1. Introduction

The transport of about 80% of world trade in volume and about 70% in value links to the maritime sector [

1]. It is attributable to a significant contribution of greenhouse gas emissions and polluting substances such as Volatile Organic Compounds (VOC), particulate matter (PM), nitrogen oxides (NO

x), and sulfur oxides (SO

x) [

2]. In particular, the International Maritime Organization (IMO) estimated that in 2018 the shipping sector caused about 2.89% of global anthropogenic CO

2 emissions, about 4–9% of global SO

x emissions, and about 15% of global NO

x emissions [

3]. Although these values seem contained, it has been estimated that around 70% of the emissions produced by the shipping sector occur within 400 km of coastal areas, especially near ports, with inevitable damage to marine and coastal ecosystems [

4].

Faced with a constant increase in the number of passengers and global trade, over the years the IMO has introduced increasingly stringent rules to counter the increase in polluting emissions by imposing limits on greenhouse gas emissions through regulations on the energy efficiency of ships (from 2025 onwards a 30% reduction in CO

2 emissions is mandatory for all ships) [

4]. Nowadays the most implemented interventions concern the hull design [

5], propulsions system, treatment of exhaust gases, and the use of alternative fuels [

6]; for example, the use of liquefied natural gas is becoming more frequent, because it has a low sulfur content, it is colorless, non-toxic, non-corrosive, and it allows for lower emissions compared to heavy fuel oils [

3,

6,

7,

8,

9]. A possible alternative to conventional technologies could be the fuel cell technology.

Fuel cells are static energy conversion systems, in which the chemical energy of the fuel is converted into electrical energy directly, without the need for intermediate conversions into thermal energy and mechanical energy. Since their operation is based on electrochemical reactions, their efficiency is not bound by Carnot’s theorem theoretically, but it can reach higher values than those of conventional heat engines [

10,

11,

12,

13]. Furthermore, being modular systems, their performance does not depend on the size of the system, and they have good characteristics even at partial load [

13,

14]. Various types of fuel cells have been developed, which differ from each other mainly in the type of electrolyte and therefore in the operating temperatures. Among the different types of fuel cells, Solid Oxide Fuel Cells (SOFC) are among the most promising ones for maritime applications [

13,

14]. SOFC systems, in fact, are characterized by great flexibility in terms of power supply as they can be fed by a wide variety of liquid and gaseous fuels, such as syngas [

15], biogas [

16,

17] methane [

18], liquefied natural gas [

3,

14,

19,

20,

21], methanol [

22,

23,

24], ethane [

25], gas oil [

26], ammonia [

27,

28,

29,

30,

31], etc. Furthermore, the use of SOFCs could bring advantages in environmental terms as they are characterized by reduced emissions of pollutants, such as nitrogen oxides (NO

x), sulfur oxides (SO

x), and carbon monoxide (CO) [

32]. SOFCs can reach electrical efficiencies in the range 45–60% in the case of stand-alone systems and can have efficiencies higher than 60% in the case of combined hybrid systems [

2,

13,

33], allowing to reduce CO

2 emissions. In ref. [

25] it is demonstrated how it is possible to obtain an Energy Efficiency Design Index (EEDI) value lower than that envisaged for all different phases, by integrating a SOFC/Gas Turbine (GT) system within a propulsion system of a cargo ship. In the different phases, a gradual reduction of CO

2 emissions is required compared to the reference value, which varies according to the type and size of the ship and in the last phase, envisaged from 2025, a reduction of CO

2 emissions of 30% is required. In ref. [

21] it is reported that by using SOFC technology it is possible to obtain a reduction of up to 53% of CO

2 emissions compared to conventional technologies. Furthermore, the possibility of recovering the high temperature heat produced by SOFCs can lead to significant reductions in fuel consumption. SOFCs, therefore, can operate in a co-generative or even tri-generative arrangement, since the electric or thermal energies produced can be exploited to conduct compression or absorption refrigeration cycles [

18,

34,

35].

However, the SOFCs and the materials they are made of are unable to track load fluctuations due to the high operating temperatures. On board ships they can be used to satisfy the base load, while load variations are tracked using components that have better dynamic characteristics [

2,

3,

14,

21,

36,

37,

38].

The application of SOFCs has also been studied in various research projects:

Within the FELICITAS project, the possibility of using a 250 kW SOFC/GT system fueled by methane in tri-generative arrangement was analyzed, so as to simultaneously satisfy the basic electrical load and the needs linked to air conditioning on board a 50 m yacht;

Within the METHAPU project a 20 kW SOFC prototype, powered by methanol, was tested on board the vehicle transport vessel MV Undine of the Wallenius Wilhelmsen group [

2,

39];

Within the schibz project a 50-kW diesel SOFC unit was tested on board the cargo ship MS Forester, which demonstrated an efficiency of up to 55% [

2,

39,

40];

Within the ShipFC project, the possibility of deliver a 2 MW SOFC fueled by Ammonia to the offshore vessel Viking Energy [

13];

Within the Nautilus project, the possibility of developing and validating a hybrid power system based on SOFC fueled by LNG, a battery system, and the existing internal combustion engine, which will be applied on board a cruise ship [

13].

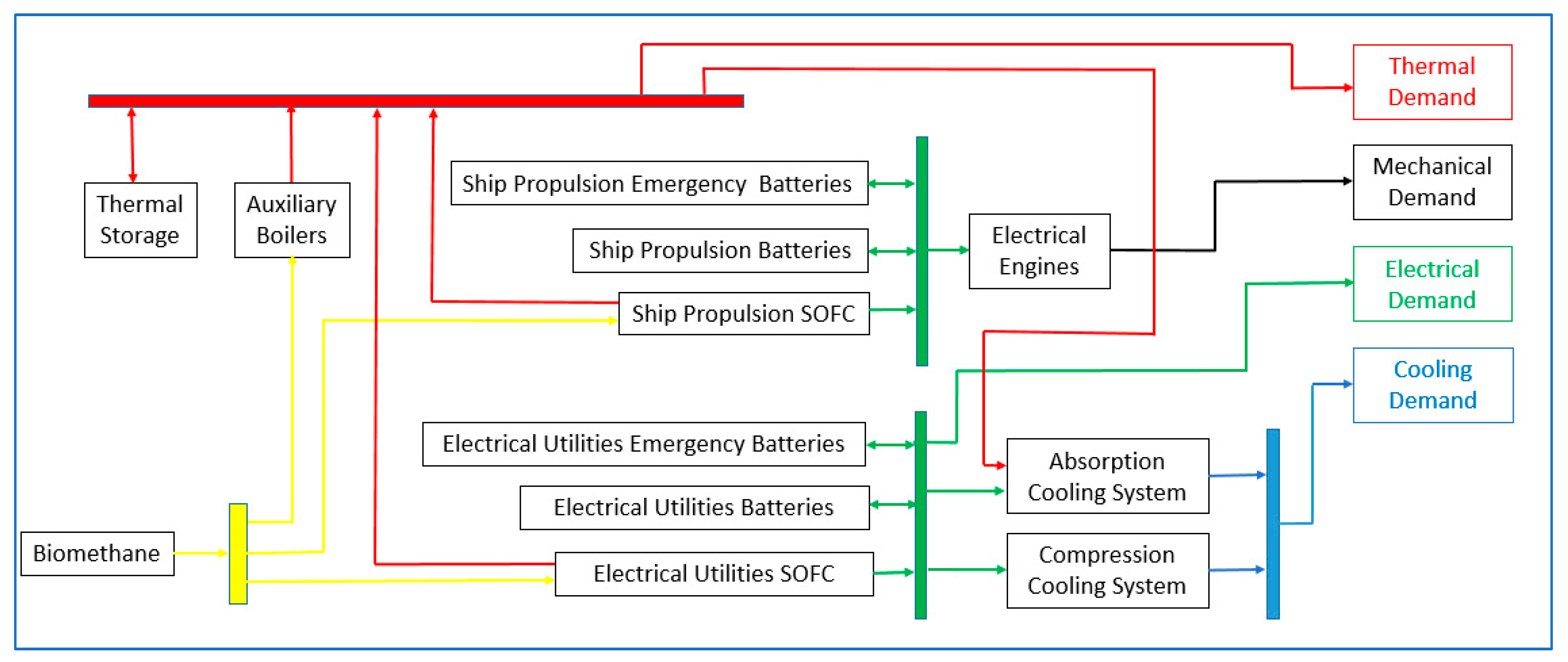

In the present article, the possibility of replacing the conventional energy system of a ship based on diesel Internal Combustion Engines (ICEs) with a more efficient and innovative energy system based on the use of SOFCs equipped with its storage systems was analyzed with reference to a particular case study.

In particular, in this case study the use of two distinct systems is envisaged: the first one, which supplies the electrical energy required for propulsion, and the second one, which powers the other utilities on board the ship. For this analysis it was decided to refer to a cruise ship since, unlike other types of ships (not intended for passenger transport) whose energy demand is mainly linked to propulsion, for this type of ship the demand for energy related to passenger comfort and services is very relevant. In particular, since the thermal requirements are also considerable, it is expected that in this type of ship it is possible to exploit the thermal energy produced by the SOFCs for co-/tri-generations purposes in order to fully or partially satisfy the thermal energy requirements on board the ship.

The proposed energy system involves the use of batteries in both ordinary and emergency operating conditions, thermal storage systems, auxiliary boilers, and absorption and compression cooling systems. The only fuel on board the vessel is expected to be bio-methane. Then the performance and expected emissions of the proposed energy system were compared with the ones of the original energy system based on diesel ICEs.

2. Features of the Ship and of the Conventional Base Energy System

The ship examined in this article is the “MS Birka Stockholm” [

41], a medium-sized cruise ship built by Aker Finnyards, in Rauma in Finland, and inaugurated in 2004, whose main features are shown in

Table 1 [

41].

In the original configuration, the “MS Birka Stockhlom” ship is equipped with eight four-stroke diesel ICEs, of which four main engines are used for the ship propulsion and four auxiliary engines are used for the generation of electric energy.

The ship propulsion system is divided into two lines, each of which consists of two main ICEs, a transmission system, and a propeller: the four main ICEs are Wärtsilä 6L46, with a rated power of 5850 kW each (the total rated power for the ship propulsion is 23,400 kW) [

42]. Therefore, due to the way the propulsion system is structured, the need for mechanical power is divided equally between the two lines and, for this reason, when there is a request for mechanical power, even if minimal, at least two ICEs are always in operation [

43].

The four auxiliary ICEs, which are used for the production of electric energy, are Wärtsilä 6L32, with a nominal power of 2760 kW each.

All ICEs are equipped with SCR (Selective Catalytic Reactors) systems for reducing nitrogen oxides (NOx).

The thermal energy demand is satisfied by recovering part of the heat dissipated by the ICEs. In fact, the four auxiliary ICEs and two of the main engines are equipped with Heat Recovery Boilers (HRB) and the temperature cooling systems of all the ICEs are connected to the heat recovery system.

Moreover, two auxiliary boilers are installed on the ship, and they are put into operation when the recovered heat is not sufficient to satisfy the entire demand (this can occur during the winter period or when the ship is moored in the port) [

42]. Each boiler is characterized by a maximum power of 4500 kW and a nominal thermal efficiency of 80% [

43].

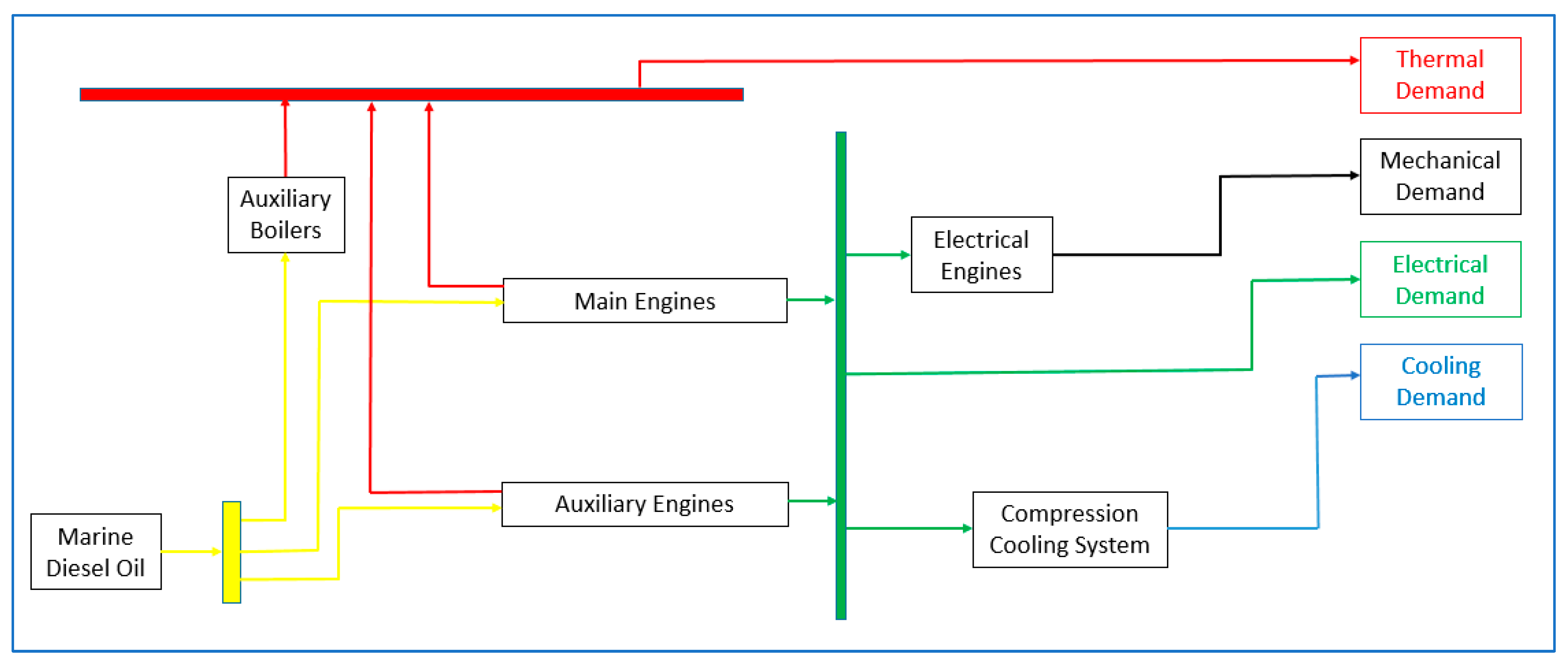

However, the ship system, which will be indicated as the base system in this article is not the original one, but it is the hybrid configuration proposed in the work [

43], whose schematic representation is shown in

Figure 1, where all the engines produce electricity, and the propulsion is achieved by means of two electric motors. Furthermore, in this configuration a compression refrigeration unit is used for cooling the rooms during the summer season. This refrigeration unit is characterized by a nominal cooling capacity of 2000 kW and an Energy Efficiency Ratio (EER) of 3.5 [

43].

All passenger accommodations are equipped with HD televisions, dressing table with chair, wardrobe, telephone, electronic safe (in wardrobe), bathroom (sink, toilet, shower, hair dryer), and user-controllable air conditioning.

In addition, there are three restaurants, a swimming pool, two Jacuzzis, a SPA with three saunas, several bars, nightclubs, dance halls, shops, casinos, and conference rooms [

41].

This cruise ship operates in the Baltic Sea and carries passengers from Stockholm (Sweden) to Mariehamn (Åland Islands, Finland). In particular, it always carries out the same daily tour lasting 22 h, 365 days a year: it departs around 18:00 from Stockholm and arrives in Mariehamn in the early hours of the morning, after stopping at open sea during the night; at 9:00 it departs from Mariehamn and arrives in Stockholm around 16:00 [

43]. The length of the route is approximately 314.8 km (170 nautical miles) [

44].

The operating profiles and the needs of the ship have been obtained from ref. [

43], in which the distinction is made regarding navigation in the open sea, stop (in the open sea or in port), and maneuvering phases. In particular, in ref. [

43], navigation in the open sea represents about 59% of the operating profiles, parking represents about 33%, while maneuvering phases represent 8%.

The main needs of the ship are as follows: mechanical energy (for propulsion), electrical energy (for ancillary services and hotel loads), thermal energy (mainly for space heating and for the production of hot water), and energy for cooling (only in the summer period) [

43].

The authors of ref. [

43] determined the hourly load profiles for the following three typical days: winter, spring/autumn, and summer.

Based on the Swedish average monthly temperatures, the following subdivision was made:

- -

Winter: 182 days (from 1 January to 15 April and from 16 October to 31 December);

- -

Spring/Autumn: 121 days (from 16 April to 30 June and from 1 September to 15 October);

- -

Summer: 62 days (1 July to 31 August);

The hourly trends of the loads for the three typical days were evaluated in ref. [

43] through an experimental data acquisition for one year on board the ship. A detailed description of the methodology employed for the evaluation of the loads is reported in ref. [

45]. The hourly profiles of the loads for the three typical days are represented graphically in ref. [

43].

As reported by the authors in Ref. [

43], the daily trends of mechanical and electric energies are always the same in all the seasons, since the ship travels the same route every day of the year. The daily trends of thermal and cooling energies vary according to the season (e.g., the thermal energy is not zero in the summer as it is necessary to satisfy the hot water requests).

The curve relating to the thermal energy requirement has a variable trend, which has peaks (the maximum value is just over 7000 kW), while the trend of the power required for cooling is almost constant with an average value of around 1000 kW.

The mechanical energy requested by the ship is equal to zero, when the ship is stopped in the port or in the open sea (case 1) and is equal to the maximum value of about 6000 kW when the ship sails in the open sea (case 2).

The same mechanical energy is equal to an intermediate value with respect to the ones in cases 1 and 2, when the ship carries out shunting operations inside the port (case 3).

The electrical and thermal loads are necessary to satisfy the ancillary services and the needs linked to the permanence of the passengers on board, therefore they are independent of the ship’s operating profiles, and they are never null.

In fact, it is always necessary to guarantee the continuity of safety services (smoke detectors, gas detectors, fire-fighting equipment, alarms, safety lighting, etc.) and those relating to on-board comfort (lighting, entertainment, air conditioning, hot water, kitchens, etc.) [

43].

4. Preliminary Design of the New Energy System

In this paragraph, the main components of the proposed energy system (SOFC systems, batteries, thermal storage system, auxiliary boilers, cooling system and desalinator) are analyzed with the aim of carrying out their preliminary design.

The commercial SOFC modules taken into consideration are the “Bluegen BG-15” ones by Solydera s.p.a., whose main technical features are shown in

Table 5.

Since SOFC systems are modular, the required power is obtained by using more modules of this type.

To reduce the thermal stresses on the SOFCs, which would reduce their useful life, the SOFC system is sized so that the SOFC modules inside can operate at a constant nominal load for 24 h a day. For this reason, the design electrical power of the SOFC system is set equal to the average value of the electrical power required throughout the day.

Two separate SOFC systems are sized: one, which supplies the electrical power for propulsion, and the other one, which produces the electrical power for all other utilities on board of the ship.

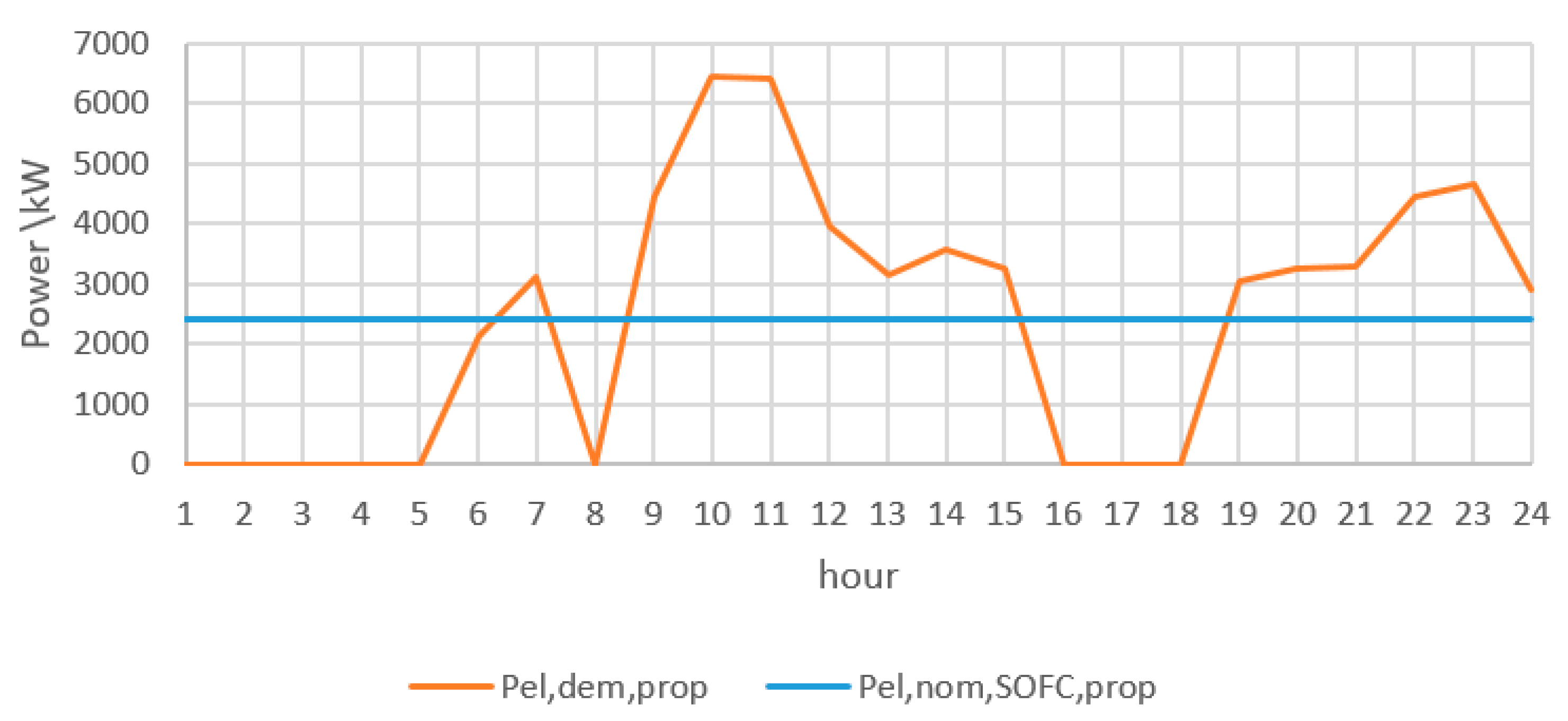

As shown in Ref. [

43], the hourly trend of the mechanical power required for propulsion is the same for all seasons; this happens because the ship travels the same route every day of the year.

The SOFC system produces electric energy at constant current and for this reason an inverter is installed downstream of the SOFC, for which an operation with a constant efficiency ηel,inv equal to 0.96 has been assumed.

Considering that electric motors have an electric efficiency η

el,mot equal to 0.96 [

43], the electric power required for propulsion was calculated through Equation (1):

The electric power requirement for propulsion depends on the type of operation carried out by the ship (stop in port or offshore, maneuvering phase, navigation in the open sea) and therefore varies significantly throughout the day.

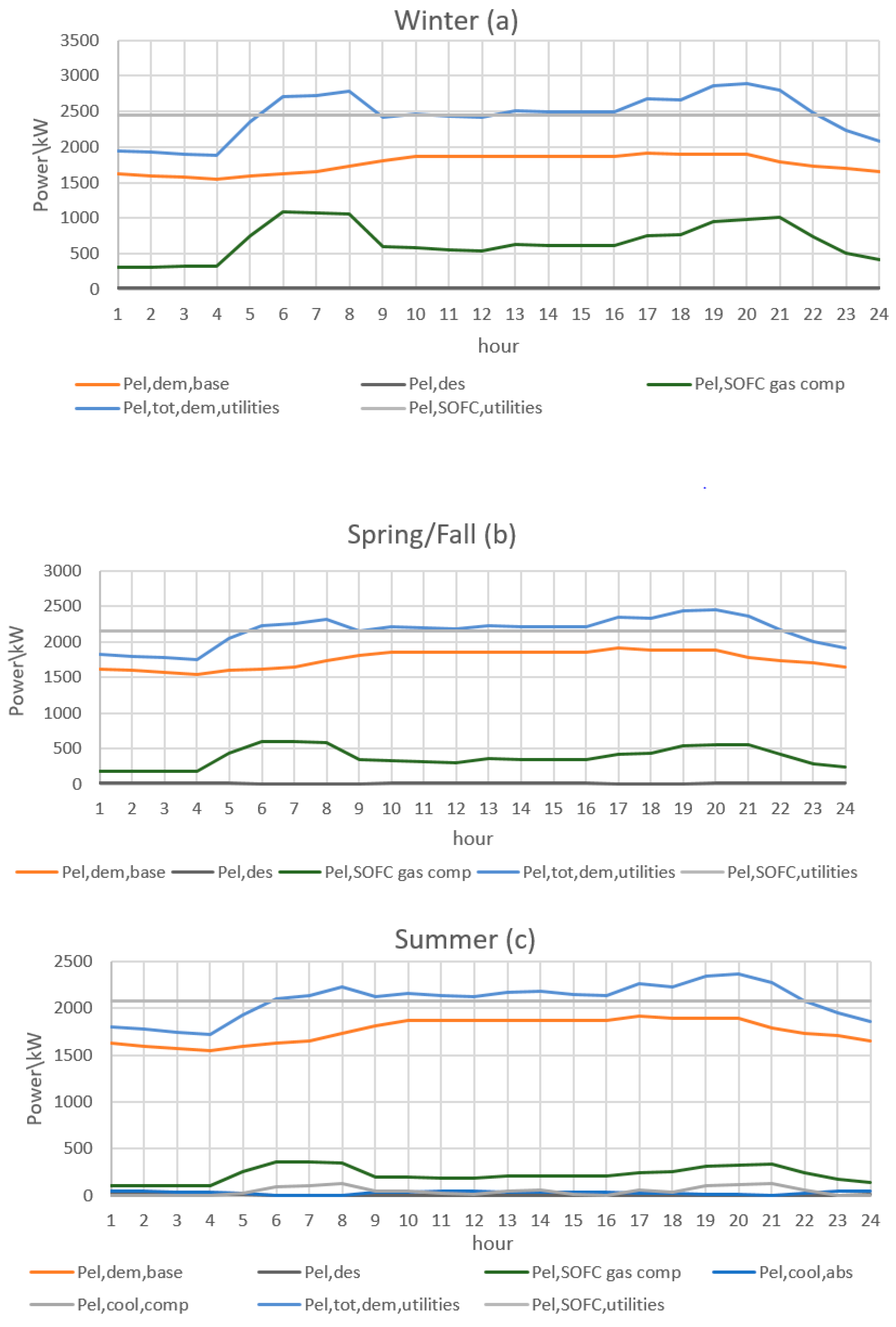

The hourly trend of the total electrical power requirement relating to the utilities on board the vessel (auxiliary systems and electrical loads relating to the various services on board the vessel) was obtained for the three typical days (winter, spring/autumn, and summer) using Equation (2):

In Equation (2):

P

el,dem,base is the electrical power required by the various users on board the ship (related to the auxiliary services and the hotel loads) obtained from ref. [

43];

Pel,des is the electric power absorbed by the desalination plant to purify the water drawn from the sea;

Pel,SOFC gas comp is the electric power required by the compressors to circulate the hot SOFC exhaust gases;

Pel,abs is the electrical power absorbed by the absorption refrigeration unit used for cooling the rooms;

Pel,comp is the electrical power absorbed by the compression refrigeration unit used for cooling the rooms.

Obviously, the electrical power required for the absorption cooling system and for the compression cooling system is only required in the summer season.

Regarding the electrical power required to circulate the hot exhaust gases of the SOFCs, Pel,SOFC gas comp, the following working hypothesis was made: for all seasons it was set equal to 15% of the thermal power request; consequently, it follows the trend of the thermal power request.

The calculation of the total electrical power required by the users was carried out through an iterative procedure. In fact, the power absorbed by the desalinator, by the absorption cooling system and by the compression cooling system depends on the power supplied by the SOFC systems. The seawater, which must be treated, depends on the water required by the SOFCs for the steam reforming of the fuel. The cooling capacity supplied by the absorption cooling system depends on the thermal capacity, which is supplied by the hot SOFC systems exhaust gases. The cooling power required from the compression cooling system depends on the cooling power that is supplied by the absorption cooling system (in fact, the compression cooling system is used to compensate for the cooling power, which the absorption cooling system cannot satisfy).

As seen in the previous paragraph, SOFC systems are sized to be in operation for all hours of the day at a power that is equal to the average value of the power required by the loads throughout the day. For this reason, there will be hours in which the electrical power supplied is greater than that required, while there will be other hours in which the opposite is true.

The batteries, therefore, carry out the task of accumulating energy when the power supplied by the SOFC systems is greater than that required by the load and of supplying energy when the opposite occurs.

Since the electrical power supplied by the SOFCs has been set exactly equal to the average of that required, it is necessary to fully accumulate the electrical energy surplus in order to be able to satisfy fully the demand in the time interval considered.

The minimum amount of electric energy, which the batteries must be able to accumulate so that there is no dissipation of the energy produced by the SOFCs, is equal to the maximum energy that can be stored during the day. This value was obtained from the trend of the cumulated electric energy, which in turn was determined starting from the hourly deviations between the electric power generated and the electric power absorbed. As was done for the SOFC systems, two separate systems were sized for the batteries: one relating to the propulsion of the ship and the other one relating to all the other electric utilities on board of the ship.

In addition to carrying out the preliminary design of electric energy storage systems necessary in the ordinary navigation conditions, the ship was equipped with emergency batteries, which must operate in the event that there should be malfunctions on the fuel cells, which can no longer produce electric energy. The emergency batteries, therefore, must allow the ship to reach the nearest port safely.

The minimum energy required in case of emergency, Emin,emerg, has been determined by referring to the worst case, i.e., the case in which the failure occurs suddenly when the ship is in the open sea at the farthest point from the two ports, i.e., after having covered half of its route. This energy value, which is the one on the basis of which emergency batteries were sized, was obtained by dividing in two equal parts the energy required to complete the journey from the port of departure to the port of arrival in the most demanding conditions. However, as regards the sizing of the emergency batteries relating to electrical utilities, it was hypothesized that, in emergency conditions, 25% of the utilities are not essential and it is possible to continue without feeding them.

Since the batteries used in ordinary conditions can continue to perform their function even in the event of a malfunction of the SOFCs, their contribution can be taken into account, when sizing the emergency batteries, to avoid adding excessive weight to the ship. Assuming the worst-case scenario where the ship has covered half of the journey and the ordinary batteries have consumed half of their charge, and considering the abovementioned energy required to complete the other half of the journey, we can calculate the total minimum electric energy that the batteries must be able to store, E

min, batt, tot, using Equation (3):

Considering the minimum electric energy that ordinary batteries must be able to store, E

min,batt,ord, then the minimum electric energy that the emergency batteries must be able to store, E

min,batt,emerg, is calculated using Equation (4):

The decision to separate the emergency batteries from the ordinary ones is linked mainly to the fact that the ordinary batteries undergo daily charge and discharge processes, while the emergency ones are used only in exceptional cases. Since the batteries require maintenance or replacement after a certain number of cycles, it is not advisable to carry out these interventions on all the batteries, but only on those that are necessary to carry out daily operations.

For the case in question, reference is made to the commercial batteries for maritime use, “Corvus Blue Whale”. The necessary energy is obtained by connecting several modular units (packs) together: each pack can store 3612 kWh of electric energy [

47].

Since the batteries chosen are lithium ion, for this type of battery the charge must never drop below 20% preferably to avoid causing premature deterioration. For this reason, the minimum energy values to be taken into consideration when sizing the batteries E

min,Li-batt,ord and E

min,Li-batt,emerg are calculated using Equations (5) and (6):

The thermal energy generated by the two SOFC systems can be exploited to satisfy, at least in part, the thermal needs on board of the ship.

In particular, in the winter and in the spring/autumn season this thermal energy can be used for the production of hot water and for space heating, while during the summer season it can be used for the production of hot water and to power the absorption cooling system.

The thermal power supplied by the two SOFC systems is always constant as they always operate in nominal conditions. Since heat losses are inevitable, it is assumed that only 95% of the thermal power supplied by SOFC systems can be exploited for cogeneration purposes.

When the thermal power supplied by the SOFC systems is greater than that required by the users, the surplus can be stored through water thermal storage systems. In this case, it is considered that the thermal storage is achieved by heating water up to a temperature of 80 °C and storing it in proper tanks.

For the case in question, a thermal storage system capable of storing all the available thermal energy was sized, so as not to waste the thermal energy produced by the SOFCs. In particular, two different storage tanks are provided, one of which stores thermal energy for the production of hot water and the other one, which stores thermal energy for space heating.

The total thermal power requirement is provided from the data available in ref. [

43]. The following hypothesis was made to make a distinction between the thermal energy required for the hot water production and the thermal energy required for space heating: the demand for thermal energy during the summer is only due to the hot water production and that the thermal energy demand for the hot water production is the same for all seasons. Based on the hypothesis it was possible to obtain by difference the thermal energy requirement for space heating in the typical winter and spring/autumn days.

Considering a constant value for the specific heat of the water equal to 4.186 kJ/(kg K) and that the water is heated up to a temperature of 80 °C, the mass of water necessary to store the surplus of thermal energy has been calculated by Equation (7):

The mass of water, which is used for sanitary purposes, is calculated considering that it is taken directly from the sea, and then it is demineralized and heated. In particular, the seasonal average temperatures of the Stockholm Sea (the average monthly temperatures were obtained from ref. [

48]) were taken as the references and it was hypothesized that the water undergoes an increase of 5 °C due to the demineralization treatment.

For heating of the spaces, it is assumed that there are high temperature terminals inside the cabins, for which suitable hot water in and out temperatures are assumed.

During the summer season, the thermal energy stored by heating water to a temperature of 80 °C cannot be used to supply the absorption cooling system, as significantly higher temperatures are required for its thermal generator. However, the hot water stored in the tanks can be supplied to the SOFCs.

In their normal operation, the SOFCs heat the water from the inlet temperature (room temperature) to the operating temperature (around 750 °C) by means of their hot exhaust gases. Providing preheated water at a temperature of 80 °C results in saving thermal energy because the temperature difference that the water must undergo to reach the operating temperature is smaller. The thermal energy saved will therefore be available in the exhaust gases and can be used to power the absorption cooling system.

The stored hot water is supplied to the SOFCs within the hour, in which the use of the absorption cooling system fed by SOFCs hot exhaust gases is also required. Producing greater cooling power through the absorption cooling system allows to reduce what needs to be generated by the compression cooling system. In this way, it is possible to save the electrical energy necessary for the operation of the compression cooling system and, at the same time, it is possible to dispose of all the surplus of thermal energy produced during the day.

When the thermal energy in the storage systems is not sufficient, the thermal power deficits will be compensated for by using the auxiliary boilers. For the case in question, “Hoval Ultragas 2000D” condensing boilers were selected with nominal power equal to 1854 kW and maximum efficiency equal to 98.3% [

49].

An absorption cooling system and a compression cooling system are used for cooling the rooms during the summer season. The absorption cooling system makes it possible to exploit the thermal energy of the SOFC system exhaust gases, however it must be kept in mind that the thermal power supplied by the SOFC system is first used to satisfy the thermal requirements and then to feed the absorption cooling system. When the cooling capacity supplied by the absorption cooling system is not sufficient to satisfy the entire requirement (this occurs above all in the hours in which there is a greater demand of thermal energy for hot water production), the compression cooling system is also put into operation.

A water/ammonia type system named “Robur GA ACF” was selected as the absorption cooling system. It is characterized by a cooling capacity of 17.72 kW and it has a Gas Utilization Efficiency (GUE) of 0.71 [

50]. In this case study, 61 units are needed to be able to exploit all the residual thermal power of the SOFCs exhaust gases.

A refrigeration unit named “Daikin EWWD-VZ” for marine applications was selected as the compression cooling system. It has a nominal cooling capacity of 410 kW [

51]; in this case study, three units are required to be installed. As shown by the graph in ref. [

52], these cooling systems can work between 20 and 100% of the load and the value of EER depends on the load, which is expressed as a percentage of the nominal cooling capacity.

The mean seawater temperature of Stockholm was obtained from ref. [

48]. In this case study, cooling is required only in the summer months (July and August) during which the average water temperature is 16 °C. The electrical power absorbed by the cooling system was determined considering an EER value corresponding to a water temperature of 18 °C.

For this case study, the use of a desalinator was set up. It is necessary to demineralize the water taken from the sea, so that it can be fed to the SOFC systems and thermal storage systems. In particular, in this case study a “Culligan RO SW EVO 8” desalinator was selected [

52].

5. Results

In this paragraph, the results on the main components of the proposed energy system (SOFC systems, batteries, thermal storage system, auxiliary boilers, and cooling systems) are presented. The fuel consumption and emissions of new energy system are then evaluated and finally a technical comparison of the new energy system with the conventional old energy system in term of primary energy consumption and of the emissions is carried out.

The SOFC systems were sized so that they can operate in nominal conditions for 24 h a day and the design electrical power was set equal to the average value of the electrical power required by the propulsion system and by the electrical users throughout the day.

The electrical power requirements for ship propulsion and for electrical utilities were calculated through Equations (1) and (2), respectively.

Table 6 shows the results obtained for the SOFC systems used for the ship propulsion and for supplying the electrical utilities on board of the ship. In particular,

Table 6 indicates the minimum number of SOFC modules “Solid Power Bluegen BG-15” type necessary to obtain the nominal electrical power of the project with the electrical power and bio-methane consumption data.

Since the hourly profile of electrical power required for vessel propulsion is the same for all three typical days, it is assumed that the SOFC system used for vessel propulsion can operate under nominal conditions throughout the year.

The hourly trend of the electrical power required for the electrical utilities on board (relative to the auxiliary loads and the needs of the hotel) varies from one season to the next. Consequently, the SOFC system used to supply the electrical utilities has been sized based on winter conditions, in which the electrical power requirements are greater. Therefore, the SOFC system for electrical users will operate in nominal conditions during the winter period, while in the other seasons it will operate at partial load.

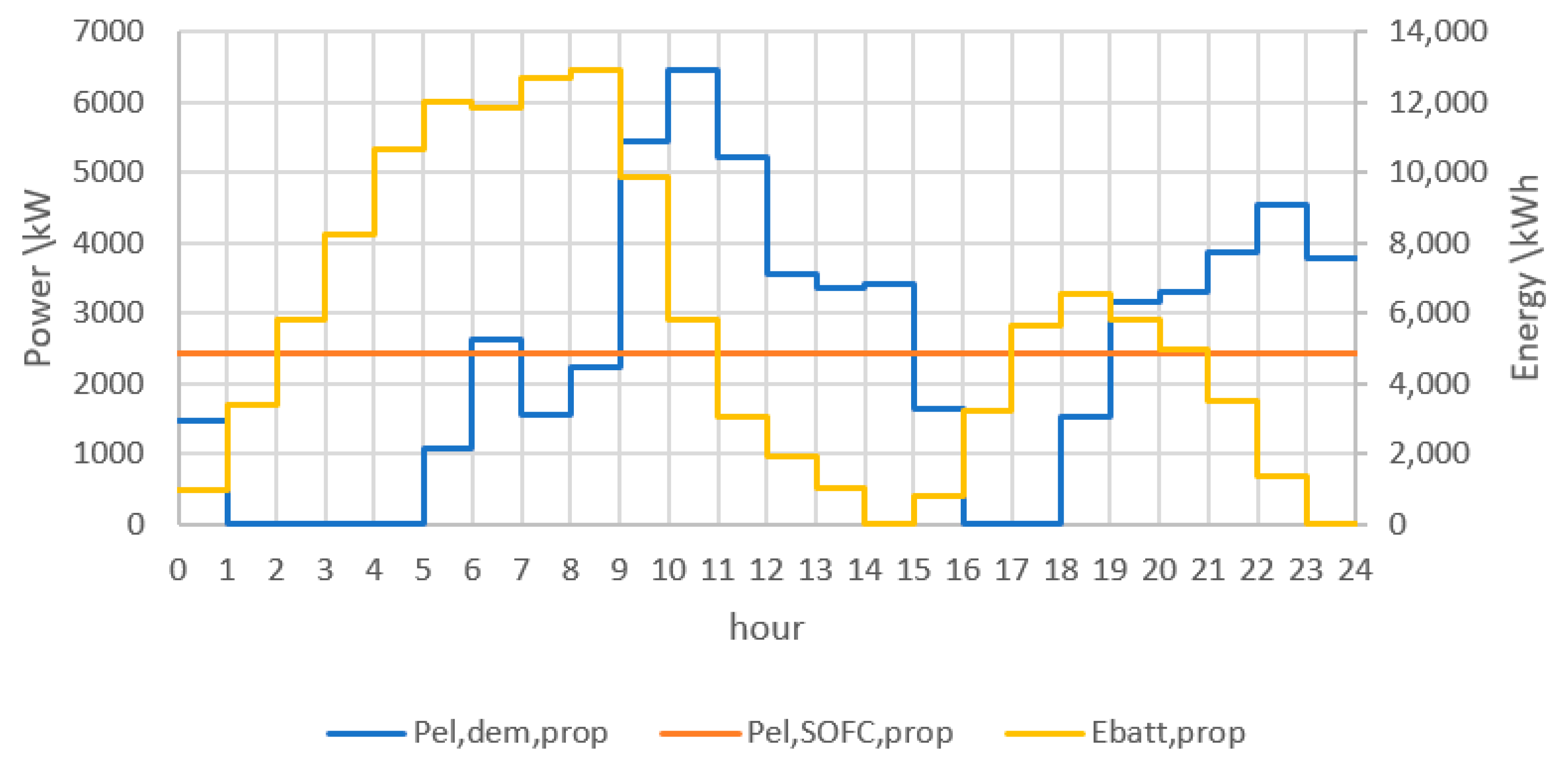

The hourly trends of the electrical power requirements and of the electrical power supplied by the SOFC systems are shown in

Figure 3 regarding the propulsion of the ship and in

Figure 4 regarding the power supply of the electric users in the three typical days.

The cumulative electric energy curve represents the energy that can be stored inside the batteries. The hourly trend of the electric energy, which can be stored in the batteries for ship propulsion (which is the same for all typical days), E

batt,prop, is shown in

Figure 5. This figure also shows the hourly trends of the electric power supplied by the SOFC system for ship propulsion, P

el,SOFC,prop, and of the electric power required for propulsion, P

el,dem,prop.

All the graphs in the figures display average hourly values of electrical power consumption and electric energy usage for different time periods throughout the day.

Figure 5 shows that the maximum value of electric energy, which can be stored during the day, is equal to 12,882 kWh; this value, therefore, represents the minimum amount of energy that the batteries must be able to store to satisfy the needs for ship propulsion, E

min,batt,ord,prop.

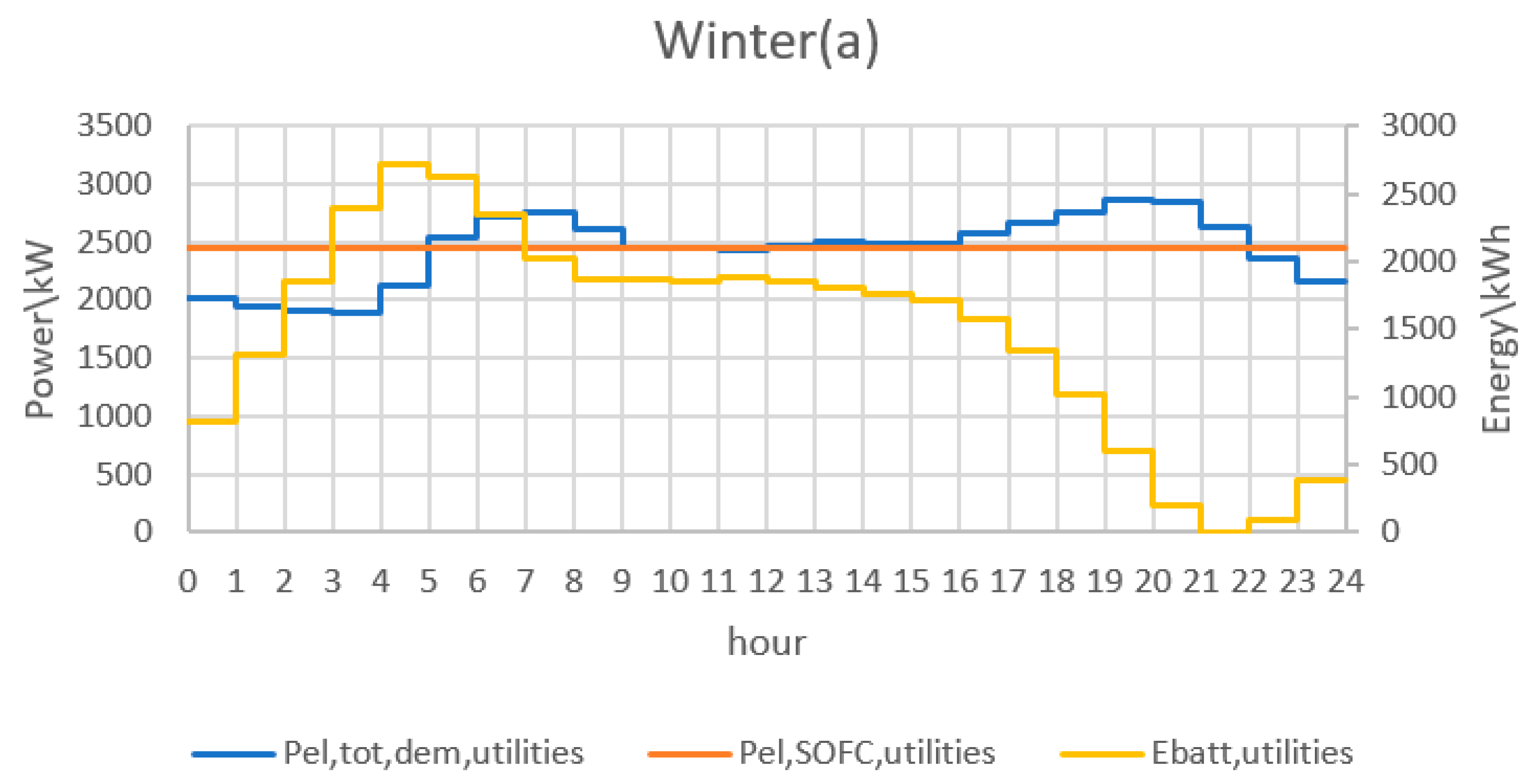

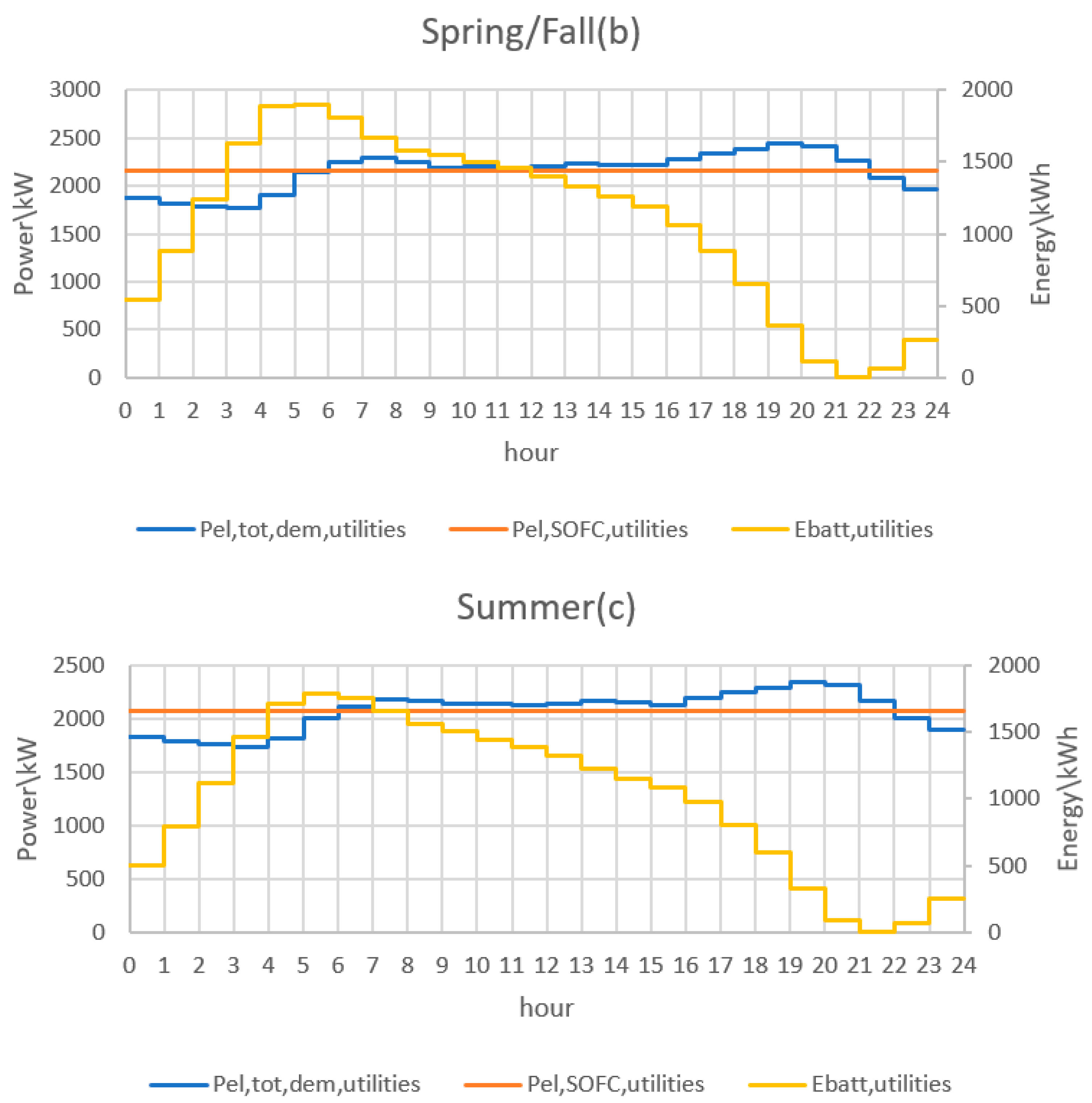

The hourly trend of the electric energy, which can be stored in the batteries relating to the electrical utilities during the day, E

batt,utilities, for the three typical days, is represented in

Figure 6a–c. These figures also show the hourly trends of the electric powers supplied by the SOFC system, P

SOFC,utilites, and of the electric power absorbed by the electric utilities, P

el,tot,dem,utilites.

Table 7 shows the maximum values of the electric energies, which can be stored during the typical winter, spring/autumn, and summer days, which represent the minimum energies that the batteries must be able to store to meet the electrical utilities’ needs, E

min,batt,ord,utilities.

Figure 5 and

Figure 6 show that, although the size of the SOFC systems for the electrical utilities and for the ship propulsion is comparable, the energy that needs to be stored in the batteries for electric utilities is significantly less than that required for ship propulsion. This is because the values of the electric power required for ship propulsion differ greatly from the average value (therefore from the electric power supplied by the SOFC system), so a greater stored energy is required than that required for electrical utilities, whose demand fluctuates just around the mean value.

The batteries relating to the electric utilities on board of the ship have been sized according to the needs of the winter season, which is the one in which the greatest quantity of electric energy needs to be stored.

The calculation of the minimum energy value, which ordinary and emergency batteries must be able to store both for ship propulsion and for electrical utilities, was carried out through Equations (3)–(6) and

Table 8 summarizes the results.

From these results, the number of the units (packs) of “Corvus Blue Whale” batteries can be evaluated. E

batt,comm,ord and E

batt,comm,emerg indicate the amounts of energy that can be stored respectively in the ordinary batteries and in the emergency batteries installed on board the ship. The results relating to the preliminary design of the electrical storage system for the ship propulsion and for the electrical utilities are shown in

Table 9.

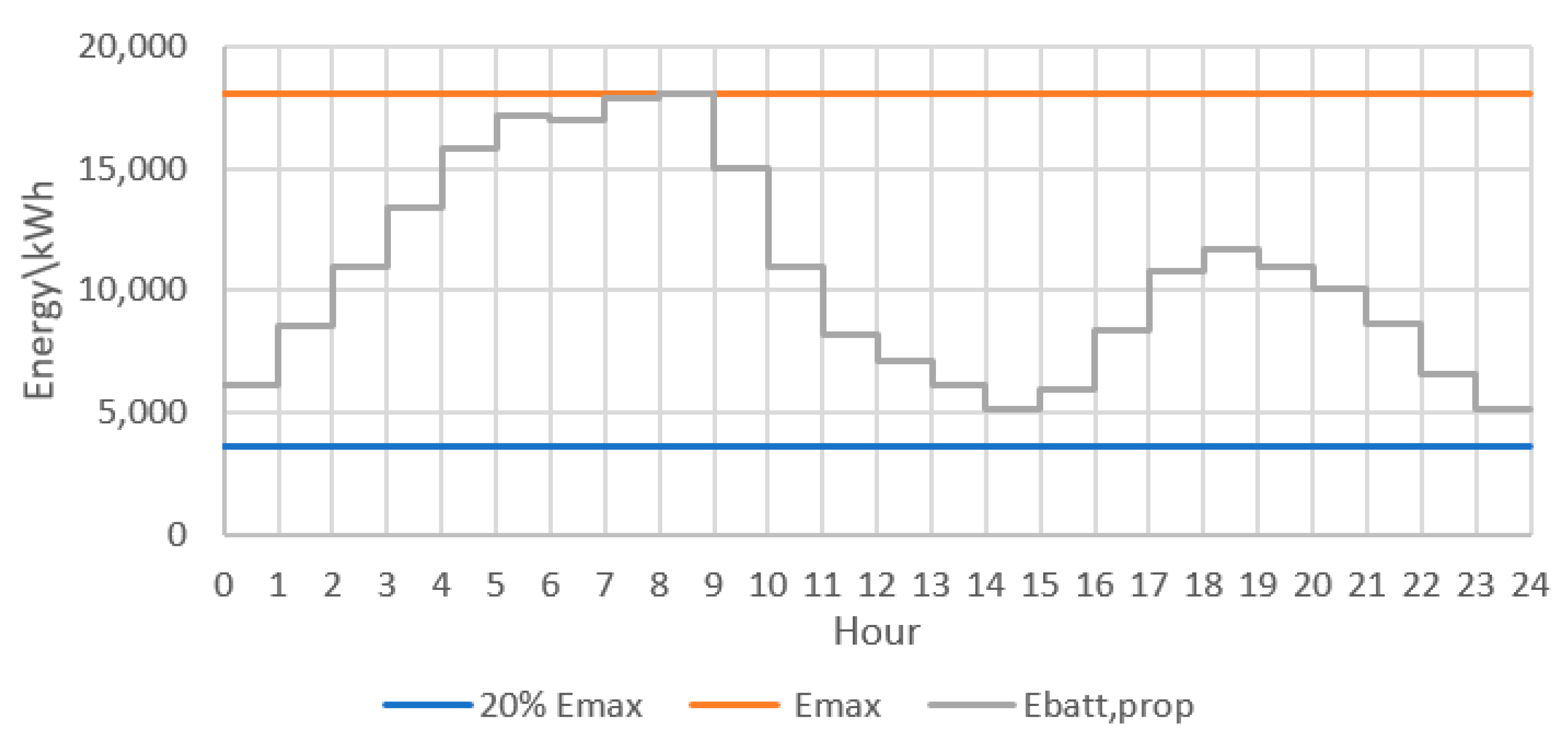

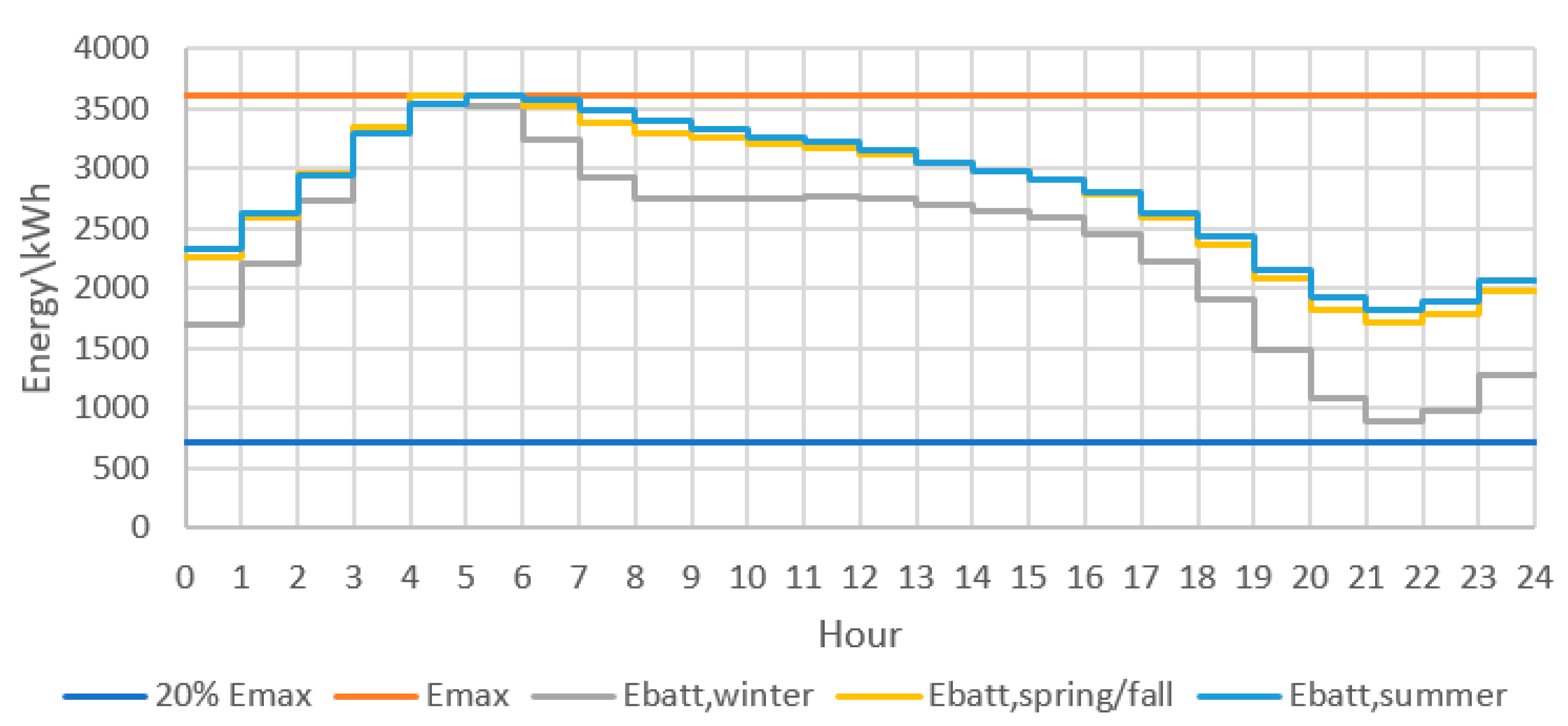

Figure 7 and

Figure 8 show the hourly trend of the energy stored in the ordinary batteries during the day for the ship propulsion, E

batt, prop, and for the electric utilities in the three typical days. The graphs also show the maximum and minimum energies. The minimum energies are equal to 20% of the total electric energy stored, 20% E

max.

Figure 7 and

Figure 8 show that the stored energy will never reach the minimum value since the batteries are slightly oversized and they will never be used to 100%.

Therefore, considering only between 20% and 100% of the total energy, the battery utilization factor is defined as expressed by the Equation (8):

In Equation (8) Emin represents the minimum energy value reached during the day.

Table 10 shows the usage factors of the batteries for the propulsion and for the electric utilities in the three typical days.

The total useful value of the thermal power produced by the SOFC systems, which can be exploited for cogeneration purposes, is shown in

Table 11.

The thermal energy, which can be stored, was determined considering the difference between the available thermal power and the required thermal power.

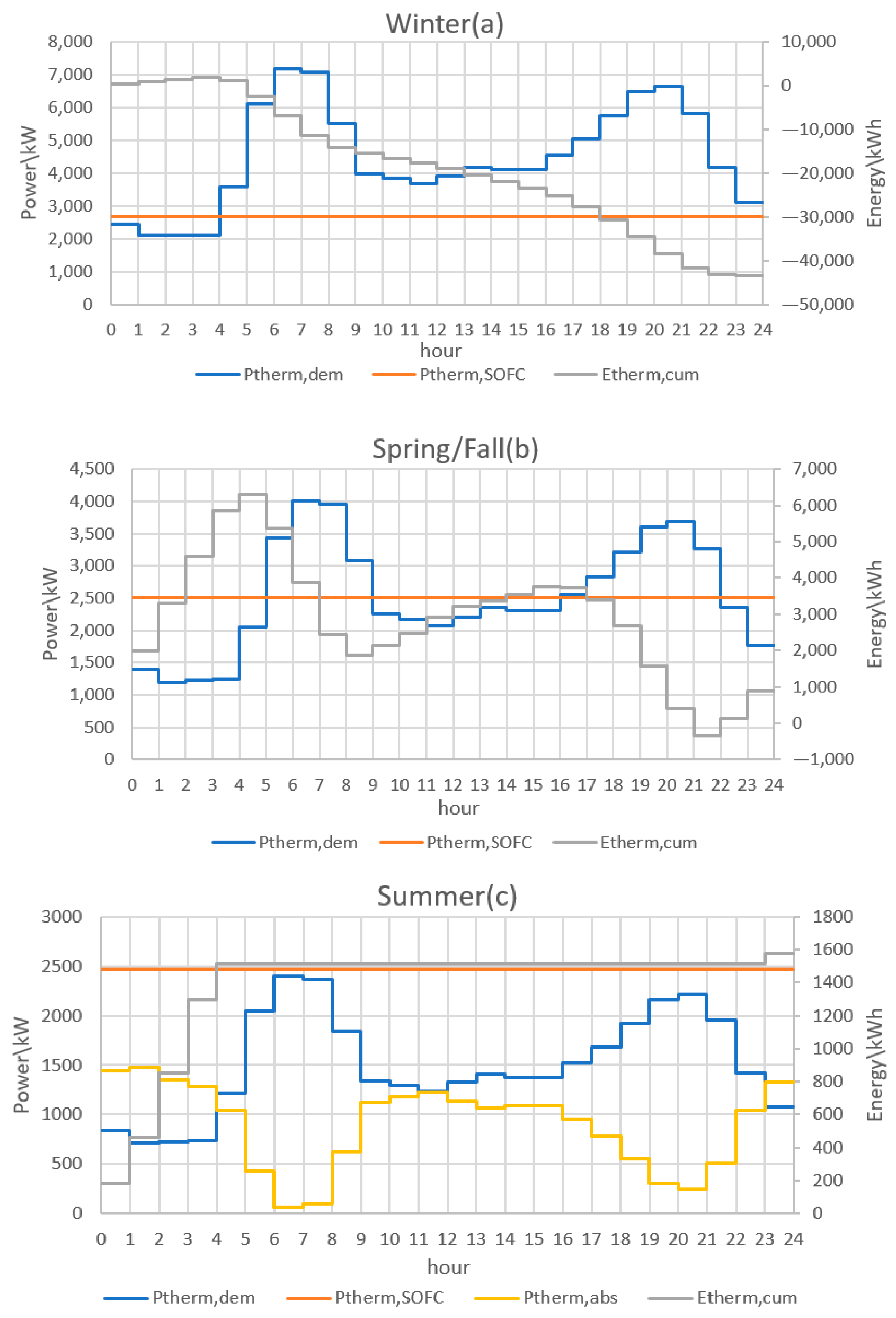

Figure 9 shows the hourly trends of the thermal power required, of the thermal power supplied by the SOFC system, and of the cumulative thermal energy available in the three typical days.

The maximum values of thermal energy, which can be stored during the three typical days, are shown in

Table 12.

Figure 9a,b show that in winter and spring/autumn, even if accumulating all the surplus energy, it is impossible to satisfy the entire requirement, so in some hours of the day it is necessary to integrate thermal energy using auxiliary boilers.

Regarding the production of hot water for domestic use, a storage tank of 50 m3 is required to store all the surplus of thermal energy produced by the SOFC systems, while a storage tank of 54 m3 is required to store the surplus of thermal energy relating to space heating.

In

Figure 9c, the graph relating to the summer thermal storage also shows the trend of the thermal power that is exploited by the absorption cooling system. Furthermore, as the

Figure 9c shows, at the end of a typical summer day there is a surplus of thermal energy equal to 1577 kWh.

The hot water stored at a temperature of 80 °C is supplied to the SOFC systems in the hours in which the use of the compression cooling system is required.

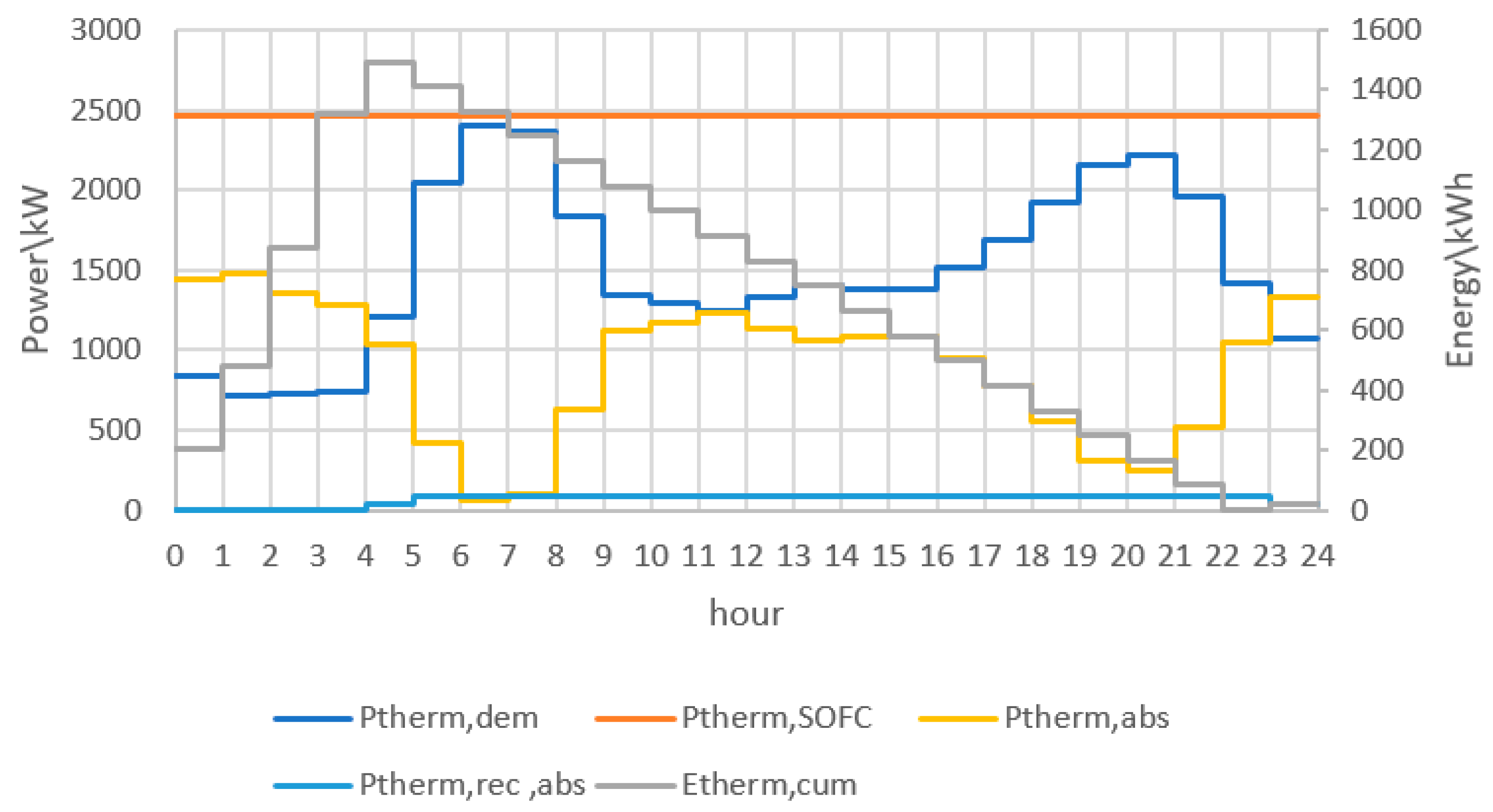

Figure 10 shows the hourly trends of the thermal power supplied by the SOFC system, the thermal power requirement for the hot water production, and the thermal power consumed by the absorption cooling system.

Figure 10 also shows the hourly trends of the thermal power exploited by the absorption cooling system, which is due to the surplus of thermal power obtained from the SOFC system, which was supplied by hot water at a temperature of 80 °C and not by cold water, and of the stored thermal energy. In particular,

Figure 10 shows the case in which the stored water is divided equally into the hours, in which there is no storage of the thermal energy. In this way, therefore, it was possible to exploit all the thermal energy stored during the day.

Figure 9a,b show that in the typical winter and spring/autumn days, while exploiting all the thermal energy that can be stored in the storage tanks, it is not possible to satisfy completely the thermal requirements.

Therefore, it is necessary to use auxiliary boilers to compensate for thermal power deficits. In particular, the auxiliary boilers are sized based on the maximum value of the thermal power that must be integrated with the one supplied by the SOFC system. In this case study, this value is equal to 4503 kW and is obtained in winter conditions.

For this case study, it is necessary to install three units of the “Hoval Ultragas 2000D” boilers to meet the thermal power requirements.

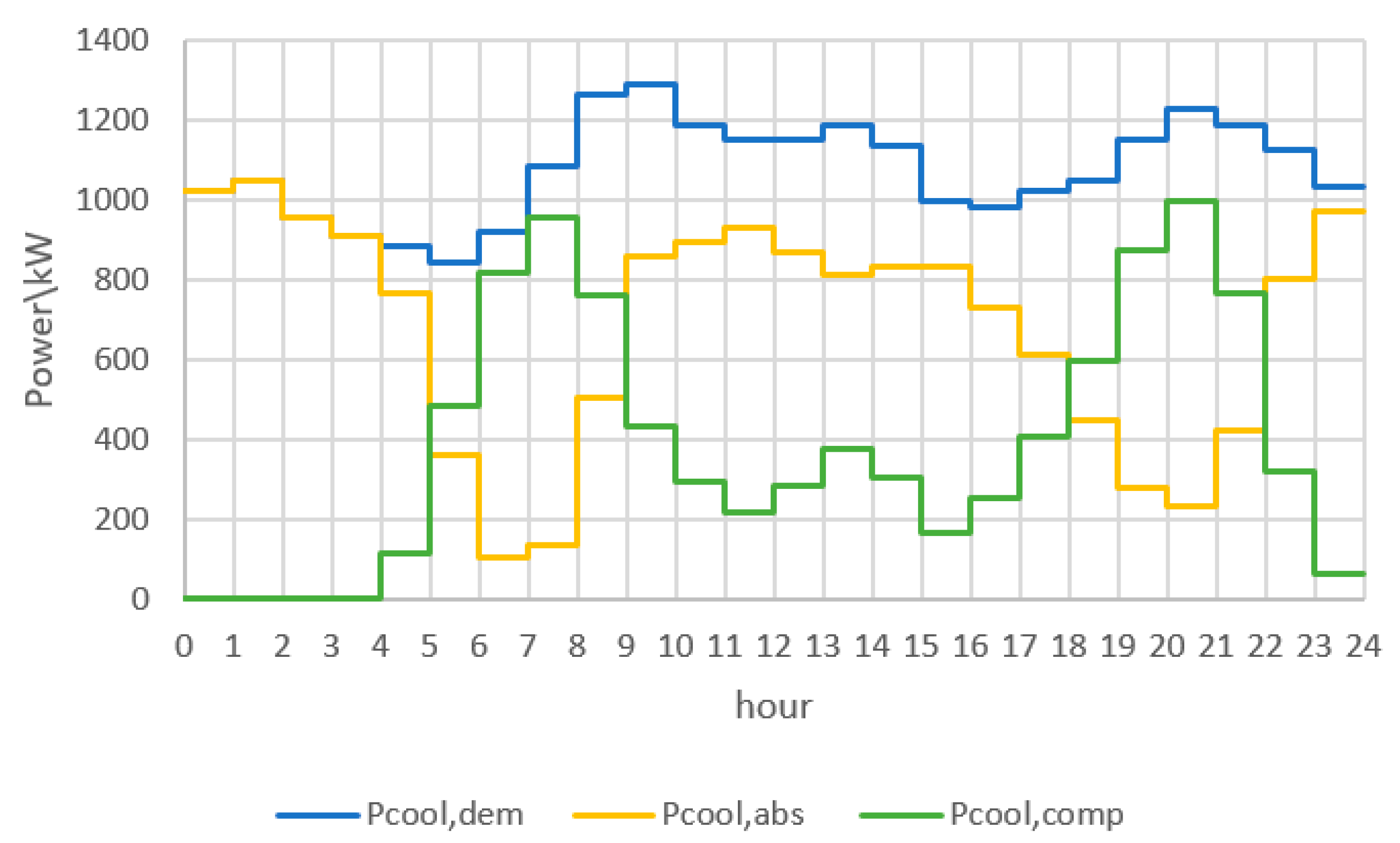

For the space cooling, the absorption cooling system, which is activated by the SOFC systems hot exhaust gases, is used. When the cooling power supplied by the absorption cooling system is not sufficient to satisfy the entire requirement (this occurs above in all the hours, in which there is a greater thermal energy demand for hot water production), the compression cooling system is also put into operation.

Figure 11 shows the hourly trends of the cooling power required and the cooling power supplied by the two machines. In particular, through the absorption cooling system, and therefore by exploiting the thermal power produced by the SOFCs, it is possible to satisfy around 63% of the cooling energy requirements for the cabins.

5.1. Fuel Consumptions and CO2 Emissions

Table 13 summarizes the total bio-methane consumption of the SOFC systems for the ship propulsion and for the electrical utilities and of the auxiliary boilers for the three typical days.

The annual consumption of bio-methane obtained is approximately 5748 t/year (8.5 MSm3/year). It is plausible to hypothesize that the bio-methane is oxidized completely inside the SOFC systems and boilers, and it is converted almost entirely into water and carbon dioxide, so that it is possible to determine the carbon dioxide (CO2) emissions starting from the bio-methane consumption.

In this case study, annual CO2 emissions results are equal to approximately 15,768 tons per year. We calculated the local emissions due to the oxidation of bio-methane. Since the use of bio-methane is envisaged in this case study, the environmental impact due to greenhouse gas emissions is lower than if methane of fossil origin were consumed on board of the ship.

In fact, bio-methane is obtained following the purification (upgrading) of the biogas. Biogas is a gas mixture that is mainly composed of methane and CO

2, and it is obtained through the natural process of organic matter anaerobic digestion [

53].

The net emissions of CO2 resulting from the combustion of biogas can be considered zero, since, referring to the entire life cycle of the biomass, the amount of CO2 released during combustion is equivalent to the amount absorbed by plants from the atmosphere during their growth.

However, when using bio-methane as fuel, the purification processes to remove CO2 from the biogas to achieve a gas mixture made up of at least 95% methane are energy-intensive. If the electric energy used for these processes is not derived entirely from renewable sources, they contribute to CO2 emissions into the atmosphere.

The purification process, which is currently used mostly for this purpose, i.e., “pressurized water scrubbing”, was considered to estimate the CO

2 emissions due to the biogas purification processes. Approximately 0.55 kWh of electric energy is required to obtain a normal cubic meter of bio-methane by using this process [

54].

The CO

2 emission factor of electric energy consumption, which represents the amount of CO

2 emitted per unit of electric energy consumed based on the Italian energy systems mix, was considered to evaluate the CO

2 emissions connected to this process. In particular, in this case the emission factor for the year 2019 obtained from the 343/2021 report of ISPRA (Higher Institute for Environmental Protection and Research) [

55] was taken into account: this factor is equal to 268.6 gCO

2/kWh. In particular, it was decided to consider the emission factor for the year 2019 since, due to the repercussions on the production and economic system due to the COVID-19 pandemic, it was considered that this value better reflected the current Italian energy scenario instead of the value for the year 2020.

Therefore, it was possible to estimate the CO

2 emissions for each kilogram of bio-methane produced starting from these data [

55]. In particular, it was evaluated that these specific emissions are equal to 0.206 kgCO

2/kgCH

4. Therefore, the net CO

2 emissions due to the use of bio-methane on board of the ship are evaluated and they are equal to 1186 tons per year.

However, in this article the greenhouse gas emissions due to methane leaks during biogas purification operations have not been considered.

5.2. Comparison between the Conventional Energy System and New Energy System

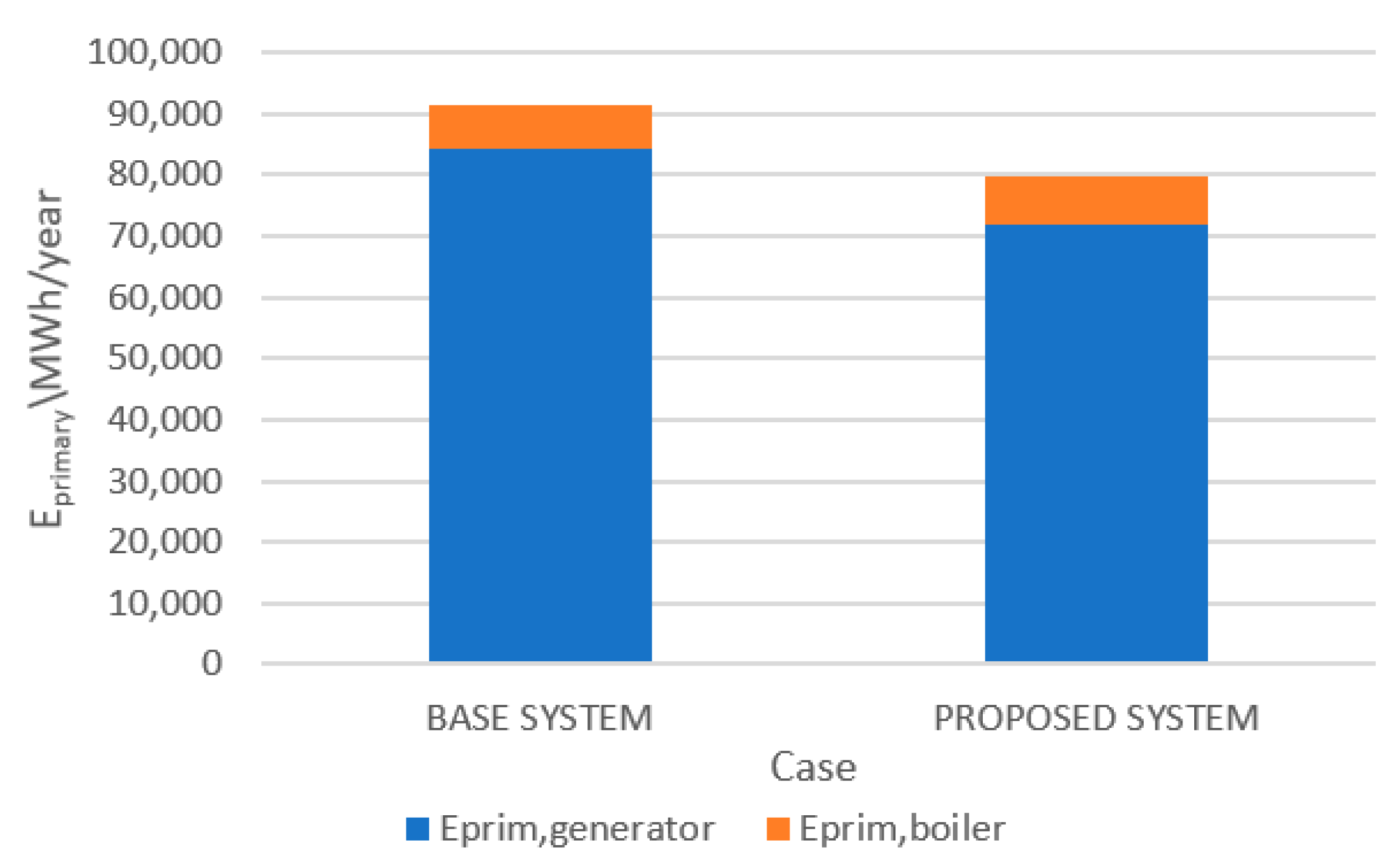

Figure 12 shows the comparison between the conventional system and the proposed system relative to the annual consumption of primary energy.

It is possible to save 12.27% of primary energy using the proposed energy system. However,

Figure 12 shows that using the proposed energy system the primary energy consumed by the auxiliary boilers is higher than using the conventional system. This is because internal combustion engines have a lower electric efficiency than that of SOFC systems, so for the same amount of electric energy produced, they produce a greater amount of heat, which can be used to meet the thermal energy needs on board the ship.

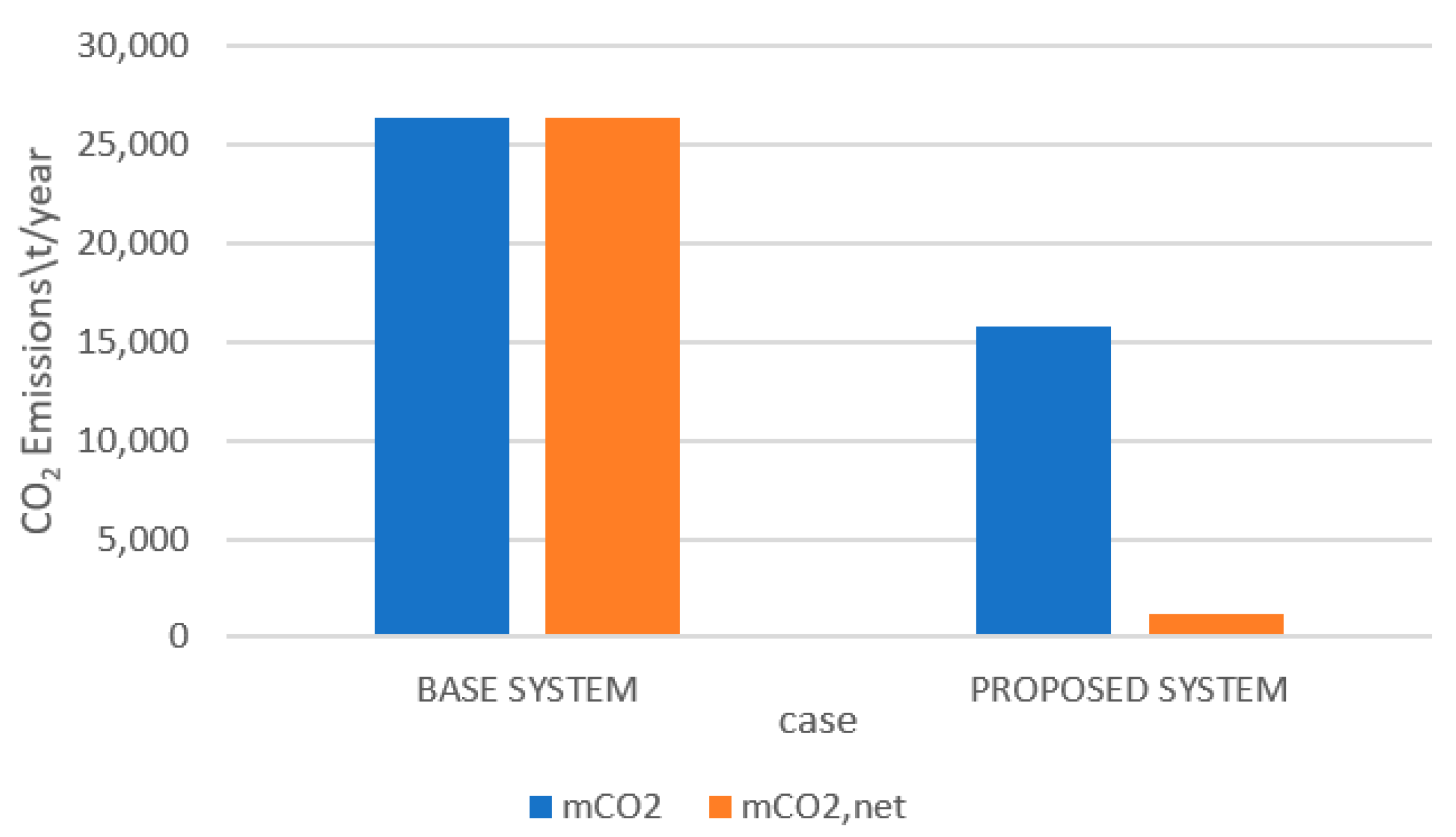

Figure 13 shows the annual CO

2 emissions for the two cases. The local CO

2 emissions are reduced by 40.23%, only because the proposed energy system is more efficient of the conventional energy system. Since bio-methane is expected to be used on board of the ship, it is possible to reduce the net CO

2 emissions by 95.50%.