Delignification as a Key Strategy for Advanced Wood-Based Materials: Chemistry, Delignification Parameters, and Emerging Applications

Abstract

1. Introduction

2. Materials and Methods

- Inclusion criteria: Studies focused specifically on solid wood, rather than wood pulp or fiber, articles presenting experimental, theoretical or review-based findings on delignification methods, mechanisms, or effects. Only peer-reviewed journal articles, conference proceedings, and patents were considered.

- Exclusion criteria: Studies focused exclusively on paper production or lignocellulosic biomass for biofuels, research on lignin post-extraction valorization, unless directly linked to delignification, non-English publications (due to translation limitations), or non-peer-reviewed materials (e.g., magazine articles and blogs).

3. Delignification Process as Fundamental Treatment

3.1. The Alkaline Systems for Delignification

3.2. The Acidic Systems for Delignification

3.3. Other Systems for Delignification

- Ionic Liquids: Ionic liquids are salts that exist as liquids at room temperature and are effective in the delignification of plant material. They are considered “green” solvents because they have low toxicity, are non-volatile, and can be recycled [76].

- Peroxides: Peroxides, such as H2O2 and Na2O2, can be used for delignification. They are environmentally friendly because they break down into H2O and O2 and they do not generate toxic byproducts [55].

- Organic Acids: Organic acids such as CH3COOH, HCHO, and citric acid can be used for delignification. They are considered green chemicals because they are naturally occurring, biodegradable, and non-toxic.

- Enzymes: Enzymes, such as laccase, manganese peroxidase, and lignin peroxidase, can be used for delignification. They are considered “green” as well because they are biodegradable, have low toxicity, and can be used under mild conditions.

3.4. Oxygen-Based Agents as Delignification Systems

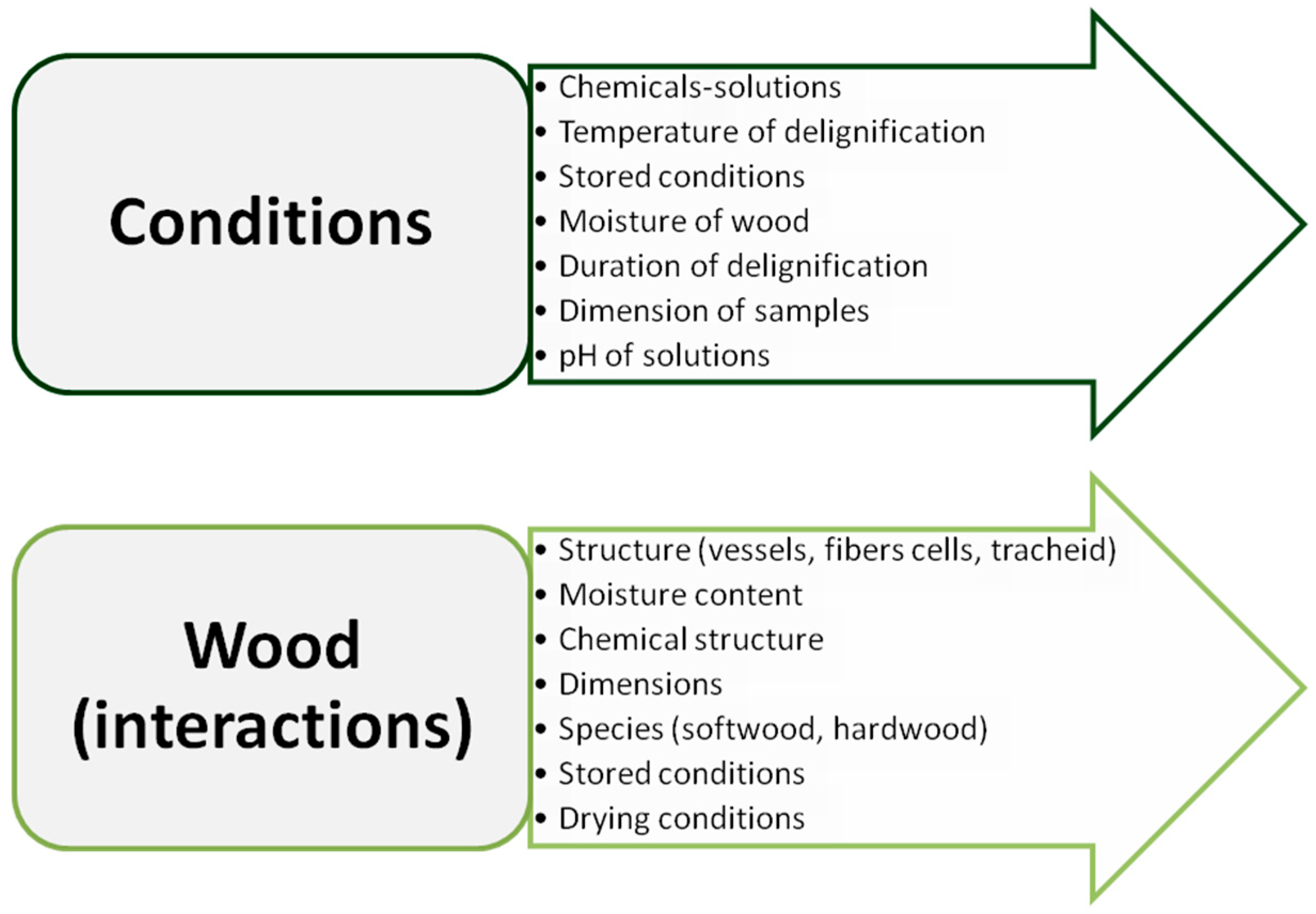

3.5. Other Conditions Affecting Treatment

4. Characteristics of Wood (And Its Interactions)

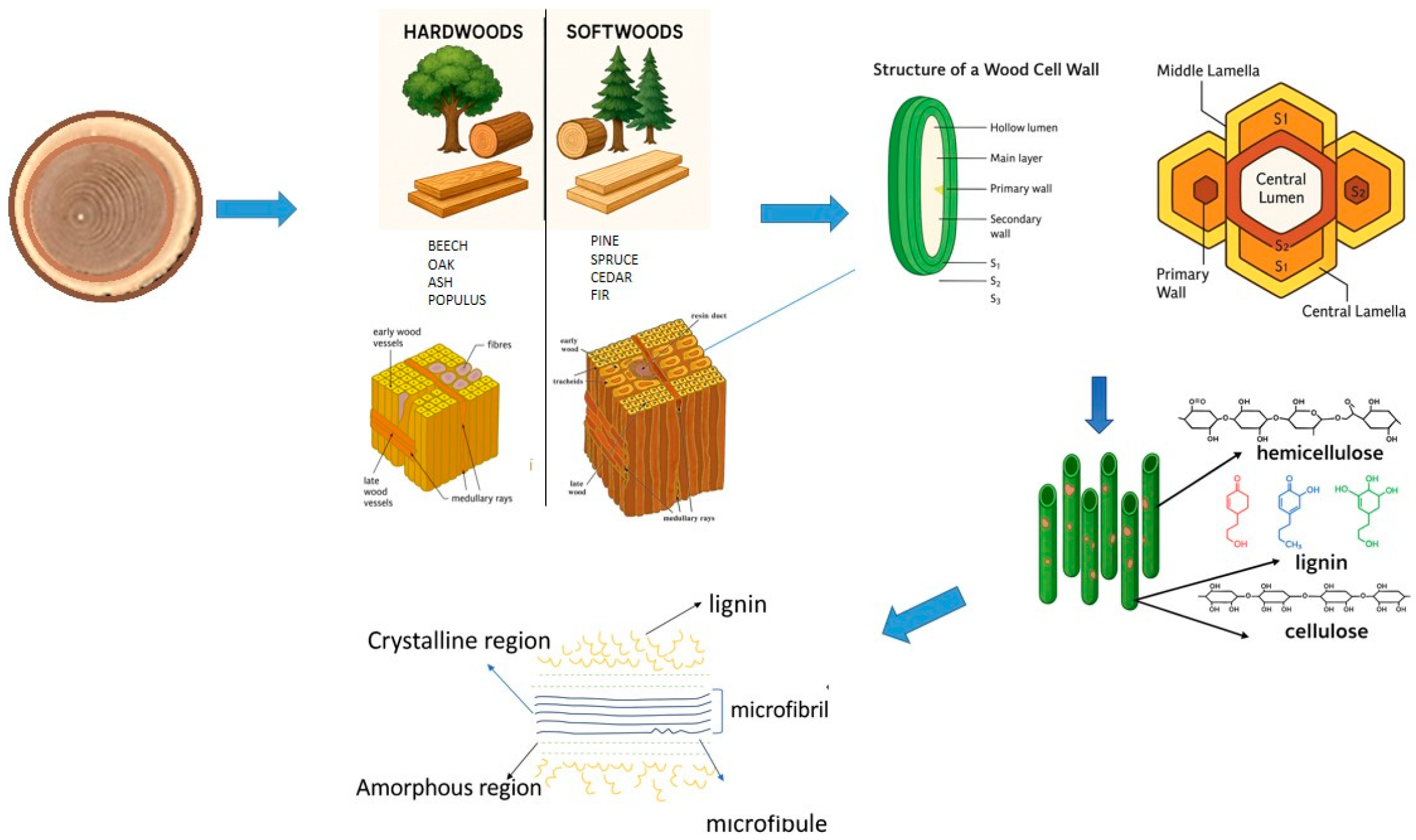

4.1. Structure (Vessels, Fiber Cells, and Tracheid)

- Lignin distribution: The distribution of lignin within the wood cell wall can affect the efficiency of the delignification process. For example, if the lignin is mainly concentrated in the middle lamella and primary cell wall layers, it may be more easily removed than if it is mainly concentrated in the secondary cell wall layer.

- Lignin content: The amount of lignin present in the wood cell wall can also affect the delignification process. High lignin content can make the wood more difficult to delignify and may require more severe delignification conditions to achieve the desired level of lignin removal.

- Lignin composition: The composition of the lignin in the wood cell wall can affect the delignification process. For example, lignin that is more condensed and cross-linked may be more difficult to remove than lignin that is more linear and less condensed.

- Cell wall structure: The overall structure and composition of the wood cell wall can also affect the delignification process. For example, wood with a high proportion of hardwood fibers, which have a more complex and rigid cell wall structure than softwood fibers, may require more severe delignification conditions to achieve the desired level of lignin removal.

4.2. Moisture Content and Drying Conditions

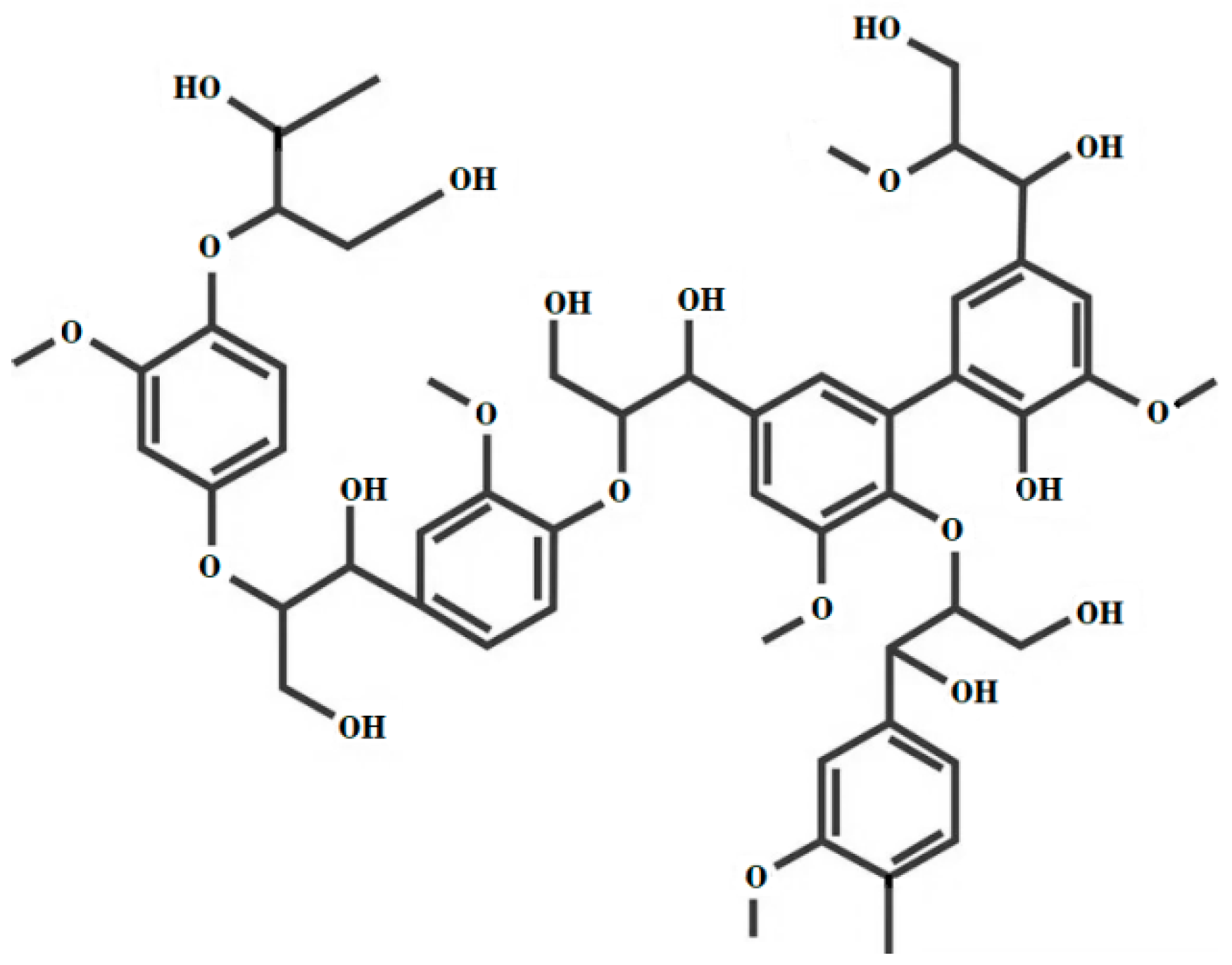

4.3. Chemical Structure

4.4. Species and Dimensions

| Ref. | Wood Species | Sample Dimensions | Chemicals/Delignification Conditions | Moisture/Storage Conditions | Lignin Content (Initial → Final) | Post-Delignification Process | Application |

|---|---|---|---|---|---|---|---|

| Van Hai et al. [112] | Pinus koraiensis | 150 × 50 × 15 mm3 | 5-step treatment: (i) 1% NaClO2 at 80 °C for 12 h (wash 2 h, water bath 1 d, oven-dry at 40 °C for 1–2 d); (ii) 2% NaClO2 at 80 °C for 12 h; (iii) Repeat step i; (iv) 0.1% NaOH suspension for 1 d (wash, water bath, oven-dry); (v) Repeat step (i) | Pre-dried in oven at 103 °C; post-densification stored in desiccator (15% RH, 23 °C) | 30.3% (native) → progressively reduced to 5% | Hot pressing at 13 MPa (4 h), 26 MPa (8 h), 52 MPa (16 h) at 100 °C | Bulk wood |

| Mai et al. [113] | Balsa | 15 × 15 × 5 mm | Boiling in 2.5 M NaOH and 0.4 M Na2SO3 at 100 °C for 12 h; then treatment with 30% H2O2 | – | – | In situ polymerization (using CTAB, CaCl2, NaCl, HMA, AAM, KPS, TEMED; aged at 50 °C for 24 h) | Ultra-flexible flame-retardant composites |

| Gao et al. [48] | Balsa | Length: 20 mm; Diameter: 2–5 mm | Soaking in a solution of 50 wt% glacial CH3COOH and 50 wt% H2O2; cooked 10–12 h at 80 °C until white and soft | Solvent exchange (acetone) to replace moisture | Treated fiber: lignin reduced to ~8%; cellulose increased to ~59% | – | “Transparent” wood composite |

| Samanta et al. [114] | Balsa and Birch | Veneers: 20 × 20 × 1 mm or 200 × 100 × 1 mm | Immersion in acetate buffer (pH ≈ 4.6) containing 1.0 wt% NaClO2 at 80 °C until color changes from brown to white; then thoroughly washed; solvent exchanged to EtOH and acetone under vacuum | – | – | Infiltration with melamine–formaldehyde resin under vacuum for ≥24 h | Fire-retardant “transparent” wood composite |

| Sun et al. [49] | Balsa (Ochromapyramidale) | 50 × 50 × 1 mm (L × R × T) | Immersion in 1 wt% NaClO2 solution (buffered with CH3COOH, pH 4.6) at 80 °C for 12 h | – | – | TEMPO-mediated oxidation, in situ lignin deposition and mechanical hot pressing | Reconstructed wood with high strength, water resistance and excellent optical properties |

| Liang et al. [91] | Poplar | 50 × 50 × 5 mm | Steam treatment with a 1:1 mixture of 30% H2O2 and glacial CH3COOH at 160 °C for 2–8 h (vapor phase) | Pre-dried in oven at 60 °C; post-treatment: freeze-dried at −60 °C overnight | 26.7% → 1.45% | Vacuum-assisted resin transfer molding with bisphenol A-type epoxy resin; densification at 23 MPa, 100 °C for 1 h | Porous material with improved compressibility |

| Ruan et al. [115] | Basswood | – | NaOH (≥96%), Na2SO3 (≥97%), H2O2 (30%), and absolute EtOH in ratio 1:0.16:20; specimens dried under supercritical CO2 (101 bar, 5 L/min) | – | – | Immersion, boiling for 5 h, ultrasonic cleaning; then treated in H2O2 and boiled; immersed in EtOH at 60 °C for 12 h | – |

| Han et al. [59] | Poplar (Populus) | 20 × 20 × 5 mm | Treatment with NaClO2 and glacial CH3COOH at 80 °C for 18 h (using CH3COOH, pH 4–5) | Post-treatment: slices frozen at −20 °C for 12 h, then freeze-dried for 24 h | – | Pyrolysis at 1000 °C for 2 h under argon | Hydrophobic, porous, flame-resistant lignocellulosic carbon material |

| Zou et al. [22] | Birch (Betula spp.) | 120 × 80 × 0.7 mm (rotary-cut) | Immersion in 2.5 M NaOH and 0.4 M Na2SO3 at 100 °C for 2 h; then immersion in boiling H2O2 for 30 min | Dried in oven at 103 °C until moisture reached 5%; densified samples cooled to 20–30 °C | Reduced from 19.8% to 11.6% | Infiltration with phenol–formaldehyde resin; densification pressing at 150 °C, 15 MPa for 15 min | Structural applications |

| Niu et al. [42] | Poplar | Not specified (wood tubes molded) | Treated with NaClO2 and CH3COOH; tubes poured into mold, frozen, then freeze-dried at −50 °C | – | Removal ~56 ± 5% | Pressing under 20 MPa, followed by carbonization at 600, 800, 1000, 1200 °C | Energy storage applications |

| Wu et al. [116] | New Zealand pine and Basswood | Veneers: 20 × 20 × 0.50 mm | Treatment with MMA, NaClO2, EtOH, glacial CH3COOH, NaOH and AIBN; samples dried at 103 °C for 24 h and stored in EtOH | – | New Zealand pine: 27.64% → 22.80%; Basswood: 23.04% → 19.11% | MMA polymerization and impregnation | “Transparent” wood composite |

| Wang et al. [12] | Poplar tree | 100 × 20 × 10 mm | Delignification using aq. NaOH (0–6 wt%) and 50 wt% MA at 155 °C for 30 min in a 1 L bomb reactor | After densification: dried in a climate chamber at 20 °C, 65% RH for 2 weeks | – | Acid hydrotropic delignification using MA hydrotropic fractionation at 100 °C for 30 min; densification from 10 mm to 8 mm at 1.0 MPa, 15 min at 150 °C | Broad applications |

| Liu et al. [21] | Balsa (Ochromalagopus Swartz) | 40 × 20 × 2 mm | Immersion in 2.5 M NaOH and 0.4 M Na2SO3, boiled for 36 h | – | – | Impregnation with solid–solid phase change materials | Energy-saving building materials |

| Yang et al. [70] | Populus Euramericana | 50 × 10 × 3 mm (L × T × R) | Hot H2O extraction with ethanol:benzene (1:2 v/v) for 48 h, then water bath at 60 °C for 3 h; delignification under −0.1 MPa vacuum for 5 h (mixture: 483.5 mL H2O, 10 g NaClO2, 6.5 mL CH3COOH); water bath at 40 °C for 30 h | Air-dried 48 h, then vacuum-dried at 80 °C until constant weight | Native wood: 22.89%; delignification rates: 1L = 12.81%, 2L = 39.12%, 3L = 52.24% | – | Investigation of dynamic mechanical and sorption behavior |

| Foster et al. [55] | Balsa | 100 × 100 mm | Two approaches: (a) Chlorite-based: 1 wt% NaClO2 in 1 N acetate buffer (pH ≈ 4.6) at 80 °C for 8–12 h; (b) Peroxide-based: Solution with 3 wt% sodium silicate, 3 wt% NaOH, 0.1 wt% MgSO4, 1 wt% EDTA, 4 wt% H2O2 at ~70 °C for ~2 h | – | Lignin content: chlorite: 11.4%; peroxide: 20.3% (vs. natural 24.8%) | Acetylation and methacrylation of delignified wood | Modified wood for enhanced properties |

| Liang et al. [19] | Hybrid poplar clones | 2 × 2 cm (cross-section) | Treatment in a 1:1 mixture of 30% H2O2 and glacial CH3COOH; boiled at 40 °C for durations of 0, 1, 6, 10, 32, 34 h | Pre-dried in oven at 60 °C; post-freeze-dried at −60 °C overnight | Reduced from 27.3% to 22.6%, 14.8%, 5.6%, 1.40%, 0.2% with increased time | Vacuum-assisted resin transfer molding with bisphenol A-type epoxy resin; densification via hot pressing at 23 MPa, 100 °C for 1 h | Porous material with improved compressibility |

| Chen et al. [73] | Balsa | 30 × 30 × 1 mm | Immersion in 2 wt% NaClO2 in CH3COOH (pH 4.6) for 2 h; preserved in EtOH; then immersed in 15 wt% NaOH at room temperature for 2 h | – | – | In situ chemical polymerization with polyacrylamide | Strong, flexible hydrogel reinforced by wood skeleton |

| Wu et al. [116] | New Zealand pine and Basswood | Veneers: 20 × 20 × 0.50 mm | Treatment with MMA, NaClO2, EtOH, glacial CH3COOH, NaOH and AIBN; samples dried at 103 °C for 24 h and stored in EtOH | – | New Zealand pine: 27.64% → 22.80%; Basswood: 23.04% → 19.11% | MMA polymerization and impregnation | “Transparent” wood composite |

| Jakob et al. [58] | Spruce veneer | 50 × 50 mm | Soaking in a 2:1 EtOH–DI H2O mixture with 1.5% CH3COOH in a 5 L pressure reactor at 170 °C, 14 bar for 180 min (heating 75 min, cooling 120 min); or immersion in 0.4 M Na2SO3 and 2.5 M NaOH at 98.5 °C for 240 min | Stored in a climate chamber at 20 °C and 65% RH | – | Densification at 120 °C under 20 MPa for 15 min (held overnight) | Densified plywood |

| Jakob et al. [17] | Spruce | 100 × 50 × 1.47 mm (axial × radial × tangential) | 20 veneers immersed in 1 L solution of 2.5 M NaOH and 0.4 M Na2SO3 at ~119 °C (0.19 MPa) for 4 h; repeatedly washed | After cooling (to 60 °C), equilibrated at 20 °C and 65% RH for 2 weeks | – | Veneers densified in tangential direction in a hot press at 120 °C, 35 MPa for 7.5 min | Load-bearing applications |

| Mi et al. [117] | Balsa | 100 × 50 × 0.8 mm | Bleaching in 5% NaClO solution for 3, 8, 12, 24 h at room temperature; rinsing with DI H2O | Samples freeze-dried, then dried in a hot oven at 60 °C for 48 h | Final lignin content ~0.8% | Infiltration with poly(vinyl alcohol) solution (8 wt% at 90 °C) with degassing under 200 Pa | “Transparent” wood composites and thermal insulators |

| He et al. [40] | Basswood | 20 mm thickness | Immersion in 2.5 M H2O2 (in DI H2O and EtOH); boiled until wood turned white; rinsed in EtOH/H2O three times | Preserved in EtOH/H2O overnight and air-dried | Final lignin content ~0.6% | Partial densification by hot pressing (thickness reduced by half, density ≈ 0.7 g/cm3) | Bulk materials via stacking delignified blocks |

| Mania et al. [118] | Poplar (Populus alba L.) and Birch (Betula pendula) | 20 (T) × 30 (R) × 20 (L) mm | Immersion in boiling 2.5 M NaOH and 0.4 M Na2SO3 solution for 7 h at 110 °C | – | Birch: 21.6% → 17.2%; Poplar: 25.2% → 16.6% | Plasticization in boiling water (1 h); then tangential pressing with clamping | Partial delignification and densification |

| Fang et al. [119] | Pinewood | 100 × 35 × 3 mm | In a 1 L autoclave: 5 g NaOH, 15 g Na2SO3, 0.03 g anthraquinone dissolved in 600 mL of 20 wt% MeOH solution (MeOH/H2O = 1:4, wood/solution = 1:20); processed for 1–7 h at 170 °C; quenched | – | – | Immersed in 20 wt% MeOH solution for 24 h; pressed at 8 MPa for 3 h, then at 90 °C for 3 min | Super-strong nanocellulose films |

| Li et al. [5] | Basswood | Various thicknesses: 0.8, 5, 40 mm; sizes: 210 × 190 mm, 100 × 50 mm, 50 × 50 mm | H2O2 (30 wt%) steam delignification: steamed until yellow color disappeared (≈2–12 h); rinsed with ultrapure H2O and EtOH | Dried at 105 °C for 24 h pre-treatment | Final lignin contents: 0.84, 0.96, 0.94 (approx.) | Infiltration with MA and epoxy polymer | “Transparent” wood composites |

| Khakalo et al. [120] | Birch | Veneers: 1.5 ± 0.1 mm; Dimensions: 10 × 10 cm | 1 wt% NaClO2 in acetate buffer (pH 4.6) in 3 L at 80 °C for 12 h | Stored at 23 °C and 50% RH | Final lignin content: 8.6% | Infiltration with ionic liquid ([EMIM]OAc) activated at 95 °C; hot pressing at 5 MPa for 16 h at 100 °C | Bulk hot-pressed high-performance wood via ionic liquid treatment |

| Wu et al. [44] | Basswood (Tilia) | Veneers: 20 × 20 × 0.42 mm | 2 wt% NaClO2, 0.1 wt% glacial CH3COOH, 97.9 wt% ultrapure H2O; treated in water bath at 80 °C (40 rpm) for 30–150 min | Dried at 103 °C for 24 h pre-treatment; then stored in EtOH | Lignin content decreases gradually (e.g., from 24% to 9%) | MMA polymerization and impregnation | “Transparent” wood composites for optical applications |

| Yang et al. [121] | Poplar | Not specified | Hot water extraction using EtOH:benzene (1:2 v/v) for 48 h; water bath at 60 °C for 3 h; then delignification: 967 mL water, 20 g NaClO2, 13 mL CH3COOH under −0.1 MPa vacuum for 5 h; water bath at 40 °C for 30 h | – | – | Wood furfurylation | Wood furfurylation |

| Han et al. [72] | Basswood | 50 × 50 × 10 mm | Bleaching in 2 wt% NaClO2 (buffered with CH3COOH at pH 3.5) for 12 h at 70 °C (repeated 3 times), followed by treatment in 5 wt% NaOH at 90 °C for 7 h | Pre-dried at 105 °C for 12 h; equilibrated in desiccator (saturated K2SO4, ~97.6% RH at 20 °C) | Final lignin content: 2.3% | Densification along radial direction: compression from 10 mm to 3.5 mm (LF) or 2.5 mm (HF); conditioned at 72 °C for 24 h then cooled | Ultra-strong and tough bulk materials via hydrogen bonding |

| Huang et al. [122] | Balsa | No tspecified | Immersion in 2 wt% NaClO2 (buffered with CH3COOH, pH 3.8) at 105 °C for 12 h (solution refreshed every 2 h); then transferred to 8 wt% NaOH at 80 °C for 12 h | – | – | – | Magnetic wood sponge for crude oil cleanup via electrothermal processes |

| Vitas et al. [20] | Beech | 2.5 cm × 1 mm (RT × L) | CH3COOH (>99.8%) and 35 wt% H2O2; samples oven-dried at 65 °C pre-treatment; post-delignification drying in oven (65 °C, 24 h) or freeze-drying (with liquid N2, then high vacuum for 5 days) | – | – | Characterization by mercury intrusion porosimetry | Porosity characterization of delignified beech wood |

| Gan et al. [123] | Basswood | 10 × 10 × 25 mm; 10 × 5 × 25 mm | Immersion in 1000 mL of mixed 2.5 M NaOH and 0.4 M Na2SO3 solution; boiled for 24 h; rinsed with distilled H2O | – | – | Densification at 100 °C under 5 MPa for ≈24 h | Fire-retardant wood structural material |

| Frey et al. [124] | Norway spruce | 100 × 10 × 20 mm | Immersion in equal-volume mixture of 35 wt% H2O2 and glacial CH3COOH at 80 °C for 6 h; repeated once with fresh solution | Stored at 20 °C/65% RH; conditioned until constant mass | – | Densification in radial direction (compression from 10 mm to 3.5 mm for LF, 2.5 mm for HF) | High-strength bulk material |

| Segmehl et al. [56] | Spruce | Not specified | Acidic bleaching with 1:1 mixture of 30% H2O2 and CH3COOH; various treatment times (0.5–4 h at 40, 60, 80 °C); also soda pulping with 10 wt% NaOH at 40 and 80 °C for 4–8 h | – | – | – | Tunable wood and functional materials |

| Song et al. [79] | Basswood, Oak, Poplar, Western Red Cedar, Eastern White Pine | 120 × 44 × 44 mm | Immersion in boiling aqueous solution of 2.5 M NaOH and 0.4 M Na2SO3 for 7 h | – | Achieved lignin removal ~45% | Pressed at 100 °C under ~5 MPa for 24 h | “Super” wood materials |

| Gan et al. [82] | Cathay poplar (Populus cathayana Rehd) | 20 × 20 × 0.5 mm | Treated with 2 wt% NaClO2 in CH3COOH (pH 4.6) at 80 °C for 12 h; rinsed; then immersed in 5 M H2O2 and boiled for 4 h | – | – | Infiltration with prepolymerized MMA and Fe3O4 nanoparticles (ratios 1000:1, 1000:2, 1000:5) under vacuum (30 min, repeated 3×); dried at 50 °C for 6 h | “Transparent” wood composites with magnetic function |

| Song et al. [125] | Balsa | 102 × 51 × 1 mm | Boiling in aqueous solution of NaOH and Na2SO3 for 1 h; then quickly transferred into a vacuum chamber | – | Final lignin content: 19.7% | – | “Super flexible” wood materials |

| Li et al. [27] | Pine, Birch, Ash | 100 × 100 × 1.5 mm | Immersion in solution of DI H2O, sodium silicate (3.0 wt%), NaOH (3.0 wt%), MgSO4 (0.1 wt%), DTPA (0.1 wt%), and H2O2 (4.0 wt%) | Samples dried at 105 °C for 24 h pre-treatment | Pine: 32.5% → 5.2%; Birch: 24.2% → 3.3%; Balsa: 23.5% → 2.2%; Ash: 27.1% → 5.3% | Immersion at 70 °C until white; washed and stored in water | “Transparent” wood composites |

| Li et al. [78] | Balsa | 20 × 20 mm; thickness: 0.6 ± 0.1, 1.0, 2.5 ± 0.1, 5.0, 8.0 mm | 1 wt% NaClO2 with acetate buffer (pH 4.6) at 80 °C; reaction time: 6 h (<3 mm) and 12 h (5 and 8 mm) | Samples dried at 105 °C for 24 h pre-treatment | Reduced from 24.9% to 2.9% | Sequential washing (DI H2O, then EtOH, then 1:1 EtOH/acetone, then pure acetone; 3 cycles); infiltration with prepolymerized MMA; polymerization at 70 °C for 4 h | “Transparent” wood composites for optical applications |

| Zhu et al. [46] | Basswood | Not specified | Boiling in NaOH (2.5 M) and Na2SO3 (0.4 M) in DI H2O for 12 h; followed by bleaching in H2O2 (2.5 M) | – | – | – | “Transparent” wood composites for solar cells (using PVP) |

| Zhang et al. [126] | Chinesefir (Cunninghamialanceolata) | 100 μm (tangential) × 10 mm (radial) × 35 mm (longitudinal) | Aqueous solution of 0.3% NaClO2 buffered with glacial CH3COOH (pH 4.4–4.8) for 4–8 h at 80 °C; then treatment with a solution (pH 2.7) containing NaClO2 (1.0 g in 150 mL water and 2.0 mL glacial acid) for 8 h at 80 °C | Samples washed and stored in refrigerator at 4–8 °C | Lignin content: 29.76, 25.37, 0.40 (values provided) | – | Analyzing mechanical properties |

| Yano et al. [57] | Hooppine veneers | 80 × 60 × 1 mm | Partial removal using 1% NaClO2 followed by 0.1% NaOH at 20 °C for 24 h; then treatment at 45 °C for 12 h with 2000 mL 1–2% NaClO2 (pH 4.5), repeated up to 3 times | – | Weight loss: 14% (1% NaClO2) or 24% (2% NaClO2) | Impregnation with low-molecular-weight PF resin; nine-ply lamination; compression at 80 MPa and 160 °C for 1 h | High-strength wood |

5. Influence of Delignification on Physical–Mechanical Properties of Resulting Wood

6. Influence of Delignification on Wood Chemical, Microstructural, Optical, and Thermal Properties, Along with the Role of Drying Conditions

7. Applications of Delignified Wood

- Structural and Construction Materials: Delignified and densified wood can be used for flooring, decking, siding, and building components, where increased strength and stability are critical for outdoor and load-bearing applications [15,32]. Furthermore, delignified wood treated with hydrophobic agents or impregnated with polymers improves resistance to decay and moisture, making it suitable for marine structures (e.g., piers and docks) and utility poles [39,128].

- Packaging: The sustainability, low weight, and high strength of modified wood make it a viable substitute for traditional, non-degradable packaging materials [12].

- Musical Instruments: Enhanced mechanical properties and dimensional stability offer potential for manufacturing high-quality, durable musical instruments with improved acoustic performance [55].

- Biomaterials and Tissue Engineering: Delignified and impregnated wood can serve as a biocompatible scaffold for medical implants, bone grafts, and tissue engineering. Its hierarchical porous structure promotes cell adhesion, proliferation, and nutrient transport. For example, anisotropic hydrogels derived from delignified wood have been used to mimic muscle tissue, while wood-based scaffolds infused with hydroxyapatite and polycaprolactone simulate bone structure and support osteogenic differentiation [79,88,140].

- Thermal Management and Insulation: Delignified wood can function both as a thermal conductor and an insulator. Densified wood may serve as an efficient heat sink or structural cooling material in buildings, while modified wood with low thermal conductivity is ideal for insulation in construction, refrigeration, and industrial high-temperature applications [28,31,47,48].

Utilization of Lignin After Delignification

- High-Value Chemicals: Lignin can be depolymerized into compounds, such as vanillin, syringol, and guaiacol, for use in flavors, fragrances, pharmaceuticals, and polymeric synthesis [138].

- Biofuels: Processes like pyrolysis, gasification, and fermentation convert lignin into biofuels, offering sustainable alternatives to fossil fuels.

- Advanced Materials: Lignin serves as a precursor for carbon fibers, graphene, and nanocellulose composites. When combined with binder polymers (e.g., PAN, PVA, and PVP), lignin-based electrospun nanofibers can be carbonized to yield materials for solar cells, catalysis, energy storage, and biomedical applications [35,139].

- Agricultural Applications: Lignin can function as a soil conditioner and fertilizer, improving soil structure and water retention, or be transformed into bio-based herbicides and pesticides.

- Adhesives and Binders: Currently, lignin is used as a binder in the chemical industry. Recent studies, such as those by Hou et al. [52], have demonstrated that lignin can reinforce cellulose paper, improving its dry and wet strength, thermostability, and UV-blocking ability.

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tenorio, C.; Moya, R. Effect of thermo-hydro-mechanical densification in the wood properties of three short-rotation forest species in Costa Rica. BioResources 2020, 15, 8065–8084. [Google Scholar] [CrossRef]

- Esteves, B.; Pereira, H. Wood modification by heat and steam. Eur. J. Wood Wood Prod. 2008, 70, 155–163. [Google Scholar]

- Kutnar, A.; Kamke, F.; Sernek, M. The mechanical properties of densified VTC wood are relevant for structural composites. Holz. Roh. Werkst. 2008, 66, 439–446. [Google Scholar] [CrossRef]

- Yano, H.; Mori, K.; Collins, P.J.; Yazaki, Y. Effects of element size and orientation in the production of high strength resin impregnated wood based materials. Holzforschung 2000, 54, 443–444. [Google Scholar] [CrossRef]

- Li, H.; Guo, X.; He, Y.; Zheng, R. A green steam-modified delignification method to prepare low-lignin delignified wood for thick, large highly transparent wood composites. J. Mater. Res. 2019, 34, 932–940. [Google Scholar] [CrossRef]

- Shams, M.I.; Yano, H. A New Method for Obtaining High Strength Phenol Formaldehyde Resin-Impregnated Wood Composites at Low Pressing Pressure. J. Trop. For. Sci. 2009, 21, 175–180. [Google Scholar]

- Shams, M.I.; Yano, H. Compressive deformation of phenol formaldehyde (PF) resin-impregnated wood related to the molecular weight of resin. Wood Sci. Technol. 2011, 45, 73–81. [Google Scholar] [CrossRef]

- Mora Mendez, D.F.; Olaniran, S.O.; Rüggeberg, M.; Burgert, I.; Herrmann, H.J.; Wittel, F.K. Mechanical behavior of chemically modified Norway spruce: A generic hierarchical model for wood modifications. Wood Sci. Technol. 2019, 53, 447–467. [Google Scholar] [CrossRef]

- Homan, W.J.; Jorissen, A.J. Wood modification developments. Heron 2004, 49, 360–369. [Google Scholar]

- Fang, C.-H.; Mariotti, N.; Cloutier, A.; Koubaa, A.; Blanchet, P. Densification of wood veneers by compression combined with heat and steam. Eur. J. Wood Wood Prod. 2012, 70, 155–163. [Google Scholar] [CrossRef]

- Pařil, P.; Brabec, M.; Maňák, O.; Rousek, R.; Rademacher, P.; Čermák, P.; Dejmal, A. Comparison of selected physical andmechanical properties of densified beech wood plasticized by ammonia and saturated steam. Eur. J. Wood Wood Prod. 2014, 72, 583–591. [Google Scholar] [CrossRef]

- Wang, J.; Minami, E.; Asmadi, M.; Kawamoto, H. Effect of delignification on thermal degradation reactivities of hemicellulose and cellulose in wood cell walls. J. Wood Sci. 2021, 67, 19. [Google Scholar] [CrossRef]

- Vieira, F.R.; Magina, S.; Evtuguin, D.V.; Barros-Timmons, A. Lignin as a renewable building block for sustainable polyurethanes. Materials 2022, 15, 6182. [Google Scholar] [CrossRef] [PubMed]

- Renders, T.; Cooreman, E.; Van den Bosch, S.; Schutyser, W.; Koelewijn, S.-F.; Vangeel, T.; Deneyer, A.; Van den Bossche, G.; Courtin, C.M.; Sels, B.F. Catalytic lignocellulose biorefining in n-butanol/water: A one-pot approach toward phenolics, polyols, and cellulose. Green Chem. 2018, 20, 4607–4619. [Google Scholar] [CrossRef]

- Frey, M.; Widner, D.; Segmehl, J.S.; Casdorff, K.; Keplinger, T.; Burgert, I. Delignified and densified cellulose bulk materials with excellent tensile properties for sustainable engineering. ACS Appl. Mater. Interfaces 2018, 10, 5030–5037. [Google Scholar] [CrossRef]

- Grönquist, P.; Frey, M.; Keplinger, T.; Burgert, I. Mesoporosity of Delignified Wood Investigated by Water Vapor Sorption. ACS Omega 2019, 4, 12425–12431. [Google Scholar] [CrossRef] [PubMed]

- Jakob, M.; Gaugeler, J.; Gindl-Altmutter, W. Effects of fiber angle on the tensile properties of partially delignified and densified wood. Materials 2020, 13, 5405. [Google Scholar] [CrossRef]

- Kumar, A.; Jyske, T.; Petrič, M. Delignified Wood from Understanding the Hierarchically Aligned Cellulosic Structures to Creating Novel Functional Materials: A Review. Adv. Sustain. Syst. 2021, 5, 2000251. [Google Scholar] [CrossRef]

- Liang, R.; Zhu, Y.H.; Wen, L.; Zhao, W.W.; Kuai, B.; Zhang, Y.L.; Cai, L.P. Exploration of effect of delignification on the mesopore structure in poplar cell wall by nitrogen absorption method. Cellulose 2020, 27, 1921–1932. [Google Scholar] [CrossRef]

- Vitas, S.; Segmehl, J.S.; Burgert, I.; Cabane, E. Porosity and pore size distribution of native and delignified beech wood determined by mercury intrusion porosimetry. Materials 2019, 12, 416. [Google Scholar] [CrossRef]

- Liu, J.; Wang, D.; Li, Y.; Zhou, Z.; Zhang, D.; Li, J.; Chu, H. Overall Structure Construction of an Intervertebral Disk Based on Highly Anisotropic Wood Hydrogel Composite Materials with Mechanical Matching and Buckling Buffering. ACS Appl. Mater. Interfaces 2021, 13, 15709–15719. [Google Scholar] [CrossRef]

- Zou, M.; Tang, Q.; Guo, W. High-strength wood-based composites via laminated delignified wood veneers with different adhesive contents for structural applications. Polym. Compos. 2022, 43, 2746–2758. [Google Scholar] [CrossRef]

- Evans, P.; Matsunaga, H.; Kiguchi, M. Large-scale application of nanotechnology for wood protection. Nat. Nanotechnol. 2008, 3, 577. [Google Scholar] [CrossRef] [PubMed]

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: Chichester, UK, 2007; Volume 5. [Google Scholar]

- Hill, C.A.S. Wood modification: An update. BioResources 2011, 6, 918–919. [Google Scholar] [CrossRef]

- Höglund, M.; Johansson, M.; Sychugov, I.; Berglund, L.A. Transparent Wood Biocomposites by Fast UV-Curing for Reduced Light-Scattering through Wood/Thiolene Interface Design. ACS Appl. Mater. Interfaces 2020, 12, 46914–46922. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Q.; Rojas, R.; Yan, M.; Lawoko, M.; Berglund, L. Lignin-Retaining Transparent Wood. ChemSusChem 2017, 10, 3445–3451. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Song, J.; Zhao, X.; Yang, Z.; Pastel, G.; Xu, S.; Jia, C.; Dai, J.; Chen, C.; Gong, A.; et al. Anisotropic, lightweight, strong, and super thermally insulating nanowood with naturally aligned nanocellulose. Sci. Adv. 2018, 4, eaar3724. [Google Scholar] [CrossRef]

- Li, J.; Chen, C.; Zhu, J.Y.; Ragauskas, A.J.; Hu, L. In Situ Wood Delignification toward Sustainable Applications. Acc. Mater. Res. 2021, 2, 606–620. [Google Scholar] [CrossRef]

- Lian, M.; Huang, Y.; Liu, Y.; Jiang, D.; Wu, Z.; Li, B.; Xu, Q.; Murugadoss, V.; Jiang, Q.; Huang, M.; et al. An overview of regenerable wood-based composites: Preparation and applications for flame retardancy, enhanced mechanical properties, biomimicry, and transparency energy saving. Adv. Compos. Hybrid Mater. 2022, 5, 1612–1657. [Google Scholar] [CrossRef]

- Lin, X.; Jia, S.; Liu, J.; Li, X.; Guo, X.; Sun, W. Thermally induced flexible wood based on phase change materials for thermal energy storage and management. J. Mater. Sci. 2021, 56, 16570–16581. [Google Scholar] [CrossRef]

- Song, J.; Chen, C.; Zhu, S.; Zhu, M.; Dai, J.; Ray, U.; Li, Y.; Kuang, Y.; Li, Y.; Quispe, N.; et al. Processing bulk natural wood into a high-performance structural material. Nature 2018, 554, 224–228. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Zhang, T.; Li, C.; Xiao, X.; Tang, Y.; Fang, X.; Peng, H.; Liu, X.; Dong, Y.; Cai, Y.; et al. Shape-reconfigurable transparent wood based on solid-state plasticity of polythiourethane for smart building materials with tunable light guiding, energy saving, and fire alarm actuating functions. Compos. Part B Eng. 2022, 246, 110260. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Y.; Yang, F.; Yang, L.; Wang, J.; Zhou, J.; Wang, J. A highly transparent compressed wood prepared by cell wall densification. Wood Sci. Technol. 2022, 56, 669–686. [Google Scholar] [CrossRef]

- Zhang, W.; Qiu, X.; Wang, C.; Zhong, L.; Fu, F.; Zhu, J.; Zhang, Z.; Qin, Y.; Yang, D.; Xu, C.C. Lignin derived carbon materials: Current status and future trends. Carbon Res. 2022, 1, 14. [Google Scholar] [CrossRef]

- Zhu, S.; Kumar Biswas, S.; Qiu, Z.; Yue, Y.; Fu, Q.; Jiang, F.; Han, J. Transparent wood-based functional materials via a top-down approach. Prog. Mater. Sci. 2023, 132, 101025. [Google Scholar] [CrossRef]

- Chen, C.; Kuang, Y.; Zhu, S.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.J.; Hu, L. Structure–property–function relationships of natural and engineered wood. Nat. Rev. Mater. 2020, 5, 642–666. [Google Scholar] [CrossRef]

- Farid, T.; Rafiq, M.I.; Ali, A.; Tang, W. Transforming wood as next-generation structural and functional materials for a sustainable future. EcoMat 2022, 4, e12154. [Google Scholar] [CrossRef]

- Gan, W.; Chen, C.; Wang, Z.; Song, J.; Kuang, Y.; He, S.; Mi, R.; Sunderland, P.B.; Hu, L. Dense, Self-Formed Char Layer Enables a Fire-Retardant Wood Structural Material. Adv. Funct. Mater. 2019, 29, 1807444. [Google Scholar] [CrossRef]

- He, S.; Chen, C.; Li, T.; Song, J.; Zhao, X.; Kuang, Y.; Liu, Y.; Pei, Y.; Hitz, E.; Kong, W.; et al. An Energy-Efficient, Wood-Derived Structural Material Enabled by Pore Structure Engineering towards Building Efficiency. Small Methods 2020, 4, 1900747. [Google Scholar] [CrossRef]

- Horikawa, Y. Structural diversity of natural cellulose and related applications using delignified wood. J. Wood Sci. 2022, 68, 54. [Google Scholar] [CrossRef]

- Niu, Q.; Tang, Q.; Sun, X.; Wang, L.; Gao, K. Wood-based carbon tubes with low-tortuosity and open tubular structure for energy storage application. J. Mater. Sci. 2022, 57, 5154–5166. [Google Scholar] [CrossRef]

- Karl’a, V. Update on Research on Transparent Wood. IOP Conf. Ser. Mater. Sci. Eng. 2019, 566, 12015. [Google Scholar] [CrossRef]

- Wu, J.; Wu, Y.; Yang, F.; Tang, C.; Huang, Q.; Zhang, J. Impact of delignification on morphological, optical and mechanical properties of transparent wood. Compos. Part A Appl. Sci. Manuf. 2019, 117, 324–331. [Google Scholar] [CrossRef]

- Mittal, N.; Jansson, R.; Widhe, M.; Benselfelt, T.; Håkansson, K.M.O.; Lundell, F.; Hedhammar, M.; Söderberg, L.D. Ultrastrong andBioactive Nanostructured Bio-Based Composites. ACS Nano 2017, 11, 5148–5159. [Google Scholar] [CrossRef]

- Zhu, H.; Luo, W.; Ciesielski, P.N.; Fang, Z.; Zhu, J.Y.; Henriksson, G.; Himmel, M.E.; Hu, L. Wood-Derived Materials for Green Electronics, Biological Devices, and Energy Applications. Chem. Rev. 2016, 116, 9305–9374. [Google Scholar] [CrossRef]

- Can, A. Thermal characterization of phase-changing materials as stabilized thermal energy storage materials in impregnated wood. Energy Storage 2022, 5, e397. [Google Scholar] [CrossRef]

- Kuai, B.; Wang, Z.; Gao, J.; Tong, J.; Zhan, T.; Zhang, Y.; Lu, J.; Cai, L. Development of densified wood with high strength and excellent dimensional stability by impregnating delignified poplar with sodium silicate. Constr. Build. Mater. 2022, 344, 128282. [Google Scholar] [CrossRef]

- Sun, H.; Bi, H.; Ren, Z.; Zhou, X.; Ji, T.; Xu, M.; Huang, Z.; Cai, L. Hydrostable reconstructed wood with transparency, Excellent ultraviolet-blocking performance, and photothermal conversion ability. Compos. Part B Eng. 2022, 232, 109615. [Google Scholar] [CrossRef]

- Wang, J.; Yue, H.; Du, Z.; Cheng, X.; Wang, H.; Du, X. Flame-retardant and form-stable delignified wood-based phase change composites with superior energy storage density and reversible thermochromic properties for visual thermoregulation. ACS Sustain. Chem. Eng. 2023, 11, 3932–3943. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, J.; Zhao, D.; Jia, L.; Qin, B.; Cao, X.; Zang, L.; Lu, F.; Liu, F. Biological degradation of lignin: A critical review on progress and perspectives. Ind. Crops Prod. 2022, 188, 115715. [Google Scholar] [CrossRef]

- Hou, D.; Li, T.; Chen, X.; He, S.; Dai, J.; Mofid, S.A.; Hou, D.; Iddya, A.; Jassby, D.; Yang, R.; et al. HydrophobicNanostructured Wood Membrane for Thermally Efficient Distillation. Sci. Adv. 2019, 5, eaaw3203. [Google Scholar] [CrossRef]

- Burgert, I.; Cabane, E.; Zollfrank, C.; Berglund, L. Bio-inspired functional wood-based materials-hybrids and replicates. Int. Mater. Rev. 2015, 60, 431–450. [Google Scholar] [CrossRef]

- Guan, Q.; Han, Z.; Yang, H.; Ling, Z.; Yu, S. Regenerated Isotropic Wood. Natl. Sci. Rev. 2020, 8, nwaa230. [Google Scholar] [CrossRef] [PubMed]

- Foster, K.E.O.; Jones, R.; Miyake, G.M.; Srubar, W.V. Mechanics, optics, and thermodynamics of water transport in chemically modified transparent wood composites. Compos. Sci. Technol. 2021, 208, 108737. [Google Scholar] [CrossRef]

- Segmehl, J.S.; Studer, V.; Keplinger, T.; Burgert, I. Characterization of wood derived hierarchical cellulose scaffolds for multifunctional applications. Materials 2018, 11, 517. [Google Scholar] [CrossRef] [PubMed]

- Yano, H.; Hirose, A.; Collins, P.J.; Yazaki, Y. Effects of the removal of matrix substances as a pretreatment in the production of high strength resin impregnated wood based materials. J. Mater. Sci. Lett. 2001, 20, 1125–1126. [Google Scholar] [CrossRef]

- Jakob, M.; Stemmer, G.; Czabany, I.; Müller, U.; Gindl-Altmutter, W. Preparation of high strength plywood from partially delignified densified wood. Polymers 2020, 12, 1796. [Google Scholar] [CrossRef]

- Han, S.; Wang, J.; Wang, L. Preparation of hydrophobic, porous, and flame-resistant lignocellulosic carbon material by pyrolyzing delignified wood. Vacuum 2022, 197, 110867. [Google Scholar] [CrossRef]

- Yang, T.; Zhong, H.; Xu, C.; Luo, D.; Mei, C. Fabrication and mechanism analysis of wood polymer composites with improved hydrophobicity, dimensional stability and mechanical strength. Cellulose 2023, 30, 3099–3112. [Google Scholar] [CrossRef]

- Zhao, J.; Li, X.; Qu, Y. Application of enzymes in producing bleached pulp from wheat straw. Bioresour. Technol. 2006, 97, 1470–1476. [Google Scholar] [CrossRef]

- Jiang, B.; Chen, C.; Liang, Z.; He, S.; Kuang, D.; Song, J.; Mi, R.; Chen, G.; Jiao, M.; Hu, L. Lignin as a Wood-Inspired Binder EnabledStrong, Water Stable, and Biodegradable Paper for Plastic Replacement. Adv. Funct. Mater. 2020, 30, 1906307. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.Y.; Yang, D.Q.; Wan, H. Dimensional stability of wood–polymer composites. J. Appl. Polym. Sci. 2006, 102, 5085–5094. [Google Scholar] [CrossRef]

- Zhang, X.; Tu, M.; Paice, M.G. Routes to potential bioproducts from lignocellulosic biomass lignin and hemicelluloses. BioEnergy Res. 2011, 4, 246–257. [Google Scholar] [CrossRef]

- Bi, Z.; Li, T.; Su, H.; Ni, Y.; Yan, L. Transparent Wood Film Incorporating Carbon Dots as Encapsulating Material for White Light-Emitting Diodes. ACS Sustain. Chem. Eng. 2018, 6, 9314–9323. [Google Scholar] [CrossRef]

- Chen, C.; Xu, S.; Kuang, Y.; Gan, W.; Song, J.; Chen, G.; Pastel, G.; Liu, B.; Li, Y.; Huang, H.; et al. Nature-Inspired Tri-Pathway Design Enabling High-Performance Flexible Li-O2 Batteries. Adv. Energy Mater. 2019, 9, 1802964. [Google Scholar] [CrossRef]

- Keplinger, T.; Burgert, I.; Frey, M. Versatile strategies for the development of wood-based functional materials. In Proceedings of the Bioinspiration, Biomimetics, and Bioreplication VIII, Denver, CO, USA, 27 March 2018; p. 36. [Google Scholar]

- Kumar, A.K.; Sharma, S. Recent updates on different methods of pretreatment of lignocellulosic feedstocks: A review. Bioresour. Bioprocess. 2017, 4, 7. [Google Scholar] [CrossRef] [PubMed]

- Seki, M.; Yashima, Y.; Abe, M.; Miki, T.; Nishida, M. Influence of delignification on plastic flow deformation of wood. Cellulose 2022, 29, 4153–4165. [Google Scholar] [CrossRef]

- Yang, T.; Cao, J.; Mei, C.; Ma, E. Effects of chlorite delignification on dynamic mechanical performances and dynamic sorption behavior of wood. Cellulose 2021, 28, 9461–9474. [Google Scholar] [CrossRef]

- Novel, D.; Ghio, S.; Gaiardo, A.; Picciotto, A.; Guidi, V.; Speranza, G.; Boscardin, M.; Bellutti, P.; Pugno, N.M. Strengthening of wood-like materials via densification and nanoparticle intercalation. Nanomaterials 2020, 10, 478. [Google Scholar] [CrossRef]

- Han, X.; Ye, Y.; Lam, F.; Pu, J.; Jiang, F. Hydrogen-bonding-induced assembly of aligned cellulose nanofibers into ultrastrong and tough bulk materials. J. Mater. Chem. A 2019, 7, 27023–27031. [Google Scholar] [CrossRef]

- Chen, C.; Wang, Y.; Wu, Q.; Wan, Z.; Li, D.; Jin, Y. Highly strong and flexible composite hydrogel reinforced by aligned wood cellulose skeleton via alkali treatment for muscle-like sensors. Chem. Eng. J. 2020, 400, 125876. [Google Scholar] [CrossRef]

- Wang, J.; Fishwild, S.J.; Begel, M.; Zhu, J.Y. Properties of densified poplar wood through partial delignification with alkali and acid pretreatment. J. Mater. Sci. 2020, 55, 14664–14676. [Google Scholar] [CrossRef]

- Millán, D.; González-Turen, F.; Perez-Recabarren, J.; Gonzalez-Ponce, C.; Rezende, M.C.; Da Costa Lopes, A.M. Solvent effects on the wood delignification with sustainable solvents. Int. J. Biol. Macromol. 2022, 211, 490–498. [Google Scholar] [CrossRef] [PubMed]

- Portela-Grandío, A.; Peleteiro, S.; Yáñez, R.; Romaní, A. Integral valorization of Acacia dealbata wood in organic medium catalyzed by an acidic ionic liquid. Bioresour. Technol. 2021, 342, 126013. [Google Scholar] [CrossRef]

- Toven, K.; Gellerstedt, G. Structural changes of softwood kraft lignin in oxygen delignification and prebleaching. In Proceedings of the 10th International Symposium on Wood and Pulping Chemistry, Yokohama, Japan, 7–10 June 1999; Volume 2, pp. 340–345. [Google Scholar]

- Li, Y.; Fu, Q.L.; Yu, S.; Yan, M.; Berglund, L. Optically transparent wood from a nanoporous cellulosic template: Combining functional and structural performance. Biomacromolecules 2016, 17, 1358–1364. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Fang, Q.; Chen, H.; Qi, F.; Ou, X.; Zhao, X.; Liu, D. Solvent-based delignification and decrystallization of wheat straw for efficient enzymatic hydrolysis of cellulose and ethanol production with low cellulase loadings. RSC Adv. 2017, 7, 10609–10617. [Google Scholar] [CrossRef]

- Pi, Q.F.; Zhu, Y.T.; Wei, L.Ü.; Liao, Y.H.; Wang, C.G. Low temperature pretreatment of poplar using deep eutectic solvent and the structural evolution of three components of poplar. J. Fuel Chem. Technol. 2021, 49, 1791–1801. [Google Scholar] [CrossRef]

- Soares, B.; da Costa Lopes, A.M.; Silvestre, A.J.D.; Rodrigues Pinto, P.C.; Freire, C.S.R.; Coutinho, J.A.P. Wood delignification with aqueous solutions of deep eutectic solvents. Ind. Crops Prod. 2021, 160, 113128. [Google Scholar] [CrossRef]

- Gan, W.T.; Gao, L.K.; Xiao, S.L.; Zhang, W.B.; Zhan, X.X.; Li, J. Transparent magnetic wood composites based on immobilizing Fe3O4 nanoparticles into a delignified wood template. J. Mater. Sci. 2017, 52, 3321–3329. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, F.; Zhu, S.; Li, H. Effects of high-pressure treatment on poplar wood: Density profile, mechanical properties, strength potential index, and microstructure. BioResources 2017, 12, 6283–6297. [Google Scholar] [CrossRef]

- Hemmilä, V.; Adamopoulos, S.; Karlsson, O.; Kumar, A. Development of sustainable bio-adhesives for engineered wood panels—A Review. RSC Adv. 2017, 7, 38604–38630. [Google Scholar] [CrossRef]

- Xia, Q.; Chen, C.; Yao, Y.; Li, J.; He, S.; Zhou, Y.; Li, T.; Pan, X.; Yao, Y.; Hu, L. A Strong, Biodegradable and Recyclable Lignocellulosic Bioplastic. Nat. Sustain. 2021, 4, 627–635. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Y.; Yang, F.; Yang, L.; Wang, J.; Zhou, J.K.; Zhang, T.; Li, C.; Xiao, X.; Tang, Y.; et al. Recent Development in Chemical Depolymerization of Lignin: A Review. J. Appl. Chem. 2013, 2013, 838645. [Google Scholar] [CrossRef]

- Ek, M.; Gellerstedt, G.; Henriksson, G. Volume 3 Paper Chemistry and Technology. In Pulp and Paper Chemistry and Technology; Walter de Gruyter: Berlin, Germany, 2009; pp. 1–371. [Google Scholar]

- Kong, W.; Wang, C.; Jia, C.; Kuang, Y.; Glenn Pastel, G.; Chen, C.; Chen, G.; He, S.; Huang, H.; Zhang, J.; et al. Muscle-inspired highly aniso-tropic, strong, ion-conductive hydrogels. Adv. Mater. 2018, 30, e1801934. [Google Scholar] [CrossRef]

- Heitner, C.; Dimmel, D.; Schmidt, J. Lignin and Lignans: Advancesin Chemistry; CRC Press: New York, NY, USA, 2019; pp. 393–471. [Google Scholar]

- Milovanović, B.; Štirmer, N.; Carević, I.; Baričević, A. Wood biomass ash as a raw material in concrete industry. Građevinar 2019, 71, 505–514. [Google Scholar]

- Liang, Y.; Zheng, G.; Xia, C.; Zuo, S.; Ge, S.; Yang, R.; Ma, X.; Fei, B.; Li, J.; Cheng, C.K.; et al. Synthesis of ultra-high strength structured material from steam-modified delignification of wood. J. Clean. Prod. 2022, 351, 131531. [Google Scholar] [CrossRef]

- Wang, J.; Simson, R.; Gleisner, R.; Fishwild, S.J.; Begel, M.; Zhu, J.Y. Carbonate pre-treatment of wood for transformative structural applications through densification. Ind. Crops Prod. 2022, 188, 115645. [Google Scholar] [CrossRef]

- Börcsök, Z.; Pásztory, Z. The role of lignin in wood working processes using elevated temperatures: An abbreviated literature survey. Eur. J. Wood Wood Prod. 2001, 79, 511–526. [Google Scholar] [CrossRef]

- Furuta, Y.; Kojiro, K.; Nakatani, T.; Nakajima, M.; Ishimaru, Y. The dynamic viscoelastic properties of wood in non equilibrium states. J. Soc. Mater. Sci. Jpn. 2008, 57, 338–343. [Google Scholar] [CrossRef][Green Version]

- Furuta, Y.; Nakajima, M.; Nakanii, E.; Ohkoshi, M. The effect of lignin and hemicellulose on thermal-softening properties of water-swollen wood. Mokuzai Gakkaishi 2010, 56, 132–138. [Google Scholar] [CrossRef]

- Hatakeyama, H.; Hatakeyama, T. Thermal properties of isolated and in situ lignin. In Lignin and Lignans: Advances in Chemistry; Heitner, C., Dimmel, D., Schmidt, J., Eds.; CRC Press: New York, NY, USA, 2010; pp. 301–316. [Google Scholar]

- Goring, D.A.I. Thermal softening of lignin, hemicellulose and cellulose. Pulp Paper Mag. Can. 1963, 64, T517–T527. [Google Scholar]

- Schaffer, E.L. Effect of pyrolytic temperatures on the longitudinal strength of dry Douglas-fir. J. Test. Eval. 1973, 1, 319–329. [Google Scholar] [CrossRef]

- Back, E.L.N.L.; Salmén, L. Glass transitions of wood components hold implications for molding and pulping processes. TAPPI J. 1982, 65, 107110. [Google Scholar]

- Sehlstedt-Persson, M. Properties of Solid Wood: Responses to Drying and Heat Treatment. Ph.D. Dissertation, Luleå Tekniska Universitet, Luleå, Sweden, 2005. [Google Scholar]

- Brebu, M.; Vasile, C. Thermal degradation of lignin—A review. Cellul. Chem. Technol. 2010, 44, 353. [Google Scholar]

- Wang, J.; Liu, J.; Li, J.; Zhu, J.Y. Characterization of microstructure, chemical, and physical properties of delignified and densified poplar wood. Materials 2021, 14, 5709. [Google Scholar] [CrossRef]

- Wiedenhoeft, A.C.; Miller, R.B. Structure and Function of Wood. In Handbook of Wood Chemistry and Wood Composites; Rowell, R.M., Ed.; CRC Press: New York, NY, USA, 2005; pp. 9–32. [Google Scholar]

- Huang, C.; Lindström, H.; Nakada, R.; Ralston, J. Cell wall structure and wood properties determined by acoustics—A selective review. Holz Roh-Werkst. 2003, 61, 321–335. [Google Scholar] [CrossRef]

- Cosgrove, D.J.; Jarvis, M.C. Comparative structure and biomechanics of plant primary and secondary cell walls. Front. Plant Sci. 2012, 3, 204. [Google Scholar] [CrossRef] [PubMed]

- Barnett, J.; Jeronimidis, G. (Eds.) Wood Quality and Its Biological Basis; Wiley-Blackwell: Hoboken, NJ, USA, 2009; ISBN 978-1-405-14781-1. [Google Scholar]

- Yin, Y.; Berglund, L.; Salmén, L. Effect of steam treatment on the properties of wood cell walls. Biomacromolecules 2011, 12, 194–202. [Google Scholar] [CrossRef]

- Zhang, C.; Shen, X.; Liu, M.; Wen, J.; Yuan, T.Q. Uncovering the structure of lignin from moso bamboo with different tissues and growing ages for efficient ambient-pressure lignin depolymerization. ACS Sustain. Chem. Eng. 2023, 11, 13778–13786. [Google Scholar] [CrossRef]

- Sen, S.; Sadeghifar, H.; Argyropoulos, D.S. Kraft lignin chain extension chemistry via propargylation, oxidative coupling, and claisen rearrangement. Biomacromolecules 2013, 14, 3399–3408. [Google Scholar] [CrossRef]

- Horvath, B.; Peralta, P.; Frazier, C.; Peszlen, I. Thermal softening of transgenic aspen. BioResources 2011, 6, 2125–2134. [Google Scholar] [CrossRef]

- Gellerstedt, G. Softwood kraft lignin: Raw material for the future. Ind. Crops Prod. 2015, 77, 845–854. [Google Scholar] [CrossRef]

- Van Hai, L.; Pham, D.H.; Kim, J. Effect of Bleaching and Hot-Pressing Conditions on Mechanical Properties of Compressed Wood. Polymers 2022, 14, 2901. [Google Scholar] [CrossRef]

- Mai, X.; Liu, H.; Mai, J.; Wang, N.; Li, X.; Wang, R.; Zhang, H. Ultra-flexible flame-retardant wood composites with resistance to extreme temperatures and mildew. Cell Rep. Phys. Sci. 2022, 3, 100732. [Google Scholar] [CrossRef]

- Samanta, A.; Höglund, M.; Samanta, P.; Popov, S.; Sychugov, I.; Maddalena, L.; Carosio, F.; Berglund, L.A. Charge Regulated Diffusion of Silica Nanoparticles into Wood for Flame Retardant Transparent Wood. Adv. Sustain. Syst. 2022, 6, 2100354. [Google Scholar] [CrossRef]

- Ruan, J.Q.; Li, Z.; Xie, K.Y.; Guo, W.; Fei, C.; Lu, M.H.; Yang, H. Multifunctional cellulose wood with effective acoustic absorption. AIP Adv. 2022, 12, 055102. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, J.; Yang, F.; Wang, Y.; Wang, J.; Zhang, J. A strong multilayered transparent wood with natural wood color and texture. J. Mater. Sci. 2021, 56, 8000–8013. [Google Scholar] [CrossRef]

- Mi, R.; Li, T.; Dalgo, D.; Chen, C.; Kuang, Y.; He, S.; Zhao, X.; Xie, W.; Gan, W.; Zhu, J.; et al. A Clear, Strong, and Thermally Insulated Transparent Wood for Energy Efficient Windows. Adv. Funct. Mater. 2020, 30, 1907511. [Google Scholar] [CrossRef]

- Mania, P.; Wróblewski, M.; Wójciak, A.; Roszyk, E.; Moliński, W. Hardness of densified wood about changed chemical composition. Forests 2020, 11, 506. [Google Scholar] [CrossRef]

- Fang, Z.; Li, B.; Liu, Y.; Zhu, J.; Li, G.; Hou, G.; Zhou, J.; Qiu, X. Critical Role of Degree of Polymerization of Cellulose in Super-Strong Nanocellulose Films. Matter 2020, 2, 1000–1014. [Google Scholar] [CrossRef]

- Khakalo, A.; Tanaka, A.; Korpela, A.; Hauru, L.K.; Orelma, H. All-Wood Composite Material by Partial Fiber Surface Dissolution with an Ionic Liquid. ACS Sustain. Chem. Eng. 2019, 7, 3195–3202. [Google Scholar] [CrossRef]

- Yang, H.; Chao, W.; Di, X.; Yang, Z.; Yang, T.; Yu, Q.; Liu, F.; Li, J.; Li, G.; Wang, C.; et al. Multifunctional wood based composite phase change materials for magnetic-thermal and solar-thermal energy conversion and storage. Energy Convers. Manag. 2019, 200, 112029. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, L.; Lai, X.; Li, H.; Zeng, X. Highly hydrophobic F-rGO@ wood sponge for efficient clean-up of viscous crude oil. Chem. Eng. J. 2019, 386, 123994. [Google Scholar] [CrossRef]

- Gan, W.; Chen, C.; Giroux, M.; Zhong, G.; Goyal, M.M.; Wang, Y.; Ping, W.; Song, J.; Xu, S.; He, S.; et al. Conductive wood for high-performance structural electromagnetic interference shielding. Chem. Mater. 2020, 32, 5280–5289. [Google Scholar] [CrossRef]

- Frey, M.; Schneider, L.; Masania, K.; Keplinger, T.; Burgert, I. Delignified Wood-Polymer Interpenetrating Composites Exceeding the Rule of Mixtures. ACS Appl. Mater. Interfaces 2019, 11, 35305–35311. [Google Scholar] [CrossRef]

- Song, J.; Chen, C.; Wang, C.; Kuang, Y.; Li, Y.; Jiang, F.; Li, Y.; Hitz, E.; Zhang, Y.; Liu, B.; et al. Superflexible Wood. ACS Appl. Mater. Interfaces 2017, 9, 23520–23527. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Wang, C.G.; Fei, B.H.; Yu, Y.; Cheng, H.T.; Tian, G.L. Mechanical Function of Lignin and Hemicelluloses in Wood Cell Wall Revealed with Microtension of Single Wood Fiber. BioResources 2013, 8, 2376–2385. [Google Scholar] [CrossRef]

- Ibarra, D.; Martín-Sampedro, R.; Wicklein, B.; Borrero-López, A.M.; Valencia, C.; Valdehíta, A.; Navas, J.M.; Eugenio, M.E. Populus alba L., an autochthonous species of Spain: A source for cellulose nanofibers by chemical pretreatment. Polymers 2021, 14, 68. [Google Scholar] [CrossRef]

- Keplinger, T.; Wittel, F.K.; Rüggeberg, M.; Burgert, I. Wood Derived Cellulose Scaffolds-Processing and Mechanics. Adv. Mater. 2020, 33, 2001375–2001394. [Google Scholar] [CrossRef]

- Vasubabu, M.; Babu, N.C.R.; Nagabhushanam, O.; Venkatesh, R.K. Chemical treatment effect on mechanical properties of Haldinacordifolia wood species. Mater. Today Proc. 2018, 5, 26424–26429. [Google Scholar] [CrossRef]

- Glass, S.V.; Zelinka, S.L. Wood Handbook: Wood as an Engineering Material; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; Chapter 4. [Google Scholar]

- Yan, G.; He, S.; Ma, S.; Zeng, A.; Chen, G.; Tang, X.; Sun, Y.; Xu, F.; Zeng, X.; Lin, L. Catechol-based all-wood hydrogels with anisotropic, tough, and flexible properties for highly sensitive pressure sensing. Chem. Eng. J. 2022, 427, 131896. [Google Scholar] [CrossRef]

- Yan, G.; He, S.; Chen, G.; Ma, S.; Zeng, A.; Chen, B.; Yang, S.; Tang, X.; Sun, Y.; Xu, F.; et al. Highly Flexible and Broad-Range Mechanically Tunable All-Wood Hydrogels with Nanoscale Channels via the Hofmeister Effect for Human Motion Monitoring. Nano-Micro Lett. 2022, 14, 84. [Google Scholar] [CrossRef]

- Fan, Z.; Sun, H.; Zhang, L.; Zhao, X.; Hu, Y. Lightweight, high-strength wood prepared by deep eutectic solvent treatment as a green structural material. ACS Sustain. Chem. Eng. 2022, 10, 9600–9611. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, Y.; Yang, Z.; Wang, X.; Li, Y.; Liu, F.; Jiang, Z.; Sun, X.; Li, X.; Zhao, Y.; et al. Turing Pattern-Inspired Highly Transparent Wood for Multifunctional Smart Glass with Superior Thermal Management and UV-Blocking Ability. Adv. Sustain. Syst. 2022, 6, 2200132. [Google Scholar] [CrossRef]

- Sulaiman, N.S.; Mohamad Amini, M.H. Review on the phase change materials in wood for thermal regulative wood-based products. Forests 2022, 13, 1622. [Google Scholar] [CrossRef]

- ASTM D143-22; Standard Test Methods for Small Clear Specimens of Timber. ASTM International: West Conshohocken, PA, USA, 2022. Available online: https://store.astm.org/d0143-22.html (accessed on 16 April 2025).

- ISO 13061-18:2022; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens. International Organization for Standardization (ISO): Geneva, Switzerland, 2022. Available online: https://www.iso.org/standard/79913.html (accessed on 16 April 2025).

- Schutyser, W.; Renders, T.; Van Den Bosch, S.; Koelewijn, S.F.; Beckham, G.T.; Sels, B.F. Chemicals from Lignin: An Interplay of Lignocellulose Fractionation, Depolymerisation, and Upgrading. Chem. Soc. Rev. 2018, 47, 852–908. [Google Scholar] [PubMed]

- Svinterikos, E.; Zuburtikudis, I.; Al-Marzouqi, M. Electrospun Lignin-Derived Carbon Micro- and Nanofibers: A Review on Precursors, Properties, and Applications. ACS Sustain. Chem. Eng. 2020, 8, 13868–13893. [Google Scholar] [CrossRef]

- Liu, J.; Yu, P.; Wang, D.; Chen, Z.; Cui, Q.; Hu, B.; Zhang, D.; Li, Y.; Chu, H.; Li, J. Wood-derived hybrid scaffold withhighly anisotropic features on mechanics and liquid transporttoward cell migration and alignment. ACS Appl. Mater. Interfaces 2020, 12, 17957–17966. [Google Scholar] [CrossRef]

| Delignification System | Function |

|---|---|

| ClO2 | Degrades lignin’s unsaturated structure, including aromatic ring components and olefinic side chains |

| NaClO | Deconstructs the quinone type of lignin, as well as decomposes the aliphatic side chain |

| H2O2 | Breaks down the ether bond in the lignin structure, producing aromatic compounds and side chains that are then oxidized into carbonyl and carboxyl compounds |

| Na2S | The ionized OH− and S2− break the lignin macromolecules |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Terzopoulou, P.; Vouvoudi, E.C.; Achilias, D.S. Delignification as a Key Strategy for Advanced Wood-Based Materials: Chemistry, Delignification Parameters, and Emerging Applications. Forests 2025, 16, 993. https://doi.org/10.3390/f16060993

Terzopoulou P, Vouvoudi EC, Achilias DS. Delignification as a Key Strategy for Advanced Wood-Based Materials: Chemistry, Delignification Parameters, and Emerging Applications. Forests. 2025; 16(6):993. https://doi.org/10.3390/f16060993

Chicago/Turabian StyleTerzopoulou, Paschalina, Evangelia C. Vouvoudi, and Dimitris S. Achilias. 2025. "Delignification as a Key Strategy for Advanced Wood-Based Materials: Chemistry, Delignification Parameters, and Emerging Applications" Forests 16, no. 6: 993. https://doi.org/10.3390/f16060993

APA StyleTerzopoulou, P., Vouvoudi, E. C., & Achilias, D. S. (2025). Delignification as a Key Strategy for Advanced Wood-Based Materials: Chemistry, Delignification Parameters, and Emerging Applications. Forests, 16(6), 993. https://doi.org/10.3390/f16060993