Impacts of Driving Conditions on EV Battery Pack Life Cycle

Abstract

1. Introduction

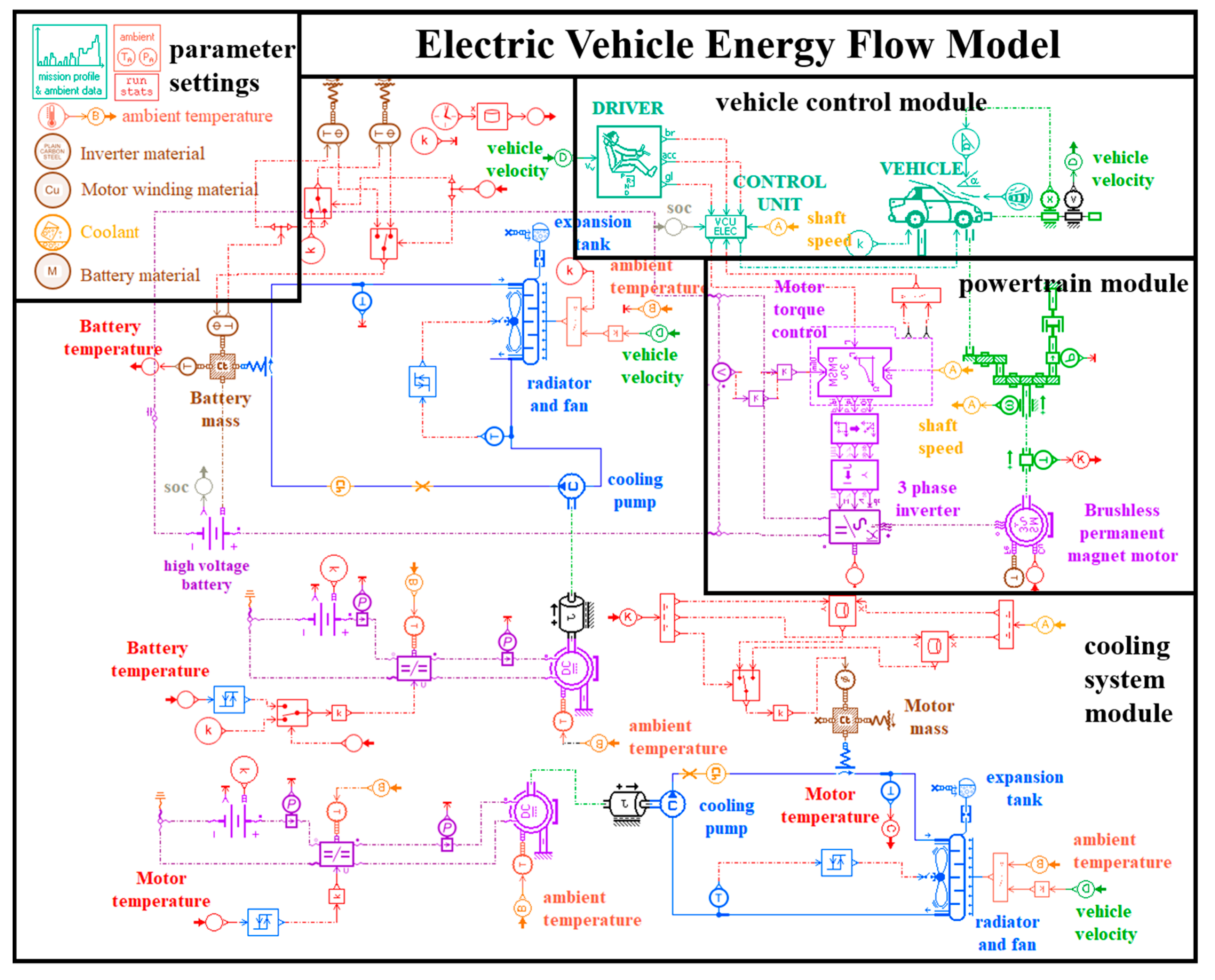

2. Electric Vehicle (EV) Energy Flow Model and Battery Aging Model

2.1. EV Energy Flow Model

- The lumped parameter method is used to model the battery pack, motor, and inverter;

- We neglect the heat dissipation in the cooling circuit (e.g., the heat dissipation on the surface of the pipe).

2.2. Battery Capacity Fade Model

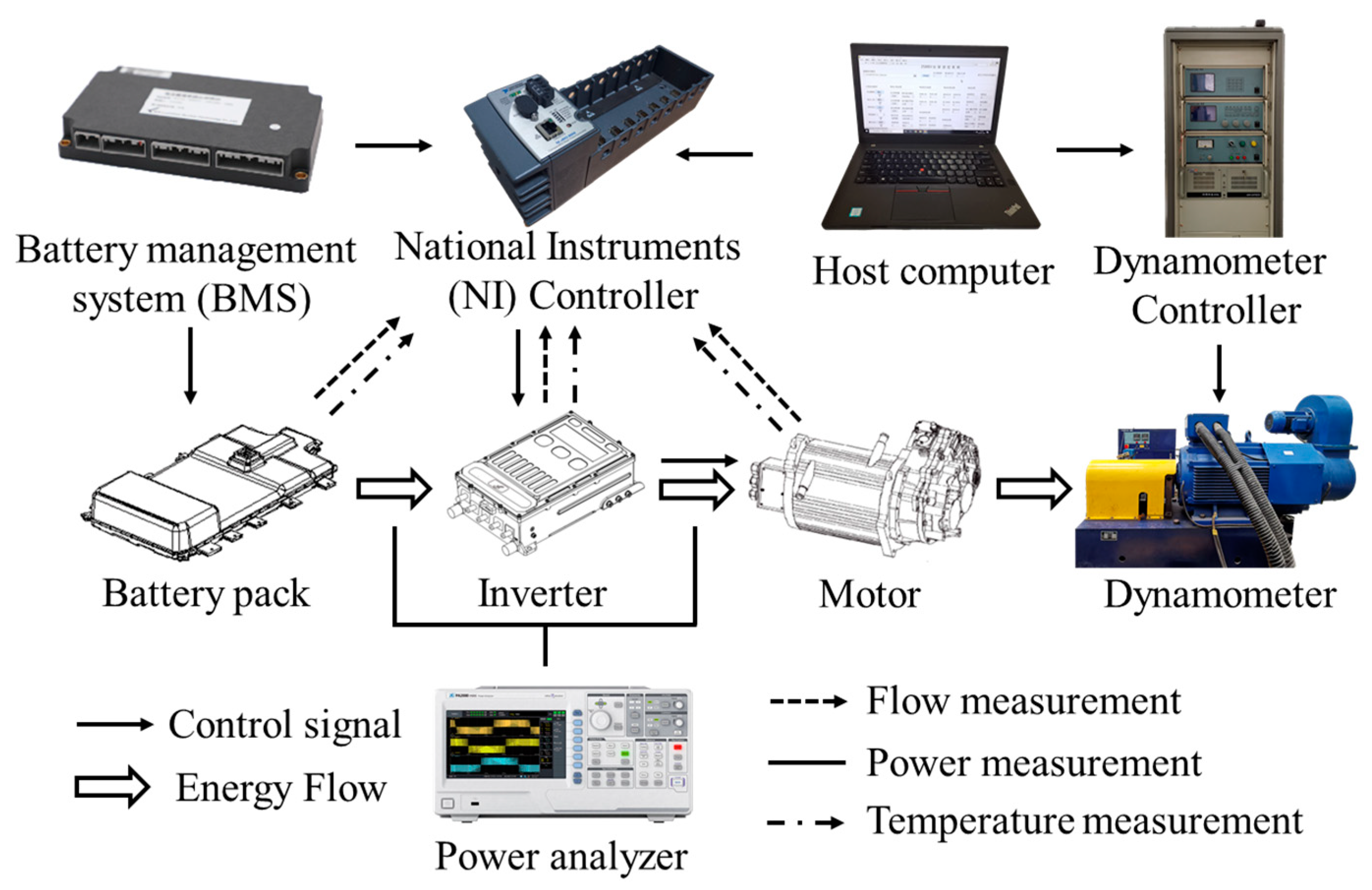

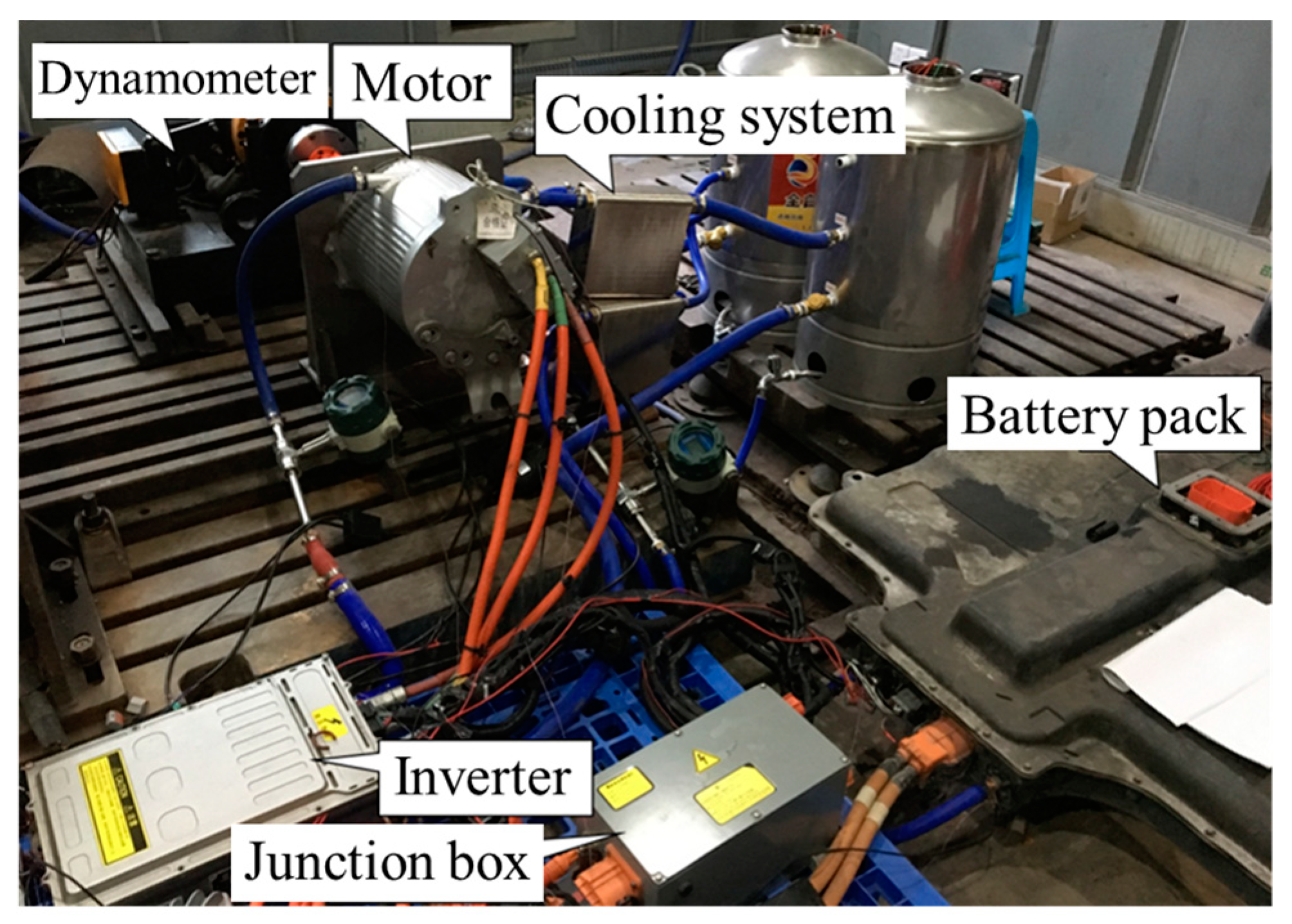

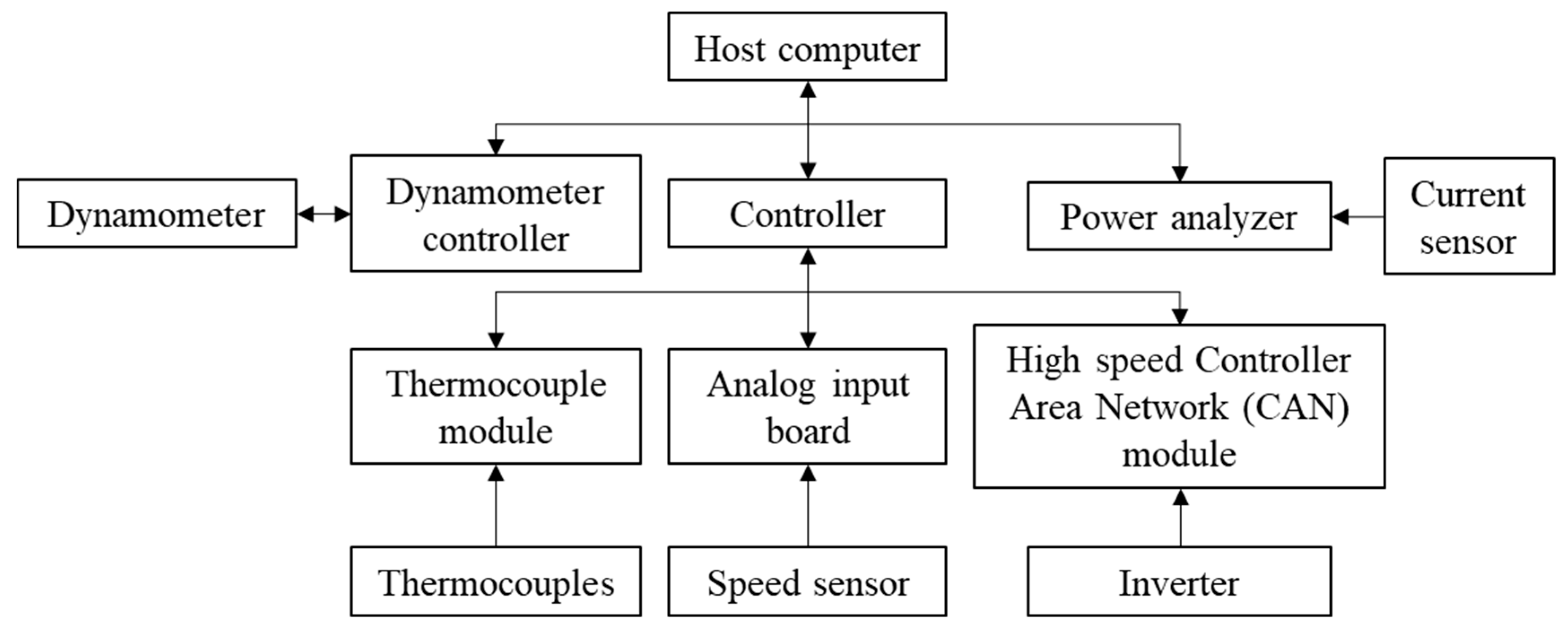

3. EV Powertrain Test and Model Verification

3.1. Test Bench Development

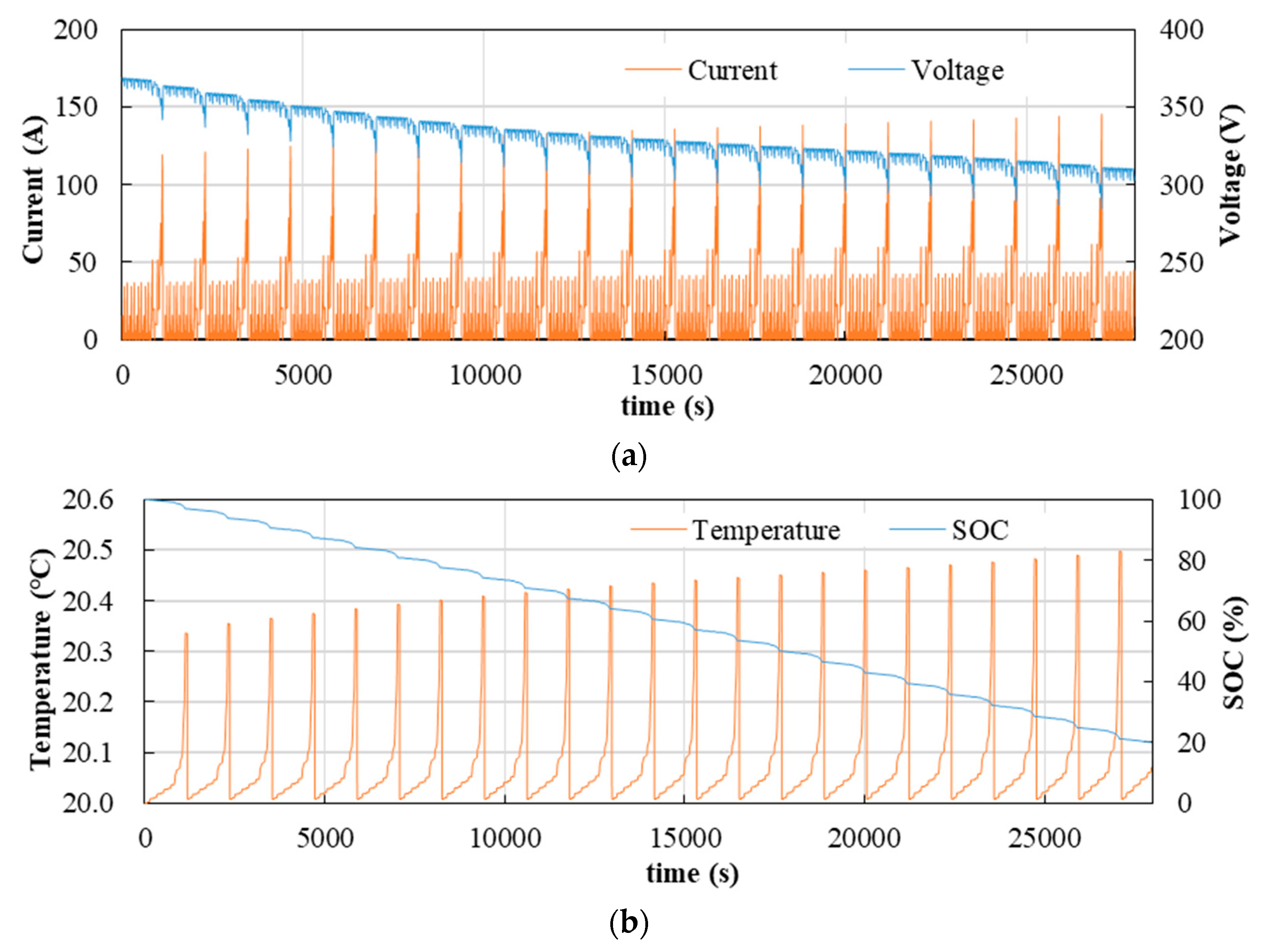

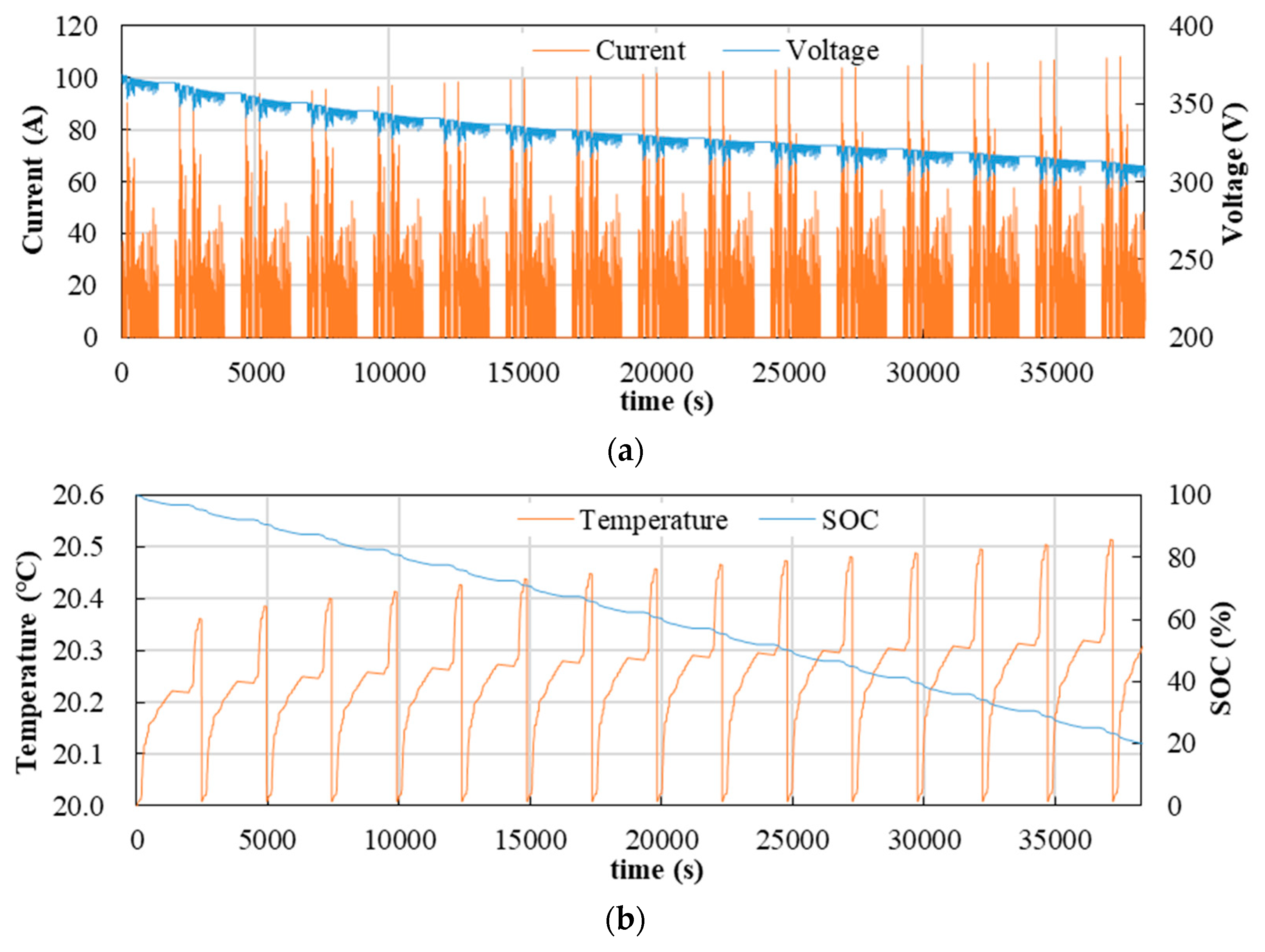

3.2. Experimental Method

3.3. Model Verification

3.4. Simulation Settings

4. Results and Discussion

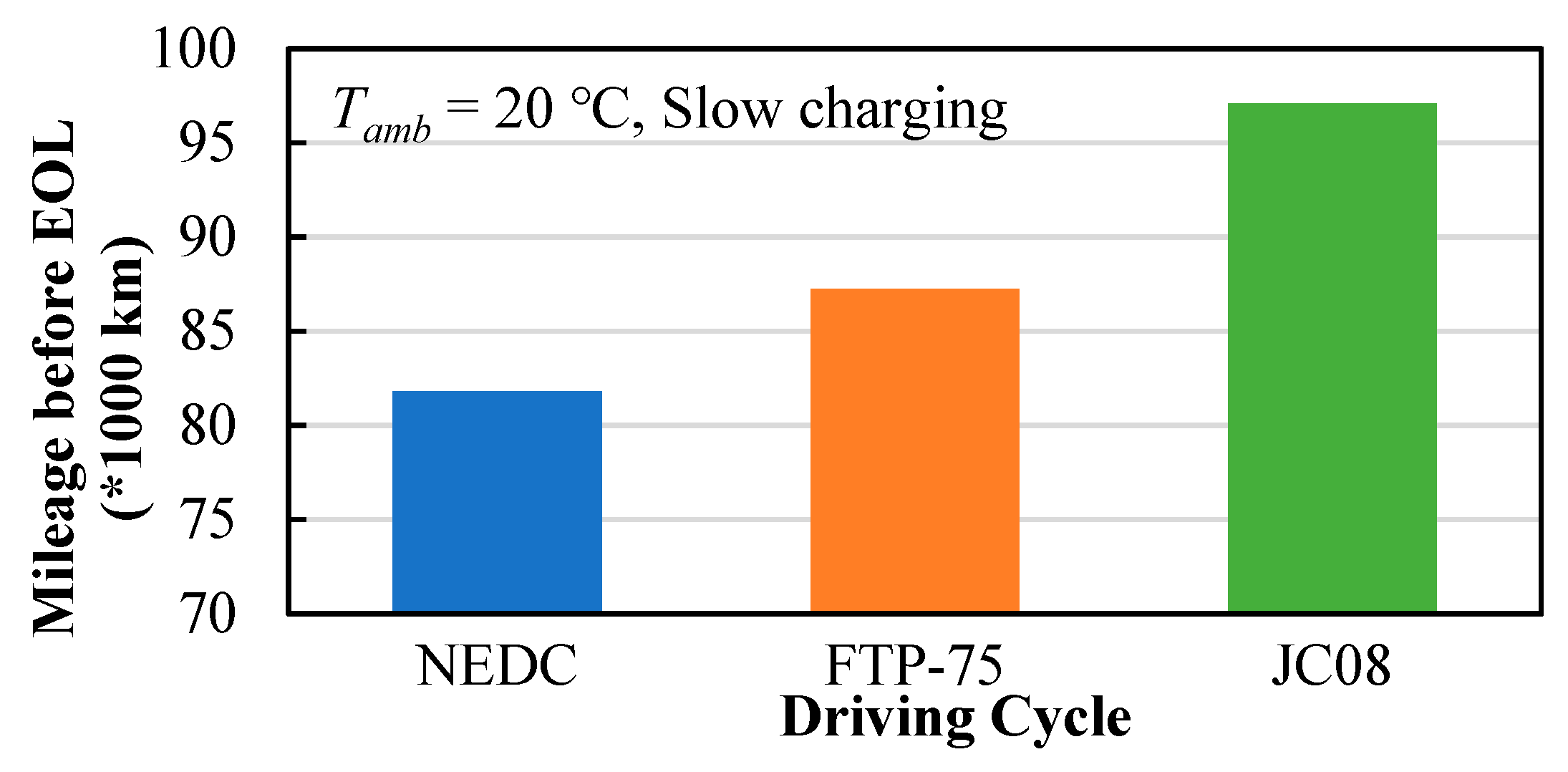

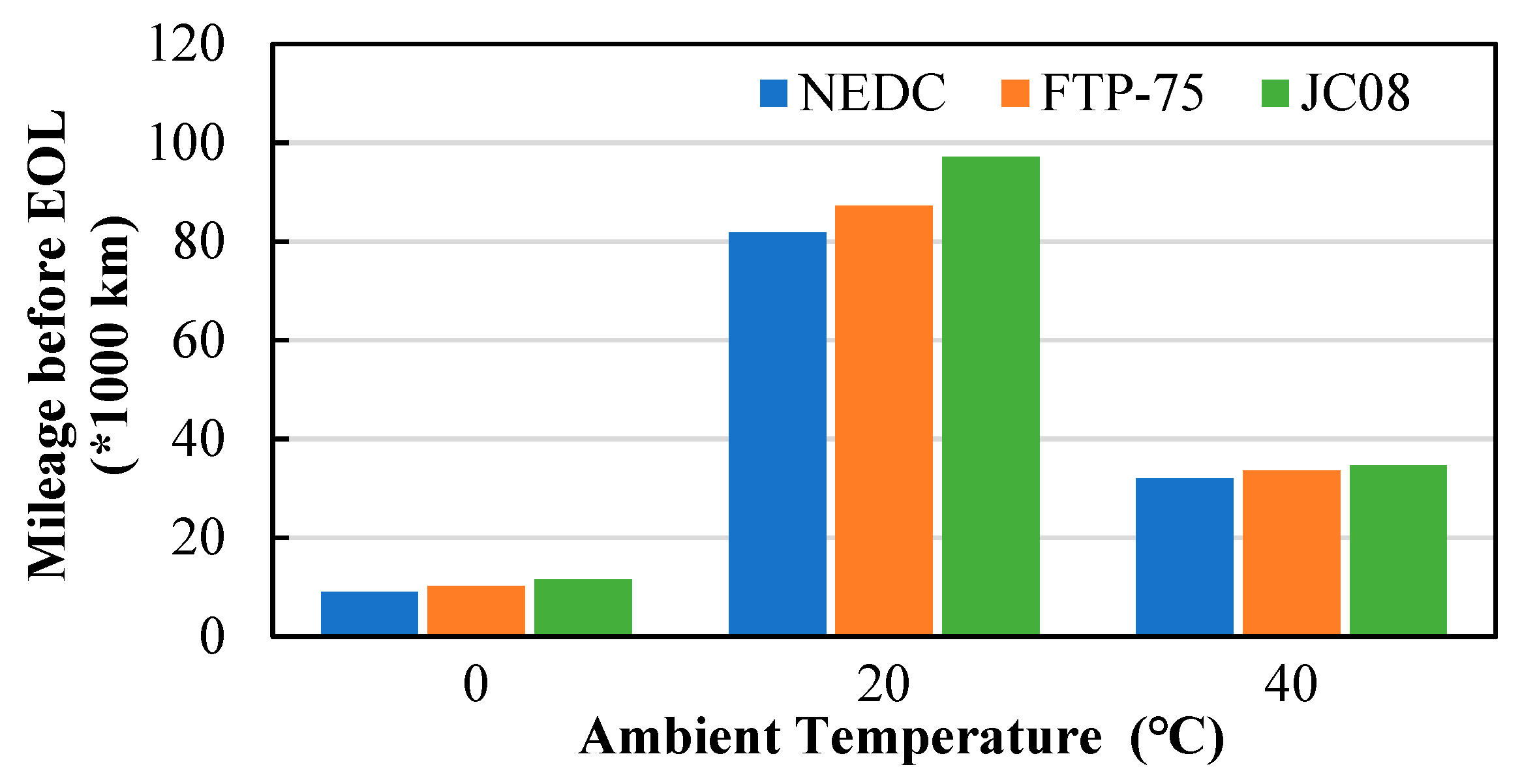

4.1. Effect of Driving Cycles on Battery Life Cycle

4.2. Effect of Ambient Temperature on Battery Life Cycle

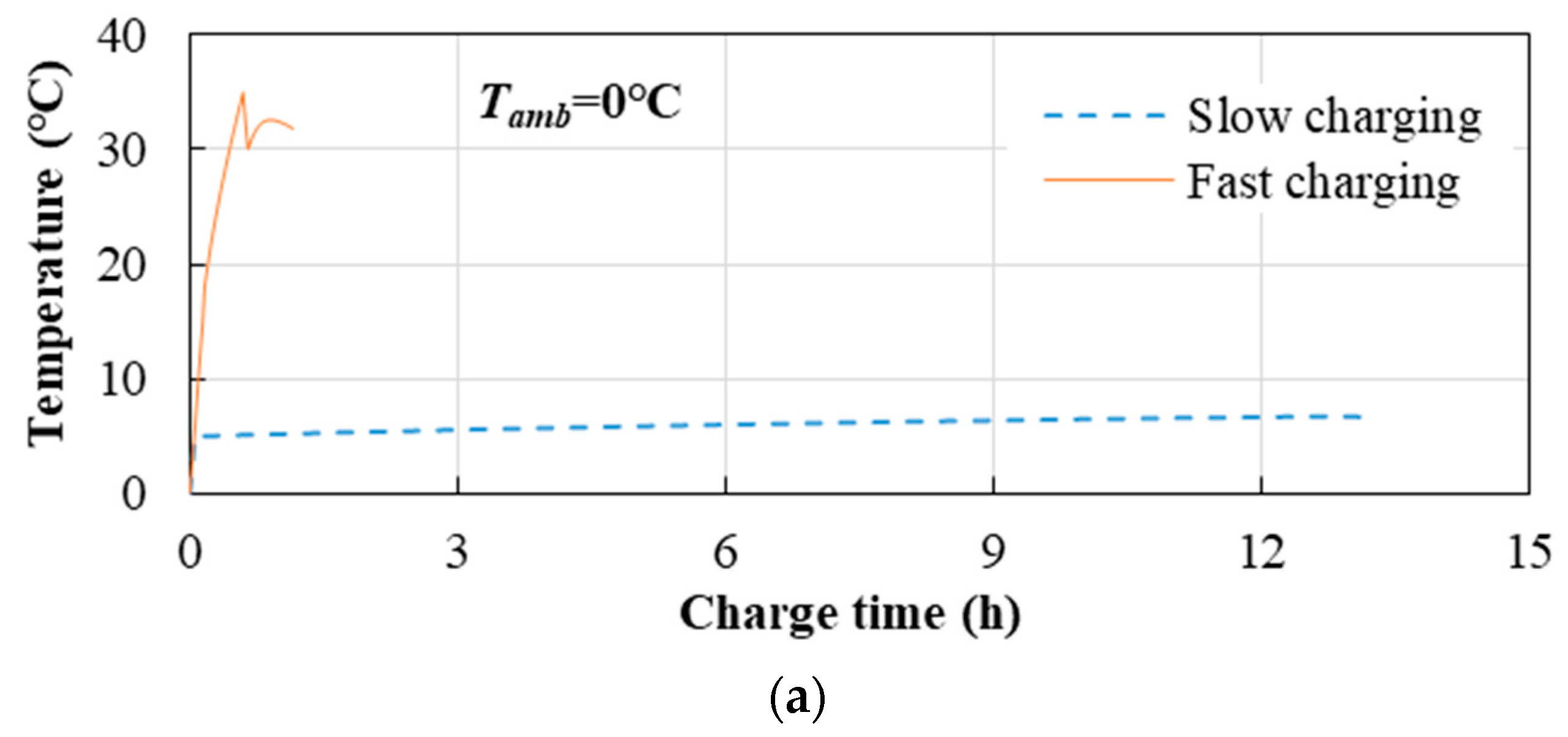

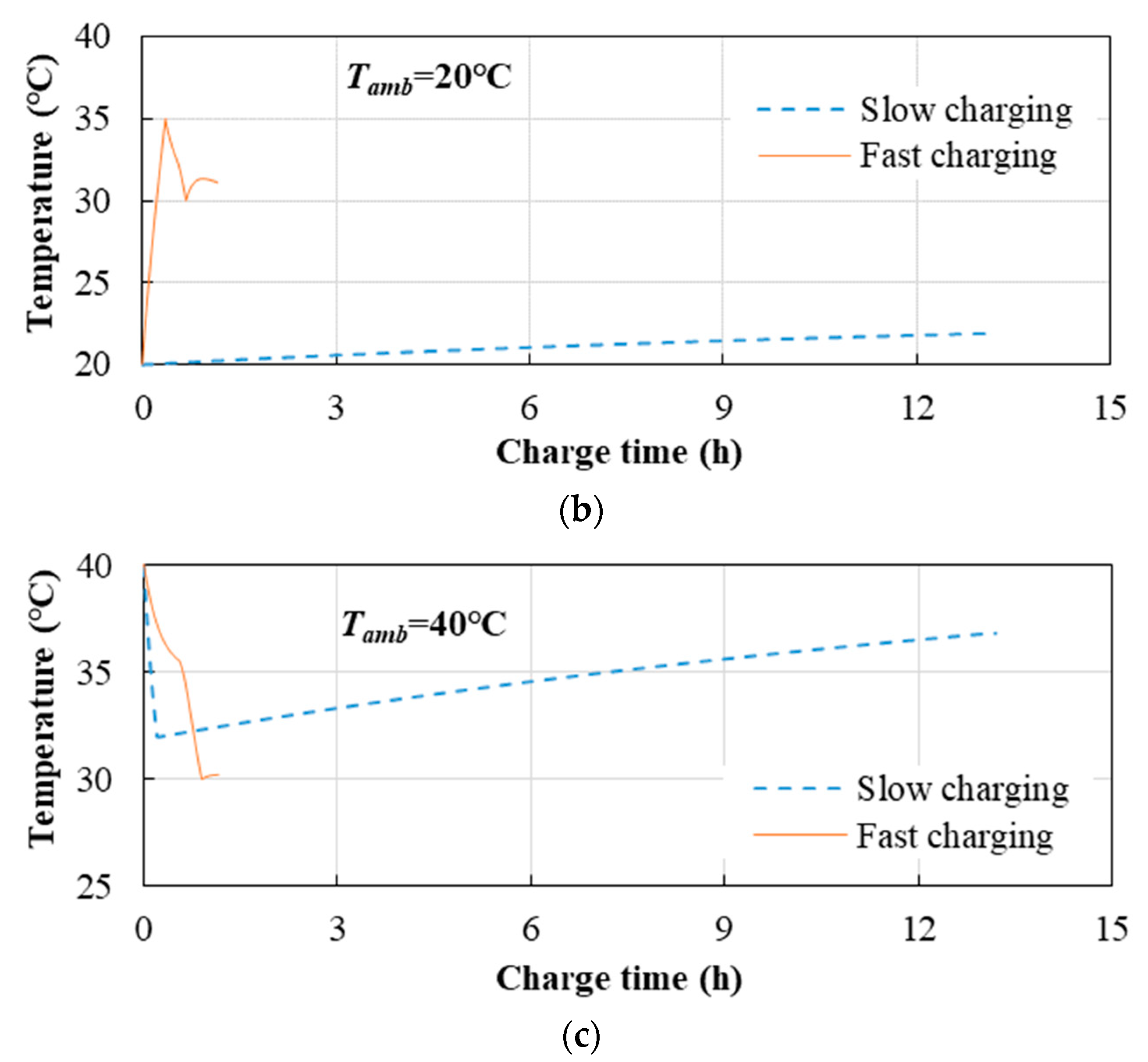

4.3. Effect of Charging Mode on Battery Life Cycle

4.4. Effect of Trip Distance on Battery Life Cycle

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Greek Symbols | |

| θ′ | Capacity fade of a single charge and discharge process |

| τ | Time |

| Ф | Mileage traveled by the vehicle before the EOL of the battery pack |

| Δ | Change |

| Symbols | |

| Ah | Ampere-hour |

| Ahthroughput | Amount of electricity output by the battery during the cycle |

| Crate | Battery charge and discharge rate |

| N | Total number of the charge and discharge cycles before EOL of battery |

| Qloss | Percentage of capacity loss |

| T | Battery temperature |

| Abbreviations | |

| BMS | Battery management system |

| BTMS | Battery thermal management system |

| CAN | Controller Area Network |

| CCCV | Constant current constant voltage |

| DOD | Depth of discharge |

| EV | Electric vehicle |

| EOL | End of life |

| FTP | Federal Test Procedure |

| HEV | Hybrid electric vehicle |

| JC08 | A Japanese chassis dynamometer emission test cycle |

| LIB | Lithium-ion battery |

| MCU | Motor control unit |

| NCM | Nickel cobalt manganese |

| NEDC | New European Driving Cycle |

| PID | Proportion Integration Differentiation |

| PTC | Positive Temperature Coefficient |

| SOC | State of charge |

| SOH | State of health |

| SEI | Solid electrolyte interface |

| VCU | Vehicle control unit |

References

- Cano, Z.P.; Banham, D.; Ye, S.; Hintennach, A.; Lu, J.; Fowler, M.; Chen, Z. Batteries and fuel cells for emerging electric vehicle markets. Nat. Energy 2018, 3, 279–289. [Google Scholar] [CrossRef]

- Birkl, C.R.; Roberts, M.R.; McTurk, E.; Bruce, P.G.; Howey, D.A. Degradation diagnostics for lithium ion cells. J. Power Sources 2017, 341, 373–386. [Google Scholar] [CrossRef]

- Barré, A.; Deguilhem, B.; Grolleau, S.; Gérard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef]

- Thackeray, M.M.; Wolverton, C.; Isaacs, E.D. Electrical energy storage for transportation-Approaching the limits of, and going beyond, lithium-ion batteries. Energy Environ. Sci. 2012, 5, 7854–7863. [Google Scholar] [CrossRef]

- Shi, W.; Hu, X.; Wang, J.; Jiang, J.; Zhang, Y.; Yip, T. Analysis of Thermal Aging Paths for Large-Format LiFePO4/Graphite Battery. Electrochim. Acta 2016, 196, 13–23. [Google Scholar] [CrossRef]

- Li, Z.; Huang, J.; Liaw, B.Y.; Metzler, V.; Zhang, J. A review of lithium deposition in lithium-ion and lithium metal secondary batteries. J. Power Sources 2014, 254, 168–182. [Google Scholar] [CrossRef]

- Zubi, G.; López, R.D.; Carvalho, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar] [CrossRef]

- Lv, W.; Wang, Z.; Cao, H.; Sun, Y.; Zhang, Y.; Sun, Z. A Critical Review and Analysis on the Recycling of Spent Lithium-Ion Batteries. Acs Sustain. Chem. Eng. 2018, 6, 1504–1521. [Google Scholar] [CrossRef]

- Yang, X.G.; Leng, Y.; Zhang, G.; Ge, S.; Wang, C.Y. Modeling of lithium plating induced aging of lithium-ion batteries: Transition from linear to nonlinear aging. J. Power Sources 2017, 360, 28–40. [Google Scholar] [CrossRef]

- Zhao, K.; Zhang, L.; Xia, R.; Dong, Y.; Xu, W.; Niu, C.; He, L.; Yan, M.; Qu, L.; Mai, L. SnO2 Quantum Dots@Graphene Oxide as a High-Rate and Long-Life Anode Material for Lithium-Ion Batteries. Small 2016, 12, 588–594. [Google Scholar] [CrossRef]

- Liu, W.; Li, X.; Xiong, D.; Hao, Y.; Li, J.; Kou, H.; Yan, B.; Li, D.; Lu, S.; Koo, A.; et al. Significantly improving cycling performance of cathodes in lithium ion batteries: The effect of Al2O3 and LiAlO2 coatings on LiNi0.6Co0.2Mn0.2O2. Nano Energy 2018, 44, 111–120. [Google Scholar] [CrossRef]

- Elia, G.A.; Ulissi, U.; Mueller, F.; Reiter, J.; Tsiouvaras, N.; Sun, Y.K.; Scrosati, B.; Passerini, S.; Hassoun, J. A Long-Life Lithium Ion Battery with Enhanced Electrode/Electrolyte Interface by Using an Ionic Liquid Solution. Chem. Eur. J. 2016, 22, 6808–6814. [Google Scholar] [CrossRef] [PubMed]

- Maheshwari, A.; Heck, M.; Santarelli, M. Cycle aging studies of lithium nickel manganese cobalt oxide-based batteries using electrochemical impedance spectroscopy. Electrochim. Acta 2018, 273, 335–348. [Google Scholar] [CrossRef]

- de Hoog, J.; Timmermans, J.M.; Stroe, D.I.; Swierczynski, M.; Jaguemont, J.; Goutam, S.; Omar, N.; Van Mierlo, J.; Van Den Bossche, P. Combined cycling and calendar capacity fade modeling of a Nickel-Manganese-Cobalt Oxide Cell with real-life profile validation. Appl. Energy 2017, 200, 47–61. [Google Scholar] [CrossRef]

- Liu, K.; Li, K.; Peng, Q.; Zhang, C. A brief review on key technologies in the battery management system of electric vehicles. Front. Mech. Eng. 2019, 14, 47–64. [Google Scholar] [CrossRef]

- Kim, J.; Oh, J.; Lee, H. Review on battery thermal management system for electric vehicles. Appl. Therm. Eng. 2019, 149, 192–212. [Google Scholar] [CrossRef]

- Neubauer, J.; Wood, E. The impact of range anxiety and home, workplace, and public charging infrastructure on simulated battery electric vehicle lifetime utility. J. Power Sources 2014, 257, 12–20. [Google Scholar] [CrossRef]

- Neubauer, J.; Wood, E. Thru-life impacts of driver aggression, climate, cabin thermal management, and battery thermal management on battery electric vehicle utility. J. Power Sources 2014, 259, 262–275. [Google Scholar] [CrossRef]

- Wang, D.; Coignard, J.; Zeng, T.; Zhang, C.; Saxena, S. Quantifying electric vehicle battery degradation from driving vs. vehicle-to-grid services. J. Power Sources 2016, 332, 193–203. [Google Scholar] [CrossRef]

- Dubarry, M.; Devie, A.; McKenzie, K. Durability and reliability of electric vehicle batteries under electric utility grid operations: Bidirectional charging impact analysis. J. Power Sources 2017, 358, 39–49. [Google Scholar] [CrossRef]

- Keil, P.; Jossen, A. Impact of Dynamic Driving Loads and Regenerative Braking on the Aging of Lithium-Ion Batteries in Electric Vehicles. J. Electrochem. Soc. 2017, 164, A3081–A3092. [Google Scholar] [CrossRef]

- Yuksel, T.; Litster, S.; Viswanathan, V.; Michalek, J.J. Plug-in hybrid electric vehicle LiFePO4 battery life implications of thermal management, driving conditions, and regional climate. J. Power Sources 2017, 338, 49–64. [Google Scholar] [CrossRef]

- Bernardi, D.; Pawlikowski, E.; Newman, J. A General Energy Balance for Battery Systems. J. Electrochem. Soc. 1985, 132, 5–12. [Google Scholar] [CrossRef]

- Reniers, J.M.; Mulder, G.; Howey, D.A. Review and Performance Comparison of Mechanical-Chemical Degradation Models for Lithium-Ion Batteries. J. Electrochem. Soc. 2019, 166, A3189–A3200. [Google Scholar] [CrossRef]

- Wang, J.; Purewal, J.; Liu, P.; Garner, J.H.; Soukazian, S.; Sherman, E.; Sorenson, A.; Vu, L.; Tataria, H.; Verbrugge, M.W. Degradation of lithium ion batteries employing graphite negatives and nickel-cobalt-manganese oxide + spinel manganese oxide positives: Part 1, aging mechanisms and life estimation. J. Power Sources 2014, 269, 937–948. [Google Scholar] [CrossRef]

- Ma, Z.; Wang, Z.; Xiong, R.; Jiang, J. A mechanism identification model based state-of-health diagnosis of lithium-ion batteries for energy storage applications. J. Clean. Prod. 2018, 193, 379–390. [Google Scholar] [CrossRef]

- Safari, M.; Morcrette, M.; Teyssot, A.; Delacourt, C. Life-Prediction Methods for Lithium-Ion Batteries Derived from a Fatigue Approach, I. Introduction: Capacity-Loss Prediction Based on Damage Accumulation. J. Electrochem. Soc. 2010, 157, A713–A720. [Google Scholar] [CrossRef]

- Safari, M.; Morcrette, M.; Teyssot, A.; Delacourt, C. Life Prediction Methods for Lithium-Ion Batteries Derived from a Fatigue Approach II. Capacity-Loss Prediction of Batteries Subjected to Complex Current Profiles. J. Electrochem. Soc. 2010, 157, A892–A898. [Google Scholar] [CrossRef]

- Giakoumis, E.G. Driving and Engine Cycles; Springer Nature: Gewerbestrasse, Switzerland, 2016; pp. 65–166. [Google Scholar]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Total weight | 1620 kg | Rolling radius | 0.324 m |

| Frontal area | 2.62 m2 | Transmission efficiency | 0.9 |

| Rolling resistance coefficient | 0.0075 | Transmission ratio | 7.79 |

| Drag coefficient | 0.363 | - | - |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Nominal voltage of the cell | 3.65 V | Configuration of the pack | 3P88S |

| Nominal capacity of the cell | 44 Ah | Filter capacitance of the pack | 1467 F |

| Open circuit voltage of the cell | 3.65 + 1.44 × (soc/100) − 2.16 × (soc/100)2 + 1.6 × (soc/100)3 V | ||

| Internal resistance of the cell [13] | exp (2910/T) × 1.36 × (288/3) × 10−7 Ω | ||

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Coil connection method | Star | Stator inductance in the d coordinate | 0.0018 H |

| Exciter type | Permanent magnet | Stator inductance in the q coordinate | 0.0022 H |

| Pole number | 3 | Rated voltage | 189 V |

| Reference temperature of stator coil | 30 °C | Rated power | 53 kW |

| Stator resistance at reference temperature | 0.215 Ω | Peak power | 95 kW |

| Modified coefficient of stator resistance | 0.45 | Rated torque | 127 N·m |

| Magnetic flux at reference temperature | 0.35 Wb | Peak torque | 260 N·m |

| Modified coefficient of Magnetic flux | 0.1 | Rated speed | 4000 r/min |

| Inductance of stator winding | 0.275 H | Maximum speed | 9000 r/min |

| Parameter | Setting |

|---|---|

| Number of phases | 3 |

| Nominal capacity | 100 kVA |

| Maximum capacity | 150 kVA |

| Rated input voltage | 345 V |

| Voltage operating range | 280–420 V |

| Mode | Slow Charging | Fast Charging | Discharging |

|---|---|---|---|

| Heating | T ≤ 0 °C, turn on T ≥ 5 °C, turn off | T ≤ 16 °C, turn on T ≥ 18 °C, turn off | T ≤ −15 °C, turn on T ≥ −12 °C, turn off |

| Cooling | T ≥ 38 °C, turn on T ≤ 32 °C, turn off | T ≥ 38 °C, turn on T ≤ 32 °C, turn off | T ≥ 38 °C, turn on T ≤ 32 °C, turn off |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| a | 8.6124 × 10−6, | d | −6.7 × 10−3, |

| b | −5.1252 × 10−3, | e | 2.35, |

| c | 7.6292, | - | - |

| Instrument/Sensor | Type | Measured Parameters | Uncertainty |

|---|---|---|---|

| Dynamometer | WE31 (H) | Motor torque | ±0.1% of full scale |

| Motor speed | ±1 r/min | ||

| Power analyzer | ZLG PA5000 | Battery voltage | ±0.1% of reading |

| Current sensor | CTA1000 | Battery current | ±0.03% of reading |

| Thermocouple | Type T | Battery temperature | ±0.36 °C |

| Flowmeter | LWGY-10 | Coolant flow rate | ±0.5% of reading |

| Torque of Motor N·m (The Speed Is 4000 r/min) | ||||

|---|---|---|---|---|

| 50 | 70 | 90 | 110 | 127 |

| Affecting Factors | Range/Level |

|---|---|

| Driving cycle | New European Driving Cycle (NEDC), Federal Test Procedure (FTP-75), JC08 [29] |

| Ambient temperature/°C | 0, 20, 40 |

| charging rate | fast charging, slow charging |

| Trip distance | short trip (a single driving cycle followed by a long rest period), long trip (drive under repeated driving cycles) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Chen, F.; Tong, Y.; Wang, Z.; Yu, X.; Huang, R. Impacts of Driving Conditions on EV Battery Pack Life Cycle. World Electr. Veh. J. 2020, 11, 17. https://doi.org/10.3390/wevj11010017

Liu H, Chen F, Tong Y, Wang Z, Yu X, Huang R. Impacts of Driving Conditions on EV Battery Pack Life Cycle. World Electric Vehicle Journal. 2020; 11(1):17. https://doi.org/10.3390/wevj11010017

Chicago/Turabian StyleLiu, Huijun, Fenfang Chen, Yuxiang Tong, Zihang Wang, Xiaoli Yu, and Rui Huang. 2020. "Impacts of Driving Conditions on EV Battery Pack Life Cycle" World Electric Vehicle Journal 11, no. 1: 17. https://doi.org/10.3390/wevj11010017

APA StyleLiu, H., Chen, F., Tong, Y., Wang, Z., Yu, X., & Huang, R. (2020). Impacts of Driving Conditions on EV Battery Pack Life Cycle. World Electric Vehicle Journal, 11(1), 17. https://doi.org/10.3390/wevj11010017