Impact of Particle and Equipment Properties on Residence Time Distribution of Pharmaceutical Excipients in Rotary Tablet Presses

Abstract

1. Introduction

1.1. Powder Flow in Rotary Tablet Presses

1.2. Continuous Manufacturing in Pharmaceutical Industry

1.3. Residence Time Distribution in Tablet Production

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Production of Tracer Powder

2.2.2. Analysis of Particle Size Distribution

2.2.3. Determination of Bulk and Tapped Density

2.2.4. Ring Shear Cell Measurements

2.2.5. Experimental Setup of Residence Time Experiments

2.2.6. Determination of Methylene Blue Concentration

2.2.7. Evaluation of RTDs

3. Results and Discussion

3.1. Impact of Dyeing Process on Powder Properties

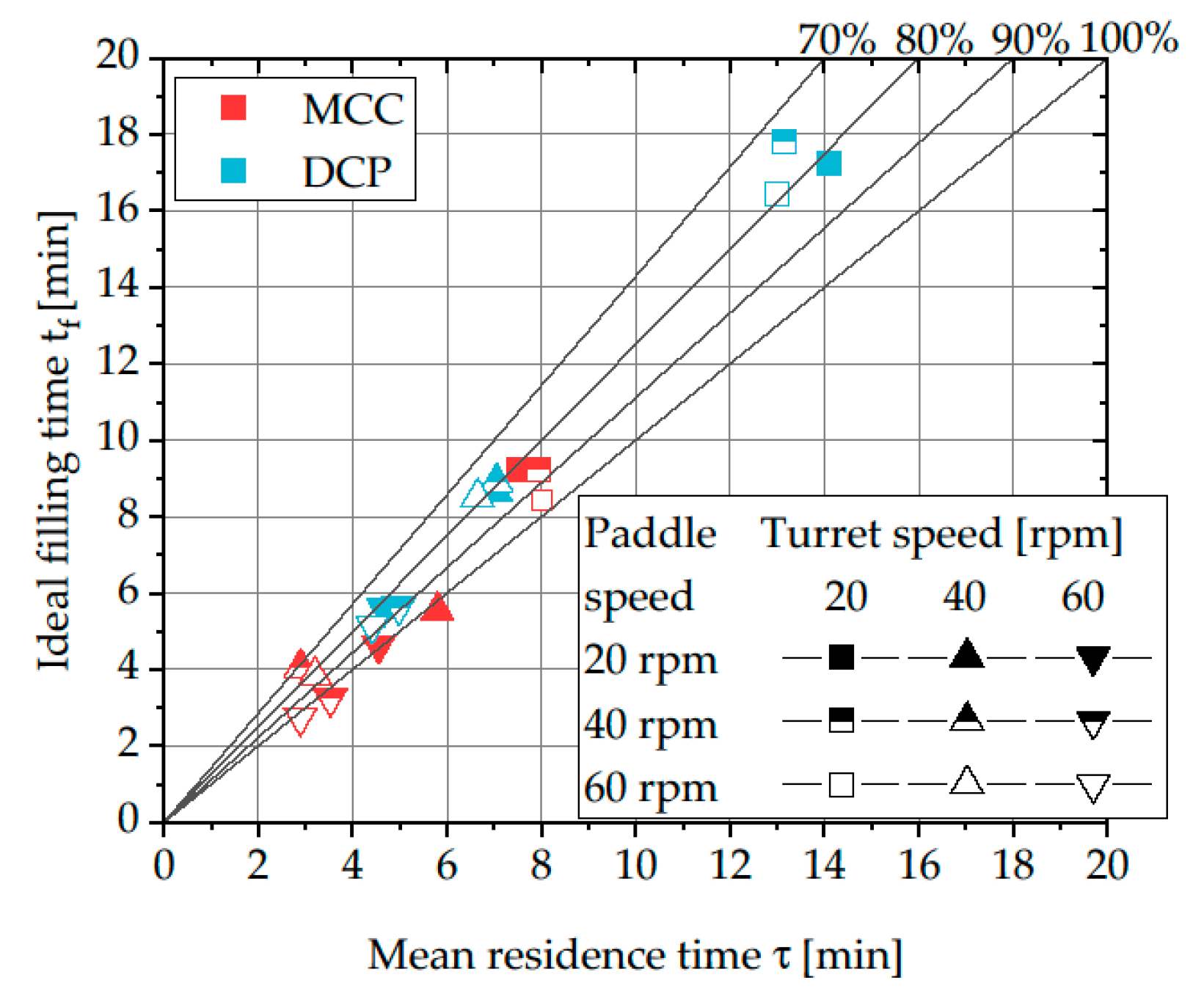

3.2. Estimation of Filling Level inside the Feed Frame of the XL 100

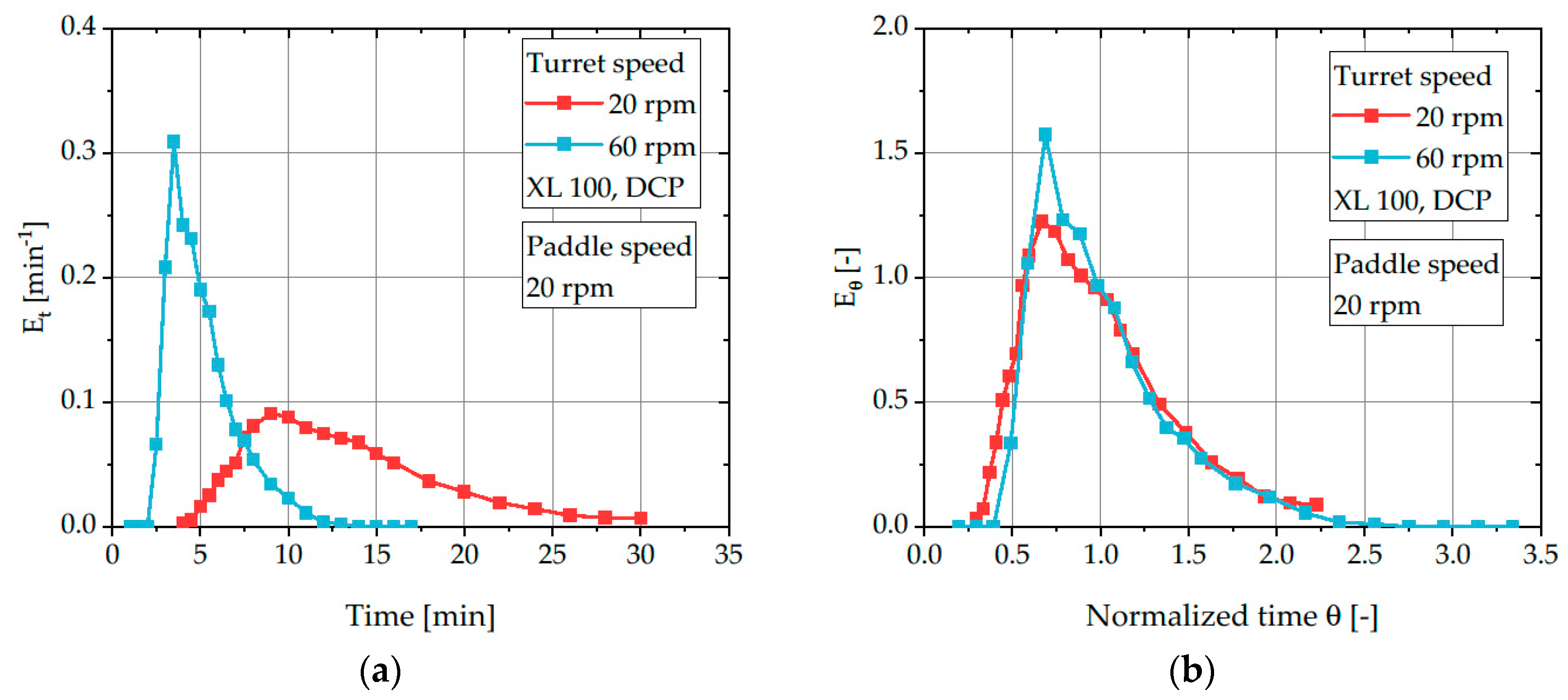

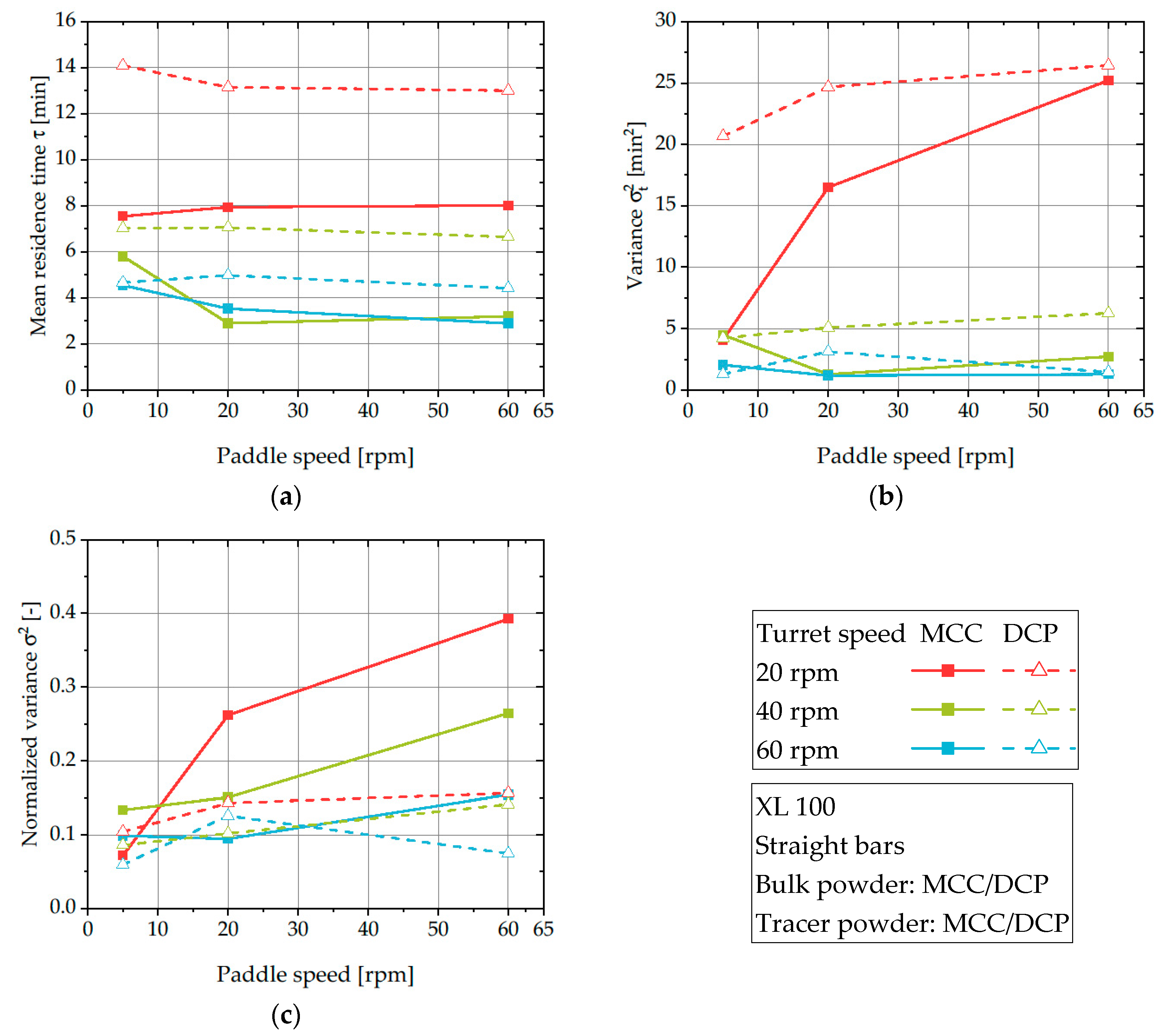

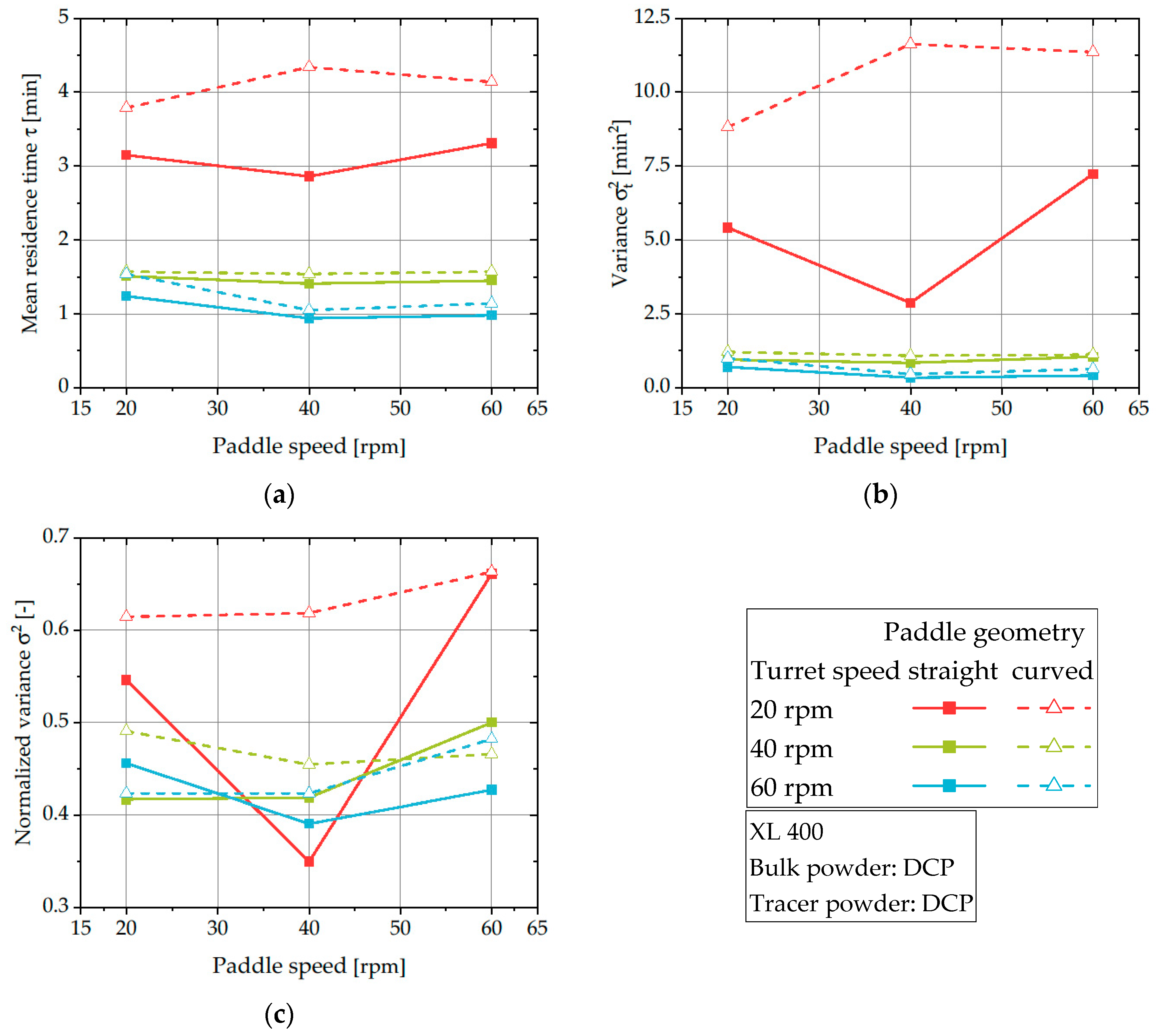

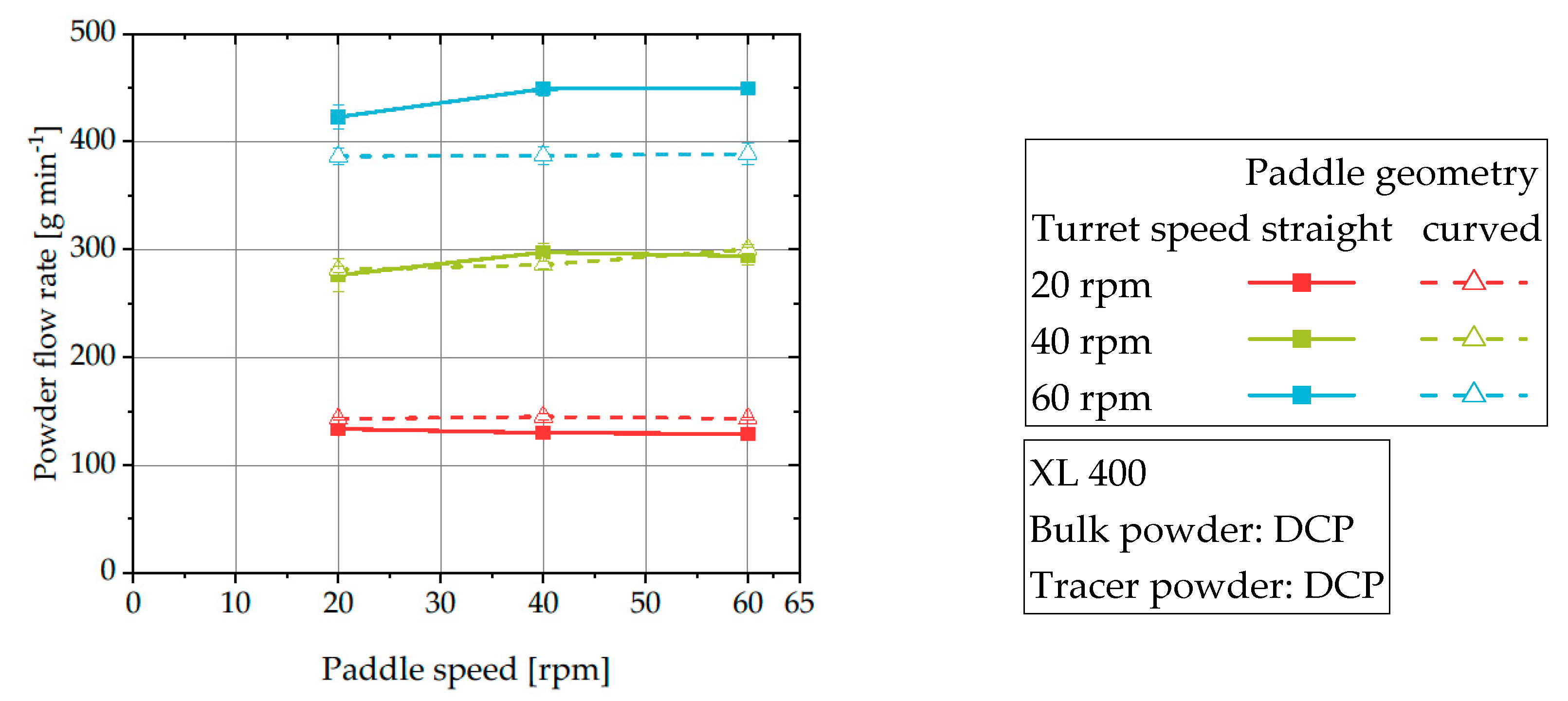

3.3. Impact of Turret and Paddle Speed on RTDs

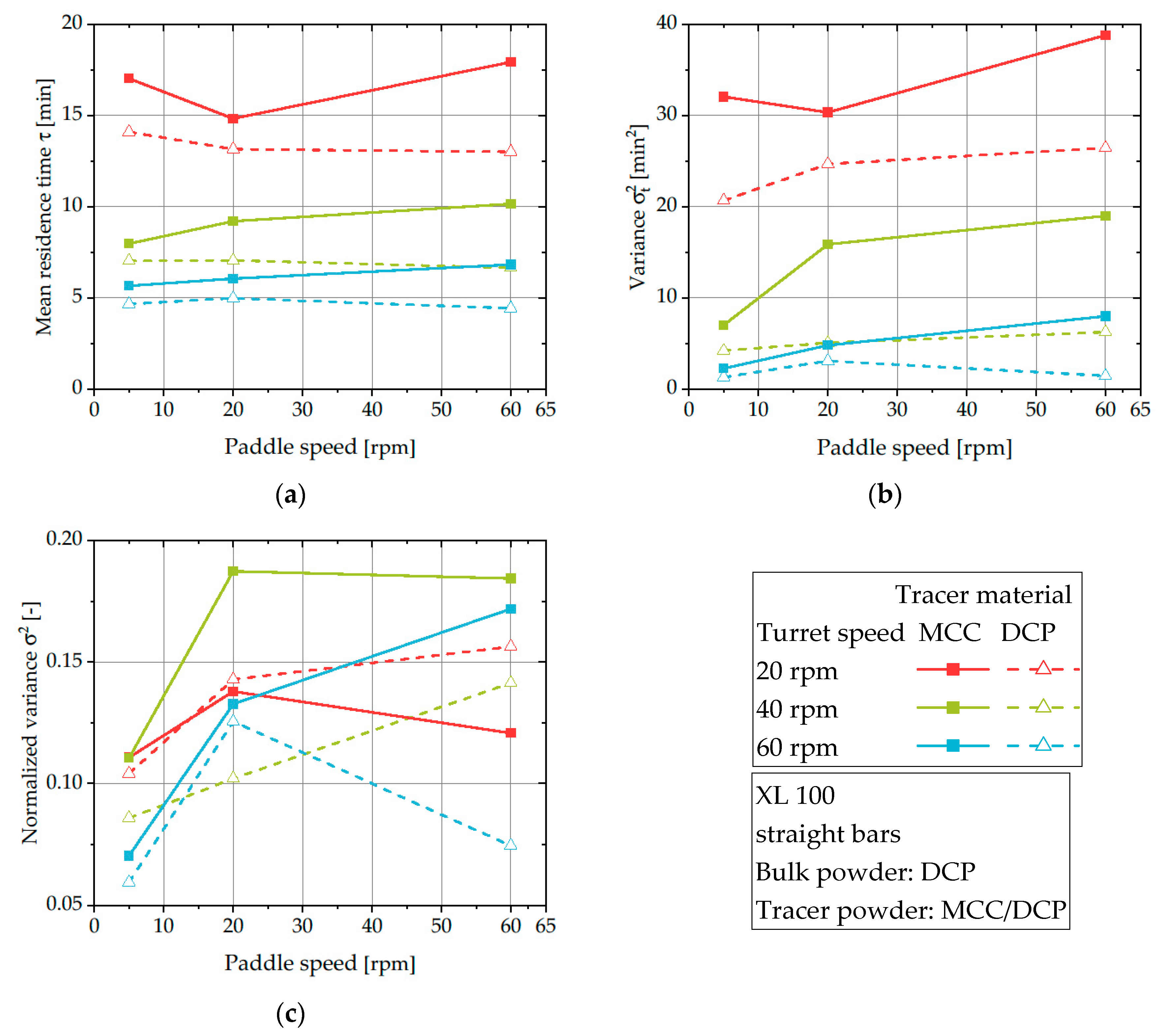

3.4. Influence of Tracer Properties on RTDs

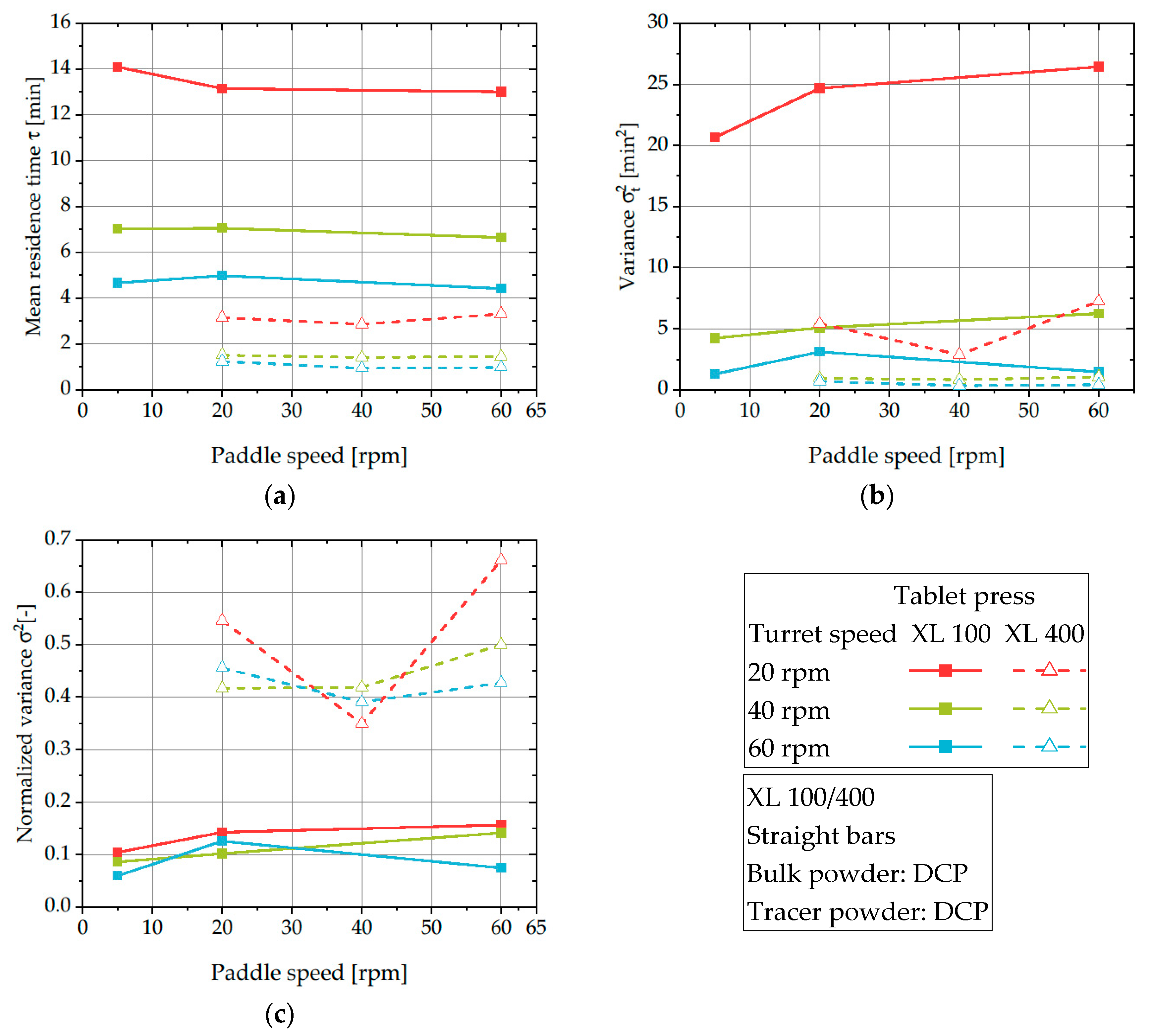

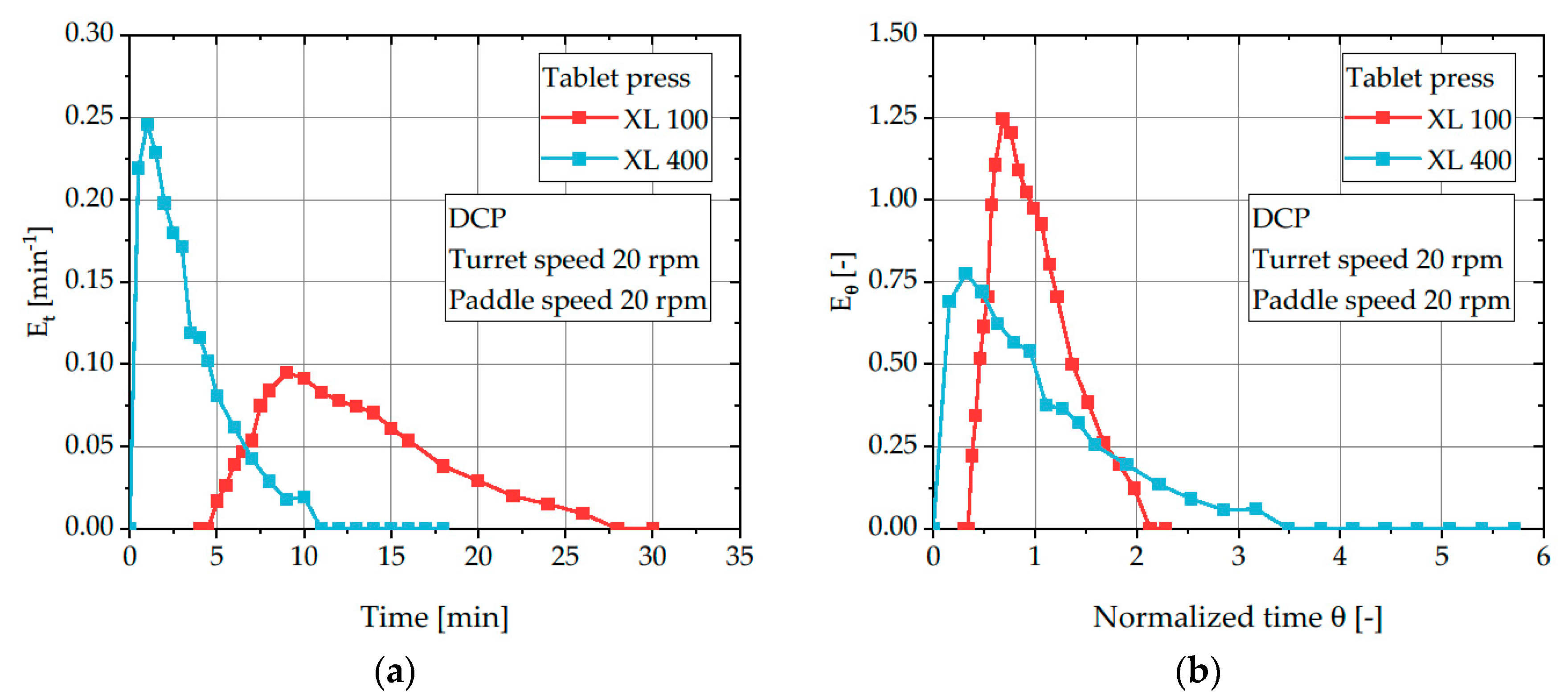

3.5. Transferability of RTDs Results Between Different Scales of Rotary Tablet Presses

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Peeters, E.; de Beer, T.; Vervaet, C.; Remon, J.-P. Reduction of tablet weight variability by optimizing paddle speed in the forced feeder of a high-speed rotary tablet press. Drug Dev. Ind. Pharm. 2015, 41, 530–539. [Google Scholar] [CrossRef] [PubMed]

- Sinka, I.C.; Schneider, L.C.R.; Cocks, A.C.F. Measurement of the flow properties of powders with special reference to die fill. Int. J. Pharm. 2004, 280, 27–38. [Google Scholar] [CrossRef] [PubMed]

- Schneider, L.; Sinka, I.C.; Cocks, A. Characterisation of the flow behaviour of pharmaceutical powders using a model die–shoe filling system. Powder Technol. 2007, 173, 59–71. [Google Scholar] [CrossRef]

- Sun, C.C. Setting the bar for powder flow properties in successful high speed tableting. Powder Technol. 2010, 201, 106–108. [Google Scholar] [CrossRef]

- Baserinia, R.; Sinka, I.C. Powder die filling under gravity and suction fill mechanisms. Int. J. Pharm. 2019, 563, 135–155. [Google Scholar] [CrossRef] [PubMed]

- Mills, L.A.; Sinka, I.C. Effect of particle size and density on the die fill of powders. Eur. J. Pharm. Biopharm. 2013, 84, 642–652. [Google Scholar] [CrossRef]

- Jackson, S.; Sinka, I.C.; Cocks, A.C.F. The effect of suction during die fill on a rotary tablet press. Eur. J. Pharm. Biopharm. 2007, 65, 253–256. [Google Scholar] [CrossRef]

- Mehrotra, A.; Chaudhuri, B.; Faqih, A.; Tomassone, M.S.; Muzzio, F.J. A modeling approach for understanding effects of powder flow properties on tablet weight variability. Powder Technol. 2009, 188, 295–300. [Google Scholar] [CrossRef]

- Prescott, J.K.; Barnum, R.A. On powder flowability. Pharm. Technol. 2000, 24, 60–85. [Google Scholar]

- Goh, H.P.; Heng, P.W.S.; Liew, C.V. Understanding effects of process parameters and forced feeding on die filling. Eur. J. Pharm. Sci. 2018, 122, 105–115. [Google Scholar] [CrossRef]

- Mendez, R.; Muzzio, F.; Velazquez, C. Study of the effects of feed frames on powder blend properties during the filling of tablet press dies. Powder Technol. 2010, 200, 105–116. [Google Scholar] [CrossRef]

- Mendez, R.; Muzzio, F.J.; Velazquez, C. Powder hydrophobicity and flow properties: Effect of feed frame design and operating parameters. AIChE J. 2012, 58, 697–706. [Google Scholar] [CrossRef]

- Narang, A.S.; Rao, V.M.; Guo, H.; Lu, J.; Desai, D.S. Effect of force feeder on tablet strength during compression. Int. J. Pharm. 2010, 401, 7–15. [Google Scholar] [CrossRef] [PubMed]

- Mendez, R.; Velazquez, C.; Muzzio, F.J. Effect of feed frame design and operating parameters on powder attrition, particle breakage, and powder properties. Powder Technol. 2012, 229, 253–260. [Google Scholar] [CrossRef]

- Hildebrandt, C.; Gopireddy, S.R.; Scherließ, R.; Urbanetz, N.A. Investigation of powder flow within a pharmaceutical tablet press force feeder—A DEM approach. Powder Technol. 2019, 345, 616–632. [Google Scholar] [CrossRef]

- Mateo-Ortiz, D.; Méndez, R. Relationship between residence time distribution and forces applied by paddles on powder attrition during the die filling process. Powder Technol. 2015, 278, 111–117. [Google Scholar] [CrossRef]

- Mateo-Ortiz, D.; Muzzio, F.J.; Méndez, R. Particle size segregation promoted by powder flow in confined space: The die filling process case. Powder Technol. 2014, 262, 215–222. [Google Scholar] [CrossRef]

- Simonaho, S.-P.; Ketolainen, J.; Ervasti, T.; Toiviainen, M.; Korhonen, O. Continuous manufacturing of tablets with PROMIS-line—Introduction and case studies from continuous feeding, blending and tableting. Eur. J. Pharm. Sci. 2016, 90, 38–46. [Google Scholar] [CrossRef]

- Lee, S.L.; O’Connor, T.F.; Yang, X.; Cruz, C.N.; Chatterjee, S.; Madurawe, R.D.; Moore, C.M.V.; Yu, L.X.; Woodcock, J. Modernizing Pharmaceutical Manufacturing: From Batch to Continuous Production. J. Pharm. Innov. 2015, 10, 191–199. [Google Scholar] [CrossRef]

- Ierapetritou, M.; Muzzio, F.; Reklaitis, G. Perspectives on the continuous manufacturing of powder-based pharmaceutical processes. AIChE J. 2016, 62, 1846–1862. [Google Scholar] [CrossRef]

- Wahl, P.R.; Fruhmann, G.; Sacher, S.; Straka, G.; Sowinski, S.; Khinast, J.G. PAT for tableting: Inline monitoring of API and excipients via NIR spectroscopy. Eur. J. Pharm. Biopharm. 2014, 87, 271–278. [Google Scholar] [CrossRef] [PubMed]

- Mateo-Ortiz, D.; Colon, Y.; Romañach, R.J.; Méndez, R. Analysis of powder phenomena inside a Fette 3090 feed frame using in-line NIR spectroscopy. J. Pharm. Biomed. Anal. 2014, 100, 40–49. [Google Scholar] [CrossRef]

- Gao, Y.; Vanarase, A.; Muzzio, F.; Ierapetritou, M. Characterizing continuous powder mixing using residence time distribution. Chem. Eng. Sci. 2011, 66, 417–425. [Google Scholar] [CrossRef]

- Mangal, H.; Kleinebudde, P. Experimental determination of residence time distribution in continuous dry granulation. Int. J. Pharm. 2017, 524, 91–100. [Google Scholar] [CrossRef]

- Reitz, E.; Podhaisky, H.; Ely, D.; Thommes, M. Residence time modeling of hot melt extrusion processes. Eur. J. Pharm. Biopharm. 2013, 85, 1200–1205. [Google Scholar] [CrossRef]

- Engisch, W.; Muzzio, F. Using residence time distributions (rtds) to address the traceability of raw materials in continuous pharmaceutical manufacturing. J. Pharm. Innov. 2016, 11, 64–81. [Google Scholar] [CrossRef]

- Dülle, M.; Özcoban, H.; Leopold, C.S. Analysis of the powder behavior and the residence time distribution within a production scale rotary tablet press. Eur. J. Pharm. Sci. 2018, 125, 205–214. [Google Scholar] [CrossRef]

- Dülle, M.; Özcoban, H.; Leopold, C.S. Investigations on the residence time distribution of a three-chamber feed frame with special focus on its geometric and parametric setups. Powder Technol. 2018, 331, 276–285. [Google Scholar] [CrossRef]

- Dülle, M.; Özcoban, H.; Leopold, C.S. Influence of the feed frame design on the powder behavior and the residence time distribution. Int. J. Pharm. 2019, 565, 523–532. [Google Scholar] [CrossRef]

- Dülle, M.; Özcoban, H.; Leopold, C.S. The effect of different feed frame components on the powder behavior and the residence time distribution with regard to the continuous manufacturing of tablets. Int. J. Pharm. 2019, 555, 220–227. [Google Scholar] [CrossRef]

- Ketterhagen, W.R. Simulation of powder flow in a lab-scale tablet press feed frame: Effects of design and operating parameters on measures of tablet quality. Powder Technol. 2015, 275, 361–374. [Google Scholar] [CrossRef]

- Carr, R.L. Evaluating flow properties of solids. Chem. Eng. 1965, 72, 163–168. [Google Scholar]

- Schulze, D. Powders and bulk solids. In Behavior, Characterization, Storage and Flow; Springer: Berlin, Germany, 2008; ISBN 978-3-540-73767-4. [Google Scholar]

- Danckwerts, P.V. Continuous flow systems. Chem. Eng. Sci. 1953, 2, 1–13. [Google Scholar] [CrossRef]

- Nauman, E.B. Residence time theory. Ind. Eng. Chem. Res. 2008, 47, 3752–3766. [Google Scholar] [CrossRef]

- Zakhvatayeva, A.; Zhong, W.; Makroo, H.A.; Hare, C.; Wu, C.Y. An experimental study of die filling of pharmaceutical powders using a rotary die filling system. Int. J. Pharm. 2018, 553, 84–96. [Google Scholar] [CrossRef]

- Dühlmeyer, K.P.; Özcoban, H.; Leopold, C.S. A novel method for determination of the filling level in the feed frame of a rotary tablet press. Drug Dev. Ind. Pharm. 2018, 44, 1744–1751. [Google Scholar] [CrossRef]

- Dühlmeyer, K.P.; Özcoban, H.; Leopold, C.S. Inline monitoring of the powder filling level within a rotary tablet press feed frame. Powder Technol. 2019, 351, 134–143. [Google Scholar] [CrossRef]

| Tablet Press | Turret Speed (rpm) | Paddle Speed of Dosing Paddle (rpm) | Paddle Geometry of Dosing Paddle |

|---|---|---|---|

| XL 100 | 20, 40, 60 | 5, 20, 60 | Rectangular, straight |

| XL 400 | 20, 40, 60 | 20, 40, 60 | Rectangular, curved |

| Round, curved |

| Tablet Press | Material | Filling Height (mm) | Dosing Height (mm) |

|---|---|---|---|

| XL 100 | MCC | 14 | 10 |

| DCP | 8 | 5 | |

| XL 400 | DCP | 14 | 9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puckhaber, D.; Eichler, S.; Kwade, A.; Finke, J.H. Impact of Particle and Equipment Properties on Residence Time Distribution of Pharmaceutical Excipients in Rotary Tablet Presses. Pharmaceutics 2020, 12, 283. https://doi.org/10.3390/pharmaceutics12030283

Puckhaber D, Eichler S, Kwade A, Finke JH. Impact of Particle and Equipment Properties on Residence Time Distribution of Pharmaceutical Excipients in Rotary Tablet Presses. Pharmaceutics. 2020; 12(3):283. https://doi.org/10.3390/pharmaceutics12030283

Chicago/Turabian StylePuckhaber, Daniel, Sebastian Eichler, Arno Kwade, and Jan Henrik Finke. 2020. "Impact of Particle and Equipment Properties on Residence Time Distribution of Pharmaceutical Excipients in Rotary Tablet Presses" Pharmaceutics 12, no. 3: 283. https://doi.org/10.3390/pharmaceutics12030283

APA StylePuckhaber, D., Eichler, S., Kwade, A., & Finke, J. H. (2020). Impact of Particle and Equipment Properties on Residence Time Distribution of Pharmaceutical Excipients in Rotary Tablet Presses. Pharmaceutics, 12(3), 283. https://doi.org/10.3390/pharmaceutics12030283