3.1. HESM Model for Optimization

This section outlines the features of the mathematical model, incorporating PWM effects, used in the HESM optimization. The application in question requires a rated power of 1720 W and a CPSR of 3.5:1 (starting from 1200 rpm to a maximum speed of 4200 rpm).

Table 2 presents two operational points considered in the optimization, which are the boundary points of the CPSR.

The calculation of the HESM characteristics for each operating point from

Table 2 is completed in two stages [

22].

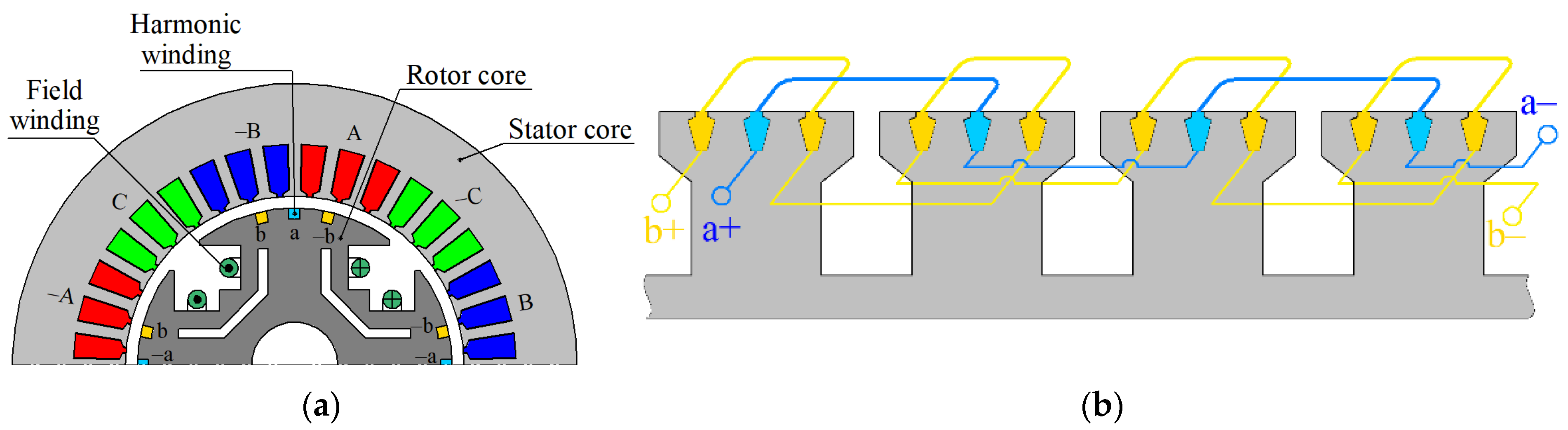

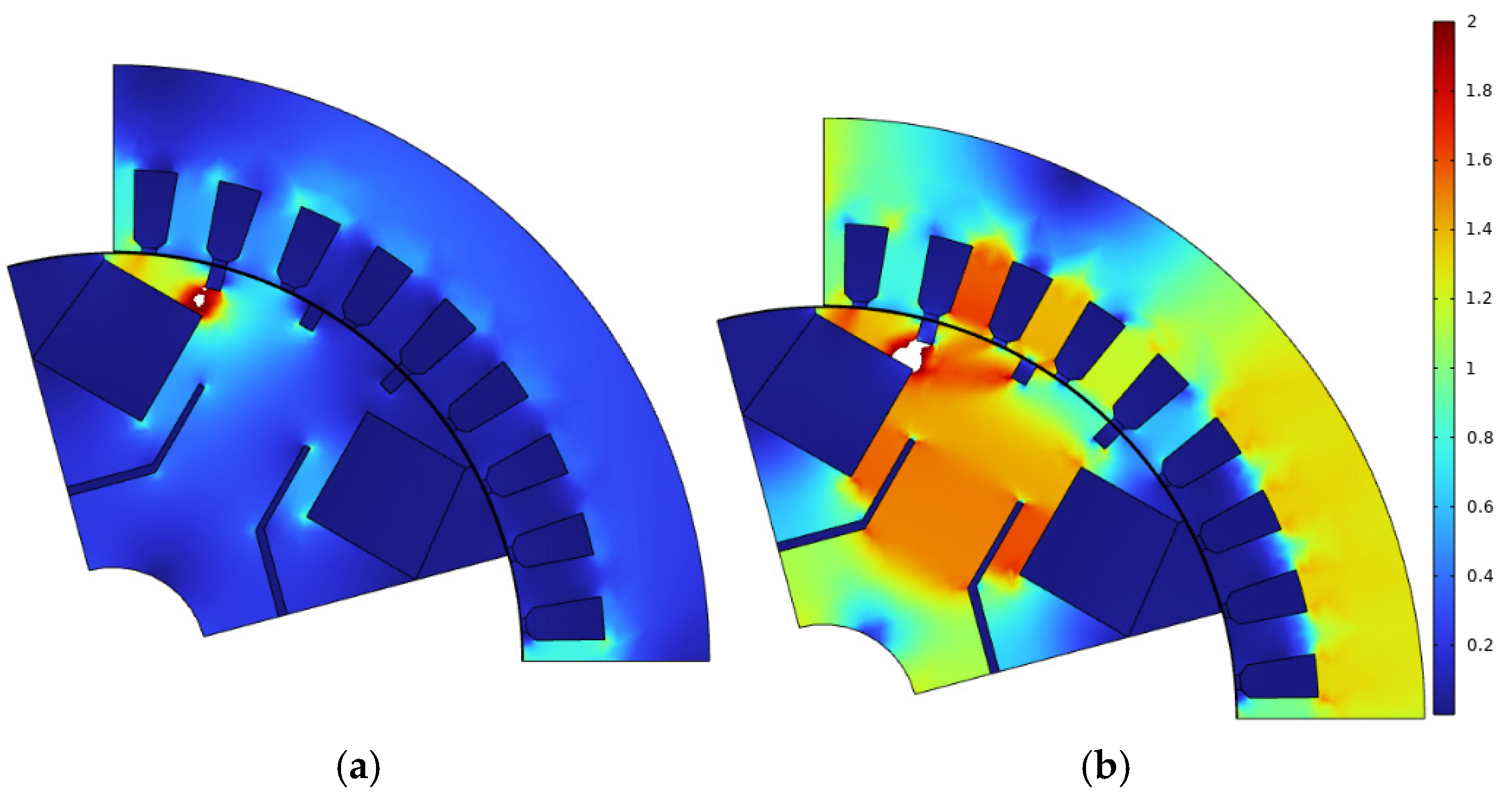

Stage 1. The HESM characteristics are computed without considering PWM using the basic model, which is an FEM-based model assuming sinusoidal stator currents and constant current in the field winding. It corresponds to the solution of a series of boundary value problems of magnetostatics at various rotor positions (the so-called multi-static model). Also, it is assumed that there is no current in the harmonic winding. The injected zero-sequence current I0 is also neglected.

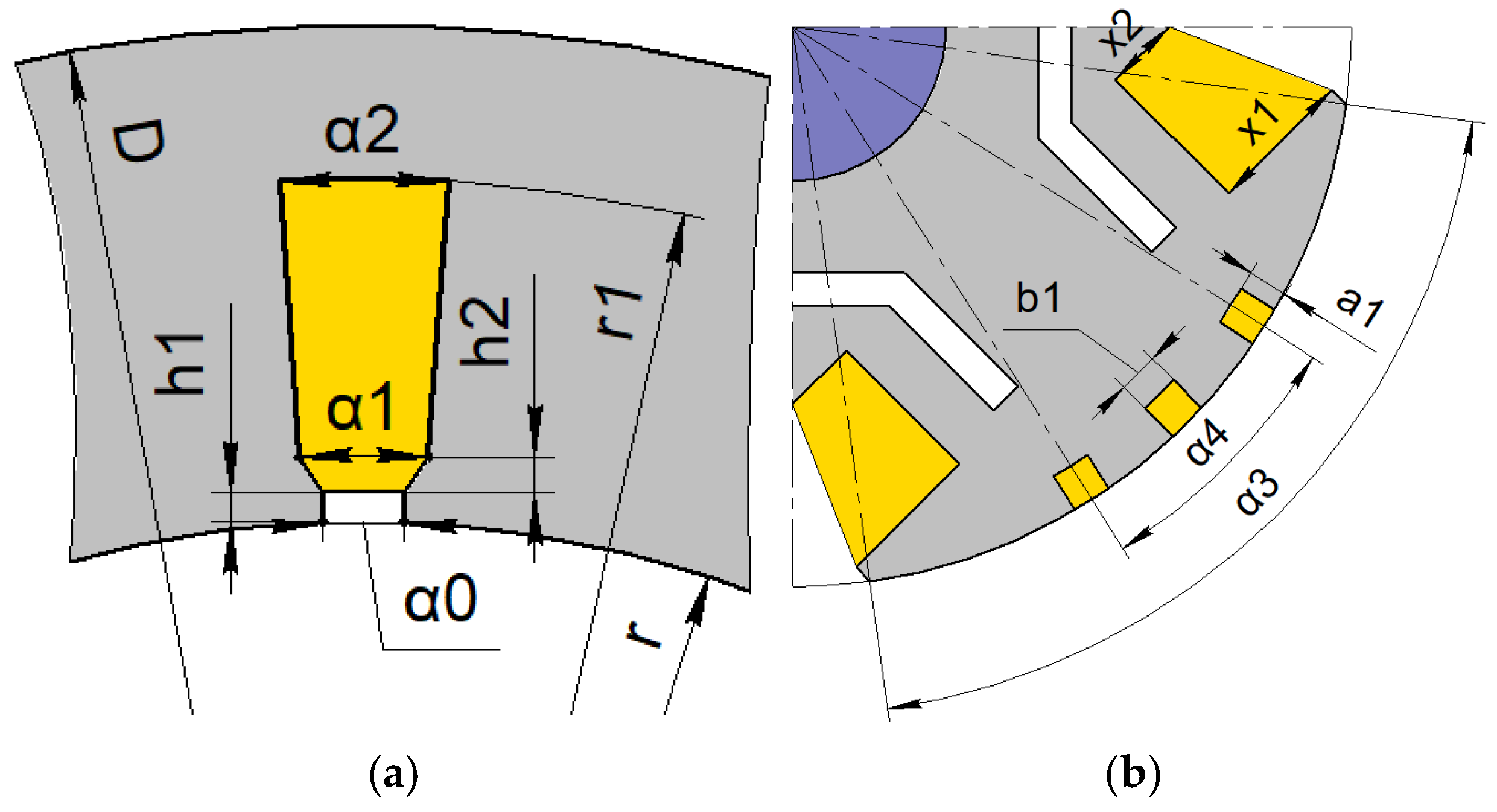

Basic-model parameter vector x consists of geometrical parameters, RMS values of the stator slot currents, phase angles of the stator slot currents, and the field winding sections’ currents.

Considering the symmetrical nature of the problem, the considered rotor positions lie within the range of 0–30 mechanical degrees. The total number of FE problems in this range is equal to 11. Linearized flux linkage dependencies on currents and rotor angular position are computed for all stator and rotor phases and normalized per one turn. Other quantities required for calculating losses [

22] are also computed.

Stage 2. Then, the linearized dependencies found at the previous stage are used to compute HESM characteristics, taking into account PWM effects using a reduced-order model (ROM). The ROM is based on a system of ordinary differential equations. This model is explained in detail in [

22]. The dependencies obtained in the previous stage can be easily recalculated for any number of turns. Losses in the transistors and diodes are not considered. Therefore, only the ratio of the numbers of turns of the harmonic and field windings, but not their absolute values, should be set. The reference number of field winding turns is assumed to be 100. It was assumed that the number of turns may take non-integer values. The turn numbers of the stator winding and of the field winding are positive. Negative values are allowed for the harmonic winding, which corresponds to reversing the connection direction of its phases, opposite to the initially chosen configuration.

The switching pulses of the power switches (gating signal) in the ROM-based simulation are formed as follows:

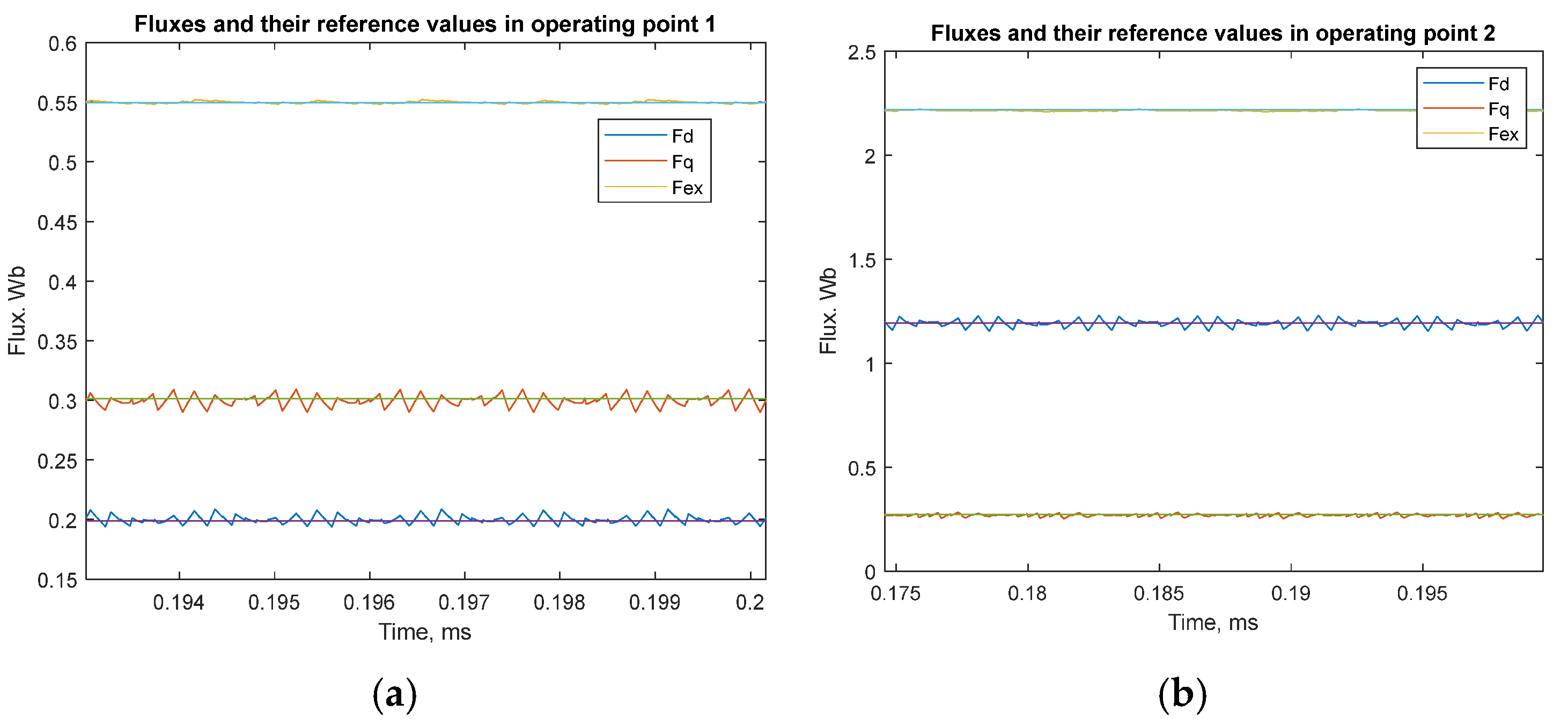

- -

Proportional–integral (PI) controllers of stator magnetic flux

dq-components are not simulated. Instead, the instantaneous phase fluxes Φ

ABC are assumed to be known (in a real system, they can be estimated, for example, using a flux observer). Since the currents in the windings are predetermined to simplify the calculations in the basic model, the

dq-magnetic fluxes exhibit only minor oscillations around their mean values as the rotor rotates. It is assumed that the lookup table stores these mean flux values Φ

dq. Assuming constant rotor speed, the rotor position for the next PWM interrupt event is calculated. The flux values Φ

dq are then transformed into the inverter reference of the phase fluxes

. The corresponding phase voltage reference is then calculated through the following equation:

- -

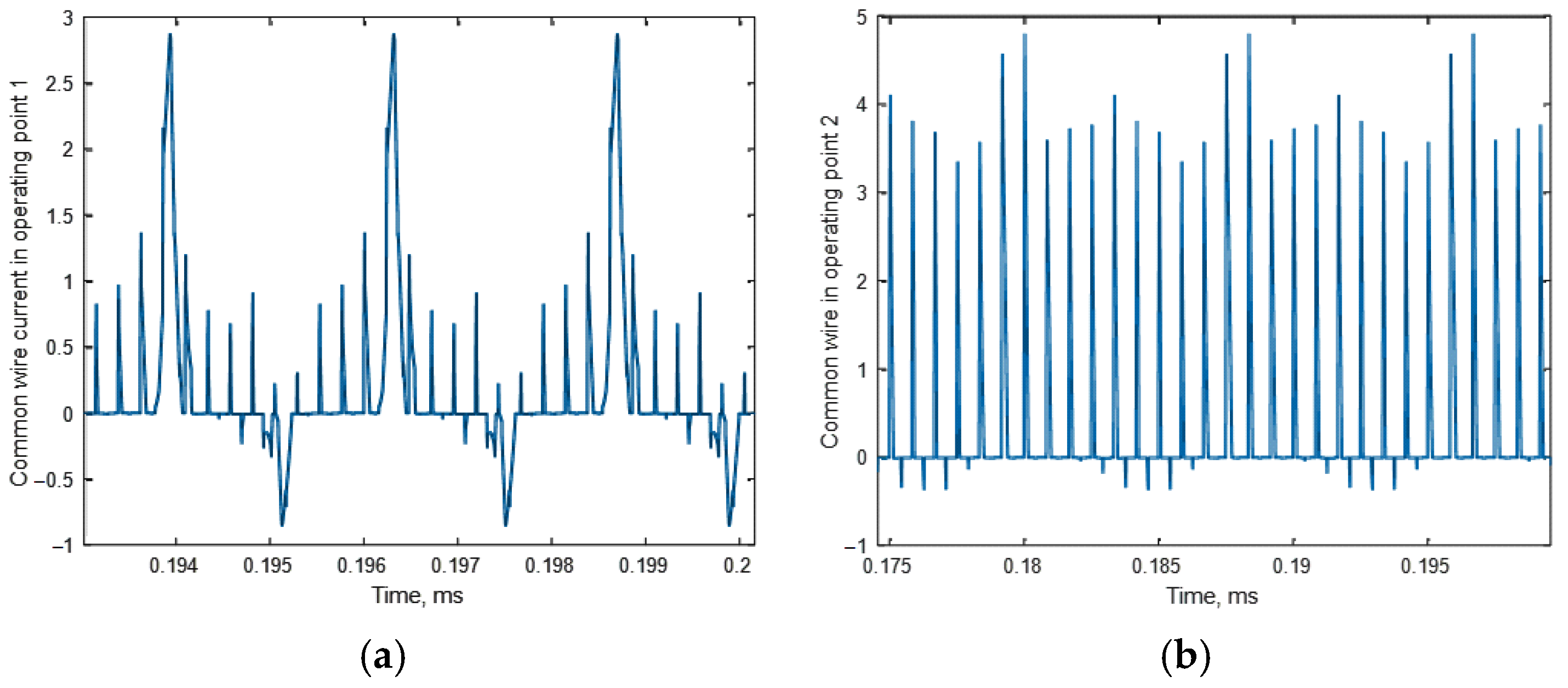

The phase voltage references are transformed into the corresponding inverter output voltage by means of symmetrical space-vector PWM (SVPWM). It should be noted that this method directly controls the dq-components of the stator flux linkage, since the symmetrical SVPWM algorithm is insensitive to the zero-sequence component.

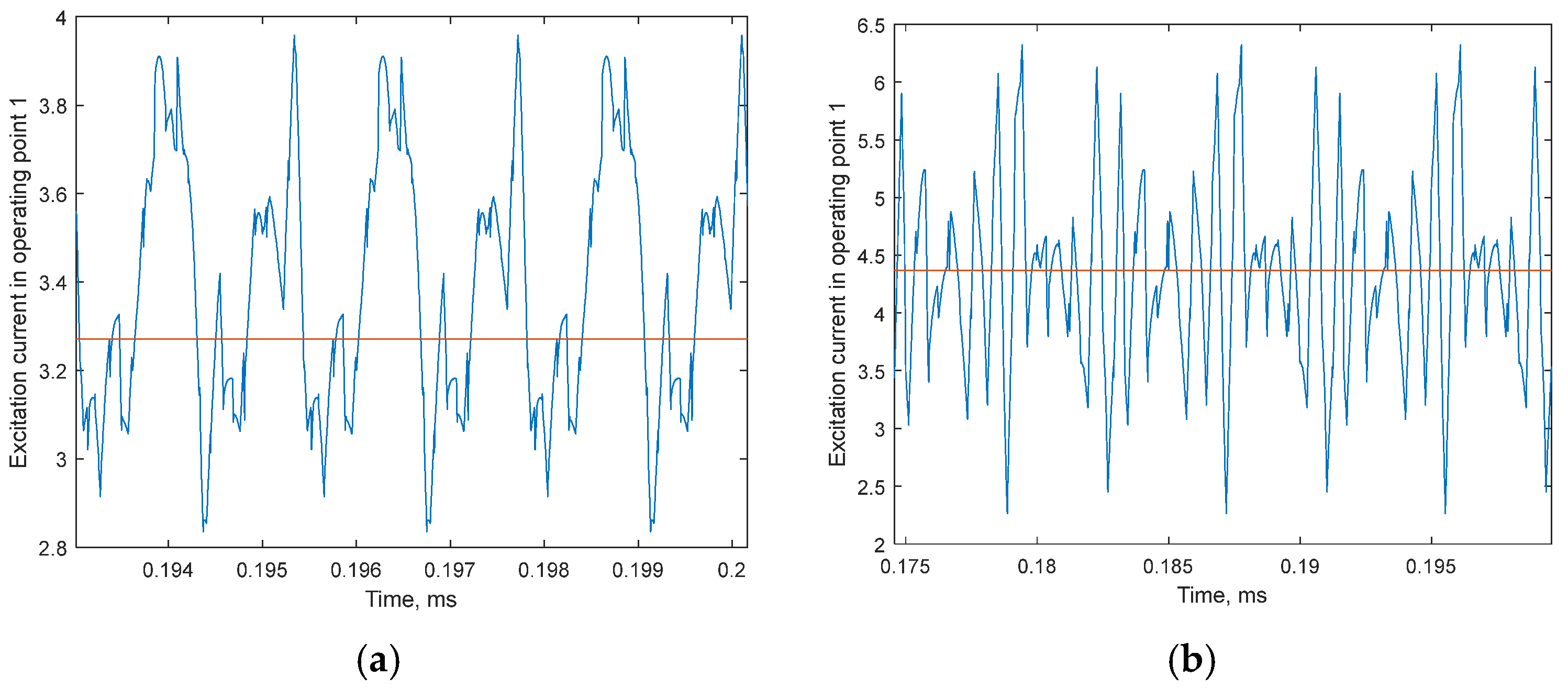

The excitation flux control algorithm (e.g., using an integral controller) is not considered in detail in this work. The duty cycle ratio of the injector switch

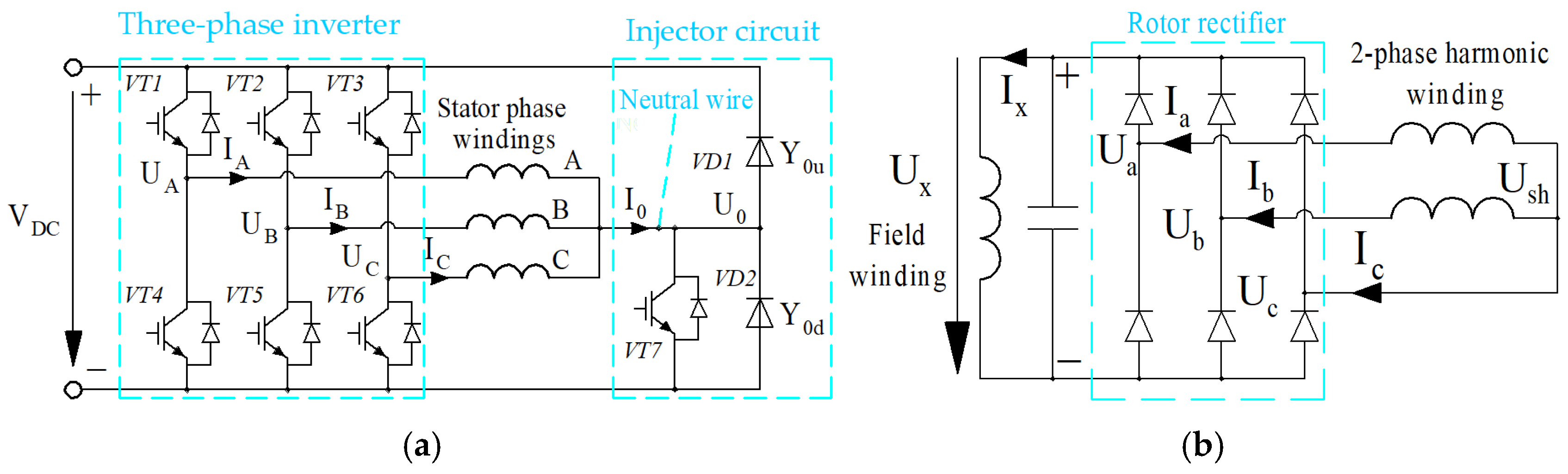

VT7 (see

Figure 2b) is assumed to be constant.

So, in addition to the dependencies obtained at the basic-model stage, ROM computation requires the vector of parameters y composed of the number of turns in the stator winding and in the harmonic winding phases, as well as the duty cycle ratios of the injector switch in both operating points.

To exclude transient processes from consideration and focus on steady-state values, the ROM simulation time is set to 0.2 s. The objective function values are evaluated over the last period of the ROM calculation. The computation of one operating point requires approximately 190 s using the basic model, followed by 12 s with the ROM. Since the evaluation of

F(x) requires the calculation of the HESM characteristics at the two operating points listed in

Table 2, this requires two basic model runs and also results in a total number of ROM runs of 2 × 45 = 90. Therefore, the computation time for

F(x) is approximately 2 × 190 + 90 × 12 = 1460 s for the proposed model.

Since the HESM performance evaluation for two operating points takes about a week (168 h, 14,515,200 s) without using the reduced-order model [

17], it can be said that the proposed approach speeds up the computations by four orders of magnitude.

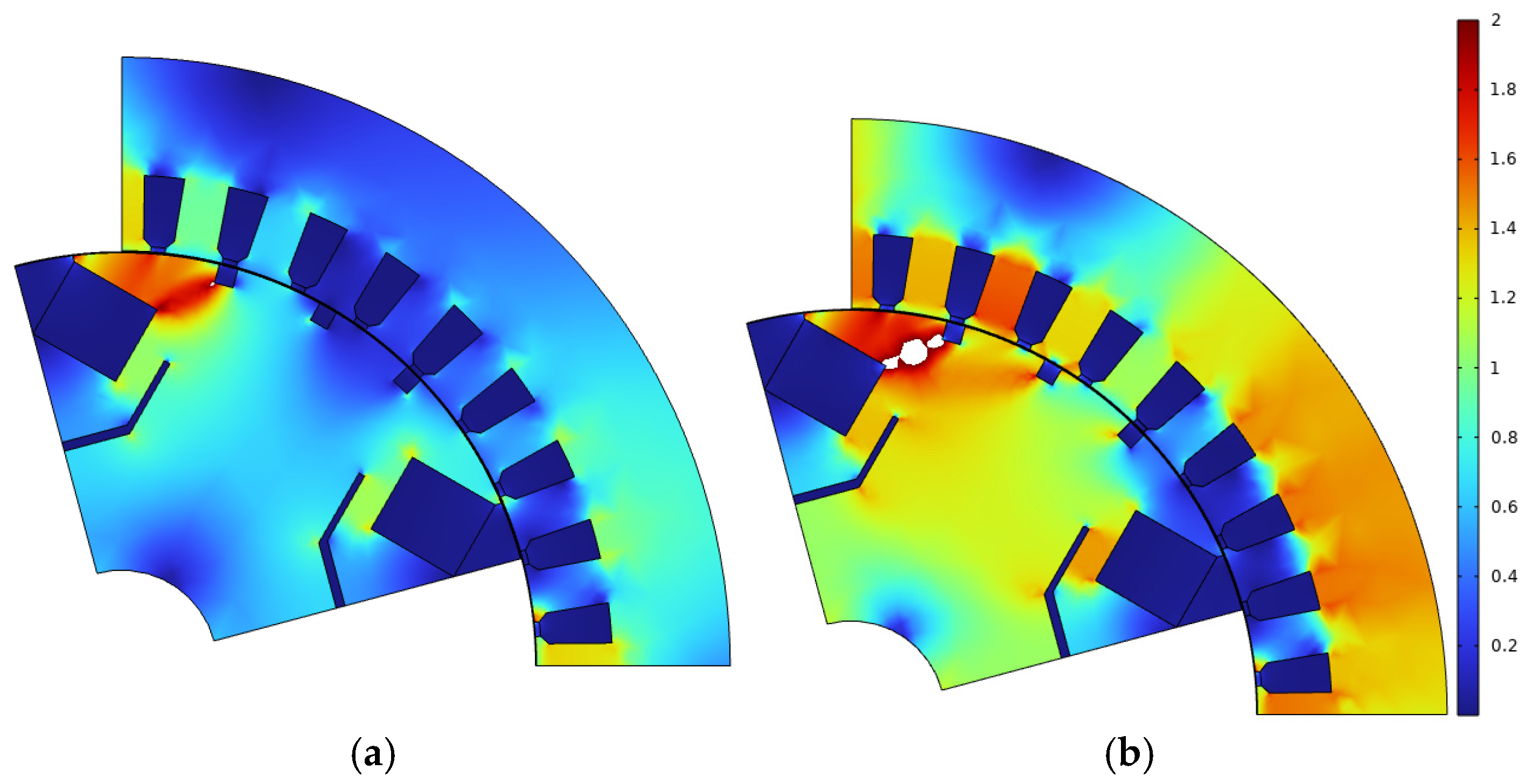

However, the ROM delivers correct results only if the considered motor working conditions are close to those in the basic model. Since the properties of magnetic circuits are defined mostly by the saturation level, a matching criterion is based on the comparison of the mean magnetic flux values. The values of the stator flux and can differ significantly in the case of overmodulation. The values of the excitation flux and can differ significantly due to an incorrect selection of the PWM duty cycle.

The measure of discrepancy between fluxes in the basic model and ROM

is determined as follows:

Thus, magnetic saturation causes nonlinearity in the motor properties. To improve the accuracy of the current–flux relationships in the linear approximation used by the ROM, the series expansion is applied in the vicinity of the closest sinusoidal current condition (the basic model). Saturation is determined by magnetic fluxes, while discrepancy ε is a measure of the closeness of magnetic fluxes in the basic model and the ROM.

During the modeling, any feedback loops that require controller parameter tuning are excluded. While such tuning is acceptable when simulating or developing a specific machine, it becomes impractical when optimizing, and plenty of machines must be modeled. The cost of such simplification is that vectors x and y are not independent: ROM provides a correct result only if saturation levels in the basic model and ROM are close, and is small. The optimization procedure to obtain the correct x, y pair is described in the next section.

Although the voltage drop across the controlled switches and diodes is not taken into account in this study for the sake of model simplicity, this is not a fundamental limitation of the proposed approach, and the drop across the switches and diodes can be taken into account if necessary.

3.2. Optimization Routine

The optimization objectives are set as follows:

- -

Efficiency maximization through the minimization of the sum of squared efficiency residuals from unity, where

Eff1 and

Eff2 are the efficiency values at the operating points of the duty cycle (see

Table 2):

- —

Stator current minimization for both operating points: FI = I12 + I22;

- —

Torque ripple minimization for both operating points: FTR = TR12 + TR22.

The use of squared terms in these criteria implies that achieving high performance at both operating points is important. If one operating point yields a poor value for a certain indicator, squaring amplifies the effect, even if the same indicator is acceptable at the other operating point. Thus, if an indicator degrades at one operating point, it must be improved at that point, while improving it at the other operating point is of limited relevance.

Also, the following penalties are included in the objective function:

- —

In order for the simulation to be correct and for x, y to correspond to each other, ε1 and ε2 (for both operating points) must be minimized.

- —

The mechanical power obtained from the basic model and from the ROM may differ. Therefore, the final power value becomes known only after both calculation stages are completed. The power deviation at the ROM stage was evaluated for each operating point, and if it falls below the target value of 1720 W for each operational point, a penalty is applied. This deviation is expressed as:

where indexes “1” and “2” correspond to the first and second operating points.

Due to the high computational complexity of even the proposed two-stage approach, the computationally efficient Nelder–Mead method is used in this study to speed up the calculations. An important advantage of the Nelder–Mead method over population-based or swarm-based methods often used for electrical machine optimization, such as the genetic algorithm, particle swarm algorithm, etc. [

23,

24,

25,

26], is the significant saving of computational time, which, without the use of supercomputers, allows for increasing the complexity of the mathematical model and number of optimization parameters, applying more complex optimization criteria, and also considering more than one operating point in the optimization process, which is particularly important for optimizing electrical machines that must provide a wide CPSR [

4].

In this study, based on the optimization goals described above, the minimized objective function has the following form:

where the values of

Feff,

FI and

FTR are given by Equation (3); the values of the flux linkage discrepancies between the ROM and the basic model ε

1 and ε

2 are given by Equation (2); the values of deviations in mechanical power based on the results of ROM calculations, compared to the basic model,

Err1 and

Err2 are given by Equation (4).

The first three terms in (5) correspond to the selected optimization goals: increasing efficiency, reducing the motor current drawn from the inverter, and reducing torque ripple. The natural logarithms of the Feff, FI and FTR functions are calculated so that the optimization function considers relative, rather than absolute, reductions in these quantities with different units of measurement.

The weighting factors of 1, 2, and 0.5 reflect the relative priorities assigned to each optimization goal, based on the authors’ accumulated experience in designing comparable machines. The most important objective is to minimize FI (factor 2), since reducing the consumed current allows for a reduction in the rating and cost of the inverter’s power semiconductor modules. The next most important objective is to increase efficiency (factor 1). Relatively less importance is assigned to the objective of reducing torque ripple (factor 0.5). A constant of 0.5 means that a 1% reduction in FTR is equivalent in importance to a 0.5% reduction in Feff. At the same time, a constant of 2 means that 0.5% reduction in FI is just as important as a 1% reduction in Feff.

The penalty sum (ε1 + ε2 + Err1 + Err2) can tend to zero, and the linear logarithm of such a value in this case will tend to infinity. Therefore, the logarithm for the last term in (5) is not calculated. The factor 7.5 is chosen to be large enough to ensure a gradual reduction in the deviations ε1, ε2, Err1, and Err2 to values acceptable for engineering calculations.

The function value depends on the basic model vector x and the inner optimization parameter vector y. The optimization procedure is based on the Nelder–Mead method and takes into account the fact that the computational time of the basic model and of the ROM differ by nearly a factor of ten.

Since ROM computation is computationally lean, the minimization of the objective function

can be performed rather fast by adjusting only the ROM parameter vector

y:

This subroutine is called inner optimization. The minimum value of the objective function

can be found as the minimum of

by adjusting only vector

x. This subroutine refers to outer optimization:

Since the proposed optimization routine is divided into outer and inner optimization subroutines, it can be called “two-level”. Thus, the algorithm for calculating F(x) and the optimal vector of the ROM parameter yopt, which allows for achieving the minimum value of F(x,y) for given x vector, is designed as follows.

- (1)

The basic model is computed at operating point 1 and linearized in its vicinity.

- (2)

The basic model is computed at operating point 2 and linearized in its vicinity.

- (3)

Optimization of the ROM parameters using the Nelder–Mead method. The termination criterion for the optimization is 45 function evaluations.

- (4)

The minimum function value and the corresponding vector yopt of the optimized ROM parameters are returned as a result.

Thus, evaluating

requires computing the HESM characteristics at the two operating points listed in

Table 2 and, therefore, two basic model runs, which result in 2 × 45 = 90 ROM runs in total. The computation time for

F(x) is approximately 2 × 190 + 90 × 12 = 1460 s.

The procedure described above is used as the objective function for the outer optimization. As a result, for each simplex vertex in the outer optimization, not only the value of F(x) is stored, but also the inner optimization parameters yopt at which is attained.

Let us consider the choice of the initial guess for the inner optimization parameters. During the first evaluation of

F(x), the initial values for the inner optimization must ensure the absence of significant overmodulation of the stator winding voltage. In particular, the number of turns in the stator winding is deliberately chosen to be small. In subsequent evaluations of

F(x), the initial inner optimization parameters should be selected as close as possible to the optimized values. Therefore, they are constructed from the optimized ROM parameter vectors

, stored for each simplex vertex

of the outer optimization:

where

is the worst function value in the simplex, with summation carried out over all vertices of the outer optimization simplex.

In this way, the better vertices (with smaller objective function values) contribute more to the formation of the initial guess.

The restriction of the inner optimization to 45 function evaluations naturally reduces its accuracy. However, the algorithm develops as follows: initially, the outer optimization relies on approximate values of the objective function F(xi) due to the limited accuracy of the inner optimization. As optimization proceeds, the initial values become increasingly close to the optimal ones, which in turn improves the performance of the inner optimization.