Abstract

With the development of the global economy and the increase in environmental awareness, energy technology in transportation, especially the application of energy storage technology in rail transportation, has become a key area of research. Rail transportation systems are characterized by high energy consumption and poor power quality due to the more flexible regulation capability of energy storage technology in these aspects. This paper summarizes the latest research results on energy storage in rail transportation systems, matches the characteristics of energy storage technologies with the energy storage needs of rail transportation, and analyzes the operation of energy storage systems in different scenarios. The adaptability of batteries, supercapacitors, and flywheels as energy storage systems for rail transportation is summarized and compared. The topologies and integration methods of various energy storage systems are studied. The control strategies under each control of rail transportation are summarized and proposed. The future development direction of energy storage system for rail transportation prospects and the corresponding reference is provided for the engineering of energy storage technology in the field of rail transportation.

1. Introduction

In the last decade, energy storage technology has been extensively researched and developed in the long term [1,2,3,4,5,6,7]. Energy storage technology is no longer limited to being a mobile power source. It has many applications in all aspects of the power system. For the power generation side, energy storage units consume renewable energy and provide virtual rotational inertia to the power system as backup capacity on the grid side. Energy storage units are mainly used for frequency regulation of the power system and to achieve spatial and temporal load balancing. For the customer side, energy storage units are mainly used for emergency backup and tariff management, and energy storage technology can also improve the power quality on the customer side.

With the development of power transmission technology and power electronics, the electrification of rail transit has become a vital crossover direction and a hot technological growth point in the transport sector and the electrical sector [8,9,10]. On the one hand, electrified drives reduce the use of mechanical structures such as drive bearings and internal combustion engines, reducing the size of the powertrain. The superior speed control performance of electric motors is unmatched by internal combustion engines, which brings technical advantages to the performance indicators of electrified transport. On the other hand, transportation electrification reduces the direct use of fossil fuels and greenhouse gas emissions, achieving good environmental benefits. The cost of power transmission is lower than that of fossil fuel transportation, which significantly reduces the energy cost of electrified transportation.

The electrification of transportation has strengthened the connection between the power and rail transportation systems. The reliability and economy of power supply have become essential factors in transportation. By adding energy storage to the power supply system of railways, energy efficiency can be increased, and the impact of power system failures can be reduced.

The application of energy storage in transport systems has been studied to some extent. Due to the mobility and off-grid operation of energy storage systems, electric vehicles with energy storage units at their core are gaining ground in the long term [11,12,13,14,15]. However, the energy storage application in rail transit is still in its infancy. The electrified rail system is closely linked to the grid; its power supply system is integral to the grid. The power supply system of railways has a higher power rating than other modes of transport, and the load characteristics are intermittent and shocking. For these reasons, using energy storage technology in rail transit has unique characteristics.

This review searches several databases, such as SCI, IEEE/IET, Science Direct, and MDPI to summarize and organize the system architecture, circuit topology, and control strategies of energy storage in rail transportation applications in recent years. The keywords used for the search include, but are not limited to, rail transit, energy storage systems, traction circuits, and control strategies.

This paper summarizes the research results of energy storage systems in rail transit systems. Firstly, this paper summarizes the functional requirements and access methods of energy storage devices in rail transit power supply systems. Secondly, this paper summarizes the topologies and system integration methods corresponding to the common forms of energy storage in rail transportation. It analyzes the scenarios in which each topology and integration method is applicable. Third, this paper analyzes the specific control objectives and designs the corresponding control strategies for applying energy storage devices in rail transit systems. Finally, the prospects of energy storage applications in transportation and the problems that need to be focused on the prospect.

2. Rail Transit Demanded by Energy Challenges

With the increasing electrification of rail transit, the speed of trains is gradually increasing, while energy consumption is increasing. As a result, rail transit is facing several challenges in the energy sector, such as the additional load from rail electrification, power fluctuations, and voltage dips caused by train operating moments [10,11].

Traction power grids can be classified according to the type of buses as DC traction power network and AC traction power network.

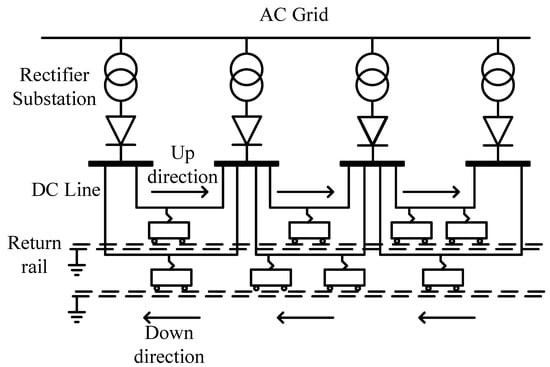

The DC traction network is the typical traction grid structure of a metro. The system consists of a grid AC bus and a supply DC bus, with the metro trains being supplied directly from the DC bus. As the metro usually contains two trains opposite each other, the metro’s DC traction power supply system consists of two parallel DC buses. Metro systems are typically supplied from the national electricity grid and use rectifier substations to convert AC voltage into 750, 1500, or 3000 V DC voltage to power the trains. Figure 1 shows the typical DC traction power network with multi-trains.

Figure 1.

The typical DC traction power network with multi-trains.

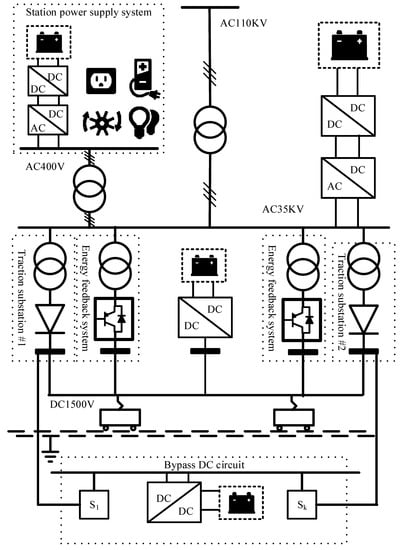

The DC power supply system is mainly used in urban rail transit, which uses the bilateral power supply and has a small power supply range. The topology of urban rail transit and the possible access location of the ground energy storage system is shown in Figure 2. There are mainly two kinds of loads in the urban rail power supply system, station load and traction load, and the existing research is summarized.

Figure 2.

The DC traction energy system topology.

When the energy storage system selects the AC400 V side or AC35 kV side for grid connection, it can realize the interaction between AC and DC grids through the energy feeder system. It can supply energy to station loads and utility loads. The minor network loss makes DC-side configuration energy storage the focus of research for rail transit configuration energy storage. The conventional energy storage configuration contains two types: the reversible substations and the railroad line configuration energy storage. The conventional energy storage configuration consists of two types: substation configuration storage and roadside ESS.

Reversible substations are obtained by configuring energy storage in the traction grid substation [16]. This option has relatively low safety constraints and construction conditions and only needs to meet the general substation energy storage construction program. The reversible substation can provide energy storage for trains throughout the zone and does not require the railway to be shut down during maintenance. However, this technical solution lacks voltage stabilization, and the storage capacity needs to be determined in conjunction with the train operating schedule. The reversible substation can participate in the grid’s electricity trading, making the solution cost recovery possible. In addition, the maturity of the technology makes the application of this solution economical.

The roadside bypass ESS is another energy storage arrangement that places the storage units along the traction power lines alongside the tracks [17,18]. The roadside ESS can provide energy storage for internal trains within a certain zone to smooth out energy fluctuations within a certain zone. The advantage of this solution is that a single energy storage unit can be used for multiple trains and does not affect rail operations during maintenance. Roadside ESSs can significantly suppress voltage dips within the zone, but incur additional energy losses due to the need to use the traction system overhead lines to transfer energy. This solution requires a smaller number of energy storage units. It is less expensive overall, but it requires the energy storage to be pre-capacitated to consider the operating characteristics of the inter-district trains. This solution requires fewer energy storage units and is less costly overall, but it requires planning for energy storage capacity about the operating characteristics of the inter-district trains.

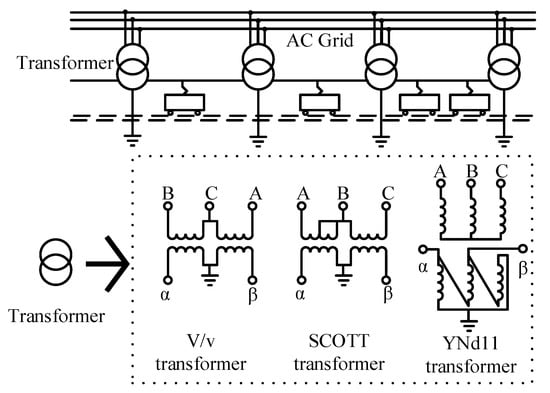

The AC traction network is the typical traction grid structure of railways. The AC traction power network supplies the trains via AC busbars based on traction transformers. The traction transformer is a step-down transformer as the grid supplying the traction system has voltage levels of 110 kV, 220 kV, and 330 kV, and the trains are supplied at 27.5 kV. There are three common forms of traction transformer wiring: v/v transformers, SCOTT transformers, and YNd11 transformers [19,20]. Figure 3 shows the typical AC traction power network with multi-trains.

Figure 3.

The typical AC traction power network with multi-trains.

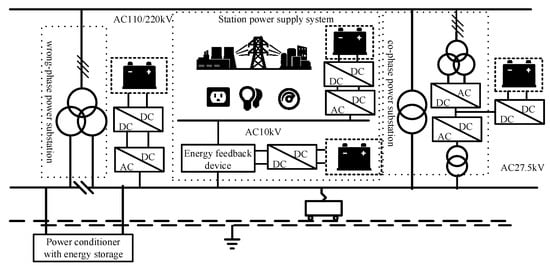

The energy storage system can be configured with the station power system or an energy feedback device in AC rail power supply systems such as Figure 4. AC rail transit substations can be divided into two types, same-phase power supply substations, and staggered-phase power supply substations [21,22,23,24]. In the same phase power supply substation, the role of the energy storage system is similar to that of the DC power supply system, which is mainly used to regulate power; in the wrong phase substation, the role of energy storage is mainly to balance the power between phases.

Figure 4.

The AC traction energy system topology.

The DC traction and AC traction power supply have structural similarities. However, the busbar structures are different, and their energy storage devices have a similar system structure, differing only slightly in technical details.

3. The Way Energy Storage Is Arranged in Rail Transit

From the above analysis, it can be seen that the energy storage needs of rail transportation are based on power type energy storage as high power capacity type energy storage. The volume and performance index of energy storage is limited to a certain extent with the existing energy storage technology. See battery energy storage, supercapacitor energy storage, and flywheel energy storage as the most promising applications. To adapt to the needs of the traction grid or the onboard power supply system of a train, the above forms of energy storage require power conversion relying on power electronics technology, which has led to a variety of system structures for energy storage systems. This paper will present the structure of energy storage systems that meet the application scenarios of rail transit.

3.1. Types of Energy Storage in Rail Transit

Energy storage is widely studied as a technology for preserving and converting electrical energy. The differences in capacity and charging rates of the different energy storage methods make it possible to classify the energy mentioned above storage systems into two main categories in terms of external characteristics: power-based energy storage and energy-based energy storage. Among them, the power type energy storage has higher power density and charging/discharging rate. Still, the capacity cost of this type of energy storage device is higher. In contrast, the capacity type energy storage device has a larger energy storage capacity and lower energy storage loss. Still, the power limits the charging/discharging rate of this type of energy storage device. The classification of energy storage methods is usually based on the charging/discharging time. The longer the charging and discharging time of an energy storage system, the more it tends to be a capacity-based energy storage system; conversely, the shorter the charging time of an energy storage system, the more it tends to be a power-based energy storage system.

Battery energy storage (BES) is the most common and widely researched form of energy storage. In the transport sector, the flexible configuration of battery energy storage makes it a regular onboard power source for electric vehicles. Batteries are the main form of onboard backup and onboard auxiliary power in areas such as aviation and marine. As for the rail sector, the fact that power supply systems mainly power trains makes batteries less used than in other transport areas.

The flywheel energy storage system is a type of energy storage system based on electromechanical energy conversion. This technology stores electrical energy in the form of kinetic energy in a flywheel rotating at high speed with the power electronic converter or the mechanical structure. Flywheel energy storage has a high energy density and a fast response time, and flywheel is entirely pollution-free. Flywheel energy storage also has limitations in its application, with its low-capacity density and high self-discharge rate. However, with the application of material technology and magnetic levitation technology, the operational efficiency of flywheel energy storage is gradually improving. Flywheel energy storage can store large amounts of instantaneous power and can be charged/discharged quickly. These characteristics match the energy characteristics of rail transit power supply systems, making rail transit a significant research and application area for flywheel energy storage.

Supercapacitors are new energy storage devices with electrical characteristics and physical structures different from conventional capacitors. Supercapacitors have a higher energy storage capacity and charge/discharge rate than conventional capacitors. In addition, supercapacitors have a long cycle life and high reliability. Due to the low power density of supercapacitor systems, they are mainly used as power-based energy storage systems. In rail transit, supercapacitors can effectively absorb the load fluctuations generated by train operation and can also be energy storage units for energy return. However, the higher price and lower individual energy storage capacity make it difficult to promote on a large scale. It usually needs to be used in conjunction with other capacity-based energy storage.

3.2. Structure of the Energy Storage System with Battery

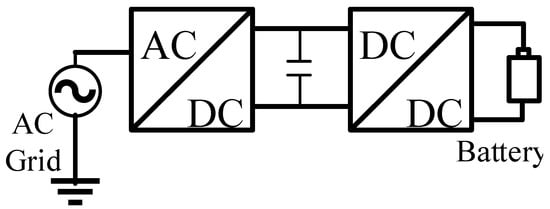

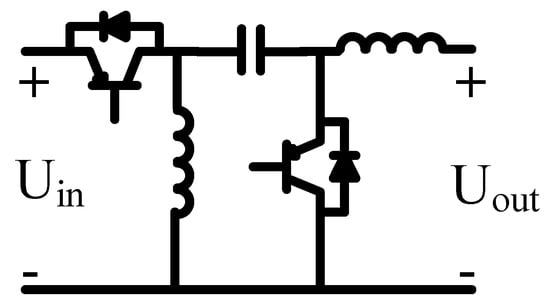

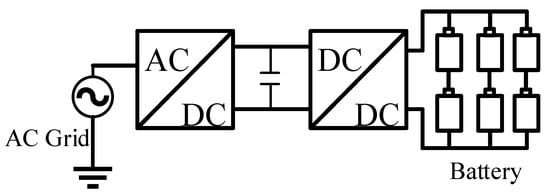

The battery is the most widely used energy storage unit, and to accommodate many different voltage levels, two-stage converters are the usual topology for battery applications. The two-stage converter consists of an AC/DC converter and a DC/DC converter. Depending on the type of AC grid, AC/DC converters are either three-phase or single-phase. The DC/DC converter is connected directly to the battery and regulates the charging current or voltage. As the battery needs to switch between charging and discharging modes, the DC/DC converter must have energy flowing in both directions. Bi-directional converters can be divided into non-isolated bi-directional converters and isolated bi-directional converters. The structural diagram of a two-stage converter is shown in Figure 5.

Figure 5.

Structural diagram of the two-stage converter.

Non-isolated bi-directional circuits are simple in construction, cost-effective, and stable in operation. Standard non-isolated circuits include half-bridge bi-directional DC/DC converters, BUCK-BOOST bi-directional DC/DC converters, Cuk bi-directional DC/DC converters, and Sepic/zeta bi-directional DC/DC converters.

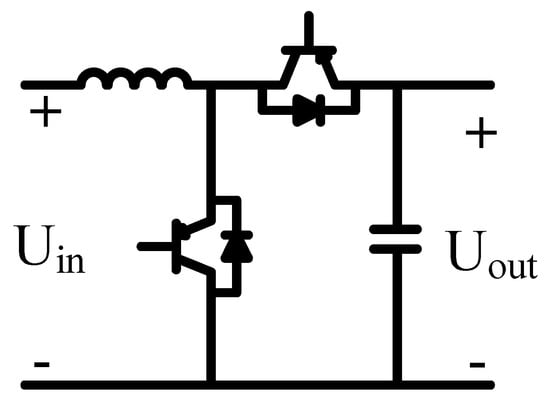

The half-bridge bidirectional DC/DC converters are the most common non-isolated converters. These bidirectional DC/DC converters are simple in structure. Still, if the system works in continuous current mode, the reverse recovery of the diodes is a severe problem, and the current is intermittent. The peak current flowing through the switching tubes will be massive. The topology of the half-bridge bidirectional DC/DC converter is shown in Figure 6.

Figure 6.

Topology of half-bridge bidirectional DC/DC converters.

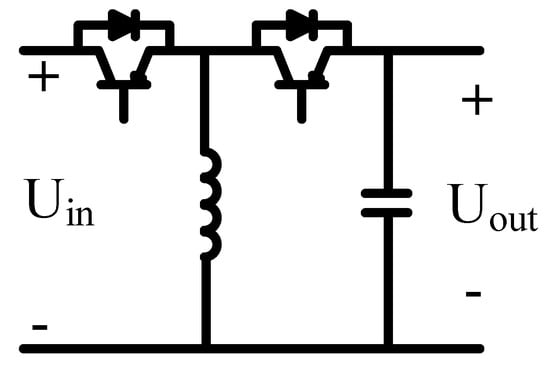

The BUCK-BOOST bidirectional DC/DC converter flange structure, in which the energy is stored and transferred through the inductor, is unsuitable for high-power applications. As with the half-bridge bidirectional DC/DC converter, the inductor current can be operated intermittently, but the peak current flow through the switching tubes becomes larger. The topology of the BUCK-BOOST bidirectional DC/DC converter is shown in Figure 7.

Figure 7.

Topology of BUCK-BOOST bidirectional DC/DC converter.

The Cuk bidirectional DC/DC converter can be seen as a boost converter and a Buck converter in series with an optimized structure. During operation, the energy is transferred to the load via three conversions. The input supply current and the output load current are continuous, and the pulsations are minimal, which facilitates the input and output filtering. However, the efficiency of the Cuk circuit is relatively low and is rarely used in practical circuits. The structural diagram of the Cuk bidirectional DC/DC converter is shown in Figure 8.

Figure 8.

Topology of Cuk bidirectional DC/DC converter.

The Sepic/zeta bidirectional DC/DC converter is obtained by converting the diodes into bidirectional switches in the Sepic or zeta. The circuit topology and energy transfer are similar to the Cuk bidirectional DC/DC converter. The topology of the Sepic/zeta bi-directional DC/DC converter is shown in Figure 9.

Figure 9.

Topology of Sepic/zeta bidirectional DC/DC converter.

Non-isolated DC/DC converters are only suitable for low-power situations. They are suitable for auxiliary power supplies such as train lighting but not for high-power scenarios where rail traction grids are used. For high-power battery storage systems, isolated DC/DC converters are often used. Isolated converters use an isolation transformer as the isolating device. The standard basic topology types are isolated full-bridge bidirectional DC/DC converters, isolated half-bridge bidirectional DC/DC converters, and isolated push–pull bidirectional DC/DC converters.

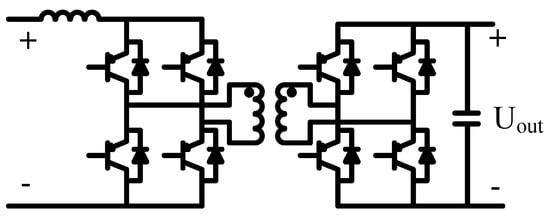

The isolated full-bridge bidirectional DC/DC converters are primarily used in high-power applications where the supply side is a current source. Due to the full-bridge conversion, the voltage and current stress on the individual power devices are reduced so that the same device can transmit more power, making it suitable for high-power applications. The topology of the isolated full-bridge bi-directional DC/DC converter is shown in Figure 10.

Figure 10.

Topology of isolated full-bridge bidirectional DC/DC converter.

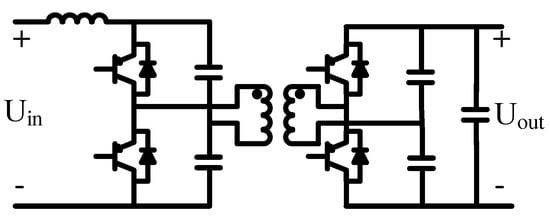

The isolated half-bridge bi-directional DC/DC converter replaces some of the switching tubes of the full-bridge circuit with a neutral point clamp capacitor. Compared to full-bridge converters, they require a higher current capacity of the power device and a higher support capacitance, making them suitable for medium and high-power applications. The structural diagram of an isolated half-bridge bi-directional DC/DC converter is shown in Figure 11.

Figure 11.

Topology of isolated half-bridge bi-directional DC/DC converter.

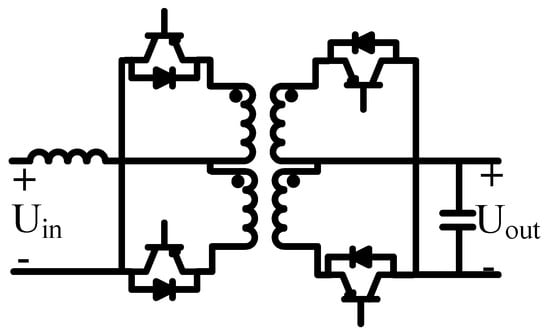

Isolated push–pull bidirectional DC/DC converters are relatively simple in structure. Still, because of the large switching voltage spikes caused by transformer leakage, the switching tubes operate under harsh conditions and are suitable for low- and medium-voltage applications. The topology of the isolated push–pull bidirectional DC/DC converter is shown in Figure 12.

Figure 12.

Topology of isolated push–pull bidirectional DC/DC converter.

The isolated DC/DC converters have a low energy transfer efficiency due to the presence of isolated devices, which can be improved by improving the structure of the isolated devices to achieve soft switching. In addition, isolated converters face problems such as component parameter degradation and resonance. However, for high-power energy storage in the rail transit sector, isolated DC/DC converters are an essential part of the energy storage system.

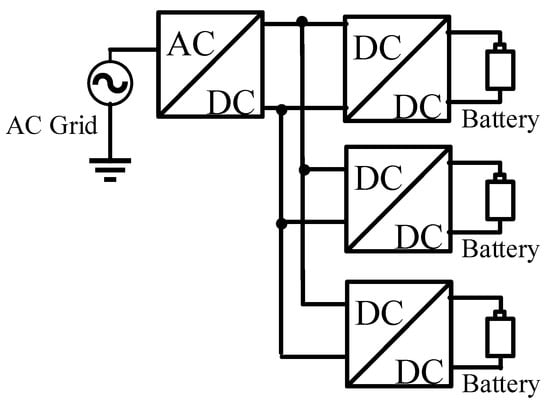

Energy storage systems need to integrate the battery for applications requiring more than one battery. Two common types of integration are single-converter integrated systems and multi-converter integrated systems [25,26].

In single converter integrated systems, several battery clusters are connected to the same converter in series or parallel such as Figure 13. In a single converter integrated system, several battery clusters are connected to the same converter in series or parallel. This technical solution requires fewer converters, operates efficiently and at a lower cost, and involves a more mature technology. However, this solution suffers from the problem of inter-cluster circulation. Because it is impossible to control individual battery cells independently, some of them still need to be fully utilized.

Figure 13.

Structural diagram of single converter integrated systems.

A system in a multi-converter integrated system where each cell is controlled by a separate DC/DC converter, which is finally brought together on the DC bus such as Figure 14. This technical solution allows for the separate control of each battery and the individual removal of faulty battery clusters. This solution suffers from converter ringing and resonance problems which need to be eliminated using control. In addition, this solution has some disadvantages in terms of system cost and efficiency due to the most power electronics required.

Figure 14.

Structural diagram of multi-converter converter integrated systems.

3.3. Structure of the Energy Storage System with Super Capacitor

The capacity limitations of supercapacitors mean that they are rarely used on their own. Supercapacitors are often used in conjunction with a load which can be either an energy-dissipating element or another energy storage device [27,28,29,30,31,32,33,34,35,36].

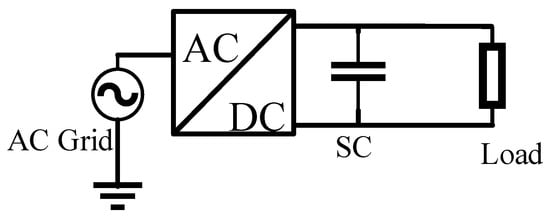

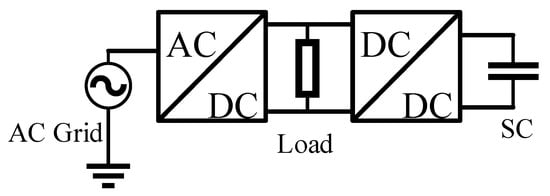

The simplest way to deploy a supercapacitor is to connect it directly in parallel with the load shown in Figure 15. The supercapacitors in this topology combine the functions of DC-side voltage regulator capacitors. This topology is simple and does not enable control of energy flow, and the supercapacitor serves to eliminate power fluctuations on the DC side. The additional load from rail electrification, power fluctuations, and voltage dips are caused by train operating moments [37].

Figure 15.

Schematic diagram of a parallel system of supercapacitors and loads.

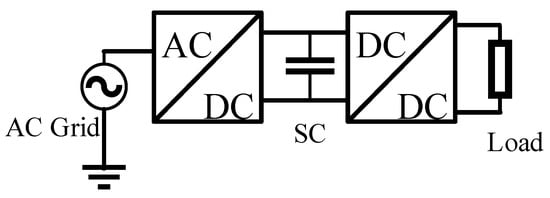

The supercapacitor application circuit modified by a two-stage bi-directional converter is a feasible solution to achieve energy management, as shown in Figure 16. A supercapacitor can replace the role of the DC bus capacitor in the topology, and the function of controlling the energy storage capacity can be achieved by controlling the voltage of the DC bus.

Figure 16.

Schematic diagram of a two-stage converter system with supercapacitor and load.

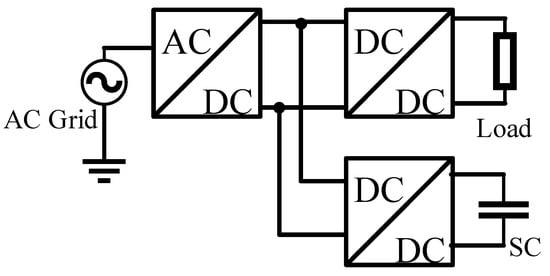

The supercapacitor’s need to support the DC bus voltage and energy storage in a direct retrofit bipolar bidirectional converter solution makes its control strategy complex such as Figure 17. The degree of loading can be simplified by swapping the position of the load and the supercapacitor in the topology. This topology corresponds to adding a DC/DC converter supercapacitor energy storage system to the load [38].

Figure 17.

Schematic diagram of a modified supercapacitor and load two-stage converter system.

The other topology with additional supercapacitors is shown in Figure 18. This topology connects the supercapacitor and the battery parallel to the DC bus by a DC/DC converter [39,40,41].

Figure 18.

Schematic diagram of the additional supercapacitor structure.

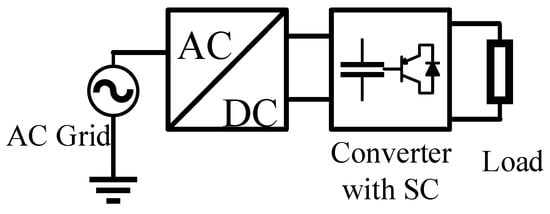

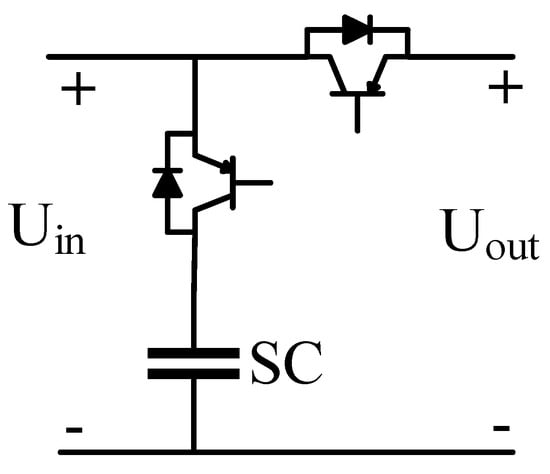

The novel topology combines a supercapacitor with a DC/DC converter as an insertion circuit between the DC side of the converter and the load, shown in Figure 19.

Figure 19.

Schematic diagram of the plug-in converter with supercapacitor.

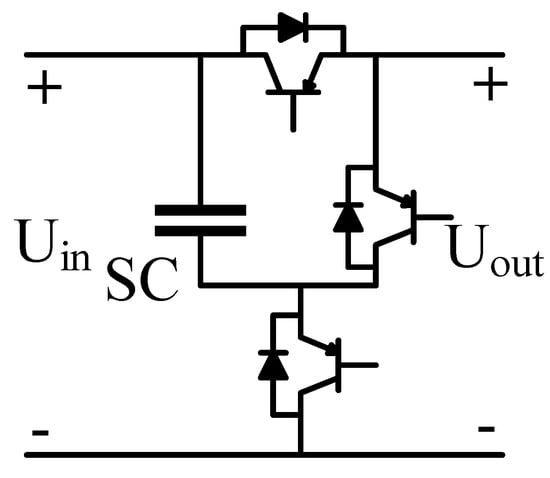

The plug-in converter topology modified from the boost circuit is shown in Figure 20. This topology is simple, and the supercapacitor can provide power support during load fluctuations. The lack of freedom of control in this topology prevents the full use of the supercapacitor’s energy storage characteristics [42,43].

Figure 20.

The plug-in converter topology with supercapacitor.

The topology containing the supercapacitor Quasi-Z source converter is shown in Figure 21, which has additional control degrees of freedom to enable energy management of the supercapacitor. In addition, the topology can be used as an insertion circuit to increase the converter’s boost ratio and efficiently use the rectifier circuit’s dead time [44].

Figure 21.

The Quasi-Z source converter topology with supercapacitor.

3.4. Structure of the Energy Storage System with Flywheel

The flywheel energy storage requires external acceleration to transfer kinetic energy. Electric motor-based drives are the primary drive method for flywheel energy storage due to their excellent speed regulation and power capacity [45,46,47,48,49,50,51,52,53,54,55]. The energy efficiency of rail transit systems using flywheel energy storage can reach 21.6% [56].

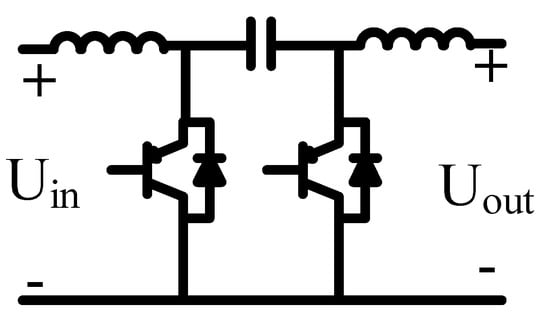

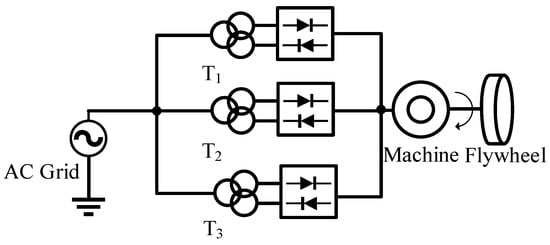

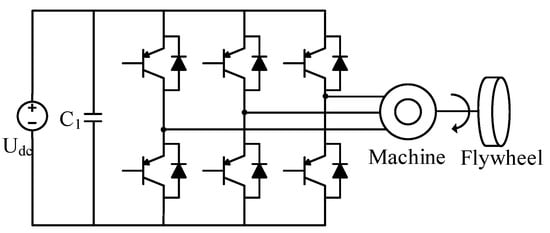

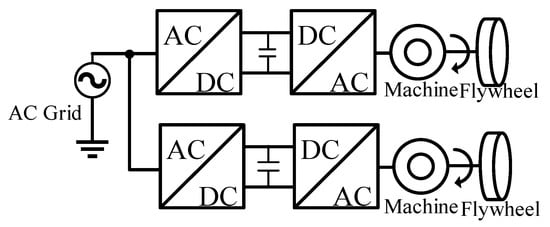

The flywheel needs to obtain a high speed through the motor, making flywheel energy storage require a power electronic converter to regulate the speed of the motor such as Figure 22. Direct AC converters are widely available for motor speed regulation circuits. The converter can be used for both load and power conversion, meeting the requirements of energy storage systems that require a bi-directional flow of energy. The topology is highly efficient as the energy only needs to be converted once.

Figure 22.

Direct AC converters with flywheel.

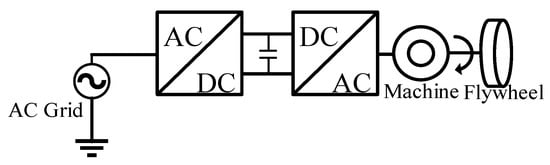

The indirect AC converter is another speed control circuit with a topology similar to the two-stage converter structure such as Figure 23. The regulated capacitor between the two converters makes the DC side of the inverter comparable to a regulated power supply, avoiding energy fluctuations during the drive motor or grid connection [52].

Figure 23.

Indirect AC converters with flywheel.

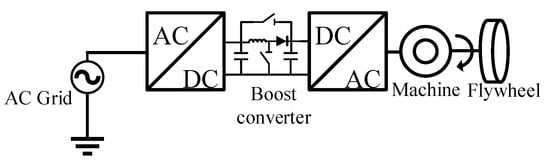

Replacing the DC regulator capacitor of the indirect AC converter with a boost converter increases the converter’s boost ratio to increase the motor’s speed range and meet the flywheel’s higher speed requirements such as Figure 24.

Figure 24.

Indirect AC converters with the boost converter.

The inverter is directly connected to the motor and its performance will directly determine the capacity and power characteristics of the flywheel energy storage; the most common full-bridge inverter circuit topology is shown in Figure 25.

Figure 25.

Topology of full-bridge inverter with flywheel.

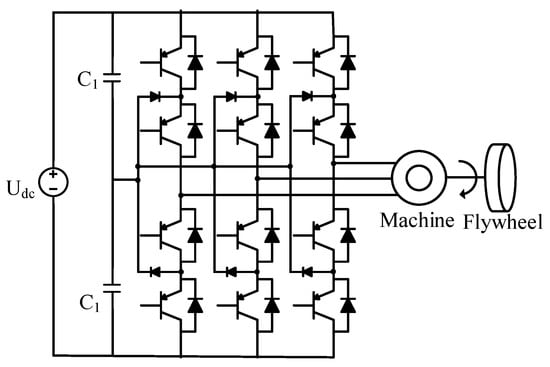

For power levels more significant than the capacity of a single switching tube, a multilevel inverter can be used to drive the motor such as Figure 26. This type of inverter increases the capacity of the inverter by increasing the shared voltage stress on the switching tubes.

Figure 26.

Topology of multilevel inverter with flywheel.

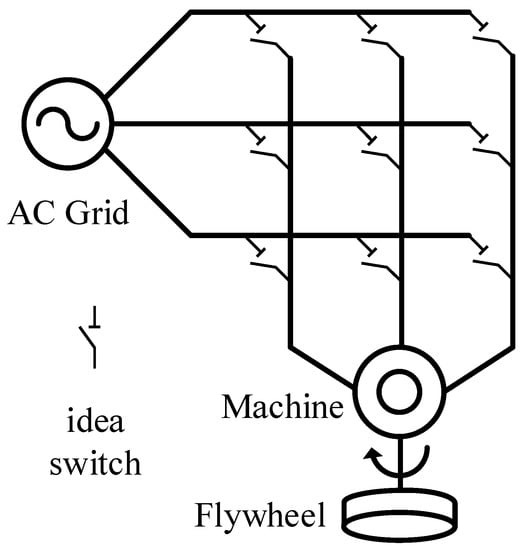

Since the matrix converter omits the DC intermediate link such as Figure 27, eliminating the bulky voltage regulator capacitors, it does not require a converter compared to direct AC converters. This is the reason matrix converters have a significant size advantage in flywheel energy storage. However, matrix converters also suffer from complex control and low voltage utilization, and their application prospects require further research.

Figure 27.

Topology of matrix converter with flywheel.

The DC bus integration scheme for flywheel energy storage is shown in Figure 28, which integrates several inverters into the DC side of the same rectifier. The DC bus integration scheme is less prone to loop currents between converters and requires a relatively small number of devices.

Figure 28.

Schematic diagram of the DC bus integration system with flywheel.

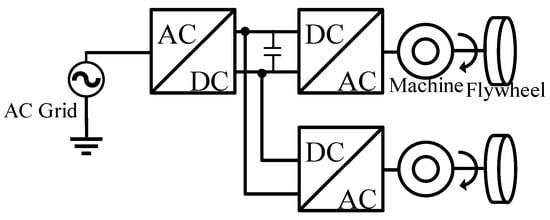

The AC bus integration solution is the direct parallel connection of several flywheel energy storage systems to an AC source (Figure 29). This integration solution makes the multiple systems independent of each other, improving system reliability and reducing the performance requirements of the rectifier.

Figure 29.

Schematic diagram of the AC bus integration system with flywheel.

4. Energy Storage Control Strategy in Rail Transit

4.1. Control Strategy for Power Quality Management in Rail Transit

With the large-scale application of electrified rail transportation, the power quality problems in electrified railroads are becoming more and more prominent. One of the most prominent problems lies in three aspects: three-phase unbalance, harmonic pollution, and voltage fluctuation [57,58,59,60,61,62,63,64].

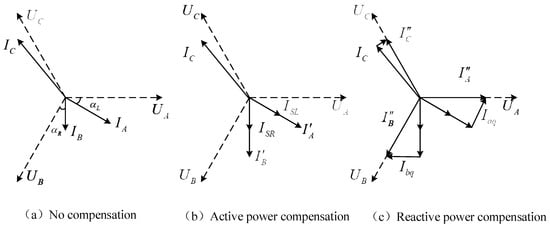

The three-phase unbalance in electrified rail transit is caused by the asymmetric power supply method of the traction transformer, which generates negative sequence currents in the power system. It is necessary to compensate for the negative sequence current. In this process, the four-quadrant operation capability of the power regulator is used to transfer the active current of the two supply arms dynamically, and the energy storage system plays the role of making up the power shortage in this process to reduce the negative sequence current and reduce the three-phase voltage unbalance. The compensation is divided into active and reactive current compensation, and the three-phase current vector diagram is shown in Figure 30.

Figure 30.

Power compensation vector diagram.

Active current compensation achieves the balance of active currents in both arms, and the active compensation currents in both supply arms can be expressed as

where ISR and ISL are active compensation current. Ies is the practical value of the compensated transfer active current of the energy storage system, and its value is determined by the charging and discharging rules of the energy storage system.

After active current compensation, there is still a phase difference between the load current of the supply arm and the three-phase voltage on the grid side, and the phase difference needs to be corrected for reactive power compensation.

where ILq and IRq are the reactive compensation current, Iaq and Ibq are the reactive component of the current to be compensated, Iap and Ibp are active components of the current to be compensated.

Electrified rail transit traction systems use many high-power power electronics, making rail transit harmonics a significant part of grid harmonics. The energy storage device achieves the purpose of eliminating the harmonic current of the moving train by generating a compensation current of equal size and opposite phase to the harmonic current of the moving train, and the size of the harmonic compensation current to be generated as:

Harmonic compensation first needs to extract the harmonic current to obtain the reference command value of the energy storage converter, i.e., harmonic compensation current, and then realize the working mode discrimination according to the real-time power of load and the remaining capacity of the energy storage system to absorb the harmonic energy or release the compensation current with the opposite phase of harmonic current. At present, the research on harmonic compensation based on energy storage systems mainly focus on the converter control strategy, and there are relatively few studies on the capacity of energy storage devices, the charging and discharging threshold of energy storage, and the optimization of real-time charging and discharging power in the process of harmonic compensation.

Network voltage stability is the basis for safe train operation, and changes in train operating conditions are the main factor causing voltage fluctuations in the traction network. Priority should be given to using energy storage for active compensation and then controlling the four-quadrant converter for reactive power compensation if the voltage still cannot meet the requirements after active compensation.

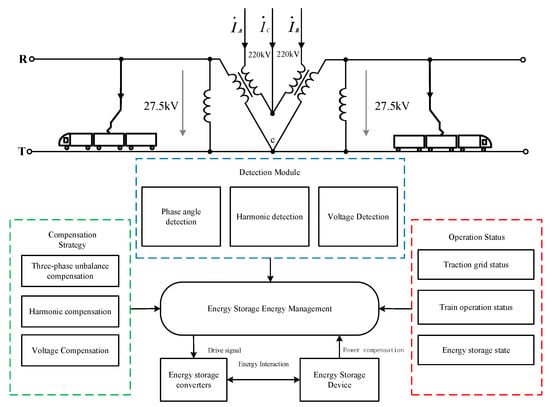

In summary, it can be seen that the power quality problem faced by rail transit is mainly reflected in the traction substation’s disturbance to the power grid. Energy storage equipment can achieve comprehensive power quality management of traction substations by adopting appropriate compensation strategies under the constraints of the rail transit operation state. The block diagram of the energy storage structure and comprehensive governance for rail transportation is shown in Figure 31.

Figure 31.

Block diagram of integrated power quality compensation logic.

4.2. Control Strategy for Power Conversion System in Rail Transit

The stable DC voltage with low ripple content needs to be provided on its DC side; for the PCS to achieve the desired compensation effect, the actual compensation current of both phases should be able to quickly and accurately track the reference current command value. The mainstream method mainly adopts a dual closed-loop voltage and current control strategy. The voltage outer loop is used to establish a stable DC side voltage and provide the current inner loop reference current; the current inner loop is used to track and control the real-time output current of the converter [37,38,39,40,41,42,43,44].

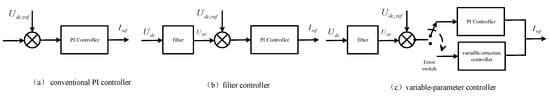

The commonly used PI control is simple and easy to implement, but there are specific tracking errors and secondary ripple problems. However, there are specific tracking errors and secondary ripple problems. Adding a filter on the DC side is a standard method to suppress the second ripple. The third harmonic in the current reference signal can be avoided by pre-separating the DC component of the voltage outer loop input signal. The filter will cause delay and hysteresis of the signal. In the presence of significant disturbances, the conventional PI controller will appear to have a significant overshoot, for which the variable structure PI controller is widely utilized. The parameters in the variable parameter PI controller are designed as a function of the voltage error correlation, and the conventional PI controller is used in the case of small perturbations. In the case of large perturbations, the variable structure controller is used to improve the response performance. The block diagram of DC outer loop control is shown as Figure 32.

Figure 32.

Block diagram of DC outer loop control.

The current inner loop tracking control performance directly affects the control effect of energy storage. The conventional control strategy is to obtain the current reference value by multiplying the current inner loop command value obtained from the voltage outer loop with the AC voltage phase.

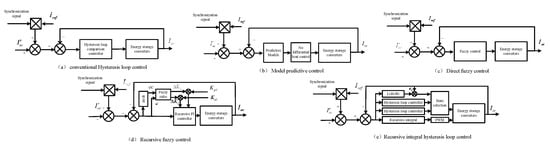

This control strategy is limited by the method of tracking the current. The hysteresis loop current comparison method is mainly used in early theoretical studies due to its fast response and unconditional stability advantages. Still, there are tracking errors during operation, and it is also more sensitive to system parameter changes. The repetitive prediction-based differential beat-free control method can effectively correct the periodic tracking error and achieve smooth current tracking. Still, the need to calculate multiple modulation periods leads to a reduced tracking speed. The direct fuzzy tracking control method has the disadvantages of more robustness and low influence factors by nonlinear disturbances. The controller is based on logic implementation, which gives the control method better control adaptability, but improving the tracking performance needs to increase the complexity of the controller significantly. The PI control method based on fuzzy recursion realizes the adaptive adjustment of the PI controller, and the method can realize the current tracking for various operating conditions. The dual hysteresis loop control method combines the rapidity of the hysteresis loop comparative tracking control method and the steady-state non-differentiation of the recursive integral method, which can effectively compensate for the significant tracking error of the hysteresis loop control and the long adjustment time of the recursive integral method and realize the complementary advantages of the two methods. The block diagram of AC inner loop control is shown as Figure 33.

Figure 33.

Block diagram of AC inner loop control.

4.3. Control Strategy for Energy Storage Management in Rail Transit

Rail transportation is a complex system, and the working state of energy storage is affected by many factors. According to different power allocation methods, the existing energy storage management strategies can be divided into voltage threshold control strategy, filtering algorithm control strategy, fuzzy logic control strategy, and model predictive control strategy [65,66,67,68,69,70,71,72].

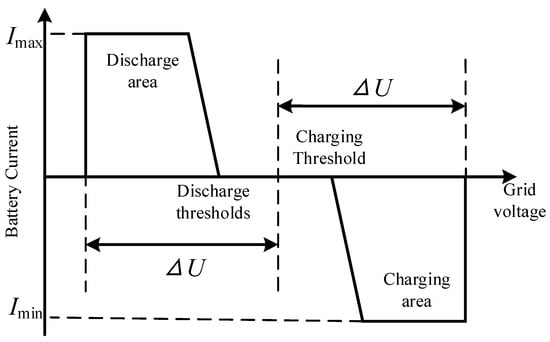

The voltage threshold control strategy is often used in DC traction systems. This control strategy is mainly used to divide the operating state of the energy storage system into several nonlinear functions by setting several voltage thresholds such as Figure 34. The control strategy can strongly suppress voltage fluctuations because the energy storage operating state is set to switch with voltage changes. The dynamic threshold-based control strategy is widely adopted to improve energy utilization further and extend the energy storage life.

Figure 34.

Voltage-based control curves for energy storage.

The filter control strategy is now widely used in the energy field, mainly decoupling the high-frequency component of the target power from the low- and medium-frequency components through a filter to provide a power reference value for the energy storage system. The filter control is simple in structure and easy to implement. For the hybrid energy storage system of the electrified railroad, the first-order low-pass filtering algorithm is usually used for the power distribution between the supercapacitor and the battery to utilize regenerative braking energy efficiently. The low-pass filter has a response lag phenomenon, for which the Kalman filter, Fourier analysis, wavelet transform, and other spectral analysis means are also widely used.

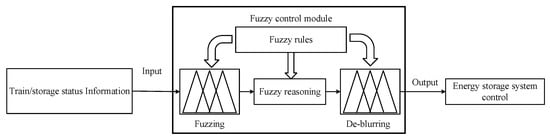

The fuzzy control strategy Is an intelligent control method based on fuzzy set theory, fuzzy linguistic variables, and fuzzy logic reasoning such as Figure 35. Its most prominent feature is that no clear relationship between input and output quantities needs to be established, which is very suitable for energy management of such complex systems as rail transportation. The fuzzy control inputs are generally the measured values of traction load power, energy storage system charge state, etc., and the outputs are the hybrid energy storage system charge and discharge thresholds or energy storage system output power reference values. The development of fuzzy rules is the key, but the fuzzy logic rule-based control method is more expert-dependent, and it is not easy to achieve optimal control. The control accuracy and dynamic quality cannot be achieved at the same time.

Figure 35.

Block diagram of fuzzy control of energy storage.

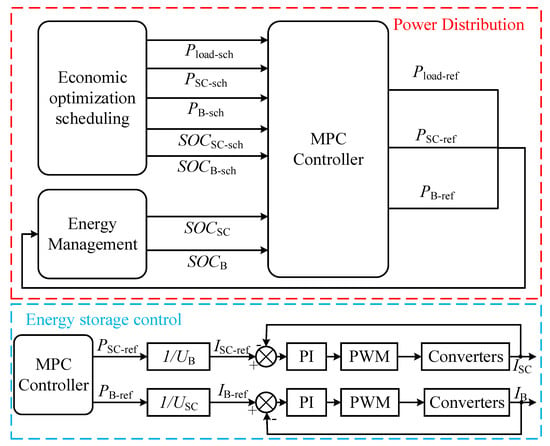

Model predictive control is a model-based closed-loop optimal control method whose core idea is a rolling time domain strategy such as Figure 36. The method establishes appropriate constraints and objective functions to optimize the configuration of energy storage capacity and can obtain the control reference value of the energy storage system. Using model predictive control, the overall energy management of the rail system can be achieved by taking into account the traction characteristics model, train operation status, energy storage status, weather, and other factors. Model predictive control relies too much on an accurate circuit model, which is less robust and increases the computational burden of the controller with a rolling optimization process.

Figure 36.

Block diagram of energy storage system model prediction.

5. Conclusions

This paper summarizes the latest research results on energy storage in rail transit systems, matches the characteristics of energy storage technologies with the energy storage requirements of rail transit, and analyzes the operation of energy storage systems in different scenarios. The adaptability of batteries, supercapacitors, and flywheels as energy storage systems for rail transportation is summarized and compared. The topologies and integration methods of various energy storage systems are studied. The control strategies under various control in rail transportation are summarized and proposed.

The following conclusions are drawn by comparing the advantages and shortcomings of existing studies.

(1) The hybrid energy storage system has the characteristics of both high energy density and high power density. It can respond quickly, delay the decay of energy storage element life and reduce the investment cost to a certain extent when facing the complex working conditions of the electrified railroad power supply system.

(2) The energy storage converter system with a two-stage converter with a DC isolation circuit is suitable for the high-power working environment of rail transportation. The high reliability and easy expansion of the integrated structure of energy storage with modular common DC bus enable it to meet the plug-and-play of energy storage devices in the electrified railroad power supply system, whose cooperative control, loop current suppression, efficiency enhancement, and capacity optimization are the focus of subsequent research.

(3) Access to an energy storage system can effectively improve the power quality problem of the traction power supply system, and its compensation degree is positively related to the charging and discharging power of the energy storage device.

Energy storage technology has significant value and broad application prospects in rail transportation, but it still faces many technical difficulties and challenges in engineering practice.

(1) The energy storage system’s response speed and power tracking capability. High-speed trains run at high speeds and generate many load fluctuations quickly. For the control system in rail transportation, it needs to improve the control accuracy by shortening the sampling period and control interval, so the control model needs to have better dynamic characteristics to adapt to the fast-changing fluctuating load; for the energy storage medium, it needs to have stronger power tracking ability, so it needs to optimize the mixed matching scheme, capacity configuration method, and energy management strategy of the energy storage medium to improve the regenerative braking energy utilization efficiency under different power scenarios. The regenerative braking energy utilization efficiency under different power scenarios.

(2) Energy storage media and variable current device life loss. Energy storage media and variable current device investment in the total investment in energy storage systems occupy a dominant position. Still, in actual operation, there are different degrees of life loss for both. For energy storage media, long-term high frequency and high depth of charge and discharge will lead to reduced service life, especially in the electrochemical energy storage media. To increase the useful life of energy storage, energy management strategies need to be designed to limit the frequency of charging and discharging, thereby extending the service life. For variable current devices, frequent switching of traction power supply system conditions and drastic power fluctuations make the operating environment of power electronics devices harsher and increase the possibility of failure and need to improve system reliability by optimizing equipment selection and increasing redundancy configuration.

(3) Energy storage system life cycle economic benefits. At present, the high initial investment cost of the energy storage system in rail transportation limits its large-scale promotion, so it is especially important to improve the whole life cycle economic benefits of the energy storage system. On the one hand, it is necessary to improve the utilization efficiency of energy storage devices as much as possible, and reduce the energy storage by reasonably optimizing the capacity configuration model of the energy storage system and effective energy management scheme; on the other hand, it is necessary to clarify the revenue model of the energy storage system in rail transportation and establish a quantitative model to measure the revenue of energy storage system in terms of energy saving and improving power quality. When conditions allow, the energy storage system in rail transit needs to participate in the grid’s peak and frequency regulation dispatch to generate additional revenue and enhance the overall economic benefits of the rail transit system.

Funding

This work was supported by Beijing Science and Technology Plan (Z20110000452).

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Abbreviation | Meaning |

| AC | Alternating current |

| DC | Direct current |

| ESS | Energy storage system |

| BES | Battery energy storage |

| SC | Super capacitor |

| ISR, ISL | Active compensation current |

| Ies | Practical value of the compensated transfer active current |

| ILq IRq | Reactive compensation current |

| ILh IRh | Harmonic compensation current |

| Iah and Ibh | Harmonic amplitude |

| Udc | DC side voltage of energy storage system |

| Udc,ref | Reference value of DC side voltage |

| UDC | DC side voltage component without disturbance |

| Iref | Energy storage current reference value |

| Iac | AC side current of energy storage converter |

| Pload-sch | Planned load output power |

| PSC-sch | Planned supercapacitor output power |

| PB-sch | Planned battery output power |

| SOCSC-sch | Planned supercapacitor charge state |

| SOCB-sch | Planned battery charge state |

| SOCSC | Supercapacitor state of charge |

| SOCB | Battery state of charge |

| Isc-ref | Supercapacitor current reference value |

| IB-ref | Battery current reference value |

References

- Boicea, V.A. Energy storage technologies: The past and the present. Proc. IEEE 2014, 102, 1777–1794. [Google Scholar] [CrossRef]

- Ursua, A.; Gandia, L.M.; Sanchis, P. Hydrogen Production from Water Electrolysis: Current Status and Future Trends. Proc. IEEE 2012, 100, 410–426. [Google Scholar] [CrossRef]

- Rajeshwar, K.; McConnell, R.; Licht, S. Solar Hydrogen Generation. Toward A Renewable Energy Future; Springer: New York, NY, USA, 2008. [Google Scholar]

- Wu, X.; Li, H.; Wang, X.; Zhao, W. Cooperative Operation for Wind Turbines and Hydrogen Fueling Stations With On-Site Hydrogen Production. IEEE Trans. Sustain. Energy 2020, 11, 2775–2789. [Google Scholar] [CrossRef]

- Agbossou, K.; Kolhe, M.; Hamelin, J.; Bose, T. Performance of a Stand-Alone Renewable Energy System Based on Energy Storage as Hydrogen. IEEE Trans. Energy Convers. 2004, 19, 633–640. [Google Scholar] [CrossRef]

- Sabillon, C.; Sighn, B.; Venkatesh, B. Technoeconomic Models for the Optimal Inclusion of Hydrogen Trains in Electricity Markets. In Proceedings of the 2020 IEEE Power & Energy Society General Meeting (PESGM), Montreal, QC, Canada, 2–6 August 2020; p. 1. [Google Scholar] [CrossRef]

- Zhou, T.; Sun, W. Optimization of Battery–Supercapacitor Hybrid Energy Storage Station in Wind/Solar Generation System. IEEE Trans. Sustain. Energy 2014, 5, 408–415. [Google Scholar] [CrossRef]

- D’Ovidio, G.; Masciovecchio, C.; Rotondale, N. City Bus Powered by Hydrogen Fuel Cell and Flywheel Energy Storage System. In Proceedings of the Electric Vehicle Conference (IEVC), Florence, Italy, 17–19 December 2014; pp. 1–5. [Google Scholar] [CrossRef]

- Abdelrahman, A.S.; Attia, Y.; Woronowicz, K.; Youssef, M.Z. Hybrid Fuel Cell/Battery Rail Car: A Feasibility Study. IEEE Trans. Transp. Electrif. 2016, 2, 493–503. [Google Scholar] [CrossRef]

- Zhou, H.; Bhattacharya, T.; Tran, D.; Siew, T.S.T.; Khambadkone, A.M. Composite Energy Storage System Involving Battery and Ultracapacitor With Dynamic Energy Management in Microgrid Applications. IEEE Trans. Power Electron. 2011, 26, 923–930. [Google Scholar] [CrossRef]

- Wu, C.; Lu, S.; Xue, F.; Jiang, L.; Chen, M. Optimal Sizing of Onboard Energy Storage Devices for Electrified Railway Systems. IEEE Trans. Transp. Electrif. 2020, 6, 1301–1311. [Google Scholar] [CrossRef]

- Al-Thani, H.; Koç, M.; Isaifan, R.J.; Bicer, Y. A Review of the Integrated Renewable Energy Systems for Sustainable Urban Mobility. Sustainability 2022, 14, 10517. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, K.; Guo, Y.; Su, W. Investigate the Impacts of PEV Charging Facilities on Integrated Electric Distribution System and Electrified Transportation System. IEEE Trans. Transp. Electrif. 2015, 1, 178–187. [Google Scholar] [CrossRef]

- Attaianese, C.; Di Monaco, M.; Tomasso, G. Power Control for Fuel-Cell–Supercapacitor Traction Drive. IEEE Trans. Veh. Technol. 2012, 61, 1961–1971. [Google Scholar] [CrossRef]

- Lukic, S.M.; Cao, J.; Bansal, R.C.; Rodriguez, F.; Emadi, A. Energy Storage Systems for Automotive Applications. IEEE Trans. Ind. Electron. 2008, 55, 2258–2267. [Google Scholar] [CrossRef]

- Dominguez, M.; Fernandez-Cardador, A.; Cucala, A.P.; Pecharroman, R.R. Energy Savings in Metropolitan Railway Substations Through Regenerative Energy Recovery and Optimal Design of ATO Speed Profiles. IEEE Trans. Autom. Sci. Eng. 2012, 9, 496–504. [Google Scholar] [CrossRef]

- Ciccarelli, F.; Iannuzzi, D.; Kondo, K.; Fratelli, L. Line-Voltage Control Based on Wayside Energy Storage Systems for Tramway Networks. IEEE Trans. Power Electron. 2015, 31, 884–899. [Google Scholar] [CrossRef]

- Geng, Y.; Yang, Z.; Lin, F. Design and Control for Catenary Charged Light Rail Vehicle Based on Wireless Power Transfer and Hybrid Energy Storage System. IEEE Trans. Power Electron. 2020, 35, 7894–7903. [Google Scholar] [CrossRef]

- Luo, A.; Wu, C.; Shen, J.; Shuai, Z.; Ma, F. Railway Static Power Conditioners for High-speed Train Traction Power Supply Systems Using Three-phase V/V Transformers. IEEE Trans. Power Electron. 2011, 26, 2844–2856. [Google Scholar] [CrossRef]

- He, X.; Shu, Z.; Peng, X.; Zhou, Q.; Zhou, Y.; Zhou, Q.; Gao, S. Advanced Cophase Traction Power Supply System Based on Three-Phase to Single-Phase Converter. IEEE Trans. Power Electron. 2013, 29, 5323–5333. [Google Scholar] [CrossRef]

- Viktor, S.; Oleksiy, D.; Petro, B.; Yevhen, K.; Vitalij, L.; Drubetskaya, T. Asymmetric power supply circuit design for electric rolling stock on the electrified DC rail. In Proceedings of the 2020 IEEE 7th International Conference on Energy Smart Systems (ESS), Kyiv, Ukraine, 12–14 May 2020; pp. 326–329. [Google Scholar] [CrossRef]

- Arboleya, P.; Diaz, G.; Coto, M. Unified AC/DC Power Flow for Traction Systems: A New Concept. IEEE Trans. Veh. Technol. 2012, 61, 2421–2430. [Google Scholar] [CrossRef]

- Ronanki, D.; Williamson, S.S. Evolution of Power Converter Topologies and Technical Considerations of Power Electronic Transformer-Based Rolling Stock Architectures. IEEE Trans. Transp. Electrif. 2017, 4, 211–219. [Google Scholar] [CrossRef]

- Feng, J.; Chu, W.Q.; Zhang, Z.; Zhu, Z.Q. Power Electronic Transformer-Based Railway Traction Systems: Challenges and Opportunities. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 5, 1237–1253. [Google Scholar] [CrossRef]

- Chymera, M.; Renfrew, A.C.; Barnes, M.; Holden, J. Simplified Power Converter for Integrated Traction Energy Storage. IEEE Trans. Veh. Technol. 2011, 60, 1374–1383. [Google Scholar] [CrossRef]

- Shu, Z.; Xie, S.; Li, Q. Single-Phase Back-To-Back Converter for Active Power Balancing, Reactive Power Compensation, and Harmonic Filtering in Traction Power System. IEEE Trans. Power Electron. 2010, 26, 334–343. [Google Scholar] [CrossRef]

- Grbovic, P.J.; Delarue, P.; Le Moigne, P.; Bartholomeus, P. A Bidirectional Three-Level DC–DC Converter for the Ultracapacitor Applications. IEEE Trans. Ind. Electron. 2009, 57, 3415–3430. [Google Scholar] [CrossRef]

- Pires, V.F.; Foito, D.; Cordeiro, A. A DC–DC Converter With Quadratic Gain and Bidirectional Capability for Batteries/Supercapacitors. IEEE Trans. Ind. Appl. 2017, 54, 274–285. [Google Scholar] [CrossRef]

- Zandi, M.; Payman, A.; Martin, J.-P.; Pierfederici, S.; Davat, B.; Meibody-Tabar, F. Energy Management of a Fuel Cell/Supercapacitor/Battery Power Source for Electric Vehicular Applications. IEEE Trans. Veh. Technol. 2010, 60, 433–443. [Google Scholar] [CrossRef]

- Cui, G.; Luo, L.; Liang, C.; Hu, S.; Li, Y.; Cao, Y.; Xie, B.; Xu, J.; Zhang, Z.; Liu, Y.; et al. Supercapacitor Integrated Railway Static Power Conditioner for Regenerative Braking Energy Recycling and Power Quality Improvement of High-Speed Railway System. IEEE Trans. Transp. Electrif. 2019, 5, 702–714. [Google Scholar] [CrossRef]

- Camara, M.B.; Gualous, H.; Gustin, F.; Berthon, A.; Dakyo, B. DC/DC Converter Design for Supercapacitor and Battery Power Management in Hybrid Vehicle Applications—Polynomial Control Strategy. IEEE Trans. Ind. Electron. 2009, 57, 587–597. [Google Scholar] [CrossRef]

- Abeywardana, D.B.W.; Hredzak, B.; Agelidis, V.G. A Fixed-Frequency Sliding Mode Controller for a Boost-Inverter-Based Battery-Supercapacitor Hybrid Energy Storage System. IEEE Trans. Power Electron. 2016, 32, 668–680. [Google Scholar] [CrossRef]

- Yildirim, D.; Aksit, M.H.; Yolacan, C.; Pul, T.; Ermis, C.; Aghdam, B.H.; Cadirci, I.; Ermis, M. Full-Scale Physical Simulator of All SiC Traction Motor Drive With Onboard Supercapacitor ESS for Light-Rail Public Transportation. IEEE Trans. Ind. Electron. 2019, 67, 6290–6301. [Google Scholar] [CrossRef]

- Zhang, Z.; Ouyang, Z.; Thomsen, O.C.; Andersen, M.A.E. Analysis and Design of a Bidirectional Isolated DC–DC Converter for Fuel Cells and Supercapacitors Hybrid System. IEEE Trans. Power Electron. 2011, 27, 848–859. [Google Scholar] [CrossRef]

- Gao, L.; Dougal, R.; Liu, S. Power Enhancement of an Actively Controlled Battery/Ultracapacitor Hybrid. IEEE Trans. Power Electron. 2005, 20, 236–243. [Google Scholar] [CrossRef]

- Lee, J.-H.; Lee, S.-H.; Sul, S.-K. Variable-Speed Engine Generator With Supercapacitor: Isolated Power Generation System and Fuel Efficiency. IEEE Trans. Ind. Appl. 2009, 45, 2130–2135. [Google Scholar] [CrossRef]

- Ariyarathna, T.; Kularatna, N.; Gunawardane, K.; Jayananda, D.; Steyn-Ross, D.A. Development of Supercapacitor Technology and Its Potential Impact on New Power Converter Techniques for Renewable Energy. IEEE J. Emerg. Sel. Top. Ind. Electron. 2021, 2, 267–276. [Google Scholar] [CrossRef]

- Golchoubian, P.; Azad, N.L. Real-Time Nonlinear Model Predictive Control of a Battery–Supercapacitor Hybrid Energy Storage System in Electric Vehicles. IEEE Trans. Veh. Technol. 2017, 66, 9678–9688. [Google Scholar] [CrossRef]

- Herrera, V.I.; Gaztanaga, H.; Milo, A.; Saez-De-Ibarra, A.; Etxeberria-Otadui, I.; Nieva, T. Optimal Energy Management and Sizing of a Battery--Supercapacitor-Based Light Rail Vehicle With a Multiobjective Approach. IEEE Trans. Ind. Appl. 2016, 52, 3367–3377. [Google Scholar] [CrossRef]

- Thounthong, P.; Chunkag, V.; Sethakul, P.; Davat, B.; Hinaje, M. Comparative Study of Fuel-Cell Vehicle Hybridization with Battery or Supercapacitor Storage Device. IEEE Trans. Veh. Technol. 2009, 58, 3892–3904. [Google Scholar] [CrossRef]

- Yoo, H.; Sul, S.-K.; Park, Y.; Jeong, J. System Integration and Power-Flow Management for a Series Hybrid Electric Vehicle Using Supercapacitors and Batteries. IEEE Trans. Ind. Appl. 2008, 44, 108–114. [Google Scholar] [CrossRef]

- Lu, S.; Corzine, K.A.; Ferdowsi, M. A New Battery/Ultracapacitor Energy Storage System Design and Its Motor Drive Integration for Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2007, 56, 1516–1523. [Google Scholar] [CrossRef]

- Cao, J.; Emadi, A. A New Battery/UltraCapacitor Hybrid Energy Storage System for Electric, Hybrid, and Plug-In Hybrid Electric Vehicles. IEEE Trans. Power Electron. 2011, 27, 122–132. [Google Scholar] [CrossRef]

- Liu, S.; Xie, X.; Yang, L. Analysis, Modeling and Implementation of a Switching Bi-Directional Buck-Boost Converter Based on Electric Vehicle Hybrid Energy Storage for V2G System. IEEE Access 2020, 8, 65868–65879. [Google Scholar] [CrossRef]

- Mukoyama, S.; Nakao, K.; Sakamoto, H.; Matsuoka, T.; Nagashima, K.; Ogata, M.; Yamashita, T.; Miyazaki, Y.; Miyazaki, K.; Maeda, T.; et al. Development of Superconducting Magnetic Bearing for 300 kW Flywheel Energy Storage System. IEEE Trans. Appl. Supercond. 2017, 27, 1–4. [Google Scholar] [CrossRef]

- Mitsuda, H.; Inoue, A.; Nakaya, B.; Komori, M. Improvement of Energy Storage Flywheel System With SMB and PMB and Its Performances. IEEE Trans. Appl. Supercond. 2009, 19, 2091–2094. [Google Scholar] [CrossRef]

- Ichihara, T.; Matsunaga, K.; Kita, M.; Hirabayashi, I.; Isono, M.; Hirose, M.; Yoshii, K.; Kurihara, K.; Saito, O.; Saito, S.; et al. Application of Superconducting Magnetic Bearings to a 10 kWh-Class Flywheel Energy Storage System. IEEE Trans. Appl. Supercond. 2005, 15, 2245–2248. [Google Scholar] [CrossRef]

- de Andrade, R.; Sotelo, G.G.; Ferreira, A.C.; Rolim, L.G.B.; Neto, J.L.D.S.; Stephan, R.M.; Suemitsu, W.I.; Nicolsky, R. Flywheel Energy Storage System Description and Tests. IEEE Trans. Appl. Supercond. 2007, 17, 2154–2157. [Google Scholar] [CrossRef]

- Li, X.; Anvari, B.; Palazzolo, A.; Wang, Z.; Toliyat, H. A Utility-Scale Flywheel Energy Storage System with a Shaftless, Hubless, High-Strength Steel Rotor. IEEE Trans. Ind. Electron. 2017, 65, 6667–6675. [Google Scholar] [CrossRef]

- Werfel, F.N.; Floegel-Delor, U.; Riedel, T.; Rothfeld, R.; Wippich, D.; Goebel, B.; Reiner, G.; Wehlau, N. Towards High-Capacity HTS Flywheel Systems. IEEE Trans. Appl. Supercond. 2010, 20, 2272–2275. [Google Scholar] [CrossRef]

- Ghosh, S.; Kamalasadan, S. An Energy Function-Based Optimal Control Strategy for Output Stabilization of Integrated DFIG-Flywheel Energy Storage System. IEEE Trans. Smart Grid 2017, 8, 1922–1931. [Google Scholar] [CrossRef]

- Murakami, K.; Komori, M.; Mitsuda, H. Flywheel Energy Storage System Using SMB and PMB. IEEE Trans. Appl. Supercond. 2007, 17, 2146–2149. [Google Scholar] [CrossRef]

- Subkhan, M.; Komori, M. New Concept for Flywheel Energy Storage System Using SMB and PMB. IEEE Trans. Appl. Supercond. 2011, 21, 1485–1488. [Google Scholar] [CrossRef]

- Lee, J.-P.; Park, B.-J.; Han, Y.-H.; Jung, S.-Y.; Sung, T.-H. Energy Loss by Drag Force of Superconductor Flywheel Energy Storage System With Permanent Magnet Rotor. IEEE Trans. Magn. 2008, 44, 4397–4400. [Google Scholar] [CrossRef]

- Komori, M.; Uchimura, Y. Improving the Dynamics of Two Types of Flywheel Energy Storage Systems With SMBs. IEEE Trans. Appl. Supercond. 2005, 15, 2261–2264. [Google Scholar] [CrossRef]

- Gee, A.M.; Dunn, R.W. Analysis of Trackside Flywheel Energy Storage in Light Rail Systems. IEEE Trans. Veh. Technol. 2015, 64, 1. [Google Scholar] [CrossRef]

- Zeraati, M.; Golshan, M.; Guerrero, J. Voltage quality improvement in low voltage distribution networks using reactive power capability of single-phase PV inverters. IEEE Trans. Smart Grid 2019, 10, 5057–5065. [Google Scholar] [CrossRef]

- Mariscotti, A.; Pozzobon, P.; Vanti, M. Distribution of the Traction Return Current in AT Electric Railway Systems. IEEE Trans. Power Deliv. 2005, 20, 2119–2128. [Google Scholar] [CrossRef]

- Zhu, Z.; Ma, F.; Wang, X.; Deng, L.; Li, G.; Wei, X.; Tang, Y.; Liu, S. Operation Analysis and a Game Theoretic Approach to Dynamic Hybrid Compensator for the V/v Traction System. IEEE Trans. Power Electron. 2018, 34, 8574–8587. [Google Scholar] [CrossRef]

- Ma, F.; Xu, Q.; He, Z.; Tu, C.; Shuai, Z.; Luo, A.; Li, Y.; Ma, F.; Shuai, Z. A Railway Traction Power Conditioner Using Modular Multilevel Converter and Its Control Strategy for High-Speed Railway System. IEEE Trans. Transp. Electrif. 2016, 2, 96–109. [Google Scholar] [CrossRef]

- Liu, L.; Dai, N.; Lao, K.W.; Hua, W. A Co-Phase Traction Power Supply System Based on Asymmetric Three-Leg Hybrid Power Quality Conditioner. IEEE Trans. Veh. Technol. 2020, 69, 14645–14656. [Google Scholar] [CrossRef]

- Chen, S.-L.; Li, R.-J.; Hsi, P.-H. Traction System Unbalance Problem—Analysis Methodologies. IEEE Trans. Power Deliv. 2004, 19, 1877–1883. [Google Scholar] [CrossRef]

- Gazafrudi, S.M.M.; Langerudy, A.T.; Fuchs, E.F.; Al-Haddad, K. Power Quality Issues in Railway Electrification: A Comprehensive Perspective. IEEE Trans. Ind. Electron. 2014, 62, 3081–3090. [Google Scholar] [CrossRef]

- Hu, S.; Xie, B.; Li, Y.; Gao, X.; Zhang, Z.; Luo, L.; Krause, O.; Cao, Y. A Power Factor-Oriented Railway Power Flow Controller for Power Quality Improvement in Electrical Railway Power System. IEEE Trans. Ind. Electron. 2016, 64, 1167–1177. [Google Scholar] [CrossRef]

- Feng, X.; Gooi, H.B.; Chen, S.X. Hybrid energy storage with multi-mode fuzzy power allocator for PV systems. IEEE Trans. Sustain. Energy 2014, 5, 389–397. [Google Scholar] [CrossRef]

- Chong, L.W.; Wong, Y.W.; Rajkumar, R.K.; Isa, D. An optimal control strategy for standalone PV system with Battery-Supercapacitor Hybrid Energy Storage System. J. Power Sources 2016, 331, 553–565. [Google Scholar] [CrossRef]

- Garcia-Torres, F.; Bordons, C. Optimal economical schedule of hy-drogen-based microgrids with hybrid storage using model predic-tive control. IEEE Trans. Ind. Electron. 2015, 62, 5195–5207. [Google Scholar] [CrossRef]

- Hredzak, B.; Agelidis, V.G.; Jang, M. A model predictive control system for a hybrid battery-ultracapacitor power source. IEEE Trans. Power Electron. 2013, 29, 1469–1479. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, Z.; Wang, W.; Yang, Y. Negative Sequence Current Optimizing Control Based on Railway Static Power Conditioner in V/v Traction Power Supply System. IEEE Trans. Power Electron. 2015, 31, 200–212. [Google Scholar] [CrossRef]

- Jabbour, N.; Mademlis, C. Supercapacitor-Based Energy Recovery System With Improved Power Control and Energy Management for Elevator Applications. IEEE Trans. Power Electron. 2017, 32, 9389–9399. [Google Scholar] [CrossRef]

- Zhang, S.; Luo, Y.; Wang, J.; Wang, X.; Li, K. Predictive Energy Management Strategy for Fully Electric Vehicles Based on Preceding Vehicle Movement. IEEE Trans. Intell. Transp. Syst. 2017, 18, 3049–3060. [Google Scholar] [CrossRef]

- Choi, M.-E.; Kim, S.-W.; Seo, S.-W. Energy Management Optimization in a Battery/Supercapacitor Hybrid Energy Storage System. IEEE Trans. Smart Grid 2011, 3, 463–472. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).