Development of α-Cyclodextrin-Based Orally Disintegrating Tablets for 4-Phenylbutyrate

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PB-CD Solid Systems

2.2.1. Physical Mixtures (PM)

2.2.2. Kneaded Systems (KN)

2.2.3. Lyophilized Systems (LYO)

2.2.4. Spray-Dried Systems (SD)

2.3. Evaluation of PB-CD Solid Systems

2.3.1. Scanning Electron Microscopy (SEM)

2.3.2. X-ray Diffraction (XRD)

2.3.3. Dissolution Studies

HPLC Conditions

2.3.4. Stability Studies

2.4. Formulation of PB-CD ODTs

2.5. Evaluation of PB-CD ODT Formulations

2.5.1. pH in Solution

2.5.2. Assay

2.5.3. Wettability

2.5.4. Water Uptake Behavior

2.5.5. Moisture Absorption on Storage

2.5.6. Disintegration Time

2.6. Statistical Analysis

3. Results and Discussion

3.1. Evaluation of PB-CD Solid Systems

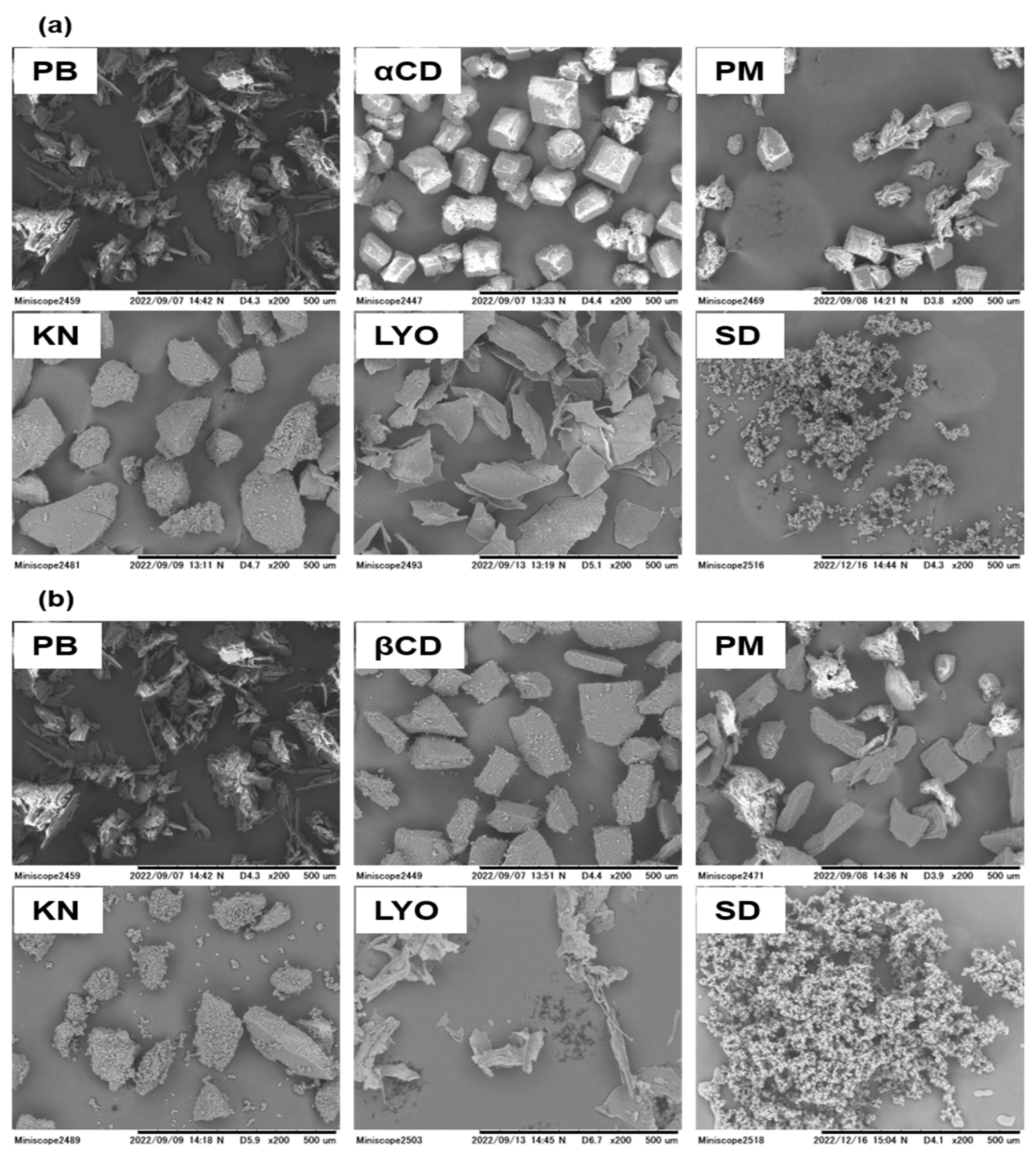

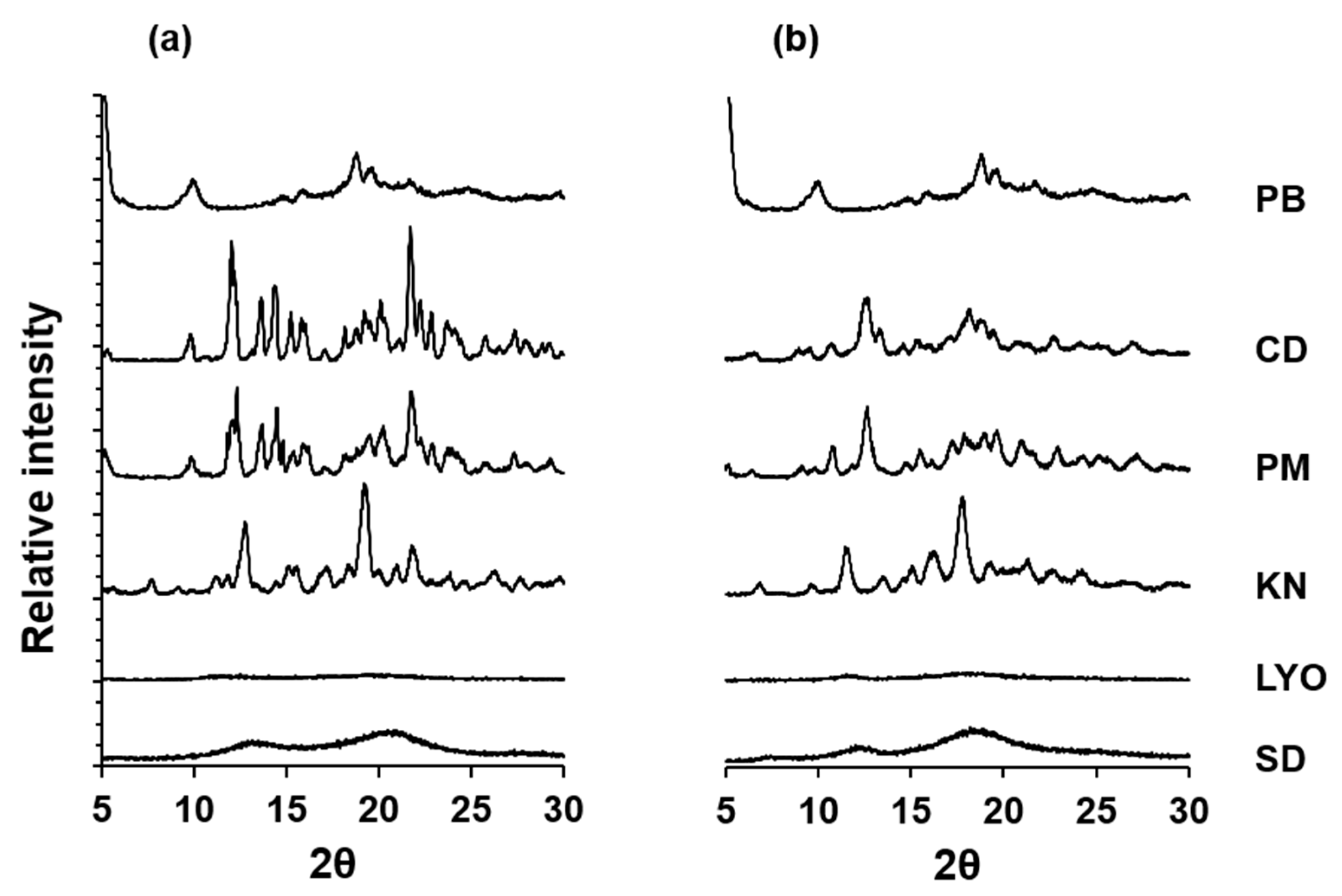

3.1.1. Morphology and Crystallinity

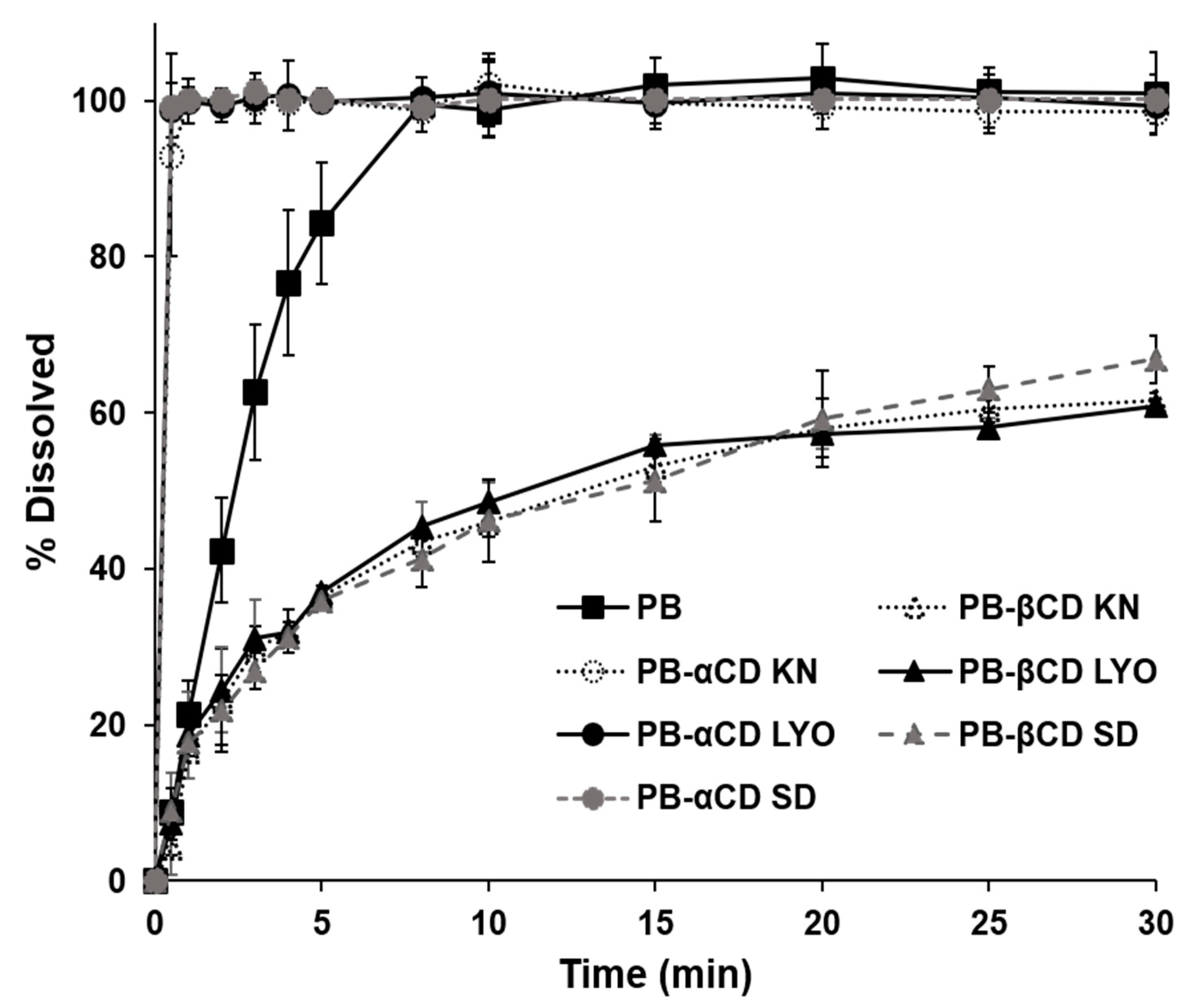

3.1.2. Dissolution Behavior

3.1.3. Storage Stability

3.2. Formulation and Evaluation of PB-CD ODTs

3.2.1. Physical Characterization of ODTs

3.2.2. Water Uptake and Disintegration Performance of ODTs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Walker, V. Ammonia Metabolism and Hyperammonemic Disorders. Adv. Clin. Chem. 2014, 67, 73–150. [Google Scholar] [CrossRef] [PubMed]

- Brusilow, S.W.; Maestri, N.E. Urea cycle disorders: Diagnosis, pathophysiology, and therapy. Adv. Pediatr. 1996, 43, 127–170. [Google Scholar] [CrossRef] [PubMed]

- Häberle, J.; Boddaert, N.; Burlina, A.; Chakrapani, A.; Dixon, M.; Huemer, M.; Karall, D.; Martinelli, D.; Crespo, P.S.; Santer, R.; et al. Suggested guidelines for the diagnosis and management of urea cycle disorders. Orphanet J. Rare Dis. 2012, 7, 1–30. [Google Scholar] [CrossRef] [PubMed]

- Iannitti, T.; Palmieri, B. Clinical and Experimental Applications of Sodium Phenylbutyrate. Drugs R & D. 2012, 11, 227–249. [Google Scholar] [CrossRef]

- Basseri, S.; Lhoták, Š.; Sharma, A.M.; Austin, R.C. The chemical chaperone 4-phenylbutyrate inhibits adipogenesis by modulating the unfolded protein response. J. Lipid Res. 2009, 50, 2486–2501. [Google Scholar] [CrossRef] [PubMed]

- Dover, G.J.; Brusilow, S.; Charache, S. Induction of fetal hemoglobin production in subjects with sickle cell anemia by oral sodium phenylbutyrate. Blood. 1994, 84, 339–343. [Google Scholar] [CrossRef] [PubMed]

- European Medicines Agency. Summary of Product Characteristics: Ammonaps. Available online: https://www.ema.europa.eu/en/documents/product-information/ammonaps-epar-product-information_en.pdf (accessed on 28 July 2022).

- Mennella, J.A.; Beauchamp, G.K. Optimizing oral medications for children. Clin. Ther. 2008, 30, 2120–2132. [Google Scholar] [CrossRef]

- Diaz, G.A.; Krivitzky, L.S.; Mokhtarani, M.; Rhead, W.; Bartley, J.; Feigenbaum, A.; Longo, N.; Berquist, W.; Berry, S.A.; Gallagher, R.; et al. Ammonia control and neurocognitive outcome among urea cycle disorder patients treated with glycerol phenylbutyrate. Hepatology. 2013, 57, 2171–2179. [Google Scholar] [CrossRef]

- US Food and Drugs Administration. Full Prescribing Information: Ravicti (Glycerol Phenylbutyrate) Oral Liquid. Available online: https://www.accessdata.fda.gov/drugsatfda_docs/label/2016/203284s004lbl.pdf (accessed on 28 July 2022).

- European Medicines Agency. Summary of Product Characteristics: Pheburane. Available online: https://www.ema.europa.eu/en/documents/product-information/pheburane-epar-product-information_en.pdf (accessed on 28 July 2022).

- Kibleur, Y.; Guffon, N. Long-Term Follow-Up on a Cohort Temporary Utilization Authorization (ATU) Survey of Patients Treated with Pheburane (Sodium Phenylbutyrate) Taste-Masked Granules. Pediatr. Drugs 2016, 18, 139–144. [Google Scholar] [CrossRef]

- Guffon, N.; Kibleur, Y.; Copalu, W.; Tissen, C.; Breitkreutz, J. Developing a new formulation of sodium phenylbutyrate. Arch. Dis. Child. 2012, 97, 1081–1085. [Google Scholar] [CrossRef]

- Loftsson, T.; Brewster, M.E. Pharmaceutical applications of cyclodextrins: Basic science and product development. J. Pharm. Pharmacol. 2010, 62, 1607–1621. [Google Scholar] [CrossRef] [PubMed]

- Stella, V.J.; Rajewski, R.A. Cyclodextrins: Their future in drug formulation and delivery. Pharm. Res. 1997, 14, 556–567. [Google Scholar] [CrossRef] [PubMed]

- Davis, M.E.; Brewster, M.E. Cyclodextrin-based pharmaceutics: Past, present and future. Nat. Rev. Drug Discov. 2004, 3, 1023–1035. [Google Scholar] [CrossRef]

- Uekama, K.; Hirayama, F.; Irie, T. Cyclodextrin Drug Carrier Systems. Chem. Rev. 1998, 98, 2045–2076. [Google Scholar] [CrossRef] [PubMed]

- Irie, T.; Uekama, K. Pharmaceutical applications of cyclodextrins. III. Toxicological issues and safety evaluation. J. Pharm. Sci. 1997, 86, 147–162. [Google Scholar] [CrossRef] [PubMed]

- Commey, K.; Nakatake, A.; Enaka, A.; Nishi, K.; Tsukigawa, K.; Yamaguchi, K.; Ikeda, H.; Iohara, D.; Hirayama, F.; Otagiri, M.; et al. Study of the inclusion complexes formed between 4-phenylbutyrate and α-, β- and γ-cyclodextrin in solution and evaluation on their taste-masking properties. J. Pharm. Pharmacol. 2023, 75, 236–244. [Google Scholar] [CrossRef] [PubMed]

- Stoltenberg, I.; Breitkreutz, J. Orally disintegrating mini-tablets (ODMTs)—A novel solid oral dosage form for paediatric use. Eur. J. Pharm. Biopharm. 2011, 78, 462–469. [Google Scholar] [CrossRef]

- Batchelor, H.K.; Marriott, J.F. Formulations for children: Problems and solutions. Br. J. Clin. Pharmacol. 2015, 79, 405–418. [Google Scholar] [CrossRef]

- Walsh, J.; Cram, A.; Woertz, K.; Breitkreutz, J.; Winzenburg, G.; Turner, R.; Tuleu, C. Playing hide and seek with poorly tasting paediatric medicines: Do not forget the excipients. Adv. Drug Deliv. Rev. 2014, 73, 14–33. [Google Scholar] [CrossRef]

- Slavkova, M.; Breitkreutz, J. Orodispersible drug formulations for children and elderly. Eur. J. Pharm. Sci. 2015, 75, 2–9. [Google Scholar] [CrossRef]

- Breitkreutz, J.; Boos, J. Paediatric and geriatric drug delivery. Expert Opin. Drug Deliv. 2007, 4, 37–45. [Google Scholar] [CrossRef] [PubMed]

- Stegemann, S.; Gosch, M.; Breitkreutz, J. Swallowing dysfunction and dysphagia is an unrecognized challenge for oral drug therapy. Int. J. Pharm. 2012, 430, 197–206. [Google Scholar] [CrossRef] [PubMed]

- Rahane, R.; Rachh, P.R. A Review On Fast Dissolving Tablet. J. Drug Deliv. Ther. 2018, 8, 50–55. [Google Scholar] [CrossRef]

- Ghourichay, M.P.; Kiaie, S.H.; Nokhodchi, A.; Javadzadeh, Y. Formulation and Quality Control of Orally Disintegrating Tablets (ODTs): Recent Advances and Perspectives. Biomed. Res. Int. 2021, 2021, 6618934. [Google Scholar] [CrossRef] [PubMed]

- Mura, P. Analytical techniques for characterization of cyclodextrin complexes in the solid state: A review. J. Pharm. Biomed. Anal. 2015, 113, 226–238. [Google Scholar] [CrossRef]

- Figueiras, A.; Carvalho, R.A.; Ribeiro, L.; Torres-Labandeira, J.J.; Veiga, F.J.B. Solid-state characterization and dissolution profiles of the inclusion complexes of omeprazole with native and chemically modified β-cyclodextrin. Eur. J. Pharm. Biopharm. 2007, 67, 531–539. [Google Scholar] [CrossRef]

- Yamasaki, K.; Kwok, P.C.L.; Fukushige, K.; Prud’homme, R.K.; Chan, H.K. Enhanced dissolution of inhalable cyclosporine nano-matrix particles with mannitol as matrix former. Int. J. Pharm. 2011, 420, 34–42. [Google Scholar] [CrossRef]

- Khan, K.A. The concept of dissolution efficiency. J. Pharm. Pharmacol. 2011, 27, 48–49. [Google Scholar] [CrossRef]

- Commey, K.L.; Nakatake, A.; Enaka, A.; Nakamura, R.; Nishi, K.; Tsukigawa, K.; Ikeda, H.; Yamaguchi, K.; Iohara, D.; Hirayama, F.; et al. Study of the Structural Chemistry of the Inclusion Complexation of 4-Phenylbutyrate and Related Compounds with Cyclodextrins in Solution: Differences in Inclusion Mode with Cavity Size Dependency. Int. J. Mol. Sci. 2023, 24, 15091. [Google Scholar] [CrossRef]

- Fell, J.T.; Newton, J.M. Determination of Tablet Strength by the Diametral-Compression Test. J. Pharm. Sci. 1970, 59, 688–691. [Google Scholar] [CrossRef]

- Watanabe, S.; Yamamura, Y.; Hoshiai, A.; Morishita, S.; Machiya, A.; Matsuda, S.; Shimojima, T.; Tohnai, I. Salivary volume in the mouth immediately before and after swallowing in children. Dent. Oral Maxillofac. Res. 2021, 7, 1–3. [Google Scholar] [CrossRef]

- Navazesh, M.; Kumar, S.K.S. Measuring salivary flow challenges and opportunities. J. Am. Dent. Assoc. 2008, 139, 35S–40S. [Google Scholar] [CrossRef] [PubMed]

- Mady, F.M.; Abou-Taleb, A.E.; Khaled, K.A.; Yamasaki, K.; Iohara, D.; Ishiguro, T.; Hirayama, F.; Uekama, K.; Otagiri, M. Enhancement of the Aqueous Solubility and Masking the Bitter Taste of Famotidine Using Drug/SBE-β-CyD/Povidone K30 Complexation Approach. J. Pharm. Sci. 2010, 99, 4285–4294. [Google Scholar] [CrossRef] [PubMed]

- Desai, S.; Poddar, A.; Sawant, K. Formulation of cyclodextrin inclusion complex-based orally disintegrating tablet of eslicarbazepine acetate for improved oral bioavailability. Mater. Sci. Eng. C 2016, 58, 826–834. [Google Scholar] [CrossRef] [PubMed]

- Popielec, A.; Loftsson, T. Effects of cyclodextrins on the chemical stability of drugs. Int. J. Pharm. 2017, 531, 532–542. [Google Scholar] [CrossRef] [PubMed]

- Mady, F.M.; Abou-Taleb, A.E.; Khaled, K.A.; Yamasaki, K.; Iohara, D.; Taguchi, K.; Anraku, M.; Hirayama, F.; Uekama, K.; Otagiri, M. Evaluation of carboxymethyl-β-cyclodextrin with acid function: Improvement of chemical stability, oral bioavailability and bitter taste of famotidine. Int. J. Pharm. 2010, 397, 1–8. [Google Scholar] [CrossRef]

- Loftsson, T.; Brewster, M.E. Cyclodextrins as Functional Excipients: Methods to Enhance Complexation Efficiency. J. Pharm. Sci. 2012, 101, 3019–3032. [Google Scholar] [CrossRef]

- Shukla, D. Mouth Dissolving Tablets I: An Overview of Formulation Technology. Sci. Pharm. 2009, 77, 309–326. [Google Scholar] [CrossRef]

- Sheshala, R.; Khan, N.; Darwis, Y. Formulation and Optimization of Orally Disintegrating Tablets of Sumatriptan Succinate. Chem. Pharm. Bull. 2011, 59, 920–928. [Google Scholar] [CrossRef]

- Markl, D.; Zeitler, J.A. A Review of Disintegration Mechanisms and Measurement Techniques. Pharm. Res. 2017, 34, 890–917. [Google Scholar] [CrossRef]

- Yang, B.; Wei, C.; Yang, Y.; Wang, Q.; Li, S. Evaluation about wettability, water absorption or swelling of excipients through various methods and the correlation between these parameters and tablet disintegration. Drug Dev. Ind. Pharm. 2018, 44, 1417–1425. [Google Scholar] [CrossRef] [PubMed]

- US Food and Drug Administration, Center for Drug Evaluation and Research (CDER). Guidance for Industry: Orally Disintegrating Tablets. Available online: http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/ucm070578.pdf (accessed on 28 July 2022).

- Rancé, F.; Deslandes, B.; Decosta, P. Acceptabilité et tolérance des comprimés orodispersibles de métasulfobenzoate sodique de prednisolone chez les enfants âgés de 2 à 12 ans. Arch. Pediatr. 2004, 11, 1127–1130. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wrzesinski, A.; Moses, M.; Bertrand, H. Comparison of superdisintegrants in orally disintegrating tablets. Pharm. Technol. 2010, 34, 54–65. [Google Scholar]

- Basalious, E.B.; Abdullah, A.; Ibrahim, M. Utility of Mannitol and Citric Acid for Enhancing the Solubilizing and Taste Masking Properties of β-Cyclodextrin: Development of Fast-Dissolving Tablets Containing Extremely Bitter Drug. J. Pharm. Innov. 2014, 9, 309–320. [Google Scholar] [CrossRef]

- Ivanovska, V.; Rademaker, C.M.A.; van Dijk, L.; Mantel-Teeuwisse, A.K. Pediatric Drug Formulations: A Review of Challenges and Progress. Pediatrics 2014, 134, 361–372. [Google Scholar] [CrossRef]

- Caruthers, R.L.; Johnson, C.E. Stability of extemporaneously prepared sodium phenylbutyrate oral suspensions. Am. J. Health-Syst. Pharm. 2007, 64, 1513–1515. [Google Scholar] [CrossRef]

- Sohi, H.; Sultana, Y.; Khar, R.K. Taste Masking Technologies in Oral Pharmaceuticals: Recent Developments and Approaches. Drug Dev. Ind. Pharm. 2004, 30, 429–448. [Google Scholar] [CrossRef]

| Ingredients | Weight (mg) | ||

|---|---|---|---|

| PB | PB-αCD | PB-βCD | |

| PB (or equivalent PB-CD solid system) | 10.00 | 71.70 a | 101.30 a |

| Microcrystalline cellulose (PH 101) | 10.00 | 10.00 | 10.00 |

| Crospovidone (Kollidon CL-SF) | 10.00 | 10.00 | 10.00 |

| D-Mannitol | 165.00 | 103.30 | 73.70 |

| Citric acid | 3.00 | 3.00 | 3.00 |

| Magnesium stearate | 2.00 | 2.00 | 2.00 |

| Total | 200.00 | 200.00 | 200.00 |

| PB | PB-αCD | PB-βCD | |||||

|---|---|---|---|---|---|---|---|

| KN | LYO | SD | KN | LYO | SD | ||

| DP2min (%) | 42.40 ± 6.71 | 100.00 ± 0.71 ** | 99.40 ± 2.09 ** | 100.20 ± 1.27 ** | 23.15 ± 6.62 * | 24.47 ± 5.46 * | 21.87 ± 4.50 * |

| DE30min (%) | 91.83 ± 1.83 | 99.27 ± 2.94 ** | 99.41 ± 1.02 ** | 99.34 ± 0.06 ** | 48.49 ± 1.74 *** | 49.05 ± 0.17 *** | 48.86 ± 3.08 *** |

| Solid System | Physical Appearance | Moisture Content (% w/w) | PB Content (% w/w) a |

|---|---|---|---|

| PB | Color change from white to off-white. Complete caking with no free flow. | 30.45 | 100.33 ± 3.41 |

| αCD | No color changes. Slight to moderate caking with limited flow. | 2.73 | - |

| PM | 4.14 | 98.19 ± 4.25 | |

| KN | 2.14 | 101.47 ± 1.39 | |

| LYO | 1.36 | 99.65 ± 2.56 | |

| SD | 2.36 | 98.95 ± 1.56 | |

| βCD | No color changes. Slight to moderate caking with limited flow. | 4.50 | - |

| PM | 2.32 | 98.62 ± 2.73 | |

| KN | 1.50 | 99.12 ± 0.73 | |

| LYO | 0.91 | 98.77 ± 0.60 | |

| SD | 1.82 | 100.04 ± 1.07 |

| Formulation | Weight (mg) a | Thickness (mm) b | Hardness (N) b | Tensile Strength (MPa) b | Friability (% w/w) | pH in solution c,d | Assay (% w/w) c |

|---|---|---|---|---|---|---|---|

| PB | 199.78 ± 0.12 | 1.94 ± 0.03 | 4.40 ± 0.52 | 0.14 ± 0.01 | 0.59 | 4.88 ± 0.02 | 96.85 ± 3.09 |

| PB-αCD | 200.00 ± 0.18 | 2.05 ± 0.10 | 33.30 ± 1.16 *** | 1.03 ± 0.02 *** | 0.79 | 5.42 ± 0.03 | 100.33 ± 1.89 |

| PB-βCD | 200.10 ± 0.16 | 2.06 ± 0.08 | 26.00 ± 1.41 *** | 0.80 ± 0.02 *** | 0.85 | 6.08 ± 0.13 | 102.52 ± 0.92 |

| Formulation | Wettability (Contact Angle, θ) (°) a | Maximum Water Uptake, Vmax (µL) a | Moisture Absorption on Storage (% w/w) b,d | Disintegration Time (s) c |

|---|---|---|---|---|

| PB | 10.40 ± 1.55 | 120.50 ± 1.35 | 2.64 ± 0.08 | 13.83 ± 2.52 |

| PB-αCD | 23.97 ± 5.35 | 160.63 ± 9.81 ### | 1.83 ± 0.12 *** | 28.17 ± 1.73 |

| PB-βCD | 39.07 ± 5.58 * | 77.21 ± 3.87 ** | 1.52 ± 0.03 *** | 93.67 ± 5.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Commey, K.L.; Enaka, A.; Nakamura, R.; Yamamoto, A.; Tsukigawa, K.; Nishi, K.; Iohara, D.; Hirayama, F.; Otagiri, M.; Yamasaki, K. Development of α-Cyclodextrin-Based Orally Disintegrating Tablets for 4-Phenylbutyrate. Pharmaceutics 2024, 16, 82. https://doi.org/10.3390/pharmaceutics16010082

Commey KL, Enaka A, Nakamura R, Yamamoto A, Tsukigawa K, Nishi K, Iohara D, Hirayama F, Otagiri M, Yamasaki K. Development of α-Cyclodextrin-Based Orally Disintegrating Tablets for 4-Phenylbutyrate. Pharmaceutics. 2024; 16(1):82. https://doi.org/10.3390/pharmaceutics16010082

Chicago/Turabian StyleCommey, Kindness L., Airi Enaka, Ryota Nakamura, Asami Yamamoto, Kenji Tsukigawa, Koji Nishi, Daisuke Iohara, Fumitoshi Hirayama, Masaki Otagiri, and Keishi Yamasaki. 2024. "Development of α-Cyclodextrin-Based Orally Disintegrating Tablets for 4-Phenylbutyrate" Pharmaceutics 16, no. 1: 82. https://doi.org/10.3390/pharmaceutics16010082

APA StyleCommey, K. L., Enaka, A., Nakamura, R., Yamamoto, A., Tsukigawa, K., Nishi, K., Iohara, D., Hirayama, F., Otagiri, M., & Yamasaki, K. (2024). Development of α-Cyclodextrin-Based Orally Disintegrating Tablets for 4-Phenylbutyrate. Pharmaceutics, 16(1), 82. https://doi.org/10.3390/pharmaceutics16010082