Nutmeg Essential Oil, Red Clover, and Liquorice Extracts Microencapsulation Method Selection for the Release of Active Compounds from Gel Tablets of Different Bases

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Material and Reagents

2.2. Microcapsules’ Formulation and Preparation

2.2.1. Lyophilization Method Conditions

2.2.2. Spray-Drying Method Conditions

2.3. Evaluation of Physical Parameters of Microcapsules

2.3.1. Microcapsule Yields

2.3.2. Moisture Content

2.3.3. Bulk and Tapped Volumes

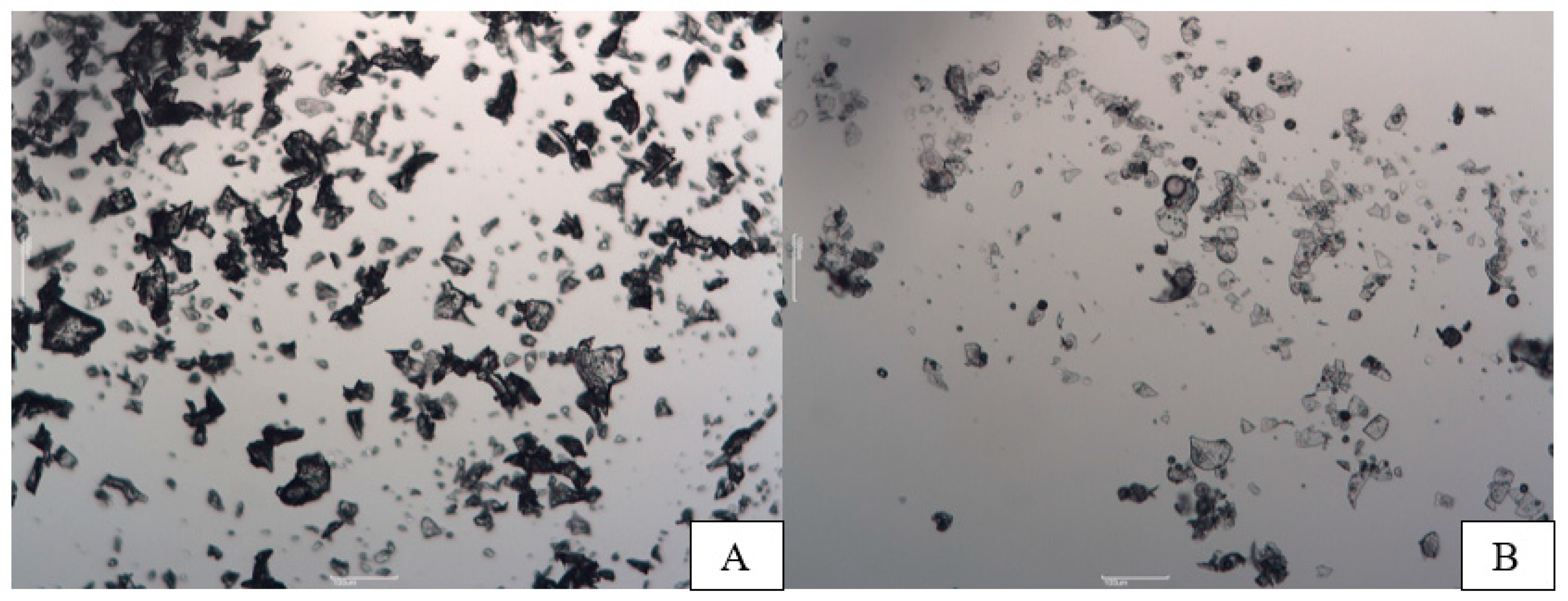

2.3.4. Shape of the Microcapsules

2.3.5. Solubility

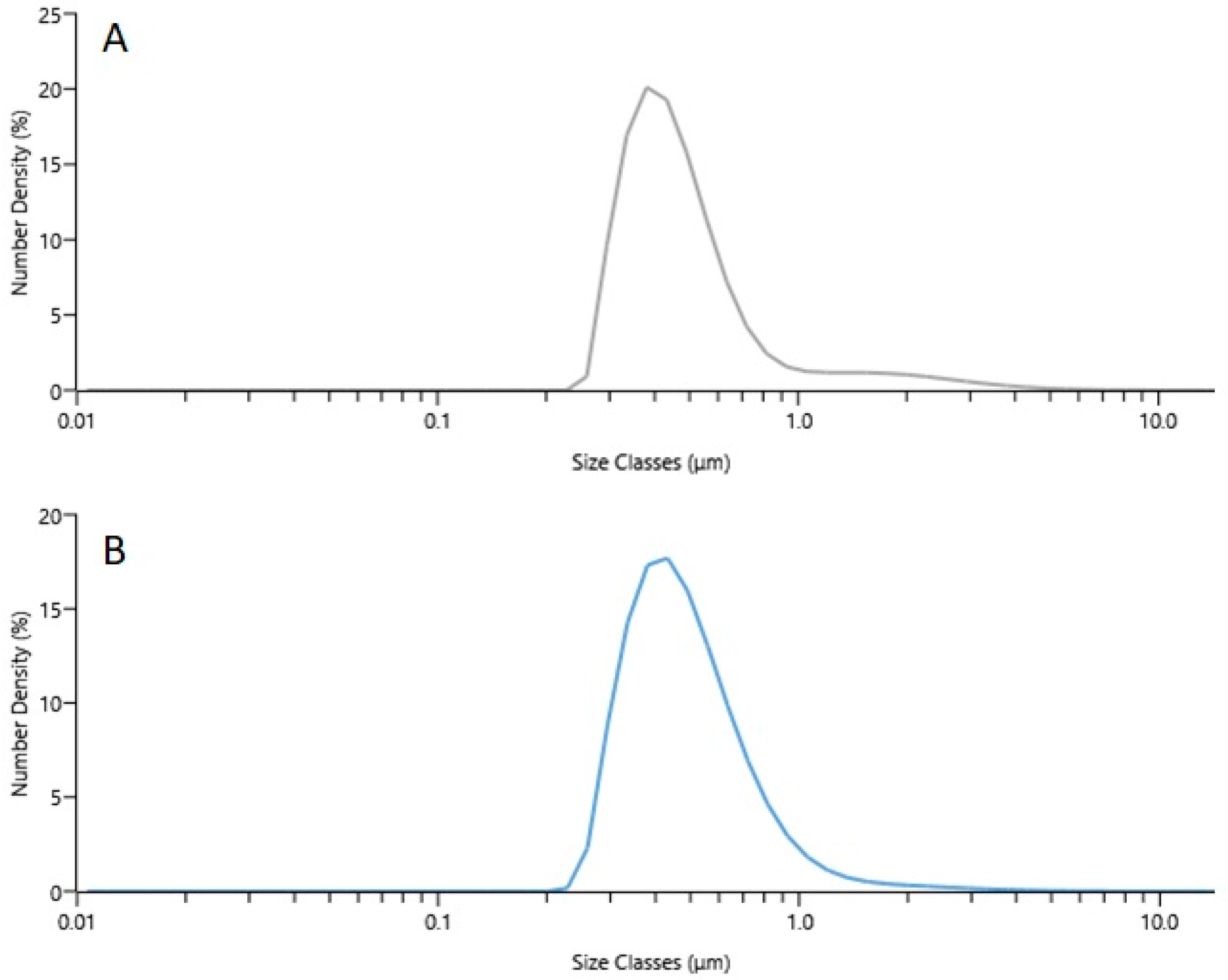

2.3.6. Size Distribution of Microcapsules

2.4. Total Content of Active Compounds and In Vitro Release and Analysis of Microcapsules and Gel Tablets

2.4.1. Total Phenolic and Flavonoid Content

2.4.2. In Vitro Release of Active Compounds

2.4.3. Chromatographic Analysis of Microcapsules

2.5. Antioxidant Activity of Microcapsules

2.6. Gel Tablets Preparation

2.6.1. Gelatin Gel Tablets’ Preparation

2.6.2. Pectin Gel Tablets Preparation

2.7. Gel Tablets’ Physical Parameters Determination

2.8. Statistical Analysis

3. Results and Discussion

3.1. Preparation of Microcapsules and Physical Parameters Evaluation

3.1.1. Evaluation of Differently Prepared Microcapsules Yield, Moisture, and Quality

3.1.2. Microcapsules’ Solubility and Essential Oil Particles’ Distribution

3.2. Antioxidant Activity of Active Compounds from Microcapsules and Release In Vitro

3.2.1. Antioxidant Activity of Microcapsules

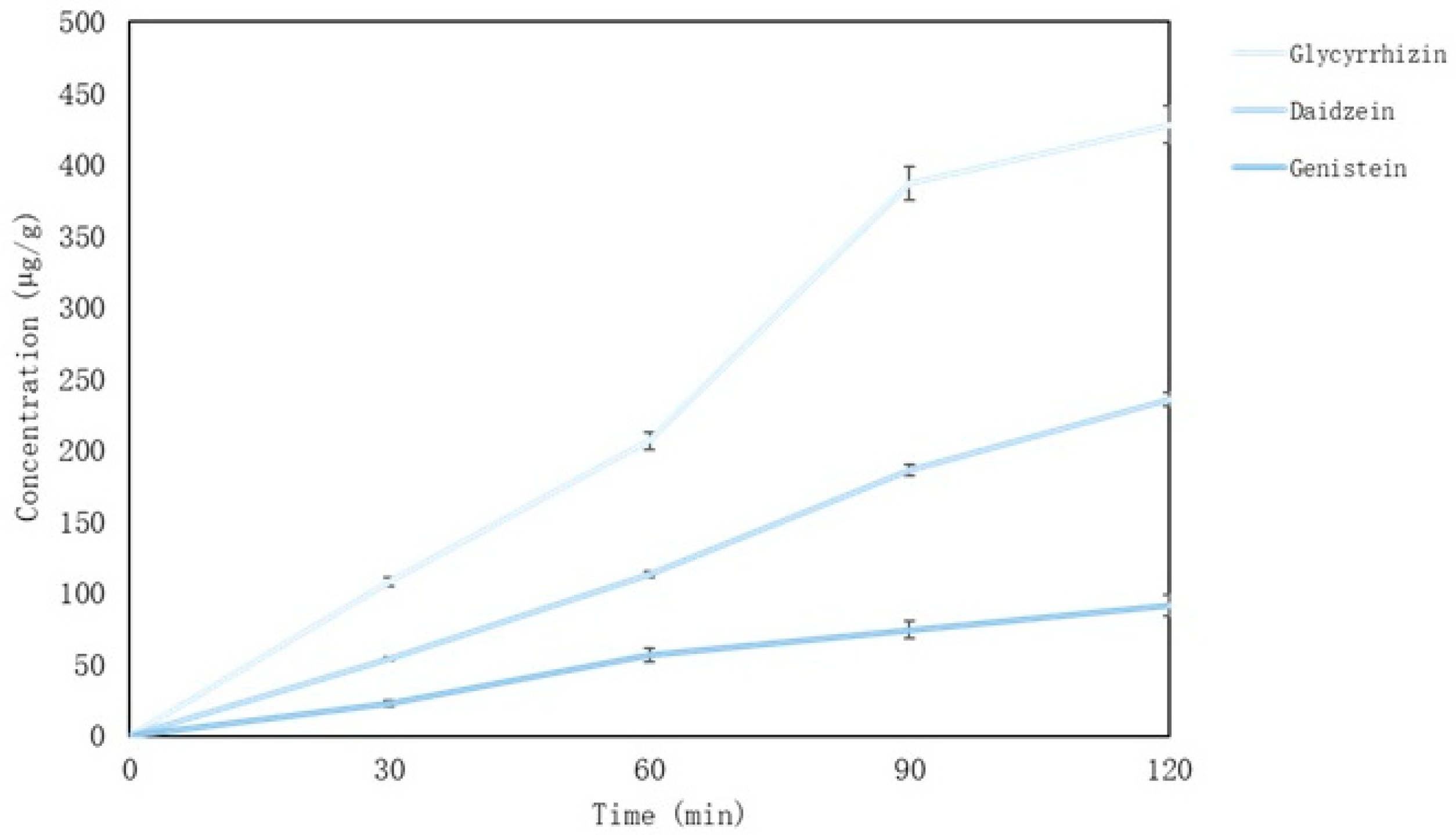

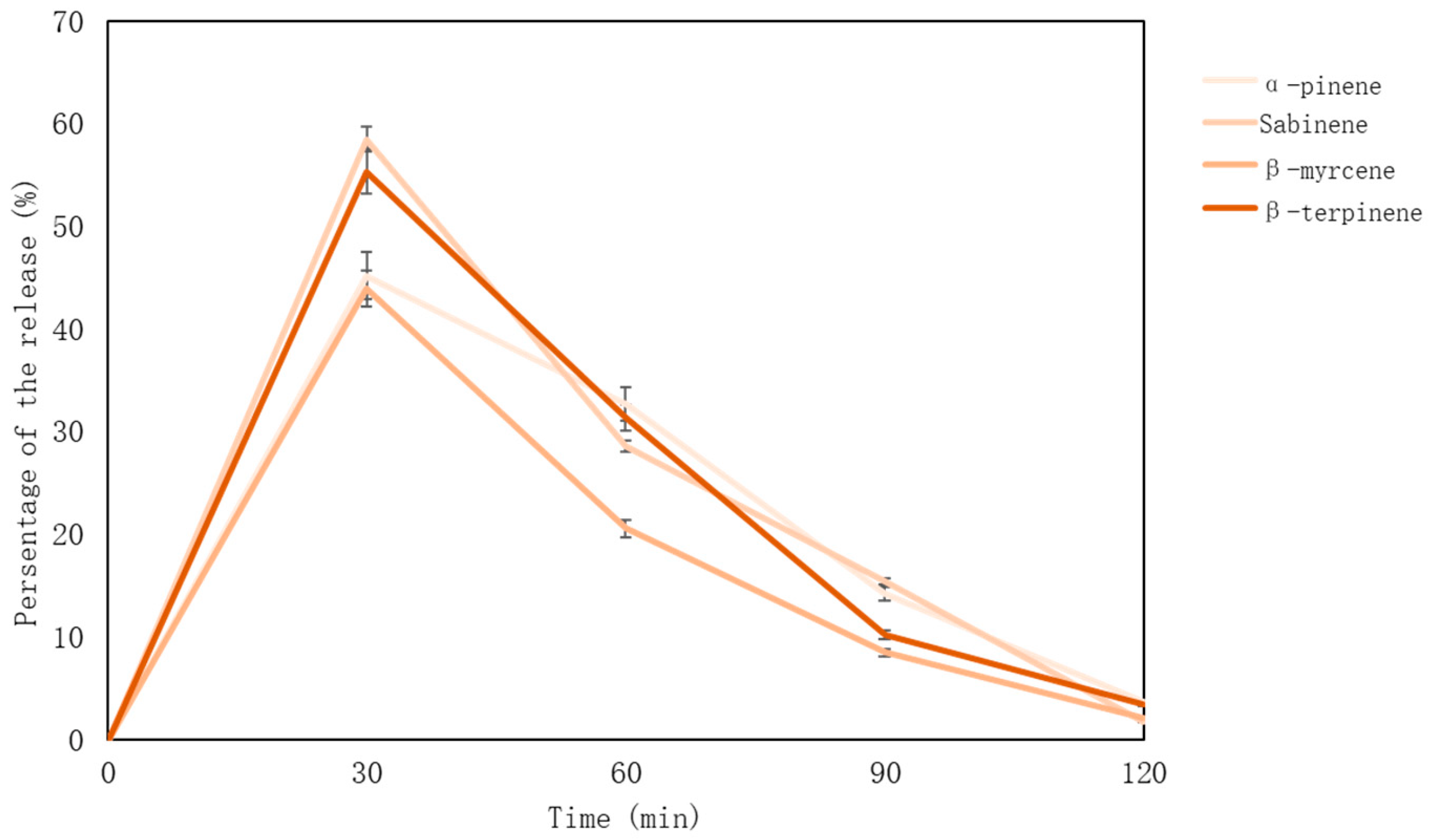

3.2.2. In Vitro Release of Active Compounds from Microcapsules

3.3. Gel Tablets Preparation and Physical Parameters’ Determination and Release in Simulated Media

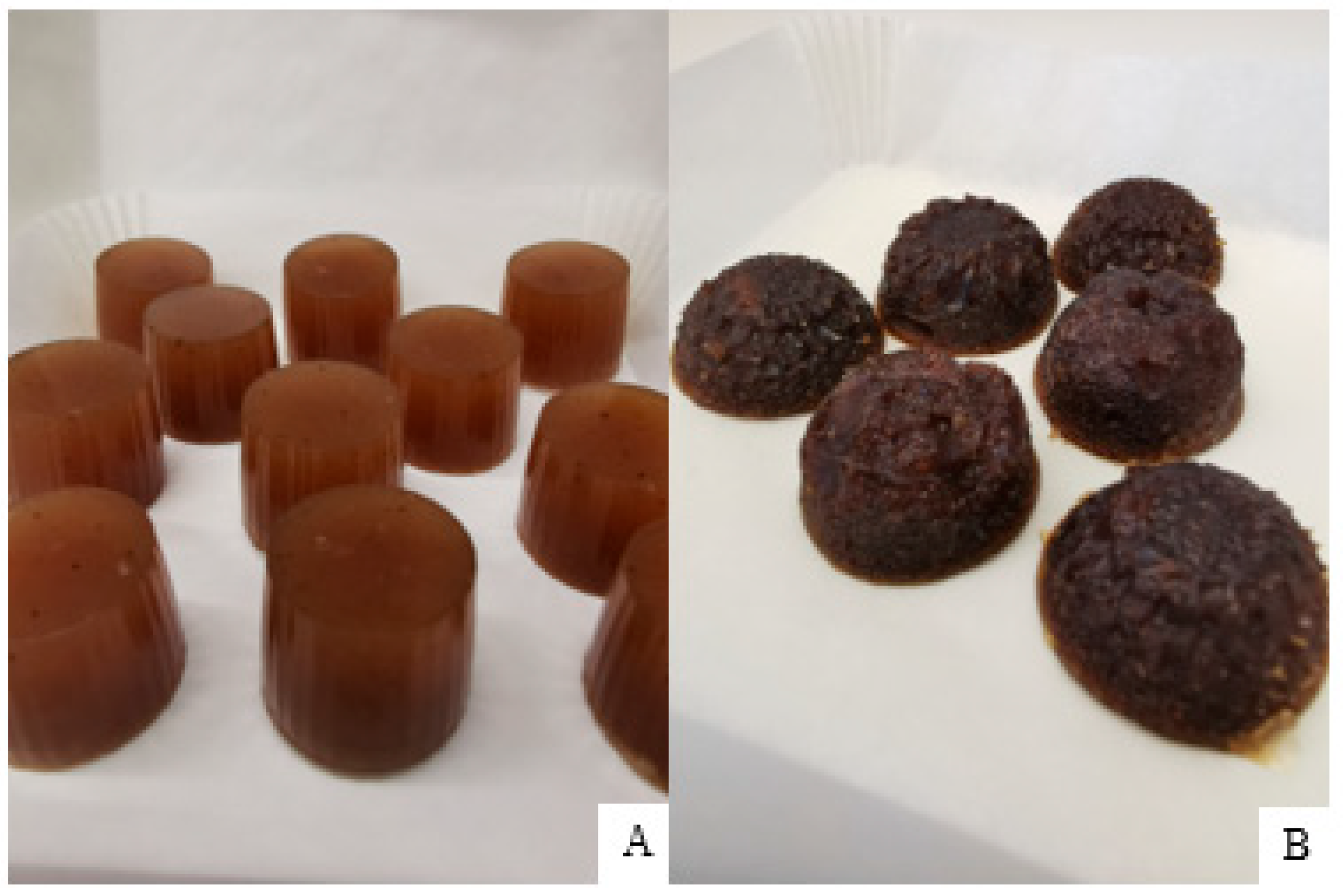

3.3.1. Physical Parameters’ Comparisons of Gel Tablets with Different Bases

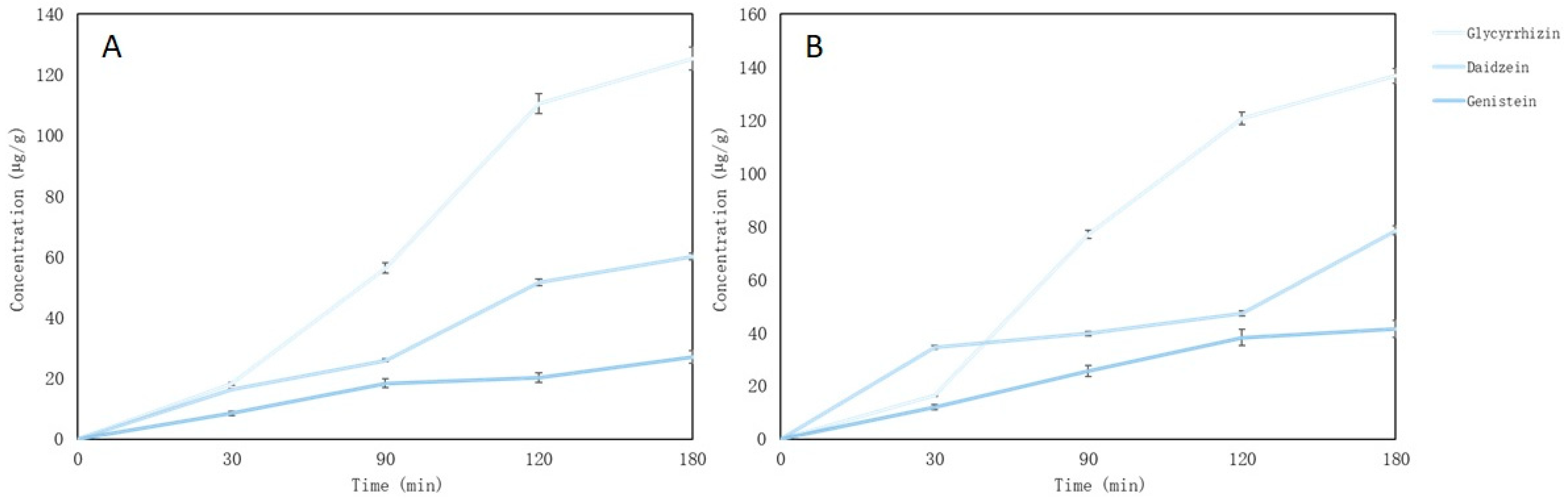

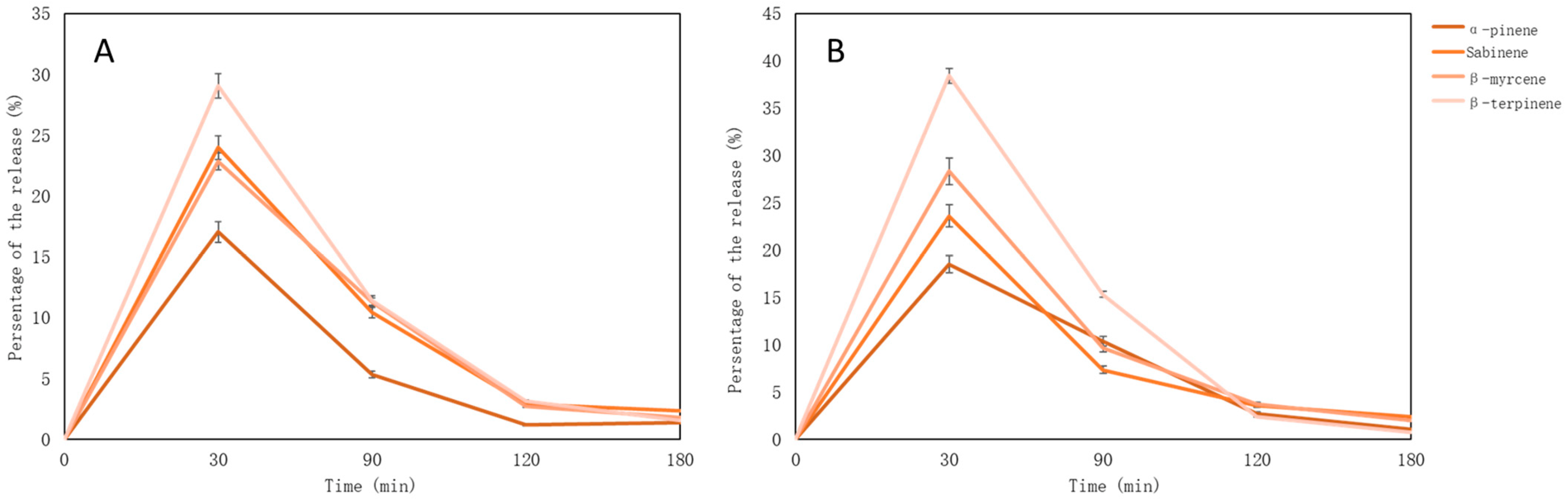

3.3.2. Release of Active Compounds from Different Bases Gel Tablets

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, M.N.; Hemant, K.S.Y.; Ram, M.; Shivakumar, H.G. Microencapsulation: A promising technique for controlled drug delivery. Res. Pharm. Sci. 2010, 5, 65–77. [Google Scholar] [CrossRef] [PubMed]

- Martins, I.M.; Barreiro, M.F.; Coelho, M.; Rodrigues, A.E. Microencapsulation of essential oils with biodegradable polymeric carriers for cosmetic applications. Chem. Eng. J. 2014, 245, 191–200. [Google Scholar] [CrossRef]

- Calderón-Oliver, M.; Ponce-Alquicira, E. The Role of Microencapsulation in Food Application. Molecules 2022, 27, 1499. [Google Scholar] [CrossRef] [PubMed]

- Buljeta, I.; Pichler, A.; Šimunović, J.; Kopjar, M. Polysaccharides as Carriers of Polyphenols: Comparison of Freeze-Drying and Spray-Drying as Encapsulation Techniques. Molecules 2022, 27, 5069. [Google Scholar] [CrossRef] [PubMed]

- Sun-Waterhouse, D.; Wadhwa, S.S.; Waterhouse, G.I.N. Spray-Drying Microencapsulation of Polyphenol Bioactives: A Comparative Study Using Different Natural Fibre Polymers as Encapsulants. Food Bioprocess Technol. 2013, 6, 2376–2388. [Google Scholar] [CrossRef]

- Hoyos-Leyva, J.D.; Bello-Pérez, L.A.; Alvarez-Ramirez, J.; Garcia, H.S. Microencapsulation using starch as wall material: A review. Food Rev. Int. 2018, 34, 148–161. [Google Scholar] [CrossRef]

- Felix, P.H.C.; Birchal, V.S.; Botrel, D.A.; Marques, G.R.; Borges, S.V. Physicochemical and Thermal Stability of Microcapsules of Cinnamon Essential Oil by Spray Drying. J. Food Process. Preserv. 2017, 41, e12919. [Google Scholar] [CrossRef]

- Altay, Ö.; Köprüalan, Ö.; İlter, I.; Koç, M.; Ertekin, F.K.; Jafari, S.M. Spray drying encapsulation of essential oils; process efficiency, formulation strategies, and applications. Crit. Rev. Food Sci. Nutr. 2022, 1–19. [Google Scholar] [CrossRef]

- Obón, J.M.; Luna-Abad, J.P.; Bermejo, B.; Fernández-López, J.A. Thermographic studies of cocurrent and mixed flow spray drying of heat sensitive bioactive compounds. J. Food Eng. 2020, 268, 109745. [Google Scholar] [CrossRef]

- Najjaa, H.; Chekki, R.; Elfalleh, W.; Tlili, H.; Jaballah, S.; Bouzouita, N. Freeze-dried, oven-dried, and microencapsulation of essential oil from Allium sativum as potential preservative agents of minced meat. Food Sci. Nutr. 2020, 8, 1995–2003. [Google Scholar] [CrossRef]

- Chen, Q.; Zhong, F.; Wen, J.; McGillivray, D.; Quek, S.Y. Properties and Stability of Spray-Dried and Freeze-Dried Microcapsules Co-Encapsulated with Fish Oil, Phytosterol Esters, and Limonene. Dry. Technol. 2013, 31, 707–716. [Google Scholar] [CrossRef]

- Moumita, S.; Das, B.; Hasan, U.; Jayabalan, R. Effect of long-term storage on viability and acceptability of lyophilized and spray-dried synbiotic microcapsules in dry functional food formulations. LWT 2018, 96, 127–132. [Google Scholar] [CrossRef]

- Öztürk, H.İ. The effect of different lyophilisation pressures on the microbiological stability, physicochemical, microstructural, and sensorial properties of yoghurt powders. Int. Dairy J. 2022, 129, 105347. [Google Scholar] [CrossRef]

- Dille, M.J.; Hattrem, M.N.; Draget, K.I. Bioactively filled gelatin gels; challenges and opportunities. Food Hydrocoll. 2018, 76, 17–29. [Google Scholar] [CrossRef]

- Baydin, T.; Arntsen, S.W.; Hattrem, M.N.; Draget, K.I. Physical and functional properties of plant-based pre-emulsified chewable gels for the oral delivery of nutraceuticals. Appl. Food Res. 2022, 2, 100225. [Google Scholar] [CrossRef]

- Kuan, Y.H.; Nafchi, A.M.; Huda, N.; Ariffin, F.; Karim, A.A. Effects of sugars on the gelation kinetics and texture of duck feet gelatin. Food Hydrocoll. 2016, 58, 267–275. [Google Scholar] [CrossRef]

- Kazlauskaite, J.A.; Matulyte, I.; Marksa, M.; Lelesius, R.; Pavilonis, A.; Bernatoniene, J. Application of Antiviral, Antioxidant and Antibacterial Glycyrrhiza glabra L., Trifolium pratense L. Extracts and Myristica fragrans Houtt. Essential Oil in Microcapsules. Pharmaceutics 2023, 15, 464. [Google Scholar] [CrossRef]

- Slinkard, K.; Singleton, V.L. Total Phenol Analysis: Automation and Comparison with Manual Methods. Am. J. Enol. Vitic. 1977, 28, 49–55. [Google Scholar] [CrossRef]

- Zhishen, J.; Mengcheng, T.; Jianming, W. The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem. 1999, 64, 555–559. [Google Scholar] [CrossRef]

- Matulyte, I.; Kasparaviciene, G.; Bernatoniene, J. Development of New Formula Microcapsules from Nutmeg Essential Oil Using Sucrose Esters and Magnesium Aluminometasilicate. Pharmaceutics 2020, 12, 628. [Google Scholar] [CrossRef]

- Directorate for the Quality of Medicines and HealthCare of the Council of Europe (EDQM). Dissolution test for solid dosage forms. In European Pharmacopeia, 11th ed.; Directorate for the Quality of Medicines and HealthCare of the Council of Europe (EDQM): Strasbourg, France, 2022; pp. 348–355. [Google Scholar]

- Matulyte, I.; Marksa, M.; Bernatoniene, J. Development of innovative chewable gel tablets containing nutmeg essential oil microcapsules and their physical properties evaluation. Pharmaceutics 2021, 13, 873. [Google Scholar] [CrossRef] [PubMed]

- Miller, N.J.; Rice-Evans, C.; Davies, M.J.; Gopinathan, V.; Milner, A. A Novel Method for Measuring Antioxidant Capacity and its Application to Monitoring the Antioxidant Status in Premature Neonates. Clin. Sci. 1993, 84, 407–412. [Google Scholar] [CrossRef]

- Blois, M.S. Antioxidant Determinations by the Use of a Stable Free Radical. Nature 1958, 181, 1199–1200. [Google Scholar] [CrossRef]

- Benzie, I.F.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef]

- Izadi, M.; Eskandari, M.H.; Niakousari, M.; Shekarforoush, S.; Hanifpour, M.A.; Izadi, Z. Optimisation of a pilot-scale spray drying process for probiotic yoghurt, using response surface methodology. Int. J. Dairy Technol. 2014, 67, 211–219. [Google Scholar] [CrossRef]

- Directorate for the Quality of Medicines and HealthCare of the Council of Europe (EDQM). European Pharmacopoeia; 11th ed.; Directorate for the Quality of Medicines and HealthCare of the Council of Europe (EDQM): Strasbourg, France, 2023. [Google Scholar]

- Mehrabi, M.; Gardy, J.; Talebi, F.A.; Farshchi, A.; Hassanpour, A.; Bayly, A.E. An investigation of the effect of powder flowability on the powder spreading in additive manufacturing. Powder Technol. 2023, 413, 117997. [Google Scholar] [CrossRef]

- Sutton, A.T.; Kriewall, C.S.; Leu, M.C.; Newkirk, J.W. Powder characterisation techniques and effects of powder characteristics on part properties in powder-bed fusion processes. Virtual Phys. Prototyp. 2017, 12, 3–29. [Google Scholar] [CrossRef]

- Tadauchi, T.; Yamada, D.; Koide, Y.; Yamada, M.; Shimada, Y.; Yamazoe, E.; Ito, T.; Tahara, K. Improving the Powder Properties of an Active Pharmaceutical Ingredient (Ethenzamide) with a Silica Nanoparticle Coating for Direct Compaction into Tablets. Powders 2022, 1, 231–242. [Google Scholar] [CrossRef]

- Shofian, N.M.; Hamid, A.A.; Osman, A.; Saari, N.; Anwar, F.; Pak Dek, M.S.; Hairuddin, M.R. Effect of Freeze-Drying on the Antioxidant Compounds and Antioxidant Activity of Selected Tropical Fruits. Int. J. Mol. Sci. 2011, 12, 4678–4692. [Google Scholar] [CrossRef]

- Veiga, R.D.S.D.; Aparecida Da Silva-Buzanello, R.; Corso, M.P.; Canan, C. Essential oils microencapsulated obtained by spray drying: A review. J. Essent. Oil Res. 2019, 31, 457–473. [Google Scholar] [CrossRef]

- Lim, K.; Ma, M.; Dolan, K.D. Effects of Spray Drying on Antioxidant Capacity and Anthocyanidin Content of Blueberry By-Products. J. Food Sci. 2011, 76, H156–H164. [Google Scholar] [CrossRef] [PubMed]

- Guergoletto, K.B.; Bonifácio, K.L.; Barbosa, D.S.; Valezi, D.F.; Salviato, A.; Di Mauro, E.; Ida, E.I.; Garcia, S. Influence of spray-drying and room temperature storage on the anti-and prooxidant properties of fermented jucara pulp. Food Technol. Biotechnol. 2020, 58, 29–37. [Google Scholar] [CrossRef] [PubMed]

- Miadoková, E. Isoflavonoids—An overview of their biological activities and potential health benefits. Interdiscip. Toxicol. 2009, 2, 211–218. [Google Scholar] [CrossRef] [PubMed]

- Ramos-Tovar, E.; Muriel, P. Phytotherapy for the Liver. In Dietary Interventions in Liver Disease; Elsevier: Amsterdam, The Netherlands, 2019; pp. 101–121. ISBN 9780128144671. [Google Scholar] [CrossRef]

- Georgetti, S.R.; Casagrande, R.; Souza, C.R.F.; Oliveira, W.P.; Fonseca, M.J.V. Spray drying of the soybean extract: Effects on chemical properties and antioxidant activity. LWT Food Sci. Technol. 2008, 41, 1521–1527. [Google Scholar] [CrossRef]

- Xin, X.; Essien, S.; Dell, K.; Woo, M.W.; Baroutian, S. Effects of Spray-Drying and Freeze-Drying on Bioactive and Volatile Compounds of Smoke Powder Food Flavouring. Food Bioprocess Technol. 2022, 15, 785–794. [Google Scholar] [CrossRef]

- Kao, T.H.; Chen, B.H. Effects of different carriers on the production of isoflavone powder from soybean cake. Molecules 2007, 12, 917–931. [Google Scholar] [CrossRef]

- Koffi, E.N.; Kassi, A.B.B.; Adje, F.A.; Lozano, Y.F.; Yves-Alain, B. Effect of freeze-drying and spray-drying on total phenolics content and antioxidant activity from aqueous extract of Justicia secunda leaves. Trends Phytochem. Res. 2020, 4, 69–76. [Google Scholar]

- Yang, Z.; Kulkarni, K.; Zhu, W.; Hu, M. Bioavailability and Pharmacokinetics of Genistein: Mechanistic Studies on its ADME. Anticancer Agents Med. Chem. 2012, 12, 1264–1280. [Google Scholar] [CrossRef]

- Setchell, K.D.R.; Faughnan, M.S.; Avades, T.; Zimmer-Nechemias, L.; Brown, N.M.; Wolfe, B.E.; Brashear, W.T.; Desai, P.; Oldfield, M.F.; Botting, N.P.; et al. Comparing the pharmacokinetics of daidzein and genistein with the use of 13C-labeled tracers in premenopausal women. Am. J. Clin. Nutr. 2003, 77, 411–419. [Google Scholar] [CrossRef]

- Qiu, F.; Chen, X.Y.; Song, B.; Zhong, D.F.; Liu, C.X. Influence of dosage forms on pharmacokinetics of daidzein and its main metabolite daidzein-7-O-glucuronide in rats. Acta Pharmacol. Sin. 2005, 26, 1145–1152. [Google Scholar] [CrossRef]

- Rowland, I.; Faughnan, M.; Hoey, L.; Wähälä, K.; Williamson, G.; Cassidy, A. Bioavailability of phyto-oestrogens. Br. J. Nutr. 2003, 89, S45–S58. [Google Scholar] [CrossRef] [PubMed]

- Rossum, T.G.J.V.; Vulto; Man, R.A.D.; Brouwer, J.T.; Schalm, S.W. Glycyrrhizin as a potential treatment for chronic hepatitis C. Aliment. Pharmacol. Ther. 1998, 12, 199–205. [Google Scholar] [CrossRef] [PubMed]

- Messier, C.; Epifano, F.; Genovese, S.; Grenier, D. Licorice and its potential beneficial effects in common oro-dental diseases. Oral Dis. 2012, 18, 32–39. [Google Scholar] [CrossRef]

- Bakry, A.M.; Abbas, S.; Ali, B.; Majeed, H.; Abouelwafa, M.Y.; Mousa, A.; Liang, L. Microencapsulation of Oils: A Comprehensive Review of Benefits, Techniques, and Applications. Compr. Rev. Food Sci. Food Saf. 2016, 15, 143–182. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Mulrey, L.; Byrne, M.; Jaiswal, A.K.; Jaiswal, S. Encapsulation of Essential Oils in Nanocarriers for Active Food Packaging. Foods 2022, 11, 2337. [Google Scholar] [CrossRef]

- Djiuardi, E.; Fardiaz, D.; Purwadaria, H.K. Stability and characteristics of encapsulated nutmeg essential oil as flavor ingredient. Acta Hortic. 2018, 1213, 41–47. [Google Scholar] [CrossRef]

- Salehi, B.; Upadhyay, S.; Erdogan Orhan, I.; Kumar Jugran, A.; L.D. Jayaweera, S.; Dias, D.A.; Sharopov, F.; Taheri, Y.; Martins, N.; Baghalpour, N.; et al. Therapeutic Potential of α- and β-Pinene: A Miracle Gift of Nature. Biomolecules 2019, 9, 738. [Google Scholar] [CrossRef]

- Ryu, Y.; Lee, D.; Jung, S.H.; Lee, K.J.; Jin, H.; Kim, S.J.; Lee, H.M.; Kim, B.; Won, K.J. Sabinene prevents skeletal muscle atrophy by inhibiting the MAPK–MuRF-1 pathway in rats. Int. J. Mol. Sci. 2019, 20, 4955. [Google Scholar] [CrossRef]

- Surendran, S.; Qassadi, F.; Surendran, G.; Lilley, D.; Heinrich, M. Myrcene—What Are the Potential Health Benefits of This Flavouring and Aroma Agent? Front. Nutr. 2021, 8, 699666. [Google Scholar] [CrossRef]

- Kim, T.; Song, B.; Cho, K.S.; Lee, I.S. Therapeutic potential of volatile terpenes and terpenoids from forests for inflammatory diseases. Int. J. Mol. Sci. 2020, 21, 2197. [Google Scholar] [CrossRef]

- Kemala Putri Jauhari, A.; Gerry Septian Riseno, J.; Hidrotunnisa, H. Microencapsulation of nutmeg essential oil (Myristica fragrans) via spray drying: Effects of feed emulsion parameters on emulsion and powder characteristics. Adv. Food Sci. Sustain. Agric. Agroind. Eng. 2022, 5, 1–20. [Google Scholar] [CrossRef]

- Dong, X.; Wu, B.; Deng, Q.; Wei, F.; Chen, H.; Yang, C.; Cong, R. Microencapsulation of nutmeg essential oil by spray-drying with different wall materials. Oil Crop Sci. 2018, 3, 258. [Google Scholar] [CrossRef]

- Matulyte, I.; Mataraite, A.; Velziene, S.; Bernatoniene, J. The Effect of Myristica fragrans on Texture Properties and Shelf-Life of Innovative Chewable Gel Tablets. Pharmaceutics 2021, 13, 238. [Google Scholar] [CrossRef]

- Jarvis, M.C. Structure and properties of pectin gels in plant cell walls. Plant Cell Environ. 1984, 7, 153–164. [Google Scholar] [CrossRef]

- Munarin, F.; Tanzi, M.C.; Petrini, P. Advances in biomedical applications of pectin gels. Int. J. Biol. Macromol. 2012, 51, 681–689. [Google Scholar] [CrossRef]

- Ge, H.; Wu, Y.; Woshnak, L.L.; Mitmesser, S.H. Effects of hydrocolloids, acids and nutrients on gelatin network in gummies. Food Hydrocoll. 2021, 113, 106549. [Google Scholar] [CrossRef]

- Marfil, P.H.M.; Anhê, A.C.B.M.; Telis, V.R.N. Texture and Microstructure of Gelatin/Corn Starch-Based Gummy Confections. Food Biophys. 2012, 7, 236–243. [Google Scholar] [CrossRef]

- Rani, K.C.; Jayani, N.I.E.; Feneke, F.; Melanda, S. Preparation and evaluation of gelatin and pectin-based Moringa oleifera chewable-gummy tablets. IOP Conf. Ser. Earth Environ. Sci. 2021, 913, 012082. [Google Scholar] [CrossRef]

| Ingredient | Amount (%) |

|---|---|

| Red clover extract | 12.4 |

| Liquorice extract | 49.59 |

| Nutmeg essential oil | 0.83 |

| Gum Arabic | 5.58 |

| Maltodextrin | 18.6 |

| Inulin | 13.2 |

| Ingredient | Amount (%) |

|---|---|

| Apple juice | 38.8 |

| Apple puree | 14.9 |

| Banana powder | 20.7 |

| Gelatin | 7.3 |

| Water | 10.3 |

| Glycerol | 8.0 |

| Ingredient | Sample | ||||

|---|---|---|---|---|---|

| A | B | C | D | E | |

| Amount (%) | |||||

| Apple juice * | 76.2 | 65.2 | 46.1 | 40.4 | - |

| Apple puree * | 20.3 | 25.3 | 41.4 | 23.2 | 55.7 |

| Blackcurrant puree * | - | - | 9.5 | - | - |

| Buckthorn puree * | - | 6.3 | - | - | - |

| Banana powder | - | - | - | - | 29.3 |

| Lingonberry powder | - | - | - | 15.4 | - |

| Pectin | 2.0 | 1.7 | 1.5 | 2.0 | 2.0 |

| Citric acid 50% solution | 1.5 | 1.5 | 1.5 | 1.5 | 2.0 |

| Water | - | - | - | 17.5 | 11.5 |

| Samples | Yield, % | Moisture, % | Carr Index, % | Hausner Ratio Value |

|---|---|---|---|---|

| LM | 85.34 ± 3.17 * | 4.45 ± 0.23 * | 20.83 | 1.263 |

| SDM | 45.12 ± 7.81 | 3.24 ± 0.36 | 38.71 * | 1.632 * |

| Sample | Total Phenolic Content, mg GA/g dw | Total Flavonoids Content, mg RU/g dw | DPPH, µg TE/g dw | ABTS, µg TE/g dw | FRAP, mg FS/g dw |

|---|---|---|---|---|---|

| LM | 11.47 ± 0.01 * | 7.56 ± 0.02 * | 8.85 ± 0.01 * | 136.73 ± 0.73 * | 252.62 ± 0.01 * |

| SDM | 8.56 ± 0.42 | 5.21 ± 0.22 | 5.27 ± 0.02 | 96.41 ± 0.93 | 173.25 ± 0.25 |

| Samples | Mass of the Sample | Firmness (g) | Stickiness (g) | Hardness (g) | Springiness (%) |

|---|---|---|---|---|---|

| P a | 5.51 ± 0.67 | 1027.8 ± 179.04 *** | −24.39 ± 1.85 *** | 609.3 ± 233.03 *** | 41.79 ± 0.74 *** |

| PLM | 6.04 ± 0.58 | 1303.3 ± 377.28 * | −27.25 ± 15.15 | 798.09 ± 201.12 | 38.38 ± 0.23 * |

| G b | 5.73 ± 0.25 | 895.12 ± 62.78 | −20.23 ± 5.92 | 738.27 ± 27.24 | 64.58 ± 1.35 |

| GLM | 5.77 ± 0.36 | 548.69 ± 12.63 ** | −34.04 ± 2.91 ** | 549.51 ± 11.36 ** | 68.02 ± 2.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kazlauskaite, J.A.; Matulyte, I.; Marksa, M.; Bernatoniene, J. Nutmeg Essential Oil, Red Clover, and Liquorice Extracts Microencapsulation Method Selection for the Release of Active Compounds from Gel Tablets of Different Bases. Pharmaceutics 2023, 15, 949. https://doi.org/10.3390/pharmaceutics15030949

Kazlauskaite JA, Matulyte I, Marksa M, Bernatoniene J. Nutmeg Essential Oil, Red Clover, and Liquorice Extracts Microencapsulation Method Selection for the Release of Active Compounds from Gel Tablets of Different Bases. Pharmaceutics. 2023; 15(3):949. https://doi.org/10.3390/pharmaceutics15030949

Chicago/Turabian StyleKazlauskaite, Jurga Andreja, Inga Matulyte, Mindaugas Marksa, and Jurga Bernatoniene. 2023. "Nutmeg Essential Oil, Red Clover, and Liquorice Extracts Microencapsulation Method Selection for the Release of Active Compounds from Gel Tablets of Different Bases" Pharmaceutics 15, no. 3: 949. https://doi.org/10.3390/pharmaceutics15030949

APA StyleKazlauskaite, J. A., Matulyte, I., Marksa, M., & Bernatoniene, J. (2023). Nutmeg Essential Oil, Red Clover, and Liquorice Extracts Microencapsulation Method Selection for the Release of Active Compounds from Gel Tablets of Different Bases. Pharmaceutics, 15(3), 949. https://doi.org/10.3390/pharmaceutics15030949