Colour Homogenisation and Photostability of Beech Wood (Fagus sylvatica L.) as Affected by Mild Steaming and Light-Induced Natural Ageing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Ageing Exposures

2.3. Evaluation of Colour Change

2.4. ATR-FTIR Spectroscopy

2.5. Statistical Analyses

3. Results

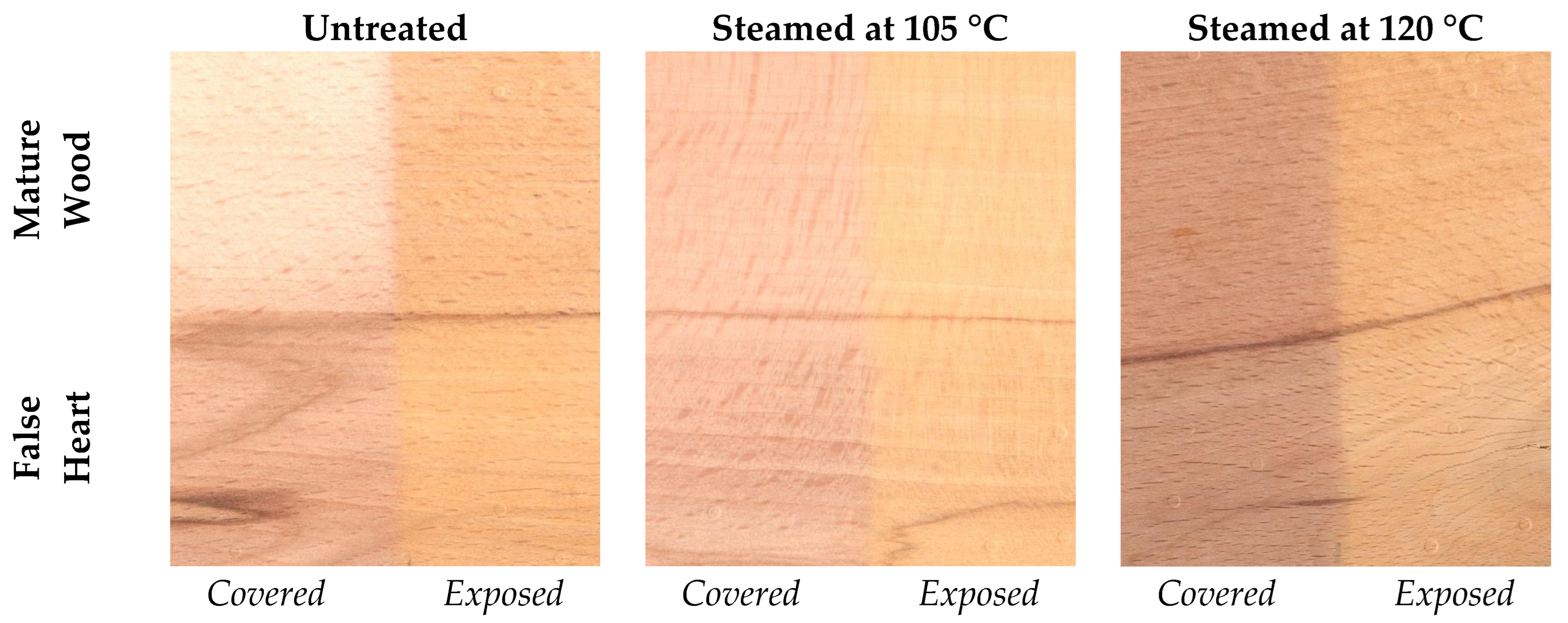

3.1. Colour Changes Due to Steaming

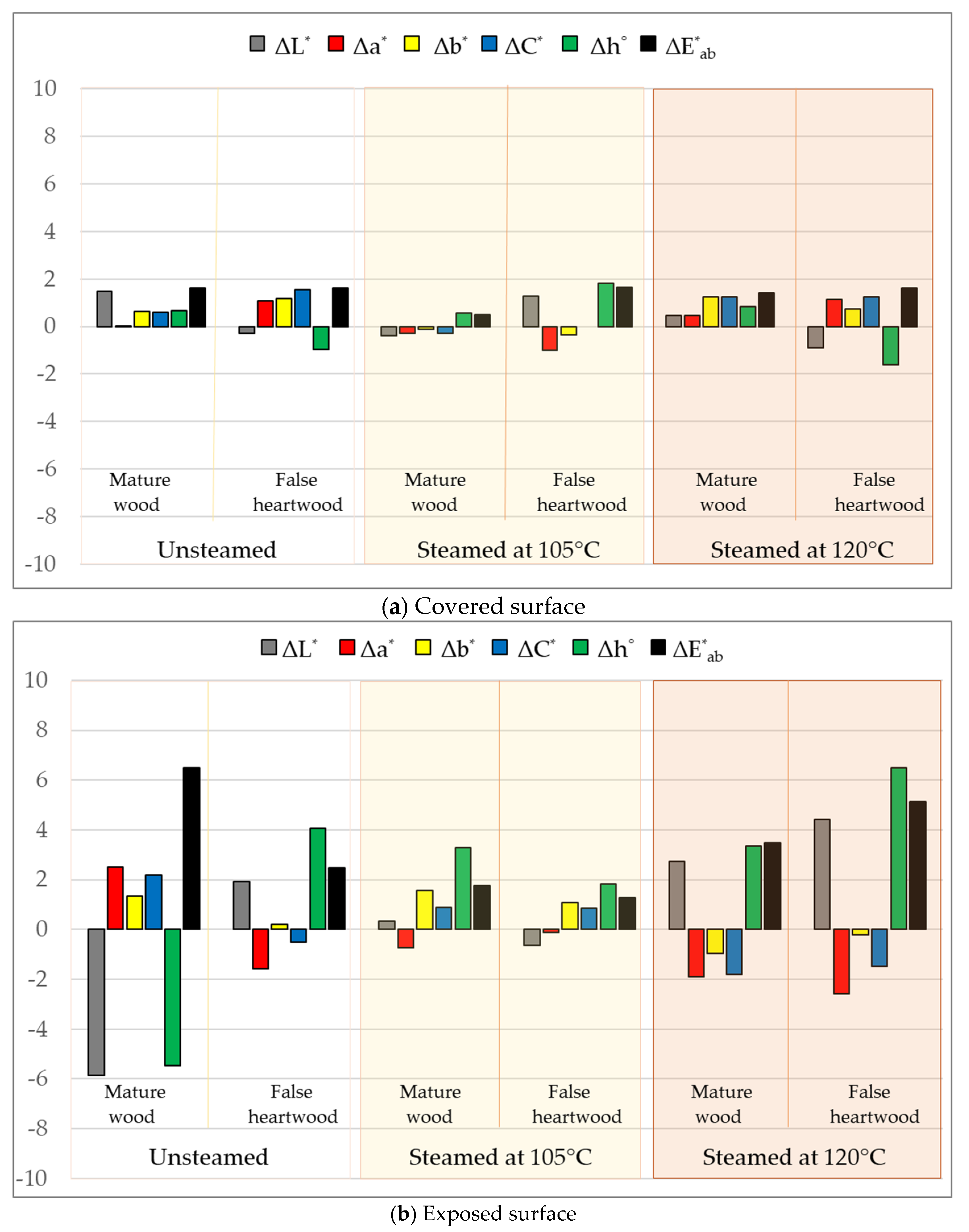

3.2. Colour Changes After Ageing

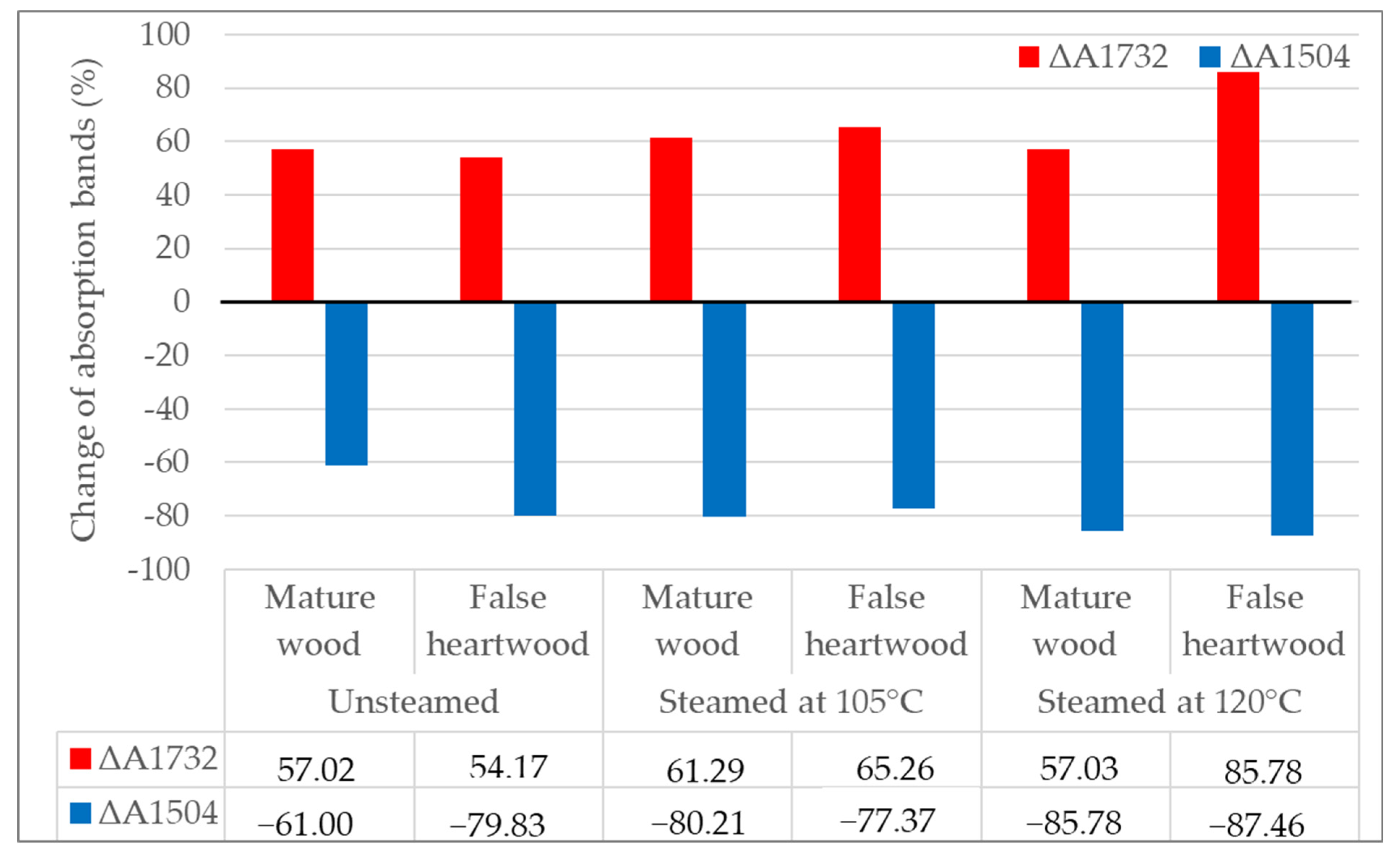

3.3. Chemical Changes Detected by ATR-FTIR

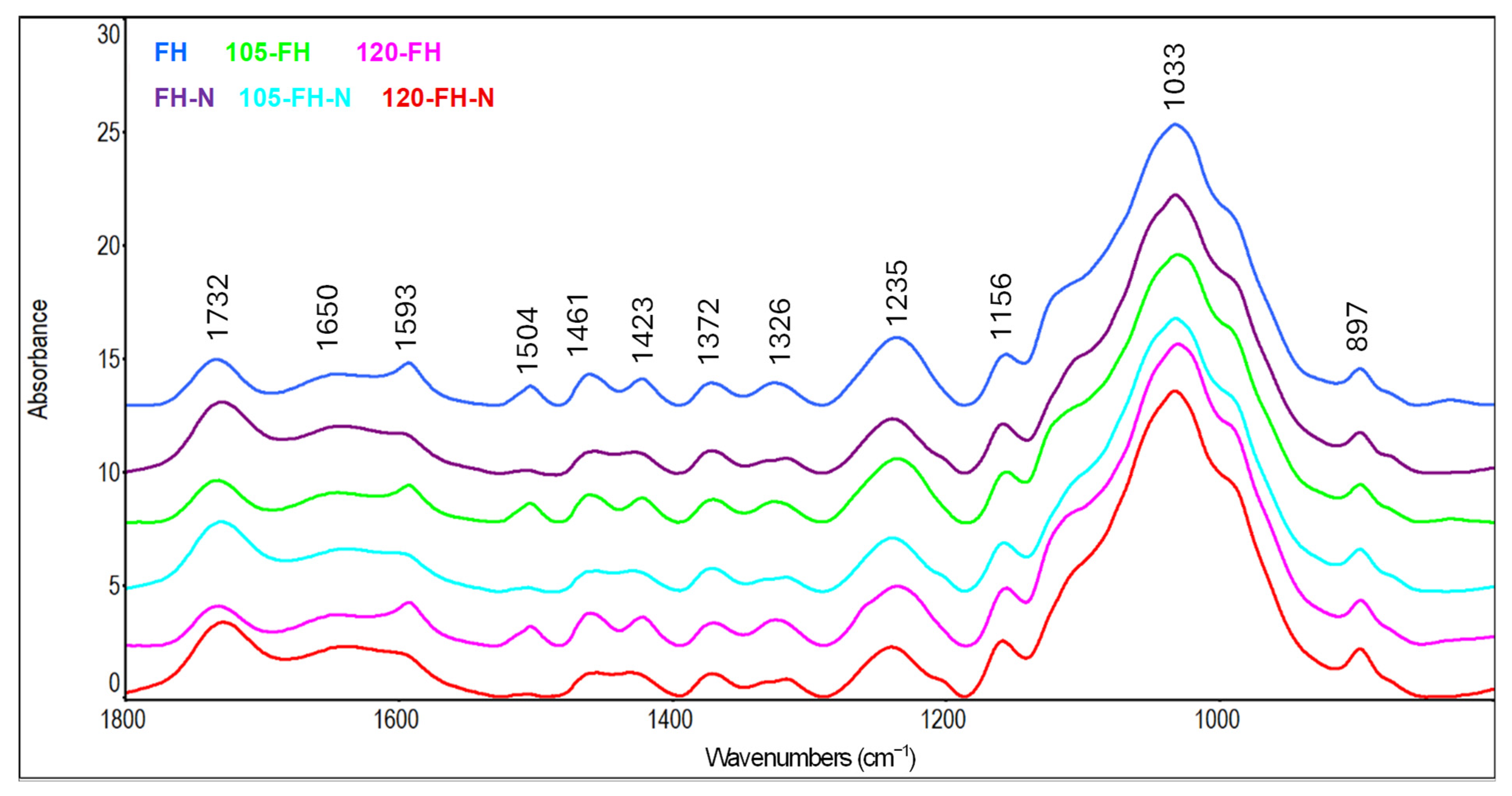

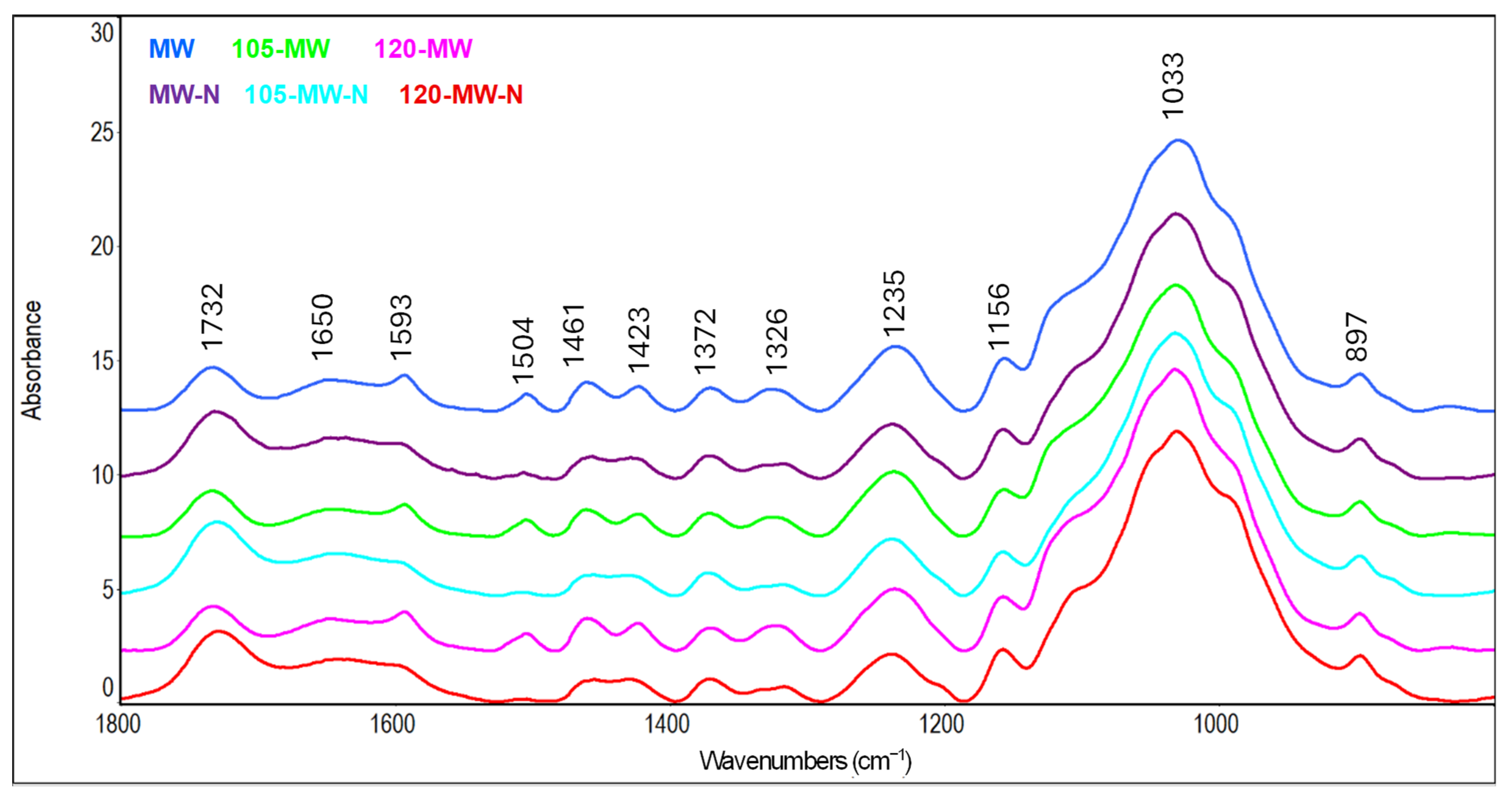

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Zhuang, Z.; Liu, Y.; Ding, F.; Tang, M. Color Classification and Texture Recognition System of Solid Wood Panels. Forests 2021, 12, 1154. [Google Scholar] [CrossRef]

- Sedliačiková, M.; Moresová, M. Are Consumers Interested in Colored Beech Wood and Furniture Products? Forests 2022, 13, 1470. [Google Scholar] [CrossRef]

- Dzurenda, L. Natural Variability of the Color of Beech Wood in the Color Space CIE L*a*b*. Forests 2023, 14, 1103. [Google Scholar] [CrossRef]

- Slabejová, G.; Vidholdová, Z.; Šmidriaková, M. Effect of Two Different Ageing Exposures on the Colour Stability of Transparent Polyurethane Finishing. Polymers 2023, 15, 3313. [Google Scholar] [CrossRef] [PubMed]

- Salca, E.-A.; Krystofiak, T.; Lis, B.; Hiziroglu, S. Glossiness Evaluation of Coated Wood Surfaces as Function of Varnish Type and Exposure to Different Conditions. Coatings 2021, 11, 558. [Google Scholar] [CrossRef]

- Dzurenda, L.; Dudiak, M.; Výbohová, E. Influence of UV Radiation on the Color Change of the Surface of Steamed Maple Wood with Saturated Water Steam. Polymers 2022, 14, 217. [Google Scholar] [CrossRef] [PubMed]

- Solmaz, M.E.; Mutlu, A.Y.; Alankus, G.; Kılıç, V.; Bayram, A.; Horzum, N. Quantifying colorimetric tests using a smartphone app based on machine learning classifiers. Sens. Actuators B Chem. 2018, 255, 1967–1973. [Google Scholar] [CrossRef]

- Joh, M.; Kumaran, S.; Shin, Y.; Cha, H.; Oh, E.; Lee, K.H.; Choi, H.J. An ensemble model of machine learning regression techniques and colour spaces integrated with a colour sensor: Application to colour-changing biochemical assays. RSC Adv. 2025, 15, 1754–1765. [Google Scholar] [CrossRef]

- Wagner, S.; Collet, C.; Madsen, P.; Nakashizuka, T.; Nyland, R.D.; Sagheb-Talebi, K. Beech regeneration research: From ecological to silvicultural aspects. For. Ecol. Manag. 2010, 259, 2172–2182. [Google Scholar] [CrossRef]

- Pramreiter, M.; Grabner, M. The Utilization of European Beech Wood (Fagus sylvatica L.) in Europe. Forests 2023, 14, 1419. [Google Scholar] [CrossRef]

- Baar, J.; Paschová, Z.; Čermák, P.; Wimmer, R. Color changes of various wood species in response to moisture. Wood Fiber Sci. 2019, 51, 119–131. [Google Scholar] [CrossRef]

- Ghorbanian Far, M.; Najafian Ashrafi, M.; Shaabani Asrami, H.; Amiri Moghadam, Y.; Bari, E.; Niemz, P.; Hosseinpourpia, R.; Ribera, J. Physical and mechanical properties of different beech wood species grown at various climate conditions: A review. Holzforschung 2024, 78, 377–386. [Google Scholar] [CrossRef]

- Klement, I.; Vilkovská, T.; Vilkovský, P. Cross warping during various drying processes of beech wood (Fagus sylvatica L.). Acta Fac. Xylolog. Zvo. 2024, 66, 13–22. [Google Scholar]

- Kučerová, V.; Hrčka, R.; Hýrošová, T. Chemical Composition as the Indicator of Thermally Treated Pine (Pinus sylvestris L.) Wood Colour. Forests 2024, 15, 1186. [Google Scholar] [CrossRef]

- da Silva, R.A.F.; Setter, C.; Mazette, S.S.; De Melo, R.R.; Stangerlin, D.M. Colorimetry of wood from thirty tropical species. Ciência Madeira 2017, 8, 36–41. [Google Scholar]

- Vidholdová, Z.; Iždinský, J.; Reinprecht, L. Aesthetic valuation of tropical wood colour by colorimetry. Ann. Wars. Univ. Life Sci. SGGW For. Wood Technol. 2018, 104, 302–306. [Google Scholar]

- Reinprecht, L.; Mamoňová, M.; Pánek, M.; Kačík, F. The impact of natural and artificial weathering on the visual, colour and structural changes of seven tropical woods. Eur. J. Wood Prod. 2018, 76, 175–190. [Google Scholar] [CrossRef]

- Dzurenda, L.; Dudiak, M. The effect of steaming on the colour change of false heartwood beech. Acta Fac. Xylolog. Zvo. 2024, 66, 14–34. [Google Scholar]

- Hon, D.S.N.; Shiraishi, N. Wood and Cellulosic Chemistry, 2nd ed.; MarcelDekker: New York, NY, USA, 2001. [Google Scholar]

- Faix, O. Classification of lignins from different botanical origins by FTIR spectroscopy. Holzforschung 1991, 45, 21–27. [Google Scholar] [CrossRef]

- Pavlič, M.; Petrič, M. Comparison of visual and instrumental assessment of colour differences on finished wooden surfaces. Drv. Ind. 2020, 71, 201–207. [Google Scholar] [CrossRef]

- Czajkowski, Ł.; Olek, W.; Weres, J. Effects of heat treatment on thermal properties of European beech wood. Eur. J. Wood Prod. 2020, 78, 425–431. [Google Scholar] [CrossRef]

- Godinho, D.; Araújo, S.; Quilhó, T.; Diamantino, T.C.; Gominho, J. The behavior of thermally modified wood after exposure in maritime/industrial and urban environments. Heliyon 2024, 10, e25020. [Google Scholar] [CrossRef] [PubMed]

- Nemeth, R.; Hill, C.A.; Takats, P.; Tolvaj, L. Chemical changes of wood during steaming measured by IR spectroscopy. Eng. Sci. 2014, 11, 95–101. [Google Scholar] [CrossRef]

- Dianišková, M.; Babiak, M.; Tolvaj, L. Color homogenisation of cherrywood (Cerasus avium L.) and black locust (Robinia pseudoaccacia L.) during steaming. Wood Res. 2008, 53, 45–58. [Google Scholar]

- Tolvaj, L.; Nemeth, R.; Varga, D.; Molnar, S. Colour homogenisation of beech wood by steam treatment. Drewno 2009, 52, 5–17. [Google Scholar]

- Dzurenda, L.; Dudiak, M. Homogenization of the colour of beech sapwood and false heartwood by the steaming process. Forests 2024, 15, 1009. [Google Scholar] [CrossRef]

- Geffert, A.; Výbohová, E.; Geffertová, J. Characterization of the changes of colour and some wood components on the surface of steamed beech wood. Acta Fac. Xylolog. Zvo. 2017, 59, 49–57. [Google Scholar]

- Feist, W.C.; Hon, D.N.-S. Chemistry and weathering and protection. In The Chemistry of Solid Wood; Rowell, R.M., Ed.; Advances in Chemistry Series 207; American Chemical Society: Washington, DC, USA, 1984; pp. 349–370. [Google Scholar]

- Timar, M.C.; Varodi, A.; Hacibektasoglu, M.; Campean, M. Color and FTIR analysis of chemical changes in beech wood (Fagus sylvatica L.) after light steaming and heat treatment in two different environments. BioResources 2016, 11, 8325–8343. [Google Scholar] [CrossRef]

- Todaro, L.; D’Auria, M.; Langerame, F.; Salvi, A.M.; Scopa, A. Surface characterization of untreated and hydro-thermally pre-treated Turkey oak woods after UV-C irradiation. Surf. Interface Anal. 2015, 47, 206–215. [Google Scholar] [CrossRef]

- Výbohová, E.; Oberle, A. Chemical characterisation of European beech (Fagus sylvatica L.) mature wood and false heartwood. Acta Fac. Xylolog. Zvo. 2023, 65, 13–23. [Google Scholar]

- Gašparík, M.; Zeidler, A.; Výbohová, E.; Kačíková, D.; Kačík, F. Chemical changes of polysaccharides in heat-treated European beech wood. J. Wood Sci. 2024, 70, 38. [Google Scholar] [CrossRef]

- Dzurenda, L.; Dudiak, M.; Kučerová, V. Differences in Some Physical and Chemical Properties of Beechwood with False Heartwood, Mature Wood and Sapwood. Forests 2023, 14, 1123. [Google Scholar] [CrossRef]

- Andrady, A.L.; Heikkilä, A.M.; Pandey, K.K.; Bruckman, L.S.; White, C.C.; Zhu, M.; Zhu, L. Effects of UV radiation on natural and synthetic materials. Photochem. Photobiol. Sci. 2023, 22, 1177–1202. [Google Scholar] [CrossRef] [PubMed]

- Volf, I.; Ignat, I.; Neamtu, M.; Popa, V.I. Thermal stability, antioxidant activity, and photo-oxidation of natural polyphenols. Chem. Pap. 2014, 68, 121–129. [Google Scholar] [CrossRef]

| Wood Colour Parameters | Unsteamed | Steamed at 105 °C | Steamed at 120 °C | |||

|---|---|---|---|---|---|---|

| Mature Wood | False Heartwood | Mature Wood | False Heartwood | Mature Wood | False Heartwood | |

| L* | 81.57 (0.88) [79.90–82.70] | 66.71 (1.76) [63.70–68.90] | 69.46 (2.53) [59.20–71.60] | 66.32 (2.40) [62.80–71.50] | 58.09 (1.68) [56.90–65.00] | 54.65 (0.97) [52.20–56.10] |

| a* | 5.74 (0.50) [4.90–6.60] | 10.88 (0.48) [10.30–11.70] | 10.81 (0.44) [10.00–11.60] | 10.03 (0.80) [8.40–11.70] | 10.85 (0.93) [7.10–11.70] | 10.87 (0.62) [10.00–11.90] |

| b* | 15.20 (0.39) [14.70–15.80] | 18.30 (0.79) [17.40–19.70] | 17.82 (0.38) [17.00–18.40] | 16.73 (0.55) [15.50–17.60] | 17.72 (0.54) [16.90–18.70] | 15.67 (0.38) [14.90–16.30] |

| C* | 16.27 (0.50) [15.70–17.10] | 21.28 (0.90) [20.20–22.70] | 20.81 (0.53) [19.70–21.70] | 19.52 (0.84) [17.90–21.10] | 20.75 (0.65) [19.50–21.80] | 19.07 (0.57) [18.00–20.00] |

| h° | 69.31 (1.29) [67.30–72.10] | 59.24 (0.52) [58.30–60.10] | 58.81 (0.67) [57.70–59.90] | 59.13 (1.45) [56.30–62.00] | 58.52 (2.45) [57.10–68.60] | 55.29 (1.26) [53.00–56.70] |

| Wood Colour Parameters | Unsteamed | Steamed at 105 °C | Steamed at 120 °C | |||

|---|---|---|---|---|---|---|

| Mature Wood | False Heartwood | Mature Wood | False Heartwood | Mature Wood | False Heartwood | |

| Covered | ||||||

| L* | 80.08 (0.83) [78.80–81.00] | 66.98 (1.40) [65.40–68.90] | 69.84 (0.87) [68.80–71.00] | 65.06 (2.20) [63.80–69.20] | 57.62 (0.56) [56.90–58.50] | 55.54 (1.52) [52.70–56.60] |

| a* | 5.72 (0.31) [5.30–6.20] | 9.80 (0.51) [9.30–10.70] | 11.10 (0.45) [10.50–11.60] | 11.02 (0.34) [10.50–11.50] | 10.38 (0.25) [10.0–10.60] | 9.74 (0.21) [9.50–9.90] |

| b* | 14.58 (0.28) [14.10–14.90] | 17.14 (0.27) [16.90–17.50] | 17.94 (0.46) [17.20–18.30] | 17.10 (0.25) [16.70–17.40] | 16.48 (1.14) [15.30–18.50] | 14.94 (0.32) [14.40–15.30] |

| C* | 15.68 (0.22) [15.40–16.00] | 19.72 (0.41) [19.40–20.40] | 21.08 (0.66) [20.10–21.70] | 19.52 (0.84) [17.90–21.10] | 19.50 (1.06) [18.30–21.30] | 17.84 (0.32) [17.30–18.20] |

| h° | 68.66 (1.38) [66.20–70.10] | 60.22 (1.14) [58.40–61.20] | 58.26 (0.50) [57.50–58.90] | 57.30 (0.81) [56.50–58.70] | 57.70 (1.36) [56.70–60.20] | 56.90 (0.55) [56.50–57.80] |

| Exposed | ||||||

| L* | 75.72 (1.21) [74.30–77.60] | 68.64 (1.81) [66.50–70.20] | 69.80 (0.49) [68.90–70.20] | 65.70 (1.94) [63.10–68.50] | 60.84 (0.30) [60.40–61.30] | 59.08 (1.21) [57.00–60.10] |

| a* | 8.26 (0.38) [7.70–8.70] | 9.32 (0.52) [8.60–10.10] | 10.08 (0.23) [9.80–10.40] | 9.90 (0.33) [9.40–10.30] | 8.94 (0.22) [8.70–9.20] | 8.30 (0.15) [8.10–8.50] |

| b* | 16.54 (0.91) [15.10–17.30] | 18.50 (0.24) [18.20–18.80] | 19.38 (0.18) [19.10–19.60] | 17.82 (0.32) [17.30–18.10] | 16.76 (0.20) [16.50–17.00] | 15.46 (0.53) [14.60–16.00] |

| C* | 18.46 (0.97) [17.20–19.40] | 20.76 (0.45) [20.20–21.40] | 21.70 (0.18) [21.50–21.90] | 20.36 (0.36) [19.90–20.80] | 18.96 (0.25) [18.70–19.30] | 17.58 (0.54) [16.70–18.10] |

| h° | 63.84 (1.50) [61.90–66.20] | 63.32 (0.99) [61.90–64.80] | 62.10 (0.16) [61.80–62.20] | 60.96 (0.83) [60.00–62.30] | 61.88 (0.29) [61.60–62.20] | 61.78 (0.50) [61.00–62.30] |

| L* | a* | b* | C* | h° | |

|---|---|---|---|---|---|

| Absolute | ●●● | ●●● | ●●● | ●●● | ●●● |

| Treatment | ●●● | ●●● | ●●● | ●●● | ●●● |

| Time | ●● | ●●● | ●●● | — | ●●● |

| Part | ●●● | ●●● | — | ● | ●●● |

| Treatment × Time | ●●● | ●●● | ●●● | ●●● | ●●● |

| Treatment × Part | ●●● | ●●● | ●●● | ●●● | ●●● |

| Time × Part | ●●● | ●●● | — | ●●● | ●●● |

| Treatment × Time × Part | ●●● | ●●● | ●● | ●●● | ●●● |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidholdová, Z.; Slabejová, G.; Výbohová, E. Colour Homogenisation and Photostability of Beech Wood (Fagus sylvatica L.) as Affected by Mild Steaming and Light-Induced Natural Ageing. Forests 2025, 16, 1104. https://doi.org/10.3390/f16071104

Vidholdová Z, Slabejová G, Výbohová E. Colour Homogenisation and Photostability of Beech Wood (Fagus sylvatica L.) as Affected by Mild Steaming and Light-Induced Natural Ageing. Forests. 2025; 16(7):1104. https://doi.org/10.3390/f16071104

Chicago/Turabian StyleVidholdová, Zuzana, Gabriela Slabejová, and Eva Výbohová. 2025. "Colour Homogenisation and Photostability of Beech Wood (Fagus sylvatica L.) as Affected by Mild Steaming and Light-Induced Natural Ageing" Forests 16, no. 7: 1104. https://doi.org/10.3390/f16071104

APA StyleVidholdová, Z., Slabejová, G., & Výbohová, E. (2025). Colour Homogenisation and Photostability of Beech Wood (Fagus sylvatica L.) as Affected by Mild Steaming and Light-Induced Natural Ageing. Forests, 16(7), 1104. https://doi.org/10.3390/f16071104