Position Sensorless Control of BLDCM Fed by FSTP Inverter with Capacitor Voltage Compensation

Abstract

1. Introduction

2. Brushless DC Motor System Driven by Four-Switch Three-Phase Inverter

2.1. Mathematical Model of BLDCM Driven by FSTP Inverter

2.2. Three-Phase Current Control of BLDCM Driven by FSTP Inverter

3. Relationship Between G(θ) Function and Commutation Point of BLDCM

4. Position Sensorless Control Method of BLDCM Driven by FSTP Inverter with Capacitor Voltage Compensation

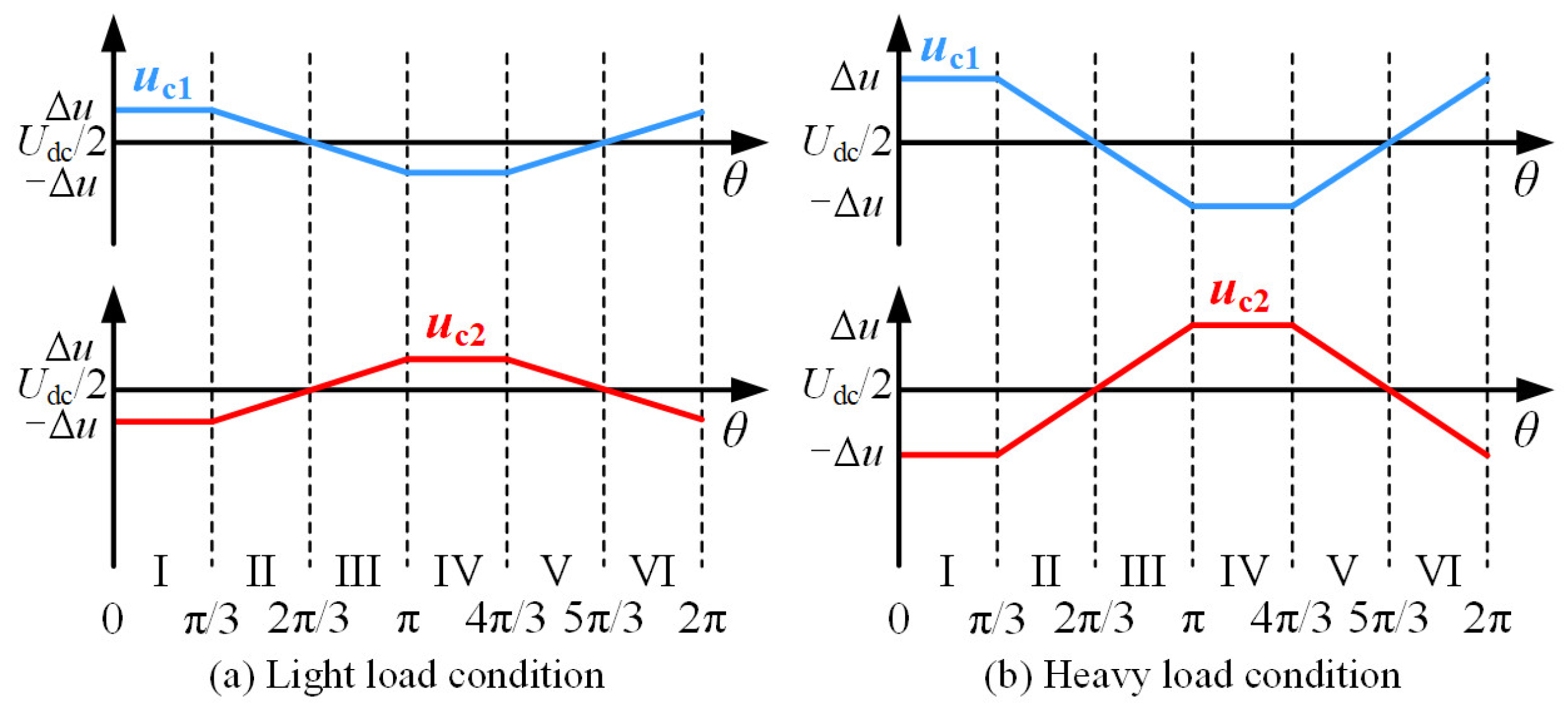

4.1. DC Side Neutral Point Potential Offset and Modeling

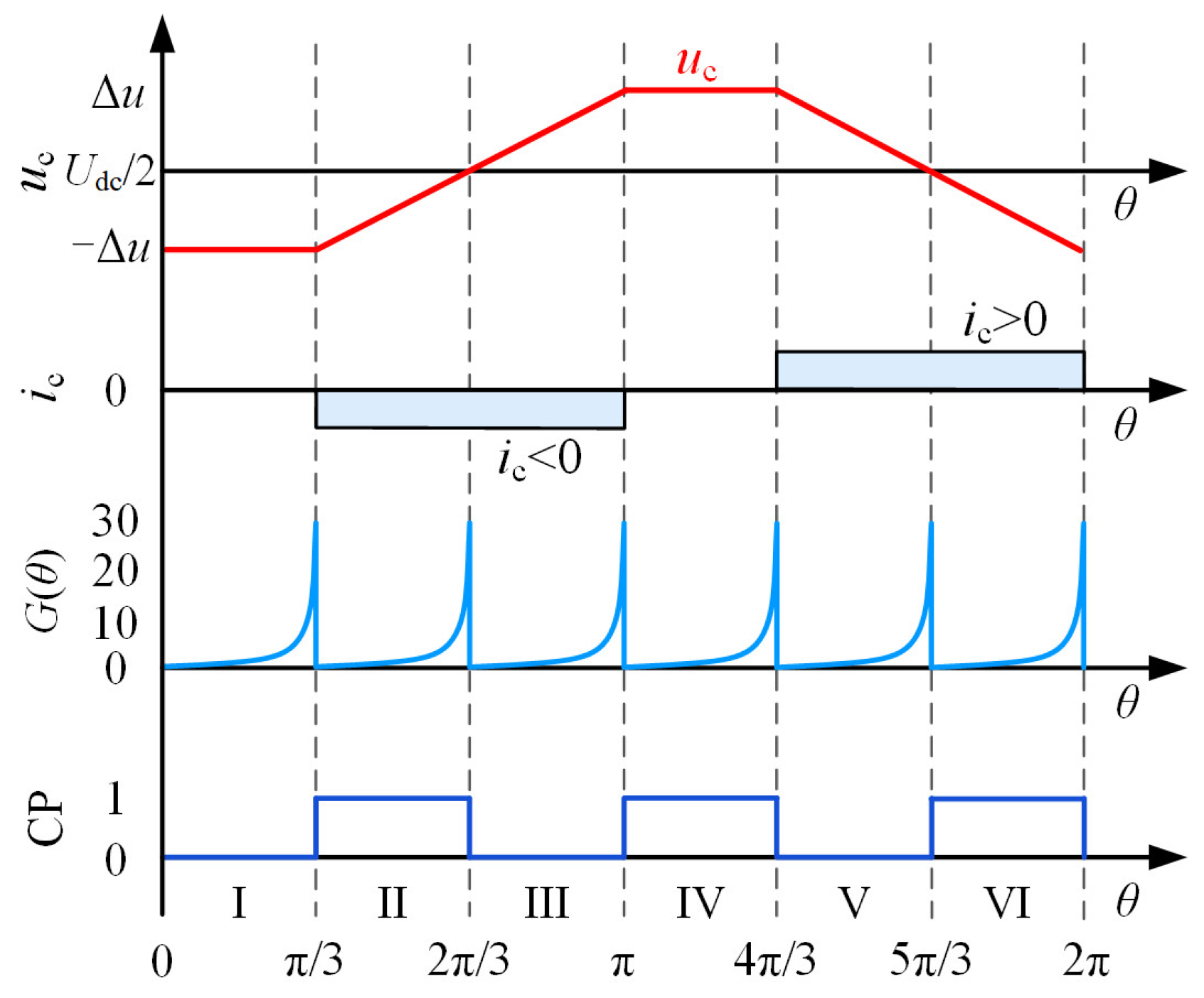

4.2. Construction and Principle Analysis of G(θ) Function

4.3. Position Sensorless Control Strategy Based on Voltage Offset Compensation

4.4. Design of Control System

5. Experimental Results and Analysis

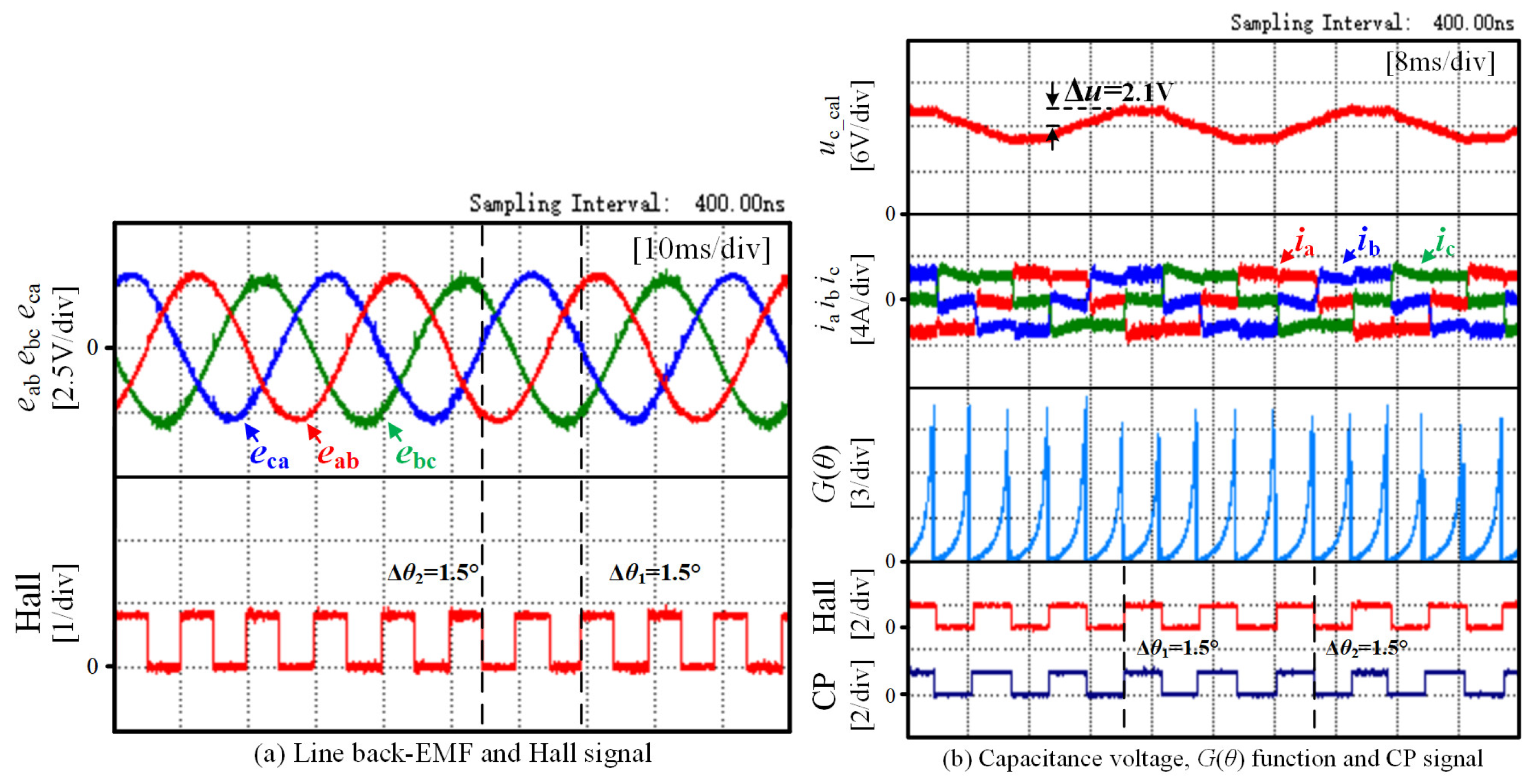

5.1. Balance Verification of Capacitor Voltage

5.2. Analysis of Experimental Results with Uncompensated Capacitor Voltage

5.3. Analysis of Experimental Results After Capacitor Voltage Compensation

5.4. Steady State Experiments Under Different Working Conditions

5.5. Dynamic Experiment Under Different Working Conditions

5.6. Quantitative Performance Analysis

6. Conclusions and Prospects

- (1)

- A method to directly calculate the three-phase terminal voltage by using the duty cycle and DC bus voltage is proposed. Because the G(θ) function method does not need to use a filter, it avoids the introduction of phase delay. Meanwhile, the proposed method compensates for the influence of capacitor voltage fluctuation on the position sensorless control algorithm and improves the accuracy of commutation.

- (2)

- The proposed method is suitable for rotor position estimation in a wider speed range. Meanwhile, it indirectly uses the zero crossing point of back-EMF to estimate the rotor position, so it does not need the motor to have an ideal back-EMF waveform.

- (3)

- The proposed method does not need to delay the detection signal by 30° electrical angle, avoiding additional error caused by the change in speed in the delay process.

- (1)

- Extend the proposed control method to kilowatt-class motors, with a focus on verifying its performance and stability under high-power and long-term operation scenarios.

- (2)

- Integrate an adaptive parameter estimation method to alleviate the impact of mismatches between stator resistance and inductance values on control performance.

- (3)

- Develop advanced modulation strategies to further improve the DC bus voltage utilization rate or system dynamic response performance under the inherent constraints of the FSTP topology.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BLDCM | Brushless DC Motor |

| FSTP | Four-witch Three-phase |

| SSTP | Six-switch Three-phase |

| CP | Commutation Point |

References

- Chen, S.; Liu, G.; Zhu, L. Sensorless startup strategy for a 315-kW high-speed brushless DC motor with small inductance and nonideal back EMF. IEEE Trans. Ind. Electron. 2019, 66, 1703–1714. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H. Fast commutation error compensation method of sensorless control for MSCMG BLDC motor with nonideal back EMF. IEEE Trans. Power Electron. 2021, 36, 8044–8054. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, X.; Tan, B.; Xu, L.; Yuan, C.; Huangfu, Y. Fast commutation error compensation for BLDC motors based on virtual neutral voltage. IEEE Trans. Power Electron. 2021, 36, 1259–1263. [Google Scholar] [CrossRef]

- Park, J.S.; Lee, K.D.; Lee, S.G.; Kim, W.H. Unbalanced ZCP compensation method for position sensorless BLDC motor. IEEE Trans. Power Electron. 2019, 34, 3020–3024. [Google Scholar] [CrossRef]

- Jin, H.; Liu, G.; Zheng, S.Q. Commutation error closed-loop correction method for sensorless BLDC motor using hardware-based floating phase back-EMF integration. IEEE Trans. Ind. Inform. 2022, 18, 3978–3986. [Google Scholar] [CrossRef]

- Gambetta, D.; Ahfock, A. New sensorless commutation technique for brushless DC motors. IET Electr. Power Appl. 2009, 3, 40–49. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Z.Q.; Wu, Z. A novel rotor initial position detection method utilizing DC-Link voltage sensor. IEEE Trans. Ind. Appl. 2020, 56, 6486–6495. [Google Scholar] [CrossRef]

- Li, P.; Sun, W.; Shen, J.X. Flux observer model for sensorless control of PM BLDC motor with a damper cage. IEEE Trans. Ind. Appl. 2019, 55, 1272–1279. [Google Scholar] [CrossRef]

- Chen, S.; Liu, G.; Zhu, L. Sensorless control strategy of a 315 kW high-speed BLDC motor based on a speed-independent flux linkage function. IEEE Trans. Ind. Electron. 2017, 64, 8607–8617. [Google Scholar] [CrossRef]

- Zhang, H.F.; Liu, G.; Zhou, X.X.; Zheng, S.Q. High-precision sensorless optimal commutation deviation correction strategy of BLDC motor with asymmetric back EMF. IEEE Trans. Ind. Inform. 2021, 17, 5250–5259. [Google Scholar] [CrossRef]

- Huang, C.L.; Wu, C.J.; Yang, S.C. Full-region sensorless BLDC drive for permanent magnet motor using pulse amplitude modulation with DC current sensing. IEEE Trans. Ind. Electron 2021, 68, 11234–11244. [Google Scholar] [CrossRef]

- Liu, G.; Chen, X.; Zhou, X.X.; Zheng, S.Q. Sensorless commutation deviation correction of brushless DC motor with three-phase asymmetric back-EMF. IEEE Trans. Ind. Electron. 2020, 67, 6158–6167. [Google Scholar] [CrossRef]

- Zeng, Z.; Zheng, W.; Zhao, R.; Zhu, C.; Yuan, Q. Modeling, modulation, and control of the three-phase four-switch PWM rectifier under balanced voltage. IEEE Trans. Power Electron. 2016, 31, 4892–4905. [Google Scholar] [CrossRef]

- Haghi, R.; Beiranvand, R.; Shahbazi, M. A quasi-Z-source four-switch three-phase inverter with null vector capability. IEEE Trans. Ind. Electron. 2023, 70, 5421–5432. [Google Scholar] [CrossRef]

- Sun, D.; Su, J.; Sun, C.; Nian, H. A simplified MPFC with capacitor voltage offset suppression for the four-switch three-phase inverter-fed PMSM drive. IEEE Trans. Ind. Electron. 2019, 66, 7633–7642. [Google Scholar] [CrossRef]

- Pan, L.; Sun, H.; Wang, B.; Su, G.; Wang, X.; Peng, G. Torque ripple suppression method for BLDCM drive based on four-switch three-phase inverter. J. Power Electron. 2015, 15, 974–986. [Google Scholar] [CrossRef][Green Version]

- Xia, C.L.; Wu, D.; Shi, T.N.; Chen, W. A current control scheme of brushless DC motors driven by four-switch three-phase inverters. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 5, 547–558. [Google Scholar] [CrossRef]

- Zhou, D.; Li, X.; Tang, Y. Multiple-vector model predictive power control of three-phase four-switch rectifiers with capacitor voltage balancing. IEEE Trans. Power Electron. 2018, 33, 5824–5835. [Google Scholar] [CrossRef]

- Zhu, C.; Zeng, Z.Y.; Zhao, R.X. Comprehensive analysis and reduction of torque ripples in three-phase four-switch inverter-fed PMSM drives using space vector pulse-width modulation. IEEE Trans. Power Electron. 2017, 32, 5411–5424. [Google Scholar] [CrossRef]

- BLee, K.; Kim, T.H.; Ehsani, M. On the feasibility of four-switch three-phase BLDC motor drives for low cost commercial applications: Topology and control. IEEE Trans. Power Electron. 2003, 18, 164–172. [Google Scholar]

- Lin, C.; Hung, C.; Liu, C. Position sensorless control for four-switch three-phase brushless DC motor drives. IEEE Trans. Power Electron. 2008, 23, 438–444. [Google Scholar] [CrossRef]

- Niasar, A.H.; Vahedi, A.; Moghbelli, H. A novel position sensorless control of a four-switch, brushless DC motor drive without phase shifter. IEEE Trans. Power Electron. 2008, 23, 3079–3087. [Google Scholar] [CrossRef]

- Qu, J.; Li, K. Model predictive direct torque control of a three-phase four-switch inverter induction motor driving system. In Proceedings of the 12th IET International Conference on Advances in Power System Control, Operation and Management (APSCOM 2022), Hybrid Conference, Hong Kong, China, 7–9 November 2022; pp. 77–82. [Google Scholar]

- Chen, W.; Zhu, L.; Wang, S.; Li, X.; Shi, T.; Xia, C. Rotating Restart Method for TPFS Inverter-Fed Sensorless PMSM Drive System Based on Dual Effective Voltage Vectors Injection. IEEE Trans. Power Electron. 2024, 39, 11708–11722. [Google Scholar] [CrossRef]

| Sector | I | II | III | IV | V | VI |

|---|---|---|---|---|---|---|

| ia | I | I | 0 | −I | −I | 0 |

| ib | −I | 0 | I | I | 0 | −I |

| ic | 0 | −I | −I | 0 | I | I |

| Sector | ua | ub | uc |

|---|---|---|---|

| II | daUdc | dbUdc | Udc/2 − Δu |

| III | daUdc | dbUdc | |

| V | (1 − da)Udc | dbUdc | |

| VI | daUdc | (1 − db)Udc |

| Sector | ic | ua | ub | uc |

|---|---|---|---|---|

| I | ic ˃ 0 | (da + dc)Udc | (1 − db)Udc (1 − db − dc)Udc (db + dc)Udc dbUdc | Udc/2 − Δu |

| ic ˂ 0 | daUdc | |||

| IV | ic ˃ 0 | (1 − da)Udc | ||

| ic ˂ 0 | (1 − da − dc)Udc |

| Sector | I and IV | II and V | III and VI |

|---|---|---|---|

| G(θ) | Gca/bc(θ) | Gbc/ab(θ) | Gab/ca(θ) |

| Parameters | Value | Unit |

|---|---|---|

| Rated power PN | 70 | W |

| Rated voltage UN | 24 | V |

| Rated current IN | 4 | A |

| Rated torque TN | 0.24 | N·m |

| Rated speed nN | 3000 | r/min |

| Phase resistance Rs | 0.316 | Ω |

| Phase inductance Ls | 0.628 | mH |

| Poles pairs p | 2 | |

| Capacitance C1 = C2 | 2500 | μF |

| PWM carrier frequency | 20 | kHz |

| Operating Conditions | of Proposed Method | of Other Methods [22] |

|---|---|---|

| Low speed with no load | 1.5° | 4° |

| Low speed with heavy load | 2.8° | 24° |

| High speed with no load | 2.7° | 4.5° |

| High speed with heavy load | 2.9° | 14° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zhou, L.; Meng, Q.; Xin, Y.; Li, X.; Li, C. Position Sensorless Control of BLDCM Fed by FSTP Inverter with Capacitor Voltage Compensation. World Electr. Veh. J. 2025, 16, 582. https://doi.org/10.3390/wevj16100582

Wang H, Zhou L, Meng Q, Xin Y, Li X, Li C. Position Sensorless Control of BLDCM Fed by FSTP Inverter with Capacitor Voltage Compensation. World Electric Vehicle Journal. 2025; 16(10):582. https://doi.org/10.3390/wevj16100582

Chicago/Turabian StyleWang, Hanrui, Lu Zhou, Qinghui Meng, Ying Xin, Xinmin Li, and Chen Li. 2025. "Position Sensorless Control of BLDCM Fed by FSTP Inverter with Capacitor Voltage Compensation" World Electric Vehicle Journal 16, no. 10: 582. https://doi.org/10.3390/wevj16100582

APA StyleWang, H., Zhou, L., Meng, Q., Xin, Y., Li, X., & Li, C. (2025). Position Sensorless Control of BLDCM Fed by FSTP Inverter with Capacitor Voltage Compensation. World Electric Vehicle Journal, 16(10), 582. https://doi.org/10.3390/wevj16100582