IoT-Based LPG Level Sensor for Domestic Stationary Tanks with Data Sharing to a Filling Plant to Optimize Distribution Routes

Abstract

:1. Introduction

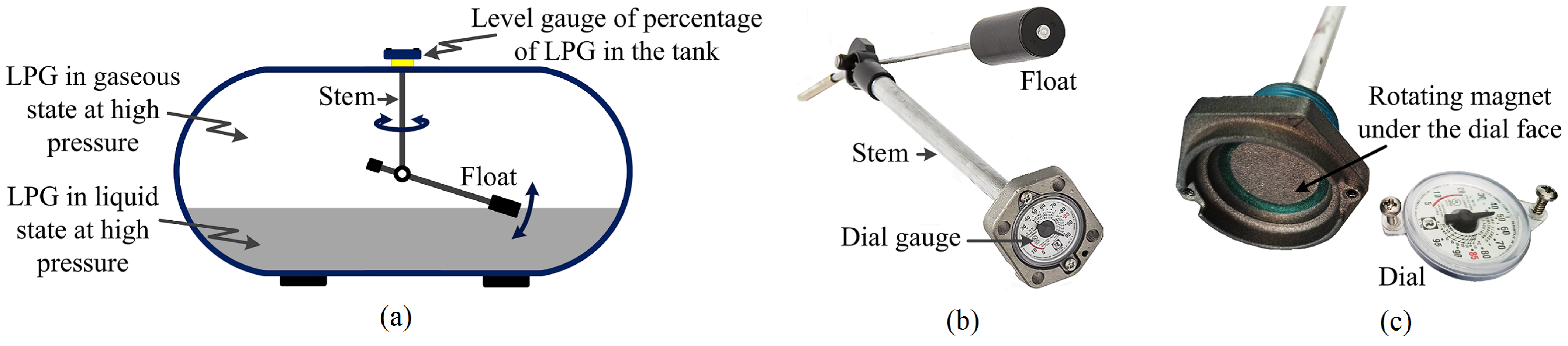

1.1. Background

1.2. A Review of Existing Wireless LPG Level Sensors for Domestic Stationary Tanks

- Levelgas® [8]: This device measures the level of LPG in the stationary tank and displays the data through a mobile application (app). It sends a notification when it detects a low gas level and has the ability to display the battery charge level. It uses Sigfox connectivity, so it only has coverage in major cities. After a trial period, a subscription to the app must be paid for. The sensor displays the data only to the tank user and cannot be shared with the gas refilling plant. It is not specified (N/S) if it uses any cybersecurity strategy. The device performs one measurement per day and uses three AAA-size alkaline batteries (Zn-MnO2) with a lifespan of up to one year. Manufacturer: Edison Effect, S.A. of C.V., San Luis Potosí, Mexico. Price: 77.50 USD.

- El gaaas® [9]: Wireless gas meter for stationary tank. It uses Sigfox wireless connection, so it only has coverage in major cities. It uses the same app as the Levelgas device, so after a trial period, you have to pay a monthly fee to get the app services. The device displays the data only to the tank owner and cannot be shared with the gas refilling plant. It is not mentioned if it uses any cybersecurity strategy. Compatible with stationary tanks from 100 to 3000 L. The sensor performs one measurement per day and uses three AAA-size alkaline batteries (Zn-MnO2) with a life span of up to one year. Manufacturer: Logística Aplicada Tugas, S.A. de C.V., Mexico City, México. Price: 78.00 USD.

- iSentinel® [10]: With this wireless device, you can measure the level of LPG in your stationary tank from your smartphone. In addition, you can also know how many liters of gas you have refilled. It can look more than one tank in a single app. It uses a Wi-Fi connection and the app is free. The device displays the data only to the tank user and cannot be shared with the gas refilling plant. It is not specified (N/S) if it uses any cybersecurity strategy. The sensor takes one measurement per day and is powered by non-rechargeable AA-size lithium/iron disulfide (Li/FeS2) batteries (not included), with an estimated lifespan of two years. Manufacturer: Cosas Web, S.A. de C.V., Jalisco, Mexico. Price: 80.30 USD.

- Redgas Touch® [11]: It is a sensor to wirelessly measure the gas level in stationary tanks autonomously through Wi-Fi communication. It informs you directly on your phone how much gas you have and warns you when you are going to run out of gas. It sends alerts if it detects a low gas level in the tank. The device displays the data only to the tank owner and cannot be shared with the gas refilling plant. It is not mentioned if it uses any cybersecurity strategy. The sensor makes one measurement per day and uses a rechargeable Li-ion (Rechg.-Li-ion) battery (size not specified) and a small photovoltaic (PV) cell. However, according to the product’s reviews and ratings, it stops working after five months because the small PV cell is not able to recharge the battery. Manufacturer: Redtapp S. de R.L. de C.V., San Luis Potosí, Mexico. Price: 85.00 USD.

- SensiGas® [12]: This is a device designed with a sensor that sends the gas level of your tank remotely to an app. It works with 4G connectivity, so coverage must be checked to be able to use the device. The app is free. The device displays the data only to the tank owner and cannot be shared with the gas refilling plant. It is not specified (N/S) if it uses any cybersecurity strategy. The Rechg.-Li-ion battery (size not specified) can have a lifespan of up to five years, transmitting once a day in excellent signal conditions. However, if the tank is located in an area with poor signal or if it has a lot of activity and there are more transmissions due to low level alerts, the battery life will decrease significantly. Manufacturer: Mobile IoT Latam, S.A.P.I. DE C.V., Jalisco, Mexico. Price: 98.50 USD.

- Gaszen® (Discontinued since 2020 [13]): This used Wi-Fi connectivity and an app to indicating the LPG level in the tank. The device showed the data only to the tank user, which could not be shared with the gas refilling plant. It did not use any cybersecurity strategy. The business model consisted of charging a commission to the gas distribution company every time users requested a refill service through their app, and there was the option of rating the service of the filling plant. Manufacturer: Gaszen Tech S.A.P.I., Guanajuato, México. Price: 100.35 USD.

1.3. Contributions and Organization of the Article

- IoT-based sensor with the ability to display data of percentage of LPG level in a stationary tank to the user and to the refilling plant of a gas company;

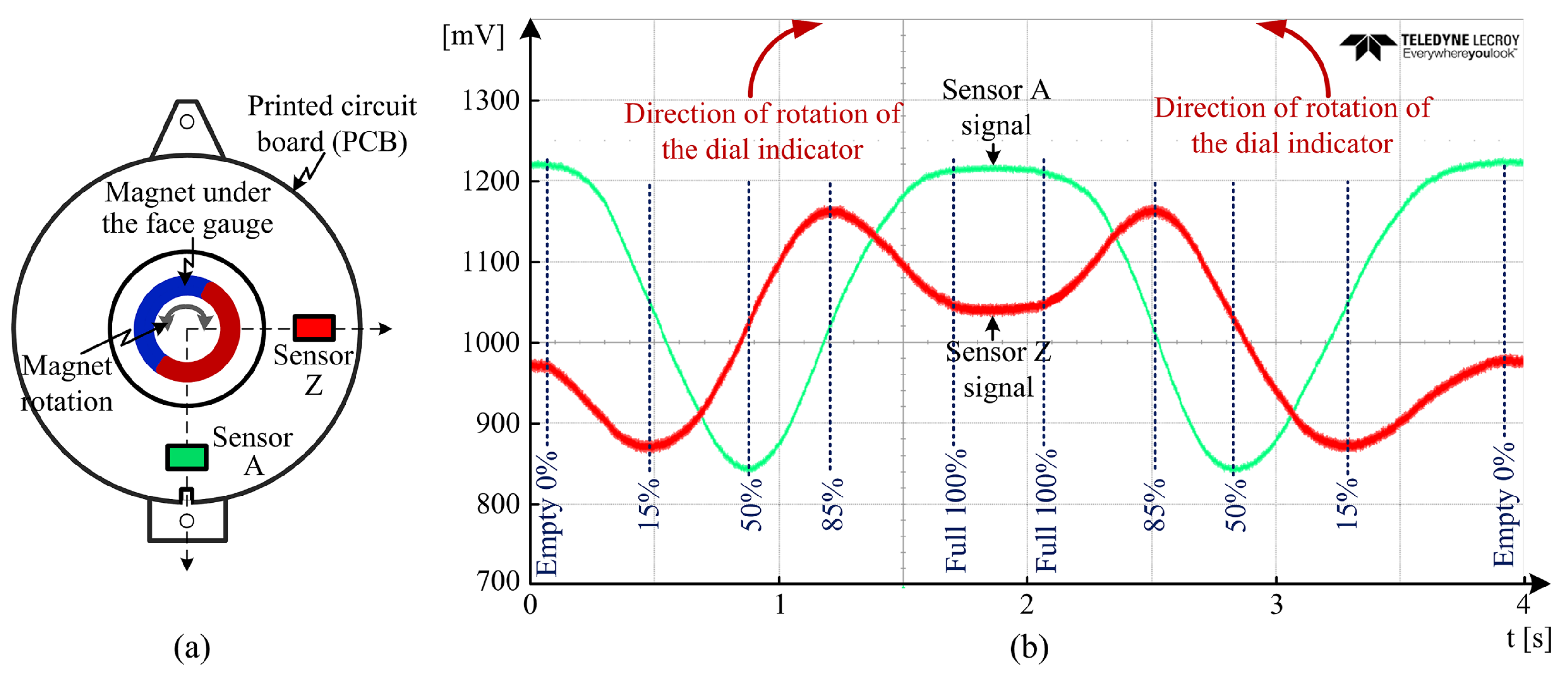

- The investigated solution estimates the percentage of the LPG level in the tank in relation to the position of the magnetic field of the magnet located under the dial;

- The sensor is more precise than the existing ones in the market;

- The device is much cheaper than the ones currently on the market;

- A mobile application (app) is implemented for the developed electronic device;

- The data are shared securely, unlike the devices in Table 1, where no security strategy is specified;

- A heuristic strategy is used to sufficiently optimize the distribution routes that the distribution tanker trucks should follow;

- Using this hardware solution, the company can perform business intelligence (BI).

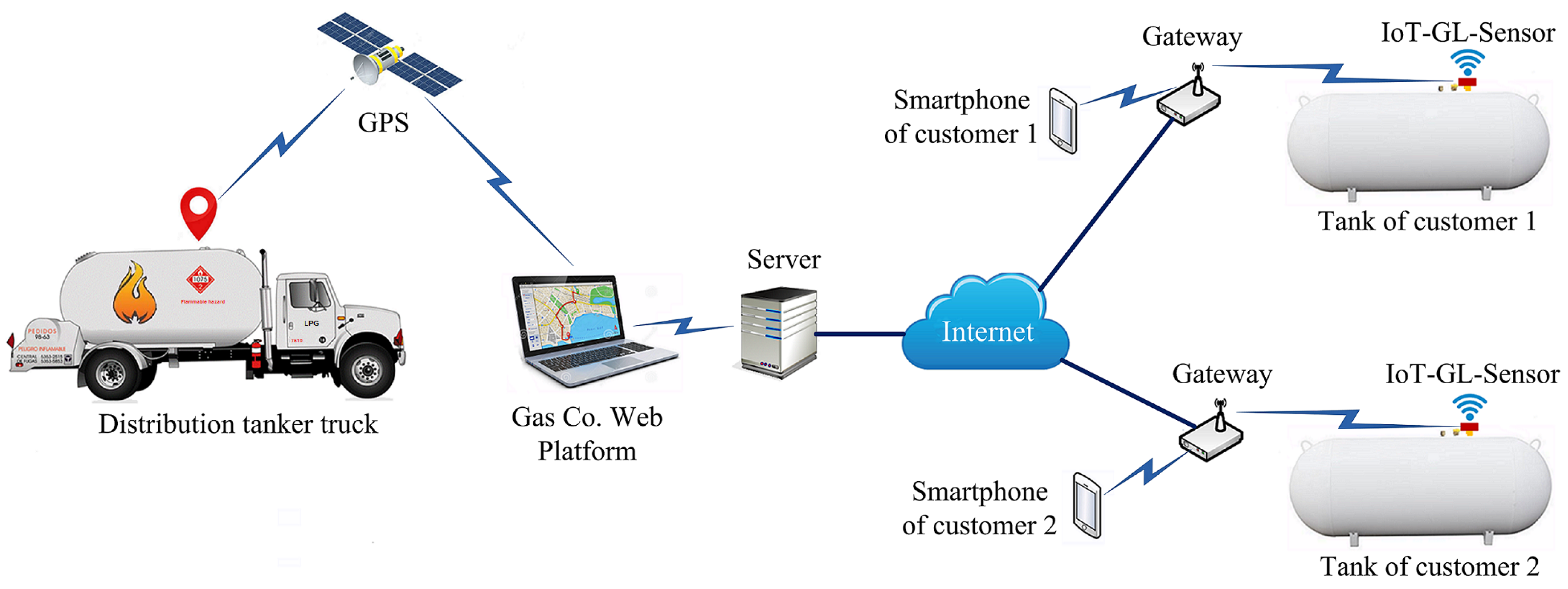

2. Business Concept with the Developed IoT-Based Gas Level Sensor

2.1. Conceptualization

- Based on the experience acquired by the gas company with residential users, it is known that 85% of them have stationary LPG tanks in a horizontal position with a capacity between 100 and 500 L, another 10% of residential customers have stationary tanks with a capacity between 1000 and 2200 L, and the remaining 5% of users have tanks with a larger capacity.

- Domestic stationary tanks are filled to a maximum of 80% for safety reasons.

- The period between recharges depends on the level of use and the size of the stationary tank. However, according to the company’s experience, the average minimum time is around 7 weeks.

- The IoT-GL-Sensor will be provided free of charge to customers so that they do not object to its use.

- It is desirable that the device uses Wi-Fi communication, as 100% of customers use Internet connectivity.

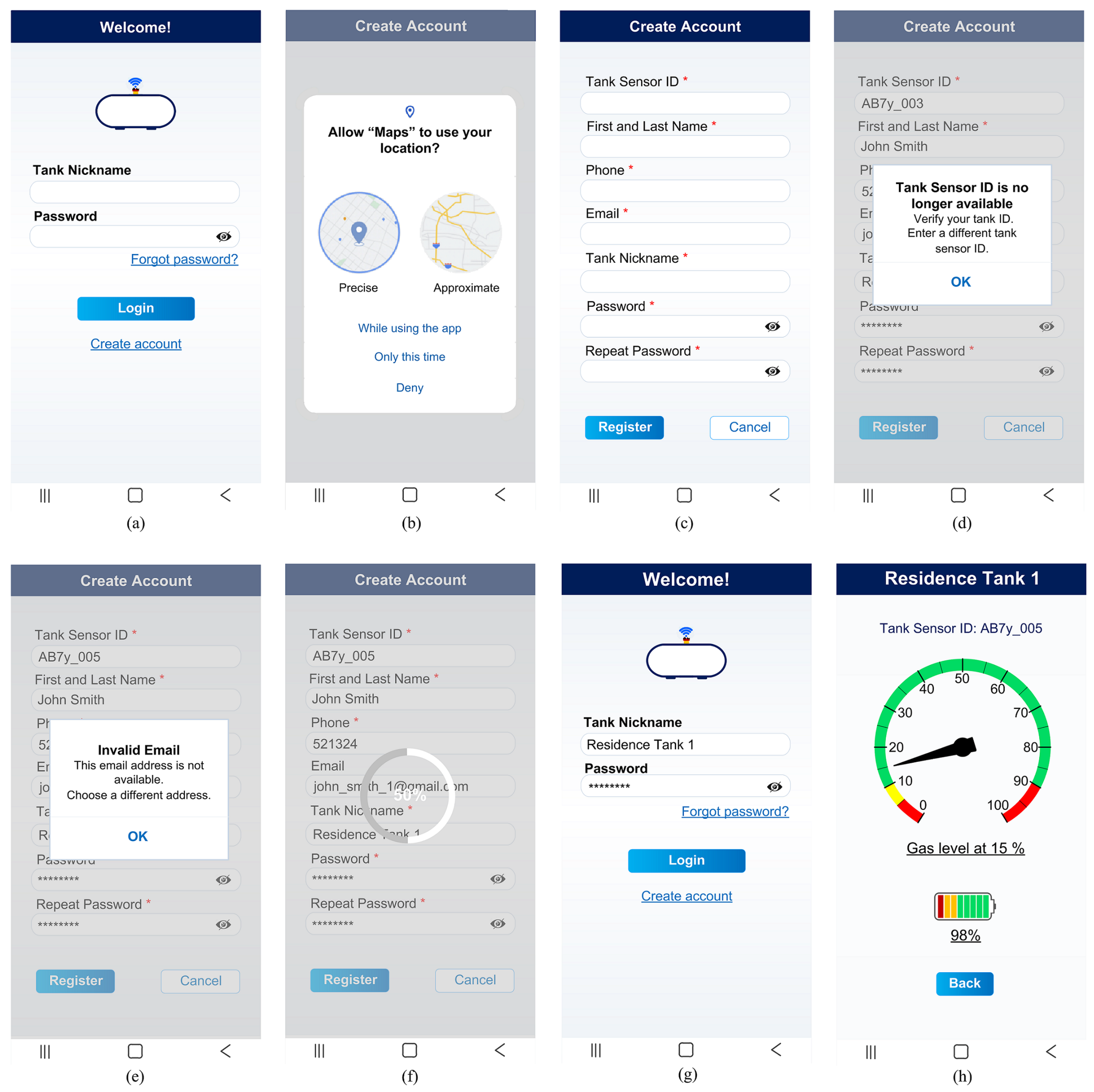

- The IoT-GL-Sensor displays both the user and the gas company the percentage of the LPG level in the tank, through an app and a web platform, respectively.

- When installing and configuring the sensor for the first time, the user will be prompted to provide the exact location of the stationary tank using Google Maps on a mobile device. The tank location is stored in the server warehouse. In this way, the gas company can offer the filling service and reduce unfair competition, such as the illegal distribution of stolen gas [4,5,6].

2.2. Requirements

- Low price;

- Wi-Fi communication;

- The sensor must perform two measurements per day (to improve data quality);

- Powered by non-rechargeable AA-size lithium/iron disulfide (Li/FeS2) batteries;

- Operating temperature range from −10 °C to 50 °C;

- Possibility of use and installation in stationary tanks from 100 to 3400 L;

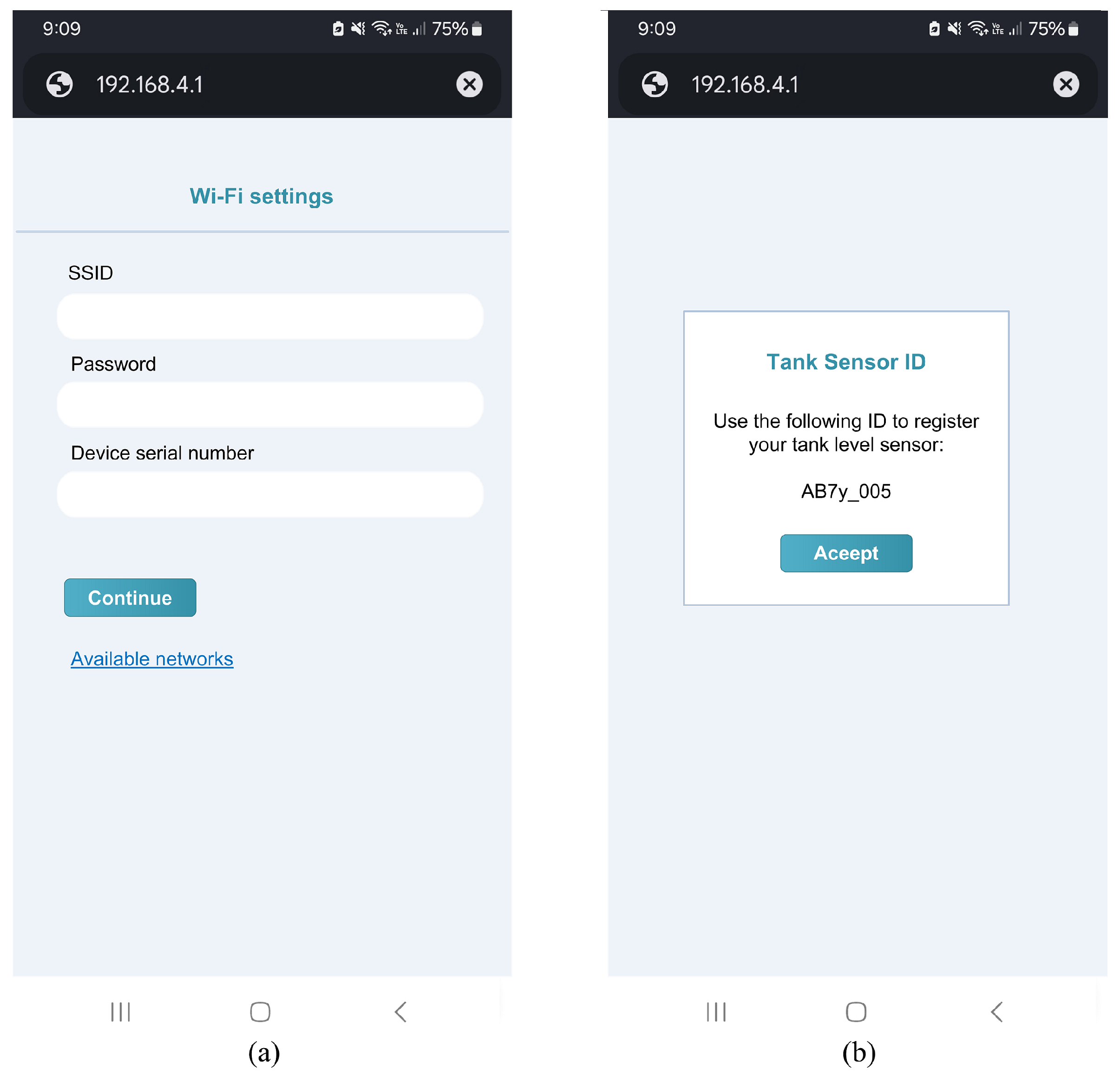

- Easy installation and configuration;

- IP65 housing;

- The location and ID of each IoT-based sensor must be known;

- It must be developed taking into account Mexican standards;

- The international standards for electronic design must be considered.

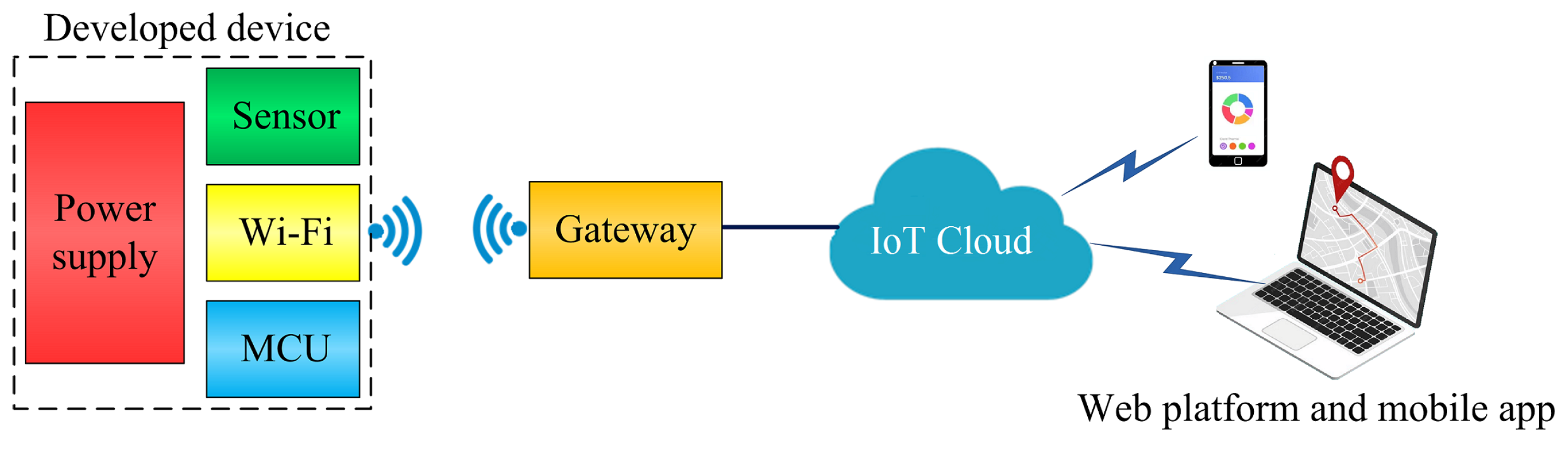

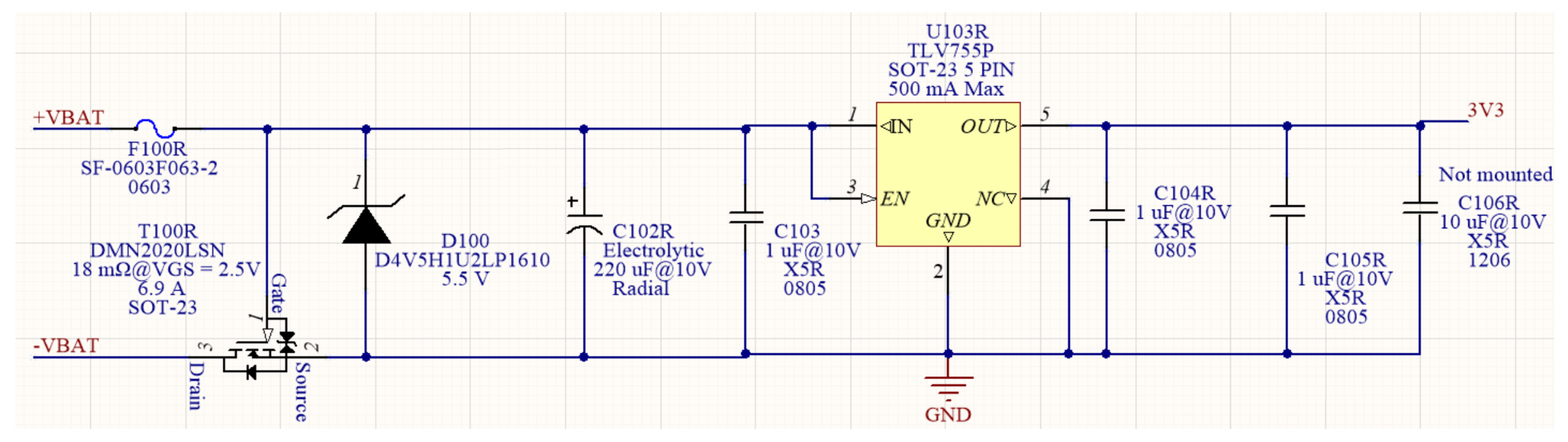

- Power supply: provides the power needed for the operation of the electronic device;

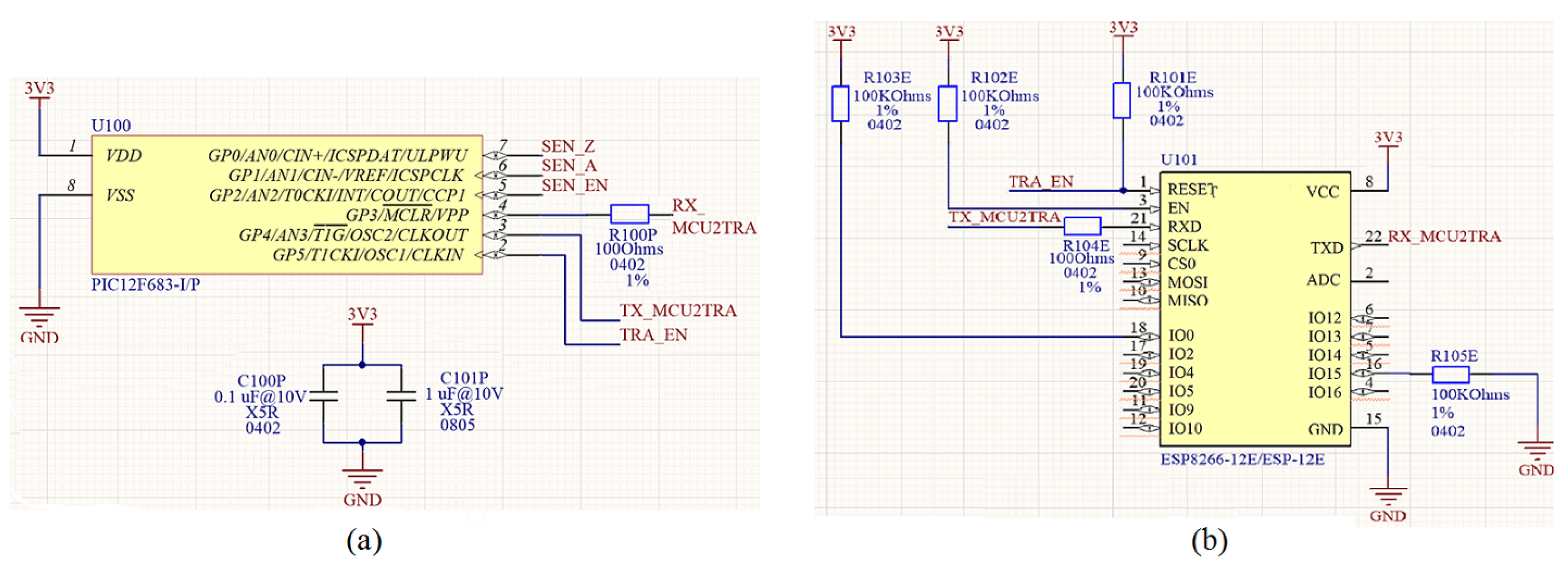

- Sensor: measures the position of the magnetic field of the dial gauge magnet, and the analog signals are shared with the MCU;

- MCU: converts the analog signal to a digital signal and processes it to determine the percentage of LPG level in the tank. Afterward, it uploads the data to the Wi-Fi;

- Wi-Fi: used to send data to the gateway, which in turn sends it to a server over the Internet.

3. Hardware Development

- IPC-2221A [17]: This defines the requirements for PCB design and establishes design principles and recommendations, including component mounting (Through-Hole Technology (THT) or Surface Mount Technology (SMT)), material selection, and thermal management, among others.

- IPC-2231 [18]: This provides guidelines for establishing a best practice methodology for use in developing a formal DFX (design for manufacturing, assembly, reliability, etc.) process for layout of printed board assemblies that utilize THT and SMT devices.

- IPC-A 610 [19]: Pictorial interpretive document that indicates various characteristics of the board and/or assembly as appropriate relating to desirable conditions that exceed the minimum acceptable characteristics indicated by the final item performance standard.

- IPC-D-325A [20]: This establishes requirements and other considerations for the documentation of printed boards and printed board assemblies.

- NOM-259-SE-2022 [21]: Systems for measuring and dispensing LP gas. Requirements and specifications.

- NMX-I-1362-NYCE-2021 [22]: Simple encryption procedure for Internet of Things (IoT) environments.

- NMX-I-4903-NYCE-2021 [23]: Key performance indicators related to smart and sustainable cities, to assess the achievement of sustainable development goals.

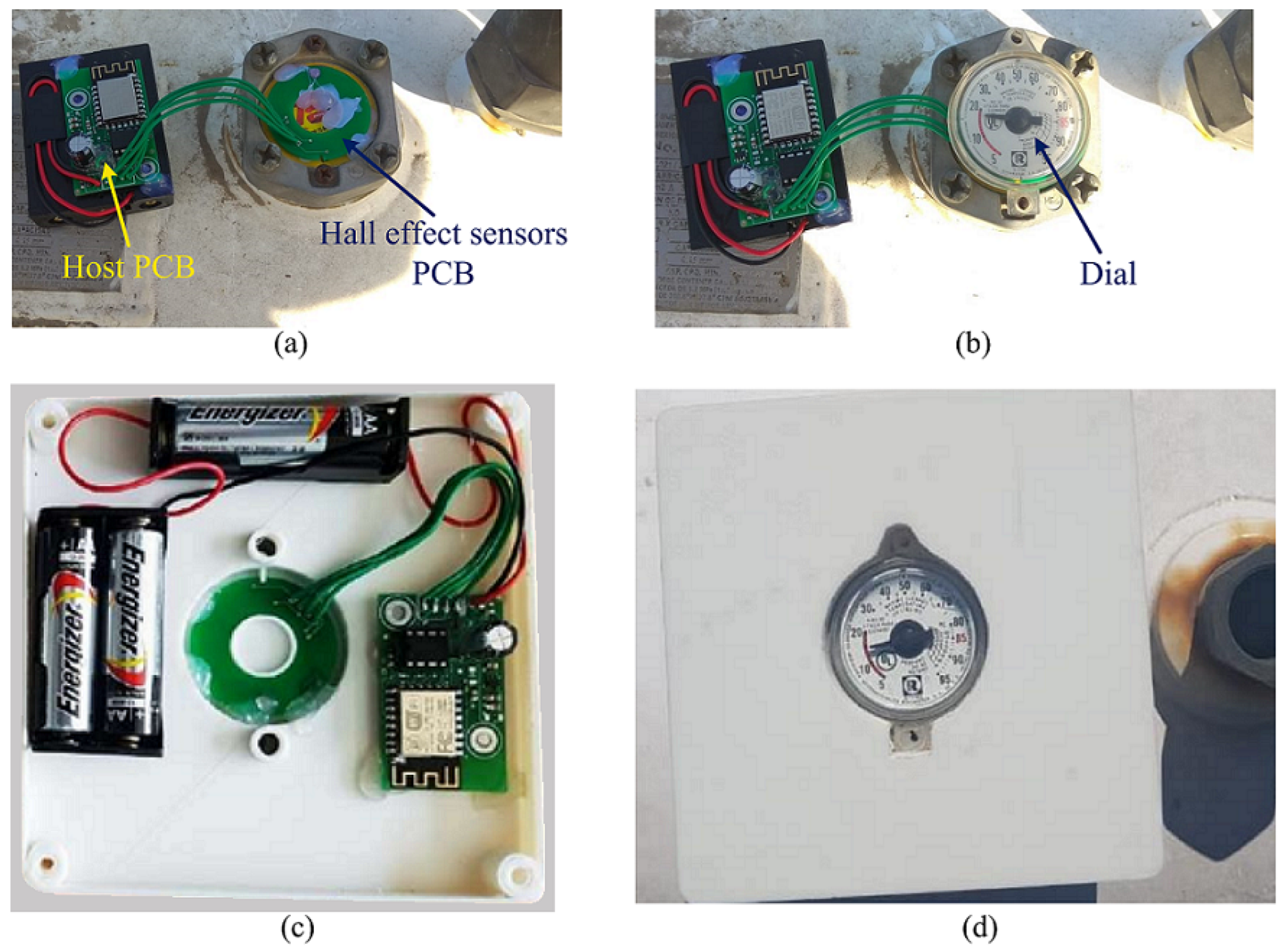

3.1. Sensors

3.1.1. Sensor Selection

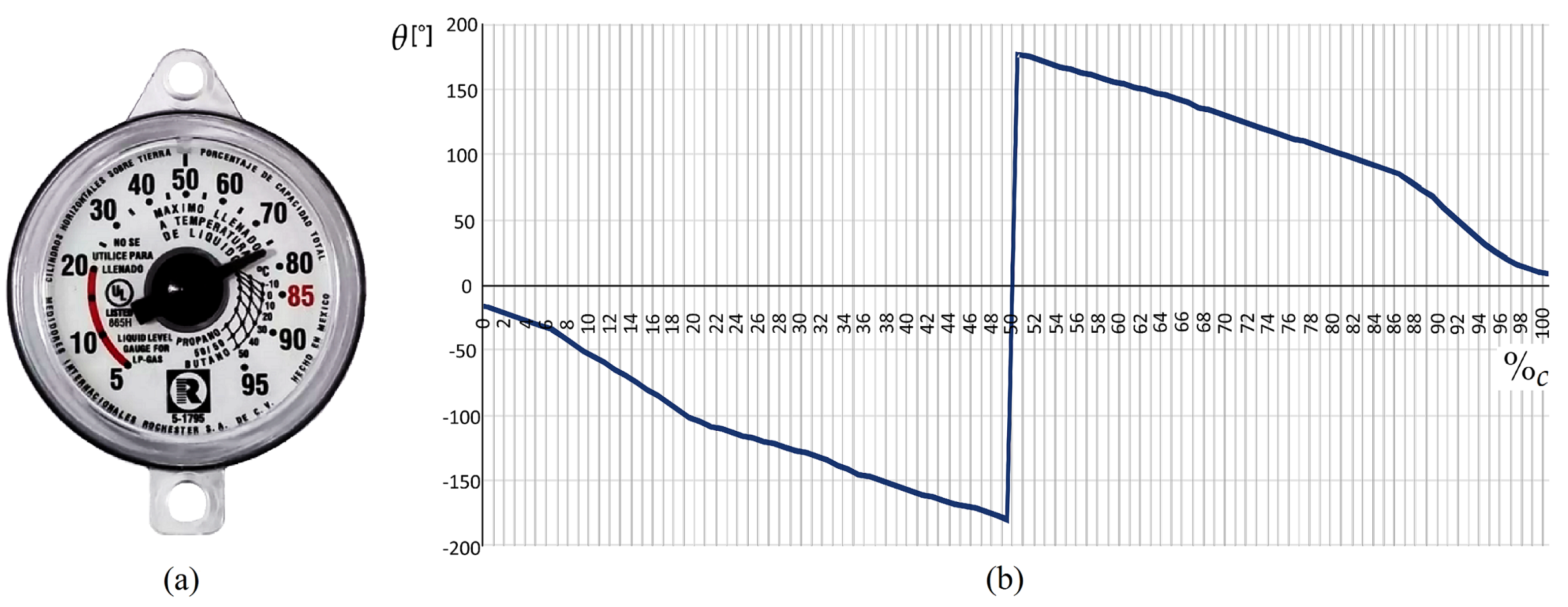

3.1.2. Obtaining the Position of the Magnetic Field

3.1.3. Calibration of the Position vs. Percentage Relationship

- For each calibration percentage, the magnet is rotated to the desired percentage and the measured voltages and the calculated are recorded. Several measurements are made for the same percentage (shown on the dial gauge). Then, a type A uncertainty assessment is performed [27]. Therefore, for each calibration percentage, an angle is recorded, which is the mean value of the different estimates.

- During normal operation, has a value between two of the angles assigned to the calibration percentages recorded previously, designated as and .

- Then, the calculated percentage () is determined from the calculated and by linear interpolation between the angles assigned to the previously recorded percentages, as:

3.2. MCU

3.3. Wi-Fi

3.4. Power Supply

3.4.1. Battery Lifetime Estimation

3.4.2. Voltage Regulator

3.5. PCB Design

4. Software

4.1. Communication Protocols

- The IoT-GL-Sensor generates the data, i.e., the percentage of the LPG level in the tank and the remaining percentage of the battery charge, and sends them to the Internet gateway using MQTT protocol [41]. MQTT is a lightweight, publish–subscribe-based messaging protocol. This means that clients, such as individual devices or gateways, publish their data to a centralized MQTT broker. In addition, the ESP maintains stable connections over MQTT that it offers smooth performance even in environments with unreliable and fluctuating network coverage and MQTT’s low bandwidth requirements help the ESP to ensure reduced power consumption. Using libraries such as OpenSSL, the ESP handles safe transfer of data over MQTT (FTPS, HTTPS). It is essential for IoT applications as data privacy is a priority. As a consequence, MQTT is widely used in IoT applications.

- The Internet gateway acts as a communication bridge between the IoT-GL-Sensor and the remote server or IoT cloud. For secure data transfer, it uses the HTTPS protocol. HTTP is a protocol to transfer data over the internet. When that data are encrypted with SSL/TLS, it is called HTTPS [42]. The HTTPS protocol encrypts the data transmitted between the client and the server using SSL/TLS encryption to ensure that it cannot be compromised or stolen by unauthorized parties, such as a hacker or cybercriminals [43].

- The server warehouse stores the data and provides an API. The API_REST uses the HTTP protocol and uses the JSON format for data transfer. It allows the mobile app or gas company’s web platform to make requests over the Internet to access the data. The interface uses security mechanisms such as authentication using a username and password. The authentication system consults a user directory, which is stored on the server. If the credentials match, the user is allowed to access the data.

4.2. Firmware

4.3. The App

4.4. Gas Company Web Platform

5. Optimization of LPG Distribution Routes Using Clark and Wright Heuristics

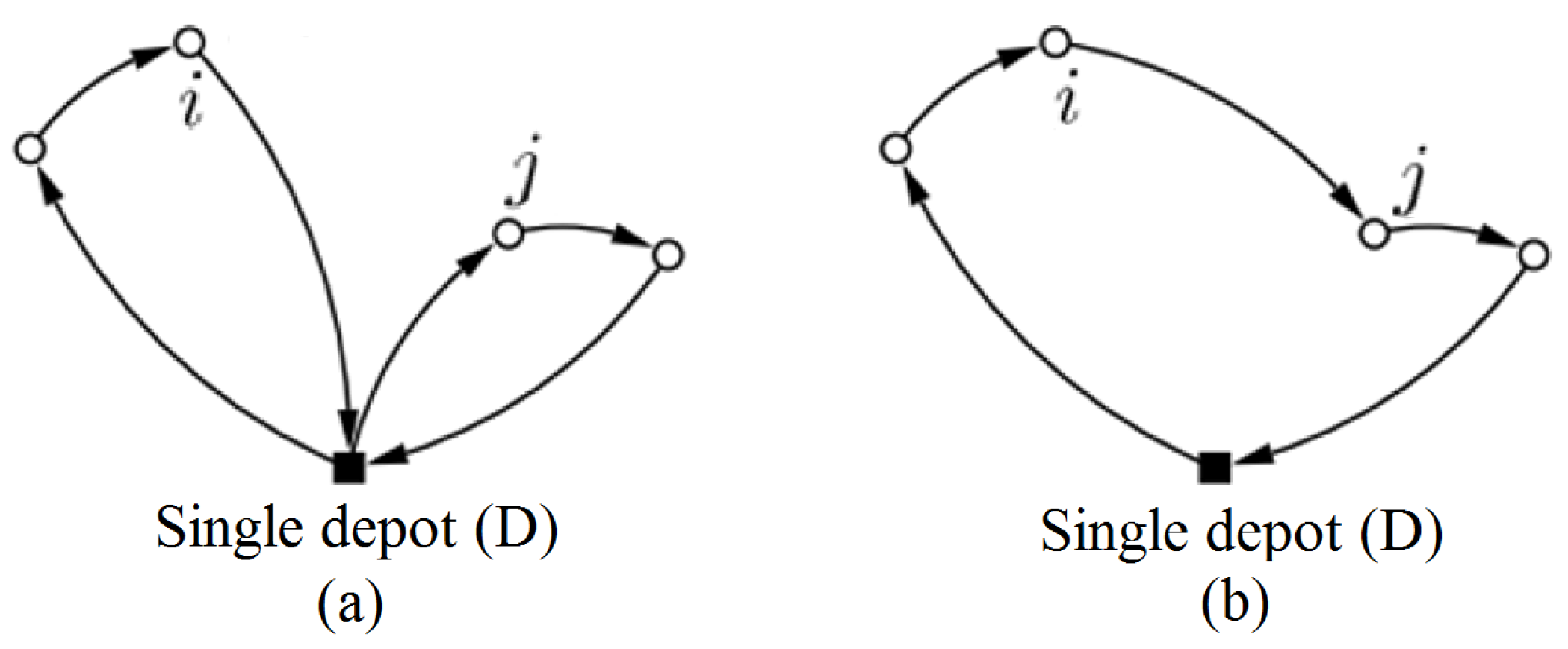

5.1. VRP

5.2. Clark and Wright Savings Algorithm

| Algorithm 1 Clark and Wright algorithm for VRP |

|

6. Results

6.1. Hardware Implementation

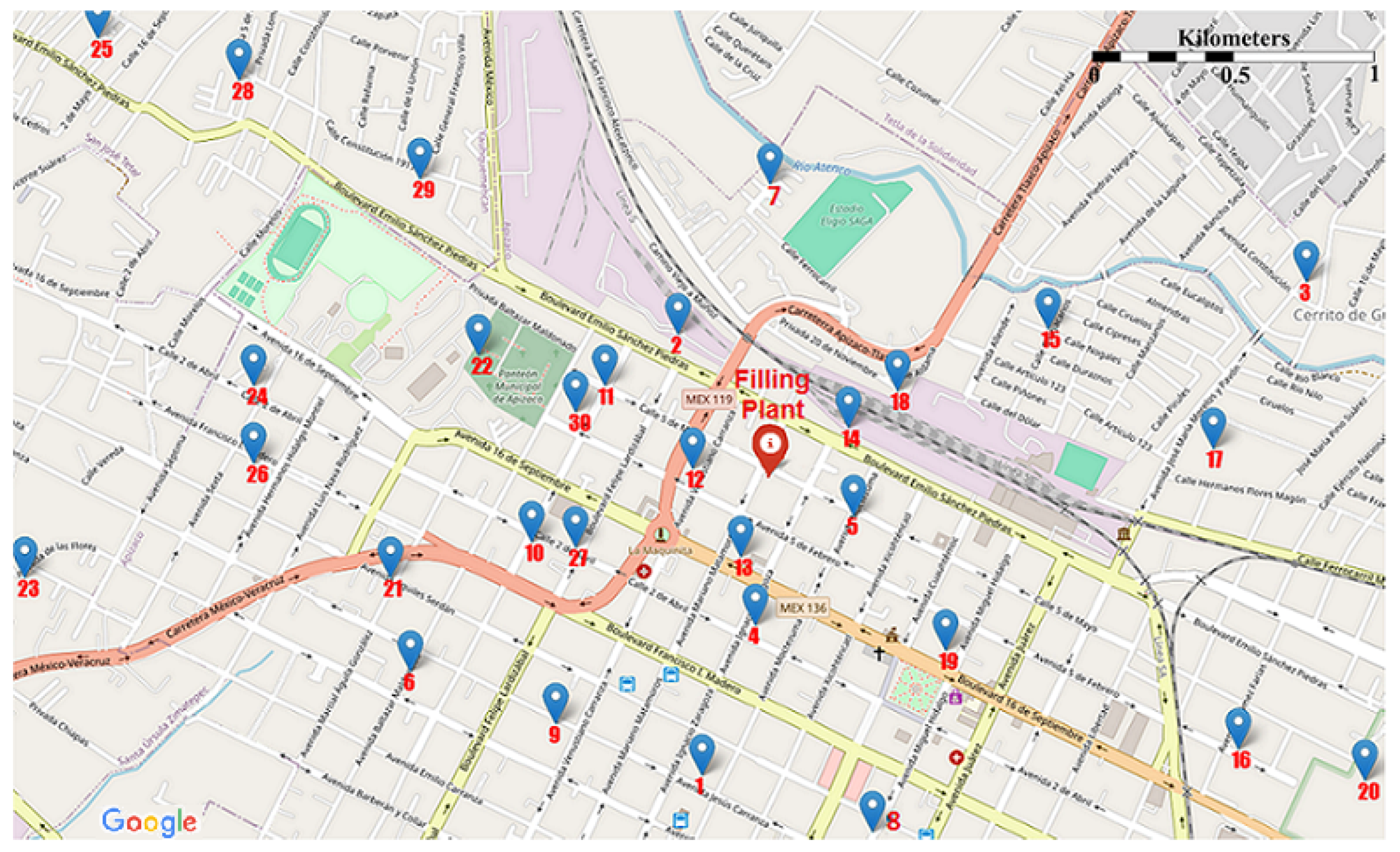

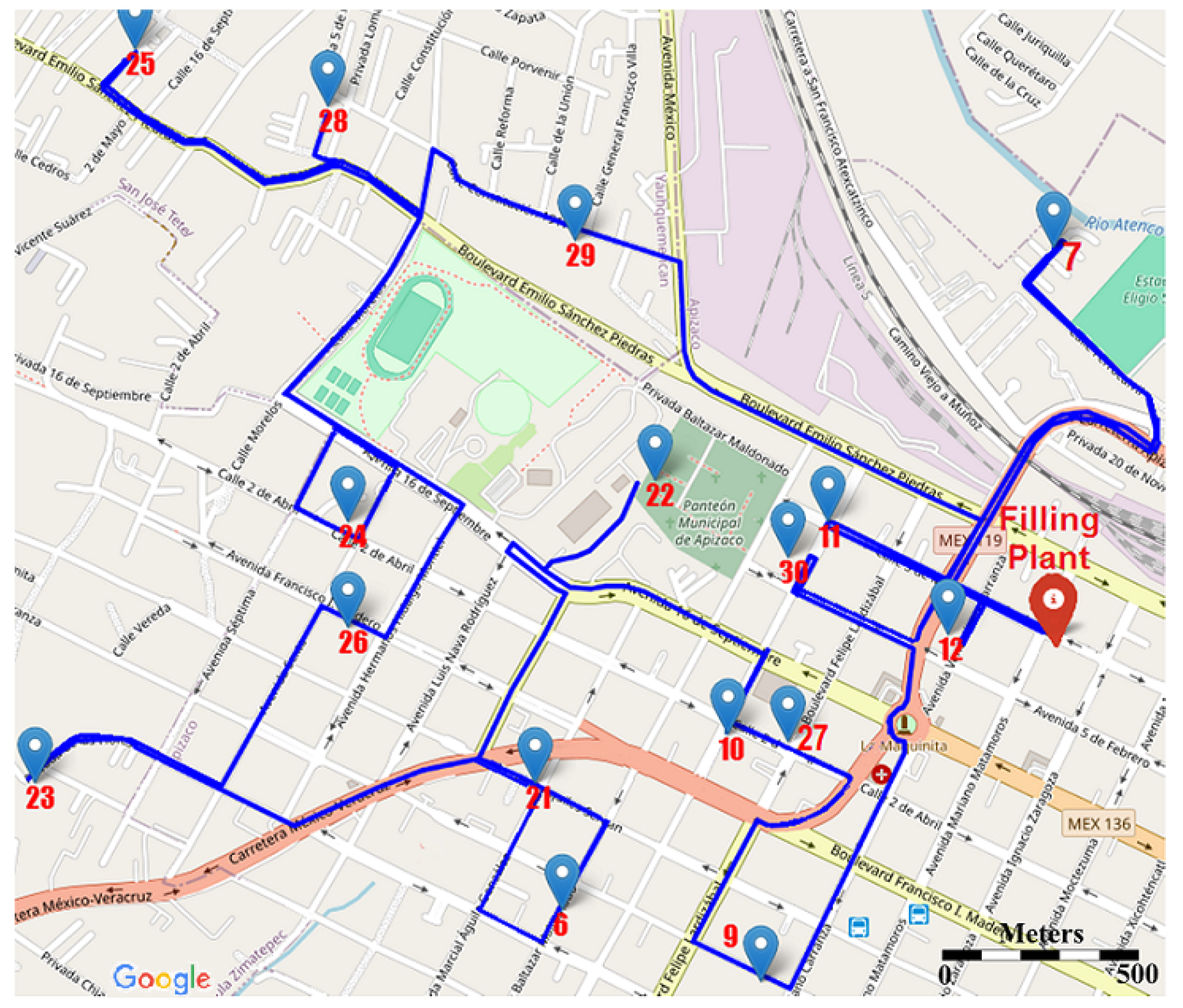

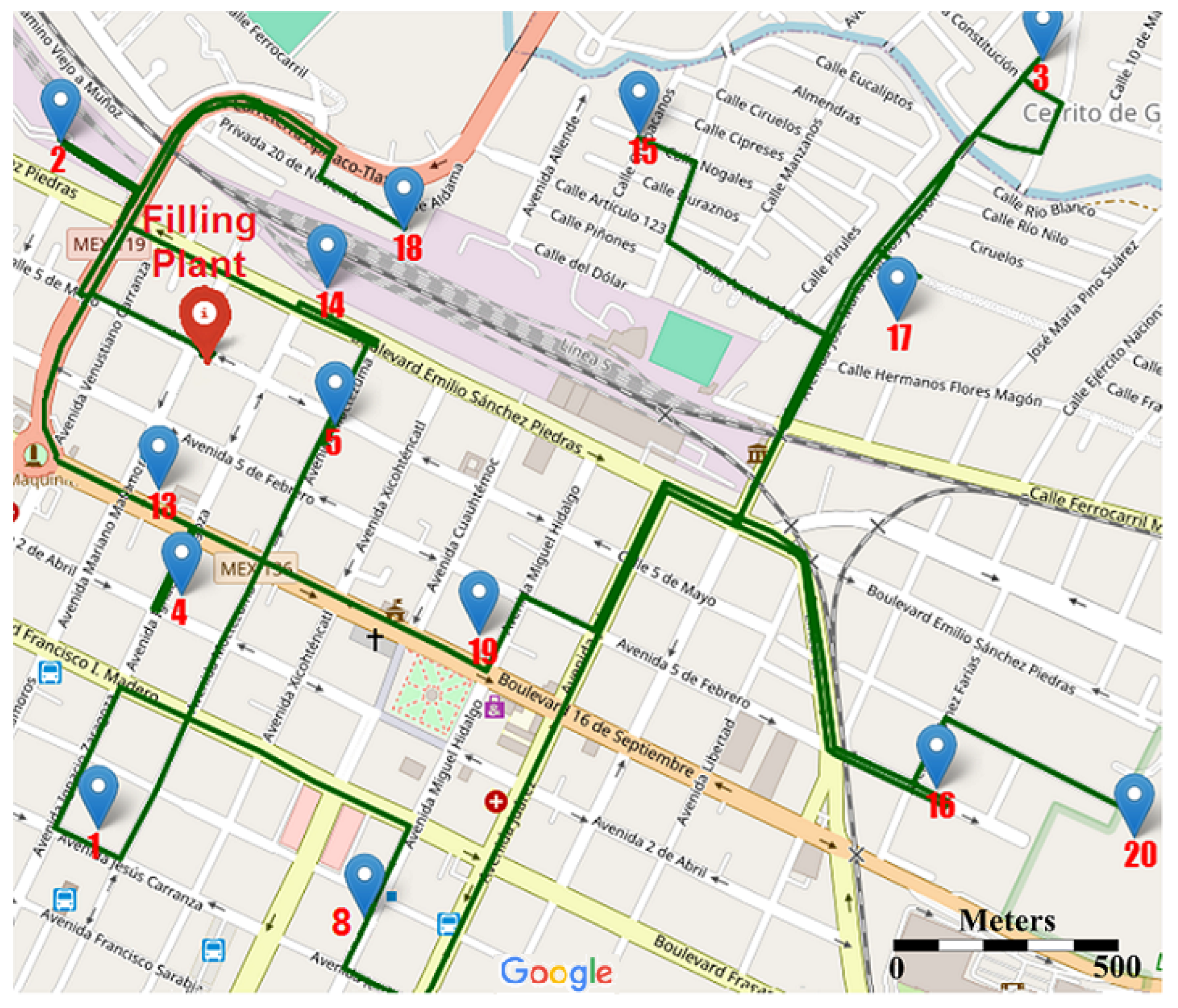

6.2. Generation of Optimized Routes with the Clark and Wright Savings Algorithm

- Route 1: Filling plant → 12 → 11 → 30 → 9 → 27 → 10 → 22 → 6 → 21 → 23 → 26 → 24 → 25 → 28 → 29 → 7 → Filling plant.

- Route 2: Filling plant → 18 → 2 → 14 → 5 → 1 → 8 → 3 → 17 → 15 → 20 → 16 → 19 → 4 → 13 → Filling plant.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- LPG Market Size, Share & Industry Analysis. Available online: https://www.fortunebusinessinsights.com/lpg-liquefied-petroleum-gas-market-106373 (accessed on 7 July 2024).

- Latin American LPG Markets in Global Context. Available online: https://www.spglobal.com/commodityinsights/en/ci/research-analysis/lpg-is-king-in-latin-america.html (accessed on 7 July 2024).

- Managing the Gas Supply at Your Home in Mexico. Available online: https://www.mexperience.com/managing-the-gas-supply-at-your-home-in-mexico/ (accessed on 10 July 2024).

- Mexican LPG Association Denounces Multi-Million Dollar Thefts. Available online: https://www.bnamericas.com/en/news/mexican-lpg-association-denounces-multi-million-dollar-thefts (accessed on 10 July 2024).

- LP Gas: Monopolies, Theft, and Corruption. Available online: https://www.eluniversal.com.mx/english/lp-gas-monopolies-theft-and-corruption/ (accessed on 21 July 2024).

- Gas Theft—Mexico’s Latest Criminal Conundrum. Available online: https://insightcrime.org/news/brief/gas-theft-mexico-criminal-conundrum/ (accessed on 21 July 2024).

- A Guide to Home Propane Tank Components, from Gauges to Regulators. Available online: https://www.amerigas.com/amerigas-blog/residential-propane/home-propane-tank-components (accessed on 29 July 2024).

- Levelgas. Available online: https://levelgas.com.mx/ (accessed on 12 August 2024).

- El gaaas. Available online: https://www.facebook.com/elgaaasmx/ (accessed on 12 August 2024).

- Isentinel. Available online: https://www.isentinel.com.mx/ (accessed on 12 August 2024).

- Redgas. Available online: https://www.redtapp.com/redgas (accessed on 17 August 2024).

- Sensigas. Available online: https://sensigas.com/ (accessed on 20 August 2024).

- Gaszen. Available online: https://jennifer-reyna.medium.com/gaszencierraen2020-58a98d8ce55c (accessed on 20 August 2024).

- Mexico Theft Makes Fuel Truck Insurance Costly. Available online: https://www.argusmedia.com/zh/news-and-insights/latest-market-news/1511807-mexico-theft-makes-fuel-truck-insurance-costly (accessed on 22 August 2024).

- Morales-Caporal, R.; Reyes-Galaviz, A.S.; Casco-Vásquez, J.F.; Martínez-Hernández, H.P. Development and implementation of a relay switch based on WiFi technology. In Proceedings of the International Conference on Electrical Engineering, Computing Science and Automatic Control (CCE), Mexico City, Mexico, 11–13 November 2020; pp. 1–6. [Google Scholar]

- IPC International, Inc. Available online: https://www.ipc.org/solutions/ipc-design (accessed on 10 October 2024).

- IPC-2221A; Generic Standard on Printed Board Design. Institute for Printed Circuits: Bannockburn, IL, USA, 2003.

- IPC-2231; Standard Only: DFX Guidelines. Institute for Printed Circuits: Bannockburn, IL, USA, 2019.

- IPC-A 610; Acceptability of Electronic Assemblies. Institute for Printed Circuits: Bannockburn, IL, USA, 2019.

- IPC-D-325A; Documentation Requirements for Printed Boards. Institute for Printed Circuits: Bannockburn, IL, USA, 1995.

- NOM-259-SE-2022; LP Gas Measurement and Dispatch Systems, Requirements, and Specifications. Gobierno de México: Mexico City, Mexico, 2024. Available online: https://platiica.economia.gob.mx/normalizacion/nom-259-se-2022/ (accessed on 10 October 2024).

- NMX-I-1362-NYCE-2021; Telecommunications–Simple Encryption Procedure for Internet of Things (IoT) Environments. Gobierno de México: Mexico City, Mexico, 2022. Available online: https://platiica.economia.gob.mx/normalizacion/nmx-i-1362-nyce-2021/ (accessed on 10 October 2024).

- NMX-I-4903-NYCE-2021; Telecommunications–Key Performance Indicators Related to Smart and Sustainable Cities, to Assess the Achievement of Sustainable Development Goals. Gobierno de México: Mexico City, Mexico, 2022. Available online: https://platiica.economia.gob.mx/normalizacion/nmx-i-4903-nyce-2021/ (accessed on 10 October 2024).

- DRV5055 Ratiometric Linear Hall Effect Sensor; Datasheet. Available online: https://www.ti.com/lit/ds/symlink/drv5055.pdf?ts=1729108442645&ref_url=https%253A%252F%252Fwww.ti.com%252Fproduct%252FDRV5055%252Fpart-details%252FDRV5055A2QLPGM (accessed on 7 June 2024).

- Angle Measurement With Multi-Axis Linear Hall-Effect Sensors; Application Note. Available online: https://www.ti.com/lit/an/sbaa463a/sbaa463a.pdf?ts=1734635270634&ref_url=https%253A%252F%252Fwww.google.com%252F (accessed on 10 June 2024).

- Morse, M. Linear Hall-Effect Sensor Angle Measurement Theory, Implementation, and Calibration; Application Note. Available online: https://www.ti.com/lit/an/slya036b/slya036b.pdf?ts=1734572638607 (accessed on 10 June 2024).

- Ferrero, A.; Salicone, S. Measurement uncertainty. IEEE Instrum. Meas. Mag. 2006, 9, 44–51. [Google Scholar] [CrossRef]

- PIC12F683; Datasheet. Available online: https://ww1.microchip.com/downloads/en/devicedoc/41211d_.pdf (accessed on 12 June 2024).

- SigFox Global Network in Mexico. Available online: https://partners.sigfox.com/companies/wnd-mexico (accessed on 17 June 2024).

- Giral-Salas, J.E.; Morales-Caporal, R.; Bonilla-Huerta, E.; Rodriguez-Rivas, J.J.; Rangel-Magdaleno, J.J. A smart switch to connect and disconnect electrical devices at home by using Internet. IEEE Lat. Am. Trans. 2016, 14, 1575–1581. [Google Scholar]

- Acosta, J.P.C.; Mojica, R.A.U.; Mosquera, L.C.D.B.; Paez-Rueda, C.; Fajardo, A. Design and implementation of a cost-effective object tracking system based on LoRa, Firebase, and Mapbox. IEEE Lat. Am. Trans. 2022, 20, 1075–1084. [Google Scholar]

- ESP-12E WiFi Module; Datasheet. Available online: https://components101.com/sites/default/files/2021-09/ESP12E-Datasheet.pdf (accessed on 21 June 2024).

- 802.11 Wireless Standards Explained. Available online: https://cdn.blackbox.com/bbcms/docs/whitepapers/802-11-mobility_whitepaper_v6.pdf (accessed on 22 June 2024).

- ESP8266: Pinout, Minimal Circuit and Technical Specifications. Available online: https://blog.hirnschall.net/esp8266-reference/? (accessed on 23 June 2024).

- Singh, R.K.; Puluckul, P.P.; Berkvens, R.; Weyn, M. Energy consumption analysis of LPWAN technologies and lifetime estimation for IoT application. Sensors 2020, 20, 4794. [Google Scholar] [CrossRef]

- Rajab, H.; Al-Amaireh, H.; Bouguera, T.; Cinkler, T. Evaluation of energy consumption of LPWAN technologies. J. Wirel. Commun. Netw. 2023, 118. [Google Scholar] [CrossRef]

- Seven Pro Tips for ESP8266. Available online: https://www.instructables.com/ESP8266-Pro-Tips/ (accessed on 10 July 2024).

- MIC5205, 150 mA low-noise LDO regulator; Datasheet. Available online: https://ww1.microchip.com/downloads/en/DeviceDoc/20005785A.pdf (accessed on 15 July 2024).

- TLV755P, 500mA, Low-IQ, Small-Size, Low-Dropout Regulator; Datasheet. Available online: https://www.ti.com/lit/ds/symlink/tlv755p.pdf (accessed on 21 July 2024).

- Morales-Caporal, R.; Pérez-Cuapio, J.F.; Martínez-Hernández, H.P.; Cortés-Maldonado, R. Design and hardware implementation of an IGBT-based half-bridge cell for modular voltage source inverters. Electronics 2021, 10, 2549. [Google Scholar] [CrossRef]

- Basic ESP8266 MQTT Example. Available online: https://github.com/internetofhomethings/ESP8266-MQTT-HTTP-Server/blob/master/PubSubClient/examples/mqtt_esp8266/mqtt_esp8266.ino (accessed on 5 August 2024).

- ESP32/ESP8266 with HTTPS and SSL/TLS Encryption. Available online: https://randomnerdtutorials.com/esp32-esp8266-https-ssl-tls/ (accessed on 7 August 2024).

- Oppliger, R. SSL and TLS: Theory and Practice, 3rd ed.; Artech: Norwood, MA, USA, 2023. [Google Scholar]

- Morales-Caporal, R.; Ramírez-Alva, M.A.; Pérez-Cuapio, J.F.; Rangel-Magdaleno, J.d.J.; Sandre-Hernández, O. A remote immobilization system with GSM and GPS technologies for cargo trailers. In Proceedings of the International Conference on Electrical Engineering, Computing Science and Automatic Control (CCE), Mexico City, Mexico, 11–13 November 2020; pp. 1–6. [Google Scholar]

- Tsindeliani, D.; Povstyana, Y.; Lishchyna, N.; Yashchuk, A. Latency reduction in real-time GPS tracking in Android and the web-based GPS monitoring system. In Proceedings of the International Conference on Dependable Systems, Services and Technologies (DESSERT), Athens, Greece, 9–11 December 2022; pp. 1–7. [Google Scholar]

- Bogyrbayeva, A.; Meraliyev, M.; Mustakhov, T.; Dauletbayev, B. Machine learning to solve vehicle routing problems: A survey. IEEE Trans. Intell. Transp. Syst. 2024, 25, 4754–4772. [Google Scholar] [CrossRef]

- Ascencio-Laguna, J.A.; Bustos-Rosales, A.; Jimenez-Sanchez, J.E.; Balbuena-Cruz, J.A.; Zamora-Dominguez, A.R. Automatic assistant for the design of distribution routes. In Publicación Técnica No. 538; Ministry of Communications and Transportation. Mexican Institute of Transport. San Fandila: Queretaro, Mexico, 2018. (In Spanish) [Google Scholar]

- Tan, S.-Y.; Yeh, W.-C. The vehicle routing problem: State-of-the-art classification and review. Appl. Sci. 2021, 11, 10295. [Google Scholar] [CrossRef]

- Lo, S.-C. A particle swarm optimization approach to solve the vehicle routing problem with cross-docking and carbon emissions reduction in logistics management. Logistics 2022, 6, 62. [Google Scholar] [CrossRef]

- Kourepinis, V.; Iliopoulou, C.; Tassopoulos, I.X.; Aroniadi, C.; Beligiannis, G.N. An improved particle swarm optimization algorithm for the urban transit routing problem. Electronics 2023, 12, 3358. [Google Scholar] [CrossRef]

- Amer, H.; Salman, N.; Hawes, M.; Chaqfeh, M.; Mihaylova, L.; Mayfield, M. An improved simulated annealing technique for enhanced mobility in smart cities. Sensors 2016, 16, 1013. [Google Scholar] [CrossRef] [PubMed]

- Jakobović, D.; Đurasević, M.; Brkić, K.; Fosin, J.; Carić, T.; Davidović, D. Evolving dispatching rules for dynamic vehicle routing with genetic programming. Algorithms 2023, 16, 285. [Google Scholar] [CrossRef]

- Qi, D.; Zhao, Y.; Wang, Z.; Wang, W.; Pi, L.; Li, L. Joint approach for vehicle routing problems based on genetic algorithm and graph convolutional network. Mathematics 2024, 12, 3144. [Google Scholar] [CrossRef]

- Lee, K.; Chae, J. Estimation of travel cost between geographic coordinates using artificial neural network: Potential application in vehicle routing problems. ISPRS Int. J. Geo-Inf. 2023, 12, 57. [Google Scholar] [CrossRef]

- Sultana, T.; Akhand, M.A.H.; Hafizur-Rahman, M.M. A variant Fisher and Jaikumar algorithm to solve capacitated vehicle routing problem. In Proceedings of the 8th International Conference on Information Technology (ICIT), Amman, Jordan, 17–18 May 2017; pp. 710–716. [Google Scholar]

- Herdianto, B.; Komarudin. Guided Clarke and Wright algorithm to solve large scale of capacitated vehicle routing problem. In Proceedings of the International Conference on Industrial Engineering and Applications (ICIEA), Chengdu, China, 23–26 April 2021; pp. 449–453. [Google Scholar]

- Cengiz Toklu, M. A fuzzy multi-criteria approach based on Clarke and Wright savings algorithm for vehicle routing problem in humanitarian aid distribution. J. Intell. Manuf. 2023, 34, 2241–2261. [Google Scholar] [CrossRef]

- Tunnisaki, F. Clarke and Wright savings algorithm as solutions vehicle routing problem with simultaneous pickup delivery. J. Phys. Conf. Ser. 2023, 2421, 1–8. [Google Scholar] [CrossRef]

- Mamoun, K.A.; Hammadiet, L.; Ballouti, A.E.; Novaes, A.G.; De Cursi, E.S. Vehicle routing optimization algorithms for pharmaceutical supply chain: A systematic comparison. Transp. Telecommun. J. 2024, 25, 161–173. [Google Scholar] [CrossRef]

- Single-Depot VRP. Available online: https://web.mit.edu/urban_or_book/www/book/chapter6/6.4.12.html (accessed on 17 August 2024).

| Designation | Ref. | Comm. Protocol | Coverage | Cyber-Security | Battery Lifespan | Measur. Daily | Data to User 1/Plant 2 | Precision | Price (USD) |

|---|---|---|---|---|---|---|---|---|---|

| Levelgas | [8] | SigFox | Only in big cities | N/S | 1 year Zn-MnO2 | 1 | ✓/x | 77.50 | |

| El gaaas | [9] | SigFox | Only in big cities | N/S | 1 year Zn-MnO2 | 1 | ✓/x | 78.00 | |

| iSentinel | [10] | Wi-Fi | Requires internet | N/S | 2 years Li-FeS2 | 1 | ✓/x | 80.30 | |

| Redgas | [11] | Wi-Fi | Limited coverage | N/S | N/S PV and Rechg.-Li-ion | 1 | ✓/x | N/S | 85.00 |

| SensiGas | [12] | 4G | Limited coverage | N/S | 5 years Rechg.-Li-ion | 1 | ✓/x | N/S | 98.50 |

| Gaszen | [13] | Wi-Fi | Requires internet | N/S | N/S | 1 | ✓/x | 100.35 | |

| Developed | – | Wi-Fi | Requires internet | SSL/TLS protocol | 1.5 years Li-FeS2 | 2 | ✓/✓ | 40.00 |

| Percentage of Gas in Tank [%] | Data Reading Periods [h] |

|---|---|

| 100—8 | 12 |

| 7—0 | 8 |

| % | [V] | [V] | [Grads] | Error [Grads] | % in App | |

|---|---|---|---|---|---|---|

| 1 | 1.0201 | 0.6666 | 0.333 | 1.0 | ||

| 5 | 0.9354 | 4.6666 | 0.333 | 5.0 | ||

| 10 | 0.6021 | 10.1851 | 10.5 | |||

| 15 | 0.1720 | 14.8148 | 0.1851 | 15.0 | ||

| 20 | 19.7727 | 0.2272 | 20.0 | |||

| 25 | 24.5454 | 0.4545 | 25.0 | |||

| 30 | 30.0 | 0 | 30.0 | |||

| 35 | 34.7222 | 0.2777 | 35.0 | |||

| 40 | 40.0 | 0 | 40.0 | |||

| 45 | 45.0 | 0 | 45.0 | |||

| 50 | 0.0476 | 177.2736 | 49.2857 | 0.7142 | 49.5 | |

| 55 | 0.2585 | 165.2014 | 54.6428 | 0.3571 | 55.0 | |

| 60 | 0.4285 | 154.6161 | 60.4166 | 60.5 | ||

| 65 | 0.5918 | 143.3583 | 65.0 | 0 | 65.0 | |

| 70 | 0.7755 | 129.2844 | 70.0 | 0 | 70.0 | |

| 75 | 0.9047 | 114.8676 | 75.3571 | 75.5 | ||

| 80 | 0.9659 | 102.5508 | 79.6428 | 0.3571 | 80.0 | |

| 85 | 0.0376 | 1.0140 | 87.8447 | 85.0 | 0 | 85.0 |

| 90 | 0.4838 | 0.8299 | 59.7567 | 90.0 | 0 | 90.0 |

| 95 | 0.8924 | 0.4149 | 24.9366 | 95.6923 | 96.0 | |

| 99 | 0.9892 | 0.1837 | 10.5183 | 98.75 | 0.25 | 99.0 |

| Device | Voltage [V] | Current in Light Sleep Mode [μA] | Current in Deep Sleep Mode [μA] |

|---|---|---|---|

| Sensor | 0 | 0 | |

| MCU | 1 | ||

| Wi-Fi | 200 | 10 |

| Device | Time Duration [s] | Voltage [V] | Current [mA] |

|---|---|---|---|

| Sensor | sensors) | ||

| MCUWuMCU | |||

| MCUMeasure | |||

| MCUProcData | |||

| Wi-FiWuWiFi | 16 | ||

| Wi-FiDataTrans | 120 |

| Device | PCB Designation | Price (USD) | Quantity |

|---|---|---|---|

| Sensors 1 | |||

| DRV5055 | Sen_A, Sen_Z | 2 | |

| GRM152R61A104KE19D | C100-C103 | 4 | |

| RC0402FR-0710KL | R100, R101 | 2 | |

| Host 2 | |||

| PIC12F683-I/P | U100 | 1 | |

| ESP8266-12E/ESP-12E | U101 | 1 | |

| TLV755P | U10R | 1 | |

| MIC5205 | U11R | 2 | |

| RES-402 | R000 | 1 | |

| RES-402 | R100P - R104E | 6 | |

| SF-0603F063-2 | F100R | 1 | |

| GRM31MR61A106M | FC103E, C106R | 2 | |

| D4V5H1U2LP161 | D100 | 1 | |

| DMN2020LSN-7 | D101 | 1 | |

| D4V5H1U2LP1610-7 | D103 | 1 | |

| 640456-2 | CON101,CON102 | 2 | |

| GRM152R61A104KE19D | C100P - C101E | 4 | |

| GRM219R61A105MA19D | C101P - C105R | 1 | |

| C1206C106M8PACTU | C102P | 1 | |

| UKL1A221MPDANA | C200E | 1 | |

| Tank ID | Coordinates (Lat. and Lon.) | Request (L) | Tank ID | Coordinates (Lat. and Lon.) | Request (L) |

|---|---|---|---|---|---|

| 1 | 19°, | 300 | 16 | 19°, | 120 |

| 2 | 19°, | 470 | 17 | 19°99″, | 260 |

| 3 | 19°, | 380 | 18 | 19°, | 190 |

| 4 | 19°, | 460 | 19 | 19°, | 200 |

| 5 | 19°, | 240 | 20 | 19°, | 480 |

| 6 | 19°, | 390 | 21 | 19°, | 240 |

| 7 | 19°, | 420 | 22 | 19°, | 350 |

| 8 | 19°, | 370 | 23 | 19°, | 230 |

| 9 | 19°, | 400 | 24 | 19°, | 190 |

| 10 | 19°, | 450 | 25 | 19°, | 420 |

| 11 | 19°, | 280 | 26 | 19°, | 370 |

| 12 | 19°, | 380 | 27 | 19°, | 260 |

| 13 | 19°, | 370 | 28 | 19°, | 420 |

| 14 | 19°, | 450 | 29 | 19°, | 330 |

| 15 | 19°, | 240 | 30 | 19°, | 190 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales-Caporal, R.; Pérez-Loaiza, R.E.; Bonilla-Huerta, E.; Hernández-Pérez, J.; Rangel-Magdaleno, J.d.J. IoT-Based LPG Level Sensor for Domestic Stationary Tanks with Data Sharing to a Filling Plant to Optimize Distribution Routes. Future Internet 2024, 16, 479. https://doi.org/10.3390/fi16120479

Morales-Caporal R, Pérez-Loaiza RE, Bonilla-Huerta E, Hernández-Pérez J, Rangel-Magdaleno JdJ. IoT-Based LPG Level Sensor for Domestic Stationary Tanks with Data Sharing to a Filling Plant to Optimize Distribution Routes. Future Internet. 2024; 16(12):479. https://doi.org/10.3390/fi16120479

Chicago/Turabian StyleMorales-Caporal, Roberto, Rodolfo Eleazar Pérez-Loaiza, Edmundo Bonilla-Huerta, Julio Hernández-Pérez, and José de Jesús Rangel-Magdaleno. 2024. "IoT-Based LPG Level Sensor for Domestic Stationary Tanks with Data Sharing to a Filling Plant to Optimize Distribution Routes" Future Internet 16, no. 12: 479. https://doi.org/10.3390/fi16120479

APA StyleMorales-Caporal, R., Pérez-Loaiza, R. E., Bonilla-Huerta, E., Hernández-Pérez, J., & Rangel-Magdaleno, J. d. J. (2024). IoT-Based LPG Level Sensor for Domestic Stationary Tanks with Data Sharing to a Filling Plant to Optimize Distribution Routes. Future Internet, 16(12), 479. https://doi.org/10.3390/fi16120479