 2. Aim to implement thermal management strategies by controlling the power of mica heating plates.

The design of a fuzzy PID controller includes the controller structure, fuzzification of controller input and output, and formulation of controller control rules.

- (1)

Controller structure

The control objective is the temperature of the lithium battery, and the system execution element is the mica heating element. The deviation and deviation change rate between the expected temperature and the actual temperature value of the battery are selected as input variables, and the correction parameters are selected as output variables. The correction parameters are used to supplement and optimize the control parameters of the PID controller, and the output variable of the controller is the power of the heating element.

- (2)

Fuzzification of controller input and output

The input and output variables are described as ML (negative large), MI (negative medium), MP (negative small), ZO (zero), FP (positive small), FI (center), and FL (positive large). After multiple tests of the positive definite controller combined with the thermal management system and experimental structural analysis, the input variables’ domain was finally set to [−6, 6], the output variables’ domain was set to [−2, 2], and a triangular function was selected as the membership function of the variables.

- (3)

Controller control rules

The control rules usually require reference to the industry’s long-term accumulated experience and analysis of actual experimental results to ultimately conclude. Based on the team’s previous research on low-temperature heating control technology for power batteries and industry experience in battery management systems, the control rule tables for various parameters of the fuzzy controller were finally obtained, as shown in

Table 2,

Table 3 and

Table 4.

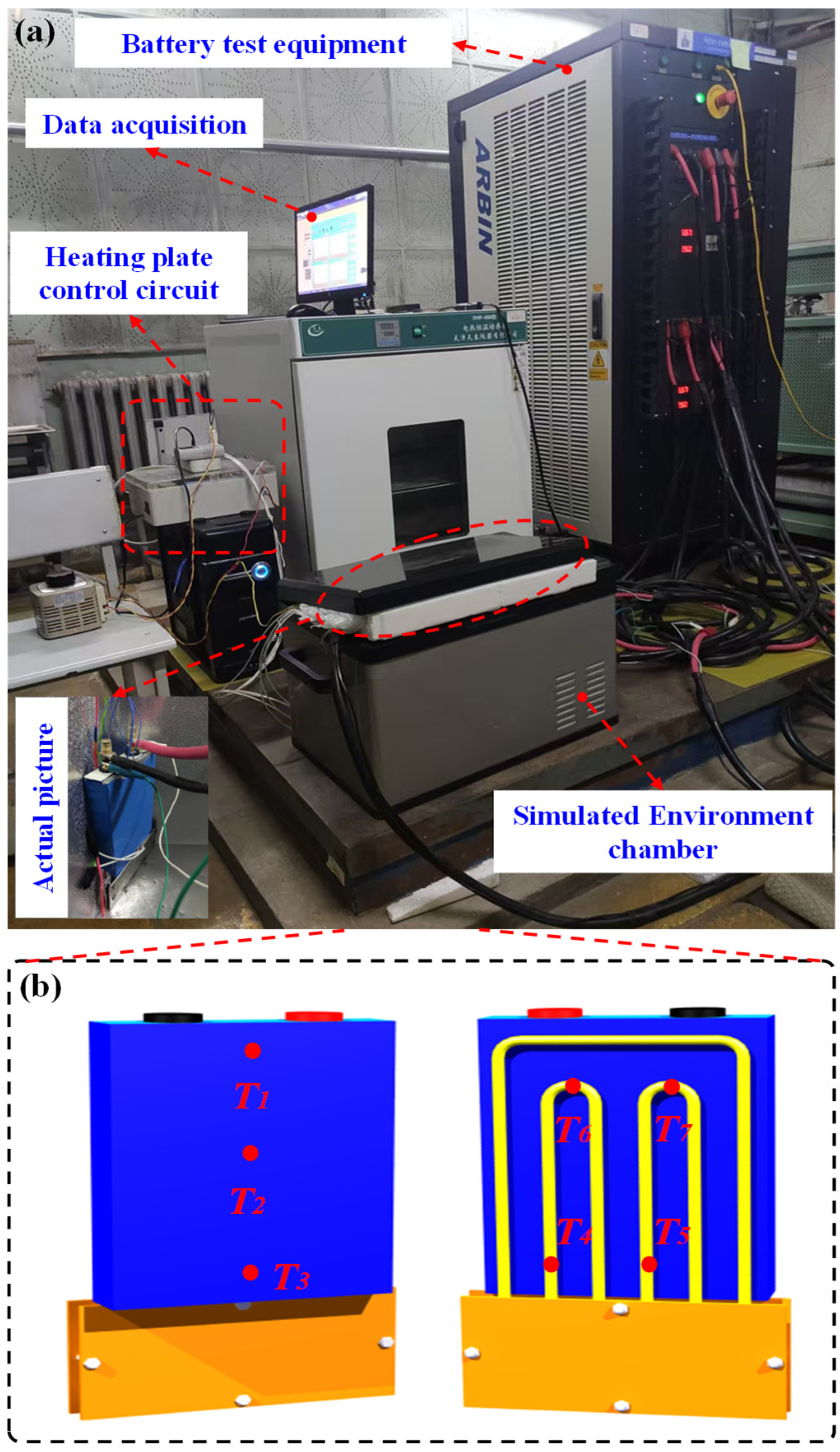

2.4. Low-Temperature Performance Testing Bench

To conduct experimental research on the low-temperature performance of battery thermal management systems with pulsating heat pipes, a performance experimental platform was built using the developed pulsating heat pipe thermal management system as the test object, in conjunction with the battery comprehensive testing system, simulated environment chamber, and mica heating plate control circuit. The experimental platform consists of four parts: a battery comprehensive testing system, a simulated environment chamber, a pulsating heat pipe thermal management system (as described in detail in

Section 2.3), and a low-temperature heating control circuit, as shown in

Figure 3a.

- (1)

Battery comprehensive testing system

The battery comprehensive testing system refers to the Arbin battery charge and discharge testing machine and the corresponding control software MITS Pro 2016. During the experiment, the pulsating heat pipe thermal management system containing a lithium battery was hard-wired to the Arbin battery charge (Texas, USA) and discharge testing machine through a charge and discharge cable. The corresponding MITS Pro software was used to set the charge and discharge status of the battery, including charge and discharge rate, charge and discharge cut-off conditions, and cycle charge and discharge.

- (2)

Simulated environment chamber

An environment chamber refers to a freezer that provides a low-temperature environment, capable of providing a temperature of −30 °C with a temperature control accuracy of ± 1.0 °C and good insulation properties. During the experiment, simulate the low-temperature characteristics of the cold region where the battery is located.

- (3)

Low-temperature heating control circuit

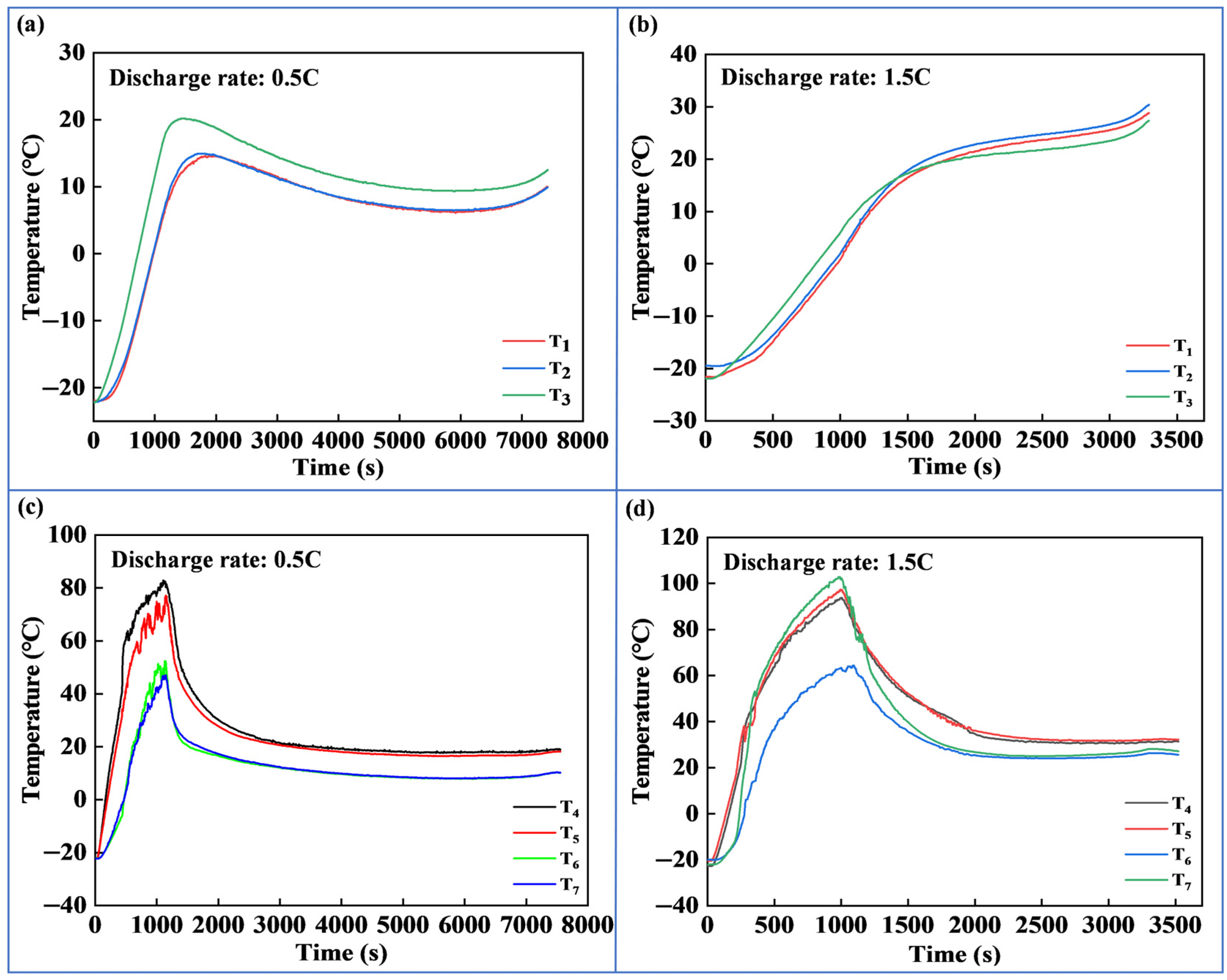

The mica heating element control circuit mainly includes three parts: information acquisition, heating control, and heating execution. The information acquisition module is responsible for recording and storing various parameters; The heating control module downloads the above thermal management strategy to the hardware control board to control its execution and sends control instructions (to control the mica heating element) to the heating execution module to achieve temperature regulation of the battery; The heating execution module includes a pulsating heat pipe, an aluminum homogenization plate, an aluminum collector plate, and mica heating plates. By adhering to the large side of the battery, the contact area between the heating execution and the large side of the battery is increased, making it easier to quickly heat the battery. During the experiment, the power of the mica heating plate was controlled by a corresponding control algorithm so that the heat generated by the heating element was transferred from the evaporation section of the pulsating heat pipe to the condensation section. The heat from the condensation section was evenly transferred to the surface of the battery through the aluminum homogenization plate. Signal acquisition utilizes temperature sensors to record temperature changes at different locations, using

,

,

,

,

,

and

, respectively, with specific positions as shown in

Figure 3b.

2.5. Performance Testing Projects

To investigate the performance of the pulsating heat pipe low-temperature thermal management system with different thermal management strategies, the following experimental projects were conducted.

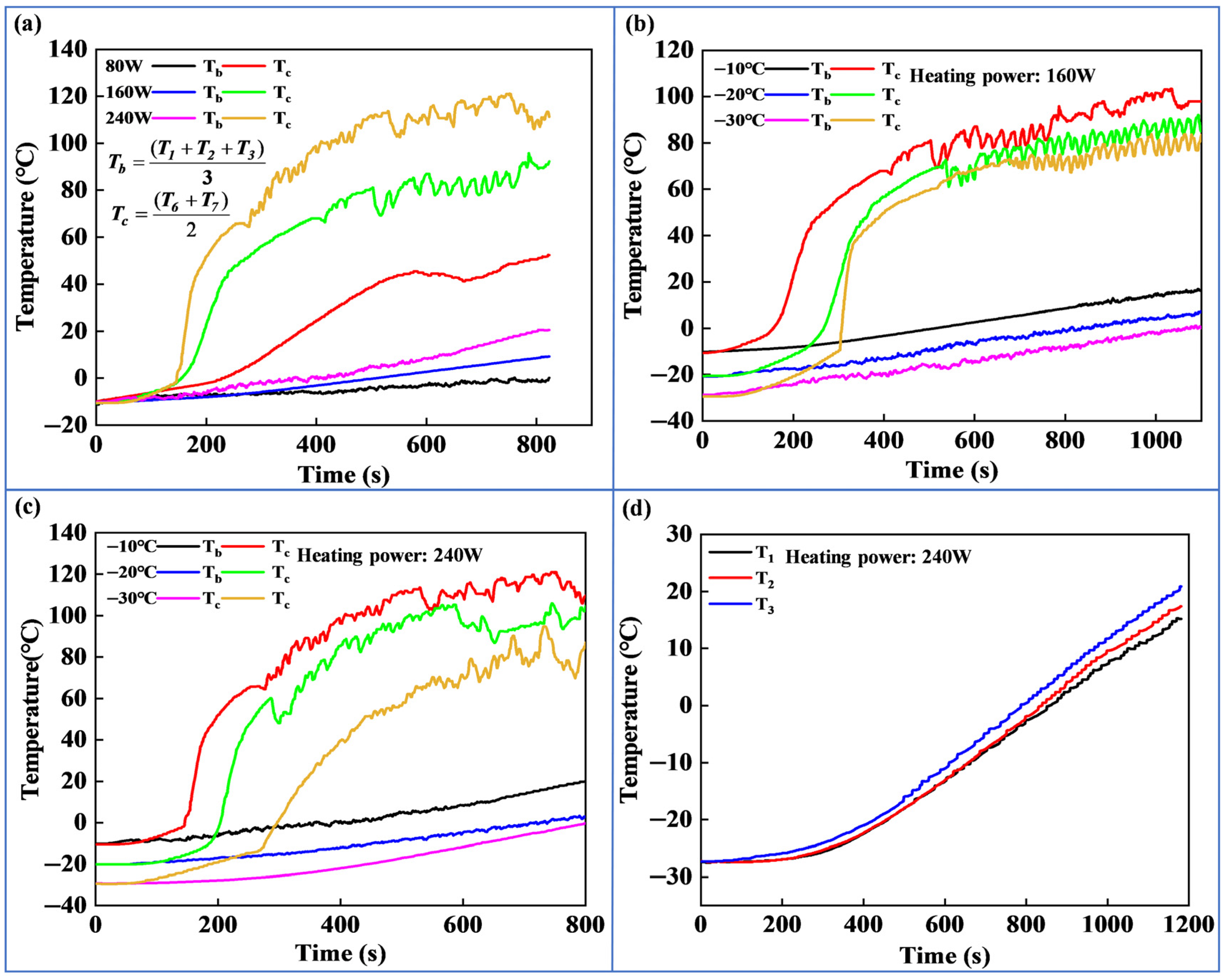

- (1)

Response of pulsating heat pipe low-temperature thermal management system under preheating conditions. The efficiency of the pulsating heat pipe thermal management system under preheating conditions is closely related to preheating power and environmental temperature. Generally speaking, for thermal management systems, it is necessary to match the system preheating power under different temperature conditions to ensure efficient operation of the system and achieve good preheating efficiency during the preheating stage.

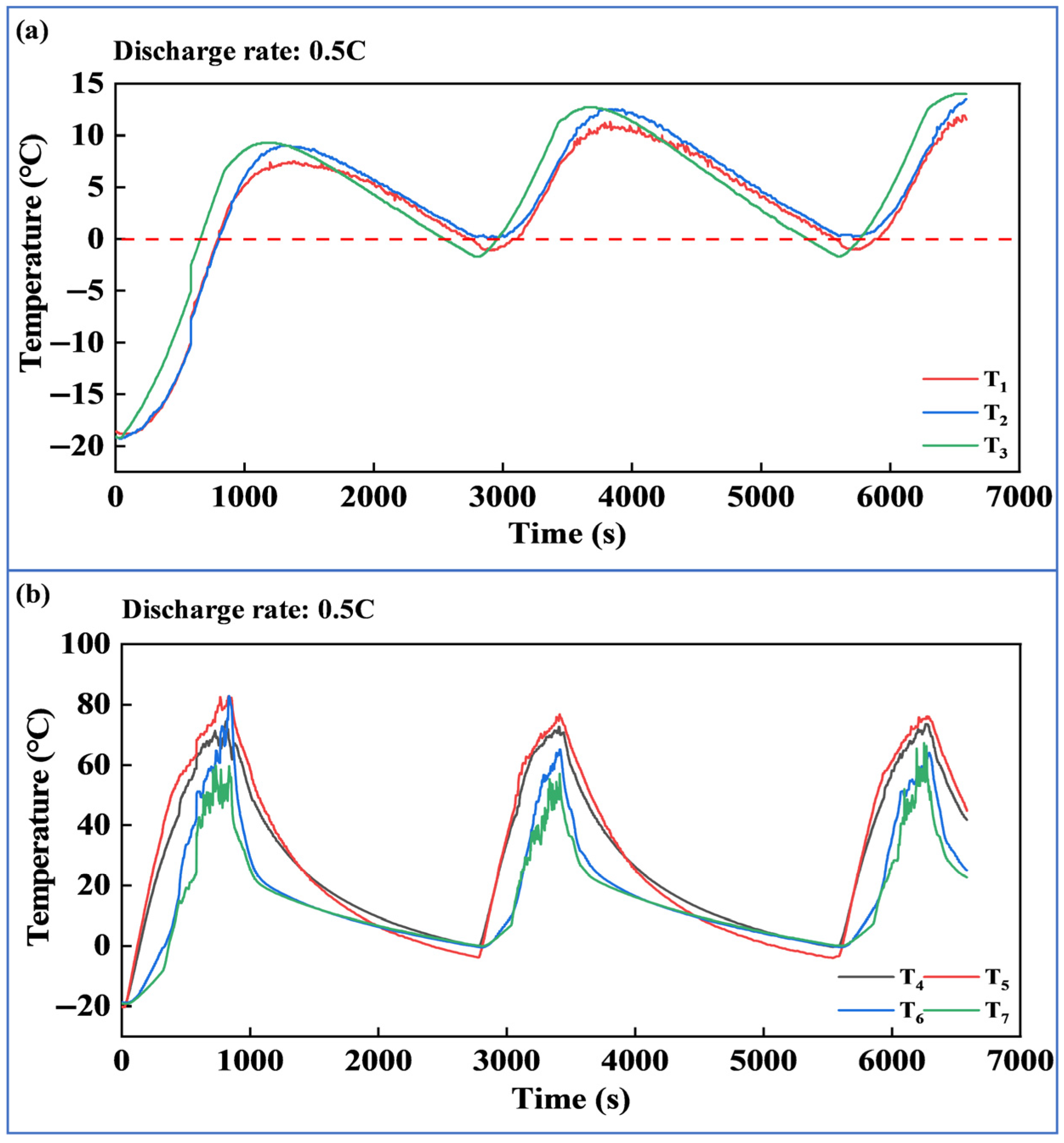

- (2)

The effectiveness of a pulsating heat pipe thermal management system with OECTMS in low-temperature discharge scenarios. The discharge scenario includes the preheating process and insulation process of the lithium battery. As mentioned earlier, OECTMS is to ensure that the battery operates within the allowable temperature range and reduce the system energy consumption caused by heating plates. This is achieved by using the fuzzy PID algorithm to control the power of the mica heating plates in real time. Therefore, it is necessary to explore the specific performance of the pulsating heat pipe thermal management system with OECTMS.

- (3)

The effectiveness of a pulsating heat pipe thermal management system with OPTMS in low-temperature discharge scenarios. Similar to OECTMS, it also includes the preheating and insulation processes. OPTMS corresponds to the continuous operation of the heating plate, ensuring that the battery operates within the optimal temperature range and maximizes its performance. Therefore, it is necessary to explore the specific performance of the pulsating heat pipe thermal management system with OPTMS.

- (4)

The effectiveness of a pulsating heat pipe thermal management system with OPTMS in low-temperature charging scenarios. Unlike discharge scenarios, low-temperature charging has a significant impact on the performance and lifespan of lithium batteries, and the role of thermal management systems is more prominent. Undoubtedly, the working temperature of lithium batteries should be raised as much as possible to reduce the negative impact of low-temperature environments. Therefore, OPTMS is preferred. Therefore, it is necessary to explore the specific performance of pulsating heat pipe thermal management systems with OPTMS in low-temperature charging scenarios.