Determination of Strength Improvements in the Acacia Hybrid Through the Combination of Age Groups at the Air-Dry Conditioning Stage

Abstract

1. Introduction

- To evaluate the physical and mechanical properties of solid and laminated Acacia hybrid wood from different age group combinations;

- To identify the ideal age combination that offers the best structural performance;

- To contribute to the development of a technical database for strength classification in accordance with standards.

| Application | Strength Group | Strength Group |

|---|---|---|

| Structural Components | ||

| Columns, beams, bearers, studs, joist, ties, and struts | A and B | SG1, SG2, SG3, and SG4 |

| Form work | A, B, and C | SG1, SG2, SG3, SG4 and SG5 |

| Roofing | ||

| Rafters, ties, struts, purlins, and bracing | A and B | SG1, SG2, SG3, and SG4 |

| Battens | A, B, and C | SG1, SG2, SG3, SG4, and SG5 |

| Staircase | ||

| Stringers, treads, trimmer beam, and handrail | A and B | SG1, SG2, SG3, and SG4 |

| Balustrades | A, B, and C | SG1, SG2, SG3, SG4, SG5, and SG6 |

| Flooring | ||

| Floor boarding and parquetry | A and B | SG1, SG2, SG3, and SG4 |

| Skirtings | A, B, and C | SG1, SG2, SG3, SG4, SG5, and SG6 |

| Walling | ||

| Wall, partition, framing, and external wall boarding | A, B, and C | SG1, SG2, SG3, SG4, SG5, and SG6 |

| Internal wall boarding and slate screens | A, B, C, and D | SG1, SG2, SG3, SG4, SG5, SG6, and SG7 |

| Facia boards | A and B | SG1, SG2, SG3, and SG4 |

| Ceiling frames | ||

| Battens to cover jointing of ceiling sheets | A and B | SG1, SG2, SG3, and SG4 |

| Ceiling strips and soffit battens | A, B, and C | SG1, SG2, SG3, SG4, SG5, and SG6 |

| Door and window frames | ||

| Door, window, and vent frames, including their stops and grounds | A and B | SG1, SG2, SG3, and SG4 |

| Door leaves, window, and vent sashes | A, B, and C | SG1, SG2, SG3, SG4, SG5, and SG6 |

| Furniture | ||

| Built-in fittings, furniture generally, and workshop furniture | A, B, and C | SG1, SG2, SG3, SG4, SG5, and SG6 |

| Science laboratory tops | A and B | SG1, SG2, SG3, and SG4 |

| Beading fillets and edgings generally | A, B, and C | SG1, SG2, SG3, SG4, SG5, and SG6 |

2. Materials and Methods

2.1. Preparation of Materials

2.2. Laboratory Work

2.3. Testing of Physical Properties

2.3.1. Moisture Content Test

2.3.2. Basic Density Test

2.4. Testing of Mechanical Properties

2.4.1. Static Bending Test

2.4.2. Compression Parallel to Grain Test

2.4.3. Compression Perpendicular to Grain Test

2.5. Statistical Analysis

3. Results and Discussion

3.1. Moisture Content Results

3.2. Basic Density Results

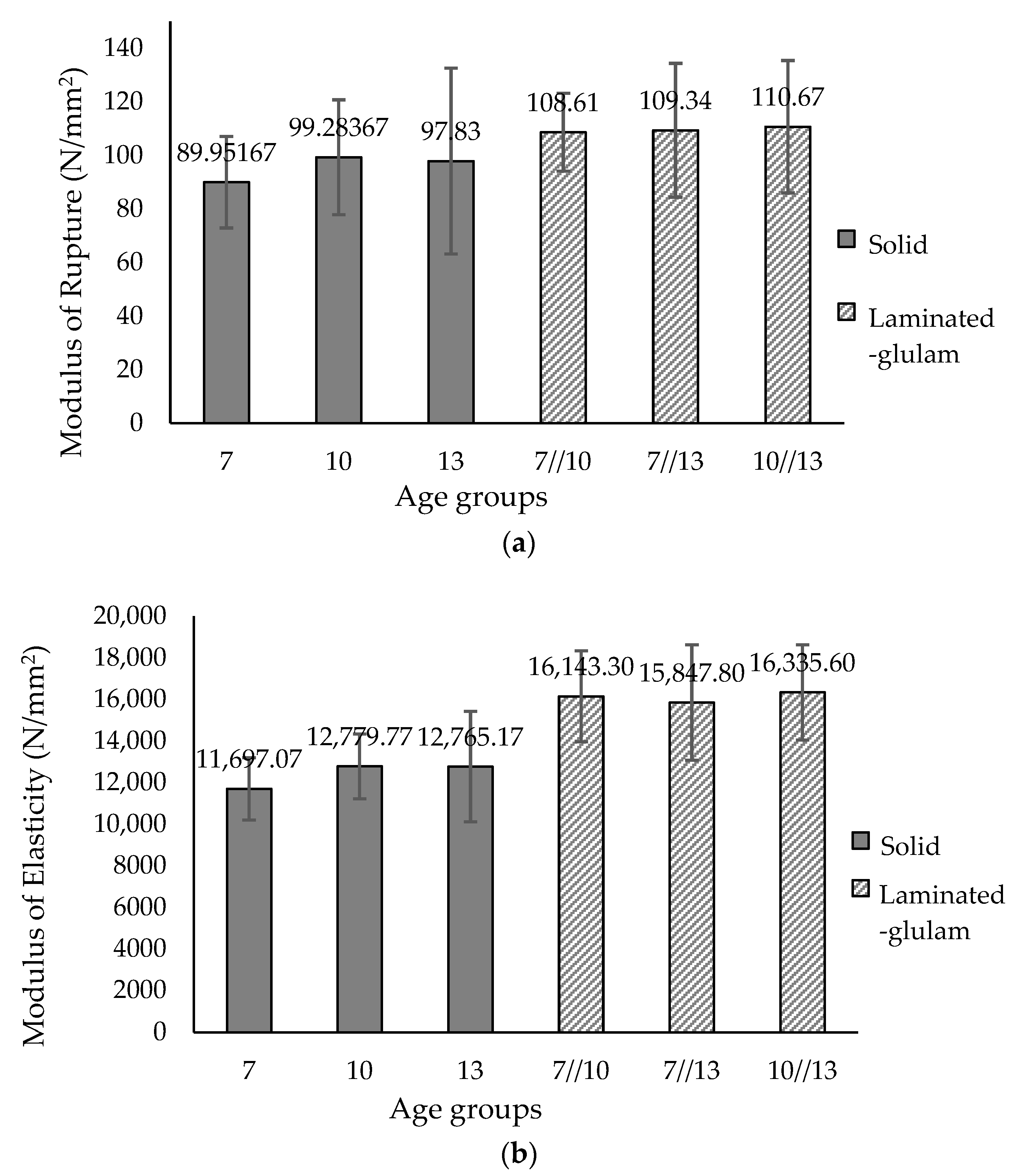

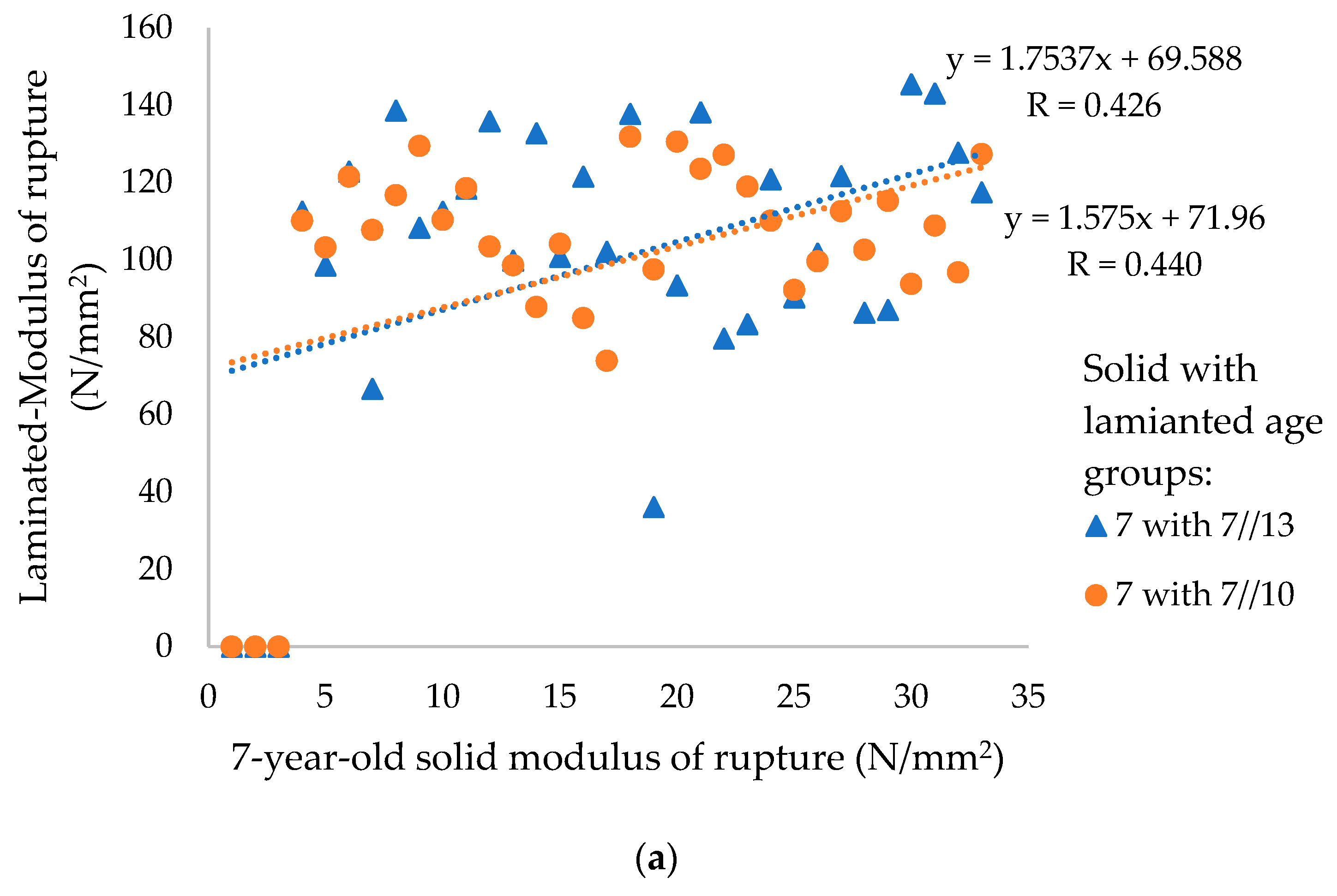

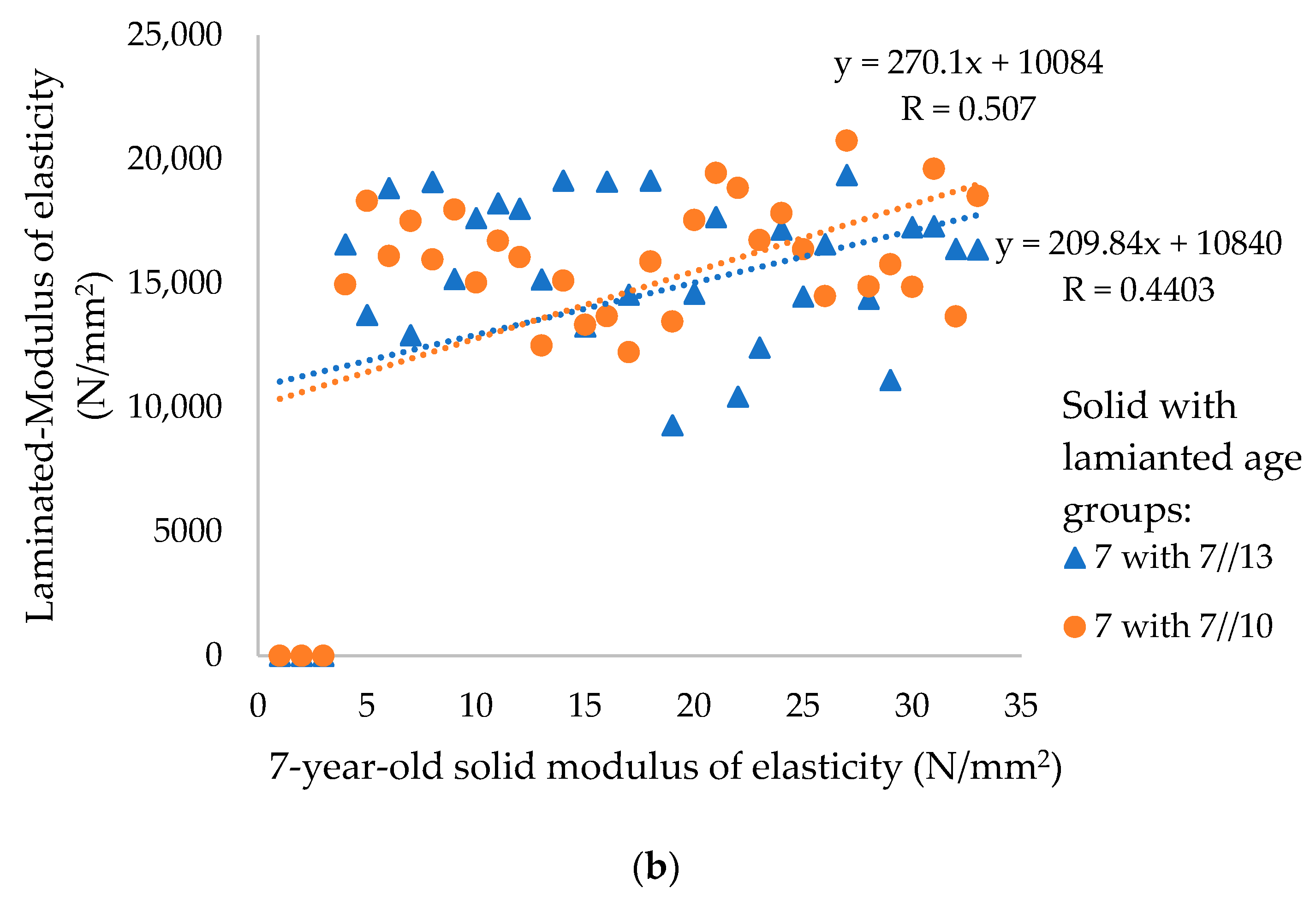

3.3. MOR and MOE

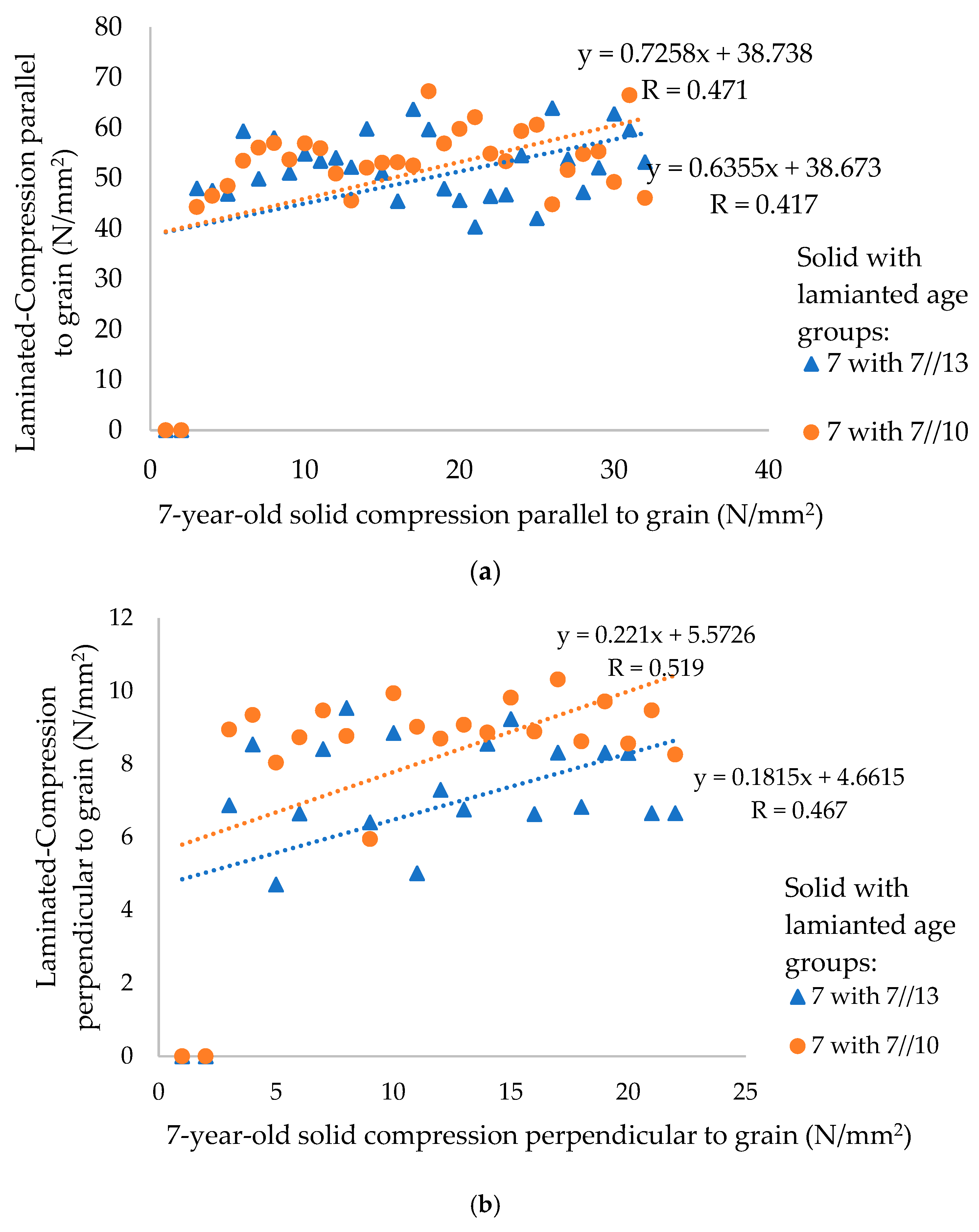

3.4. Compression Stress Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohd Yusof, N.; Md Tahir, P.; Lee, S.H.; Khan, M.; Mohammad Suffian James, R. Mechanical and physical properties of Cross-Laminated Timber made from Acacia mangium wood as function of adhesive types. J. Wood Sci. 2019, 65, 20. [Google Scholar] [CrossRef]

- Duju, A. Structural Stress Grading of Selected Sarawak Timber Using Non-Destructive Tests. Ph.D. Thesis, University Sains Malaysia, Pulau Pinang, Malaysia, 2009. [Google Scholar]

- Milner, H.; Woodard, A. Sustainability of Construction Materials; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar]

- Ramage, M.H.; Burridge, H.; Wicher, M.B.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, L.; Fleming, P.; Tingley, D.; Allwood, J.; et al. The wood from trees: The use of timber in construction. J. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Structural Timber Association. Engineered Wood Products and an Introduction to Timber Structural System; The Structural Timber Association: Alloa, UK, 2014. [Google Scholar]

- Aicher, S.; Stapf, G. Block Glued GlulamBridges, Beams and Arches. In Proceedings of the World Conference on Timber Engineering (WCTE 2014), Quebec, Canada, 10–14 August 2014. [Google Scholar] [CrossRef]

- Yang, S.; Choi, G.; Kim, J.; Lee, H.; Kang, S. Comparison of mechanical properties according to the structural materials of lumber, GLT, CLT, and Ply-lam CLT. BioResources 2023, 18, 6971–6985. [Google Scholar] [CrossRef]

- Lineham, S.A.; Thomson, D.; Bartlett, A.I.; Bisby, L.A.; Hadden, R.M. Structural Response of Fire-Exposed Cross-Laminated Timber Beams under Sustained Loads. Fire Saf. J. 2016, 85, 23–34. [Google Scholar] [CrossRef]

- Purba, C.Y.C.; Pot, G.; Viguier, J.; Ruelle, J.; Denaud, L. The Influence of Veneer Thickness and Knot Proportion on the Mechanical Properties of Laminated Veneer Lumber (LVL) Made from Secondary Quality Hardwood. Eur. J. Wood Prod. 2019, 77, 393–404. [Google Scholar] [CrossRef]

- Oh, S. Experimental Study of Bending and Bearing Strength of Parallel Strand Lumber (PSL) from Japanese Larch Veneer Strand. J. Korean Wood Sci. Technol. 2022, 50, 237–245. [Google Scholar] [CrossRef]

- Kang, E.-C.; Lee, M.; Lee, S.-M.; Park, S.-H. Mechanical Properties of the Oriented Strand Board (OSB) Distributed in the Korean Market. J. Korean Wood Sci. Technol. 2023, 51, 253–269. [Google Scholar] [CrossRef]

- MS544; Malaysian Standard. Malaysian Standard: Part 2. Code of Practice on Structural Use of Timber (First Revision). Department of Standards Malaysia: Putrajaya, Malaysia, 2017.

- Engku, A.R.C. Basic and grade stresses for some Malaysian timbers. Malay. For. 1971, 34, 131–134. [Google Scholar]

- Chu, Y.P.; Ho, K.S.; Mohd Shukari, M.; Abdul Rashid, A.M. Timber Design Handbook; Forest Research Institute Malaysia: Kepong, Malaysia, 1997. [Google Scholar]

- Lee, Y.H.; Engku, A.R.C.; Chu, Y.P. The Strength Properties of Some Malaysian Timbers; Timber Trade Leaflet No. 34; Forest Department: Kuala Lumpur, Malaysia, 1993. [Google Scholar]

- Forest Department Sarawak. Handbook of Some Sarawak Timbers; Forest Department Sarawak: Kuching, Malaysia, 1999. [Google Scholar]

- Cheng, J.S.K.; Mamit, J.D.; Nibu, A.N. Strength Properties of Dipterocarp Timbers of Sarawak; Technical Report TR/1; Timber Research and Technical Training Centre, Forest Department: Kuching, Sarawak, Malaysia, 1985. [Google Scholar]

- Malaysia Timber Industry Board. 100 Malaysian Timbers, 5th ed.; Malaysia Timber Industry Board: Kuala Lumpur, Malaysia, 2008. [Google Scholar]

- Ismaili, G.; Enduat, E.; Yahya, N.S.; Malek, F.M.; Jaimudin, N.A.; Abdul Rahim, K.K.; Wasli, M.E.; Kalu, M.; Openg, I.; Rizalman, A.N.; et al. Physical and Mechanical Properties Performance between Untreated and Treated with CCA Treatment at Different Age Groups of Fast-Growing Acacia hybrid Species. Forest 2022, 13, 1969. [Google Scholar] [CrossRef]

- Dang, D.V.; Ma, T.; Inagaki, T.; Nguyen, T.K.; Nghiem, Q.C.; Tsuchikawa, S. Physical and Mechanical Properties of Fast Growing Polyploid Acacia Hybrids (A. auriculiformis × A. mangium) from Vietnam. Forests 2020, 11, 717. [Google Scholar] [CrossRef]

- Cown, D.J. Wood: Density. In Encyclopedia of Materials: Science & Technology, 1st ed.; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilshner, B., Kramer, E.J., Mahajan, S., Veyssiere, P., Eds.; Elsevier: New York, NY, USA, 2001; pp. 9620–9622. [Google Scholar]

- Dinh Kha, L.; Harwood, C.E.; Kien, N.D.; Baltunis, B.; Hai, N.D.; Thinh, H.H. Growth and wood basic density of acacia hybrid clones at three locations in Vietnam. New For. 2012, 43, 13–29. [Google Scholar] [CrossRef]

- Jusoh, I.; Suteh, J.K.; Adam, N.S. Growth and Yield of Acacia mangium Based on Permanent Sampling Plots in a Plantation. Trans. Sci. Technol. 2017, 4, 513–518. [Google Scholar]

- Nazeri, A.; Jusoh, I.; Wasli, M.E. Growth of Acacia mangium at Different Stand Ages and Soil Physicochemical Properties in Sarawak, Malaysia. Pertanika J. Trop. Agric. Sci. 2021, 44, 773–793. [Google Scholar] [CrossRef]

- Malaysia Timber Industry Board. Strength Groups of Timber and Their Applications; Malaysia Timber Industry Board: Kuala Lumpur, Malaysia, 2019. [Google Scholar]

- Tan, Y.E.; Lim, N.P.T.; Gan, K.S.; Wong, T.C.; Lim, S.C.; Thilagawathy, M. Testing Methods for Plantation Grown Tropical Timbers. ITTO Project on Improving Utilisation and Value Adding of Plantation Timbers from Sustainable Sources in Malaysia; FRIM: Kepong, Selangor, Malaysia, 2010. [Google Scholar]

- BS 373:1957; Methods of Testing Small Clear Specimens of Timber. British Standards Institution: London, UK, 1957.

- ASTM D 5751–99; Standard Specification for Adhesives Used for Laminate Joints in Nonstructural Lumber Products, (Reapproved 2005). American Society for Testing and Materials International: West Conshohocken, PA, USA, 2019.

- JAS-1152; Ministry of Agriculture, Forestry and Fisheries (MAFF). Japanese Agricultural Standard for Glued Laminated Timber, Notification No. 234. Japan Plywood Inspection Corporation: Tokyo, Japan, 2003.

- Serrano, E.; Enquist, B. Compression Strength Perpendicular to Grain in Cross-Laminated Timber (CLT). In Proceedings of the 11th World Conference on Timber Engineering 2010 (WCTE 2010), Trentino, Italy, 20–24 June 2010; Available online: https://www.diva-portal.org/smash/get/diva2:330397/FULLTEXT01.pdf (accessed on 5 April 2024).

- ASTM D143-14; Standard Test Methods for Small Clear Specimens of Timber. ASTM International: West Conshohocken, PA, USA, 2014.

- Dhanavan, S. Application of Garret ranking technique: Practical approach. Int. J. Libr. Inf. Stud. 2016, 6, 135–140. [Google Scholar]

- Rokeya, U.K.; Hossain, M.A.; Ali, M.R.; Paul, S.P. Physical and mechanical properties of (Acacia auriculiformis x A. mangium) Hybrid Acacia. J. Bangladesh Acad. Sci. 2010, 32, 181–187. [Google Scholar] [CrossRef]

- Zobel, B.J.; Sprague, J.R. Juvenile Wood in Forest Trees; Springer: Berlin/Heidelberg, Germany, 1998; p. 189. [Google Scholar] [CrossRef]

- Walker, J.C.F.; Butterfield, B.G.; Langrish, T.A.G.; Harris, J.M. Primary Wood Processing: Principles and Practice, 2nd ed.; Springer: Dordrecht, The Netherlands, 2013; p. 203. [Google Scholar] [CrossRef]

- Kretschmann, D.E. Juvenile Wood Properties. In Encyclopedia of Forest Sciences; Burley, J., Ed.; Elsevier: Oxford, UK, 2010; pp. 505–511. [Google Scholar]

- Mohamad Yakub, B.; Ismaili, G.; Openg, I.; Ismaili, Z.; Yahya, N.; Kalu, M.; Wasli, M. Comparison of Compression Parallel to Grain of Acacia hybrid for Untreated and Treated at Different Combination of Age Groups. Mater. Sci. 2025, 32, 1–10. [Google Scholar] [CrossRef]

- Gerhards, C.C. Effect of moisture content and temperature on the mechanical properties of wood: An analysis of immediate effects. Wood Fiber 1980, 14, 4–36. [Google Scholar] [CrossRef]

- Gaddafi, I. Engineering Properties of Selected Sarawak Fast-Growing Indigenous Timber Species. Ph.D. Thesis, Universiti Sains Malaysia, Pulau Pinang, Malaysia, 2012. [Google Scholar]

- Oktapiani, C.; Damayanti, R.; Karlinasari, L.; Agustiningrum, D.A.; Pari, R.; Djarwanto, D.; Rahmanto, R.G.H.; Sofianto, I.A.; Dewi, L.M.; Dwianto, W.; et al. The effect of anatomical structure on hygroscopicity of four wood species. In Proceedings of the 14th International Symposium of Indonesian wood Researcher Society (IWoRS) 2022, Bandung, Indonesia, 3–4 August 2022; Volume 3172, p. 020039. [Google Scholar] [CrossRef]

- Panshin, A.J.; De Zeeuw, C. Textbook of World Technology, 4th ed.; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Jusoh, I.; Zaharin, F.A.; Adam, N.S. Wood quality of Acacia hybrid and second-generation Acacia mangium. BioResources 2014, 9, 150–160. [Google Scholar] [CrossRef]

- Tsoumis, G.T. Wood as a Material. Encyclopædia Britannica. Available online: https://www.britannica.com/science/wood-plant-tissue/Bark-and-bark-products (accessed on 23 March 2023).

- Mohd Jamil, A.W. Strength Assessment of Structural Size Malaysia Timbers. Master’s Thesis, University of Malaya, Kuala Lumpur, Malaysia, 2013. Available online: http://studentsrepo.um.edu.my/8642/7/jamil.pdf (accessed on 5 April 2024).

- Nur Emilia Azira, K.; Gaddafi, I. Strength Performance of Hevea Brasiliensis at Structural Size. Int. Adv. Res. J. Sci. Eng. Technol. 2015, 2, 144–147. [Google Scholar] [CrossRef]

- Desch, H.E.; Dinwoodie, J.M. Timber Its Structure, Properties and Utilisation, 7th ed.; Macmillan: Basingstoke, UK, 1981. [Google Scholar]

- Laurila, R. Wood Properties and Utilization Potential of Eight Fast-Growing Tropical Plantation Tree Species. J. Trop. For. Prod. 1995, 1, 213. [Google Scholar]

- Yahya, N.S.; Ismaili, G.; Kalu, M.; Wasli, M.E.; Openg, I.; Jaimudin, N.A.; Hashim, M.Z.; Rizalman, A.N.; Mohammad, H.; Abdul Rahim, K.K. The Mechanical Strength Properties, Treatability Retention and Hazard Classification of Treated Small-Clear Fast-Growing Acacia mangium Superbulk at Different Age Groups. Forests 2023, 14, 1529. [Google Scholar] [CrossRef]

- Sattar, M.A.; Kabir, M.F.; Bhattacharjee, D.K. Physical, Mechanical and Seasoning Properties of A. mangium and A. auriculiformis; Bulletin 15, Timber Physics Series; Bangladesh Forest Research Institute (BFRI): Chittagong, Bangladesh, 1993; p. 6. [Google Scholar]

- Ismaili, G.; Abdul Rahim, K.K.; Duju, A.; Openg, I.; Ismaili, Z. Strength Classification of Aras as Fast-Growing Indigenous Species Timber in Sarawak. Appl. Mech. Mater. 2014, 695, 617–621. [Google Scholar] [CrossRef]

- Ismaili, G.; Abu Bakar, B.H.; Abdul Rahim, K.K. The Behaviour of Strength Properties from Three Different Tree Boles of Aras in Sarawak. J. Civ. Eng. Sci. Technol. 2011, 2, 48–52. [Google Scholar] [CrossRef]

- Ismaili, G.; Abu Bakar, B.H.; Abdul Rahim, K.K. Basic and grade stress for some timber in Sarawak. UNIMAS E J. Eng. 2011, 2, 35–38. [Google Scholar] [CrossRef]

- CP 112; The Structural Use of Timber. BSI: London, UK, 1967.

- Sharma, S.K.; Shukla, S.R.; Sujatha, M. Physical and Mechanical Evaluation of 8-Years-old Acacia Hybrid (Acacia mangium x A. auriculiformis) Clones for Various End Uses. Indones. J. For. Res. 2018, 5, 95–102. [Google Scholar] [CrossRef]

- Bodig, J.; Jayne, B.A. Mechanics of Wood and Wood Composites; Van Nostrand Reinhold: New York, NY, USA, 1982; pp. 124–125. [Google Scholar]

- Nakada, R.; Fujisawa, Y.; Hirakawa, Y. Effects of Clonal Selection by Microfibril Angle on the Genetic Improvement of Stiffness in Cryptomeria japonica D. Don. Holzforschung 2003, 57, 553–560. [Google Scholar] [CrossRef]

- Zhu, J.; Tadooka, N.; Takata, K.; Koizumi, A. Growth and Wood Quality of Sugi (Cryptomeria japonica) Planted in Akita Prefecture (II): Juvenile/Mature Wood Determination of Aged Trees. J. Wood Sci. 2005, 51, 95–101. [Google Scholar] [CrossRef]

- Ross, R.J. Wood Hanbook-Wood as an Engineering Material; General Technical Report FPL-GTR-190; Department of Agriculture, USDA Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; ISBN 978-1484859704. [Google Scholar]

- Zobel, B.J.; Buijtenen, J.P. Wood Variation: Its Causes and Control; Springer: Berlin/Heidelberg, Germany, 1989. [Google Scholar]

- Ismaili, G. Engineering Properties of Fast-Growing Indigenous Timber in Sarawak Compare to Acacia mangium: Aras. Int. J. Sci. Mod. Eng. 2015, 3, 8–121. [Google Scholar]

| Strength Group | Dry Ultimate Compression Parallel to Grain (N/mm2) |

|---|---|

| A | >55.2; extremely strong |

| B | 41.2–55.2; very strong |

| C | 27.6–41.4; strong |

| D | <27.6; weak |

| Moisture Content (%) | ||||||

|---|---|---|---|---|---|---|

| Age groups | Solid | Laminated (Glulam) | ||||

| 7 | 10 | 13 | 7//10 | 10//13 | 7//13 | |

| Sample size | 30 | 30 | 30 | 30 | 30 | 30 |

| Mean (%) | 15.32 | 15.95 | 15.06 | 14.94 | 14.27 | 13.75 |

| Std Dev | 0.53 | 0.53 | 0.76 | 2.12 | 0.93 | 0.71 |

| CV (%) | 3.48 | 3.45 | 5.02 | 14.19 | 6.49 | 5.17 |

| Standard error, SE | 0.10 | 0.10 | 0.14 | 0.39 | 0.17 | 0.13 |

| 95% confidence interval, CI | 0.19 | 0.19 | 0.28 | 0.77 | 0.34 | 0.26 |

| Basic Density (g/cm3) | ||||||

|---|---|---|---|---|---|---|

| Age groups | Solid | Laminated (Glulam) | ||||

| 7 | 10 | 13 | 7//10 | 10//13 | 7//13 | |

| Sample size | 30 | 30 | 30 | 30 | 30 | 30 |

| Mean (g/cm3) | 0.693 | 0.694 | 0.678 | 0.69 | 0.710 | 0.708 |

| Std Dev | 0.06 | 0.09 | 0.10 | 0.063 | 0.066 | 0.08 |

| CV (%) | 9.30 | 12.98 | 15.28 | 9.11 | 9.25 | 11.11 |

| Standard error, SE | 0.01 | 0.02 | 0.02 | 0.0115 | 0.0119 | 0.0143 |

| 95% confidence level, CI | 0.02 | 0.03 | 0.04 | 0.023 | 0.024 | 0.029 |

| (a) | ||||||

| Modulus of Rupture (MOR) | ||||||

| Solid | Laminated (Glulam) | |||||

| Age groups | 7 | 10 | 13 | 7//10 | 7//13 | 10//13 |

| Sample size | 30 | 30 | 30 | 30 | 30 | 30 |

| Mean ultimate stress (N/mm2) | 89.95 | 99.28 | 97.83 | 108.61 | 109.34 | 110.67 |

| Std Dev | 17.09 | 21.44 | 34.71 | 14.52 | 24.96 | 24.71 |

| CV (%) | 19.00 | 21.60 | 35.48 | 13.37 | 22.83 | 22.33 |

| Standard error SE | 3.12 | 3.91 | 6.34 | 2.65 | 4.56 | 4.51 |

| 95% confidence level CI | 6.24 | 7.83 | 12.67 | 5.3 | 9.11 | 9.02 |

| (b) | ||||||

| Modulus of Elasticity (MOE) | ||||||

| Solid | Laminated (Glulam) | |||||

| Age groups | 7 | 10 | 13 | 7//10 | 7//13 | 10//13 |

| Sample size | 30 | 30 | 30 | 30 | 30 | 30 |

| Mean ultimate stress (N/mm2) | 11,697.07 | 12,779.77 | 12,765.17 | 16,143.30 | 15,847.80 | 16,335.60 |

| Std Dev | 1498.68 | 1560.43 | 2661.22 | 2186.49 | 2774.25 | 2296.79 |

| CV (%) | 12.81 | 12.21 | 20.85 | 13.54 | 17.51 | 14.06 |

| Standard error SE | 273.62 | 284.89 | 485.87 | 399.2 | 506.51 | 419.33 |

| 95% confidence level CI | 547.24 | 569.79 | 971.74 | 798.39 | 1013.01 | 838.67 |

| Age Groups | Significant Difference p-Value (p < 0.05) | ||

|---|---|---|---|

| Age Group | MOR | MOE | |

| 10//13 | 7//10 | 0.69 ** | 0.73 ** |

| 7//13 | 0.88 ** | 0.52 ** | |

| 7 | 7//10 | 0.00003 * | 0.00000 * |

| 7//13 | 0.00087 * | 0.00000 * | |

| (a) | ||||||

| Compression Parallel to Grain (N/mm2) | ||||||

| Age Groups | Solid | Laminated (Glulam) | ||||

| 7 | 10 | 13 | 7//10 | 7//13 | 10//13 | |

| Sample size | 30 | 30 | 30 | 30 | 30 | 30 |

| Mean ultimate stress (N/mm2) | 48.020 | 60.275 | 53.474 | 54.09 | 52.44 | 56.99 |

| Std Dev | 5.39 | 8.94 | 10.02 | 5.83 | 6.35 | 6.04 |

| CV (%) | 11.23 | 14.83 | 18.74 | 10.78 | 12.12 | 10.6 |

| Standard error SE | 0.98 | 1.63 | 1.83 | 0.39 | 0.42 | 0.4 |

| 95% confidence level CI | 1.97 | 3.26 | 3.66 | 0.78 | 0.84 | 0.8 |

| (b) | ||||||

| Compression Perpendicular to Grain (N/mm2) | ||||||

| Age Groups | Solid | Laminated (Glulam) | ||||

| 7 | 10 | 13 | 7//10 | 7//13 | 10//13 | |

| Sample size | 30 | 30 | 30 | 20 | 20 | 20 |

| Mean ultimate stress (N/mm2) | 4.017 | 8.395 | 5.743 | 8.92 | 7.4237 | 7.4242 |

| Std Dev | 0.29 | 1.18 | 0.91 | 0.91 | 1.33 | 0.74 |

| CV (%) | 7.27 | 14.05 | 15.87 | 10.18 | 17.88 | 9.92 |

| Standard error SE | 0.48 | 0.94 | 1.06 | 0.2 | 0.3 | 0.16 |

| 95% confidence level CI | 0.97 | 1.87 | 2.12 | 0.41 | 0.59 | 0.33 |

| Compression Parallel to Grain | Age group | 10//13 | Age Group | 7//10 | 7//13 |

| p-value | 0.063 ** | 0.006 * | |||

| 7 | Age Group | 7//10 | 7//13 | ||

| p-value | 0.000097 * | 0.005226 * | |||

| Compression Perpendicular to Grain | 7//10 | Age Group | 10 + 13 | 7 + 13 | |

| p-value | 0.00 * | 0.00 * | |||

| 7 | Age Group | 7//10 | 7//13 | ||

| p-value | 0.00000 * | 0.00000 * |

| Engineering Properties | Unit | Age Group Combination (Single-Laminated) | ||

|---|---|---|---|---|

| 7//10-Year-Old | 7//13-Year-Old | 10//13-Year-Old | ||

| Moisture content | Mean (%) | 14.94 | 13.75 | 14.27 |

| Percentile Position | 83.33 | 16.67 | 50.00 | |

| Garret Score | 31 | 69 | 50 | |

| Basic density | Mean (g/cm3) | 0.69 | 0.708 | 0.71 |

| Percentile Position | 83.33 | 16.67 | 50.00 | |

| Garret Score | 31 | 69 | 50 | |

| Modulus of elasticity (MOE) | Mean (N/mm2) | 16143.3 | 15847.8 | 16335.6 |

| Percentile Position | 50.00 | 83.33 | 16.67 | |

| Garret Score | 50 | 31 | 69 | |

| Modulus of rupture (MOR) | Mean (N/mm2) | 108.61 | 109.34 | 110.67 |

| Percentile Position | 83.33 | 50.00 | 16.67 | |

| Garret Score | 31 | 50 | 69 | |

| Compression parallel to grain | Mean (N/mm2) | 54.09 | 52.44 | 56.99 |

| Percentile Position | 50.00 | 83.33 | 16.67 | |

| Garret Score | 50 | 31 | 69 | |

| Compression perpendicular to grain | Mean (N/mm2) | 8.92 | 7.4237 | 7.4242 |

| Percentile Position | 16.67 | 83.33 | 50.00 | |

| Garret Score | 69 | 31 | 50 | |

| Average score | 43.67 | 46.83 | 59.50 | |

| Ranking | 3 | 2 | 1 | |

| Age | SG | MOR (N/mm2) | Comp// (N/mm2) | Comp⊥ (N/mm2) | MOE (N/mm2) | Application |

|---|---|---|---|---|---|---|

| 10//13 | SG5 | 110.67 (24.71) | 56.99 (6.04) | 7.4242 (0.74) | 16,335.6 (2296.79) | Form work, battens, balustrades, skirtings, wall, partition, framing and external wall boarding, internal wall boarding, slate screens, ceiling strips and soffit battens, door leaves, window and vent sashes, built-in fittings, general furniture and workshop furniture, beading fillets, and general edgings |

| 7//13 | SG5 | 109.34 (24.96) | 52.44 (6.35) | 7.4237 (1.33) | 15,847.8 (2774.25) | |

| 7//10 | SG5 | 108.61 (14.52) | 54.09 (5.83) | 8.92 (0.91) | 16,143.3 (2186.49) | |

| 7 | SG6 | 89.95 (17.09) | 48.020 (5.39) | 4.017 (0.29) | 11,697.07 (1498.68) | Balustrades, skirtings, wall, partition, framing and external wall boarding, internal wall boarding, slate screens, ceiling strips and soffit battens, door leaves, window and vent sashes, built-in fittings, general furniture and workshop furniture, beading fillets, and general edgings |

| 10 | SG5 | 99.28 (21.44) | 60.275 (8.94) | 8.395 (1.18) | 12,779.77 (1560.43) | Form work, battens, balustrades, skirtings, wall, partition, framing and external wall boarding, internal wall boarding, slate screens, ceiling strips and soffit battens, door leaves, window and vent sashes, built-in fittings, general furniture and workshop furniture, beading fillets, and general edgings |

| 13 | SG5 | 97.83 (34.71) | 53.474 (10.02) | 5.743 (0.91) | 12,765.17 (2661.22) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malek, F.M.; Ismaili, G.; Jainudin, N.A.; Kalu, M.; Wasli, M.E.; Jobli, A.F.; Hashim, M.Z.; Rizalman, A.N.; Yahya, N.S.; Ripot, S. Determination of Strength Improvements in the Acacia Hybrid Through the Combination of Age Groups at the Air-Dry Conditioning Stage. Forests 2025, 16, 1048. https://doi.org/10.3390/f16071048

Malek FM, Ismaili G, Jainudin NA, Kalu M, Wasli ME, Jobli AF, Hashim MZ, Rizalman AN, Yahya NS, Ripot S. Determination of Strength Improvements in the Acacia Hybrid Through the Combination of Age Groups at the Air-Dry Conditioning Stage. Forests. 2025; 16(7):1048. https://doi.org/10.3390/f16071048

Chicago/Turabian StyleMalek, Fanthy Moola, Gaddafi Ismaili, Noor Azland Jainudin, Meekiong Kalu, Mohd Effendi Wasli, Ahmad Fadzil Jobli, Mohamad Zain Hashim, Ahmad Nurfaidhi Rizalman, Nur Syahina Yahya, and Semilan Ripot. 2025. "Determination of Strength Improvements in the Acacia Hybrid Through the Combination of Age Groups at the Air-Dry Conditioning Stage" Forests 16, no. 7: 1048. https://doi.org/10.3390/f16071048

APA StyleMalek, F. M., Ismaili, G., Jainudin, N. A., Kalu, M., Wasli, M. E., Jobli, A. F., Hashim, M. Z., Rizalman, A. N., Yahya, N. S., & Ripot, S. (2025). Determination of Strength Improvements in the Acacia Hybrid Through the Combination of Age Groups at the Air-Dry Conditioning Stage. Forests, 16(7), 1048. https://doi.org/10.3390/f16071048