1. Introduction

Since its inception in the 1970s, computed tomography has been widely used in the medical and healthcare fields. However, with advancements in imaging techniques and X-ray sources, it has gradually found broader application in the testing of both homogeneous and heterogeneous materials [

1,

2,

3,

4,

5].

Since the 1990s, medical computed tomography (CT) has been increasingly applied in the forestry and woodworking industries to non-destructively examine the internal structures of logs. Research and development in this area have been ongoing for over 40 years. Wood is inherently heterogeneous in terms of structure, density, and size, which presents significant challenges for image analysis. Medical CT systems, originally developed to detect human diseases and organ damage, are generally not suitable for processing and analyzing images of wood [

6]. The complexity and variability of wood make standard medical CT software inadequate for reconstructing and evaluating its internal features. Consequently, medical CT is not well-suited for research or practical applications related to the structural and qualitative assessment of wood [

6].

For adequate visualization of wood material, nearly twice the X-ray dose is required compared to that used for the human body [

7]. New and faster CT scanners have been developed, enabling a 15% increase in evaluation efficiency for coniferous trees and a 24% increase for deciduous trees [

8]. Currently, computed tomography (CT) also provides a non-destructive method for determining the moisture content of wood in three dimensions, requiring two scans—one before and one after drying [

9]. However, because CT operates on the principle of measuring density through X-ray absorption, limitations have been identified, particularly for qualitative features that do not differ significantly in density from the surrounding wood tissue [

10].

Recently, several methods have been tested to improve the identification of qualitative features in CT scan image outputs, including mathematical algorithms, neural network training, and enhanced image analysis techniques [

10,

11,

12,

13,

14]. The most promising results have been achieved in the identification and evaluation of knots [

15,

16,

17]. Accurate detection of knots is particularly crucial in the evaluation of coniferous sawlogs, as it plays a key role in optimizing cutting plans and maximizing the yield of high-quality lumber. Additionally, good results have also been obtained in the identification and assessment of piths [

12,

18,

19].

Computed tomography techniques can also be used to evaluate the quantitative parameters of raw wood assortments. However, since quantitative evaluation is primarily based on externally “visible” parameters, conventional optoelectronic methods—already widely used in forestry and timber processing operations—are generally sufficient for this purpose [

20,

21].

Recent advancements in computer hardware and increased computing power have significantly contributed to the development of artificial intelligence and more sophisticated, efficient neural networks. Current research is particularly focused on “Transformers” technology [

22], which underpins models such as ChatGPT and is also being applied in image analysis [

23]. Ongoing technological progress enables the deployment of these algorithms to achieve reliable results in qualitative assessments based not only on external macroscopic features of logs or cuts but also on internal qualitative features.

Internal qualitative features are especially important, as they are often overlooked in conventional assessments conducted during forestry operations due to their inaccessibility without the use of specialized destructive, semi-destructive, or non-destructive methods. However, these internal features can significantly affect the final classification and potential use of a particular piece of raw wood [

24,

25,

26].

The gradual adoption of precision forestry and close-range methods of wood quality assessment in conventional forestry operations is often hindered by several factors. These include high acquisition costs, specific operating requirements, and increased demands for maintenance and service [

27,

28]. Another barrier is the inherent conservatism within the forestry sector and a limited willingness to adopt new methods of wood quality assessment. Despite these challenges, the integration of such technologies is steadily becoming a reality.

Automation in the assessment of forest stand conditions and the comprehensive inventory of harvested wood is gaining traction in forestry operations [

29,

30]. However, the deployment of automated systems for evaluating harvested wood remains constrained by factors such as material throughput, space availability, and financial resources, due to the significant investment required. Nonetheless, these technologies have been proven to increase the overall economic returns and enhance wood yield for high-value processing applications [

8].

Among these technologies, CT scanning lines represent a particularly advanced form of automation in the qualitative assessment of wood. Despite their high installation and procurement costs, they offer substantial benefits—especially for the processing industry, but also for forestry operations. Knowledge of the internal structure and quality of log cuts can improve forestry processes across multiple disciplines, including silviculture, forest management, logging, and transport. Moreover, these technologies can facilitate the optimization of wood trade and management, especially in the context of auction-based sales of raw wood assortments.

Currently, only a limited number of such CT devices are installed worldwide, with most being used in operations processing coniferous sawlogs. In our study, we utilized a unique CT scanner specifically designed for research purposes and capable of evaluating hardwood raw wood assortments.

The primary aim was to compare the qualitative assessment of oak logs using the conventional forestry method with that of a CT scanning line. Identifying potential differences in the evaluation of oak assortments is of both economic and technological significance, particularly in terms of processing optimization and market positioning.

The goal is also to underscore the practical value of CT-based qualitative assessment in operational forestry conditions, where conventional methods are limited by several factors—such as contaminated log surfaces, incomplete visibility of the round trunk surface, and the challenges associated with measuring and evaluating visible qualitative features.

2. Materials and Methods

2.1. Experimental Material

Roundwood from pedunculate oak and sessile oak (

Quercus robur and

Quercus petraea) was selected for the analysis. These species were chosen primarily due to their long-standing presence in the market, high economic value, and consistent demand for their high-quality wood [

31,

32]. All logs were harvested during the same winter and spring period of 2024 and originated from forests in southwestern Slovakia, a region that accounts for 10.3% of the country’s forest area [

33].

A total of 125 logs from these two oak species were selected for the study, purchased primarily for high-value processing, specifically for the production of oak barrels. The quantitative parameters of each log were measured using dendrometric methods, employing a certified diameter tape with centimeter division and a measuring band with millimeter division. Measurements were conducted in accordance with the EN 1309-2 standard [

34].

The volume of the logs was calculated using Slovak volume tables as defined in STN 48 0009 [

35] and Huber’s Formula (1), which is used to determine the volume of logs without bark [

36]:

V—represents the volume of the log in cubic meters. d1/2 denotes the average mid-length diameter of the log measured without bark, or after subtracting the bark thickness, in meters. L is the length of the log in meters.

Table 1 presents the basic descriptive statistics for the analyzed sample of oak logs and their quantitative parameters. The most common log length was approximately 4 m, and the average mid-length diameter was 40.1 cm. Based on these quantitative characteristics, all logs were classified as roundwood suitable for higher-value processing applications.

The total volume of the analyzed logs was 60.15 m3 according to the STN 48 0009 volume tables and 71.71 m3 when calculated using Huber’s formula. The volume calculated using Huber’s method thus shows a noticeable overestimation. However, for the purposes of this analysis, this discrepancy was not critical, as the qualitative assessment was based primarily on minimum diameter and length requirements defined for each quality class.

The quantile intervals show that 99% of all evaluated logs had a mid-cut thickness of up to 68 cm and a length of up to 7.6 m. Similarly, the volume of almost the entire sample, as calculated according to STN 48 0009, did not exceed 1 cubic meter (0.965 m

3). When the volume was calculated using Huber’s formula, 99% of the analyzed logs had a volume of up to 1.145 m

3 (

Table 1).

The standard deviations of thickness and length indicate that the log sample was quantitatively homogeneous, with most logs not differing significantly from the average values (5.813 cm for thickness and 1.476 m for length). The variability in volume was even lower, providing a solid basis for a comparative qualitative analysis.

2.2. Visual Qualitative Analysis

Qualitative sorting of logs in forestry operations is typically performed visually, based on both quantitative and qualitative parameters exhibited by the logs. The qualitative analysis of oak logs was conducted in April 2024 at the LignoSilva Center of Excellence of the National Forestry Center, located in the cadastre of the city of Zvolen, in the urban district of Stráže, Slovakia (GPS: 48.58168002738527, 19.09225780915406). The measurement of qualitative features was carried out manually, following the EN 1309-3 (2018) standard [

37].

Based on the occurrence and extent of these qualitative features, the logs were classified into quality classes as defined by the STN 48 0056 Standard for the Qualitative Sorting of Hardwood Logs (2007) [

38]. Visible qualitative features were measured using a measuring tape with millimeter divisions. According to the standard, Roundwood is classified into six quality classes: I.—Special logs for the production of veneers, sports equipment, and musical instruments; II.—Logs for the production of veneers and special logs; III.—Sawmill roundwood (three subclasses: III.A, III.B, III.C); IV.—Mining logs and poles; V.—Pulp and industrial wood; VI.—Firewood, Energywood.

This is the standard method of qualitative analysis used in regular forestry operations, as internal (hidden) qualitative features cannot be assessed through conventional visual inspection.

2.3. Qualitative Analysis Based on CT Scans

After visual qualitative analysis, 125 oak logs were separately scanned using a Microtec CT scanner in the same area of the LignoSilva Center of Excellence of the National Forestry Center (

Figure 1).

Scanning was performed within 14 days of the visual assessment of the oak logs. During this period, some partial qualitative changes may have occurred, such as the expansion of drying cracks or changes in color. Each log section was documented photographically, and any such changes that occurred were excluded from the comparative analysis of the qualitative assessment.

Scanning of the logs is performed using three-dimensional computed tomography. During the scanning process, the log is smoothly fed into a rotating circle via a rubber conveyor belt. The X-ray source is positioned opposite the detectors on both sides of the circle. Computer processing assigns corresponding radiation absorption values to each point in space within the scanned section. Based on these absorption values, a grayscale image is generated. The resulting data is then used to reconstruct the log sections in the desired planes. A detailed description of the methodology for creating scans and their digitization has been provided in our previous works [

8,

21]. A large industrial CT scanner with a through diameter of 900 mm was used for scanning. This through-diameter (up to 900 mm) allows the scanning of logs of any diameter at the same resolution. For logs up to 750 mm in diameter, the resolution quality is 1 mm × 1 mm × 10 mm, which ensures sufficient visibility of qualitative features. For logs exceeding 750 mm in diameter, image quality deteriorates due to noise. However, this does not prevent the identification of qualitative features, and in our case, we did not analyze logs of such large dimensions. The same scanner settings were used for all logs. The CT scanner was calibrated by the manufacturer, Microtec, and has been in operation for approximately 2 years.

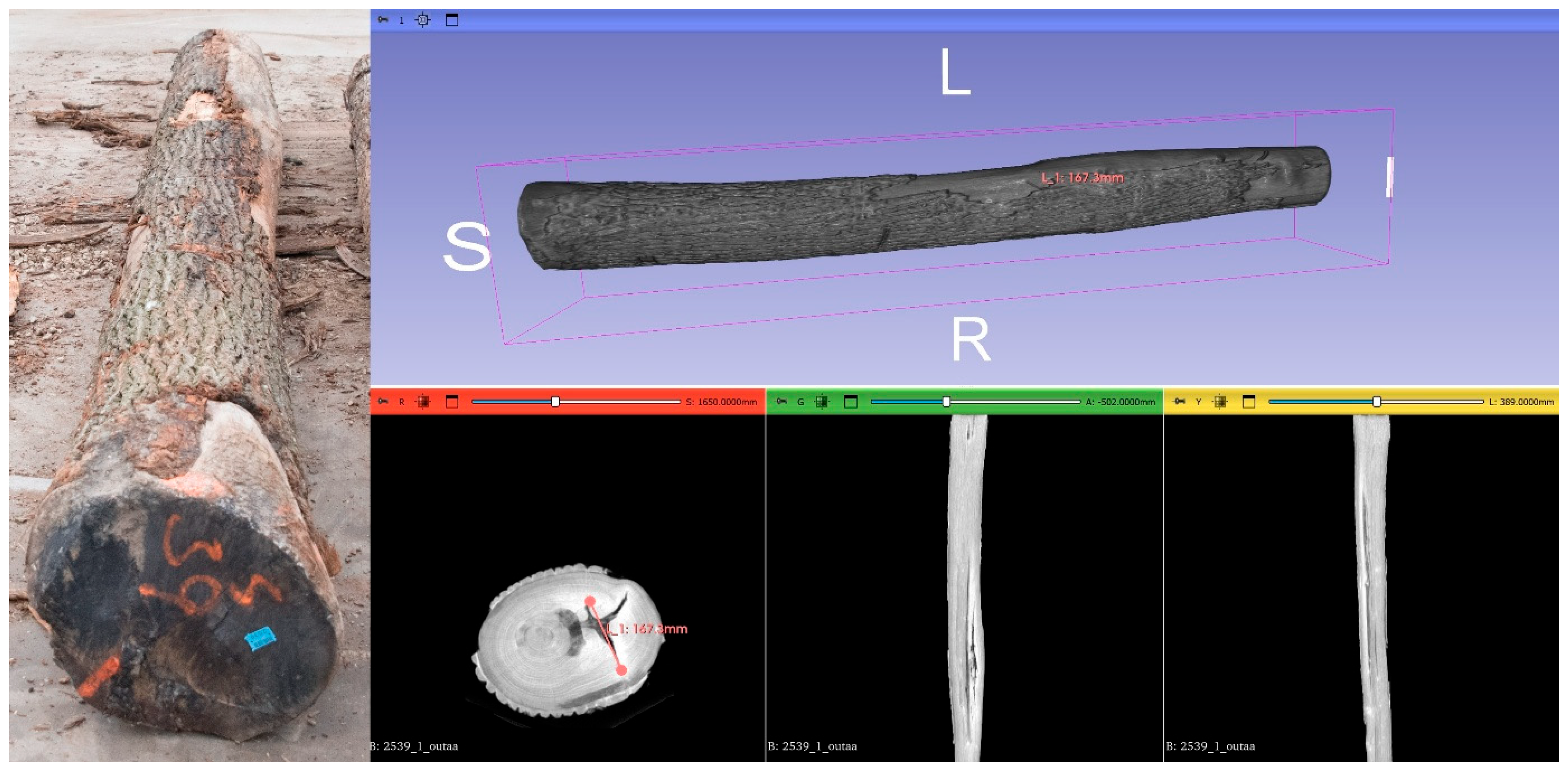

The qualitative assessment from CT scans involved evaluating and measuring both external and internal qualitative features of the transverse and longitudinal sections of the log, as well as its 3D model in the 3D Slicer software (Version 5.8.1) (

Figure 2). This software, which is freely available, was originally developed for medical use but also offers excellent tools for the qualitative assessment of logs from CT images, including the measurement of individual qualitative features [

39,

40].

The 3D model of the log is reconstructed from CT images, which are generated by the CT scanner as cross-sections composed of voxels with dimensions of 1 mm × 1 mm × 10 mm. For instance, a log with a length of 5000 mm consists of 500 images, each representing an individual section of the analyzed log. Qualitative features are detected based on differences in density relative to healthy wood, which causes varying X-ray absorption and results in different grayscale renderings in the image. Lower-density areas are represented by darker shades of gray (lower brightness values), while higher-density areas are depicted by lighter shades.

The density of wood in the cross-section also shows significant variability, depending on factors such as the structure of growth rings and the presence of qualitative features like knots, cracks, and rot. Each CT image of the log underwent initial setup and contrast adjustment in the 3D Slicer software. External and internal qualitative features were then evaluated and measured directly within the software, in millimeters, according to the EN 1309-3 standard [

37].

The qualitative classification was conducted under the same technical conditions as the visual analysis in the conventional method (

Section 2.2). The classification of the log sections into quality classes was also carried out in accordance with the STN 48 0056 standard [

38].

For the analysis of the obtained results, commonly used statistical methods were applied using the STATISTICA 14.0 software (Tibco Software Inc., Palo Alto, CA, USA). To determine the statistical significance of differences in quality classification between the two approaches, a parametric paired

t-test was conducted [

41]. Data recording and basic calculations were performed using MICROSOFT EXCEL 365 (Microsoft Inc., Redmond, WA, USA).

2.4. Economic Comparison of Qualitative Sortings

To quantify the economic difference between the two methods of qualitative assessment, the average prices of oak logs per cubic meter (excluding VAT) for the country, as reported in the Bulletin of the National Forestry Centre for the second quarter of 2024 [

42], were used. The price of each assortment was calculated by multiplying the volume determined according to STN 48 0009 by the price per cubic meter from the price list. The average monetization for both assessment methods was calculated as the arithmetic mean of the monetization values for all logs.

3. Results

3.1. Comparative Analysis of Qualitative Assessment of Logs

Figure 3 shows a histogram depicting the frequency of classification of oak logs into individual quality classes, based on both the conventional visual method and the evaluation of CT images and 3D models from image analysis. Subclasses III.A, B, and C correspond to sawmill roundwood logs, while quality class V. represents fiber and industrial wood.

The histogram clearly shows that the qualitative assessment from CT images revealed additional qualitative features that generally moved the logs to a lower-quality class, as the frequency of logs in lower-quality classes increased with this method.

Table 2 provides a detailed comparison of how the qualitative classification from CT images affected the classification of individual logs into quality classes compared to the visual qualitative classification. Nearly half of all assessed logs were classified into the same quality class by both methods. However, a significant portion of the logs (almost 33%) was classified as one quality class lower when analyzed using CT images. This can tentatively be attributed to the presence of hidden features inside the log, as well as the more precise measurement and assessment capabilities provided by 3D models and CT image sections. It is also worth noting that more than 10% of the evaluated logs were classified in a higher quality class compared to the visual assessment. This may be due to the improved ability to measure and evaluate crucial qualitative features in the given sections.

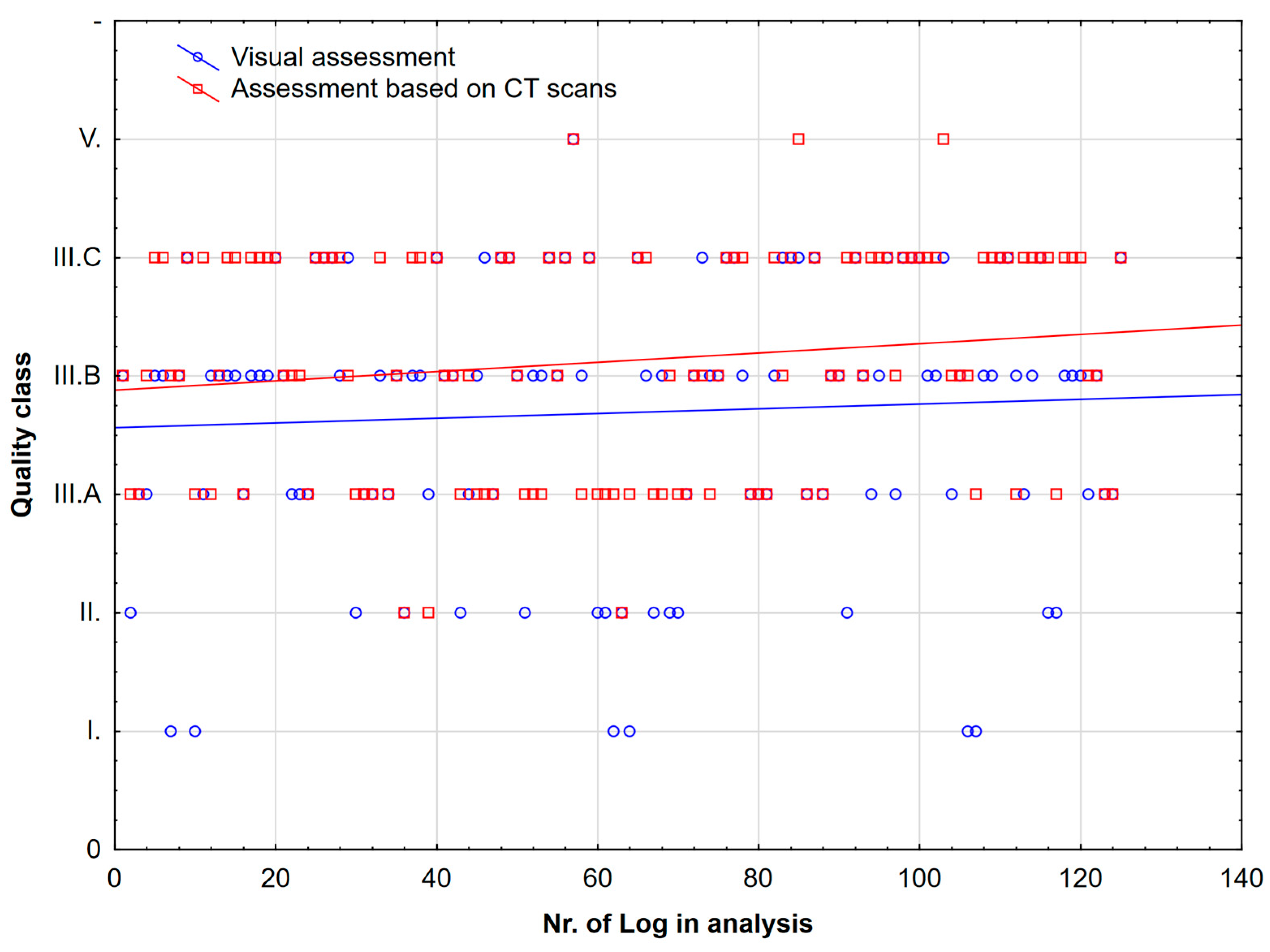

Figure 4 shows the specific classification into qualitative classes of all 125 logs in both qualitative assessment methods in a scatter plot.

3.2. Analysis of Differences in Two Quality Assessment Approaches

To assess the significance of the differences between the two qualitative assessment methods, a paired t-test was performed under the null hypothesis that the mean difference between the methods is zero. The resulting p-value (0.0000002533) is well below the commonly accepted significance level of 0.05, indicating that the difference between the assessment methods is statistically significant. The calculated t-value of −5.46 suggests that the CT-based assessments, on average, assigned the logs to lower-quality classes compared to the conventional visual method. This confirms a significant difference between the visual and CT-based classifications, with the CT analysis tending to result in a more critical (i.e., lower) classification of the assessed logs.

Table 3 provides an overview of the qualitative features that led to the reclassification of oak logs into lower-quality classes when assessed from CT images. In 60% of cases, the qualitative features were identifiable during the visual assessment, but their dimensions were not measured with sufficient accuracy (last row of

Table 3). During manual measurement, it is often not possible to accurately assess certain features, such as simple or complex sweep, due to the placement of the log section on a rigid surface. This frequently results in an inaccurate measurement of the feature’s extent along the entire log section, whereas an electronic 3D model allows for a much more precise evaluation of such characteristics. For some features that are assessed based on surface area (e.g., rot, discoloration), their dimensions may be distorted during visual evaluation due to surface contaminants such as dust, mud, or moisture from atmospheric precipitation. CT scanning enables more accurate measurement of these features, as the CT image primarily reflects differences in density between the defect and healthy wood. CT image analysis, in contrast, enables more precise measurement (see

Figure 5). The most common reason for reclassification was the detection of overgrown knots and the more accurate measurement of their dimensions, accounting for 16.8% of cases.

Figure 5 presents an assessment of log number 2539, where an overgrown knot is visible on the log’s surface. However, accurate measurement and classification of this feature are only feasible using CT imaging. In the same region, internal core rot was also detected, which is invisible during conventional visual inspection.

In 9.6% of reclassified cases, multidirectional curvature was the cause. Logs exhibiting such curvature are automatically classified into a maximum quality class III.C. Minor sweeps can be difficult to identify visually, as their detection often depends on the position of the log on the ground and the presence of debris or uneven surfaces underneath. A significant proportion of reclassifications were also due to the presence of heartshakes, where the extent of the crack determines the quality class (III.A—maximum 1/3 of the cross-sectional diameter; III.B—maximum 1/4). Thus, the ability to measure these features accurately in CT images plays a crucial role in determining the correct classification.

Qualitative assessment based on CT imaging provides significantly more convenient and detailed options for evaluating individual qualitative features. The ability to detect hidden internal defects—features that cannot be identified or accurately measured through conventional visual methods—has proven to be essential in the evaluation of oak logs. In addition, CT analysis allows for a more precise assessment of certain external features, such as multiple sweeps, which are often underestimated or overlooked during visual assessment due to limitations in visibility, positioning of the log, or surface contamination. These advantages underscore the added value of CT imaging in achieving a more objective and reliable classification of Roundwood.

3.3. Economic Analysis of Detected Qualitative Differences

A more precise qualitative assessment of the logs can also be reflected in their economic valuation. As the CT-based evaluation resulted in the reclassification of more than 40% of the analyzed sections into lower-quality classes, it is evident that the average monetization of these logs is consequently reduced. For the approximate calculation of the economic value, the unit prices presented in

Table 4 were applied. The monetary values were calculated based on the volumes of the logs determined according to the STN 48 0009 standard.

Table 5 shows the calculated monetization of the total volumes of individual quality classes according to two approaches to qualitative classification. The average monetization per 1 m

3 with the conventional visual method of qualitative assessment was 157.32 EUR. With qualitative classification based on CT images, the average monetization per 1 m

3 was 127.16 EUR (−30.16 EUR/1 m

3). This difference may be economically relevant, particularly for wood processors handling large volumes of timber. In such cases, classification into higher quality grades can also play a significant role, potentially bringing economic benefits to these companies in the long term.

The economic evaluation presented above should be interpreted solely based on official list prices. It does not account for market dynamics, such as trade trends within a particular country or region, regional relationships with trading partners, or the structure of the wood processing industry—all of which can significantly influence the final valuation and sale price of timber. In practice, it is not uncommon for timber in lower-quality classes to be sold at higher prices than timber classified in higher quality categories. Such cases frequently occur, for instance, during wood auction sales. Therefore, a more accurate qualitative assessment—particularly the identification of internal quality characteristics—can play a critical role in optimizing wood valuation processes and refining supplier-customer relationships.

We did not evaluate the operational economics. Operational costs, such as the acquisition, installation, and operation of such equipment, were not addressed. However, these costs can be minimized by outsourcing the wood scanning service externally. In this case, the cost per cubic meter of wood is minimal, especially when the customer does not incur high transportation costs to deliver the timber to the CT scanner.

4. Discussion

Image analysis methods have long served as a tool for automation and optimization in the qualitative assessment of wood, with specific measurement and evaluation techniques applied to play a crucial role. For instance, an exact assessment of the qualitative features of false heartwood—based solely on its area in the cross-section of the log end—conducted using ImageJ software (Version 1.48) on 63 beech trunks resulted in an improved economic valuation by nearly 17% [

43]. However, current legislative frameworks for measuring and evaluating qualitative characteristics tend to systematically overestimate the dimensions of features when based on area measurement [

44]. When digital image analysis methods are applied to refine assessments under existing technical standards, it can be expected—consistent with our findings—that a greater proportion of logs will be classified into lower-quality classes at the expense of higher ones.

Gaining insight into the internal structure of standing or felled trees can yield entirely new and essential knowledge for qualitative classification. In this context, acoustic stress tomography still exhibits notable limitations in detection accuracy, particularly in soft deciduous and certain coniferous species, where tomographic methods have been shown to underestimate the extent of qualitative features by nearly 30% [

25] and overestimate the proportion of healthy wood in oak logs [

45]. In contrast, computed tomography (CT) scanning offers relatively high precision, with deviations in feature location detection averaging up to 1.21%, and dimensional assessment errors of qualitative features in some hardwood species limited to approximately 3.5%. As such, CT scanning represents a highly effective tool for more detailed visual assessment of both external and internal qualitative features, as well as for precise volume quantification [

46].

The distribution of individual qualitative features within a tree trunk generally follows consistent patterns in specific trunk sections. For instance, in pine, the primary zone for the occurrence of qualitative features has been identified between 6 and 8 m along the trunk length, with trunk diameter and site conditions showing no significant effect on the frequency of such traits [

47]. In contrast, studies on beech and oak have demonstrated that certain site-specific environmental parameters, as well as silvicultural interventions applied within the forest stand, can influence both the presence and extent of qualitative features [

44].

The results obtained can be further enhanced by integrating non-destructive wood evaluation methods with semi-destructive techniques. When appropriately interpreted, the data from such combined approaches also facilitates the assessment of the mechanical properties of the analyzed wood [

48]. It is equally important to consider that a substantial number of qualitative features may develop only after the tree has been felled. These include production-related defects, improper handling, suboptimal storage conditions or durations, and inadequate sales management. Such post-harvest factors can significantly alter the final qualitative classification of the wood compared to the classification performed while the tree is still standing in the forest [

49].

Magnetic resonance imaging has also demonstrated very high accuracy in assessing wood damage caused by fungal activity, primarily due to its sensitivity to moisture and water content within the wood structure [

50]. Similarly, the acoustic-laser method has proven effective in accurately detecting qualitative features near the rounded surface of tree trunks—features that are often missed by conventional sonic tomography techniques, especially when sensors are distributed randomly [

51].

Qualitative analysis using computed tomography is primarily based on wood density analysis. However, it has been demonstrated that the distribution of this parameter within wood is inherently variable. In the radial section of European beech, for example, wood density is influenced by trunk diameter—density values tend to increase from the pith outward but begin to decline toward the bark after reaching a peak [

52]. Similar patterns have been observed in Norway spruce, where Beaulieu et al. [

53] reported density differences between radial sections of varying sizes; however, these variations were largely attributed to differences in cambium age. Additionally, the accuracy of density-based assessments is significantly influenced by the wood’s moisture content, which must be taken into account during evaluation [

54].

The suitability of computed tomography (CT) for assessing the qualitative features of knots has been well established in previous studies. CT scanning technology enables precise detection of knots in terms of both their position and quantity, with the diameter of knots measurable with an average error of only 2 mm [

55]. This level of accuracy is more than adequate for qualitative classification into the quality classes used in our study, where sorting is performed by size in centimeters. Additionally, several studies have focused on the development of algorithms for the automatic detection of knots and other qualitative features [

18,

56]. However, for the sake of greater informative value, our work did not employ automatic detection algorithms.

The accuracy of the resulting qualitative assessment can also be influenced by the experience of the operators and their ability to identify and precisely measure specific qualitative features.

While most studies on CT scanning and the qualitative assessment of wood have relied on experimental or medical tomography, only a few have utilized industrial tomographs designed specifically for wood assessment, complete with appropriate software. As a result, a comprehensive comparison of our results with those from other studies is challenging. However, current trends suggest that these tools, when integrated with automation algorithms, will play a crucial role in the future of wood quality assessment.

5. Conclusions

In the past two decades, the use of non-destructive computed tomography (CT) methods for qualitative wood assessment has gained significant attention in both forestry operations and research. This growing interest underscores the promising potential of this non-destructive assessment technique. Research has primarily focused on four key areas: (1) variability in wood density and the determination of annual growth increments, (2) the moisture content of wood and its distribution within the tree trunk, (3) wood degradation, and (4) external features of small trees, such as branch geometry and crown density [

57]. In this study, we aimed to highlight the importance of CT-based qualitative assessment for valuable oak roundwood and assess its impact on the resulting quality structure. We found that, compared to traditional visual grading, qualitative classification based on CT image analysis corresponded in only approximately half of the analyzed logs (47.2%). However, this method also led to an upgrade to a higher quality class in nearly 10% of cases. Statistical analysis revealed significant differences between the two evaluation methods, with overall quality ratings being lower when classification was based on CT images. This is further supported by the economic calculation based on timber prices for individual quality classes of oak logs, where CT-based assessment resulted in a decrease in average revenue by 30.16 EUR per cubic meter of logs. Operational costs, such as the acquisition, installation, and operation of such equipment, were not addressed. However, these costs can be minimized by outsourcing the wood scanning service externally. In this way, the cost per cubic meter of wood is minimal, especially when the customer does not incur high transportation costs to deliver the timber to the CT scanner.

In forestry operations, the processes related to wood assortment and qualitative assessment often lack sufficient professionalism. There is inadequate attention given to enhancing the knowledge base of workers, and a system of positive and negative motivation is generally absent. The automation of these processes has the potential to gradually address these issues and improve overall quality and efficiency.

It is important to recognize that this method has certain limitations. Some internal structures are more challenging to identify, such as the density of wood around knots, which often resembles that of moist sapwood [

58]. As a result, detecting and measuring knots in logs has been difficult in the past. However, recent advancements in CT scanning technology, combined with image processing algorithms, have shown significant potential in overcoming this issue. These methods now allow for better visualization of qualitative features and variations in wood properties. While these new algorithms enhance wood quality assessment for optimized forest product production, they are also valuable for evaluating the impact of silviculture techniques on the production of higher-quality raw wood assortments [

57].

A more accurate assessment of the quality of grown wood will play a decisive role in the future for the optimization of the entire forestry and timber complex and wood production based on the principles of bioeconomy.