Proton Exchange Membrane Fuel Cell Ejector Test Platform Design and Ejector Test Analysis

Abstract

:1. Introduction

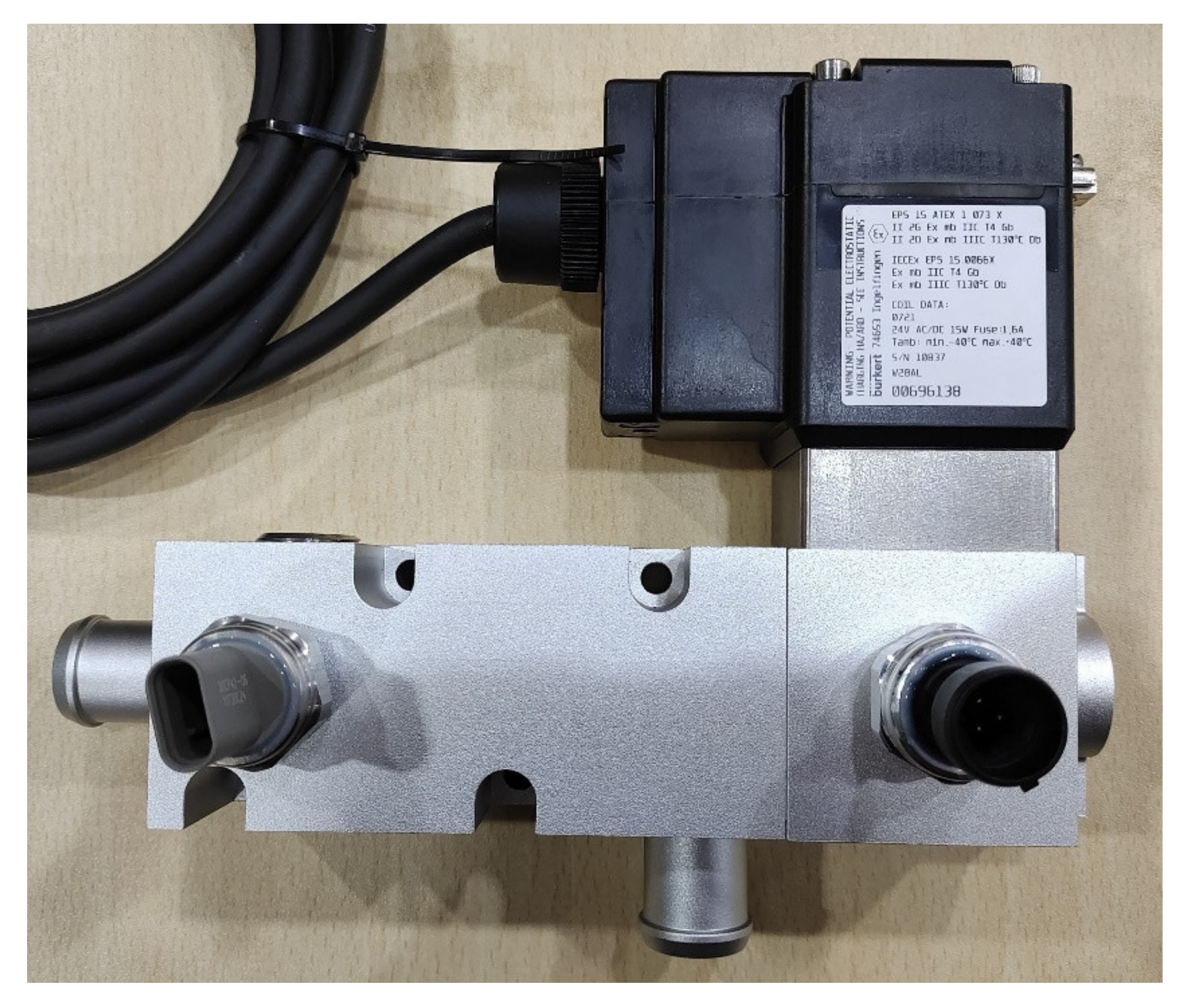

2. Ejector Test Platform Design

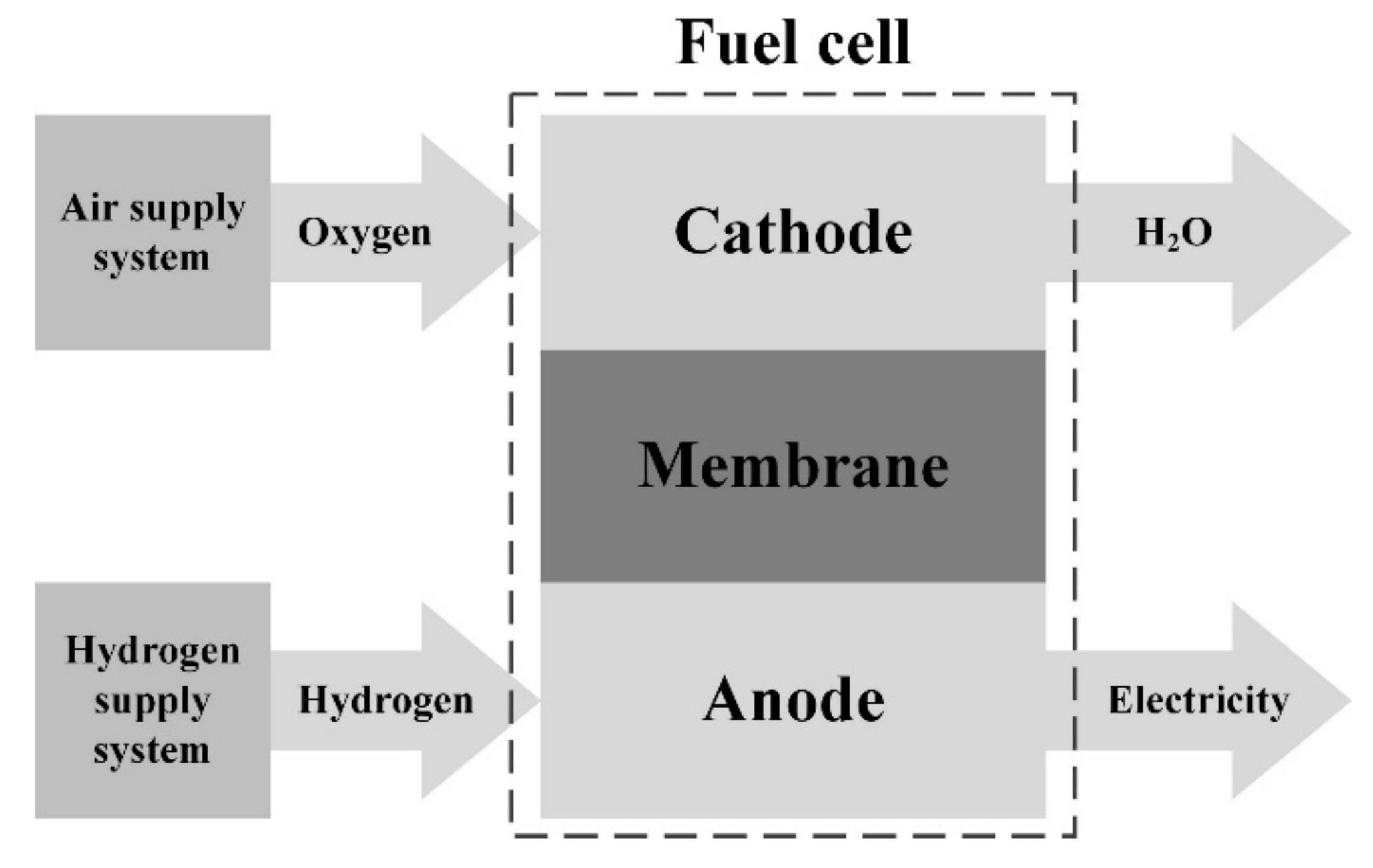

2.1. Fuel Cell Operational Principle

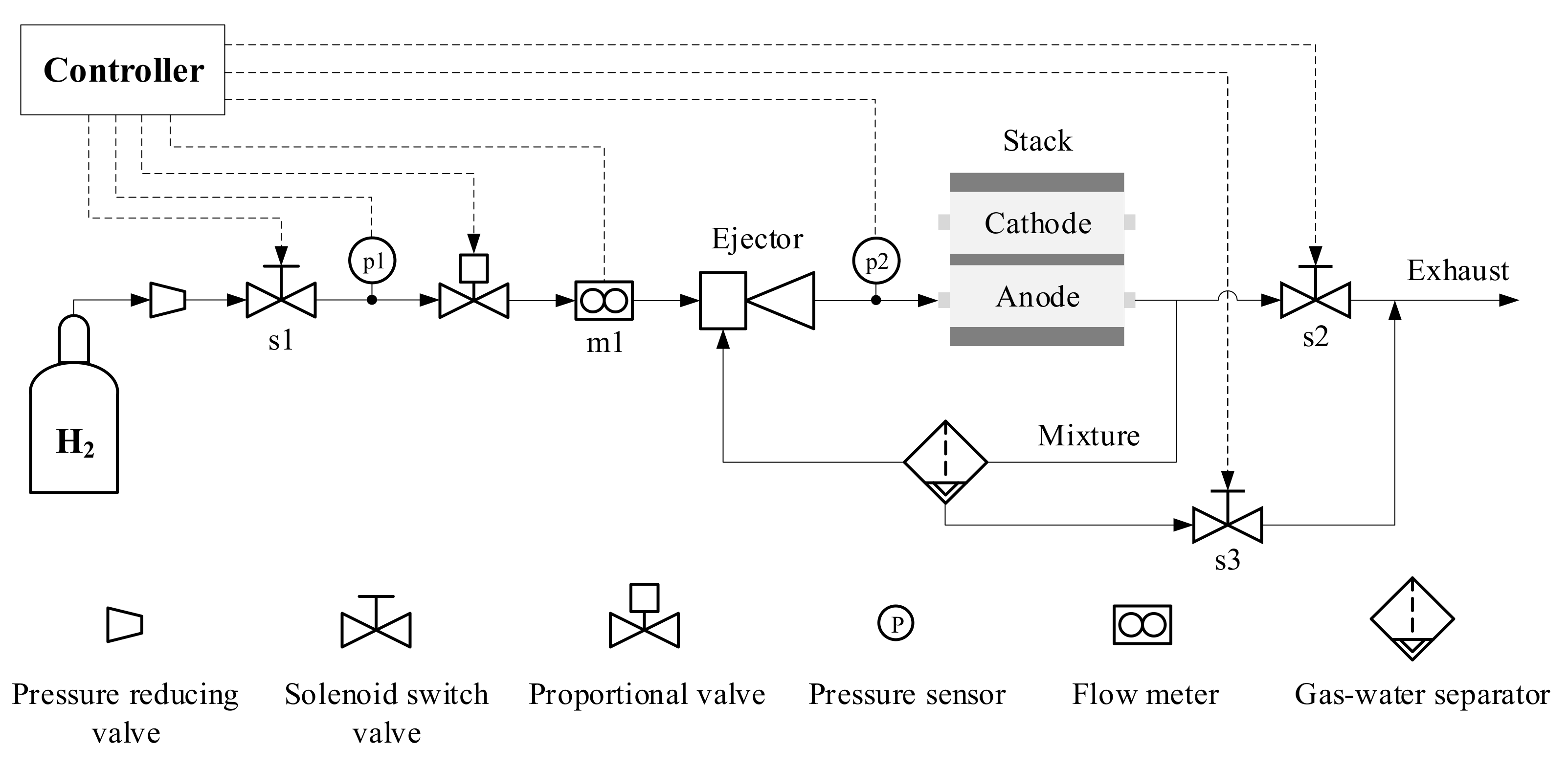

2.2. Fuel Cell Hydrogen Supply System

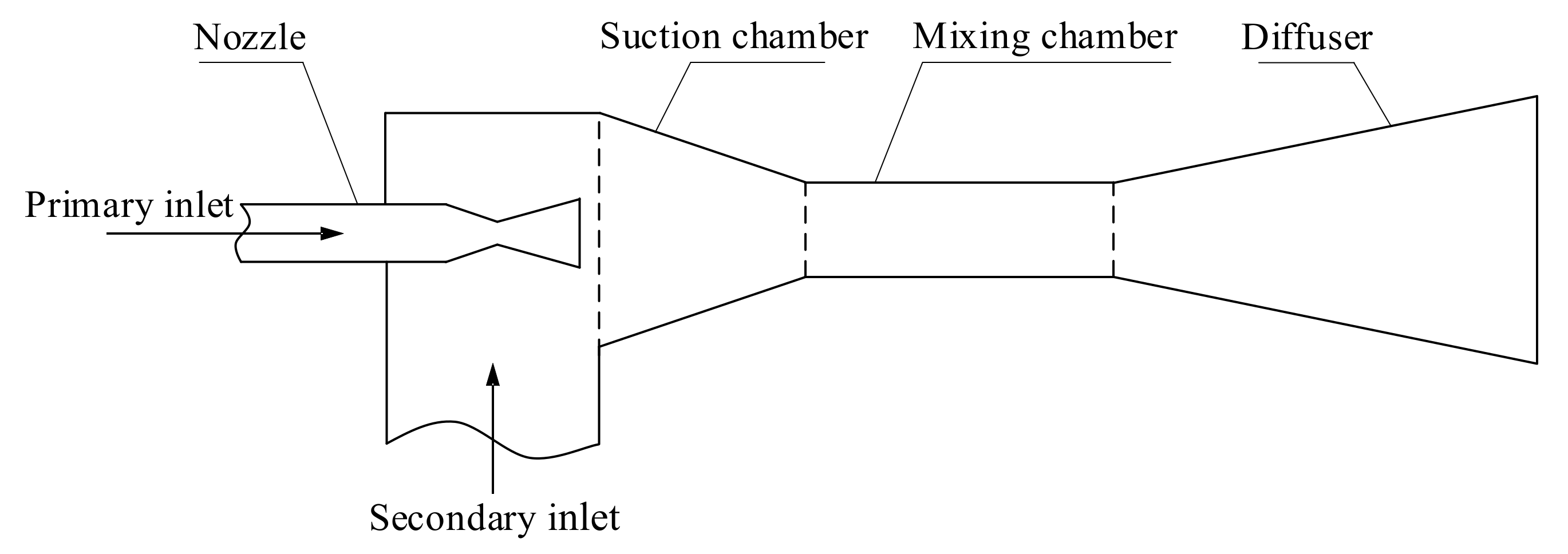

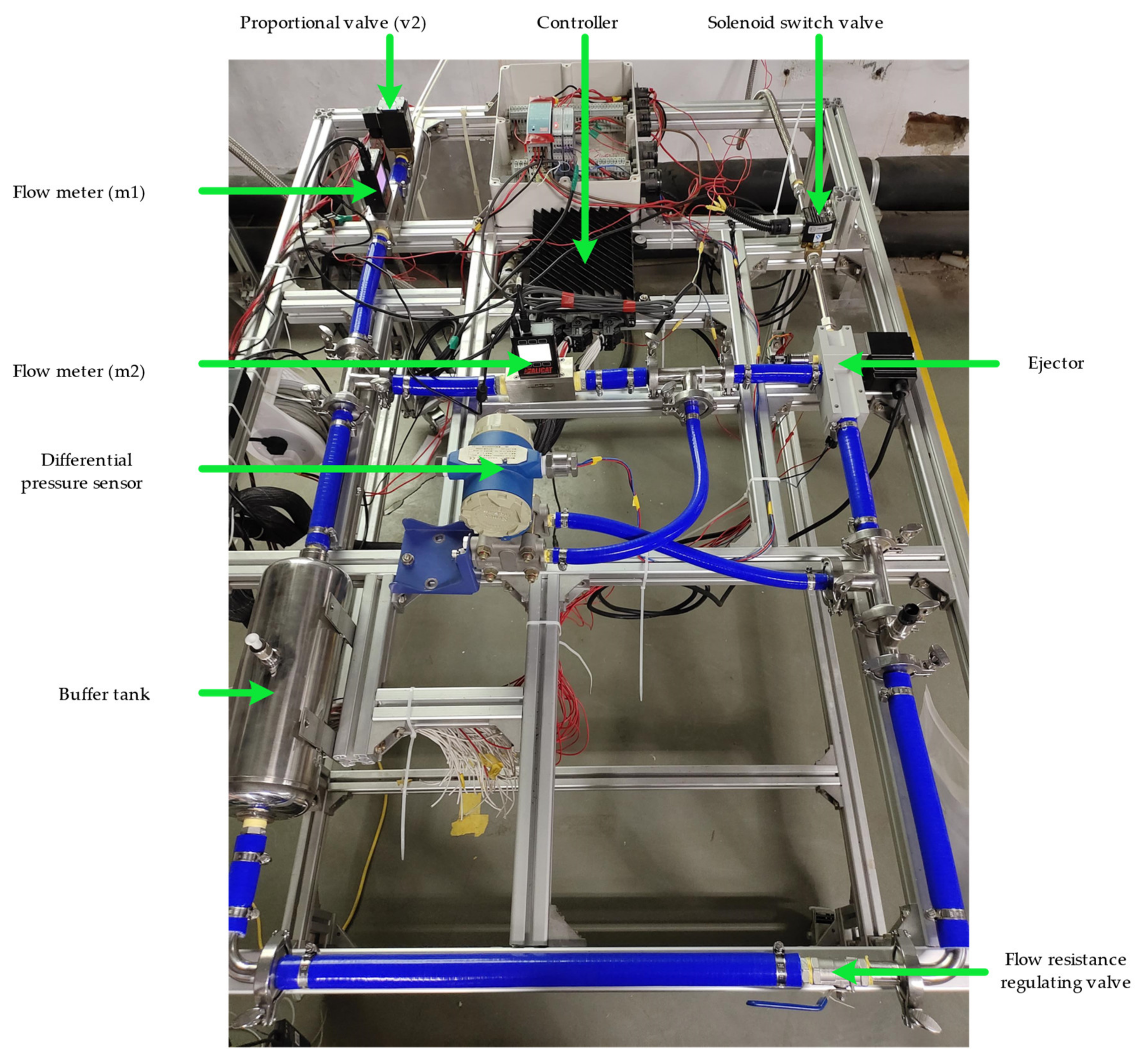

2.3. Fuel Cell Ejector Test Platform Design

3. Ejector Simulation and Test

3.1. Ejector Simulation

3.2. Ejector Test

4. Results and Discussions

4.1. Comparison of Test and Simulation

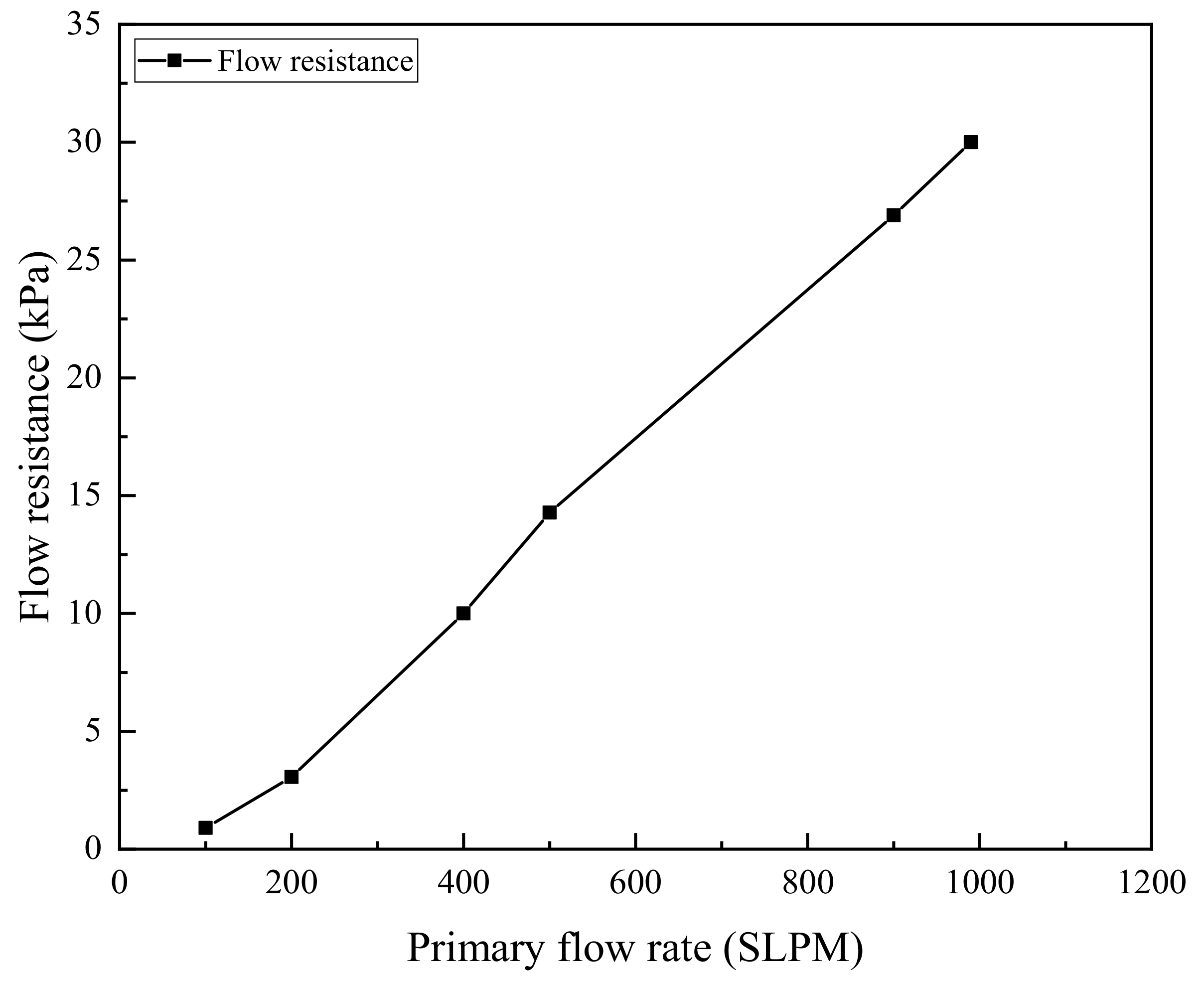

4.2. Primary Flow Rate and Flow Resistance

5. Conclusions

- 1.

- The physical characteristics of the fuel cell hydrogen supply system can be simulated utilizing the buffer tank and flow resistance valve. The ejector test platform established in this study can test the entertainment ratio of the ejector accurately.

- 2.

- The Standard k-e model is more accurate than other turbulence models at a low and medium flow rate. The Realizable k-e model is more accurate than other turbulence models at a large flow rate. The Standard k-e model and the Realizable k-e model are more suitable for ejector simulation and can be used to evaluate the performance of fuel cell ejectors.

- 3.

- When the system design is completed, the flow resistance increases when the flow rate increases. Along with the flow resistance of other operating conditions changing with the change of flow rates, testing the ejector with the method that fixes the flow resistance at the rated power operating condition can reflect the ejector performance at the full operating conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Hong, Z.; Li, Q.; Han, Y.; Shang, W.; Zhu, Y.; Chen, W. An energy management strategy based on dynamic power factor for fuel cell/battery hybrid locomotive. Int. J. Hydrogen Energy 2018, 43, 3261–3272. [Google Scholar] [CrossRef]

- Peng, X.; Xu, S. Three-dimensional Modeling of Gas Purge in a Polymer Electrolyte Membrane Fuel Cell with Co-flow and Counter-flow Pattern. Fuel Cells 2017, 17, 794–808. [Google Scholar]

- Dadvar, M.; Afshari, E. Analysis of design parameters in anodic recirculation system based on ejector technology for PEM fuel cells: A new approach in designing. Int. J. Hydrogen Energy 2014, 39, 12061–12073. [Google Scholar] [CrossRef]

- Wang, X.; Xu, S.; Xing, C. Numerical and experimental investigation on an ejector designed for an 80 kW polymer electrolyte membrane fuel cell stack. J. Power Sources 2019, 415, 25–32. [Google Scholar] [CrossRef]

- Chang, X.; Ma, T.; Wu, R. Impact of urban development on residents’ public transportation travel energy consumption in China: An analysis of hydrogen fuel cell vehicles alternatives. Int. J. Hydrogen Energy 2019, 44, 16015–16027. [Google Scholar] [CrossRef]

- Liu, F.; Zhao, F.; Liu, Z.; Hao, H. The impact of fuel cell vehicle deployment on road transport greenhouse gas emissions: The China case. Int. J. Hydrogen Energy 2018, 43, 22604–22621. [Google Scholar] [CrossRef]

- Shimpalee, S.; Lilavivat, V.; McCrabb, H.; Khunatorn, Y.; Lee, H.-K.; Lee, W.-K.; Weidner, J. Investigation of bipolar plate materials for proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2016, 41, 13688–13696. [Google Scholar] [CrossRef] [Green Version]

- Chen, F.; Gao, Y. An Algorithm for On-line Measurement of the Internal Resistance of Proton Exchange Membrane Fuel Cell. Fuel Cells 2015, 15, 337–343. [Google Scholar] [CrossRef]

- Jang, J.H.; Yan, W.M.; Chiu, H.C.; Lui, J.Y. Dynamic cell performance of kW-grade proton exchange membrane fuel cell stack with dead-ended anode. Appl. Energy 2015, 142, 108–114. [Google Scholar] [CrossRef]

- Tostado-Véliz, M.; Arévalo, P.; Jurado, F. A comprehensive electrical-gas-hydrogen Microgrid model for energy management applications. Energy Convers. Manag. 2021, 228, 113726. [Google Scholar] [CrossRef]

- Zhang, Q.Q.; Feng, J.M.; Zhang, Q.Q.; Peng, X.Y. Performance prediction and evaluation of the scroll-type hydrogen pump for FCVs based on CFD-Taguchi method. Int. J. Hydrogen Energy 2019, 44, 15333–15343. [Google Scholar] [CrossRef]

- Hou, J.; Yang, M.; Zhang, J. Active and passive fuel recirculation for solid oxide and proton exchange membrane fuel cells. Renew. Energy 2020, 155, 1355–1371. [Google Scholar] [CrossRef]

- Xue, H.; Wang, L.; Zhang, H.; Jia, L.; Ren, J. Design and investigation of multi-nozzle ejector for PEMFC hydrogen recircula-tion. Int. J. Hydrogen Energy 2020, 45, 14500–14516. [Google Scholar] [CrossRef]

- Besagni, G.; Mereu, R.; Inzoli, F.; Chiesa, P. Application of an integrated lumped parameter-CFD approach to evaluate the ejector-driven anode recirculation in a PEM fuel cell system. Appl. Therm. Eng. 2017, 121, 628–651. [Google Scholar] [CrossRef]

- Yang, L.; Zhengkai, T.; Siew, H.C. Applications of ejectors in proton exchange membrane fuel cells: A review. Fuel Process. Technol. 2021, 214, 1–12. [Google Scholar]

- Yang, Y.; Du, W.; Ma, T.; Lin, W.; Cong, M.; Yang, H.; Yu, Z. Numerical studies on ejector structure optimization and performance prediction based on a novel pressure drop model for proton exchange membrane fuel cell anode. Int. J. Hydrogen Energy 2020, 45, 23343–23352. [Google Scholar] [CrossRef]

- Jenssen, D.; Berger, O.; Krewer, U. Improved PEM fuel cell system operation with cascaded stack and ejector-based recircula-tion. Appl. Energy 2017, 195, 324–333. [Google Scholar] [CrossRef]

- Yang, Q.; Shi, W.; Chang, J.; Bao, W. Maximum thrust for the rocket-ejector mode of the hydrogen fueled rocket-based com-bined cycle engine. Int. J. Hydrogen Energy 2015, 40, 3771–3776. [Google Scholar] [CrossRef]

- Chen, Q.; Yan, G.; Yu, J. Performance analysis of an ejector enhanced refrigeration cycle with R290/R600a for application in domestic refrigerator/freezers. Appl. Therm. Eng. 2017, 120, 581–592. [Google Scholar] [CrossRef]

- Šarevski, M.N.; Šarevski, V.N. Characteristics of R718 refrigeration/heat pump systems with two-phase ejectors. Int. J. Refrig. 2016, 70, 13–32. [Google Scholar] [CrossRef]

- Chen, Z.; Dang, C.; Hihara, E. Investigations on driving flow expansion characteristics inside ejectors. Int. J. Heat Mass Transf. 2017, 108, 490–500. [Google Scholar] [CrossRef]

- Tamburini, A.; Cipollina, A.; Micale, G.; Piacentino, A. CHP (combined heat and power) retrofit for a large MED-TVC (multi-ple effect distillation along with thermal vapour compression) desalination plant: High efficiency assessment for different de-sign options under the current legislative EU framework. Energy 2016, 115, 1548–1559. [Google Scholar] [CrossRef]

- Askari, I.B.; Ameri, M. Techno economic feasibility analysis of Linear Fresnel solar field as thermal source of the MED/TVC desalination system. Desalination 2016, 394, 1–17. [Google Scholar] [CrossRef]

- Toghyani, S.; Afshari, E.; Baniasadi, E. A parametric comparison of three fuel recirculation system in the closed loop fuel supply system of PEM fuel cell. Int. J. Hydrogen Energy 2019, 44, 7518–7530. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Z.; Jiao, K.; Yang, Z.; Zhou, X.; Du, Q. Numerical investigation of ejector transient characteristics for a 130-kW PEMFC system. Int. J. Energy Res. 2020, 44, 3697–3710. [Google Scholar] [CrossRef]

- Hwang, J.J.; Cho, C.C.; Wu, W.; Chiu, C.H.; Chiu, K.C.; Lin, C.H. Numerical and experimental investigation into passive hy-drogen recovery scheme using vacuum ejector. J. Power Sources 2015, 275, 539–546. [Google Scholar] [CrossRef]

- Nikiforow, K.; Koski, P.; Karimäki, H.; Ihonen, J.; Alopaeus, V. Designing a hydrogen gas ejector for 5 kW stationary PEMFC system—CFD-modeling and experimental validation. Int. J. Hydrogen Energy 2016, 41, 14952–14970. [Google Scholar] [CrossRef]

| Operating Conditions | Primary Flow Rate (SLPM) | Outlet Pressure (kPa) |

|---|---|---|

| 1 | 100 | 130 |

| 2 | 200 | 140 |

| 3 | 400 | 160 |

| 4 | 500 | 180 |

| 5 | 900 | 230 |

| 6 | 990 | 250 |

| Operating Conditions | Primary Flow Rate (SLPM) | Outlet Pressure (kPa) | Flow Resistance (kPa) | Entrainment Ratio | ||||

|---|---|---|---|---|---|---|---|---|

| k-e Standard | k-e RNG | k-e Realizable | k-w SST | Test | ||||

| 1 | 100 | 130.00 | 0.90 | 0.63 | 0.66 | 0.68 | 1.09 | 0.62 |

| 2 | 200 | 140.00 | 3.06 | 0.77 | 0.81 | 0.83 | 0.97 | 0.86 |

| 3 | 400 | 160.00 | 10.00 | 1.03 | 1.11 | 1.08 | 1.27 | 1.02 |

| 4 | 500 | 180.00 | 14.28 | 1.11 | 1.21 | 1.14 | 1.35 | 1.05 |

| 5 | 900 | 230.00 | 26.90 | 1.16 | 1.22 | 1.09 | 1.31 | 0.94 |

| 6 | 990 | 250.00 | 30.00 | 1.14 | 1.20 | 1.08 | 1.29 | 0.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Hou, M.; Li, J.; Pei, Y.; Wang, Y. Proton Exchange Membrane Fuel Cell Ejector Test Platform Design and Ejector Test Analysis. World Electr. Veh. J. 2021, 12, 103. https://doi.org/10.3390/wevj12030103

Chen F, Hou M, Li J, Pei Y, Wang Y. Proton Exchange Membrane Fuel Cell Ejector Test Platform Design and Ejector Test Analysis. World Electric Vehicle Journal. 2021; 12(3):103. https://doi.org/10.3390/wevj12030103

Chicago/Turabian StyleChen, Fengxiang, Mingtao Hou, Jianhui Li, Yaowang Pei, and Yangyang Wang. 2021. "Proton Exchange Membrane Fuel Cell Ejector Test Platform Design and Ejector Test Analysis" World Electric Vehicle Journal 12, no. 3: 103. https://doi.org/10.3390/wevj12030103

APA StyleChen, F., Hou, M., Li, J., Pei, Y., & Wang, Y. (2021). Proton Exchange Membrane Fuel Cell Ejector Test Platform Design and Ejector Test Analysis. World Electric Vehicle Journal, 12(3), 103. https://doi.org/10.3390/wevj12030103